Automatic horizontal cartoning solution

Optimize your production line efficiency with a versatile cartoning system that accommodates a wide range of beauty and personal care products, ensuring precise packaging and protection for items from lipsticks to hair dye kits.

Cartons, Labels, and Packs Beauty Products

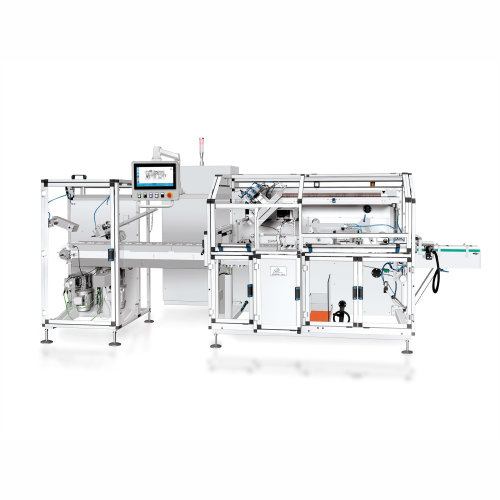

The V2000 cartoning machine by Marchesini Group is designed to meet the diverse packaging needs of the cosmetic and personal care industry. This automatic, intermittent motion cartoner is engineered for flexibility, efficiently handling a wide range of products, from mascara and lip gloss to jars and bottles. Built with a robust balcony construction, it allows easy access for maintenance, cleaning, and product visibility during operation. The V2000 features reliable positive carton opening mechanisms, ensuring effective handling of square or hard cartons with low grammage. Integrated with rubber toothed belts, it prevents friction and marking on carton surfaces. With a throughput of up to 120 cartons per minute, it is optimized for high-speed operations while supporting multiple product feeds and coding options, including embossing, inkjet, and laser printing. The compact footprint and quick changeover capability further enhance its adaptability in dynamic production environments. Configurations support seamless integration into existing lines, and customization options are available to meet specific engineering and production requirements.

Benefits

- Enhances packaging efficiency with high-speed cartoning up to 120 units per minute.

- Minimizes maintenance time with easy access design and robust construction.

- Prevents product damage with gentle, friction-free carton handling.

- Accommodates diverse product types and sizes, offering customization flexibility.

- Seamlessly integrates into existing production lines, optimizing workflow and output.

- Applications

- Personal care, Hair colour kits, Sachets, Mascara, Lip gloss, Jars, Tubes, Cosmetics, Bottles, Soap, Beauty products, Lipsticks

- End products

- Lip gloss wands, Shampoo sachets, Liquid soap dispensers, Hair dye kits, Face creams, Shampoo bottles, Sunscreen tubes, Lipstick bullets, Lip balm jars, Conditioner sachets, Foundation jars, Hand sanitizers, Bar soaps, Hand lotions, Body moisturizers, Mascara tubes

- Steps before

- Product Sorting, Product Loading

- Steps after

- Carton Labeling, Over-Wrapping, Banding, Shrinking, Casepacking, Palletising, End-to-end Serialisation

- Input ingredients

- bottles, tubes, lipsticks, mascara, lip-gloss, trousses, sachets, stick packs, leaflets, booklets

- Output ingredients

- cartons

- Market info

- Automation

- Automatic intermittent motion

- Changeover method

- Easy and fast from operator side

- Control panel

- Touch screen control

- Carton opening system

- Highly reliable positive carton opening

- Carton transport

- Rubber toothed belts

- Product feed options

- Bottles, tubes, lipsticks, mascara, lip-gloss, trousses, sachets, stick packs

- Coding and print systems

- Embossing, inkjet, and laser

- Machine footprint

- Compact-sized

- Output speed

- Up to 120 cartons/min

- Carton dimensions

- Width

- Working mechanism

- Automatic intermittent motion

- Changeover time

- Easy and fast from operator side

- Product feed options

- Multiple products

- Carton transport method

- Rubber toothed belts to avoid friction

- Carton opening reliability

- Highly reliable positive carton opening

- Control panel

- Touch screen for machine management

- Customisation flexibility

- Available

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- No

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Carton width range

- 25 mm - 110 mm

- Carton height range

- 15 mm - 60 mm

- Carton length range

- 55 mm - 200 mm

- Carton transport method

- Rubber toothed belts

- Multiple product feed options

- Bottles, tubes, lipsticks, etc.

- Control panel type

- Touch screen

- Control panel type

- Touch screen control panel

- Integration possibilities

- Multiple product feed options (bottles, tubes, lipsticks, mascara, lip-gloss, trousses, sachets, stick packs)

- Carton size flexibility

- Carton width

- Coding and printing systems

- Embossing, inkjet, and laser

- Customization flexibility

- Flexibility for customisation