Industrial and Commercial Sauce Making Equipment

Connect directly with innovative technology suppliers for your sauce production line

Sauces bring personality to a dish. From a spicy, dense Zhoug to a tangy, runny Suero, sauces add an extra dimension of flavor, texture, and mouthfeel. But developing recipes into industrial products with long shelf lives and consistent tastes is a complex process. Specialized sauce making equipment prepares and combines the ingredients into delicious, high-quality foods. The result is a sauce ready to elevate meals.

Innovative sauce equipment solutions

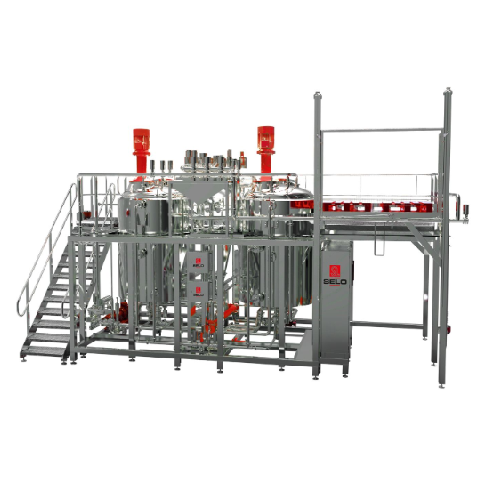

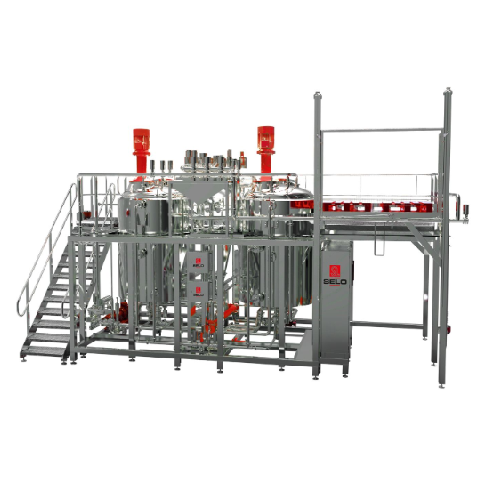

