Cosmetics Manufacturing Equipment

Find innovative cosmetics equipment and connect directly with world-leading technology suppliers

According to a legend, Cleopatra soaked her sails in her perfume so that Mark Antony could smell her ships before they arrived. This is to say that, from soaps and shampoos to perfumes, conditioners and pomades, cosmetics have always been highly valued and used for their properties of aesthetic enhancement. Cosmetics are a broad class of topical agents applied for various purposes such as cleansing, protecting, beautifying, or otherwise altering your appearance. As a result, a wide array of processing equipment is used in the cosmetics industry.

Innovative solutions for manufacturing cosmetics

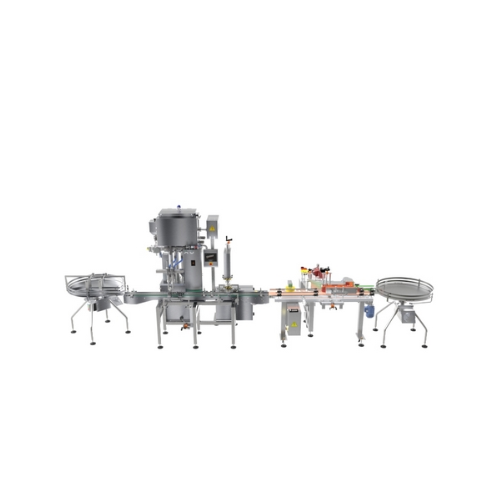

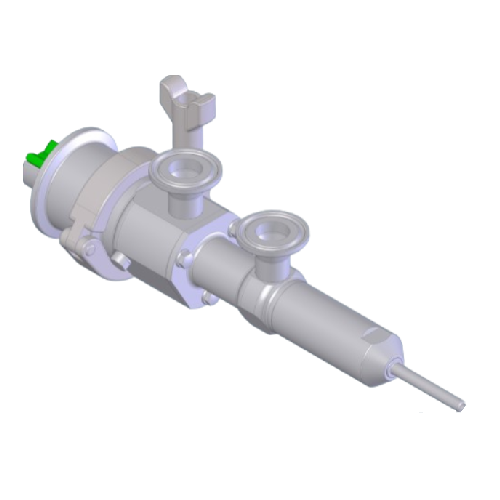

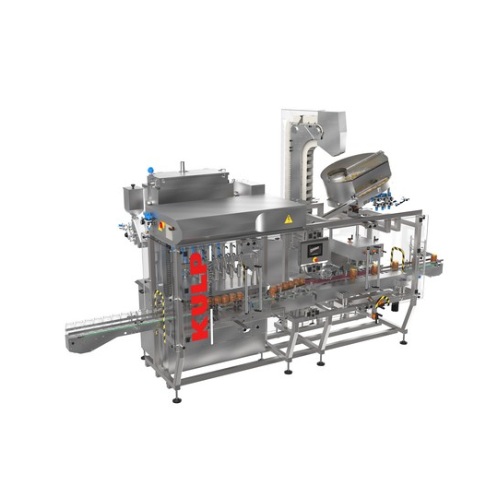

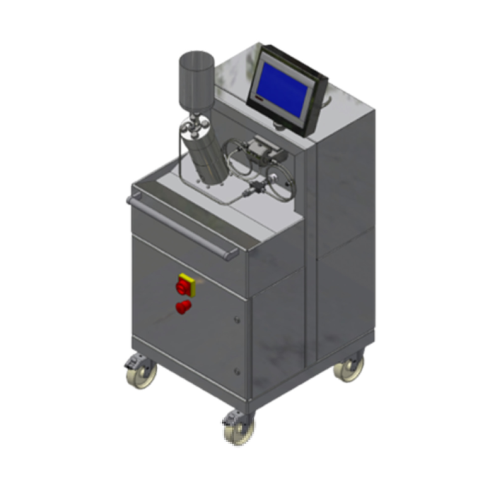

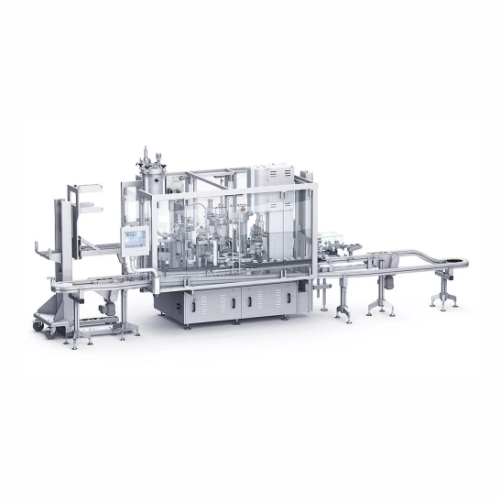

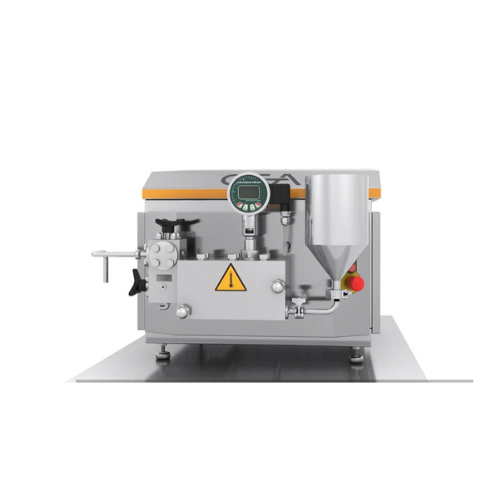

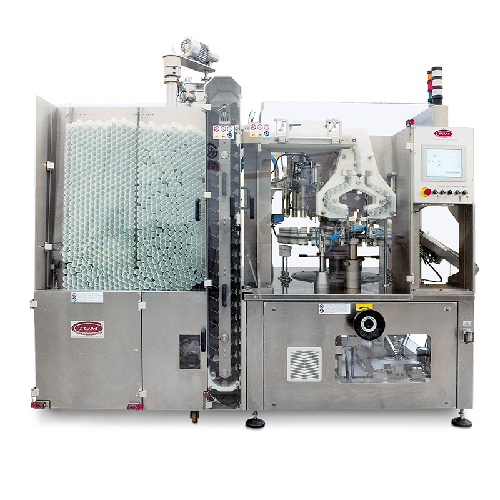

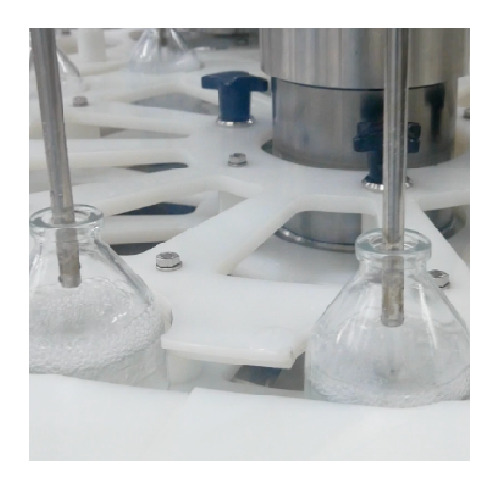

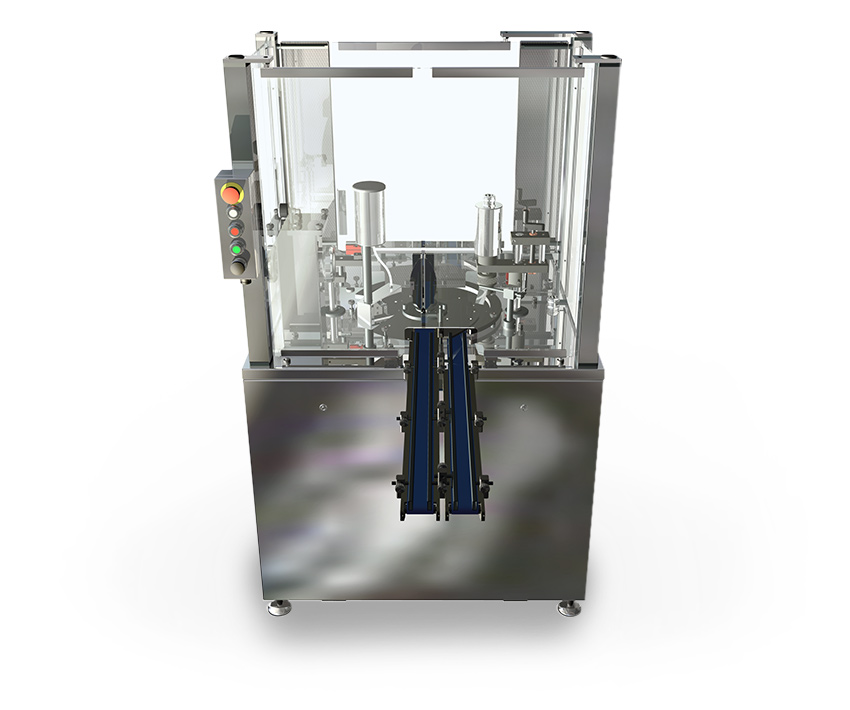

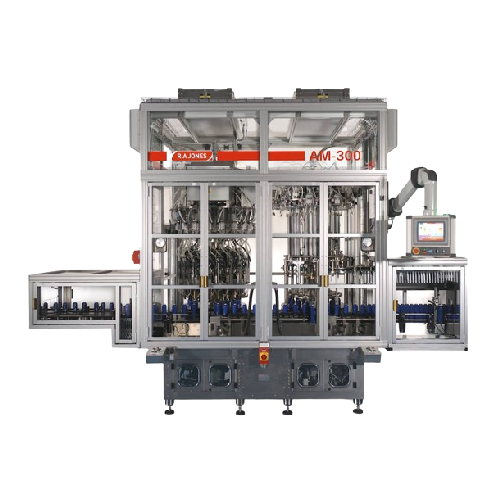

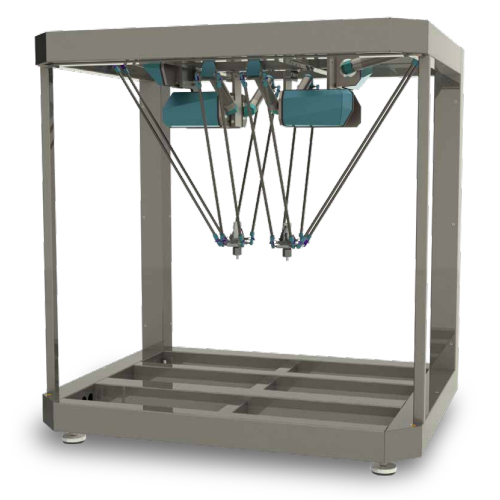

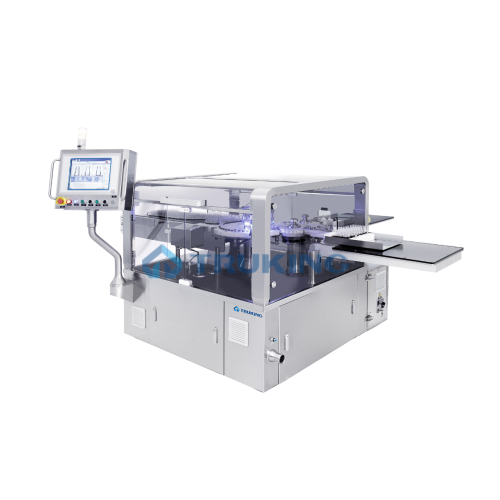

Cosmetic cream filler

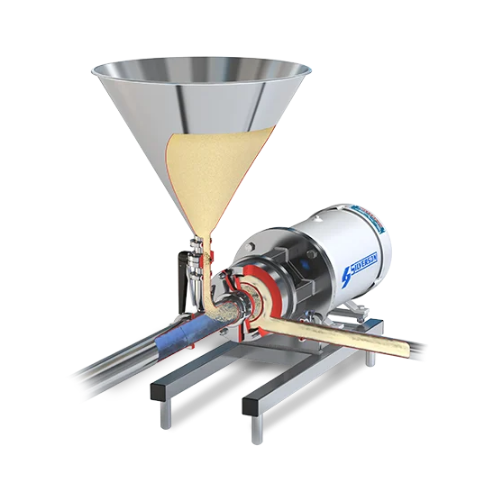

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

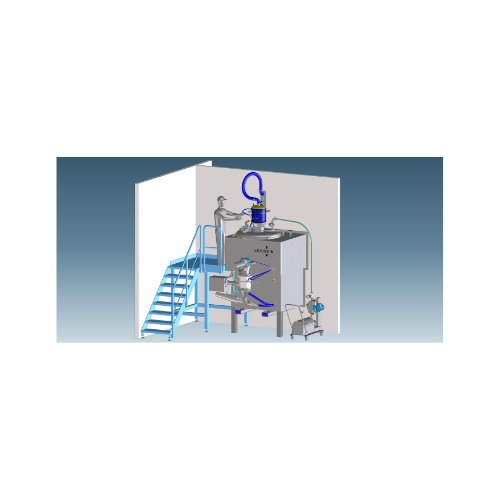

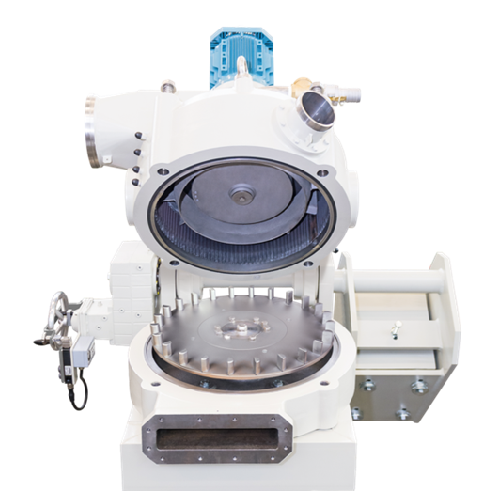

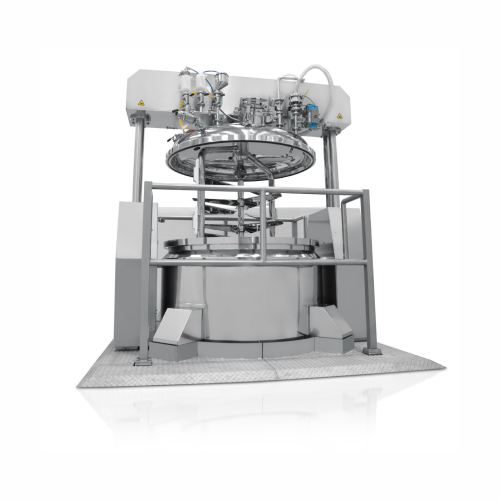

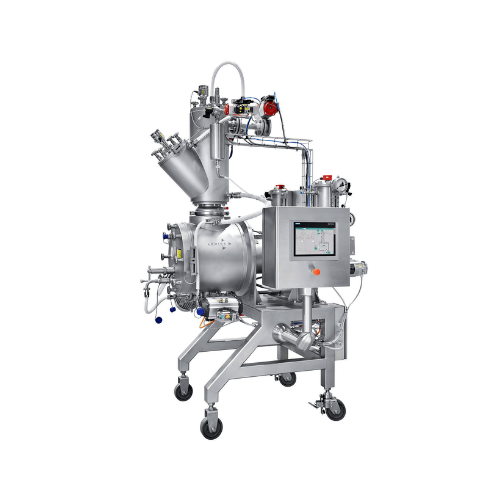

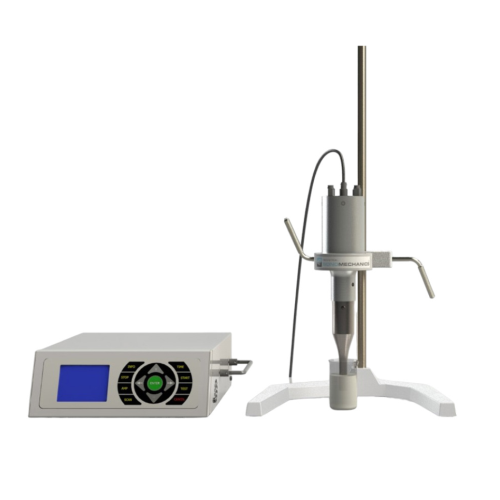

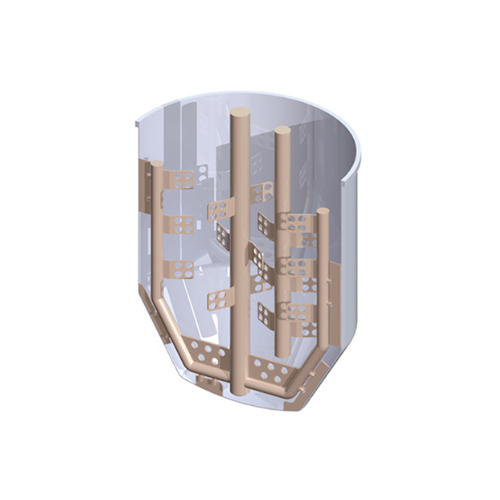

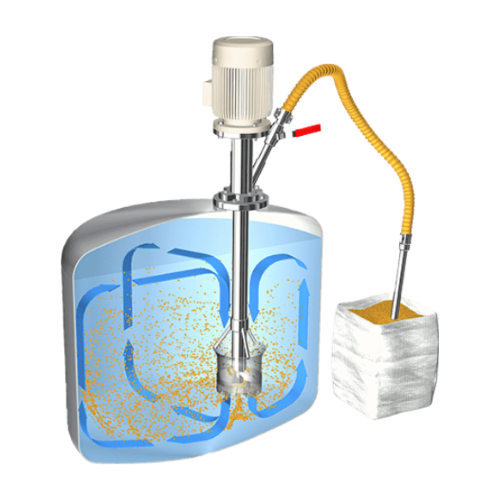

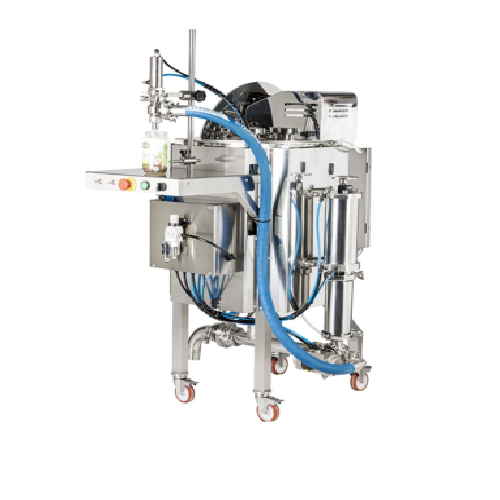

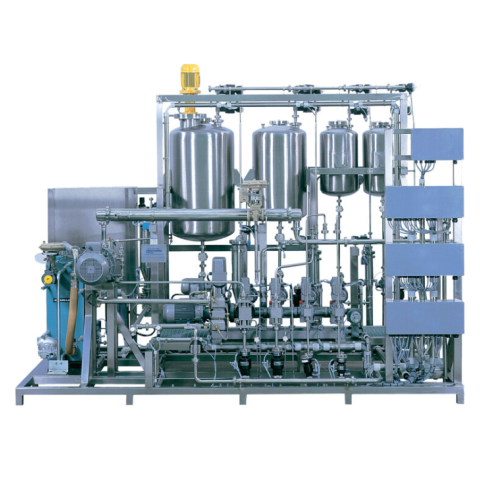

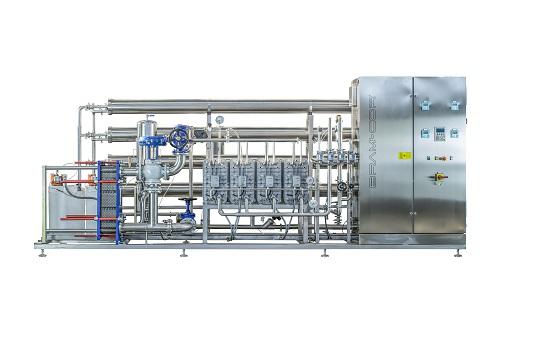

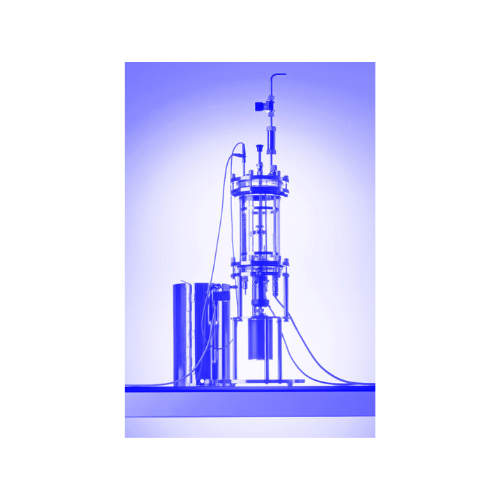

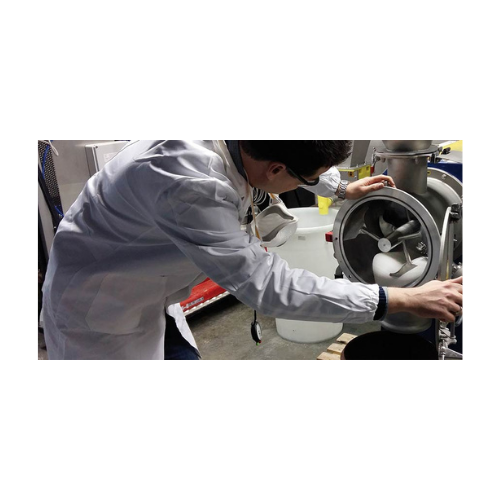

Emulsifier for cosmetic creams

The process of making cream and lotion involves mixing of water phase and oil phase to create...

