Pigment Manufacturing

Find innovative pigment equipment and connect directly with world-leading technology suppliers

Pigments are colorants that are not soluble in the host material and scatter light and are therefore opaque. Pigments can be organic or man-made and derive from animals, plants, rocks or minerals and metal oxides, like for example titanium oxide.

Top picks for pigment processing

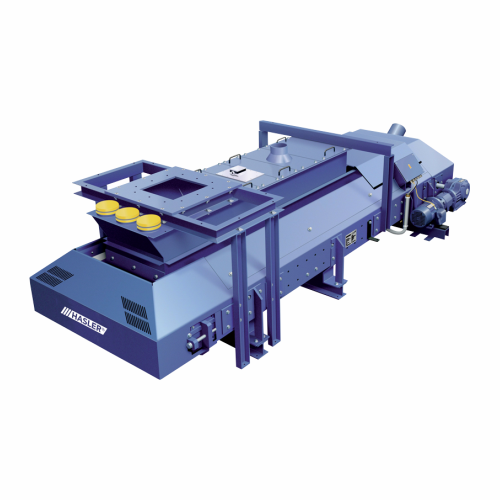

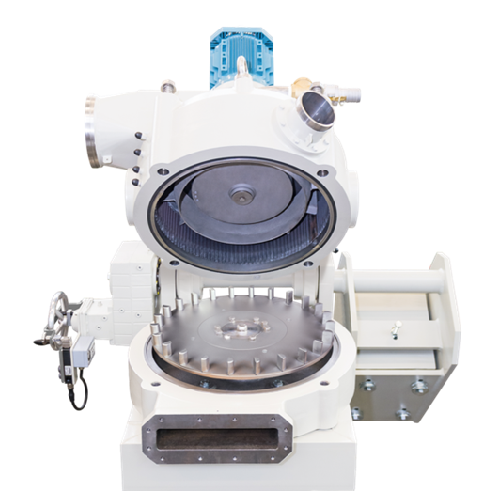

Dryer for pigments and hydroxides

Achieve precision drying of complex suspensions and pastes into uniform powders, optimizi...

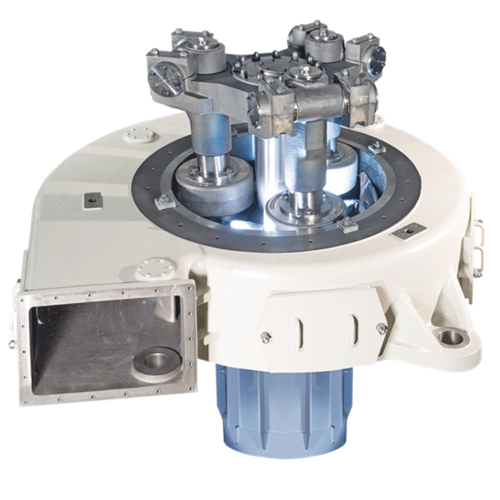

Basket mill for paint and varnish production

Achieve optimal particle size and product consistency with this advanced bask...

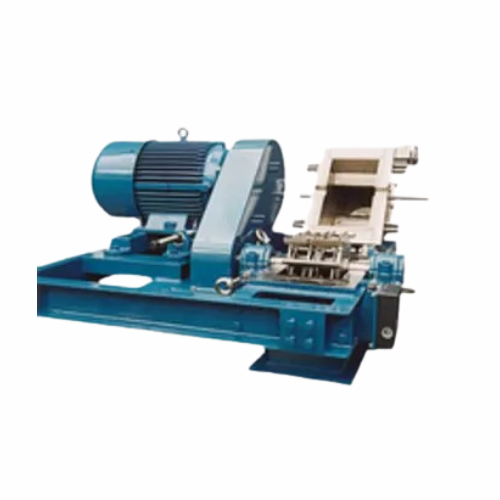

Explosion-proof production disperser for paint manufacturing

Ensure safe and efficient dispersion in volatile environmen...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Stories about pigment

Select your pigment process

Tell us about your production challenge

Generally, pigments and paints are not bound chemically to the covered surface, water-soluble dies react with fibers in a mordant bath. Apart from colored, decorative paints, white and black pigments have high importance. White titanium dioxide plays an important role in the painting industry, due to its stability, high covering effect, and UV-light absorbing property. Approximately 4.6 million tons of TiO2 pigment are produced annually worldwide, and its use continues to rise. On the other end of paints, carbon black is essential as a toner of the laser printer and filler in tires and other plastics, also due to its stability and UV-light absorbing capability.

Pigment manufacturing process

Natural sources of paint lost their importance. Lead oxide pigment dispersed in oil was widely used as primer paint, due to its excellent anticorrosive feature. Since heavy metal lead is poisonous, this red paint is nowadays forbidden. Indigo was extracted from plants cultivated in Asia, nowadays the blue die for denim cloth coloration is synthesized almost exclusively by the chemical industry. The coloring materials were solved in organic solvents, benzene, toluene, xilols, turpentine, and nitro thinner. All these solvents pollute the environment, and some of them are carcinogens. Nowadays water-based products are common; however most part of paints are not water-soluble. In order to avoid segregation, stable dispersion should be formed where the pigments do not sediment.