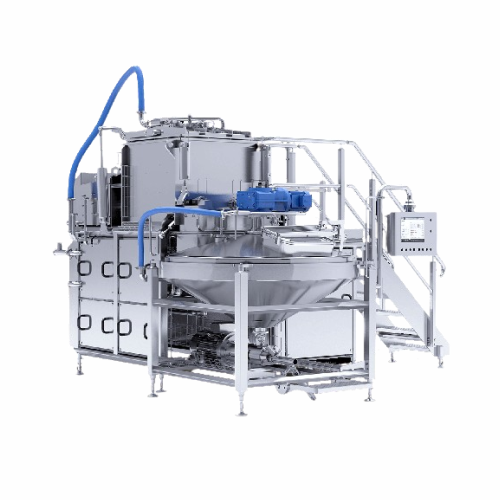

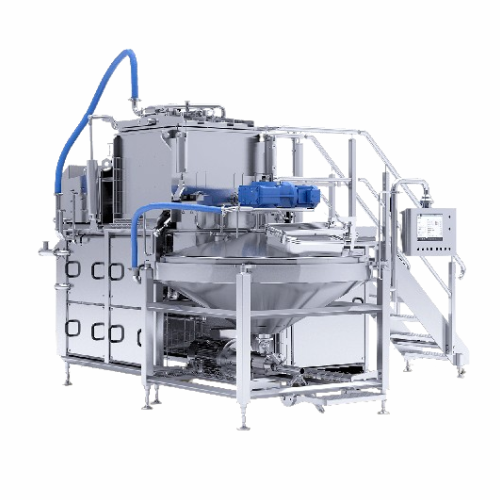

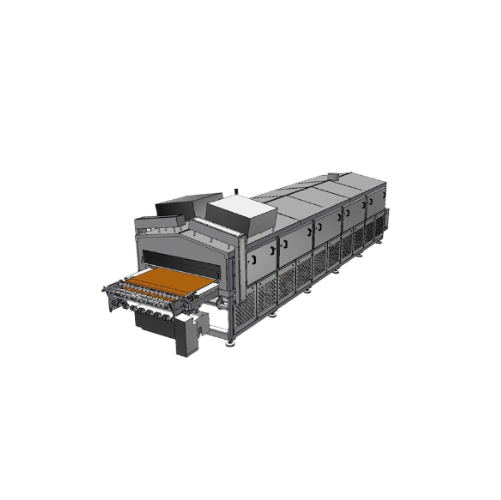

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

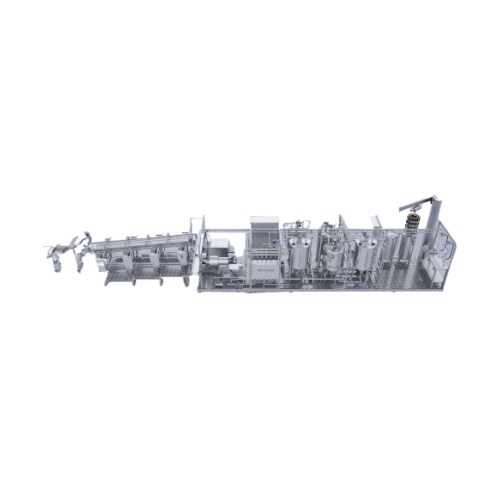

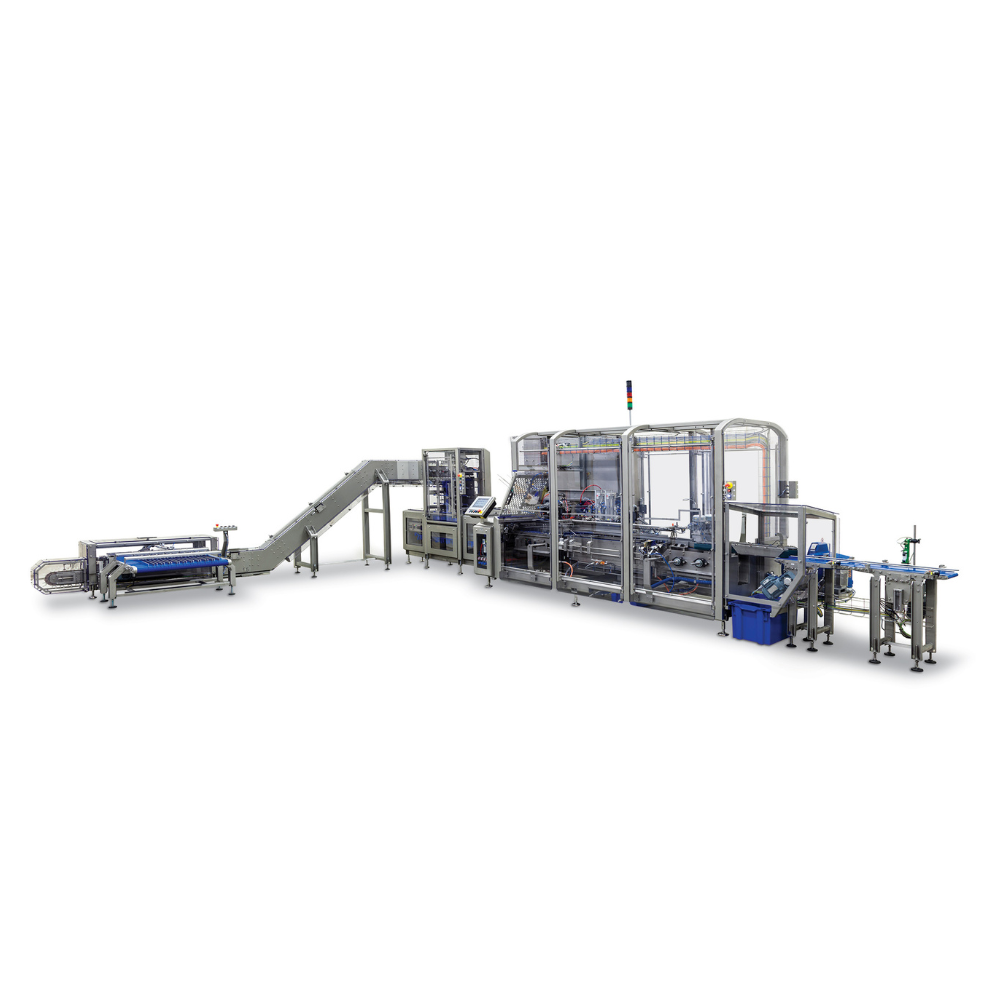

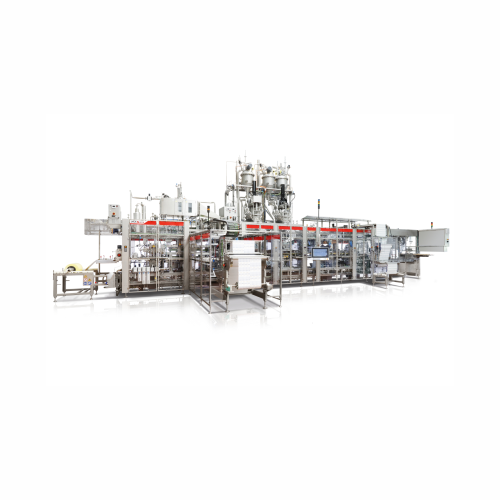

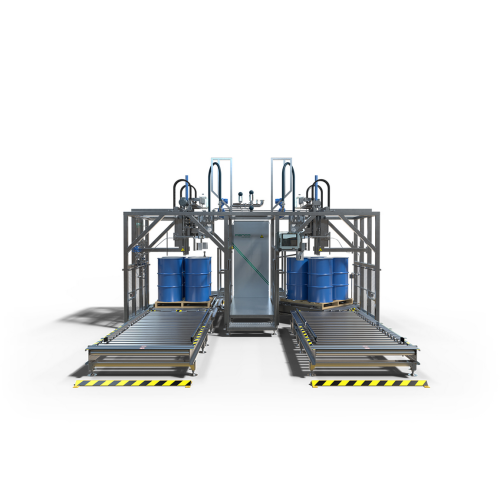

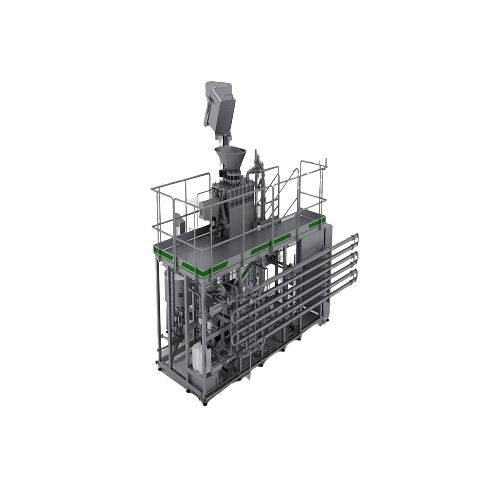

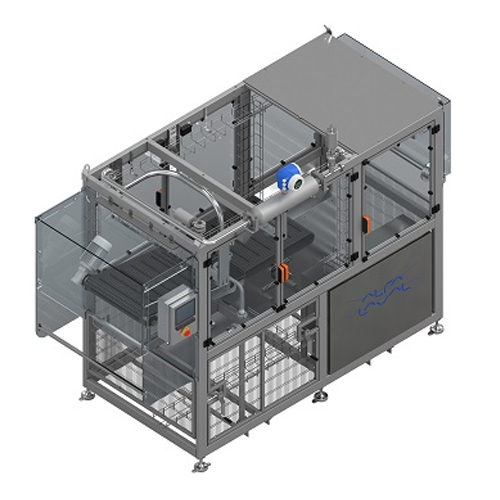

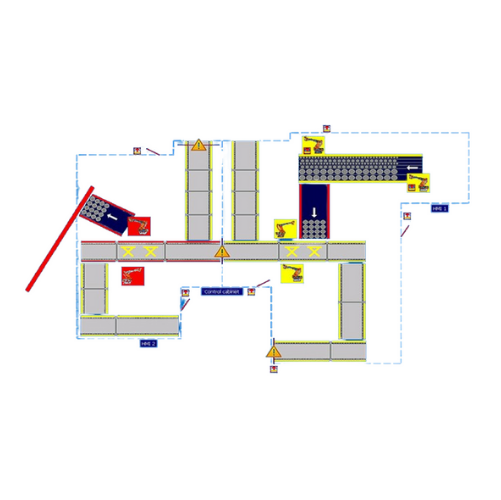

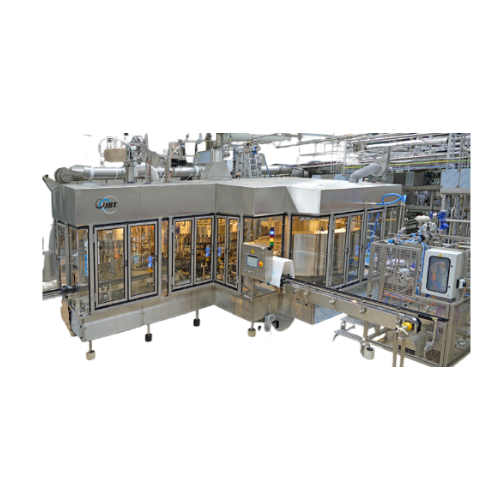

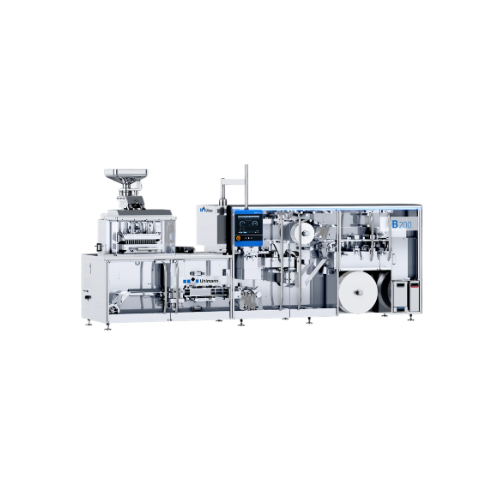

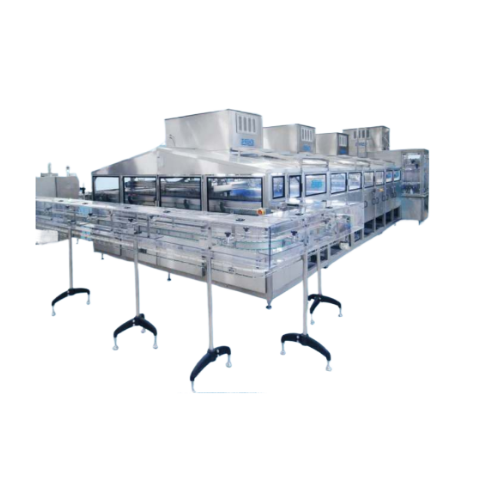

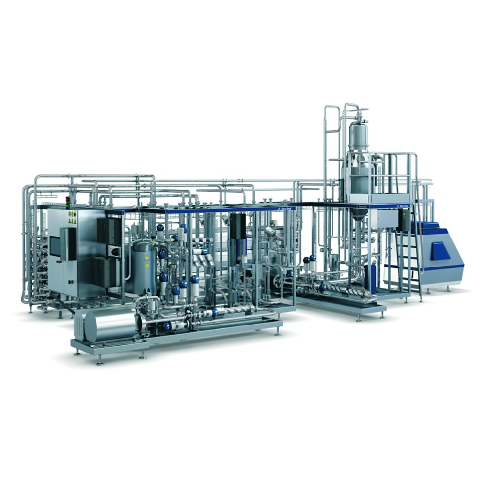

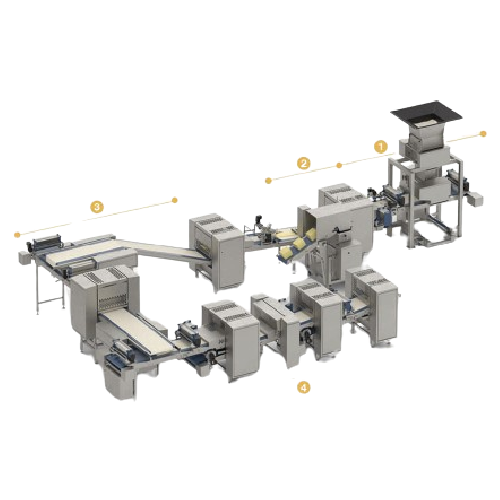

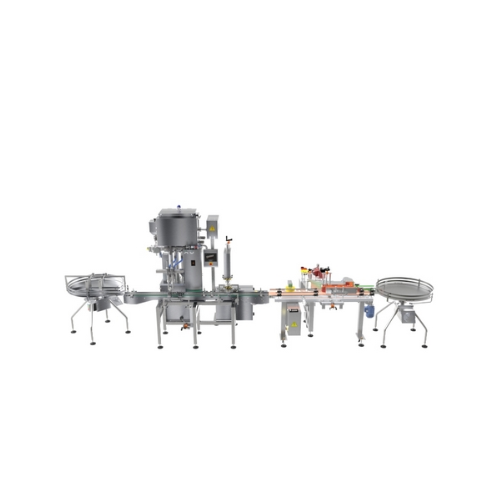