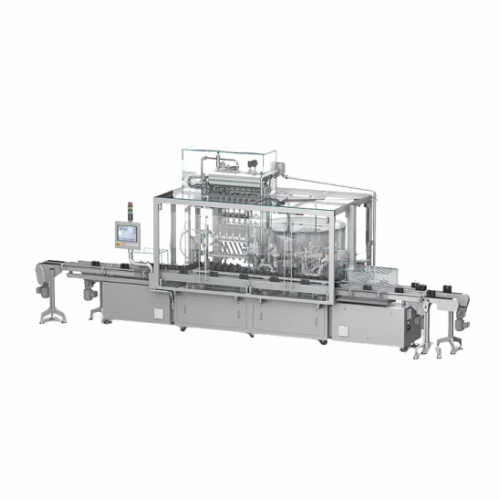

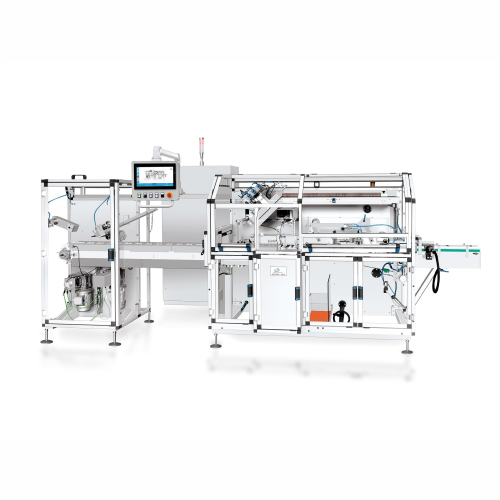

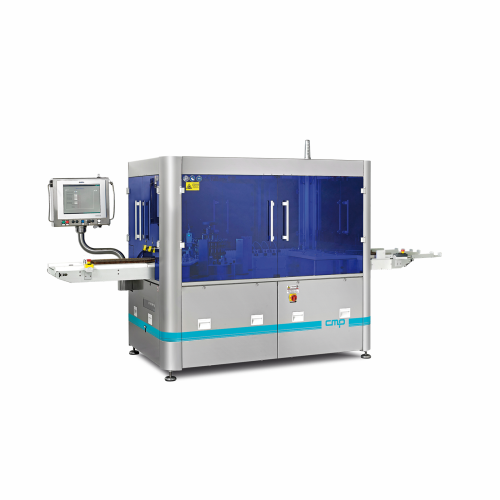

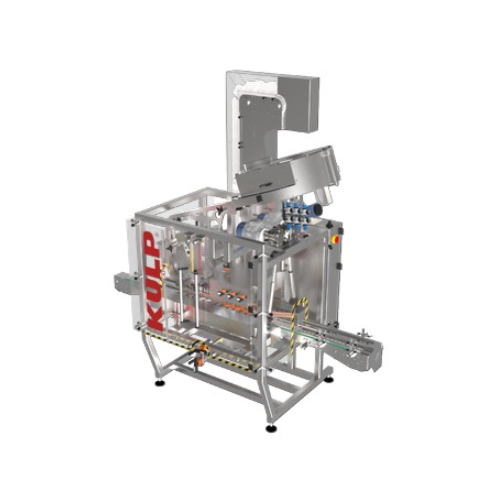

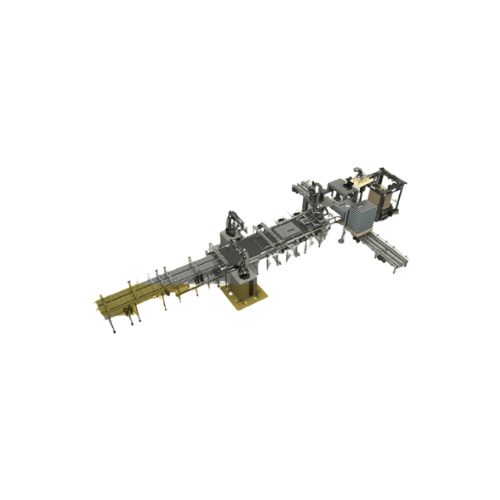

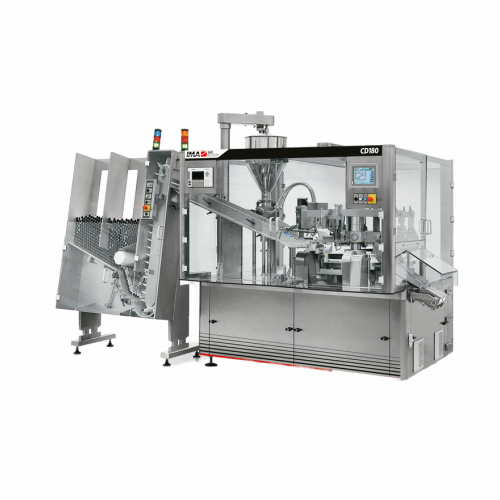

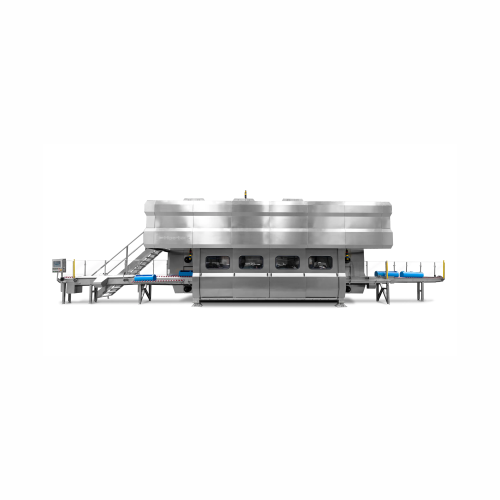

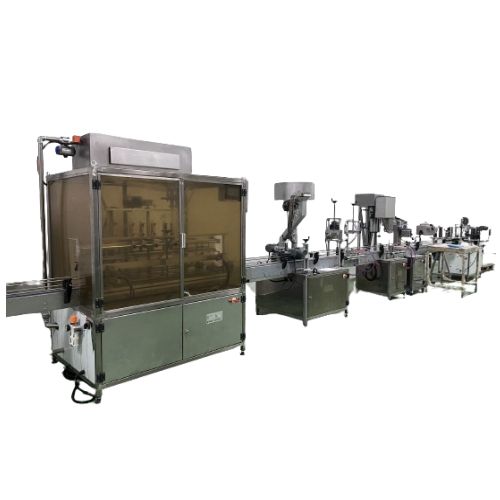

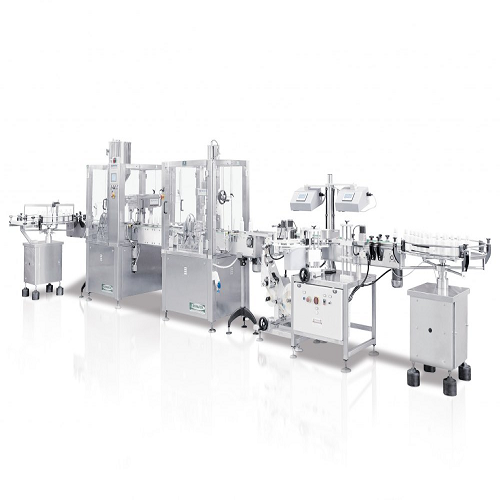

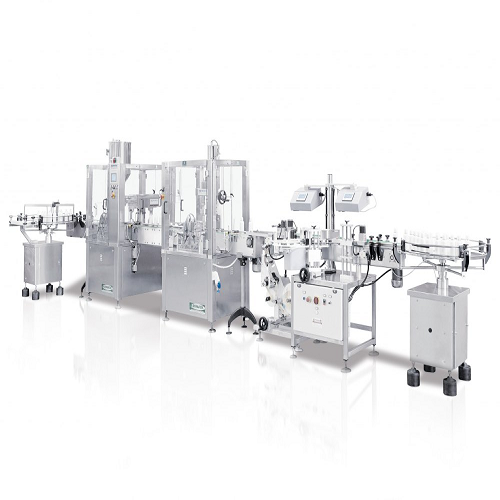

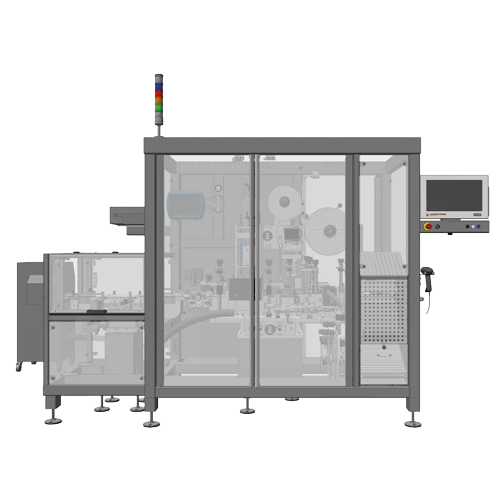

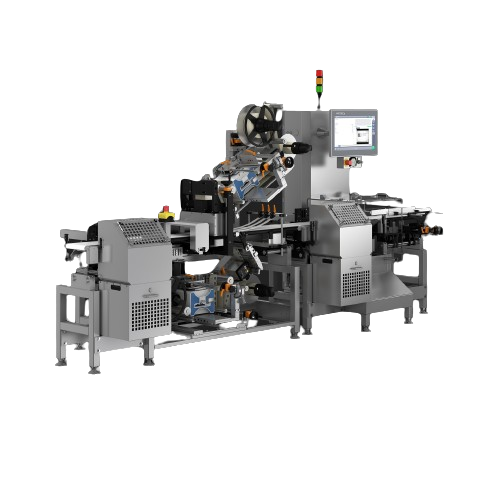

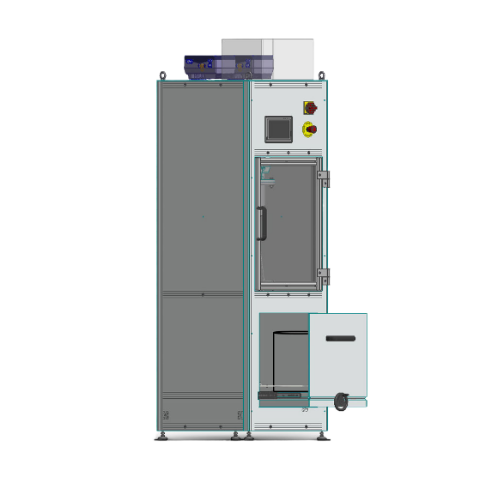

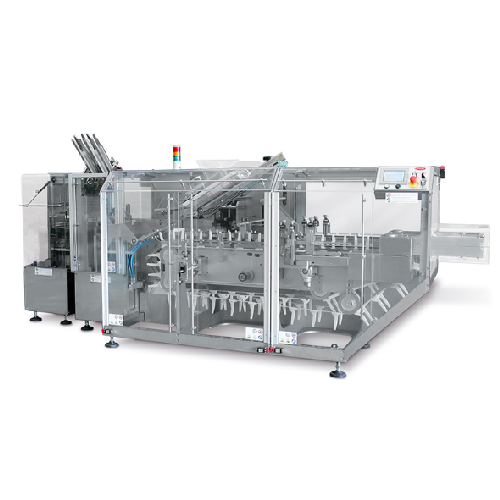

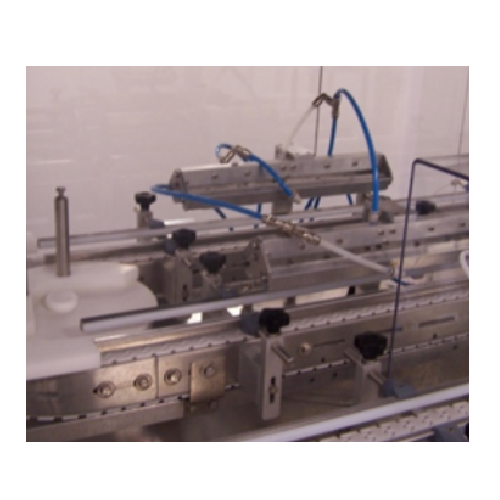

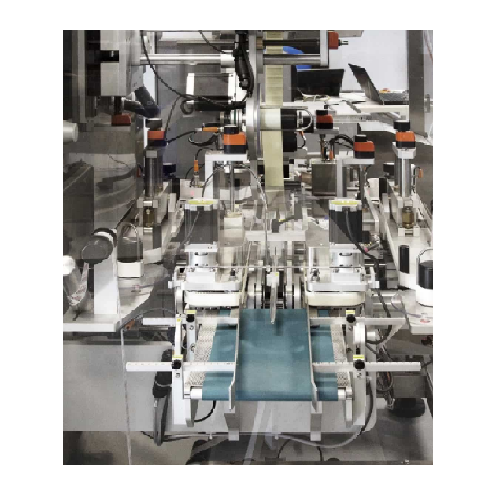

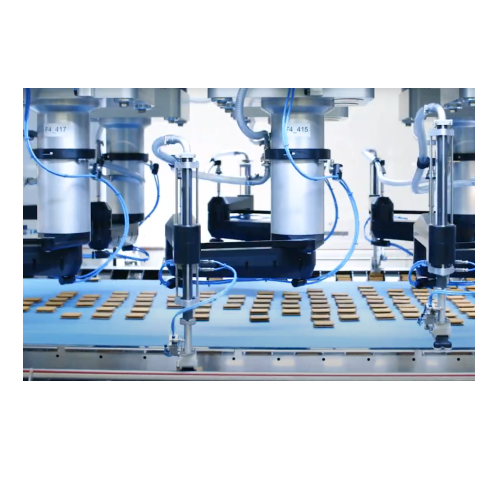

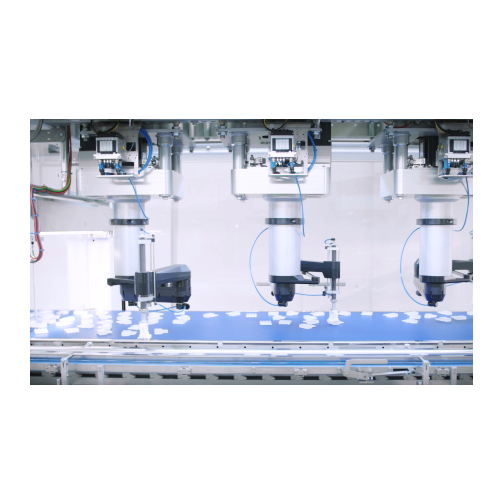

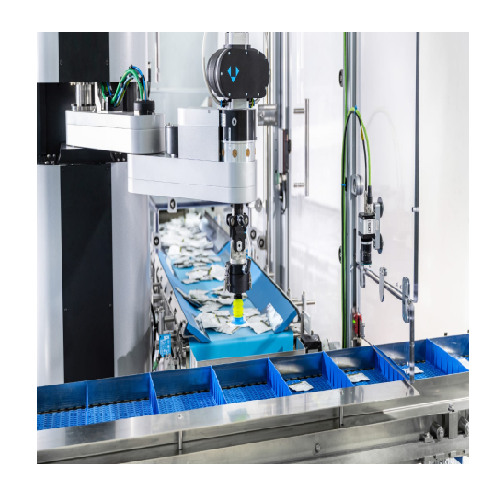

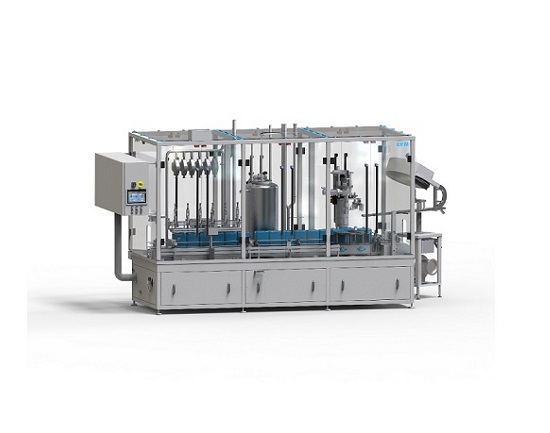

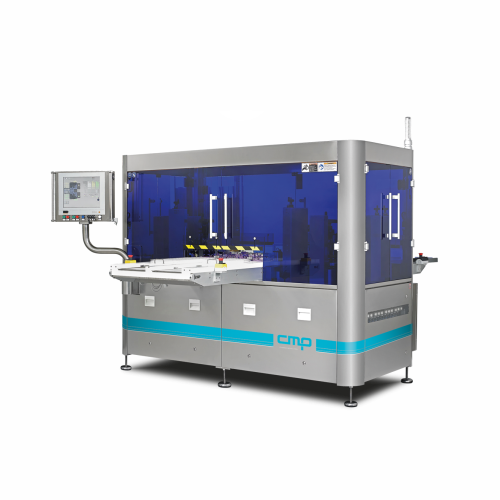

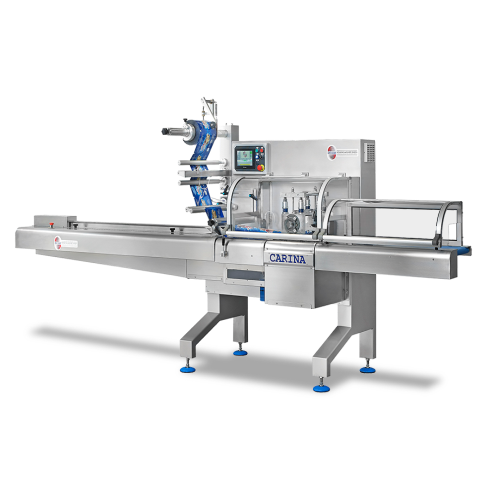

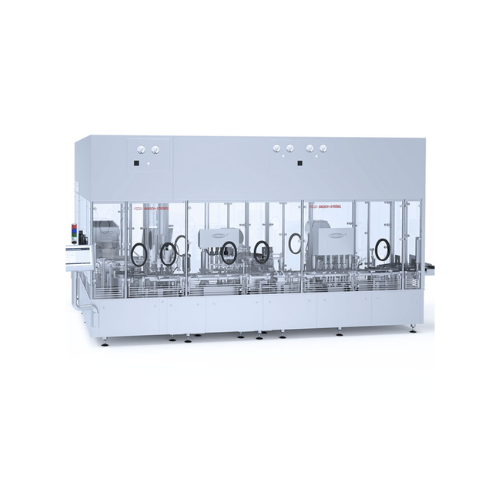

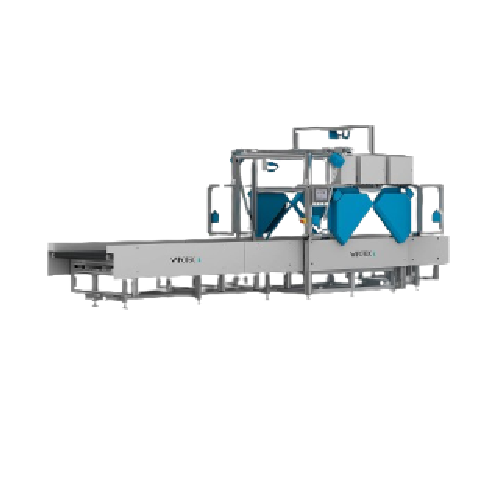

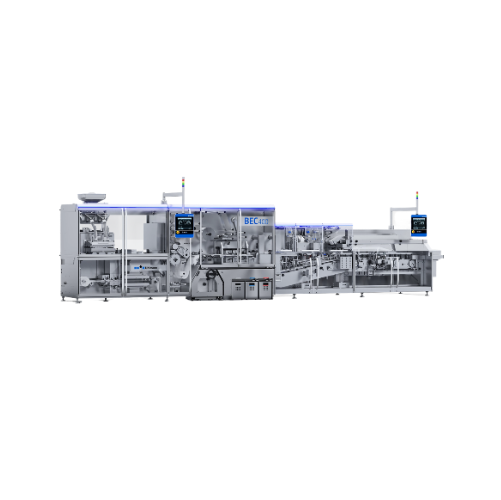

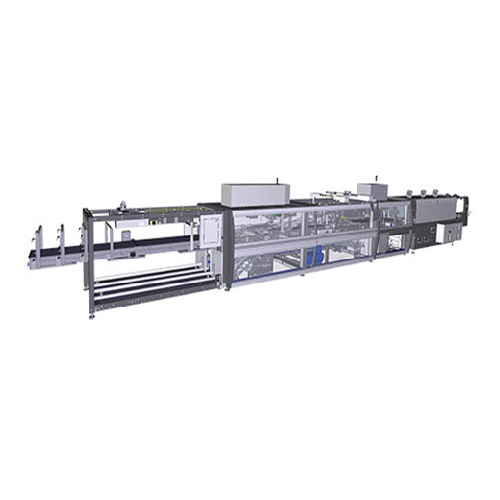

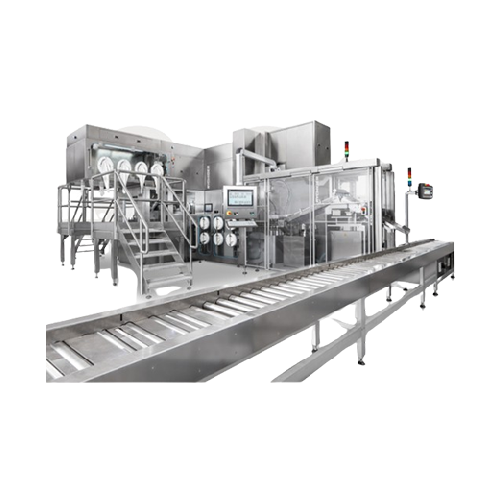

Filling and sealing system for creams and lotions

Achieve precise, high-speed filling and secure sealing of cosmetic cont...

