Making Mascara

Find innovative production technology for making mascara and connect directly with world-leading specialists

Mascara is a cosmetic makeup used to thicken, lengthen and darken your eyelashes to give brighter, bigger-looking eyes. Made of coal dust and petroleum jelly, the first mascara formula was created during the Victorian era, as Victorian ladies were so vain to spend hours upon hours beautifying themselves. The mascara manufacturing process known today includes the anhydrous and emulsion methods in which both involve a base mixture of pigments, waxes, and oils.

Tell us about your production challenge

Science of beauty – The mascara chemical formula...

The secret to your good mascara is all in the chemical mix: pigments such as titanium dioxide and iron oxides to give the color; waxes such as paraffin wax, carnauba wax and beeswax to keep the color attached to your lashes; and oils like castor oil or lanolin to help the pigment coat your lash thickly, and provide some water resistance. Cosmetics manufacturers generally follow the same type of process globally.

… and the mascara manufacturing process

There are two methods of making Mascara, anhydrous and emulsion methods. In the anhydrous method, waxes, oils, and pigments are mixed in a mixing tank, heated, and stirred using a propeller blade. As the name goes, this method does not include water as an ingredient.

In the emulsion type of the mascara manufacturing process, the water and thickeners are combined together, while the waxes and emulsifiers are heated in a separate container where the pigment is then added. A homogenizer mixes both of these mixtures to break down the oils and waxes and hold them in suspension in the water. Mixing continues until the mixture becomes the dark paste we all die for.

Water-resistant vs waterproof mascara

Since mascara is applied to your lashes with a bristle brush, its degree of water-resistance might be a deciding factor for someone who would like to spend a day at the beach. Water-resistant mascaras are oil-in-water emulsions and mainly contain waxes of natural and mineral origin, which can resist the penetration of water only to a certain degree. Whereas, water-proof mascaras are water-in-oil emulsions, which contain water rebuffing ingredients like isoparaffins, isododecane, or siloxanes. This acts as a shield against water which gives the required resilience against sweat, tears, and even complete water submersion at the beach!

Safety and regulations when making mascara

Did you know that there are people who believe that mascara is made of bat droppings, i.e. guano? This misunderstanding stems from a similarity of words since a crystalline form of ‘guanine’ is used in some mascaras. The FDA and European regulations have actually authorized ‘guanine’, and not ‘guano’, as a colour additive for cosmetics. Colour additives intended as coal-tar hair dyes need to have FDA approval before they go to the market. For example, kohl is a color additive considered illegal in the United States.

The European Commission bans 1328 chemicals like formaldehyde, petroleum, parabens, hydroquinone and more from cosmetics that are suspected to be harmful to human being. FDA also bans the inclusion of the following chemicals in a cosmetic: biothional, choloroform, halogenated salicylanilides, hexachlorophene, methylene chloride, vinyl chloride and mercury compounds, as they are known to be highly toxic to our human body. As an exception, mercury compounds can be occasionally found as a preservative in mascara and eye make-up such as eyeshadow for the eyebrows.

Processing steps involved in mascara making

Which mascara technology do you need?

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Automatic top load case packer for bottles and jars

Streamline your packaging process with reliable case packing for prod...

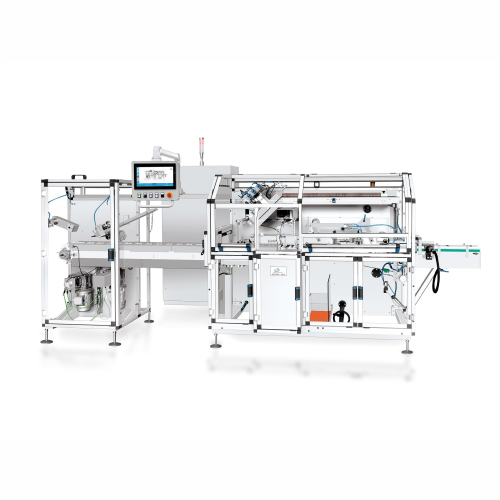

Automatic horizontal cartoning solution

Optimize your production line efficiency with a versatile cartoning system that acc...

Automatic horizontal cartoning solution for various products

Optimize your packaging line with this advanced cartoning s...

Automatic vertical cartoning solution for jars and bottles

Streamline your production line with a versatile packaging so...