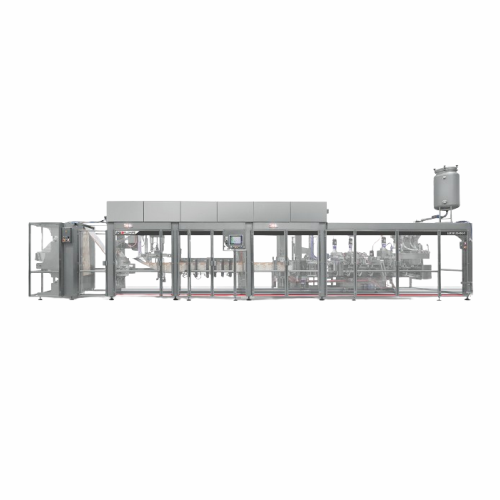

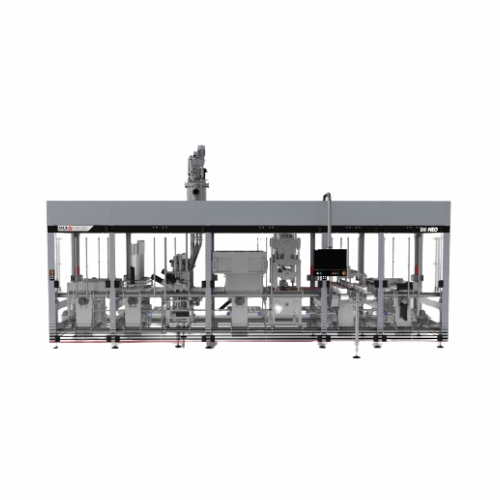

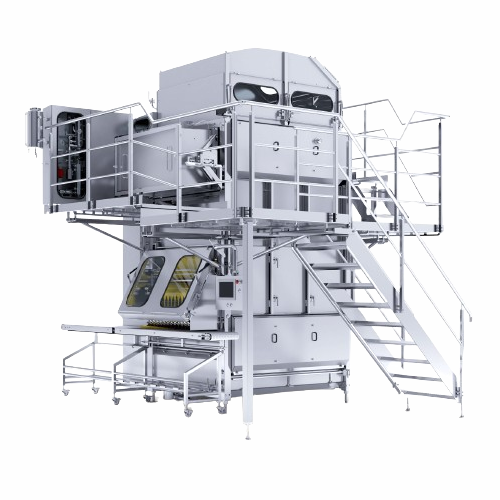

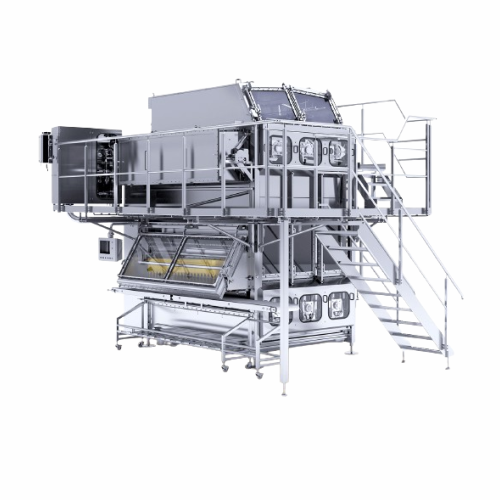

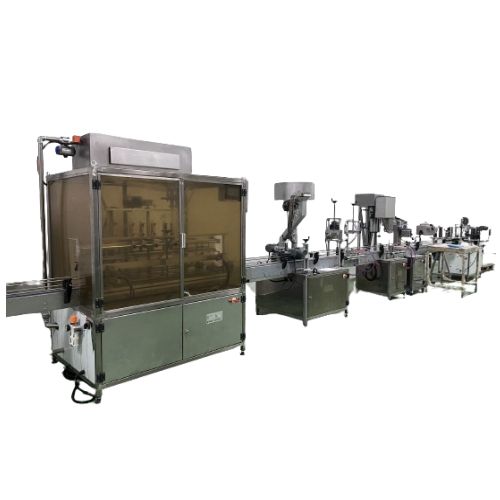

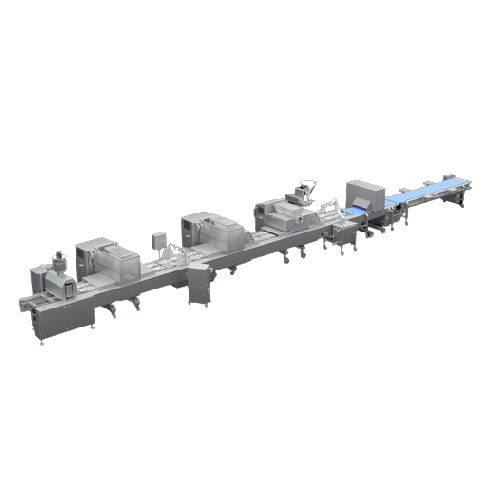

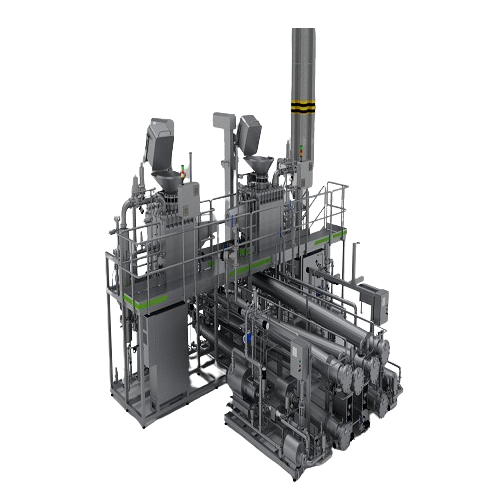

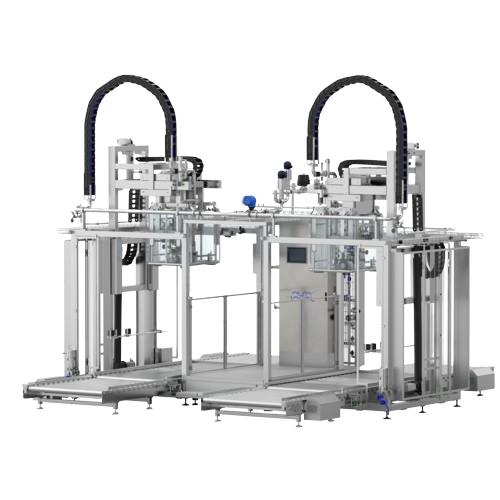

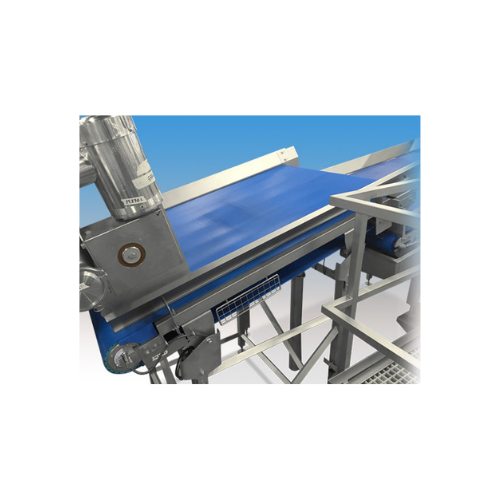

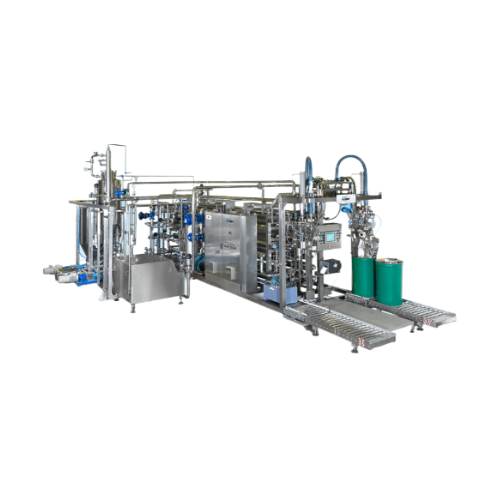

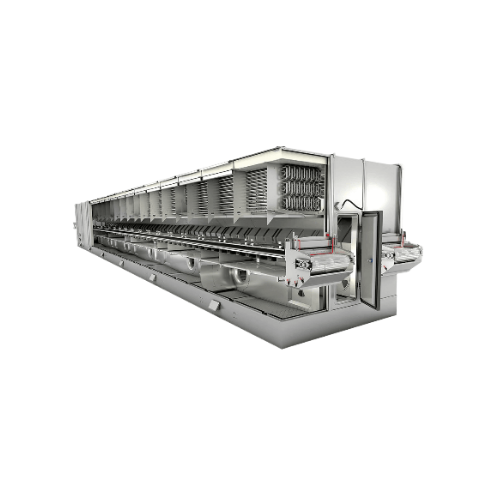

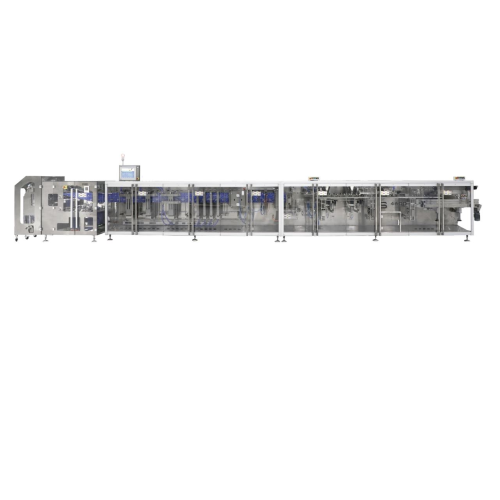

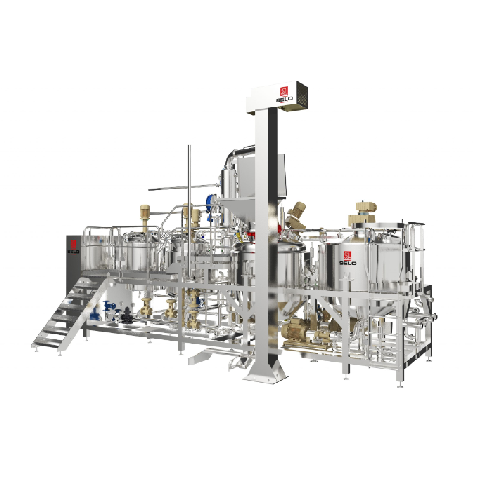

Automated sauce production lines

Streamline your sauce production with flexible lines designed for rapid recipe changeovers,...