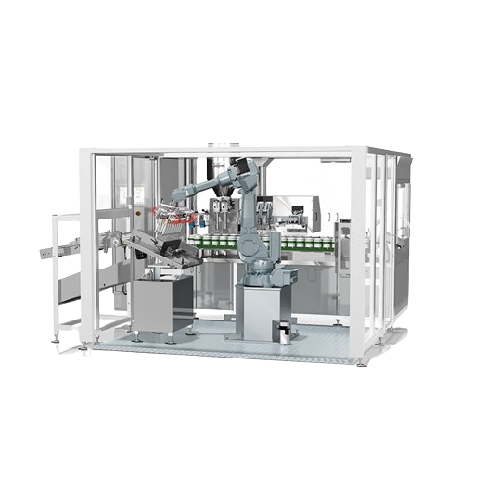

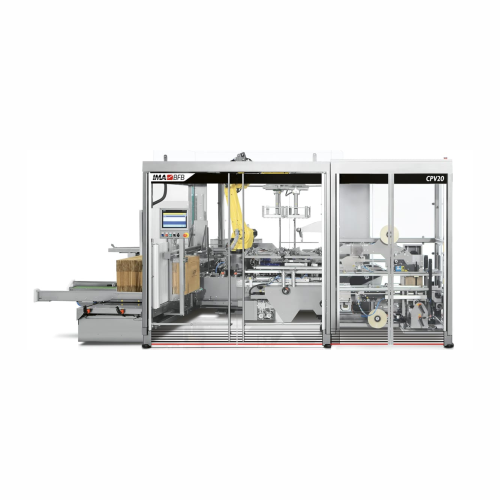

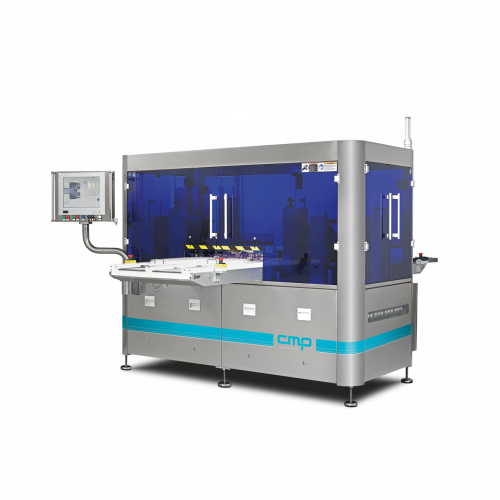

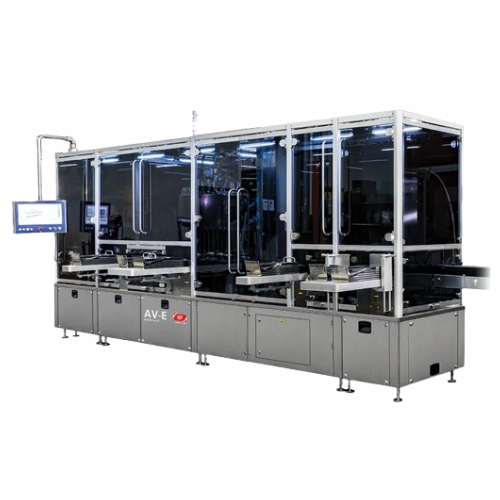

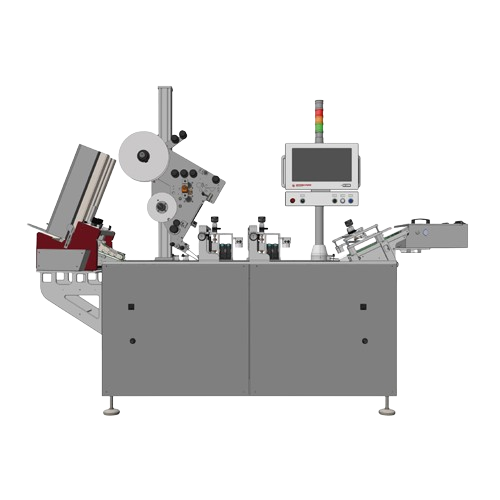

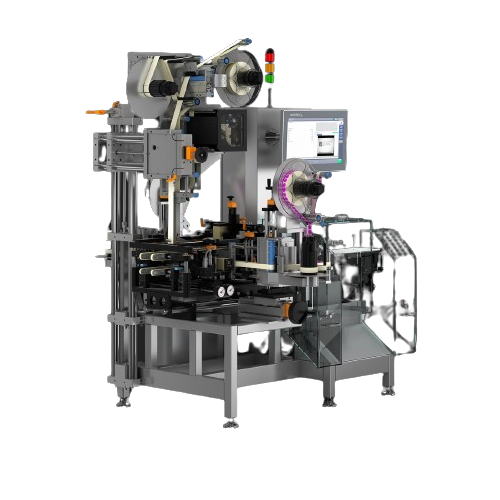

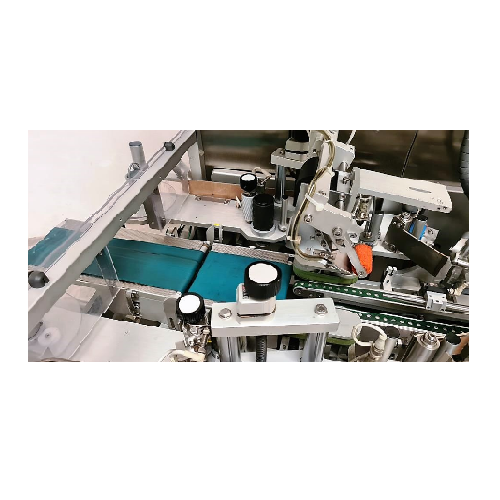

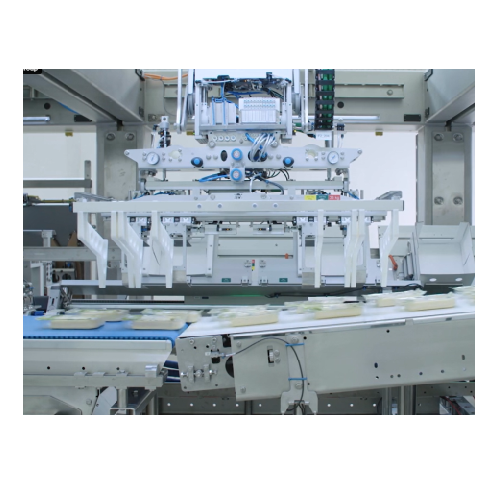

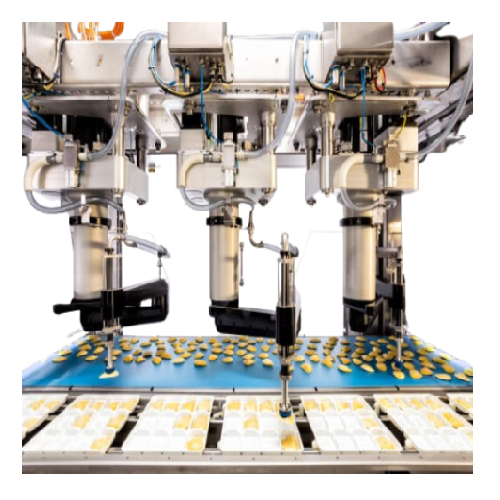

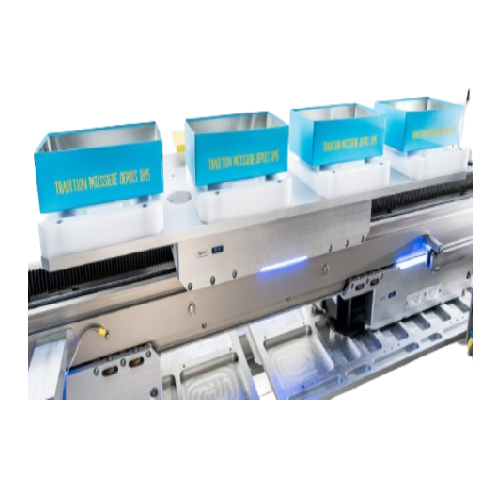

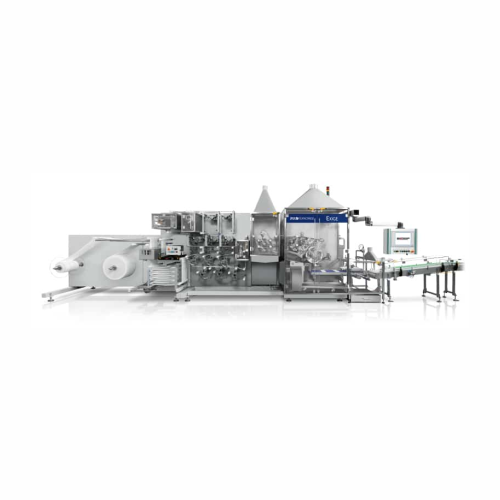

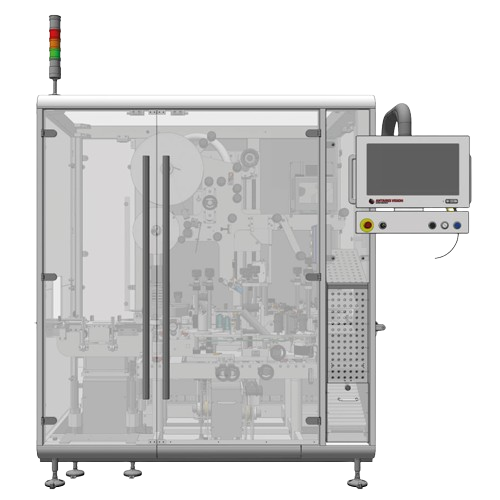

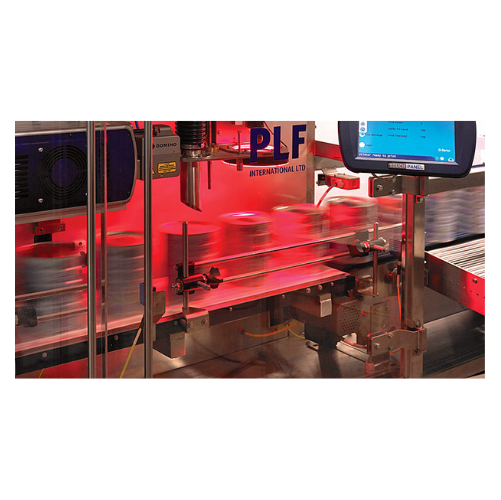

Automatic cartoning solution for cosmetic and fragrance samples

Streamline your cosmetic and fragrance sample packaging ...

Select your cosmetics process

What are you making?

Beauty products

Body care

Body wash

Bundles

Wax

Sun care

Soap bars

Soap

Skin care

Shower gel

Lip balm

Moisturizers

Hair gel

Hair dye kits

Hair conditioner

Hair care products

Hyaluronic acid serums

Gel nail polish

Hand cream

Foundation cream

Facial moisturizers

Face cream

Deodorants

Anti-dandruff shampoo

Anti-aging cream

Cosmetic serums

Cosmetic powders

Cosmetic lotions

Cosmetic emulsions

Aloe vera gel

Conditioner

Deoderant

Wet wipes

Infusions

Perfume

Facial Tissues

Refill tablets

Agar-agar

Serums

Lotions

Gels

Sunscreen

Ointment

Body lotion

Emulsions

Cosmetic creams

Shampoo

Hand soap

Toothpaste

Mascara

Lipstick

Face powder

Nail polish

Cosmetic foundation

Lip gloss

Eyeshadow

Flower extract

Echinacea extract

Sea buckthorn oil

Lavender oil

Rose oil

Tea tree oil

Collagen powder

Chamomile oil

Hyaluronic acid

Eucalyptus oil

Tell us about your production challenge

Natural chemistry, a shift towards more organic skincare

There is a growing dissatisfaction with the chemical constituents of traditional cosmetics and personal care products, especially among younger generations. Many newer cosmetics have dropped such problematic chemicals for natural alternatives much to the satisfaction of their consumers. Our understanding of natural compounds has dramatically improved in recent years, and these high quality alternatives often perform as well or even better than the chemicals they replace. Paraben preservatives may be replaced by plant-derived formulations of salicylic acid for example, and petro-chemical agents may be replaced by novel, natural polysaccharide compounds. Renewable, natural, and biodegradable cosmetics appeal to consumers wanting to live more in harmony with both their bodies and the environment.

Achieving regulatory compliance in making cosmetic products

All cosmetics are subject to some form of regulation, but the specifics vary from region to region. European guidelines provide rules for the whole of the EU constituents, while the US has its own set. While many aspects are similar, the EU has a significantly more extended list of banned substances in making cosmetic products such as parabens and formaldehyde permitted in the US. Among others, regulations generally emphasize safety, the appointment of a responsible party, directives for sampling, analysis, animal testing and labeling, and good manufacturing practices.

How cosmetic labeling forms the basis of regulation

A crucial aspect of the cosmetic regulatory process, proper labeling is essential for regulatory approval. A prospective cosmetic in the EU must include the list of ingredients, expiration date, warnings, purpose, batch number, and nominal contents at the time of packing. In addition, you must declare the business name and related information, such as the registered office and the responsible party. You may be asked to provide other data deemed necessary to meet regulations, so take care to check with your local authorities. Due to the broad range of products classified as cosmetics, the scrutiny given to a product may also vary, but more scientifically complex will generally be more heavily reviewed before approval.

In labeling cosmetics, the International Nomenclature of Cosmetic Ingredients provides standardized names for over 16,000 ingredients. The list is maintained regularly, provides a reference for how ingredients should be consistently labeled worldwide, and independently assesses the safety of those ingredients in unbiased analysis. Ingredients are labeled in order from the most abundant to the least.

Which cosmetics technology do you need?

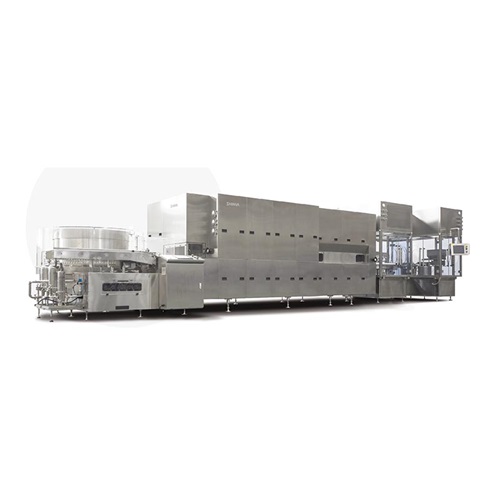

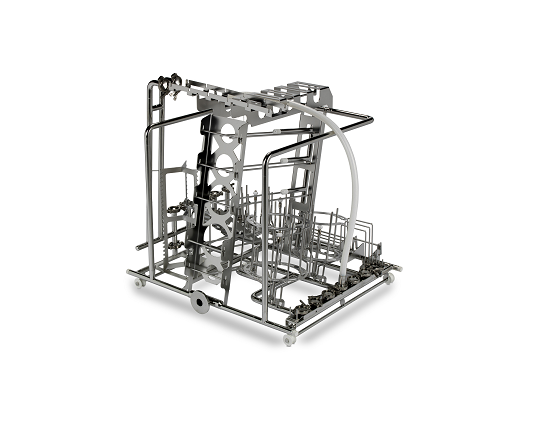

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

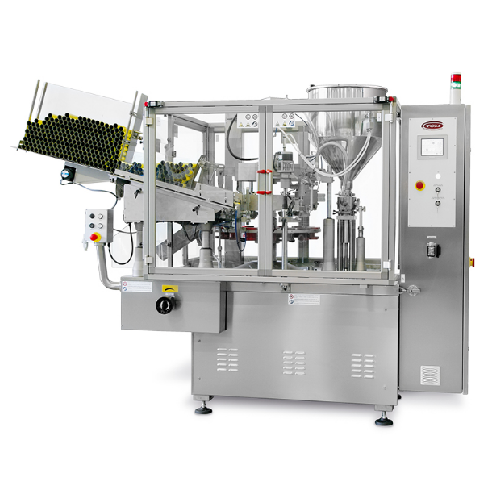

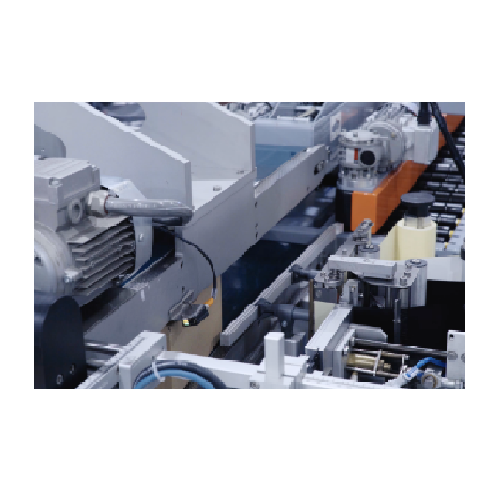

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

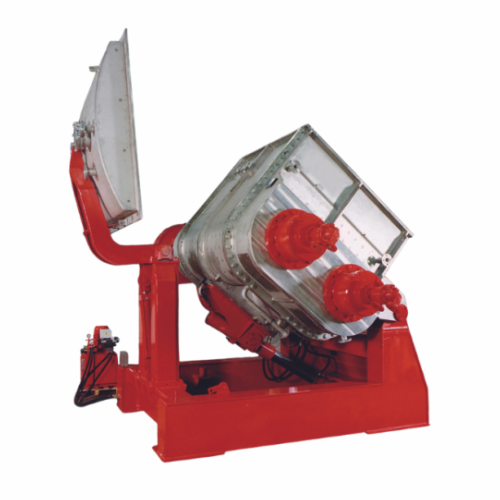

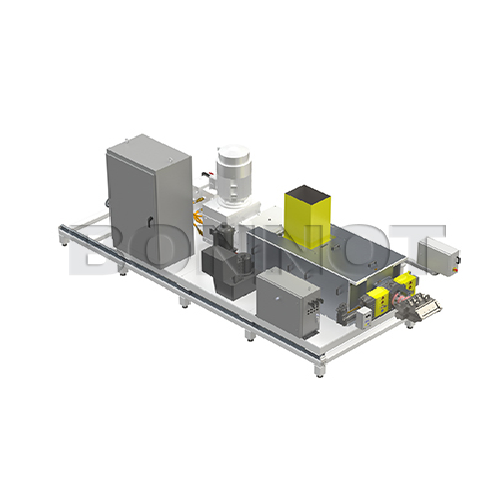

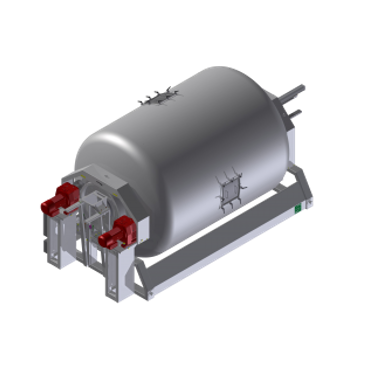

Industrial melter for cosmetic product processing

Streamline your production with this versatile melter, designed to effi...

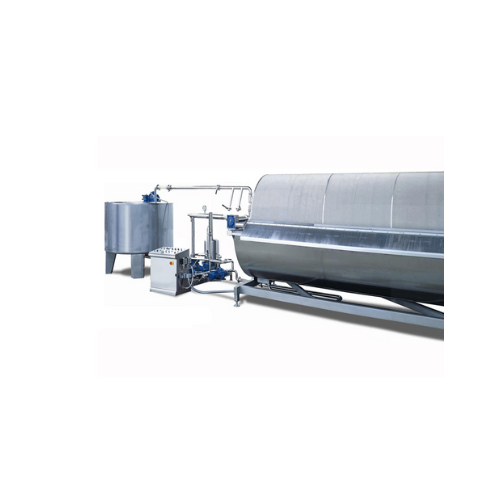

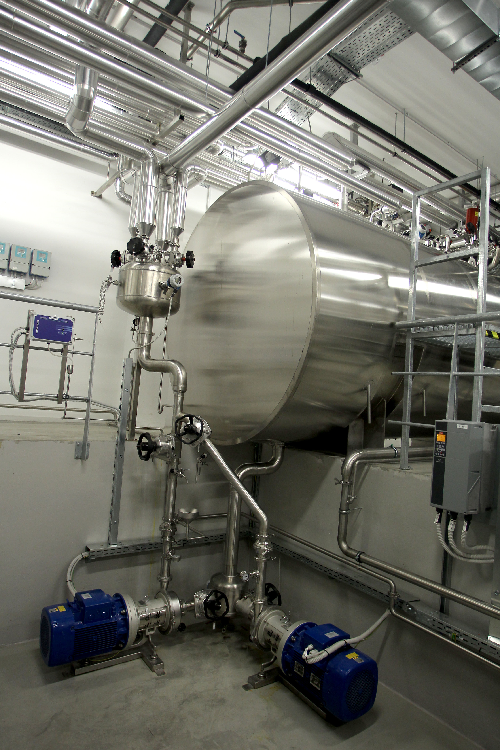

Melting tank for cosmetic production

Achieve precise and consistent melting and dosing of cosmetic liquids, from face cream...