Metal tube crimping system

Optimize your packaging line with this semi-automatic system designed to efficiently crimp metal ...

Versatile industrial melter for raw ingredients

Enhance your formulation capabilities with a flexible melter designed for ...

Pre-glued case cartoning solution

Elevate your cosmetics packaging line with high-speed cartoning, ensuring seamless integr...

Mobile melting tank for hot filling lipstick

Optimize your cosmetics production with precise melting and hot filling techn...

Lipstick filling solution for high output production

Achieve precision and efficiency in lipstick production with advance...

Lipstick moulding system

Achieve precision and efficiency in your cosmetic production line with advanced moulding and dosing ...

Lipstick packaging fit tester

Ensure precise packaging fit for lipsticks, improving product quality and decreasing return ra...

Semi-automatic screw capper for bottles and jars

Ensure your packaging line operates smoothly by seamlessly capping a wide...

Mascara and lip gloss filling and capping system

Optimize your cosmetic production line with a high-speed system designed ...

High-speed rotary self-adhesive labelling system for bottles and jars

For cosmetics producers seeking precise and effic...

Laboratory demoulding unit for lipstick samples

Streamline your laboratory’s lipstick sampling process with a versat...

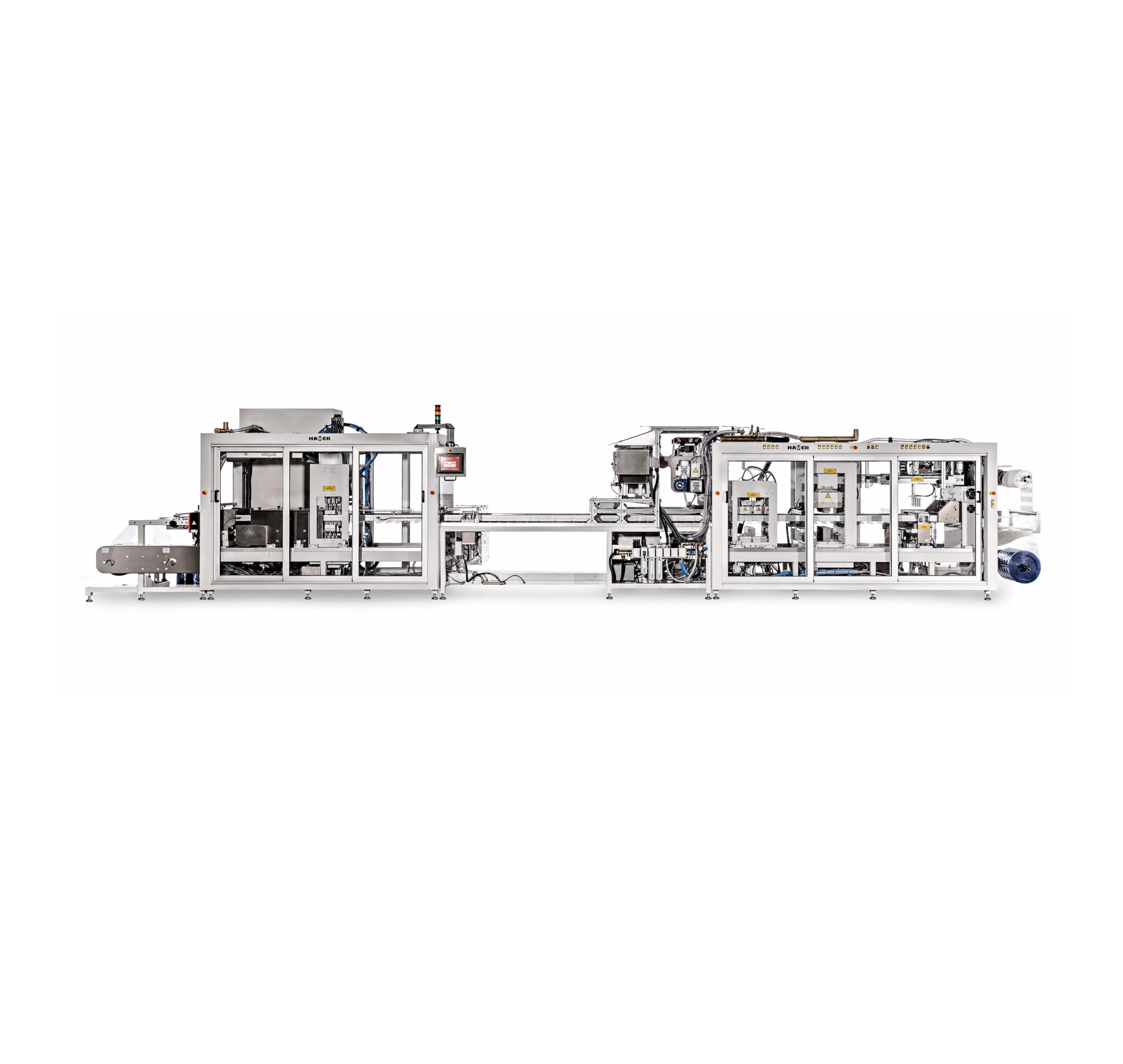

Continuous motion cartoning solution for diverse products

Streamline your packaging line with a versatile, high-speed ca...

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

Automatic case packing solution for cosmetic products

Streamline your cosmetic production line with efficient case packin...

Automatic cartoning solution for cosmetic and fragrance samples

Streamline your cosmetic and fragrance sample packaging ...

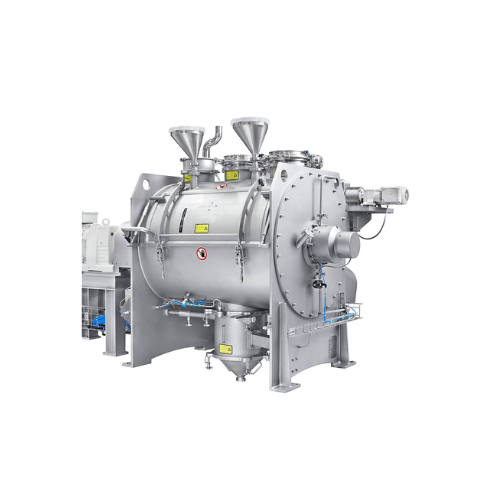

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Blender for high viscous products

Tackle high-viscosity challenges with an advanced blending solution designed for efficien...

Volumetric filling system for cosmetic products

Streamline your production line with precise volumetric control, ensuring ...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

High-speed overwrapping for cosmetic and toiletry items

Achieve precise and efficient over wrapping of cosmetic and toile...

Mascara and lip gloss filling system for cosmetics

Optimize your cosmetic product filling operations with precision, hand...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

Vacuum processing units for lab scale applications