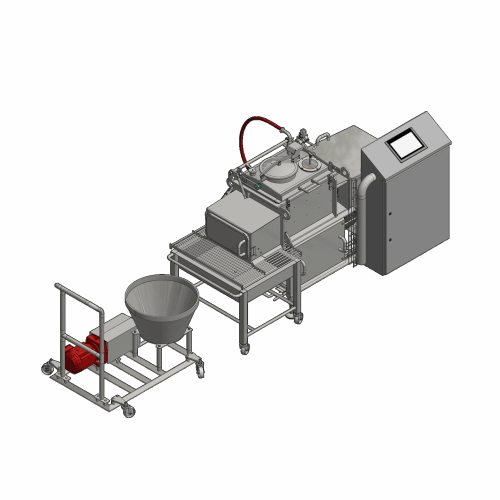

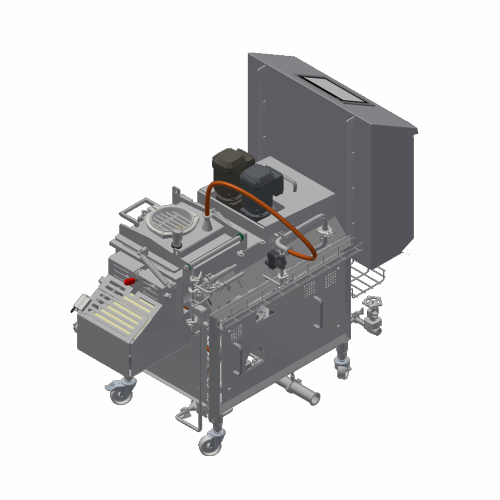

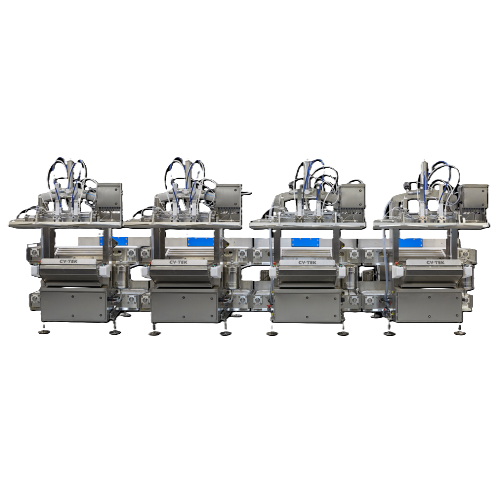

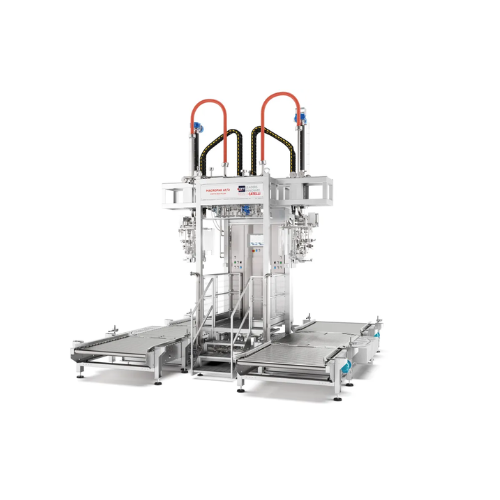

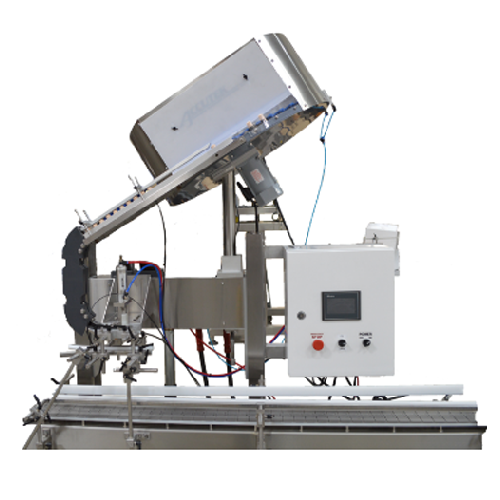

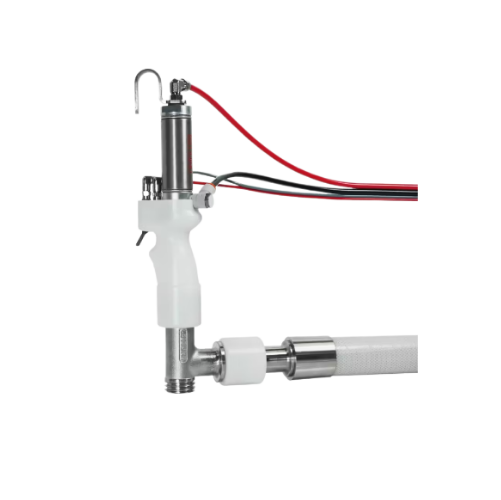

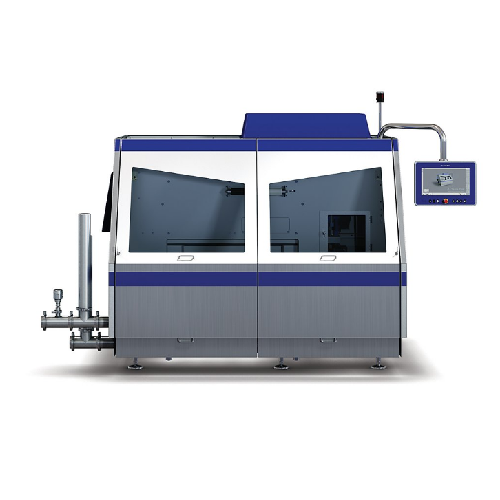

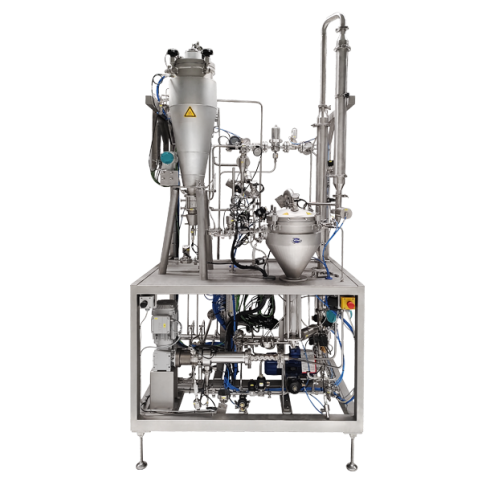

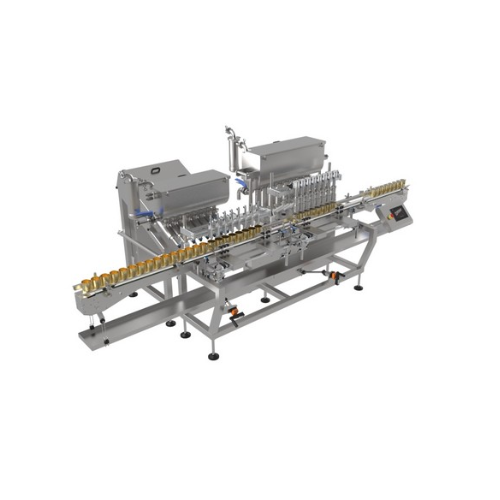

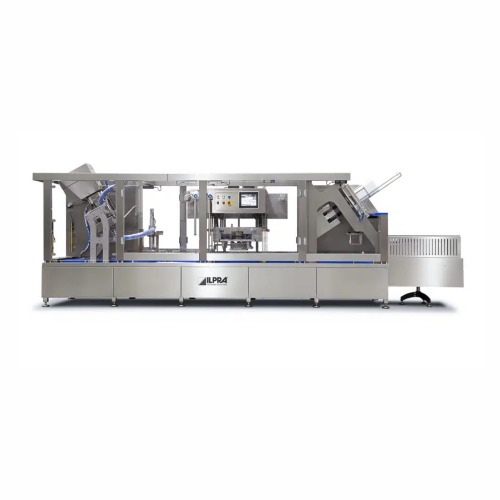

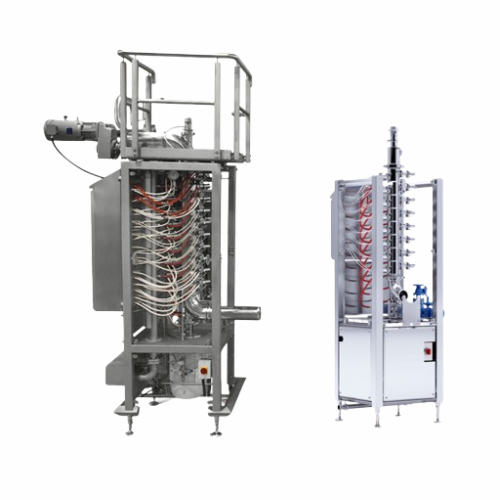

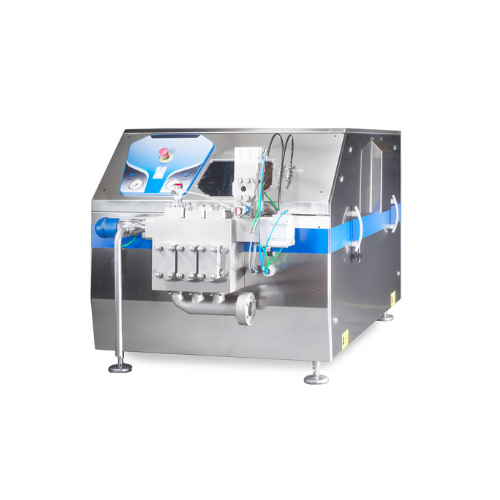

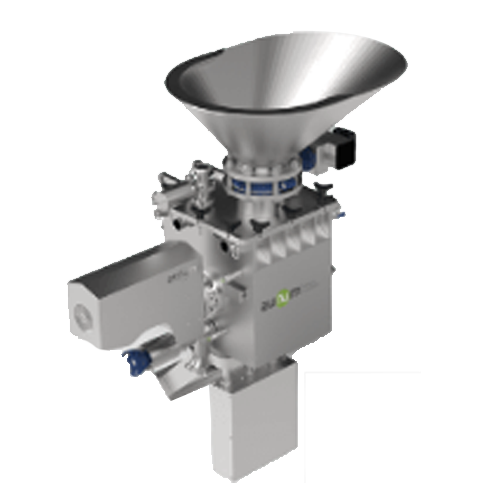

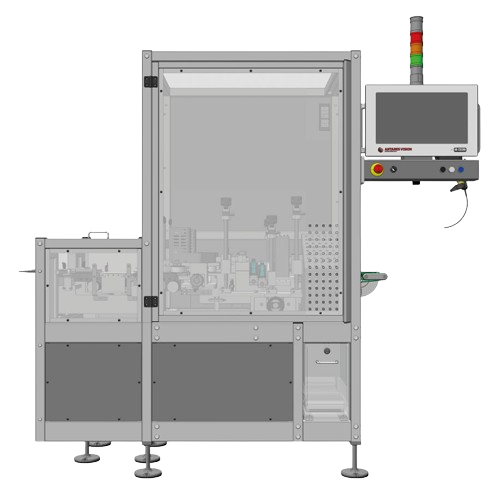

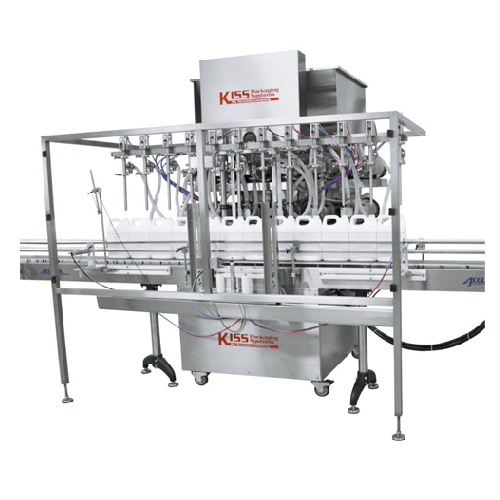

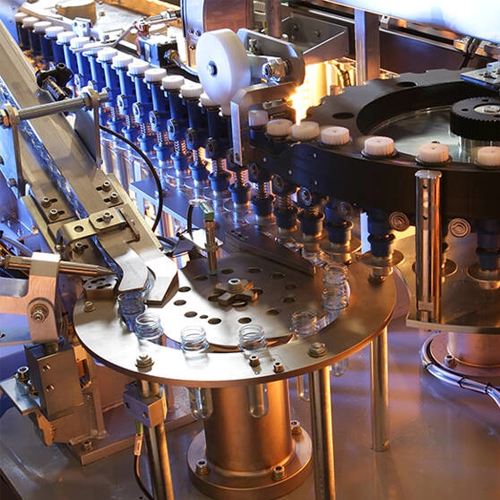

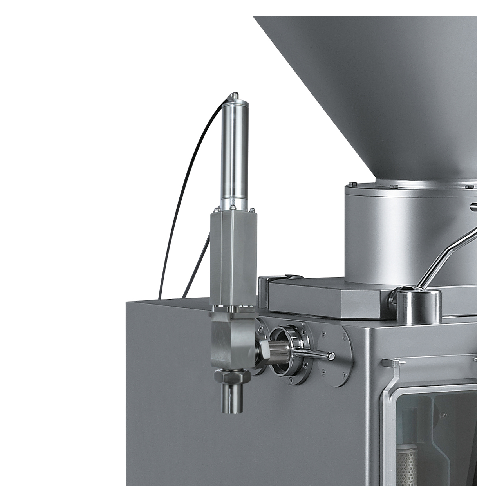

Automatic hot-fill dosing system for soups and sauces

Ensure consistent portioning and minimize occupational risks when h...