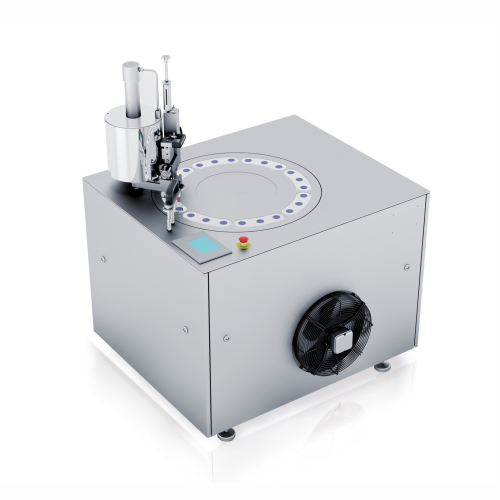

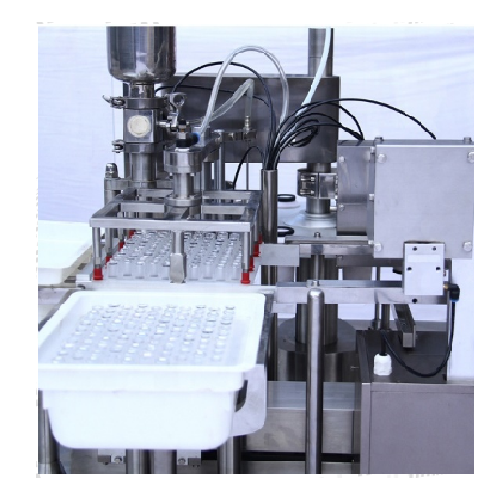

Cosmetic pencil filling system

Streamline your cosmetic production with high-speed filling and precise molding capabilities,...

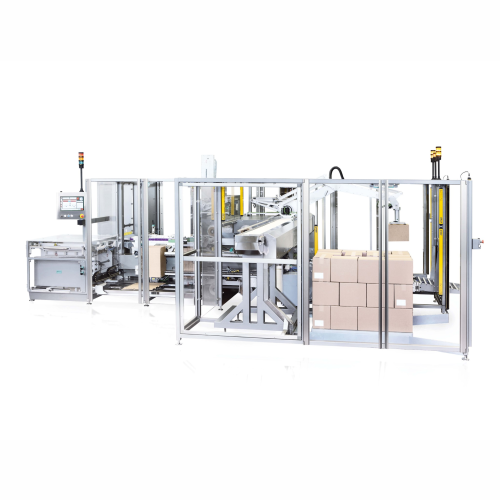

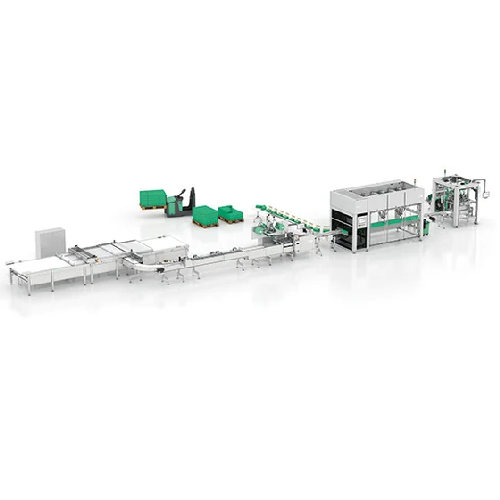

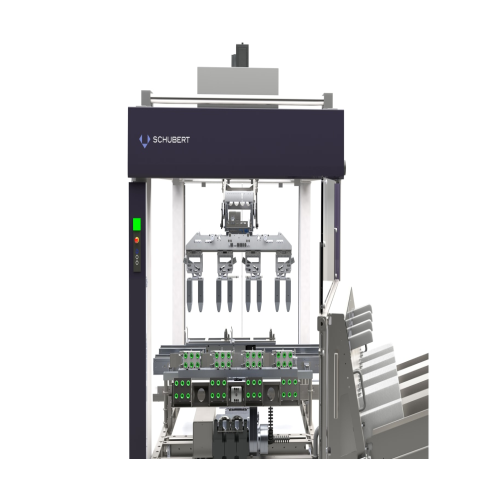

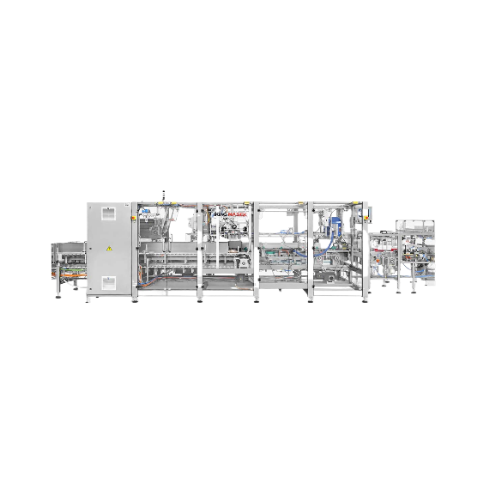

Automatic vertical case packer and palletizer for cosmetic sector

Optimize your packaging process with a compact soluti...

Automatic case packing solution for cosmetic products

Streamline your cosmetic production line with efficient case packin...

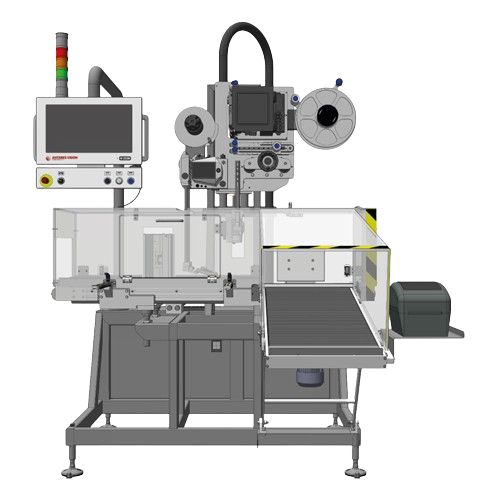

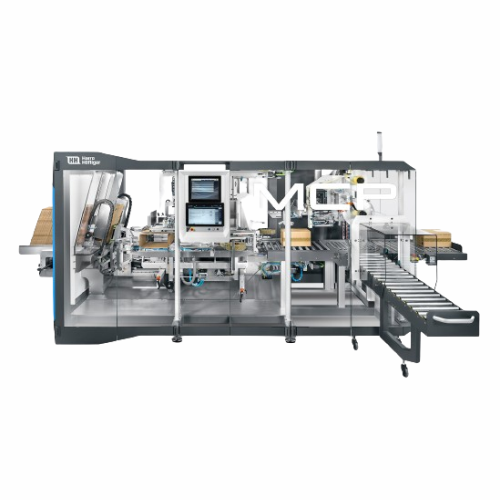

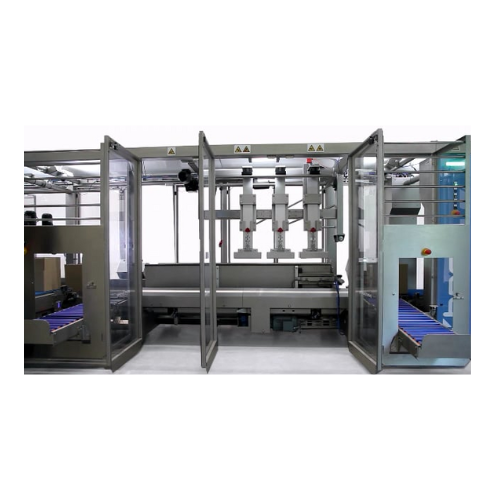

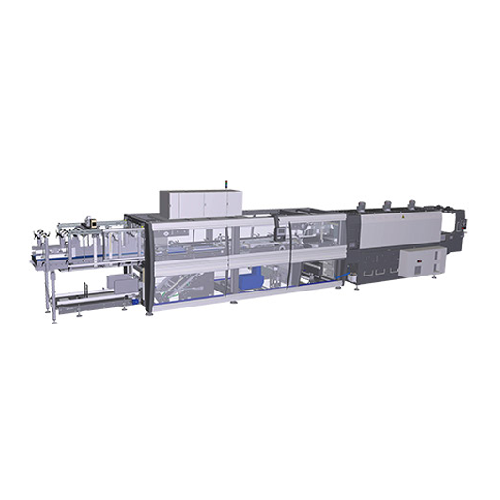

Automatic cartoning solution for cosmetic and fragrance samples

Streamline your cosmetic and fragrance sample packaging ...

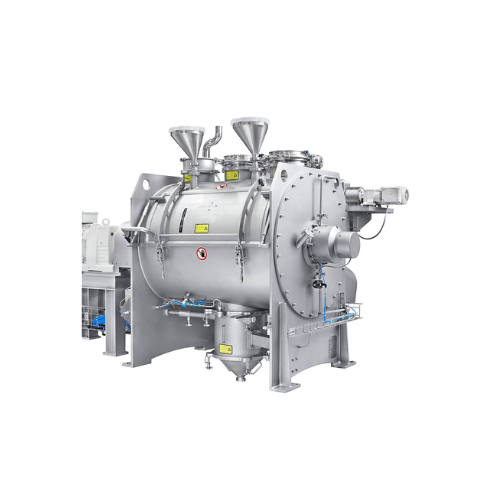

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

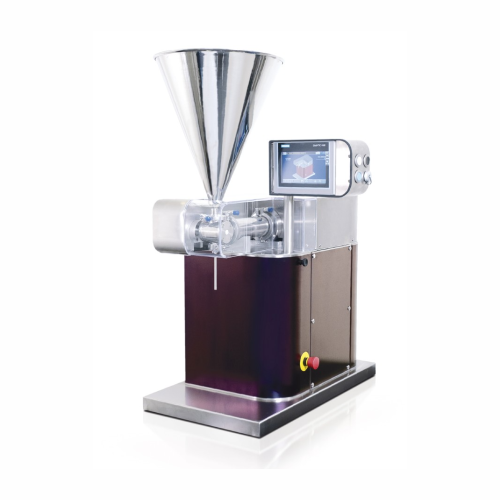

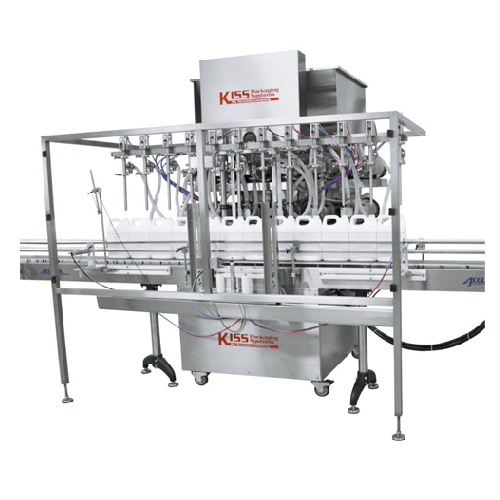

Volumetric filling system for cosmetic products

Streamline your production line with precise volumetric control, ensuring ...

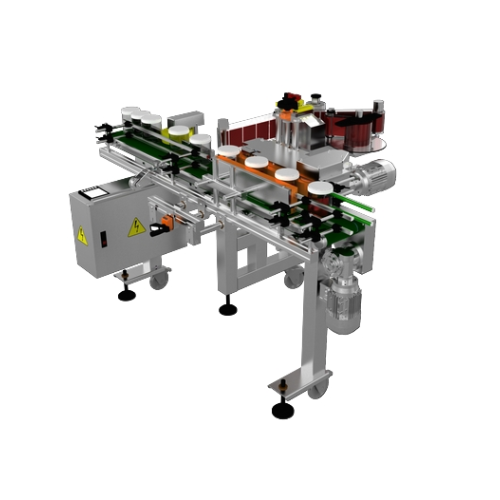

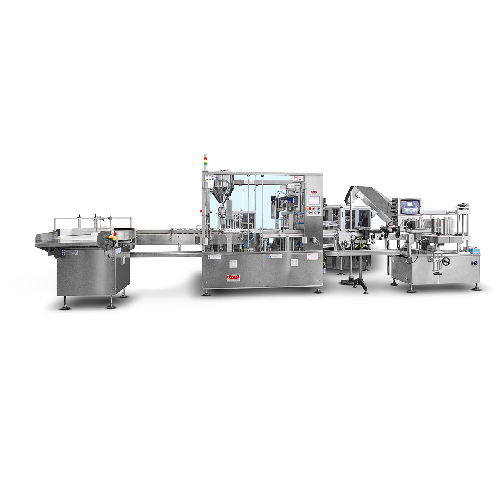

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

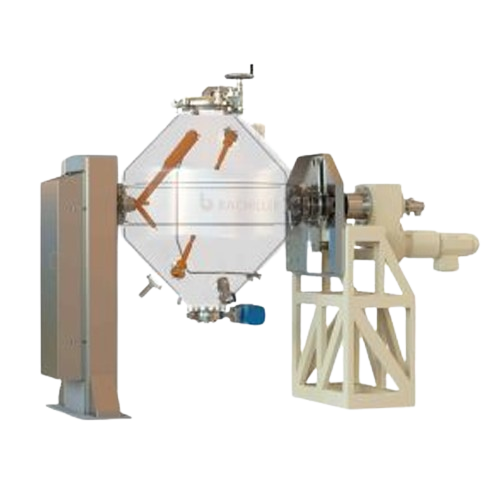

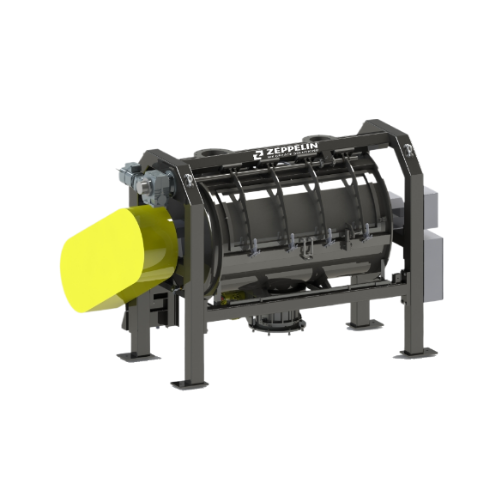

Counter-rotating blender for cosmetic and pharmaceutical mixing

Achieve precise mixing and homogenizing of complex formu...

Top-loading case packer for pharmaceutical and cosmetic products

Ensure precision and flexibility in packaging with this...

Tablet pressing system for solid chemicals and cosmetic products

Optimize your tableting process for diverse solid produ...

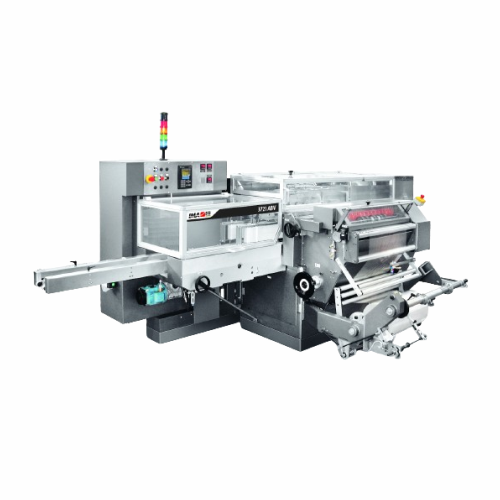

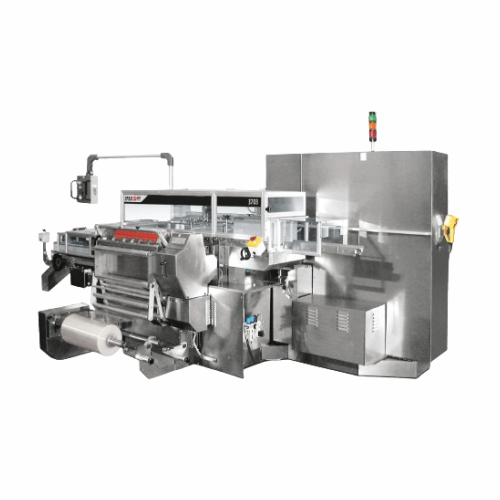

High-speed overwrapping for cosmetic and toiletry items

Achieve precise and efficient over wrapping of cosmetic and toile...

Overwrapping system for cosmetic and toiletry items

Ensure precise overwrapping of cosmetic and toiletry items with advan...

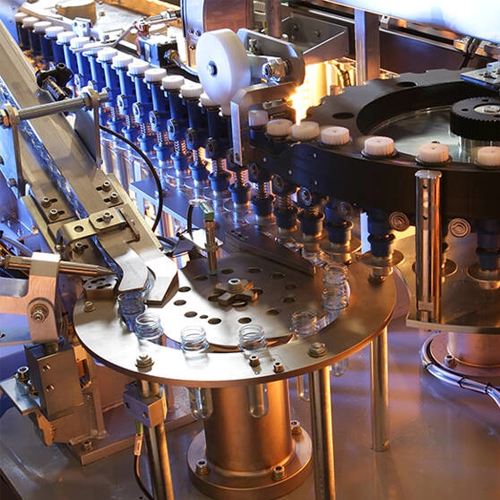

Automatic perfume filling line for cosmetic production

Ensure efficient and precise filling of perfume bottles and liquid...

Mascara and lip gloss filling system for cosmetics

Optimize your cosmetic product filling operations with precision, hand...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel cooking kettle for food, pharma, and cosmetics

Efficiently streamline your production with versatile sta...

Industrial storage tanks for chemical and cosmetic industries

Need reliable storage that withstands aggressive chemical ...

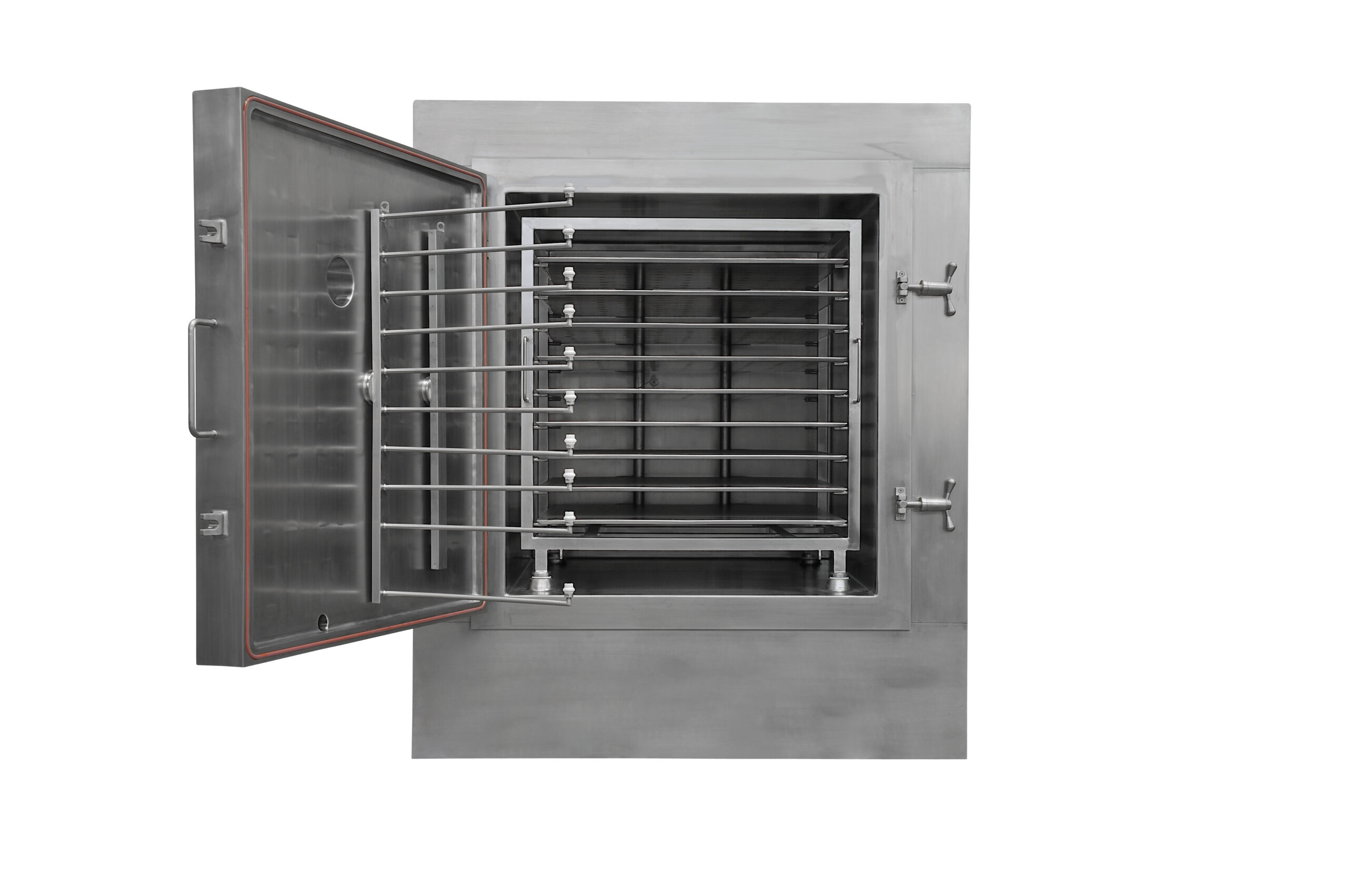

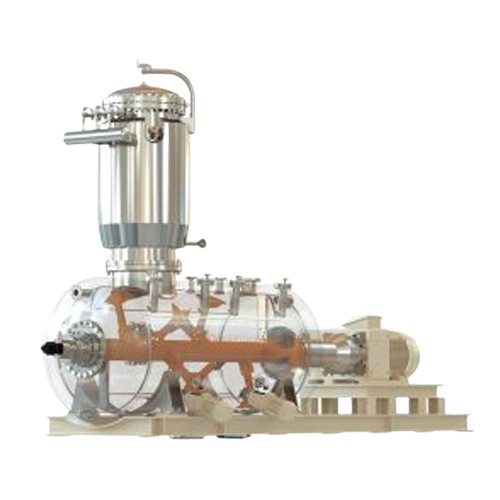

Drying solution for cosmetic slurries

Streamline the drying process of cosmetic slurries with precision control to achieve ...