Optimize the development and scaling of cosmetic and pharmaceutical pr...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Tube in-feed conveyor for cosmetic packaging lines

Streamline your packaging process with precision by efficiently transf...

Automatic tube filling and closing system

Enhance your packaging efficiency with a high-speed tube filling and closing sol...

X ray inspection for unstable cosmetic products

Ensure product integrity by detecting contaminants in unstable packaging w...

Dual lane x-ray inspection system for cosmetics

Optimize your production line with dual-lane x-ray technology that ensures...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Tube feeder for pharmaceutical and personal care industries

Optimize your production line with this high-speed tube feed...

Pump feeding system for mascara production

Optimize your high-speed production line with a reliable pump feeding system th...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Dual view x-ray inspection for canned goods

Enhance your production line with advanced dual-view X-ray inspection, ensurin...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

Batch-control system for dosing, mixing, and weighing processes

Enhance your process control by automating dosing, mixin...

Laboratory disperser for small batch processing

Achieve precise dispersion and homogenization of high-viscosity mixtures w...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Automatic bottle filling and capping solution

When dealing with fragile or unstable bottles, precise filling and capping a...

Semi-automatic mascara bottle filling and capping

Streamline your production line with a solution designed for precision ...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Top loader robots for precision packaging

Optimize packaging operations with versatile robotic top loaders that achieve hi...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Semi-automatic filler

When you are a small or a medium-sized manufacturer the manual filling processes might often lead to in...

Up to four head automatic filling machine

When your consumer demand is increasing you will need new and more effective pac...

Automatic blister sealing machine for retail products

Blister packages for retail are usually designed with a paperboard ...

Industrial blister packaging machine for retail products

A blister can be simply defined as a type of packaging that cons...

Mascara filling machine

For smaller production volumes, a fully automatic filling solution for mascara, eyeliner, lip gloss a...

Automatic mascara filling machine

Do you need to increase your efficiency and production volumes whilst reducing your costs...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...