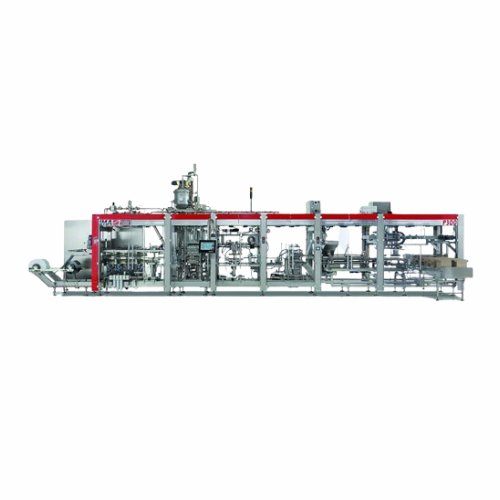

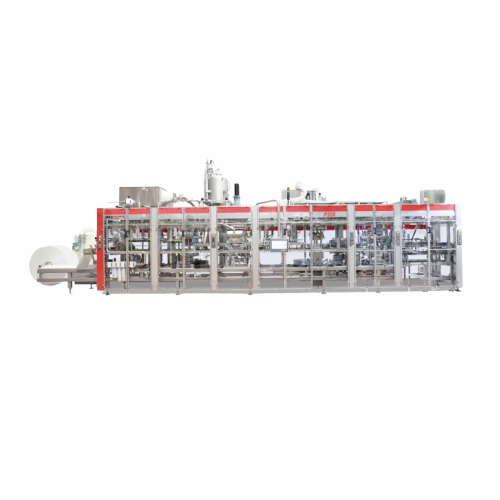

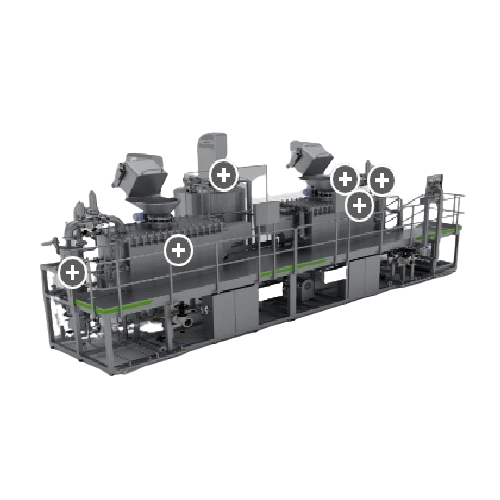

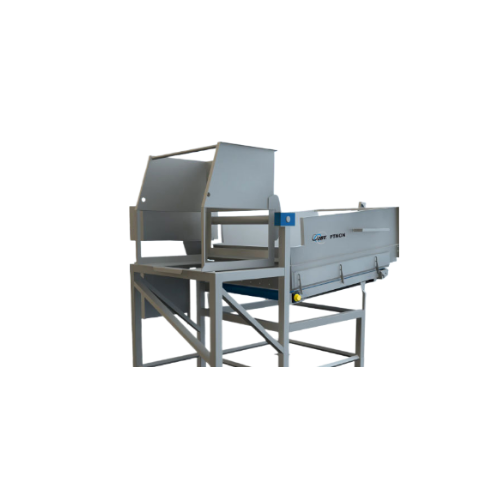

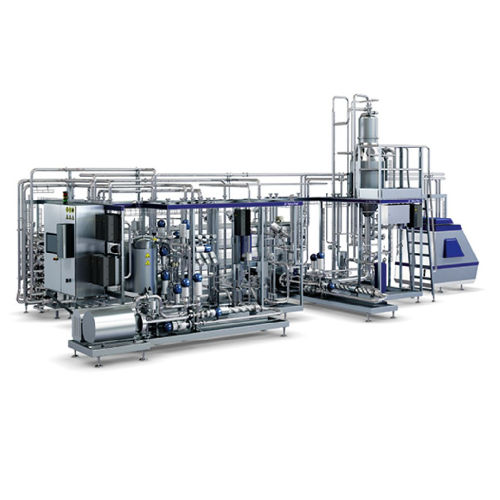

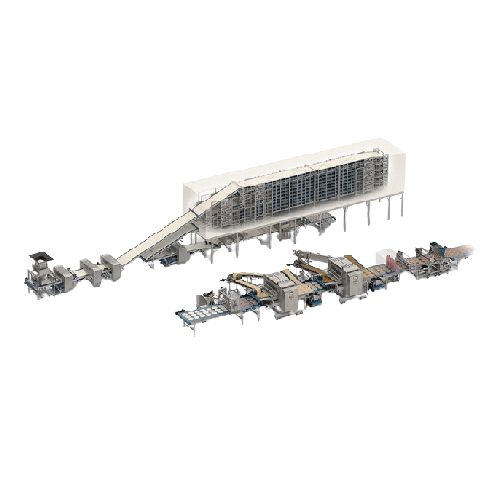

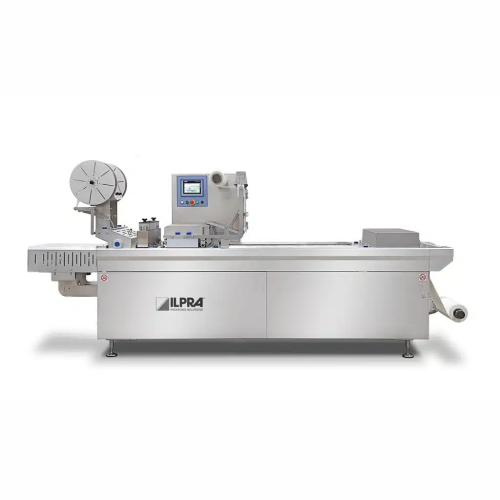

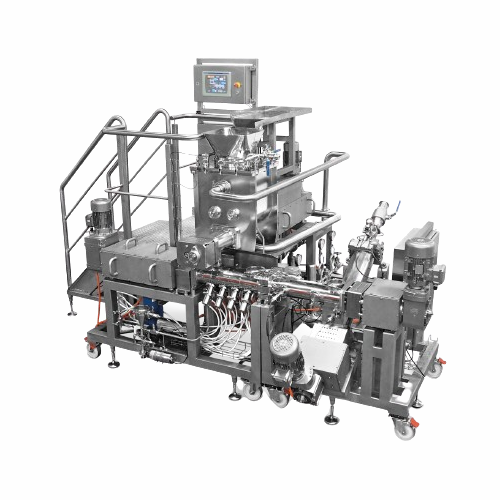

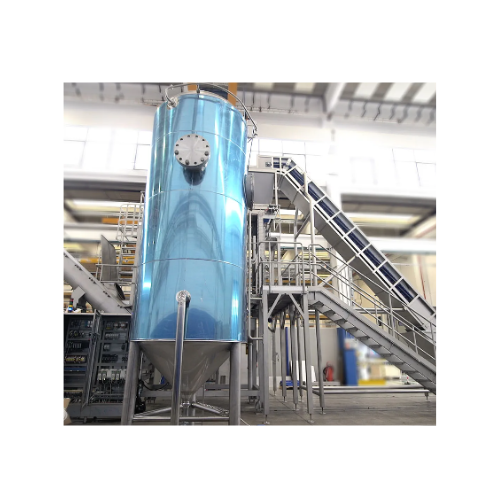

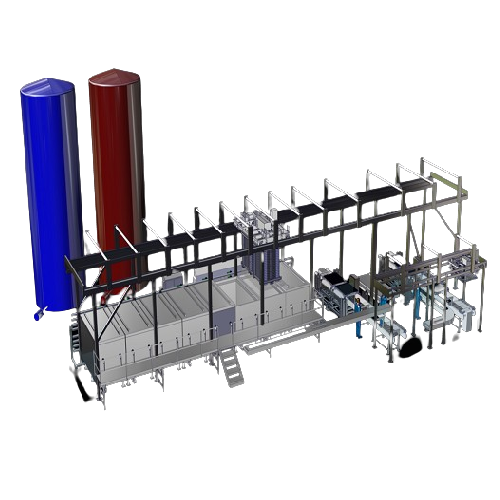

Ketchup and sauce processing line

Achieve precise mixing, cooking, and concentration for your sauces and purees, ensuring o...

Stories about sauce

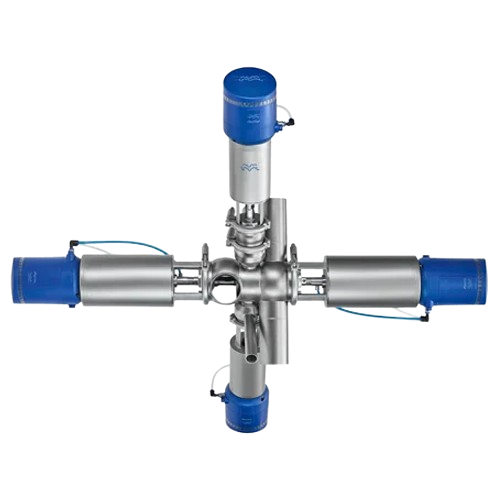

#Changemaker: clean even the stickiest products from your pipes by using air

#Changemaker: detect & reject truly low-density foreign bodies in your pumpable foods

Webinar: master mayo-making

Make a batch of mayo before you can finish a bag of fries

From granulated to invert sugar: the liquid therapy to prevent crystals in your jam processing line

#Changemaker: Fava bean umami extract for your vegan diet!

Ketchup shows its true colors with vacuum cooking

Unpacking the world of stick pack cartoning

What are you making?

Beef gravy

Bechamel sauce

Barbecue sauce

Bolognese sauce

Vinaigrette dressing

Vegan mayonnaise

Tomato paste

Tomato concentrate

Tartar sauce

Soy sauce

Salsa

Ranch dressing

Pasta sauce

Marinara sauce

Marinades

Italian dressing

Gravy

Hot sauce

Hollandaise sauce

Dressings

Dips

Dijon mustard

Curry paste

Alfredo sauce

Condiments

Chutneys

Chili paste

Chicken curry

Cheese sauce

Guacamole

Pesto

Truffle cream

Chili sauce

Tomato sauce

Salad dressing

Mustard

Ketchup

Mayonnaise

Tell us about your production challenge

Process base ingredients before reducing them into a sauce

Sauce making equipment applies the principle of reduction at an industrial scale. This involves cooking down a base liquid and aromatics to concentrate and meld flavors.

Vegetable and fruit-based sauces need technology that can handle fresh products, even if they can also be made with concentrates, frozen or aseptic packaged products. The ingredients are ground into smaller pieces and then juiced into a liquid. A strainer removes unwanted residues, such as seeds or stems, before they go for cooking.

Mixers are essential sauce making equipment for emulsified products

Emulsified sauces such as Hollandaise, Bechamel, or Mayonnaise develop their rich mouthfeel by suspending fat in water.

These sauces are produced by rapidly mixing suspended butter or oil into egg yolks. The dispersion breaks the butter or oil into tiny droplets held in suspension by lecithin content in the emulsifier.

Treat tomato-based sauces with heat to inactivate enzymes

Tomatoes are the quintessential sauce base. They can be processed into concentrates, ketchup, pasta sauces, and peeled tomatoes. Harvested tomatoes are sorted, washed, and milled to prepare them for production. Peeled tomatoes are scalded before skinning, while chopped and diced tomatoes go through a stainless steel cutter.

After crushing or emulsifying with augers, the tomato mixture goes to a hot break treatment unit for enzymatic inactivation. This essential sauce making equipment balances the consistency and viscosity of the sauce. The mixture is then refined, concentrated through evaporation, and pasteurized or sterilized.

Adapt the mixer with a whisking arm to emulsify vinaigrettes

Vinaigrettes and salad dressings are produced in two different steps. First, the flavor makers, spices, and preservatives are premixed with a liquid base like water or vinegar. The mixture is then dispersed into a continuous phase.

The second step is to extend with oil while whisking rapidly in a mixer. This dispersion method creates a more homogeneous emulsion. Finally, add stabilizers like pectin to thicken the sauce.

Use sterile packaging to extend the shelf-life of your sauce

Aseptic processing is a technique to thermally sterilize your sealed jars, making shelf-stable products that do not need refrigeration.

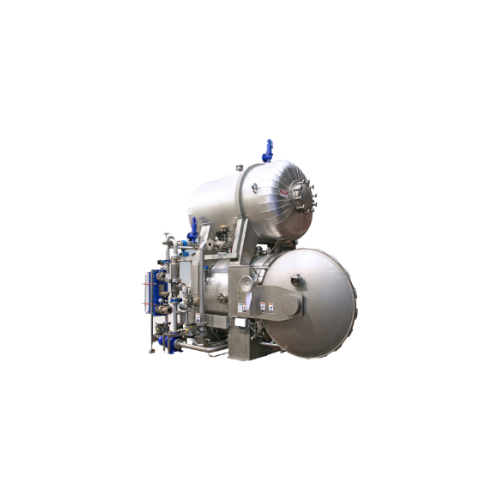

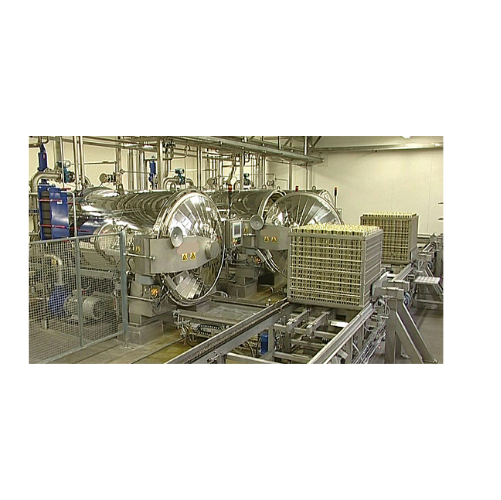

Alternatively, apply a hot-fill solution to sterilize your products. The heat from the injected hot liquid destroys microorganisms both in the sauce and the container. However, only high-acid sauces can go without refrigeration in this case. Another option is retort processing, where non-sterile products are filled into non-sterile packaging and sterilized in an autoclave with pressurized steam.

Which sauce technology do you need?

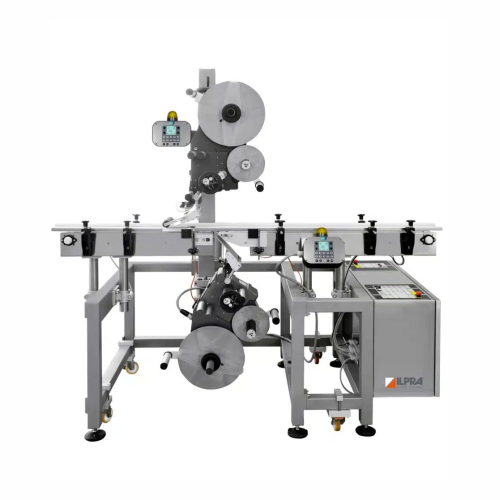

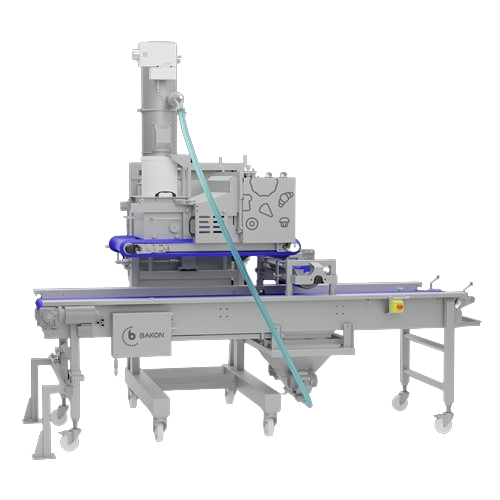

Baguette cutting and sauce filling system

Optimize your bakery production with an innovative system that seamlessly cuts a...