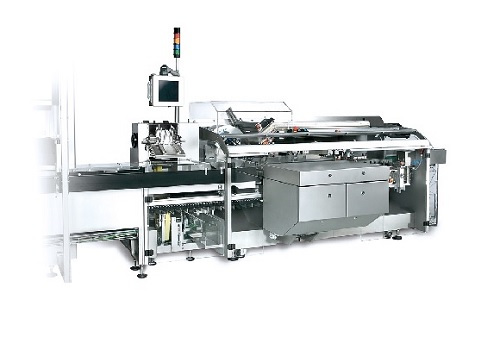

Horizontal cartoner for cosmetic applications

Perfect for packaging fragile cosmetic items, this cartoner efficiently mana...

Lipstick moulding solution for cosmetics manufacturing

Streamline lipstick production with high-speed molding and flexibl...

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

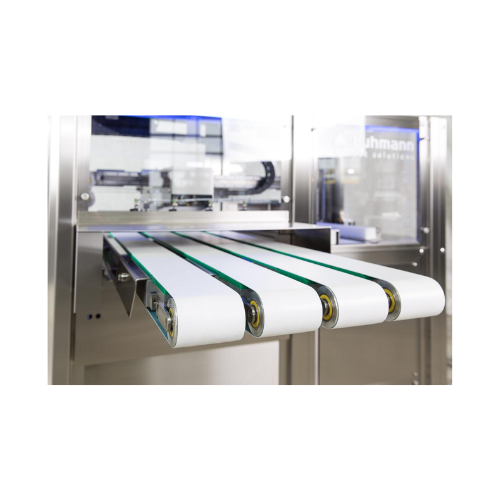

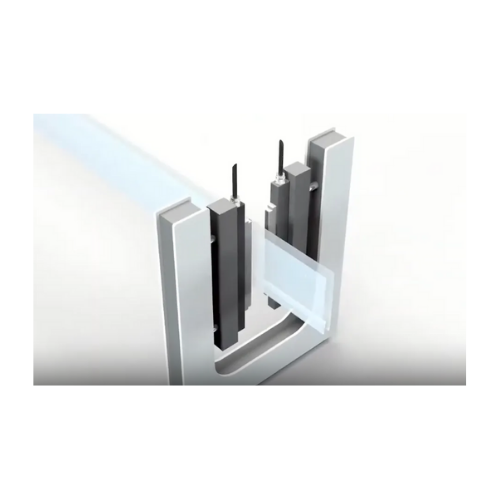

Tube in-feed conveyor for cosmetic packaging lines

Streamline your packaging process with precision by efficiently transf...

Intermittent motion overwrapper for cosmetic and food products

Achieve flawless packaging with precision wrapping and se...

High-pressure reactor for cosmetic and pharmaceutical production

Ensure precise formulation and enhanced product stabili...

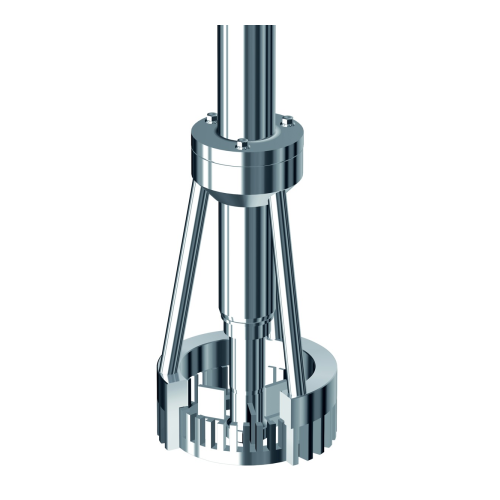

Undervacuum homogenizer for cosmetic and pharmaceutical creams

Optimizing the production of creams and lotions, this und...

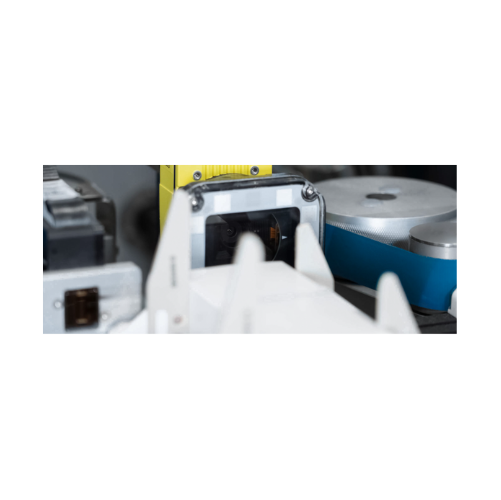

X ray inspection for unstable cosmetic products

Ensure product integrity by detecting contaminants in unstable packaging w...

Dual lane x-ray inspection system for cosmetics

Optimize your production line with dual-lane x-ray technology that ensures...

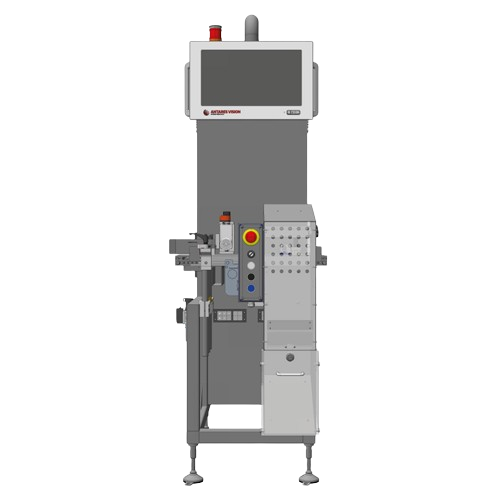

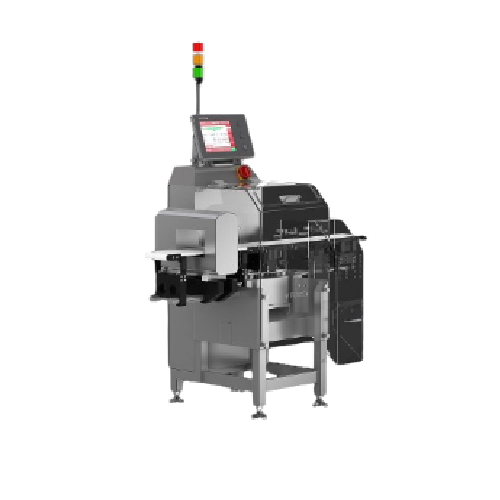

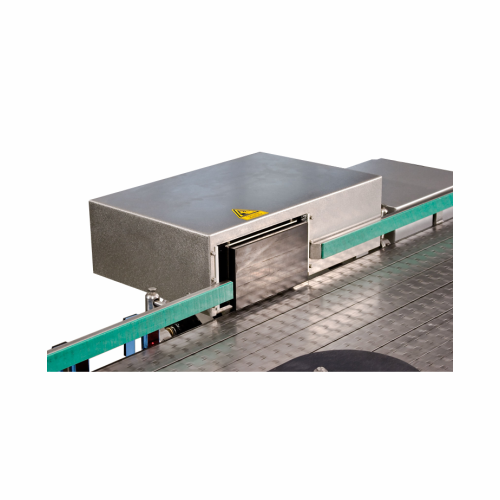

Metal detector and checkweigher for cosmetics production

Ensure seamless quality control by combining metal detection and...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

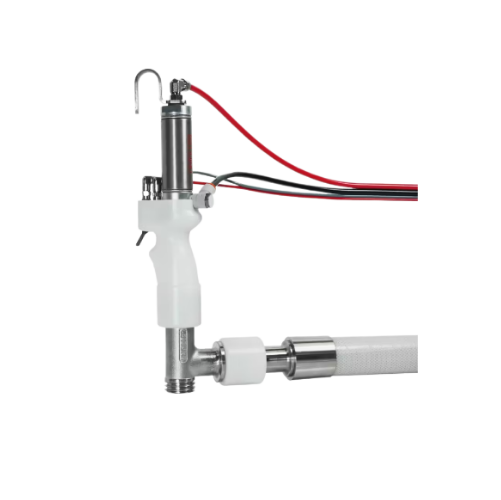

Hygienic dispenser for precise dosing in food and cosmetics

Achieve precise dosing and application of high-viscosity liq...

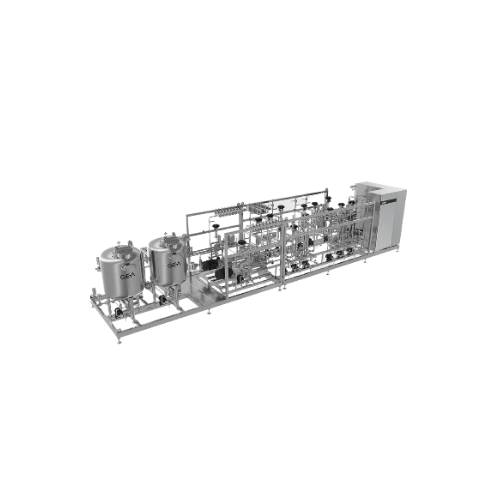

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

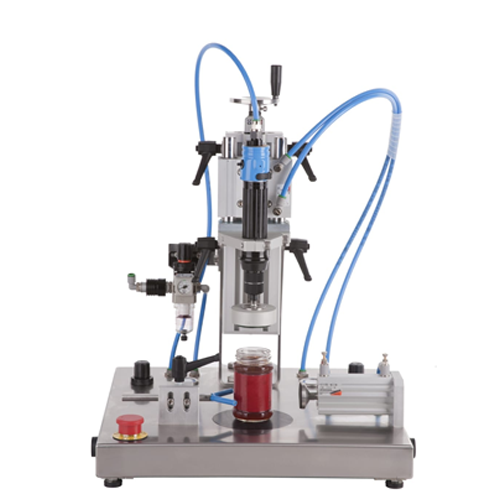

Semi-automatic capping solution for beverage and cosmetic bottles

Streamline your bottling process with versatile bench...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Emulsifier for cosmetic creams

The process of making cream and lotion involves mixing of water phase and oil phase to create...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

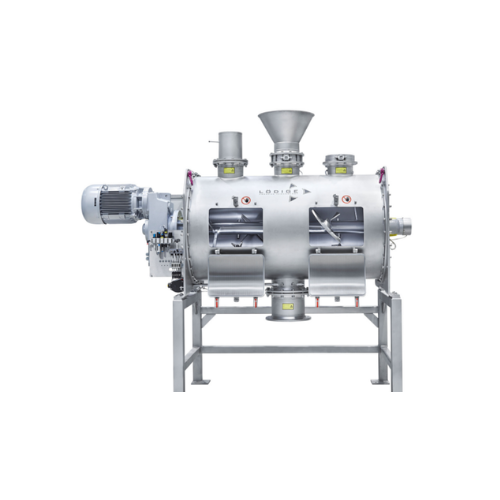

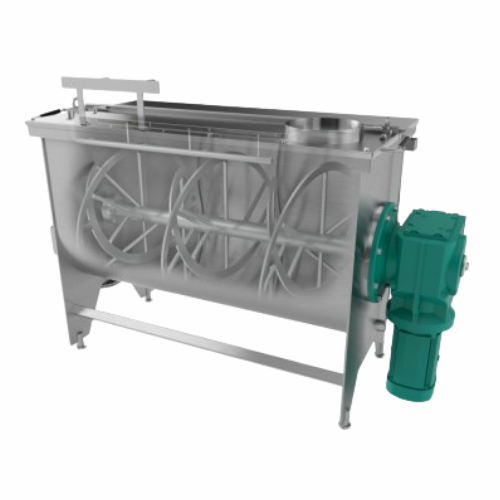

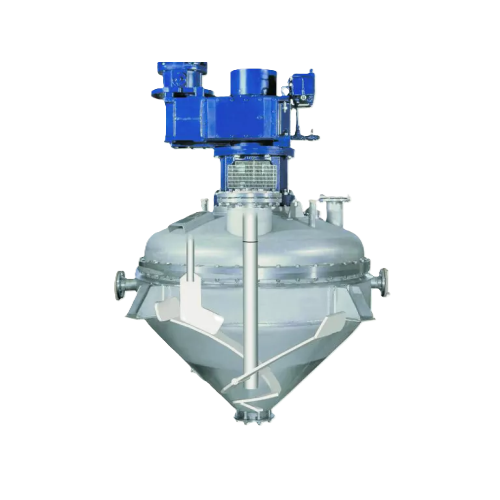

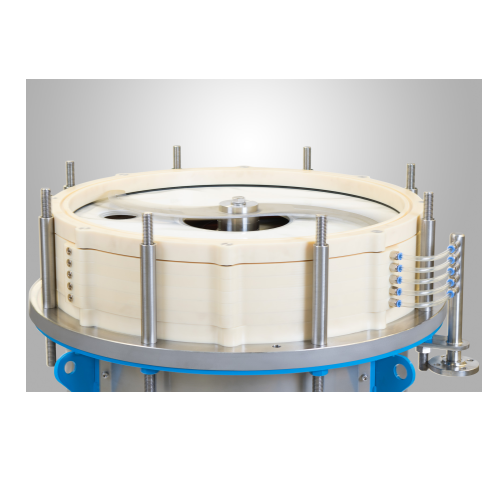

Blending tank for cosmetic powders

The production of high-quality cosmetics powders requires perfect mixing and dispersal o...

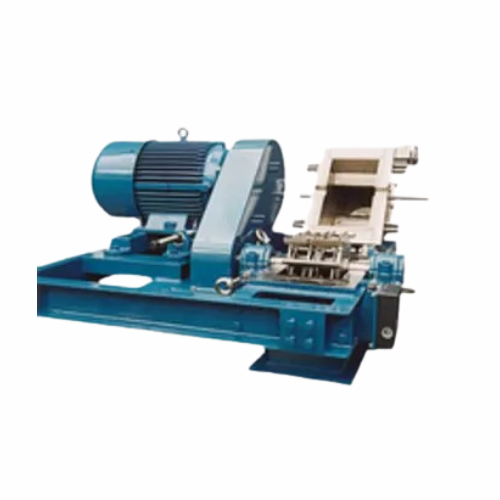

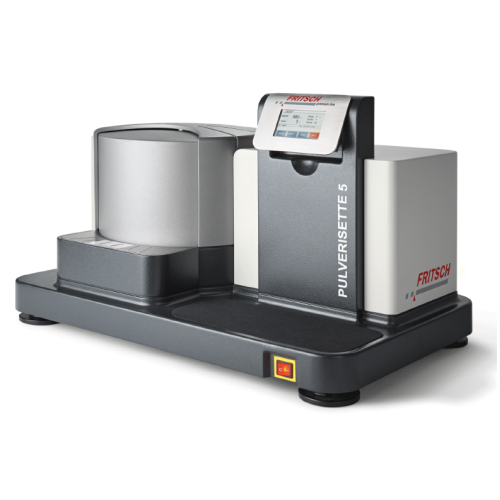

Manual cosmetic powder press

The design, manufacture and testing of new cosmetic powder products require a small-scale press...

Mixing tanks for liquid cosmetic products

When producing liquid solutions for cosmetics, such as eyeshadow, it’s vital to ...

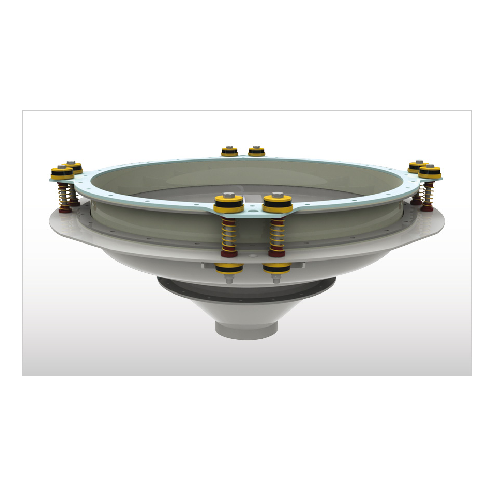

Vibrating screen for cosmetic powders

Dense or viscous compounds can be difficult to prepare for use in cosmetic products. ...

Cosmetic powder pressing machine

For the medium and large-scale production of compressed powder cosmetics, a fully-automatic...

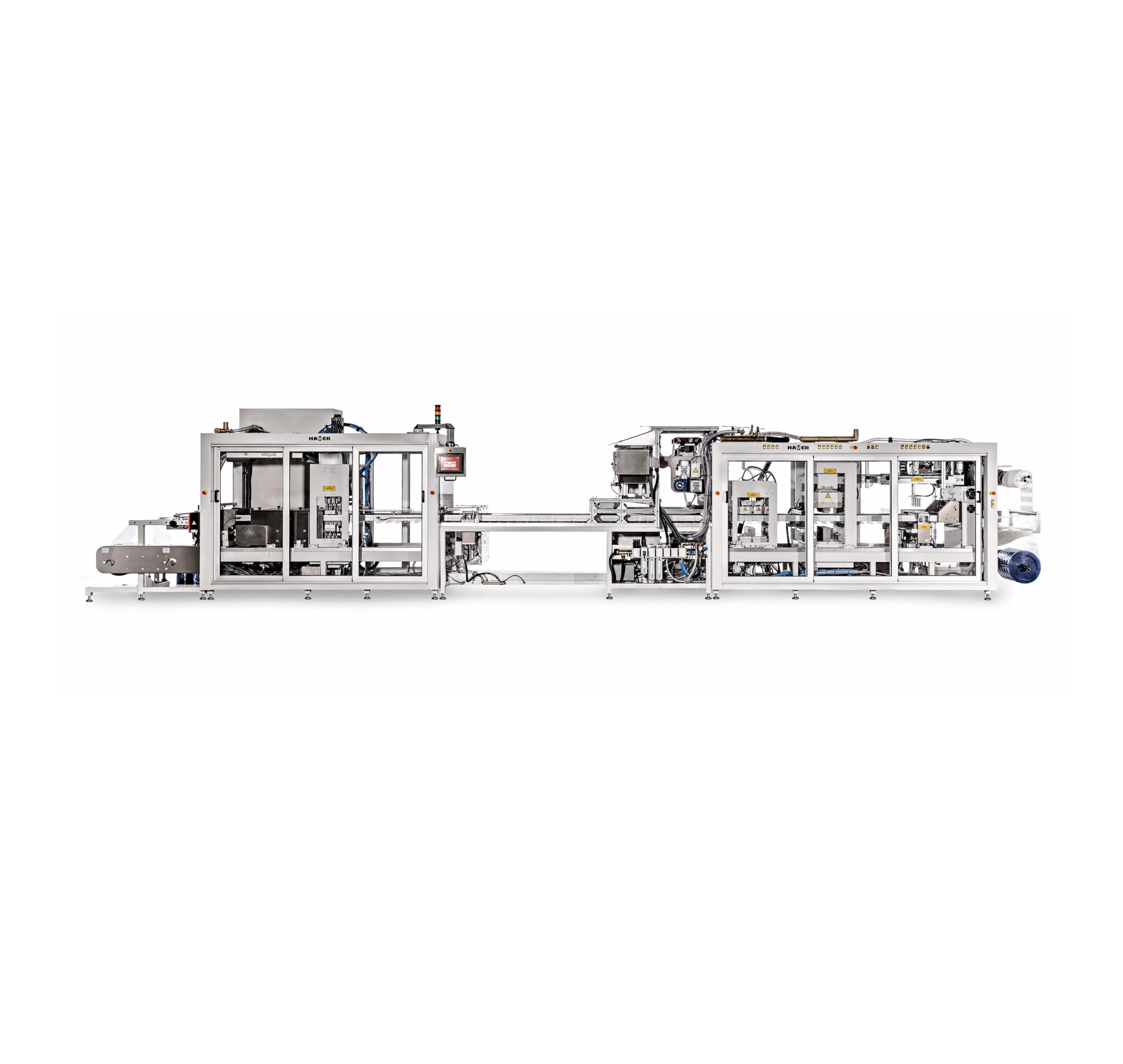

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

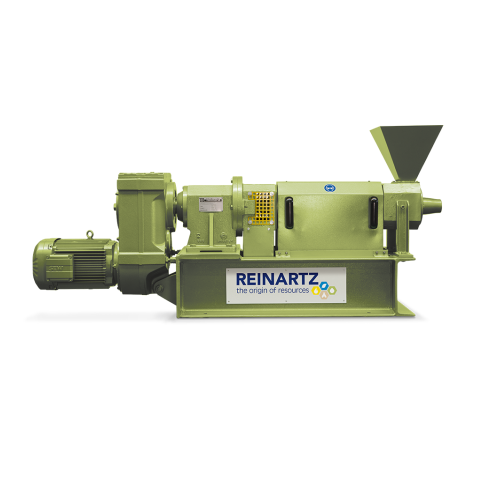

Cold press for extracting vegetable oils

Efficiently extract high-quality oils from diverse seeds while preserving vital nu...

