Stirred reactors with heating and cooling system

Optimize your production line with versatile stirred reactors, designed to handle complex processes like mixing, heating, and cooling, while ensuring precise temperature and pressure control for consistent product quality.

Mixes, Heats, and Cools for Process Optimization

The Stirred Reactors with Heating and Cooling System by Bachiller are engineered for precise process control, accommodating diverse industrial needs from pharmaceuticals to petrochemicals. These reactors feature dual jacket heating and cooling, capable of full vacuum to 50 bar pressure, and temperatures ranging from -50ºC to 400ºC. Designed for batch and continuous operations, they handle viscosities up to 2,000,000 cps, ideal for tasks like emulsification and polymerization. Standard configurations include stainless steel construction, ensuring chemical compatibility and durability, with options for austenitic and duplex steels for enhanced corrosion resistance. Automation is facilitated via PLC control, with CIP/SIP systems aiding efficient maintenance. All units are compliant with CE and ATEX certifications, ensuring safety in varying operational zones. Customization includes agitator design and thermal insulation options, supported by comprehensive engineering services for optimal configuration in your production line.

Benefits

- Enhances process efficiency with precise thermal management.

- Supports high-viscosity operations, enabling versatile applications.

- Minimizes maintenance downtime with integrated CIP/SIP systems.

- Ensures safety in hazardous areas with ATEX-certified designs.

- Offers extensive customization for tailored process integration.

- Applications

- Essences and aroma, Cosmetics, Natural extracts, Wood and derivates, Minerals, Engineering, Food, Biotechnology, Fine chemicals, Waste treatment, Biocides, Refining (oil, Plastics and polymer, Pulp and paper, Chemical, Petrochemical, Resins, Pharmaceutical and veterinary, Gas)

- End products

- Pharmaceutical antibiotics, Mineral slurries, Epoxy resin coatings, Particleboard, Silicone sealants, Vanilla extract, Polyethylene film, Refined diesel fuel, Pigment dispersions, Biogas, Kraft paper, Hydrolyzed protein supplements, Herbicides, Aromatic essential oils, Extracted plant oils, Anti-aging creams, Polymer resins

- Steps before

- Purification, Filtration, Pre-mixing, weighing, Dissolution

- Steps after

- Cooling, Separation, Packing, Distillation

- Input ingredients

- aerations, oxidations, autoclaves, catalyst processes, enzyme processes, concentration, crystallization, dispersions, dissolutions, distillation, emulsions, ethoxylation, fermentation, fusion, high viscosity materials, homogenization, hydrogenation, light suspensions, mixing of dissimilar liquids, neutralization, polymerization, precipitation, reaction, suspensions, thermal transfer

- Output ingredients

- aerated products, oxidized products, autoclaved products, catalyzed products, enzymatically processed products, concentrates, crystalized materials, dispersed products, dissolved solutions, distillates, emulsified products, ethoxylated compounds, fermented products, fused materials, homogenized products, hydrogenated products, lightly suspended products, mixed liquids, neutralized solutions, polymerized products, precipitates, reacted compounds, suspended products, heat treated outputs

- Market info

- Bachiller specializes in industrial engineered-to-order equipment, known for high-quality process equipment in the chemical, petrochemical, pharmaceutical, and food industries. They are recognized for their expertise in designing and manufacturing pressure vessels, reactors, and mixing equipment.

- Volume

- up to 300, 000L

- Pressure

- Full vacuum to 50 bar(g)

- Temperature Range

- -50ºC to +400ºC

- Agitator Power

- 0.5 KW to 300 KW

- Agitation Regimen

- Turbulent or laminar, up to 2, 000, 000 cps

- Heating/Cooling System

- Double jacket, half coils, dimple jacket

- Agitator Type

- Axial flow, radial, or combined double flow

- Surface Finish

- Internally mechanical polished, Ra ≤ 1.2 µm to Ra ≤ 0.2 µm

- Vacuum System

- Available

- Cooling/Heating Control

- Internal coils or heated baffles

- Thermal Insulation

- Stainless steel tight welded cover

- Working Pressure

- Full vacuum up to 50 bar(g)

- Operating Temperature

- –50º C up to +400º C

- Heating/Cooling Medium

- Double jacket, half coils, dimple jacket

- Agitation Type

- Axial flow, radial, combined double flow

- Agitation Regimen

- Turbulent or laminar

- Installation Power

- 0.5 KW up to 300 KW

- Automation Level

- Manual / PLC-controlled

- Cycle Design

- Designed for working in cycles

- Floating Mechanical Seal

- Pressurized with nitrogen

- Internal Zone Certification

- ATEX Certified for internal zone 0/20

- CIP/SIP System

- Validatable by Riboflavin test

- Thermal Insulation

- Stainless steel tight welded cover

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE marking

- Yes

- ATEX certification

- Yes

- Safety for Machinery Directive 2006/42/CE

- Yes

- ASME

- ASME VIII div.1

- DIN standards

- DIN-28136

- AD-2000

- Yes

- EN-13445

- Yes

- Volume

- up to 300, 000L

- Design Temperature Range

- –50º C to +400º C

- Design Pressure

- Full vacuum to 50 bar(g)