Pizza topping system for tomato sauce and ingredients

Streamline your pizza production with precise depositing of sauces ...

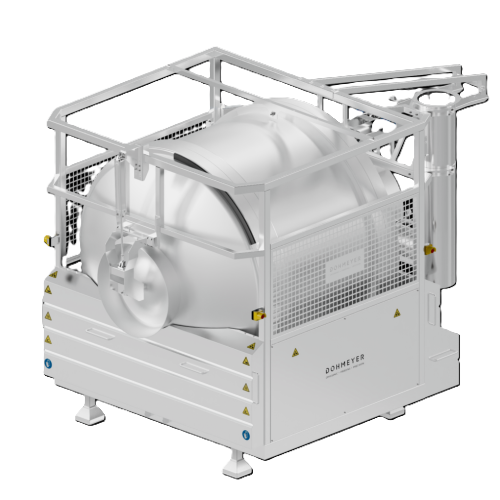

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

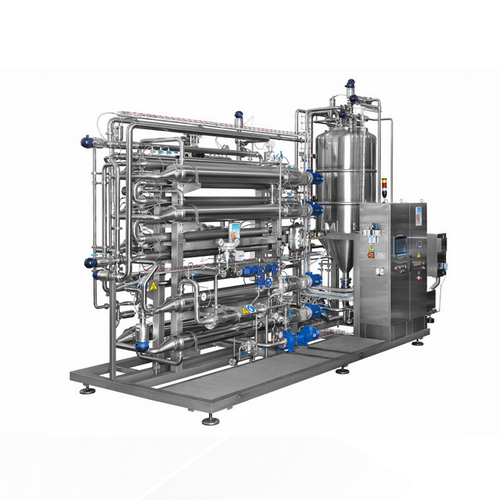

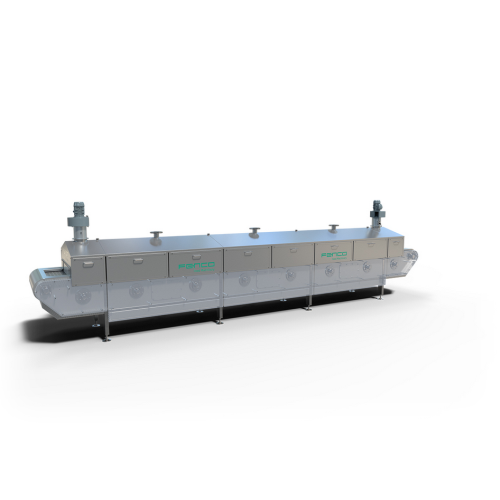

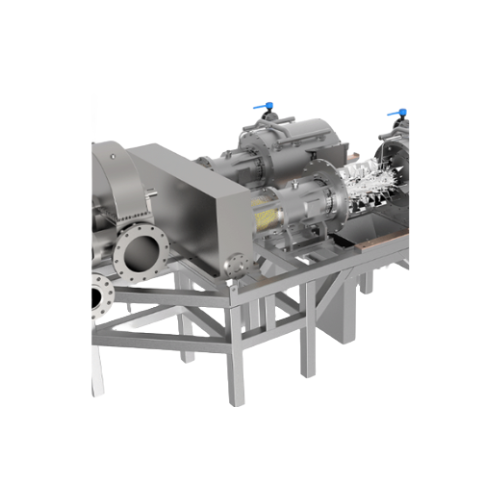

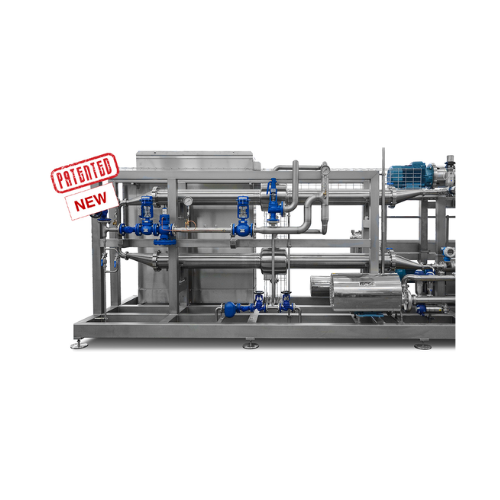

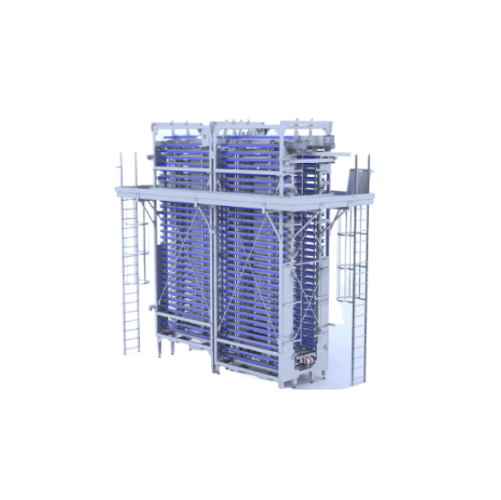

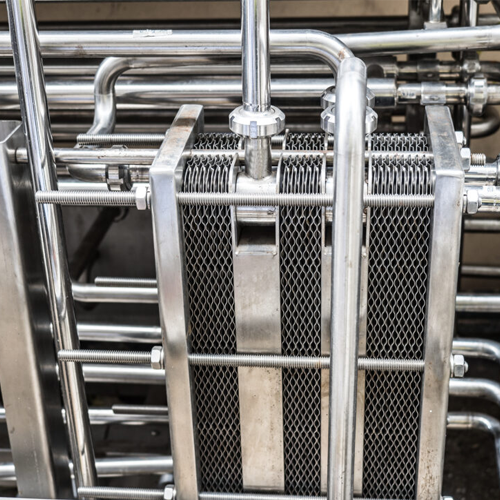

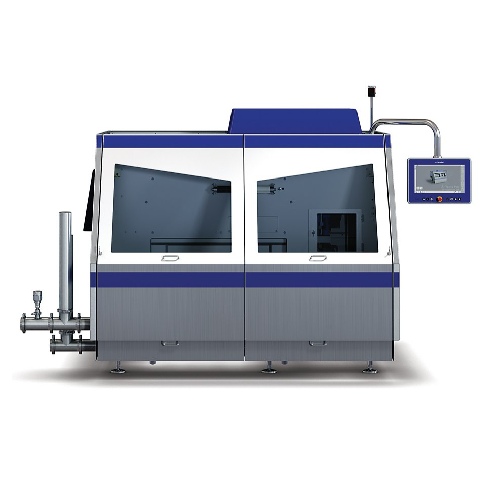

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

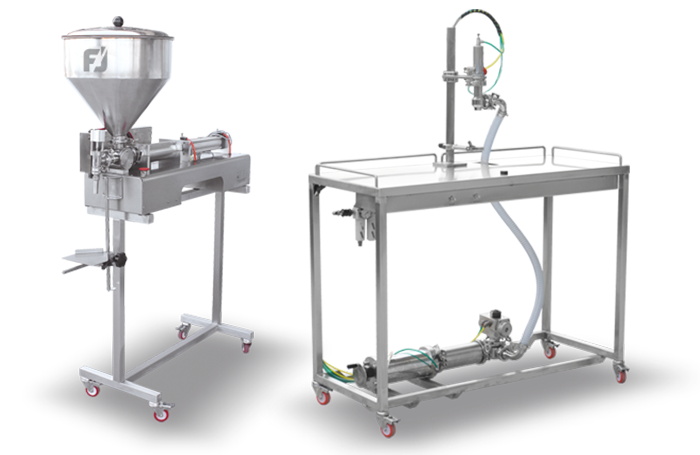

Professional dosing system for creams and sauces

Streamline your production with precise dosing of creams and sauces, tail...

Soup and sauce chiller for rapid cooling

Reduce cooling time drastically and maintain quality with a chilling solution that...

Hot-fill dosing system for soups and sauces

Efficiently dose hot soups, sauces, and porridges while ensuring workplace saf...

Hot-fill dosing system for soups and sauces

Ensure precise and efficient dosing of hot and cold liquid foods with integrat...

Automatic hot-fill dosing system for soups and sauces

Ensure consistent portioning and minimize occupational risks when h...

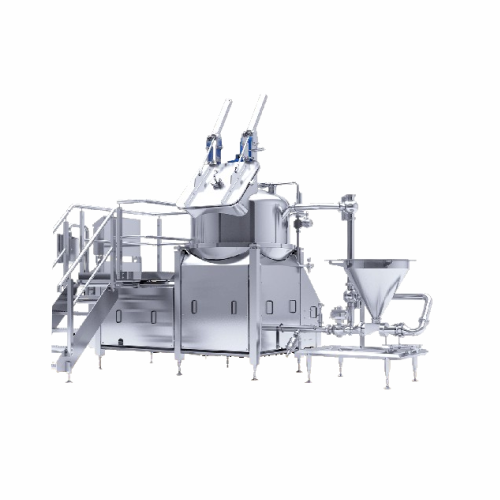

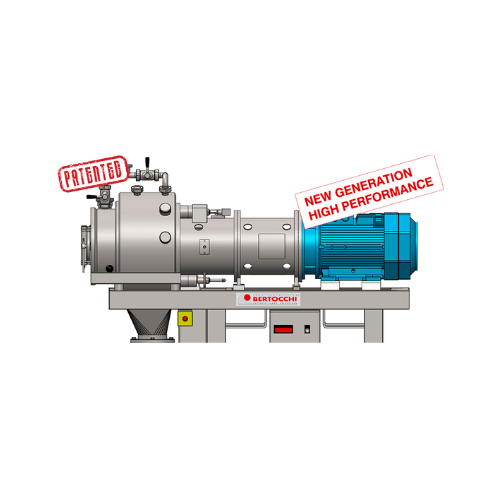

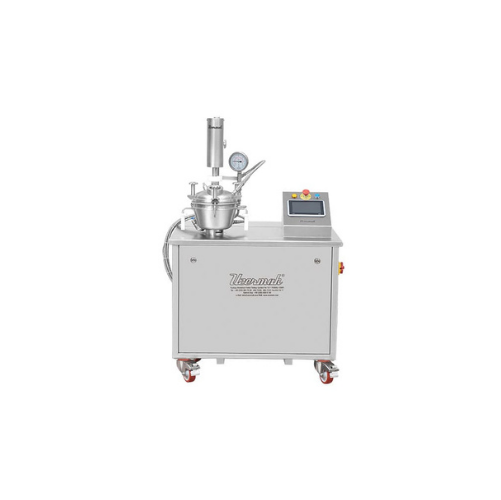

Industrial vacuum cooker for sauces

Enhance your sauce and jam production with an industrial vacuum cooker that offers cutt...