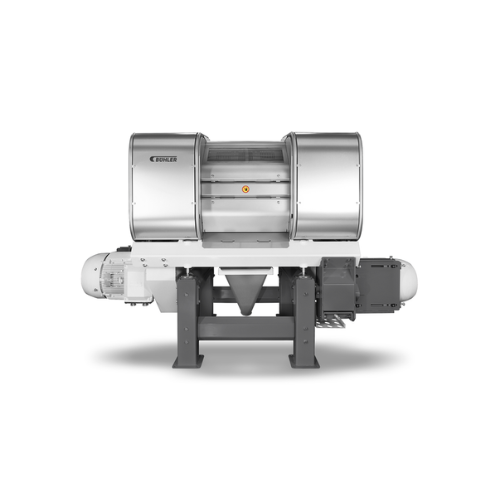

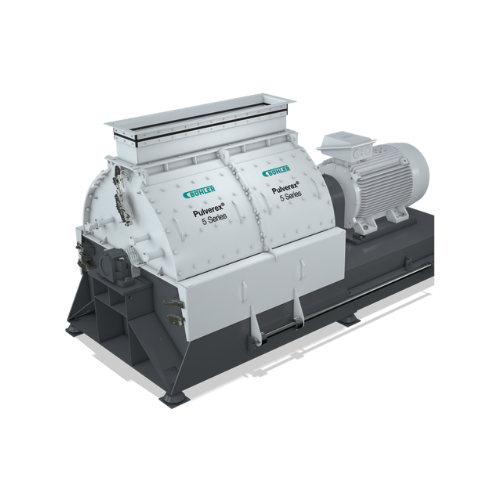

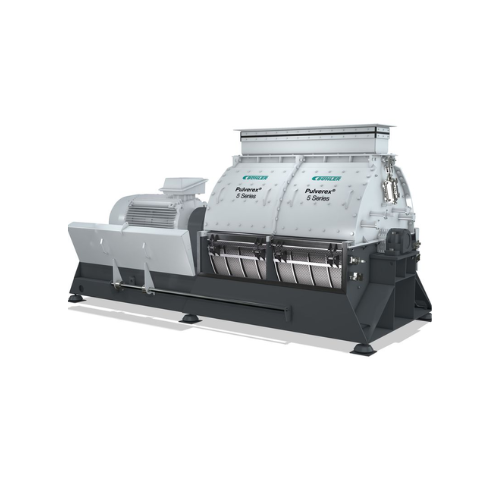

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

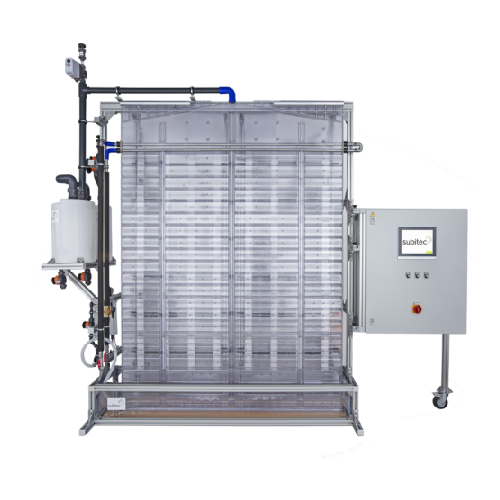

Indoor microalgae cultivation technology

Enhance sustainability and productivity in microalgae cultivation with a vertical ...

Perforated disc mill for food and chemical processing

Streamline your processing workflow with a versatile solution that ...

Perforated disc mill for pre-comminution and mashing

Achieve precise granulating and mashing of diverse materials with th...

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Horizontal colloid mill for precise grinding

Achieve precise particle size reduction and reproducible results with our adv...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Multistage mixer for emulsions and dispersions

Enhance your production with a versatile multistage mixer that ensures opti...

Multistage mixers for emulsions and dispersions

Experience efficient emulsification and dispersion processes with this ver...

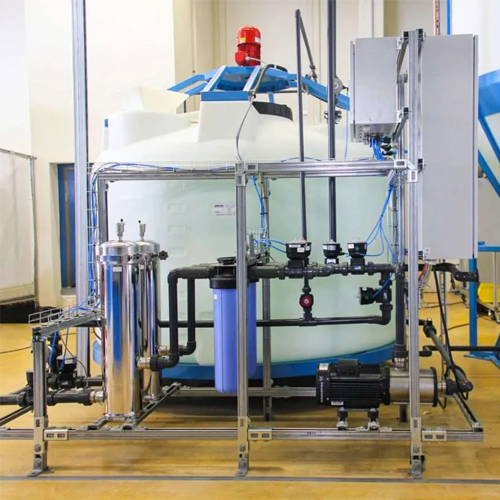

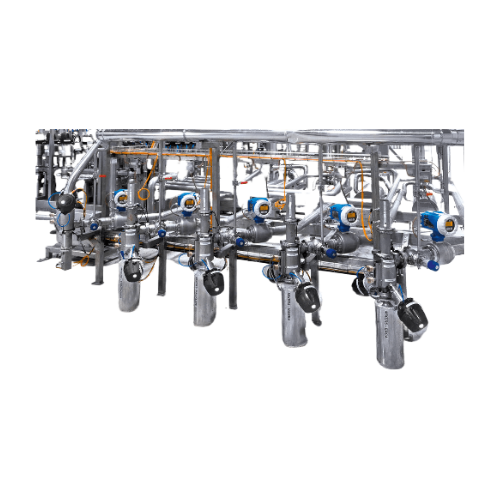

Clean-in-place system for industrial cleaning needs

Optimize your production efficiency with a system that seamlessly int...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

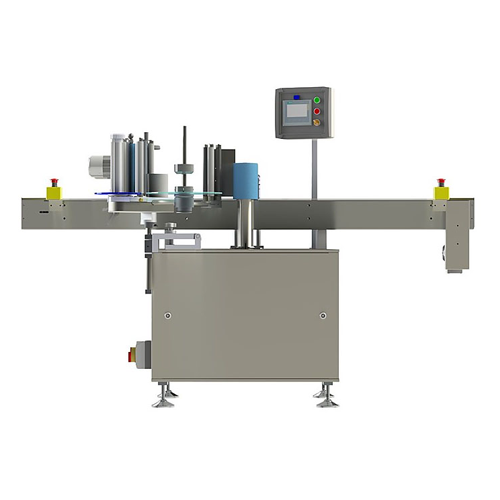

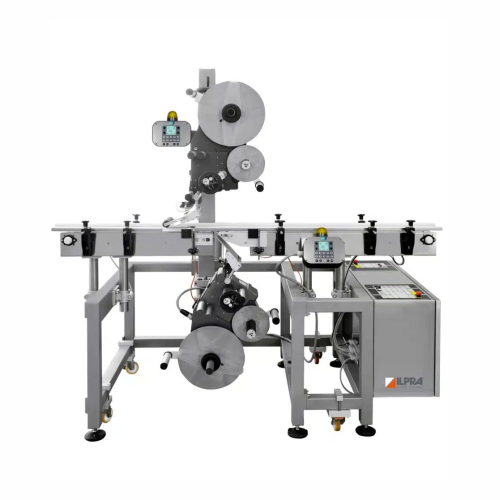

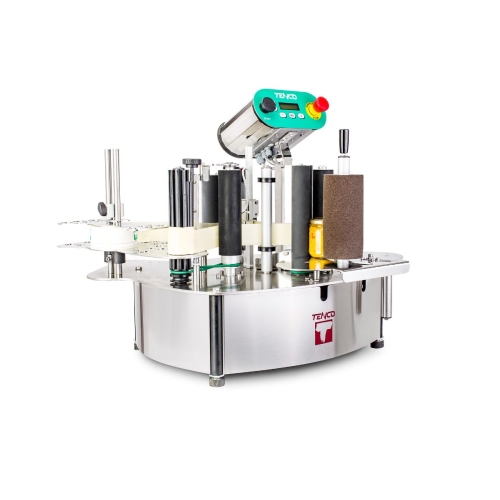

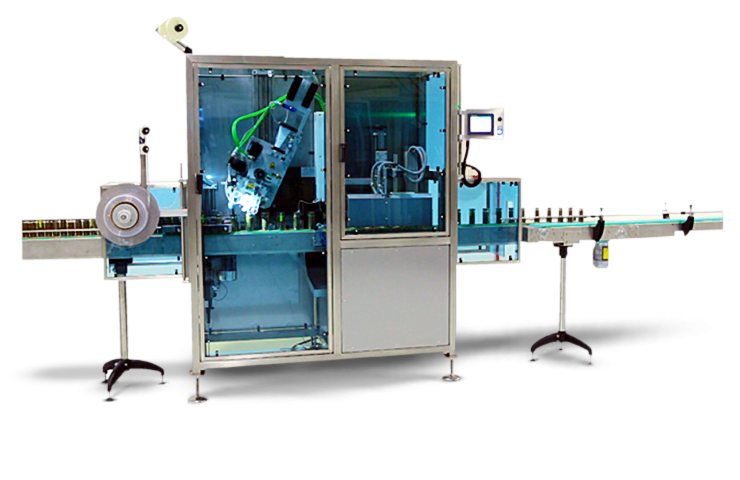

Rotary labeling solution for bottles and containers

Optimize your labeling process with high-speed precision, handling va...

Semiautomatic labelling solution for cylindrical bottles

Effortlessly apply precise labels to various cylindrical and squ...

Gravimetric filling and capping system for chlorine solutions

Optimize your filling and capping processes for chlorinate...

Cartoning solution for tube applications

Streamline your cartoning operations with a machine designed for flexible size cha...

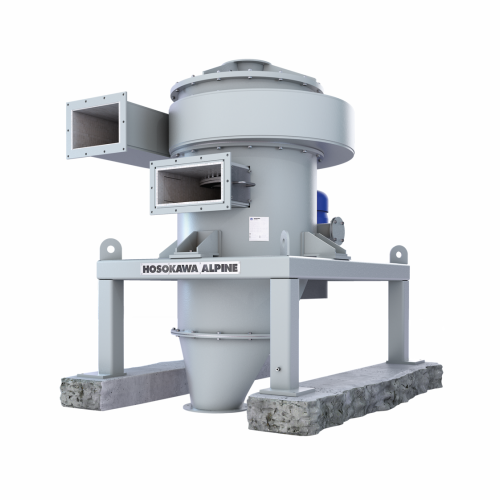

Impact classifier mill for fine grinding of brittle materials

Achieve precise particle size distribution with advanced g...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

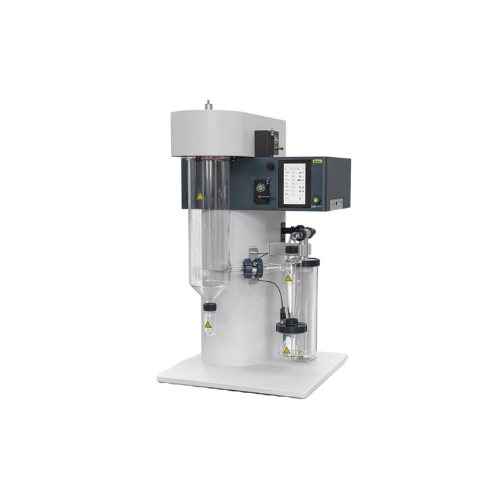

Stability analyzer for emulsions, suspensions, and foams

Accurately detect and quantify changes in dispersibility and sta...

Multi-sample stability analyzer for emulsions and suspensions

Achieve precise, non-destructive stability analysis of emu...

Nanoparticle size analyzer

Master precise nanoparticle and zeta potential analysis with dynamic light scattering technology,...

Zeta potential analyzer for colloidal stability

Achieve precise control over colloidal stability and particle interactions...

Horizontal continuous motion cartoner

Streamline your packaging process with a high-speed cartoning solution that ensures p...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Membrane filtration system for bioburden and water testing

Ensure accurate microbial detection and efficient filtration ...

Automatic horizontal cartoning solution

Optimize your production line efficiency with a versatile cartoning system that acc...

Automatic horizontal cartoning solution for various products

Optimize your packaging line with this advanced cartoning s...

Automatic vertical cartoning solution for jars and bottles

Streamline your production line with a versatile packaging so...

Metal tube crimping system

Optimize your packaging line with this semi-automatic system designed to efficiently crimp metal ...

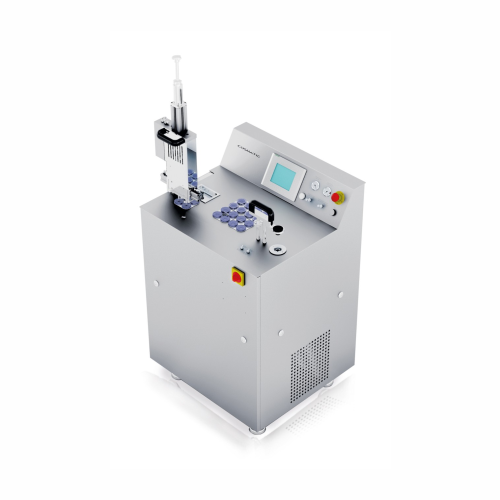

Lab-scale liquid and cream filling system

Streamline your lab production with precise filling of liquids, creams, and past...

Laboratory filling system for liquid and creamy products

Optimize your laboratory processes by precisely handling liquid,...

Versatile industrial melter for raw ingredients

Enhance your formulation capabilities with a flexible melter designed for ...

Vacuum turboemulsifier for liquid and creamy products

Achieve precise emulsification and mixing of liquid and creamy form...

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboe...

Vacuum turboemulsifier for medium-scale production

Achieve precise emulsification and consistent quality in liquid and cr...

Vacuum turboemulsifier for small-scale production

Optimize your product development with versatile vacuum turboemulsifier...

Pre-glued case cartoning solution

Elevate your cosmetics packaging line with high-speed cartoning, ensuring seamless integr...

Mobile melting tank for hot filling lipstick

Optimize your cosmetics production with precise melting and hot filling techn...

Preparation system for lipstick production in stores

Streamline your cosmetic production by transforming raw ingredients ...

Lipstick filling solution for high output production

Achieve precision and efficiency in lipstick production with advance...

Lipstick moulding system

Achieve precision and efficiency in your cosmetic production line with advanced moulding and dosing ...

Semi-automatic lipstick moulding system

Streamline your lipstick production with a versatile system that effortlessly mould...

Lipstick production laboratory system

Optimize lipstick production with precise moulding and controlled temperature systems...

Lipstick packaging fit tester

Ensure precise packaging fit for lipsticks, improving product quality and decreasing return ra...

Semi-automatic screw capper for bottles and jars

Ensure your packaging line operates smoothly by seamlessly capping a wide...

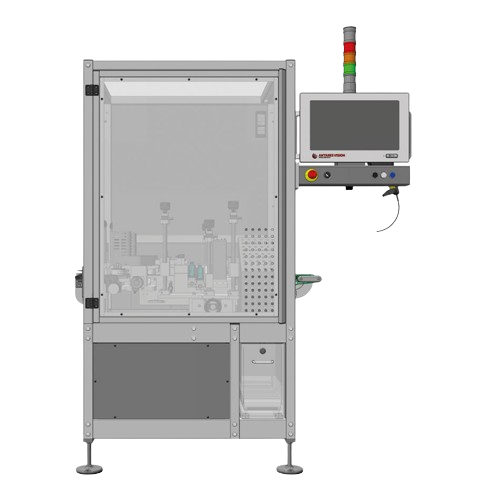

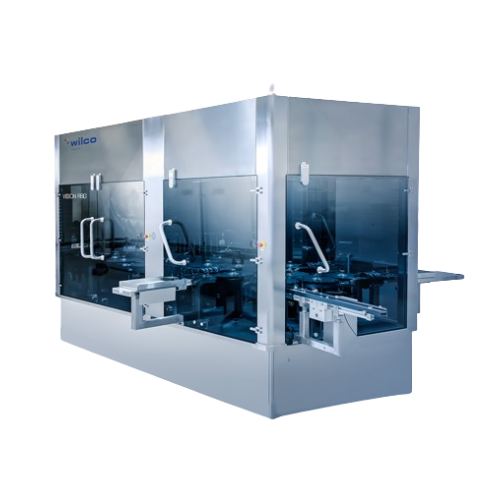

Inspection system for glass containers

Ensure precise inspection of liquid, freeze-dried, and powdered products in glass co...

Mascara and lip gloss filling and capping system

Optimize your cosmetic production line with a high-speed system designed ...

Automatic rotary jar filling and capping system

Optimize your personal care product line by efficiently filling and cappin...

High-speed rotary self-adhesive labelling system for bottles and jars

For cosmetics producers seeking precise and effic...

Laboratory demoulding unit for lipstick samples

Streamline your laboratory’s lipstick sampling process with a versat...

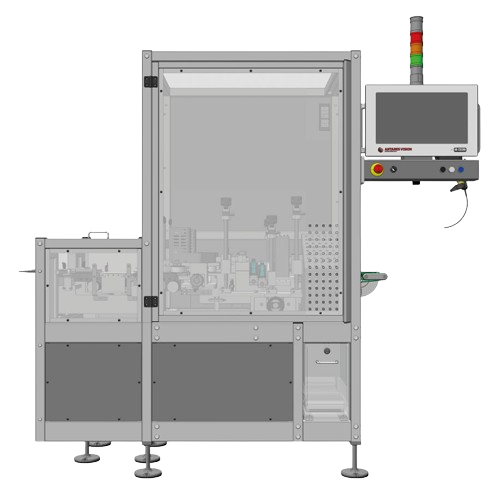

360 and leak Inspection system for glass containers

Ensure the integrity of every glass container with a comprehensive in...

Inspection for glass containers

Ensure the integrity and quality of your liquid formulations with high-speed inspection and ...

Filling and capping solution for bottles

Optimize your bottling efficiency with a robust solution designed to streamline fi...

Continuous motion cartoning solution for diverse products

Streamline your packaging line with a versatile, high-speed ca...

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

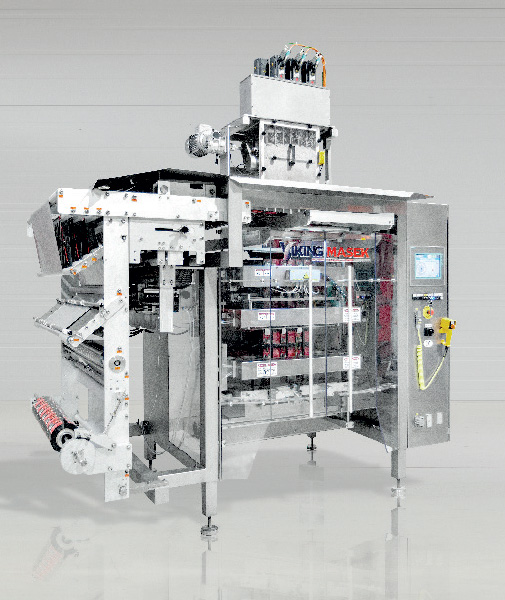

Automatic sachet filling and sealing system for liquids and creams

Optimize your cosmetic and personal care production ...

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

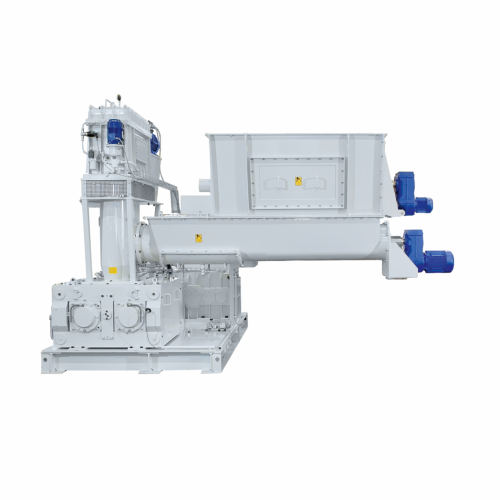

Batch mixer for powdery, granular, and fibrous materials

Achieve precise consistency and high batch reproducibility in yo...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

4 head sealing system for plastic and glass jars

Achieve precision sealing for jars of various materials with this high-sp...

Continuous inline capping system

Perfect for high-speed operations, this system ensures precise capping of diverse container...

Container labeling for jars and bottles

Achieve precise labeling for diverse container shapes, from jars to square bottles,...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Paste filling system for high viscosity products

Efficiently fill high viscosity products with precision and speed, reduci...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Hollow fiber membranes for clarification in food and beverage industry

Optimize filtration and separation processes wit...

High pressure homogenizer for pharma applications

Achieve precise particle size reduction and stability in liquid formula...

High pressure homogenizer for lab applications

Achieve precise control over droplet size and consistency in high-viscosity...

Industrial ultrasonic liquid processor for high volume applications

For large-scale liquid formulations, achieving cons...

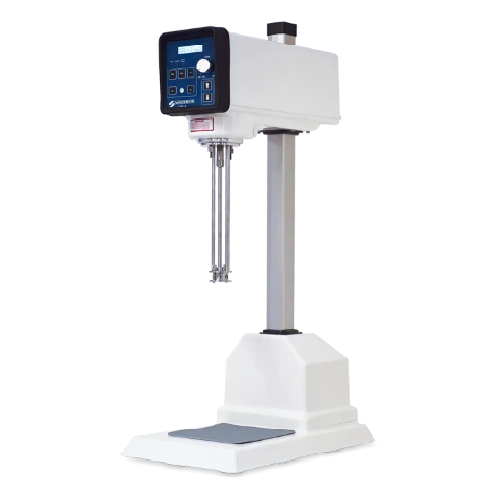

Laboratory mixer for homogenizing and mixing samples

Achieve precise sample preparation and efficient mixing with this ve...