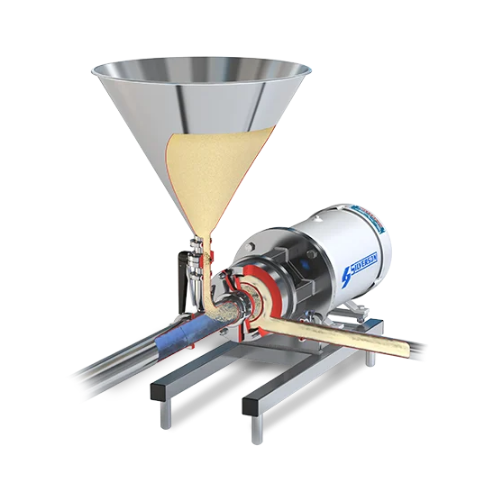

In order to eliminate solvents, powder coating is used for painting and decorating vehicles and other metal surfaces. Pigments are mixed with polymers, then extruded and milled. Classifier mills are preferable for a narrow particle size distribution

High sheer mixing for powder paints

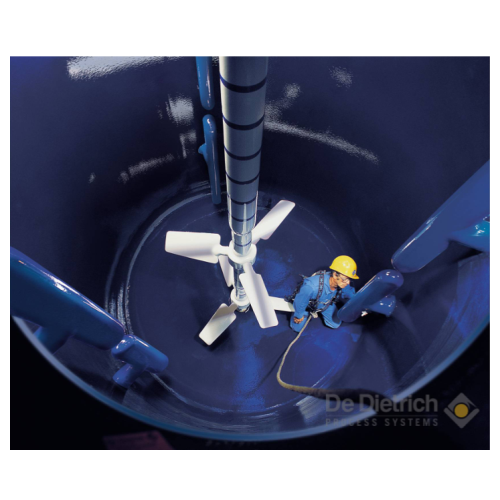

Powder coatings are a solvent-free painting form where pigment is mixed with a polymer, a carrier material that melts in the painting oven so that the pigments adhere to metal objects. Pigments are micronized to have a smooth surface and become miscible with polymer beads. High shear mixing is necessary to break the force of cohesive powders and form polymer-pigment particles avoiding sedimentation in further processing. The video below shows a high-shear mixer for this purpose with a conical shape that provides a vertical upward movement along the wall.

How dispersion improves paint quality

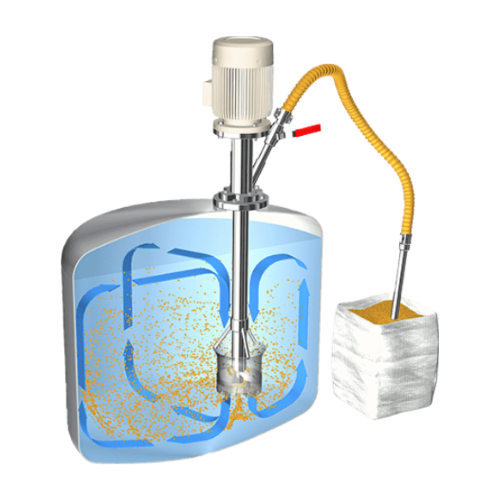

In emulsion paint, the binding agent is dispersed in water. Dispersion as such an important process that has a big influence on the quality of the final product. Dispersing machines process immiscible materials in a high shear chamber, where sharp edge tools of high-speed rotor reduce the size of the paint particles and disperse them into the oily or water base matrix. A rotor can have paddles as well, to serve as a recirculation pump. The video below shows how at the top of the rotor a vacuum occurs, sucking in the ingredients, liquids, and powders.

Which pigment technology do you need?

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Dryer for pigments and hydroxides

Achieve precision drying of complex suspensions and pastes into uniform powders, optimizi...

Ultrafine powder mill for coatings and pigments

Optimize your ultra-fine powder production with this precise grinding and ...

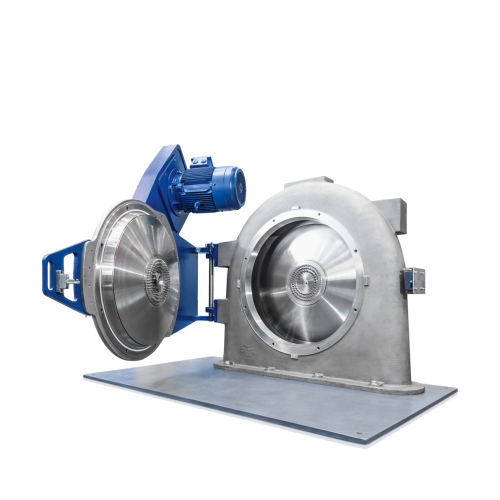

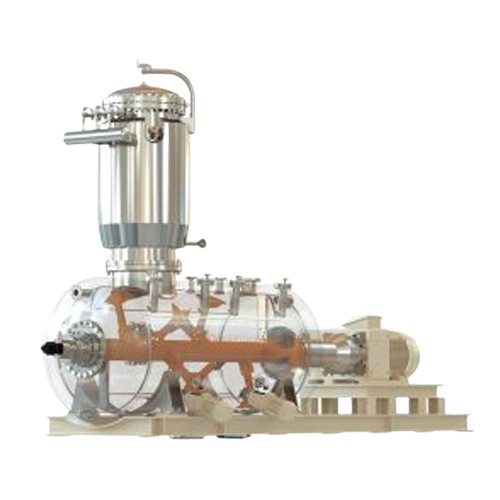

Horizontal batch centrifuge for chemical industry

Optimize your solid-liquid separation with a centrifuge designed for pr...

Bag inserter for drums

Effortlessly streamline your packaging process by automatically inserting custom-made bags into drums,...

Pendulum mill for fine grinding and drying

Achieve efficient and precise grinding for soft to medium-hard materials while ...