Industrial vacuum kettle for sauce production

Achieve optimal flavor retention and nutrient preservation with an industria...

Steam jacketed kettle for cooking sauces and dressings

Enhance your sauce production with a steam jacketed kettle that en...

Batch processing system for processed cheese and sauces

Optimize your food processing line with a versatile batch process...

Steam-heated hemispherical bottom cookers for sauce production

Streamline your sauce and condiment production with multi...

Ketchup and sauce processing line

Achieve precise mixing, cooking, and concentration for your sauces and purees, ensuring o...

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

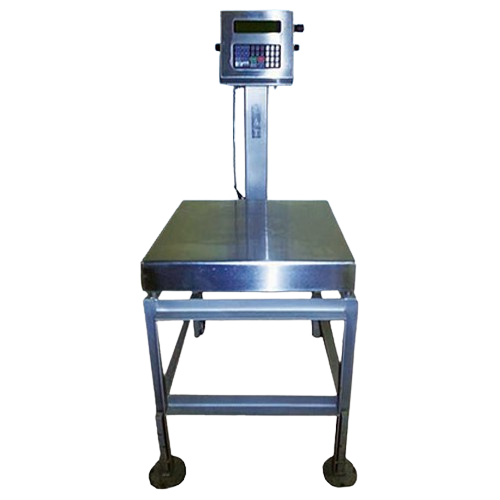

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Tomato processing plant for sauce and paste

Efficiently transform raw tomatoes into a variety of high-demand products, fro...

Vacuum cooker-cooler for jams and sauces

Optimize your food production with a vacuum cooker-cooler that enhances flavor whi...

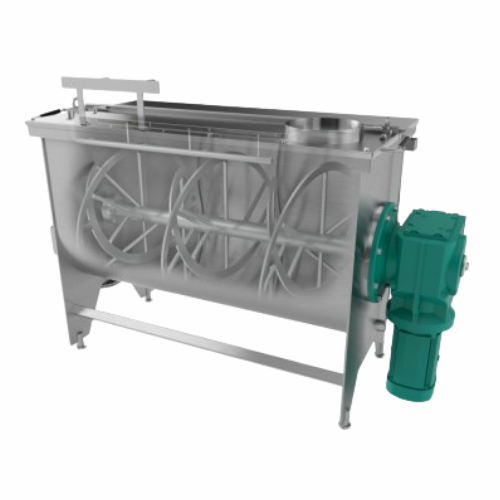

Mixing tank for soups, sauces, and dressings

Streamline your soup and sauce production with advanced mixing technology des...

Processing vessel for liquid, sauce, or cream products

Efficiently mix and integrate liquid, cream, or slurry products wi...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Multifunctional cheese and sauce processor

Optimize your production of sauces, dressings, and confectionery fillings with ...

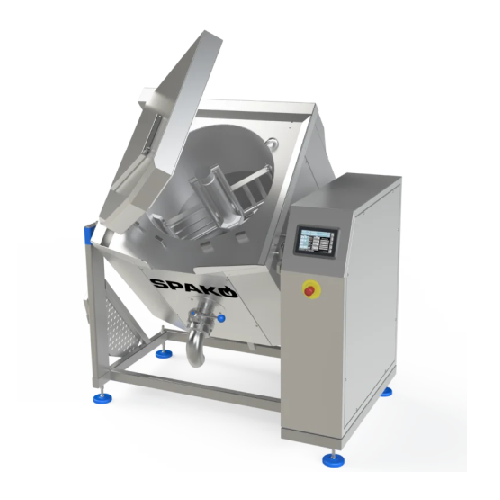

Multifunctional industrial mixer for processed cheese and sauces

Optimize your batch production with a versatile solutio...

Multi piston food depositor for sauces and dips

Efficiently fill and deposit sauces, dips, and more with precision across ...

Small-scale fruit processing line for juices and sauces

Streamline your small-scale production with a versatile line that...

Jacketed kettle for porridge and sauce cooking

Efficiently heat and mix diverse liquid and slurry products with precise te...

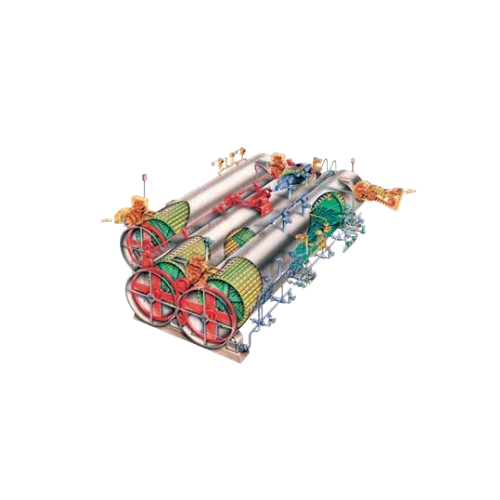

Milk and sauce sterilization with low-frequency shaking

Ensure your liquid products maintain quality and freshness with a...

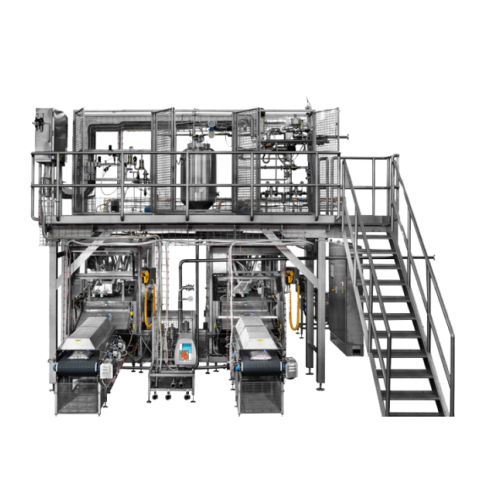

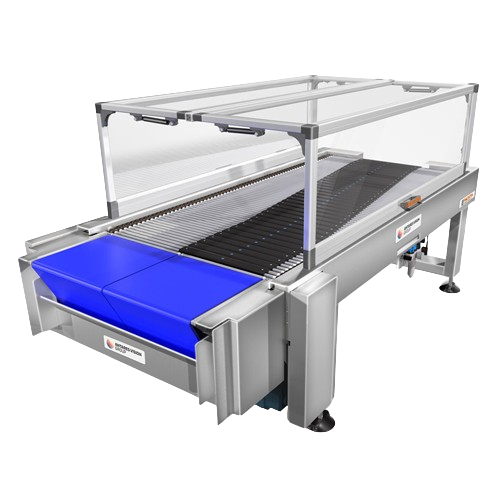

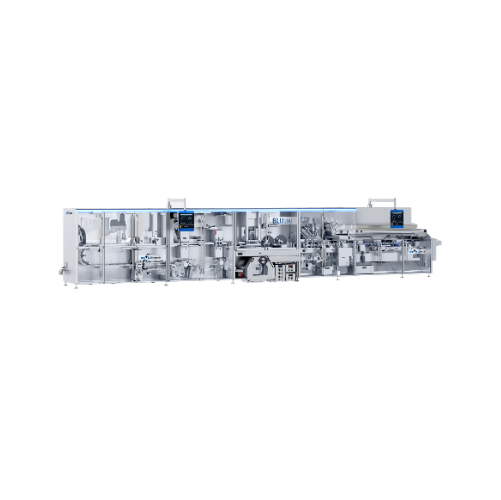

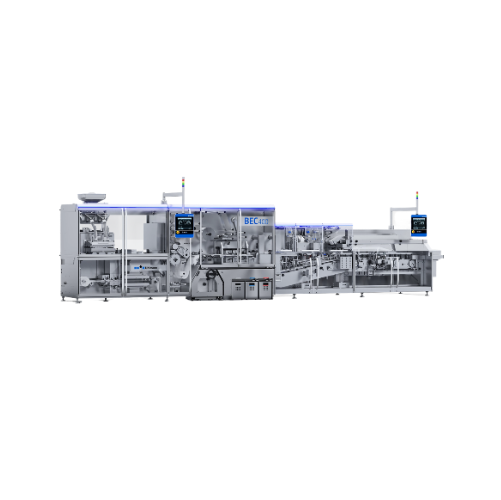

Automated sauce production lines

Streamline your sauce production with flexible lines designed for rapid recipe changeovers,...

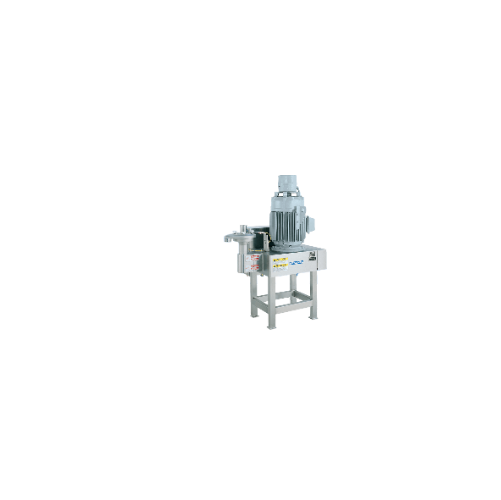

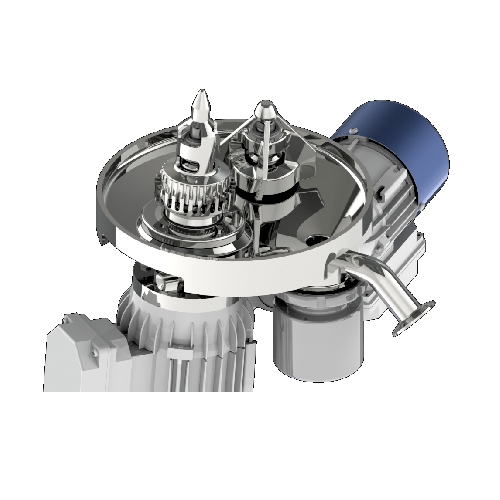

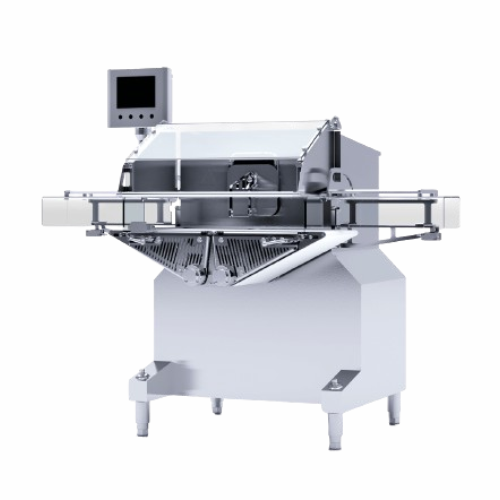

Industrial Sauce Homogenization and Emulsifying System

Texture and consistency are critical to foods with delicate compos...

Vegan Sauce Processing System

Having a multipurpose machine allows one to perform different tasks like cooking, frying, brai...