- Agitation Type

- Turbulent or laminar regimen

- Agitator Power Range

- 0.5 KW to 300 KW

- Heating/Cooling System

- Double jacket, half coils or dimple jacket

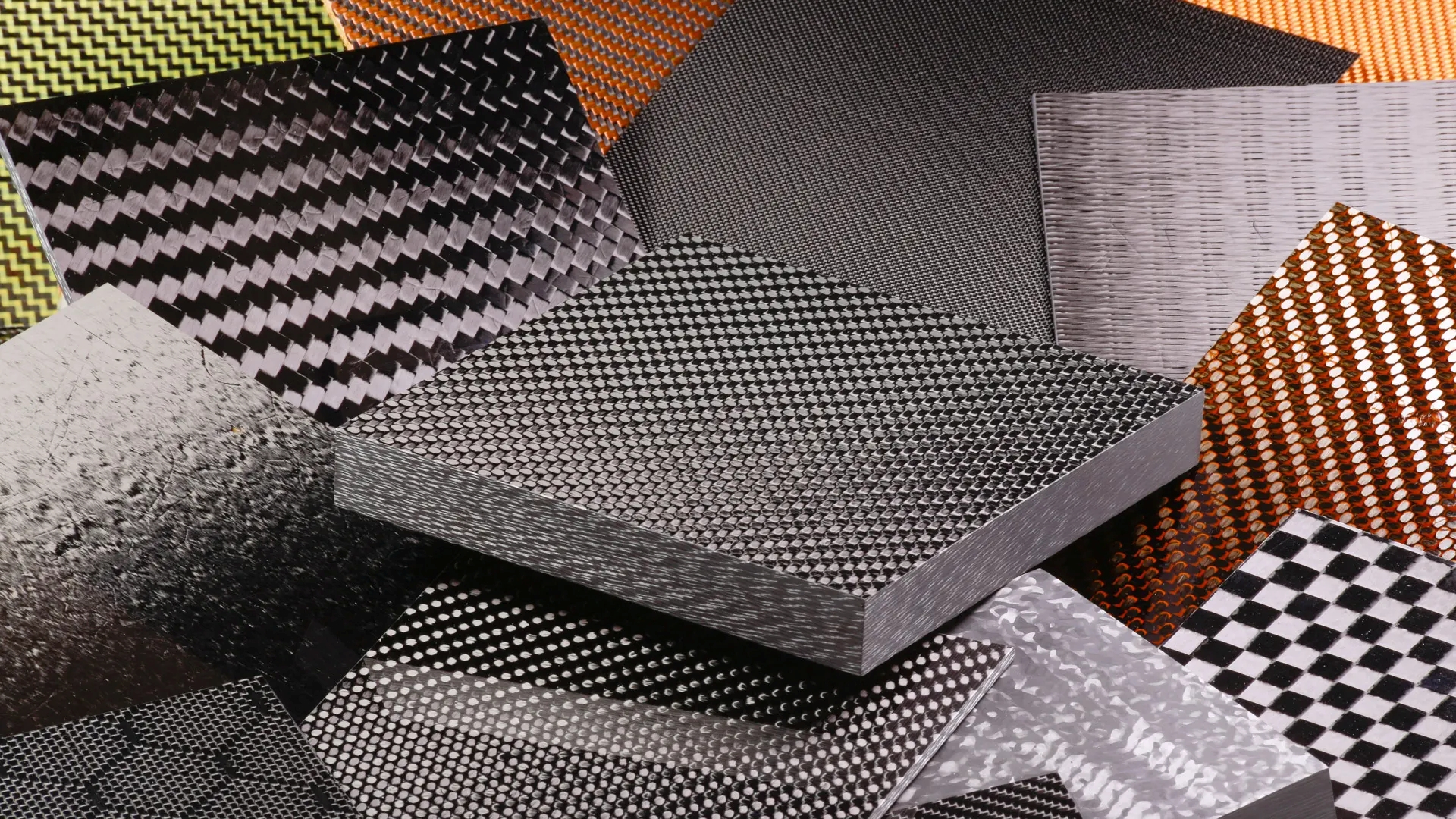

- Construction Materials

- Austenitic Stainless Steels, Duplex Steels, Nickel Alloys, Titanium

- Design pressure range

- Full vacuum up to 50 bar(g)

- Design temperature range

- – 50º C up to + 400º C

- Heating/Cooling system

- Double jacket, half coils, dimple jacket

- Agitator flow type

- Axial, radial, combined double flow

- Agitation regimen

- Turbulent or laminar

- Installed power range

- 0.5 KW up to 300 KW

- Internal finish

- Mechanical polishing Ra ≤ 1.2 µm up to Ra ≤ 0.2 µm

- Internal electropolishing

- Yes

- Thermal insulation

- Stainless steel tight welded cover

- Agitation systems

- Mechanical seals, single or double

- Floating mechanical seal

- Pressurized with nitrogen

- ATEX execution

- Certified for internal zone 0/20

- Automatic systems

- For solids load and dosing

- Condensate and reflux systems

- Available

- Vacuum systems

- Available