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

Immersion mill for particle reduction

Achieve streamlined particle size reduction and enhanced mixture homogeneity with imm...

Vertical peeler centrifuge for chemical industry

Maximize throughput in continuous chemical processes with a versatile ver...

Powder belt feeder for accurate powder metering

Achieve precise powder metering with a specialized feeder that maintains d...

Heavy duty analytical sieve shaker for coarse-grained materials

Need precise particle size distribution for large minera...

Tapped density tester for pharmaceutical and chemical powders

Ensure precise density measurements for pharmaceuticals an...

Industrial pan dryer for pharmaceuticals

For heat-sensitive powders and pastes requiring precise moisture levels, this pan ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Vertical forced feeder for extruders

Enhance your extrusion process with a vertical forced feeder designed for precise dosi...

Crossflow filtration for microfine to nanoscale suspensions

Optimize your production line with advanced crossflow filtra...

Crossflow filtration with sieve filter for difficult suspensions

Achieve precise separation and recovery in challenging ...

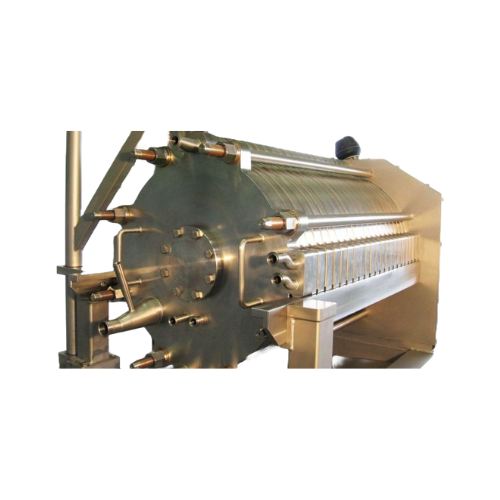

Pressure drum filter for fine-grained products

Achieve exceptional precision in fine particles processing with this pressu...

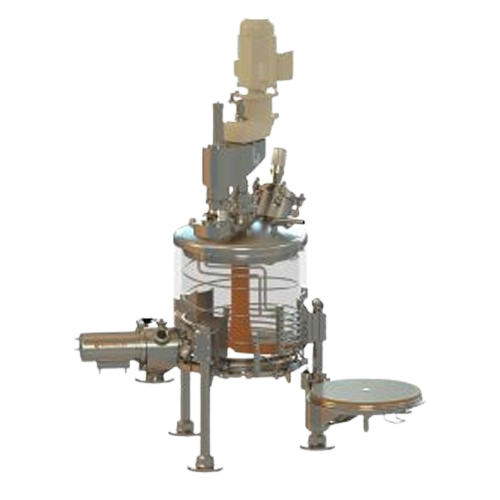

Agitated nutsche filter for solid-liquid separation

Ensure high-purity solid-liquid separation with minimized contaminati...

Horizontal vacuum paddle dryer for thermosensitive products

For high-viscosity products like active pharmaceuticals or p...

Feeding, dosing, weighing and mixing system for granulate

Achieve precise granulate mixing and rapid color changes with ...

Indirect cooling drums for process heat recovery

Optimize your production by effectively cooling hot solids while recaptur...

Flash dryer for high-moisture bulk materials

Tackle high-moisture challenges head-on with rapid drying solutions that effi...

Industrial roller compaction for chemical applications

Enhance material flow and density with advanced roller compaction ...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

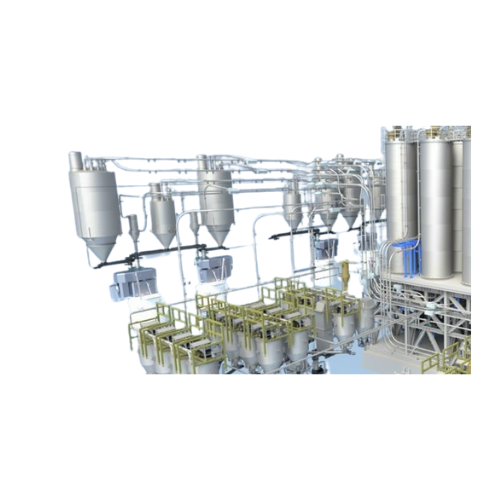

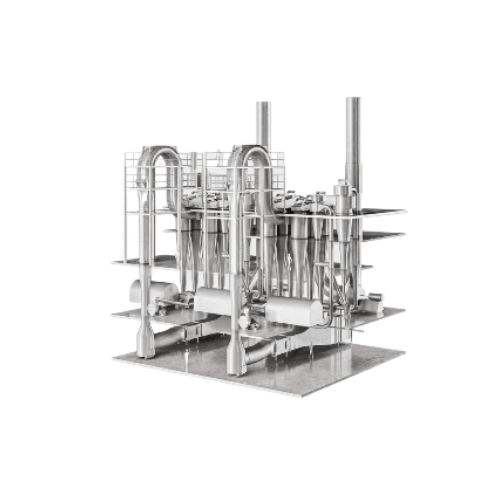

Dispersion paint production systems

Achieve 100% color accuracy and flexible production with our advanced system, ensuring ...

Vacuum dissolver for high-viscosity products

Elevate your production with precision mixing and deaeration, ideal for tackl...

Continuous mill for nano range fine grinding

Achieve ultra-fine particle size in continuous processes, ensuring consistent...

Industrial basket mill for medium viscosity products

Achieve precise particle size reduction and rapid pigment dispersion...

Explosion-proof basket mill for large scale production

Enhance your production line with an explosion-proof basket mill t...