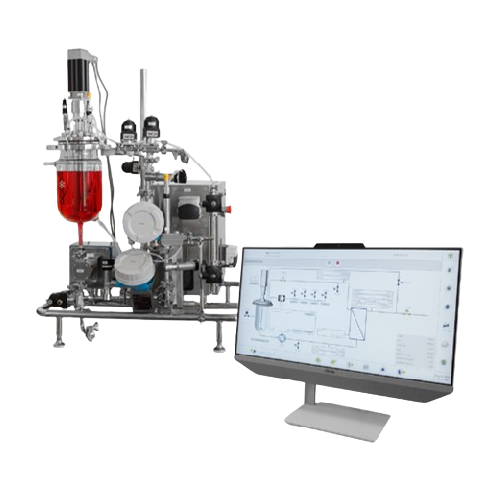

Laboratory dispersion reactor for 2l mixing and reaction processes

Streamline your laboratory processes with a versatil...

Membrane emulsifying system for double emulsions

Achieve precise control over emulsion droplet sizes and distributions, en...

Super high shear inline disperser for nanoparticle production

Achieve unmatched particle size reduction with cutting-edg...

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Easyclean design disperser for batch processing

Achieve precise homogenization and emulsification with a versatile dispers...

Laboratory dispersion reactor for 10l batch processes

Enhance precision and efficiency in lab-scale liquid formulations w...

Ultrasonic liquid processor for feasibility testing and procedure optimization

Optimize your liquid formulations by en...

High-performance palletizer for cans, Pet, and glass containers

Elevate your palletizing efficiency with cutting-edge ro...

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

Sterile inline dispersers for pharmaceutical production

Optimize sterile production environments with precision-engineere...

Hygienic pipeline product recovery system

Efficiently recover valuable residuals from pipelines while streamlining your cl...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

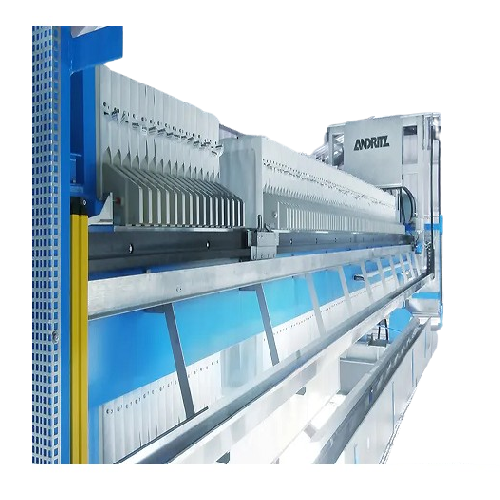

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Industrial sheet filter for liquid filtration

Optimize your liquid product purity with precise filtration, maintaining int...

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuri...

Hydroalcoholic gel mixing system

Ensure seamless production of hydroalcoholic gels with an advanced mixing system designed f...

Hydrocolloid powder dispersion unit

Achieve seamless dispersion of hydrocolloid powders in liquids, eliminating common issu...

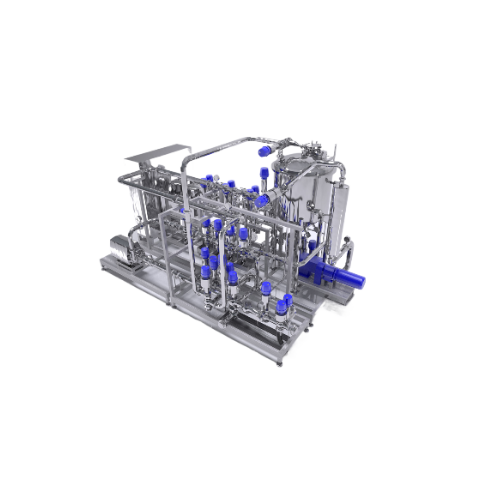

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

Industrial magnetic agitator for homogenizing pharmaceutical products

Achieve precise dispersion and homogenization in ...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

Blender for high viscosity products

When handling thick mixtures that challenge conventional systems, this specialized blen...

Powder liquid blender for food processing

Achieve seamless integration of solids into liquids with precision-engineered bl...

Automated Cip system for small facilities

Ensure impeccable hygiene with a mobile cleaning system designed to efficiently ...

Manual Cip system for food processing hygiene

Designed for small-scale hygiene needs, this mobile clean-in-place system en...

Tank bottom mixer for high viscosity applications

Achieve seamless emulsification and homogenization of high-viscosity pr...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

High shear vertical mixer for dispersion and emulsification

Achieve seamless emulsification and homogenization in divers...

Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid ty...

Counter-rotating agitator for high viscosity products

Achieve seamless heat transfer and precise mixing with a counter-ro...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Automatic tubefiller for pharmaceutical tubes

Streamline your tube packaging process with this versatile solution, optimiz...

Cone mill for particle size reduction

For precise particle size reduction, the cone mill offers flexible screening options ...

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

Complete over wrapping for parallelepiped products

Optimize your packaging line with high-speed over wrapping for precisi...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Packaging solution for small bottles and jars

Effortlessly seal and fill non-stackable containers, ensuring precision for ...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

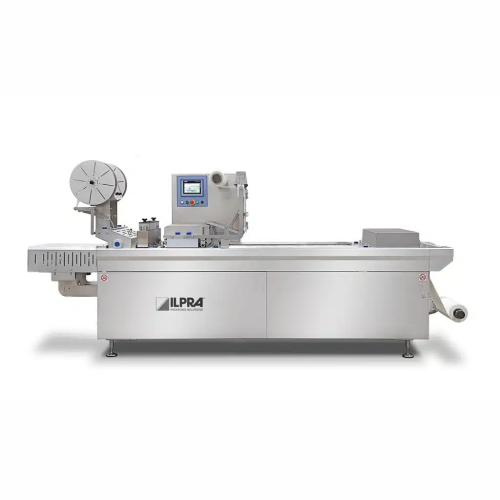

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Top loading case packer for automated box sealing

Streamline your packaging line with a top-loading case packer that effi...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

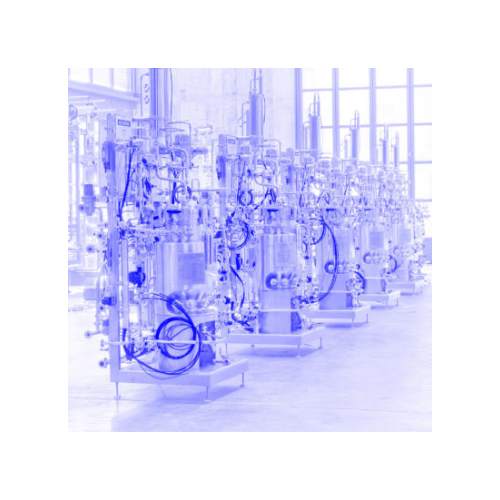

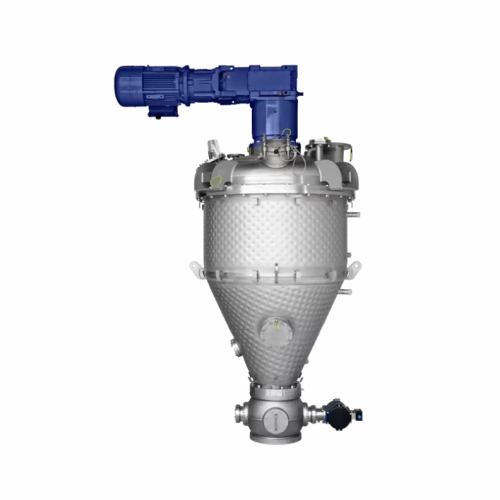

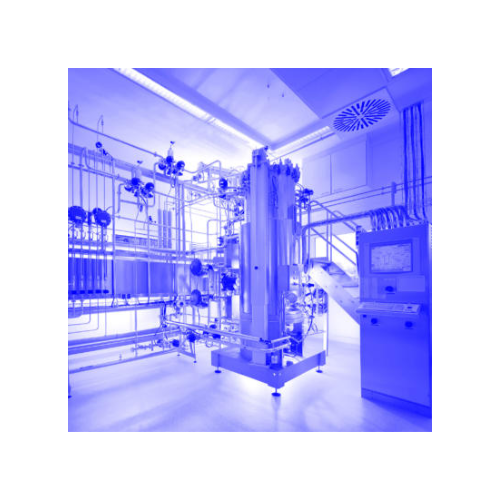

Pharma and biopharma manufacturing vessels

Optimize critical processes with customizable manufacturing vessels designed to...

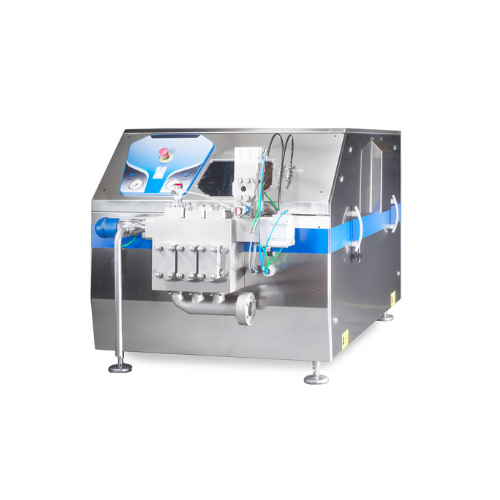

High-pressure homogenizers for liquid products

Achieve consistent emulsions and stable dispersions with high-pressure homo...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

High-pressure homogenizers for dairy and juice processing

Ensure superior texture and stability in your liquid formulati...

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate produc...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Super high shear mixer for nano to micron powders

Achieve high-precision mixing and surface treatment of nano to micron-s...

Lab mixer for powder formulations

Achieve precise particle mixing and coating with this stand-alone high-shear lab mixer, d...

Lab mixer for high-accuracy powder and paste mixing

Achieve precise mixing of powders and pastes with a gentle convective...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Fine cutting mill for soft to medium-hard plastics

Achieve precise size reduction and smooth particle shapes in plastic p...

Drum mixer for dispersions & agitations

Achieve seamless fluid formulation and agitation with a compact, high-speed drum mi...

Immersion mill with sweep blade for high-viscosity products

Optimize your production line with this immersion mill desig...

Dual shaft mixer for high viscosity products

Achieve uniform dispersions in high-viscosity processes with a dual-shaft mix...

Triple shaft mixer for high viscosity products

Achieve uniform mixing and dispersion for high-viscosity materials with tri...

High pressure food processing system

Achieve extended shelf life and enhanced food safety with a cutting-edge high-pressure...

Compact full product inspection system for pharmaceuticals

Easily detect fill level inaccuracies, closure misalignments,...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

High-performance cartoning system for pharmaceutical products

Optimize your packaging line with a flexible cartoning sol...

Filling and sealing system for creams and lotions

Achieve precise, high-speed filling and secure sealing of cosmetic cont...

Filling solution for consumer healthcare products

Navigate complex liquid product formulations with a versatile filling s...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Spouted bed processing for food, feed, and fine chemicals

Tackle the challenge of processing temperature-sensitive and s...

Optical inspection system for large parenteral containers

Ensure the quality and safety of liquid pharmaceutical product...

Optical inspection for ampoules, vials, cartridges, and syringes

Ensure product integrity and safety with this advanced ...

Superheated water sterilizer for large volume parenterals

When sterilizing large volumes of liquid products, achieving p...

Industrial steam washer for pharmaceutical and food industry

For production lines requiring efficient and eco-friendly c...

Vertical laboratory sterilizer for pharmaceutical use

Ensure sterilization precision for diverse lab applications with th...

Lab glassware washer for food and bio-pharmaceutical applications

Ensure precision cleaning of complex lab glassware us...

Steam air sterilizer for aqueous solutions

Overcome the pressure challenge in sterilizing aqueous solutions, effectively p...

Planetary stirrer for creams and ointments mixing

Achieve homogeneous mixing of creams, ointments, and pastes efficiently...

All-purpose mixer and processor for laboratory and small scale production

Optimize your small-scale production with a ...

Precision ointment filling and dosing system

Achieve precise filling of liquid formulations with a versatile system capabl...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Horizontal flat pouching line for liquid soaps

Streamline your liquid product packaging with a dual-lane flat pouching lin...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Vacuum processing units for lab scale applications

Optimize the development and scaling of cosmetic and pharmaceutical pr...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Inline system for personal care product production

Optimize your personal care production with precise mixing, heating, a...

High-shear mixer granulator for pharmaceutical production start-up

Effortlessly achieve optimal granule consistency and...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Pharmaceutical high-shear mixer granulator

Enhance your production efficiency with a high-shear mixer granulator, designed...

Pilot single-pot processor for granulation and drying

For efficient pilot production, streamline your mixing, granulating...

Versatile entry-level mixer granulator

Solve complex mixing and granulating challenges with this compact solution, offering...

High-capacity universal mixer for industrial applications

Optimize your batch processing with a versatile high-speed mix...

Laboratory granulator and coating system

Optimize your research with a versatile benchtop unit that combines fluid-bed proc...

Industrial wendel mixer for dough production

Optimize your dough and bar production with reduced kneading times and increa...

Hygienic design dough mixer

Achieve superior dough consistency and safety with our hygienic design mixer, ideal for reducing...

Granulation line for pharmaceutical manufacturing

Enhance your batch production with integrated mixer and fluid-bed techn...

Pharmaceutical granulation line

Streamline your production with an integrated system that combines mixing, granulation, and ...

Containment solutions for pharmaceutical production

Enhance operator safety and product integrity with advanced containme...

Single-pot processor for wet granulation and vacuum drying

Achieve efficient mixing, granulation, and swift vacuum dryin...

Laboratory unit for mixing, granulating, and vacuum drying

Achieve precise mixing, granulating, and drying in laboratory...

Industrial dough feeding elevator tipper

Optimize your dough handling process with a robust elevator tipper designed for se...

Elevator tipper for flexible dough handling

Achieve maximum flexibility in your production line with a versatile lifting s...

Fluid bed processor for large batch spray granulation

Optimize your production with precision granulation, drying, and co...

Midilab for efficient laboratory-scale product development

Streamline your laboratory and pilot-scale production process...

Planetary stirrer for creamy and foamy masses

Achieve consistent texture and optimal air incorporation in your products wi...

Interchangeable tool stainless steel kneader

Streamline your batch processing with this flexible mixing technology that of...

Laboratory fluid-bed dryer and tablet coater

Experience seamless transition from laboratory to production scale with a ver...

Laboratory coater and fluid bed processor

Optimize your research and development with a versatile benchtop unit that integ...

Industrial elevator tipper for efficient material handling

Optimize your material handling process with a high-performan...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Compact cooker for confectionery and catering

Effortlessly prepare diverse culinary and cosmetic creations, from sauces to...

Industrial cooker for food processing

Enhance your production line with versatile cooking solutions designed for precise te...

Vertical cartoning solution for fragrance and skincare products

Effortlessly carton even the most delicate cosmetics wit...

Tube filling solution for health and beauty applications

Achieve consistent quality and efficiency in tube filling operat...

Tube filling solution for health and beauty products

Achieve rapid production with precision in tube filling for personal...

Self-adhesive labelling system for bottles

Enhance your bottling line with a versatile labelling system that supports medi...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

Compact combined labelling solution for bottling lines

Optimize your bottling line with a versatile, compact labelling so...

Combined wet glue and self-adhesive labeling system

Achieve seamless labeling with combined wet glue and self-adhesive te...

Self-adhesive labeling system for bottles

Streamline your bottling operations with high-precision labeling that enhances p...

Bag-in-box filler with dual heads and automatic features

Boost your liquid production efficiency with a dual-head filling...

Horizontal case-packer for medium-sized shipping cases in pharma and food

Streamline your packaging line with a versat...

Integrated case-packing and case-palletizing system

Streamline your production line with an all-in-one system that seamle...

Intermittent motion horizontal cartoner for large products

Simplify your packaging process with a solution that ensures ...

Intermittent motion horizontal cartoning system

Streamline your packaging operations with a high-speed cartoning solution ...

High-speed continuous motion overwrapper for thin films

For those needing high-speed, efficient wrapping, this equipment ...

Shrink-sleeve application system for packaging

Enhance your packaging line with efficient, precise shrink-sleeve applicati...

Volumetric filling and capping system for pharmaceuticals

Optimize your liquid filling and capping operations with a ver...

High-speed continuous motion cartoner

Streamline your packaging line with precise cartoning operations, ensuring secure and...

High speed horizontal cartoner for large size products

Streamline your packaging line with high-speed, continuous cartoni...

Twin screw pelletizer for continuous production 150 kg/h

Achieve precise pellet density adjustments and seamless integrat...

Small batch mixer granulator blender

Effortlessly manage small batch mixing, blending, and granulation with a compact solut...

Conveyor system for aligning, sorting, and transporting products

Streamline your packaging line by efficiently aligning,...

Industrial three-roll mill for high-quality grinding

Achieve unparalleled precision in grinding and dispersing with our a...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Full-volume bead mill for wet grinding applications

Achieve superior dispersion and particle size consistency with advanc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

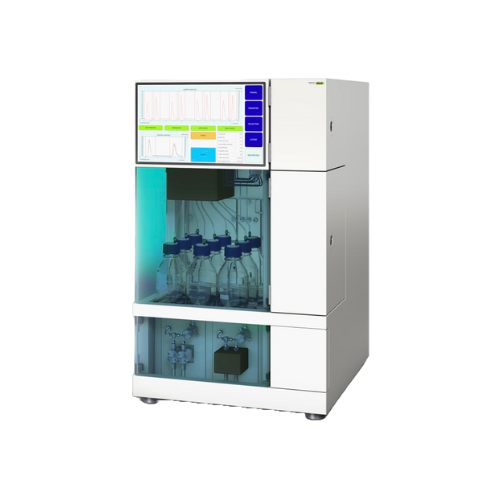

Supercritical fluid chromatography system for preparative separations

For complex substance formulations requiring rapi...

Measuring mixer for small grain samples

Optimize the precision of your formulation processes with a solution designed for p...

Vertical mixer for creams and desserts

Achieve uniform mixing and precise temperature control for diverse creamy and liquid...

Turbo mixer for homogeneous solutions in food and pharmaceutical industries

Effortlessly achieve uniform suspensions a...

Autoclavable and in-situ sterilizable lab-scale fermentors

For researchers seeking precise control in bioprocessing, the...

Modular bioreactor for low-volume production

Optimize your bioprocessing with a scalable solution designed for precise con...

Lab-scale fermenters for research and development

Optimize your small-scale production with compact bioreactors designed ...

Cleaning in place systems for bioreactors

Ensure seamless sanitization with a mobile cleaning system designed to maintain ...

Laboratory homogenizer for pharmaceutical and biotech applications

Achieve precise homogenization for your laboratory n...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Industrial homogenizer for high pressure applications

Achieve consistent product texture and stability for your emulsions...

Industrial homogenizers for high-pressure applications

Optimize homogenization with high-pressure solutions designed for ...

Colloidal mill for industrial homogenization

Achieve consistent emulsification, size reduction, and uniform particle distr...

Laboratory vacuum mixer reactor for liquids and semi-solids

Achieve precise emulsification and mixing for high-viscosity...

Vacuum mixer for liquid and cream processing

When dealing with high-viscosity liquids and creams, achieving uniform consis...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Vacuum deaerator for elimination of gases

Optimize your product quality by eliminating occlusive gases with this advanced ...

Homogenizer for high viscosity emulsion and dispersion

Achieve unparalleled dispersion and emulsification with a system d...

Horizontal vacuum paddle dryer for thermosensitive products

For high-viscosity products like active pharmaceuticals or p...

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Cip system for process tanks

Ensure high-level cleanliness and compliance in your production line with an efficient in-place...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Double cone vacuum dryer for thermosensitive products

For precise drying of heat-sensitive powders, this double cone vacu...

Advanced powder dosing system for continuous production

Achieve precise powder integration into your liquid processes, en...

Automatic tube filling and closing system

Enhance production efficiency with a high-speed tube filling and closing system ...

Semi-automatic tube filling and closing system

Achieve precise filling and secure closing for diverse tube types, optimizi...

Vacuum homogenizer for high-quality mixing and emulsification

Achieve optimal consistency and enhanced product stability...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Industrial under vacuum homogenizer

Optimize the consistency and texture of creams and lotions with precision-controlled mi...

Vacuum homogenizer for creams and ointments

Streamline your production with cutting-edge vacuum homogenization, perfect fo...

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrat...

Filling, capping, labeling line for hair color products

Streamline your hair color production with an integrated line tha...

Linear filling and capping for stable bottles

Enhance your production efficiency with a solution designed for precise liqu...

Manual sealing machine for aluminum tubes

Ideal for laboratories and small-scale production, this compact manual sealing m...

Manual tube sealer for plastic and laminated tubes

Secure precise and reliable seals on plastic and laminated tubes with ...

Melter for vacuum turboemulsifiers

Achieve optimal mixing, dispersion, and temperature control with precision-engineered me...

Pneumatic dosing system for dense and semi-dense products

For precise dosing of dense and semi-dense liquids, this pneum...

Pneumatic dosing system for dense and semi-dense products

Easily handle dense and semi-dense products with precision dos...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Automatic tube filling and closing system

Enhance your packaging efficiency with a high-speed tube filling and closing sol...

Cip clean-in-place system for undervacuum homogenizers

Ensure seamless sanitation for your undervacuum homogenizers with ...

Cleaning system Cip for internal equipment maintenance

Ensure optimal hygiene and production efficiency with this portabl...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

Industrial water chiller for homogenizers and filling machines

Optimize your production line with customizable water chi...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Automatic bottles and jars filling and capping line

Streamline your liquid product packaging with this high-speed solutio...

Soft gel encapsulation system

Efficiently produce high-quality soft gel capsules with precision encapsulation, rapid drying,...

Serialization system for small-scale pharmaceutical production

Ensure precise serialization and inspection of small prod...

In-line aggregation module for serialized item management

Optimize your serialization process by seamlessly managing and...

