Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensuring consistent particle size reduction and product uniformity for a diverse range of applications, from food to cosmetics.

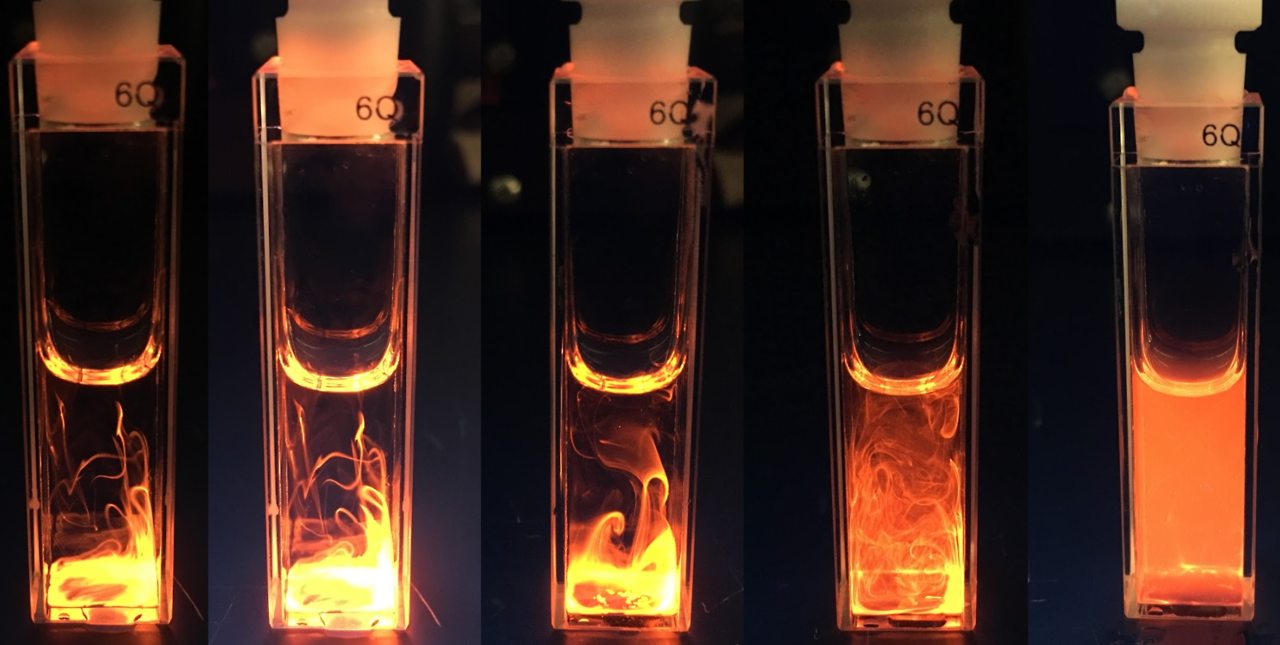

Processes and Emulsifies Diverse Product Lines

The ProXES Microcut and Universal Machine are versatile solutions designed for precise cutting and emulsifying across food, cosmetic, and pharmaceutical industries. Featuring a high-capacity design, the Microcut excels in low-viscosity operations, handling up to 15,000 liters per hour inline. Its cutting, dispersing, and homogenizing capabilities make it ideal for applications ranging from meat emulsions to API suspensions.

The Universal Machine supports direct and indirect heating, vacuum processing, and indirect cooling, perfect for small to medium batch processing. It integrates seamlessly into production lines, facilitating processes from lab to industrial scale. Both machines offer significant energy efficiency gains, adaptable to various product forms, whether solid, liquid, or slurry. Constructed from durable materials, these machines ensure compliance with stringent industry standards, providing robust performance and ease of maintenance through features like CIP systems for seamless cleaning.

Benefits

- Enhances production efficiency with high-capacity processing for large-scale operations.

- Reduces energy consumption through optimized motor control for cost-effective performance.

- Provides versatile processing options suitable for a wide variety of applications and product types.

- Ensures compliance with industry standards for safe and reliable operation.

- Simplifies cleaning and maintenance with integrated CIP systems, minimizing downtime.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Confectionary (ganache), Sauces), Ointment, Vegan, Chocolate, Convenience food (purées, Hummus, Soups, Soft gels, Mascara, Dairy (processed cheese), Toothpaste, Chemical suspensions, Fertiliser, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Vegetable grinding, Api suspensions, Pet food, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Meat emulsions, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Bath gel, Vinaigrette, Beef stew, Dog kibble, Outdoor paint, Infant formula, Wood lacquer, Apple puree, Chocolate ganache, Engine oil, Porcelain tile slurry, Peanut butter, Baby shampoo, Red lipstick, Truffles, Antibiotic ointment, Cheddar cheese sauce, Dijon mustard, Tea tree shampoo, Carrot puree, Iron oxide suspension, Croissants, Vegan paté, Cream cheese spread, Smoothie blends, Mint toothpaste, Hollandaise sauce, Chocolate spread, Tomato soup, Insecticide concentrate, Chickpea hummus, Sausages, Moisturizing cream, Artificial tears, Waterproof mascara, Matte nail polish, Styling gel, Vitamin e soft gels, Almond filling, Nitrogen fertilizer, Liquid foundation, Tomato ketchup

- Steps before

- Aseptic processing, Cooling, Crystalising, Deaerating

- Steps after

- Pasteurizing, Sterilizing, Vacuum cooling, Evaporating, Packing

- Input ingredients

- meat, vegetables, low viscous products, api suspensions, ceramics, chemical suspensions

- Output ingredients

- fine cut materials, emulsions, dispersed products, homogenized products, processed cheese, purées, sauces, ganache

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity (Microcut,Standalone)

- Up to 4, 500 l/h

- Capacity (Microcut,Inline)

- Up to 15, 000 l/h

- Capacity (Universal Machine)

- Up to 1, 000 l/h

- Heating Temperature

- Up to 125 °C

- Particle Size Reduction

- Nano to Micrometers

- Vacuum Processing

- Yes

- Cooling Option

- Indirect via Double Jacket

- Functions (Microcut)

- Cutting, Dispersing, Emulsifying, Homogenizing

- Functions (Universal Machine)

- Mixing, Cutting, Emulsifying, Heating, Cooling

- Working mechanism

- Cutting, dispersing, emulsifying, homogenizing

- Integrated steps

- Direct/indirect heating, vacuum processing, indirect cooling

- Batch vs. continuous operation

- Batch / Inline Continuous

- Capacity

- Up to 15, 000 l/hours (inline setup)

- CIP Principles

- CIP systems available

- Automation level

- Lab to industrial scale

- Capacity for Universal Machine

- Up to 1000 l/hour

- Application viscosity

- Low viscous products

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Touchscreen / Button interface

- Integration possibilities

- Inline / Standalone

- Discharge method

- Continuous / Batch

- System scalability

- From lab to industrial scale

- Footprint options

- Compact / Modular

- Heating/Cooling configurations

- Direct/Indirect heating, cooling

- Operating mode

- Automatic / Semi-automatic

- Batch processing capabilities

- Small to medium batches

- Processing range

- Low viscous products