Jet milling system for super fine particle size reduction

Achieve ultra-fine particle sizes with precision milling techn...

Efficient grinding and drying mill

Transform your production line with a versatile mill that simultaneously grinds, dries, ...

Industrial plow mixer for efficient solid and liquid mixing

Experience unparalleled mixing precision with high-speed plo...

Particle size reduction air conveying system

Achieve precise particle size reduction and contamination-free processing for...

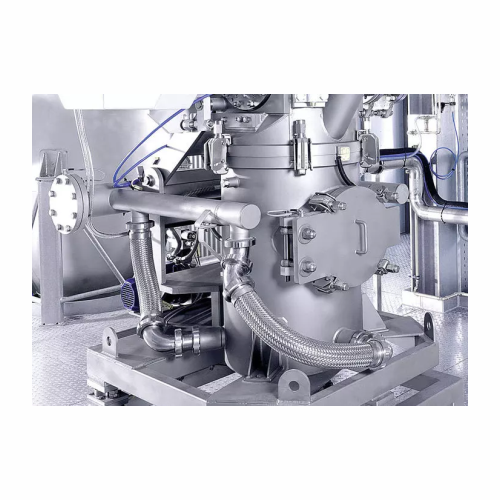

Horizontal disc bead mill for liquid chemicals

Processing toxic chemicals requires high compliance with safety standards a...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Laboratory scale active freeze dryer

The laboratory-scale active freeze-drying is used for dehydrating high-value products ...

Thin film dryers

Dry dissolved or slurried crystallizing or amorphous products to a pourable powder.

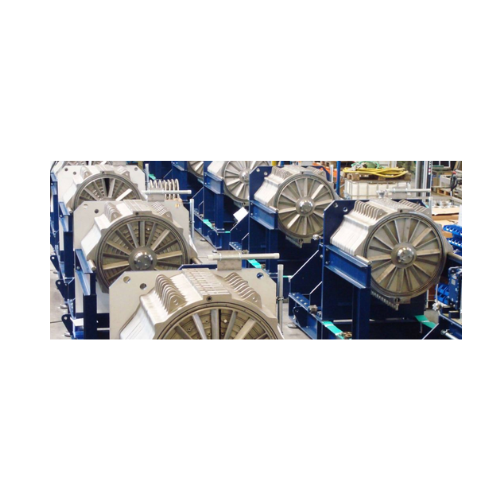

Vertical scraper centrifuges

Vertical Bottom discharge Centrifuges work discontinuously, discharging the solids to the botto...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

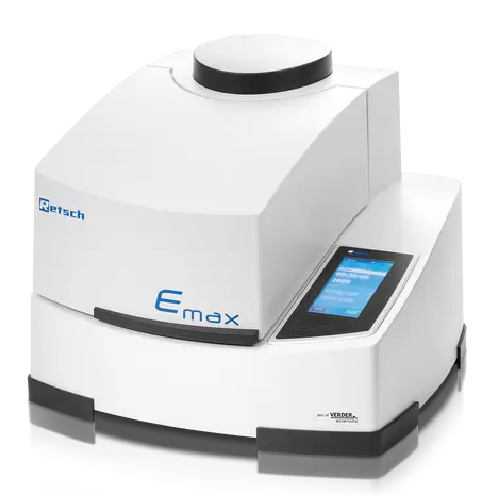

High energy ball mill for ultrafine grinding

Achieve nanoscale precision and unmatched particle uniformity with high-energ...

High-torque cutting mill for tough and fibrous materials

Tackle the toughest materials and ensure consistent particle siz...

Laboratory drum mill for large sample volumes

Efficiently process large volumes of diverse materials into precise particle...

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

Planetary ball mill for high throughput grinding

For precise material engineering, achieve efficient size reduction, homog...

High energy untra fine ball mill

Achieve ultra-fine particle sizes rapidly with this high energy milling solution, designed ...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Impact classifier mill for fine grinding of brittle materials

Achieve precise particle size distribution with advanced g...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

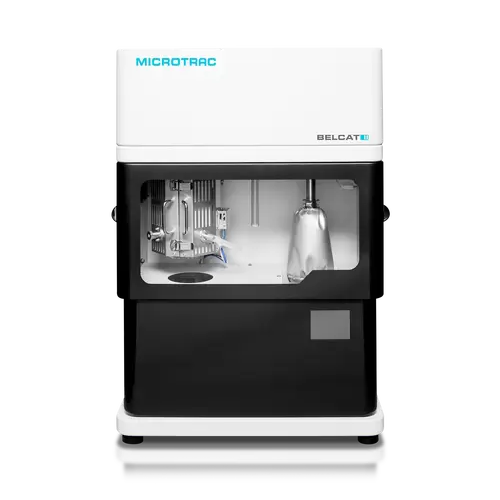

Specific surface area & pore size analyzer for materials

Achieve unparalleled precision in material characterization by m...

Pore size distribution analyzer

Optimize your material analysis with a system that delivers precise pore size distribution a...

Laser diffraction particle size analyzer

Achieve precise particle size analysis with laser diffraction technology, ensuring...

Catalyst characterization analyzer

Achieve precise catalyst characterization and optimization with advanced techniques like...

Gas pycnometer for true density measurement of solids and powders

Achieve highly precise density measurements of solid ...