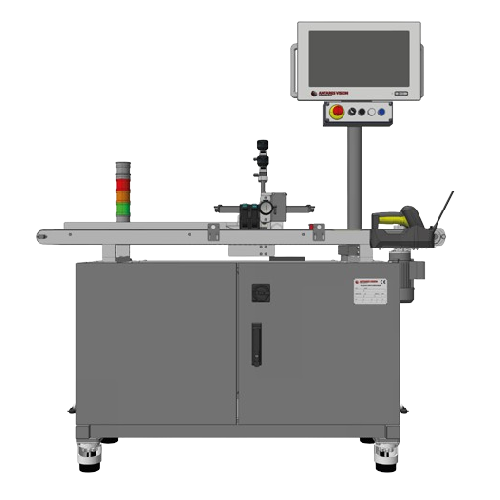

Label inspection for vertical products

Ensure label quality and accuracy with advanced inspection technology designed for p...

Standalone print & apply station for bottle and carton aggregation

Streamline your packaging operations by automating t...

Serialization system for printing and verifying carton codes

Ensure accurate serialization with high-speed printing and ...

In-line checkweighing and printing system for cartons

Ensure precision and efficiency in your packaging line with a compa...

Serialization system for flat cartons

Ensure precise serialization of flat cartons with integrated printing and inspection....

In-line printing and verification for cartons

Optimize your packaging line with seamless printing, verification, and seali...

Special checkweighers for industrial applications

Enhance your production line efficiency by precision weighing your prod...

Combi x-ray inspection and checkweighing for small products

Optimize your production line’s quality control with a...

Fill level inspection system for beverage bottling

Ensure compliance and optimize quality control with a system that accu...

X-ray inspection for contaminants in horizontal products

Ensure your packaged and unpackaged products are contaminant-fre...

Industrial checkweighers for medium-large products

Manage large and heavy packagings with precision and efficiency, ensur...

Integrated metal detector and checkweigher for small/medium formats

Ensure precise quality control and contaminant-free...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Semi-automatic Pet bottle blow molding solution

Optimize your production with precise and efficient blow molding for creat...

Semi automatic Pet bottle blow molding for 5l bottles

Maximize production efficiency by precisely forming PET containers ...

Semi automatic Pet bottle blow molding solution

Streamline your production with a semi-automatic solution designed for eff...

Semi automatic Pet bottle blow molding system

Enhance your production efficiency with a versatile blow molding system that...

Automatic Pet bottle blowing solution

Achieve precise PET bottle molding with high-speed, automated operations that seamles...

Automatic single side adhesive labeling solution

Streamline your packaging line with precision; this solution offers effic...

Servo type Pet bottle blowing molding solution

Optimize your production with high-speed PET bottle molding, designed to st...

Automatic bottle self adhesive labeling solution

Enhance your production line with precision labeling for diverse containe...

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Automatic edible oil filling & capping solution

Streamline your liquid packaging operations with precise, high-speed filli...

Automatic servo Pet bottle blower

Elevate your production capabilities with a PET bottle blowing machine designed for high-...

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

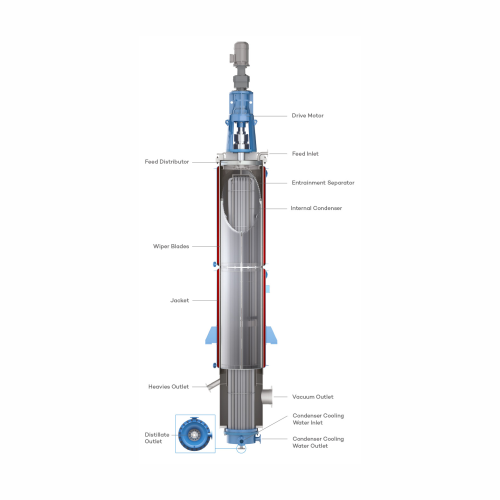

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Emulsion processing system for homogenizing solids into liquids

Achieve precision in emulsifying and homogenizing proces...

Benchtop mixer for lab-scale product development

Easily scale up your formulations with precise and repeatable lab-scale m...

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

Pump feeding system for mascara production

Optimize your high-speed production line with a reliable pump feeding system th...

Pneumatic cap press for bottles and jars

Streamline your packaging process with a pneumatic solution designed for precision...

Automated bottle and jar filling solution

Streamline your production and minimize waste with a versatile filling solution,...

Filler and capper for bottles and jars

Optimize your production with a compact filling and capping solution that delivers f...

Tube filler & sealer for metal and plastic tubes

Streamline your production line by efficiently filling and sealing metal ...

Efficient tube filler and sealer

Optimize your production line with a semi-automatic tube filling and sealing solution, desi...

Compact filler and closer for vial processing

Efficiently streamline your vial filling and closing processes with a compac...

Tube filling and sealing for metal and plastic tubes

Achieve precise tube filling and sealing with high speed and efficie...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Benchtop screw capper for diverse bottle sizes

Ensure precision and efficiency in your capping process with this adaptable...

Semi-automatic flowmeter boom filler for large volume containers

Effortlessly handle large volume liquid filling with pr...

Compact wraparound labelling system for bottles

Streamline your packaging process with a fast and reliable wraparound labe...

High precision three-roller wraparound labeller

Achieve precise label placement on round containers effortlessly with a th...

Front and back labelling for small production lines

Streamline your labelling process with precise front and back applica...

Pneumatic bottle capping solution

Efficiently secure a variety of bottle caps with ease, using a pneumatic system that acco...

Sterilizer for finished liquid products

Ensure precise thermal control and asepsis in your liquid product sterilization pro...

Heat sealer for thermoplastic bags

Ensure airtight seals on thermoplastic bags with precise temperature control and adjusta...

Ultrasonic tube sealer for plastic tubes

Seal plastic tubes with precision and speed using our ultrasonic technology, ensur...

Automatic bottle washer for packaging lines

Ensure your bottles are impeccably clean and ready for filling, as this soluti...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Automatic labeler for low profile containers

Optimize container labeling with precision and efficiency, addressing the cha...

Dual head labeler for top and bottom label applications

Ensure precise and wrinkle-free labeling on containers and packag...

Tabletop labeler with integrated thermal printer for round containers

Efficiently label and print variable data on roun...

Bottle unscrambler for plastic containers

Efficiently organize and streamline your production line by ensuring plastic con...

Customizable sanitary conveyor systems

Efficiently transport and handle diverse products with a sanitary conveyor system de...

Semi-automatic timed flow filler for aqueous solutions

Handle diverse liquid filling needs with precision, from thin oils...

Automatic pressure sensitive labeling system

Enhance your production line’s efficiency with a versatile labeling sys...

Indexed stomp capper for continuous bottle capping

Solve the challenge of manual snap cap placement with a seamless, cont...

Automatic capper for dual head o-ring chuck

Ensure precise cap application with dual-head precision, handling various bott...

Retorquer for tamper-evident bottle caps

Ensure seal integrity and maintain tamper-evidence in high-speed production lines ...

Tabletop spindle tightener for screw caps

Eliminate inconsistencies and errors in cap tightening with this tabletop spindl...

Aseptic sampling system for industrial applications

Achieve reliable, aseptic sampling with precision and safety during c...

Twin screw pump for viscous media

Streamline your production with a twin screw pump that effortlessly handles viscous media...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Pilot plant homogenizer for continuous operation

Achieve consistent fluid textures and prolonged shelf life with high-pres...

Laboratory homogenizer for small production processes

Optimize your production of nanoemulsions, vitamin suspensions, and...

Inline real-time fluid quality monitoring system

Optimize fluid quality control with continuous, inline measurements that ...

Powder wetting and dispersion system

Revolutionize your production with a system that seamlessly inducts, wets, and dispers...

Laboratory disperser for powder induction and wetting

Optimize your pilot and laboratory processes with a high-speed disp...

Inline disperser for homogeneous emulsions and suspensions

Achieve precise control over particle size and distribution w...

Industrial jetstream mixer for homogeneous mixing

Achieve consistent product quality with precise micro and macro mixing ...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

Multipurpose mixing equipment for chemical and pharmaceutical production

Achieve unparalleled flexibility with modular,...

X-ray scanner for contaminant detection in packaging

Ensure your products remain contamination-free with advanced X-ray s...

Dual view x-ray inspection for canned goods

Enhance your production line with advanced dual-view X-ray inspection, ensurin...

X-ray and optical inspection system for product safety

Ensure the safety and integrity of your products with a single sys...

X-ray inspection system for wet environments

Ensure unparalleled product inspection under extreme cleaning conditions with...

Integrated x-ray, checkweighing, and vision inspection unit

Ensure product safety and compliance by seamlessly detecting...

Modular end-of-line system for quality control

Streamline your end-of-line operations with seamless integration of weighin...

Compact serialisation system with tamper-evident and vignette labeler

Streamline your packaging operations with a high-...

Label printing and inspection system

Ensure flawless label application with meticulous inspection and verification, prevent...

Compact serialisation solution for cartons

Optimize your packaging line with a versatile serialisation solution designed t...

Bottle and vial inspection and coding system

Ensure seamless coding and inspection of vials and bottles with rapid 360° ev...

Compact x-ray scanner for foreign body detection

Ensure product quality with a space-saving x-ray scanner designed for hig...

Checkweighers for accurate weight control in production

Ensure precise weight compliance and complete data acquisition th...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

Checkweigher with integrated metal detector for food industry

Ensure comprehensive quality control in your production li...

Batch coding system for product verification

Optimize your production line with an integrated system that accurately marks...

Laboratory disperser for high-viscosity products

Optimize your laboratory processes with precise mixing and dispersing of ...

Vacuum dissolver for high-viscosity products

Elevate your production with precision mixing and deaeration, ideal for tackl...

Mixing and dispersing solution for ultra high-viscous products

Efficiently process ultra high-viscous and thixotropic ma...

High-performance mill for paint and varnish industry

Achieve superior fine dispersing and grinding efficiency for liquid ...

Basket mill for paint and varnish production

Achieve optimal particle size and product consistency with this advanced bask...

Continuous mill for nano range fine grinding

Achieve ultra-fine particle size in continuous processes, ensuring consistent...

High-efficiency disperser for viscous products

Achieve precise control over the mixing and dispersing of high-viscosity ma...

Triple shaft mixer for high-viscosity products

Achieve precision mixing and dispersing of high-viscosity products with a p...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

Batch-control system for dosing, mixing, and weighing processes

Enhance your process control by automating dosing, mixin...

Advanced dissolver for high-viscosity products

Handle ultra-high viscosity mixing challenges effortlessly with this advanc...

Visual inspection for small volume parenterals

Ensure pristine injectable solutions by detecting cosmetic and particle def...

Automated visual inspection for small volume parenterals

Ensure the integrity of high-value parenteral drugs by detecting...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Omnidirectional inspection system for bottles and vials

Ensure precise serialization and aggregation with a 360° inspecti...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Horizontal flat pouching for top-cap pouches

For manufacturers aiming to streamline pouching operations, this high-speed h...

Planetary mixers for baking and food industries

Achieve precise mixing and consistency across a range of products with adv...

Adjustable industrial mixers for thick product blending

Experience precise blending and control for thick and high-viscos...

Vacuum homogenizers for cosmeto-pharma and fine chemistry

Bring precision and efficiency to your formulation processes w...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Vacuum dissolver for high viscosity products

Optimize your production with a vacuum dissolver designed to efficiently prev...

Vacuum disperser for high-viscosity products

Optimize high-viscosity product dispersion and prevent air inclusions with a ...

Vacuum dissolving system for high-viscosity products

Achieve flawless dispersion of high-viscosity substances under vacuu...

Rotor-stator homogenizer for high shear batch processing

Achieve ultra-fine particle distribution and stable emulsions wi...

Horizontal bead mill for fine grinding in continuous process

Achieve ultrafine particle dispersion and consistent mixing...

High-efficiency immersion mill for medium viscosity products

Achieve precise particle size reduction and superior disper...

Production dissolver with scraper for high-viscosity products

Efficiently tackle high-viscosity material processing with...

Explosion-proof dissolver with scraper for high viscosity substances

Ensure flawless dispersion with enhanced safety, d...

ATEX vacuum dissolver for high viscosity products

Ensure safe and efficient dispersion of high-viscosity materials under...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Explosion-proof dissolvers for laboratory use

Ideal for safely dispersing and mixing chemical substances in potentially ex...

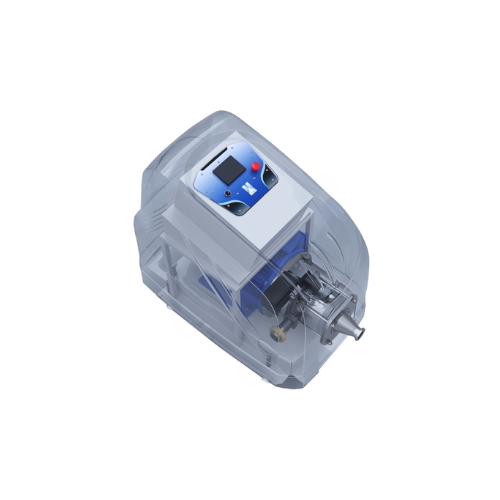

Dosing pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with flexibility in dosing volu...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Dosing and filling pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with compact, hygi...

Continuous mixing and filling system for viscous materials

Experience precise, pulsation-free mixing and filling of visc...

Dosing and filling pump for hygienic applications

Optimize your production line with this dosing and filling pump, design...

Precision dispenser for high-viscosity fluids

Achieve unparalleled precision in dosing and application with a dispenser de...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Homogenizer for high viscosity liquids and solid suspensions

Struggling with homogenizing high-viscosity ingredients and...

High-volume dispensing for single-component fluids and pastes

Enhance your production line with a pump that delivers lar...

Industrial stativ mixer with adjustable height

Achieve precise mixing and stirring across diverse batches with a mobile, a...

Laboratory stirrer for high-viscosity materials

Streamline your laboratory mixing processes with a powerful stirrer design...

Laboratory stirrer for small batch mixing

Achieve consistent mixing and blending in small-scale environments with minimal ...

Industrial container mixing system for high viscosity media

Effortlessly blend high-viscosity liquids and slurries with ...

Drum blender for closed barrels

Efficiently mix liquids and slurries inside closed drums with a specialized agitator designe...

Semi-automatic stands blender for facade paints

Optimize your paint production with a versatile stirring system designed f...

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

In-line mixer for solid-liquid blending

Efficiently combine powdered and liquid ingredients in real-time with high-shear pr...

Solid-liquid in-line mixer for chemical product manufacturing

Effortlessly integrate and disperse high-solids content in...

In-line mixer for liquid-liquid and solid-liquid processes

Optimize your mixing operations with an efficient solution th...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Single piston depositors for bakery and food production

Optimize your depositing and filling processes with versatile equ...

Industrial homogenizers for liquid processing

Achieve consistent product quality and energy efficiency in liquid processin...

Servo multi food portioner

Achieve precise portion control and high-speed depositing for diverse applications with this adva...

Food spraying and flocking system for bakery applications

Enhance your production line with precision spraying and flock...

Multi piston depositors for bakery production

For bakeries seeking precision in depositing and filling, these multi piston...

Multi piston depositors for high-volume baking production

Optimize your high-speed production line with precision deposi...

Food transfer and dosing pumps for bakeries

Enhance efficiency in food processing with pumps designed for precise transfer...

Industrial food filling and depositing equipment

Optimize your production line with precise, gentle depositing and filling...

Dual or triple lane food depositor

Enhance your production efficiency with a depositor that seamlessly handles a variety of...

Servo multi piston depositor for bakery production

Streamline your bakery production with precise portion control and hig...

Industrial food spraying and flocking system

Reduce waste from single-use canisters in food production while achieving pre...

Servo driven multi-piston depositor for batters and fillings

Ensure precise portion control and maintain product integri...

Automated syrup sprayer for bakery products

Achieve uniform coating and infusion with precision spraying systems designed ...

Bakery and food grade conveyor systems

Optimize your bakery and food production with versatile conveyors designed for seaml...

Industrial depositors for flowable food products

Enhance your production line’s efficiency with precision depositing...

Pneumatic Rp depositor for bakery and food plants

Optimize your production line with a high-speed depositor designed to d...

Servo multi depositor for food portioning

Achieve precise portion control and high-speed depositing with versatility acros...

Single piston food depositor

Achieve precise portion control for diverse food products, from soups to chunky fillings, with ...

Semi-automated depositor with handheld nozzle

Maintain portion precision and reduce ingredient waste with a versatile depo...

Single piston food depositor for temperature-sensitive environments

Optimize your production with a versatile depositor...

Sanitary vessels for pharmaceutical applications

Ensuring the highest standards of aseptic processing, these sanitary vess...

Automatic inspection system for ampoules and vials

Ensure precision in pharmaceutical production with a comprehensive ins...

Aroma recovery system for natural juice extraction

Maximize aroma recovery in your juice production with a fully automate...

Aseptic rotary cup filling and closing solution

Maximize your production capacity with this cutting-edge aseptic solution,...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Jet milling system for super fine particle size reduction

Achieve ultra-fine particle sizes with precision milling techn...

Medium volume bottle and jar filling system

Efficiently manage filling operations for diverse liquid and semi-dense produc...

Compact carton overwrapping system

Optimize your packaging line with a compact solution designed to seamlessly overwrap a v...

Automatic mono-dose strip filling system

Optimize your liquid product packaging with a multi-functional system designed for...

Automatic tube filling for multi-color products

Achieve precision in multi-color product packaging with seamless co-extrus...

Automatic tube filler for multi-color coextruded products

Achieve precise dual- or tri-color product designs with except...

Automatic bottle filling and capping solution

When dealing with fragile or unstable bottles, precise filling and capping a...

Automatic tube filling for coextruded products

Maximize efficiency in high-volume production with precision co-extruding c...

Automatic tube filling solution for high-volume production

Effortlessly streamline your production with this high-speed ...

Automatic tube filler for co-extruded products

Achieve precise multicolor co-extrusion filling with high-speed accuracy, o...

Turbo emulsifier for creams, gels, toothpastes

Achieve perfect emulsification and homogenization for your creams, gels, an...

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robus...

Horizontal cartoning machine for medium to high-speed production

Optimize your cartoning process with precise loading an...

Vertical cartoning solution for manual product loading

Streamline your cartoning process with a versatile solution design...

Vertical cartoner for fast and efficient packaging

Streamline your high-speed production by seamlessly integrating vertic...

Automatic case packer for cartons and bundles

Optimize your packaging process by efficiently inserting single cartons and ...

Small batch tube filling system for metal and plastic tubes

Optimize your small-batch production with precise tube filli...

Semi-automatic mascara bottle filling and capping

Streamline your production line with a solution designed for precision ...

Syringe filling and capping system for pharma industry

Enhance your production line with precise syringe filling and capp...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Pneumatic dosing syringes for precise liquid dispensing

Achieve precise and reliable liquid dosing with pneumatic syringe...

Automatic liquid filling solutions for various containers

Ensure precise liquid packaging for diverse container types, e...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Manual monoblock for filling and capping spouted pouches

For those handling liquid or semi-dense products, this manual mo...

Semi-automatic capping machine for aluminium screw caps

Ensure consistent cap application across diverse container format...

Bottle and jar rinsing system

Achieve optimal internal sanitization and cleanliness for bottles and jars with a versatile ri...

Self-adhesive label applicator for cylindrical and shaped bottles

Simplify label application on varied bottle shapes wi...

Bench-top labeling system for cylindrical and shaped containers

Effortlessly label diverse bottle shapes and sizes with ...

Manual dosing and capping for semi-dense products

Enhance your production line efficiency by seamlessly integrating manua...

Manual monoblock for filling and capping jars

Optimize your jar filling and capping processes, even with high-temperature ...

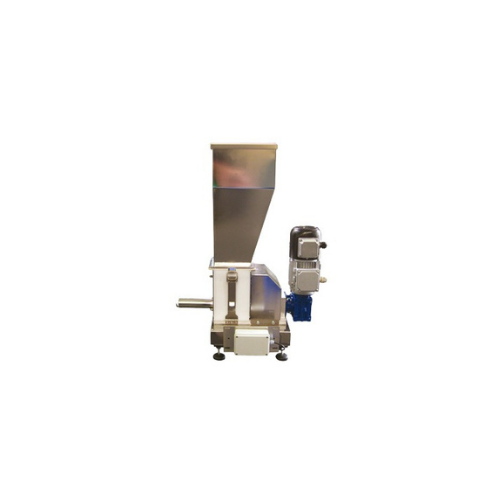

Feed hopper for volumetric feeders

Optimize product consistency while handling a variety of viscosities with this feed hopp...

Manual heat shrink capsule applicator

Quickly and precisely apply shrink capsules to bottlenecks, ensuring perfect adherenc...

Manual system for filling and capping jars

Ideal for efficiently handling liquid and semi-dense products, this manual syst...

Manual filling and capping for spouted pouches

Optimize your production line with a versatile solution for filling and cap...

Manual filler and capper for spouted pouches

Easily manage filling and capping for flexible pouches with precise volumetri...

Pneumatic syringe dosing system

Streamline your liquid dosing process with precision and efficiency, ensuring each applicati...

Semi-automatic capping solution for small to medium operations

Streamline and personalize your capping processes with ve...

Semi-automatic capping solutions for small to medium production

Streamline your capping process with versatile, customiz...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Interchangeable kits for enolmaster filling system

Achieve precision and versatility in liquid filling with adaptable kit...

Vacuum bottling equipment for wineries and breweries

Optimize your bottling process with a vacuum solution that fills up ...

Automatic line for filling and capping spouted pouches