High shear plough mixer for powders, granules, and pastes

Achieve rapid and efficient blending with high shear mixers de...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

High-pressure homogenizers for dairy and juice processing

Ensure superior texture and stability in your liquid formulati...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Vacuum dryers for powders and bulk solids

Achieve precise drying and mixing of sensitive materials with advanced vacuum te...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Super high shear mixer for nano to micron powders

Achieve high-precision mixing and surface treatment of nano to micron-s...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab mixer for powder formulations

Achieve precise particle mixing and coating with this stand-alone high-shear lab mixer, d...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Laboratory vacuum dryer for heat-sensitive materials

Optimize moisture control in heat-sensitive materials with precise a...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

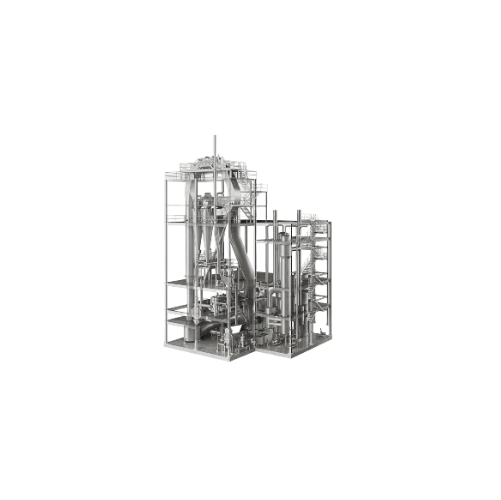

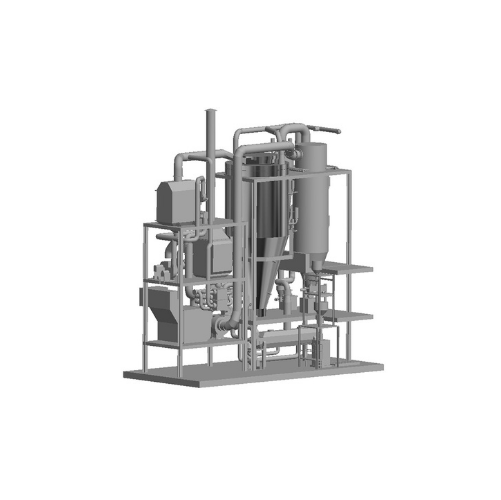

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

Ultra-fine powder grinding with jet mills

Achieve unparalleled fineness and purity in powder production with cutting-edge ...

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Air classifier for classifying industrial minerals

Achieve precise particle separation with advanced air classifiers, par...

Immersion mill for pail and drum-sized batches

Streamline your production with a versatile solution that efficiently handl...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...

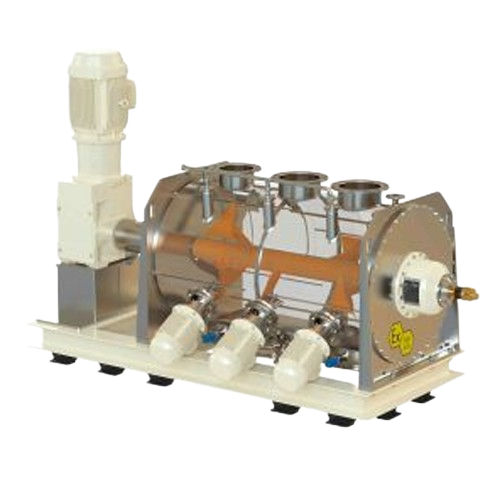

Horizontal pilot plant centrifuge for chemical processing

Enhance your R&D and pilot-scale processes with a centrif...

Inverting filter centrifuge for difficult-to-filter products

Designed for challenging filtration tasks, this centrifuge ...

Top discharge centrifuge for pharmaceutical production

Optimize your product yield and quality with precise filtration an...

Pharmaceutical horizontal peeler centrifuge

Optimize product consistency and purity with precise separation and filtration...

Double-stage rotary weigh feeder for precise powder dosing

Ensure consistent dosing and precise weighing of challenging ...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Powder synthesis reactors for nanometer and micrometer particles

Achieve precise particle control and enhance material p...

Pneumatic dilute phase conveying system for powders and bulk materials

Optimize your production line’s efficiency...

Deagglomerator for consistent particle size reduction

Struggling with inconsistent particle sizes or unwanted lumps in yo...

Laboratory mortar grinder for wet and dry grinding

Ensure precise blending of fine powders, pastes, and creams with contr...

Vertical pharma vacuum blender for bulk solids

Optimize your mixing of fine chemicals and pharmaceutical powders with high...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

R&d mixer for small batch experimentation

Perfect your mixing techniques swiftly with precision-controlled small batch exp...

Glass-lined reactor for enhanced mixing performance

Optimize your chemical processes with a reactor that enhances mixing ...

Vacuum drying for heat-sensitive products

Ensure moisture-sensitive formulations are dried efficiently without compromisin...

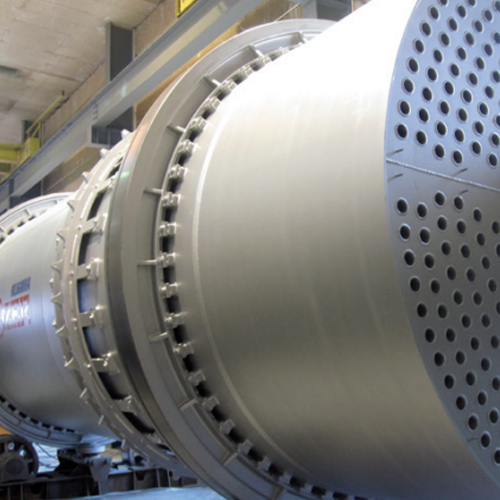

Corrosion-resistant shell and tube heat exchangers for pharmaceuticals

Ensure efficient thermal management in high-puri...

Agitated nutsche filter and filter-dryer for pharmaceuticals

Ensure precise filtration, washing, and drying of sensitive...

Big bag emptying station for powder handling

Ensure safe and efficient powder discharge with precision containment, adapta...

Condensation and separation unit for solvent handling

Enhance solvent management and VOC recovery with this compact conde...

Powder handling drum dock station

Ensure safe and efficient powder transfers with high containment levels, minimizing opera...

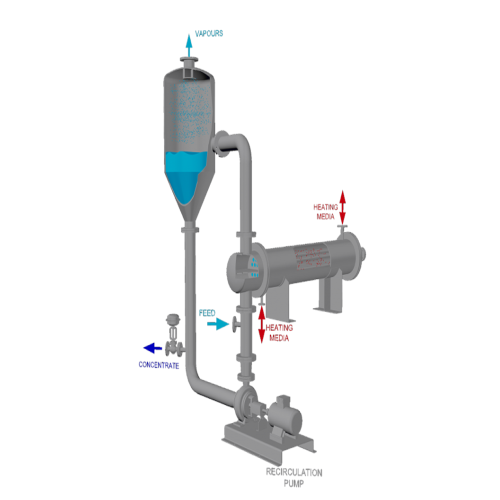

Force circulation evaporator for high viscous products

Optimize energy efficiency and manage challenging liquid compositi...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

Vertical flash dryer for industrial drying applications

Optimize your production line with an energy-efficient vertical f...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Oil absorption testing instrument for carbon black and silica

Accurately measure oil absorption in powders to enhance fo...

Laboratory crossflow filtration test system

Efficiently test and determine optimal filtration parameters with this portabl...

Compact filtration device for laboratory and field use

Achieve precise filtration with minimal sample sizes for rapid ana...

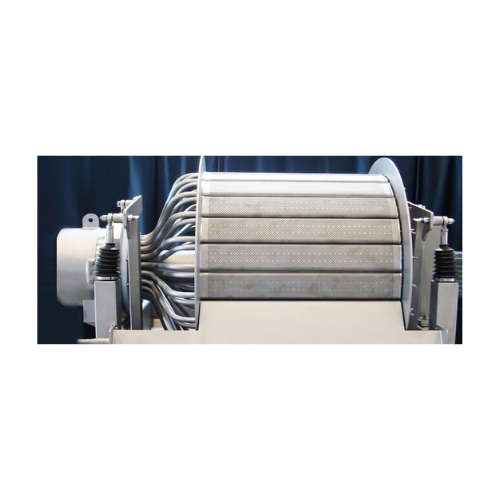

Industrial drum vacuum filter for filtration and washing

Efficiently manage filtration, washing, and dewatering tasks wit...

Industrial homogenizer for high pressure applications

Achieve consistent product texture and stability for your emulsions...

Vertical ribbon vacuum dryer for thermosensitive products

Achieve optimal drying of thermo-sensitive materials like powd...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Agitated nutsche filter dryer for solid-liquid separation

Achieve high-purity solid-liquid separation with optimized thr...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Stirred reactors with heating and cooling system

Optimize your production line with versatile stirred reactors, designed t...

Homogenizer for high viscosity emulsion and dispersion

Achieve unparalleled dispersion and emulsification with a system d...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal vacuum paddle dryer for thermosensitive products

Achieve precise drying and mixing of high-viscosity, thermos...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Vertical conical screw vacuum dryer

Achieve precise moisture control with ultra-vacuum batch drying, ideal for thermo-sensi...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

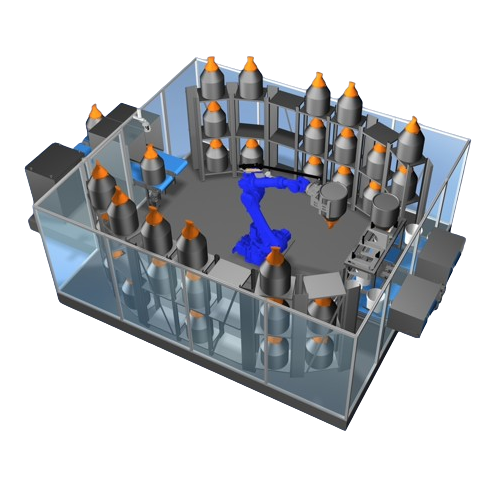

Robotic dosing system for accurate micro quantities

Achieve precise and reproducible micro dosing of challenging raw mate...

Bead mill for nano-preparation grinding

Achieve precise nano-processing and efficient wet grinding for pharmaceuticals and ...

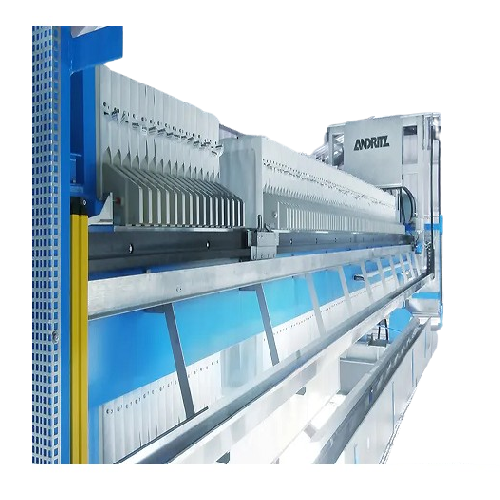

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

Planetary ball mill for powder material mixing and alloying

Achieve precise control in particle size reduction and homog...

Automatic labeler for low profile containers

Optimize container labeling with precision and efficiency, addressing the cha...

Tabletop labeler with integrated thermal printer for round containers

Efficiently label and print variable data on roun...

Pilot plant homogenizer for continuous operation

Achieve consistent fluid textures and prolonged shelf life with high-pres...

R&d spray drying solution for small batch production

Efficiently convert liquid solutions into precise, uniform powders f...

Feed-type ring dryer for industrial drying processes

Optimize your production with a versatile drying solution designed f...

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming...

Vibrating fluid bed for final stage powder drying

Enhance powder processing precision with a vibrating fluid bed that ens...

Short base skirt silo for bulk material storage

Optimize your bulk material handling with adaptable discharge and rapid lo...

Industrial bin vent filter for fine dust particles

Enhance your production line with efficient fine dust filtration to en...

Powder wetting and dispersion system

Revolutionize your production with a system that seamlessly inducts, wets, and dispers...

Multipurpose mixing equipment for chemical and pharmaceutical production

Achieve unparalleled flexibility with modular,...

Inline disperser for lithium-ion electrode slurry mixing

Achieve highly efficient dispersion and homogeneity for battery ...

Dissolver for high-viscosity products through floor installation

Optimize production of ultra-high viscosity products wi...

Laboratory disperser for high-viscosity products

Optimize your laboratory processes with precise mixing and dispersing of ...

Dispersing system for high-viscous products

Achieve precise mixing and dispersing of high-viscous products with advanced f...

Top-mounted disperser for high-viscosity products

Achieve rapid, uniform dispersion of ultra-high viscosity materials wit...

Basket mill for paint and varnish production

Achieve optimal particle size and product consistency with this advanced bask...

Laboratory basket mill for fine grinding in industrial applications

Optimize your laboratory’s efficiency with hi...

Milling beads for wet grinding in paint industry

Enhance product uniformity and grinding efficiency with specialized milli...

Triple shaft mixer for high-viscosity products

Achieve precision mixing and dispersing of high-viscosity products with a p...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

Advanced dissolver for high-viscosity products

Handle ultra-high viscosity mixing challenges effortlessly with this advanc...

Bulk solids discharging and loading solution

Optimize your bulk material handling with equipment that ensures efficient an...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Explosion-proof production disperser for paint manufacturing

Ensure safe and efficient dispersion in volatile environmen...

Vacuum basket mill for high-viscosity product processing

Achieve exceptional fine milling results while preventing air in...

Vacuum disperser for high-viscosity products

Optimize high-viscosity product dispersion and prevent air inclusions with a ...

Vacuum dissolving system for high-viscosity products

Achieve flawless dispersion of high-viscosity substances under vacuu...

Production dissolver for high-viscosity products

Achieve optimal dispersion and grinding of high-viscosity substances with...

Explosion-proof horizontal bead mill

For manufacturers seeking precise particle sizing, this explosion-proof bead mill ensu...

High-performance production dissolver for large batches

Achieve precise and repeatable dispersion for complex formulation...

Dissolving system for high-viscosity products

Optimize the dispersion of high-viscosity liquids and pastes with this versa...

Explosion-proof dissolver with scraper for high viscosity substances

Ensure flawless dispersion with enhanced safety, d...

Explosion-proof dissolver for high-viscosity products

Optimized for safely processing high-viscosity products, this explo...

Explosion-proof dissolver for high viscosity products

Optimize your high-viscosity material processing with an explosion-...

Vacuum basket mill for highly viscous products

Achieve precision in fine milling under vacuum to prevent air inclusions in...

Vacuum basket mill for high-viscosity product milling

Achieve refined particle size and smooth texture in your high-visco...

ATEX vacuum dissolver for high viscosity products

Ensure safe and efficient dispersion of high-viscosity materials under...

Explosion-proof vacuum dissolver for high viscosity products

Achieve precise dispersion of high-viscosity products under...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Explosion-proof immersion mill for paints and varnishes

Optimize high-performance coatings production with an explosion-p...

Agglomerate dispersion solution for high viscosity materials

Optimize your production efficiency by integrating a dual-f...

Spray drying system for heat sensitive products

For heat-sensitive products requiring precision drying, this spray drying ...

Dual-motion rectangular separator for pulp and paper industry

Optimize your production line with a versatile separation ...

Vacuum coater for petfood and livestock feed

Enhance nutritional value and product quality with precision liquid incorpora...

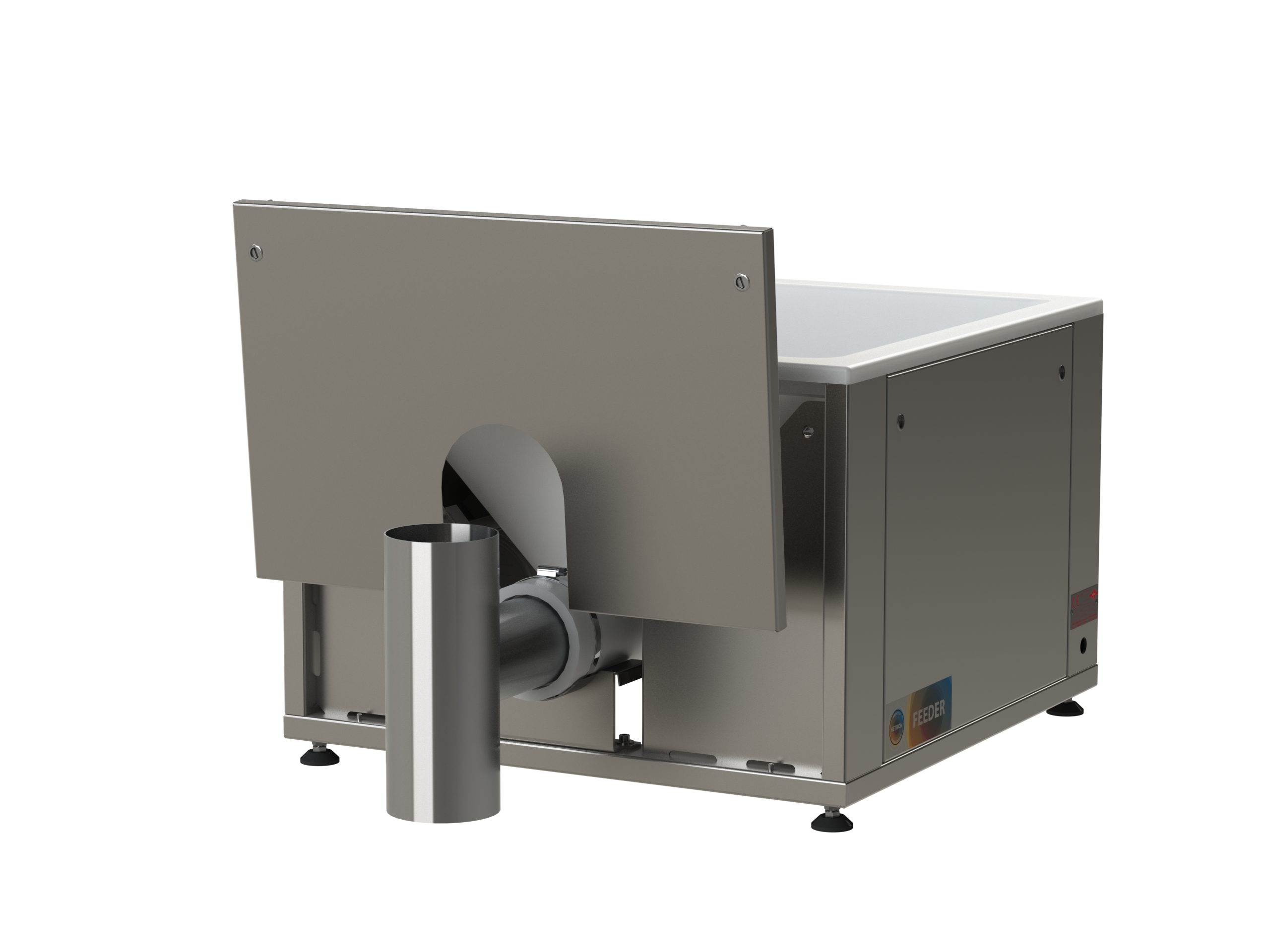

Twin screw feeder with stirring agitator for poor flowing powders

Optimize your processing line with a highly adaptable...

Weigh-belt feeder for industrial processes

Efficiently manage material flow and precision with a dependable weigh-belt fee...

High shear powder mixing solution

Achieve agglomerate-free, homogeneous mixing of powders and liquids with high shear effic...

Industrial batch mixers for pet food

Achieve homogenous mixing of complex multi-ingredient formulations with precision and ...

Feeding system for filter cake and wet pet food

Achieve seamless material handling and agitation for solid shortening and ...

Solid flow meter for granular and powdered bulk materials

Ensure accurate mass flow measurement and seamless integration...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Vertical ring-roll mill for pulverizing minerals

Achieve precise particle size control and efficient material processing w...

Solids flow meter for bulk solid streams

Ensure precise bulk material measurement with a system designed for accuracy and r...

Loss-in-weight feeder for bulk solids

Ensure precise and reliable dosing of bulk solids with a compact feeder that eliminat...

Loss-in-weight feeder for small volume bulk solids

Achieve precision feeding for small volume bulk solids with this advan...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

U-belt conveyor for bulk material transport

Optimize your high-speed bulk material transport with this space-saving convey...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

Ultra fine bead mill for nanosuspensions

Ensuring the quality, efficiency, and reproducibility of nanosuspensions throughou...

Self-cleaning bead mill for highly viscous materials

To prevent blockages, clogging, and cross-contamination coming from ...

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain ...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

Automatic can sealer

If you need to cap paint, glues, and solvents containers and are currently manually placing the lids, yo...

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

Side bar filter press

Production of dry cakes is required in a variety of industries and robust, low-cost side bar filtration...

2-way diverter valves for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

Dense phase conveyor for normal wearing materials

Dense phase pneumatic conveying is used for powders, granules, and grai...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

Horizontal chemical scraper centrifuge

For slurries difficult to discharge, a scraper can improve process reliability, effi...

Horizontal pharmaceutical scraper centrifuge

For slurries difficult to discharge, a scraper can improve process reliabilit...

Isolator centrifuge

For transferring highly active pharmaceutical ingredients (HAPI) without contamination from the isolator ...

Mobile pilot plant centrifuge

The system is perfectly suited for pilot plants as well as small-quantity productions in the f...

Vertical top discharge centrifuge

Discharge solids vertically upward through manual action, optionally using a filter bag o...

Vertical peeler centrifuge

A vertical peeler centrifuge is used to separate solids, usually to separate fine particles from ...

Pusher centrifuge

Pusher centrifuges are continuously operating filter centrifuges and can have several basket stages dependi...