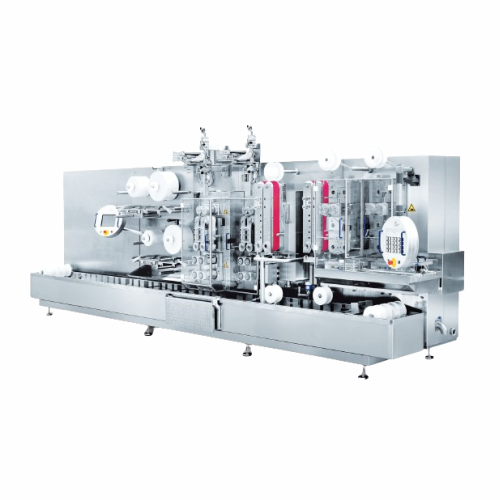

Standard FFS machine for spreads and sauces in mini portions

In the food industry, from a microbiological point of view,...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Mobile high speed depositor of pizza sauce

As the demand for ready-made pizzas continues to grow, businesses face tremendo...

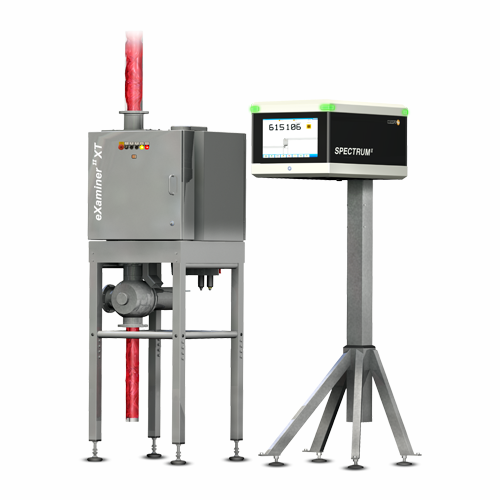

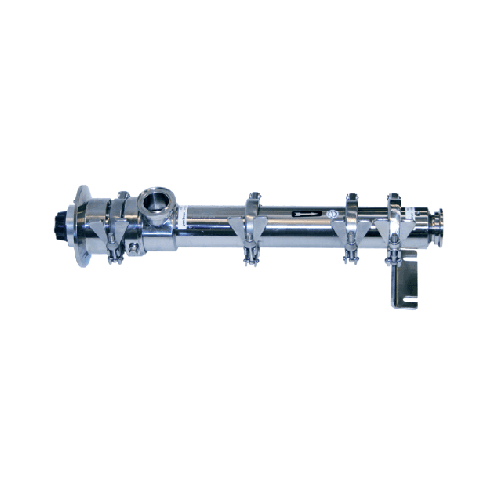

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

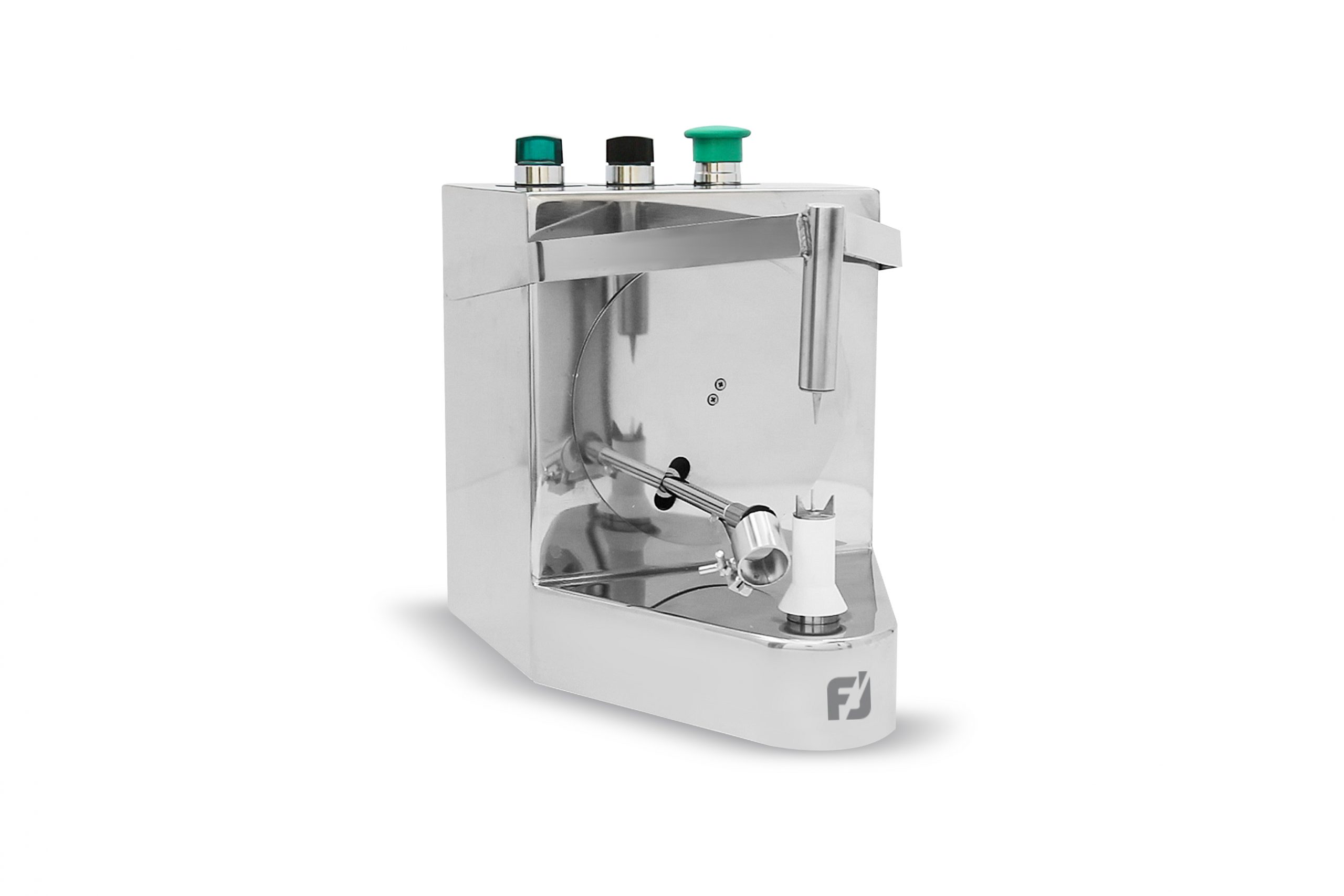

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Vacuum cooker for concentrating sauces and purees

When producing high quality prepared food, concentrating products for s...

Compact industrial sauce pan

Safe, reliable cookers that operate unobtrusively are required in any kitchen where space and t...

Industrial sauce pan

For the small and medium food industry, economical use of time, space and human resources is critical wh...

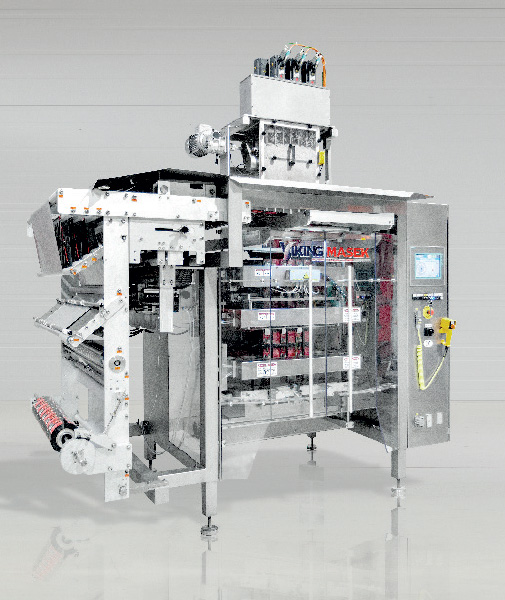

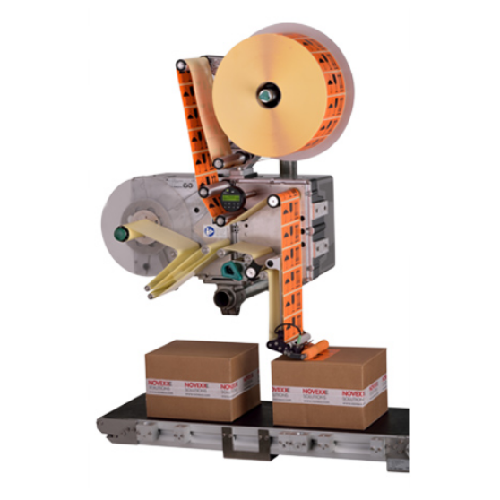

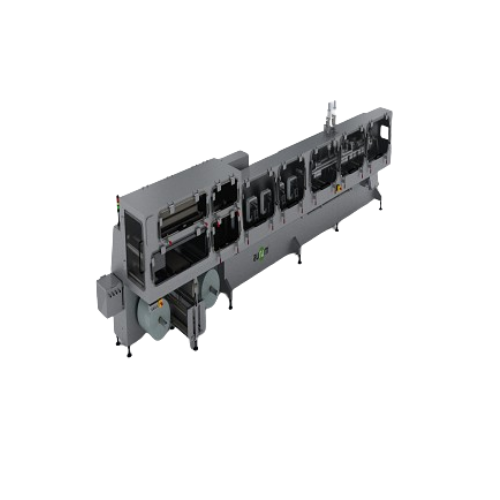

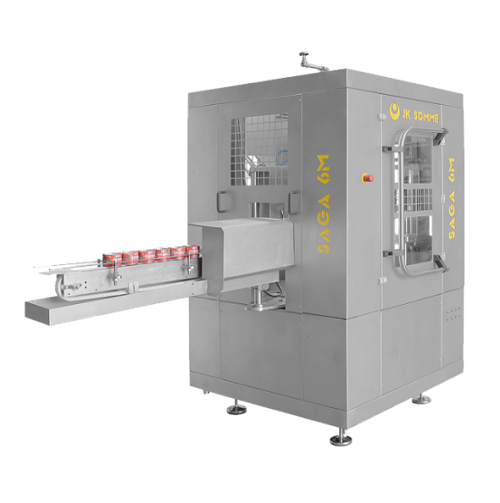

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Industrial premixing system for batch and inline processing

Streamline your production with advanced premixing systems d...

Turnkey food and beverage processing solutions

Optimize your production line with integrated processing systems designed t...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Clean-in-place system for industrial cleaning needs

Optimize your production efficiency with a system that seamlessly int...

Industrial cooling vessel for ready meal components

Enhance your production with precise cooling and gentle handling of t...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Pilot system for high-viscosity product processing

Efficiently handle high-viscosity or large particle products with this...

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

Small-scale in-container spray pasteurizer for laboratory use

Optimize your R&D processes with precise control over...

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

Food cutter for professional kitchens

Optimize your food preparation with precision mincing, cutting, and homogenizing, pre...

Professional food cutter for various ingredients

Streamline your food preparation with a versatile cutter designed to effi...

Pouch cooling system for food processing

Experience rapid cooling for your pouched food products, minimizing time in the ba...

High-capacity pouch cooling system

Move pouched foods swiftly through critical temperature zones, ensuring rapid cooling fo...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Cryogenic chilling systems for food processing

Efficiently maintain precise temperatures to enhance product quality and sa...

Cryogenic tunnel freezer

Achieve efficient and rapid freezing with state-of-the-art cryogenic technology, ideal for maintaini...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Industrial mixer for baby food and dairy production

Optimize your production line efficiency with a versatile mixing solu...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Emulsifying and blending system for liquid and semi-liquid food products

Efficiently emulsify and blend liquid and semi...

Powder dissolver for large liquid quantities

Achieve uniform powder blending swiftly with a vacuum-assisted system that pr...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

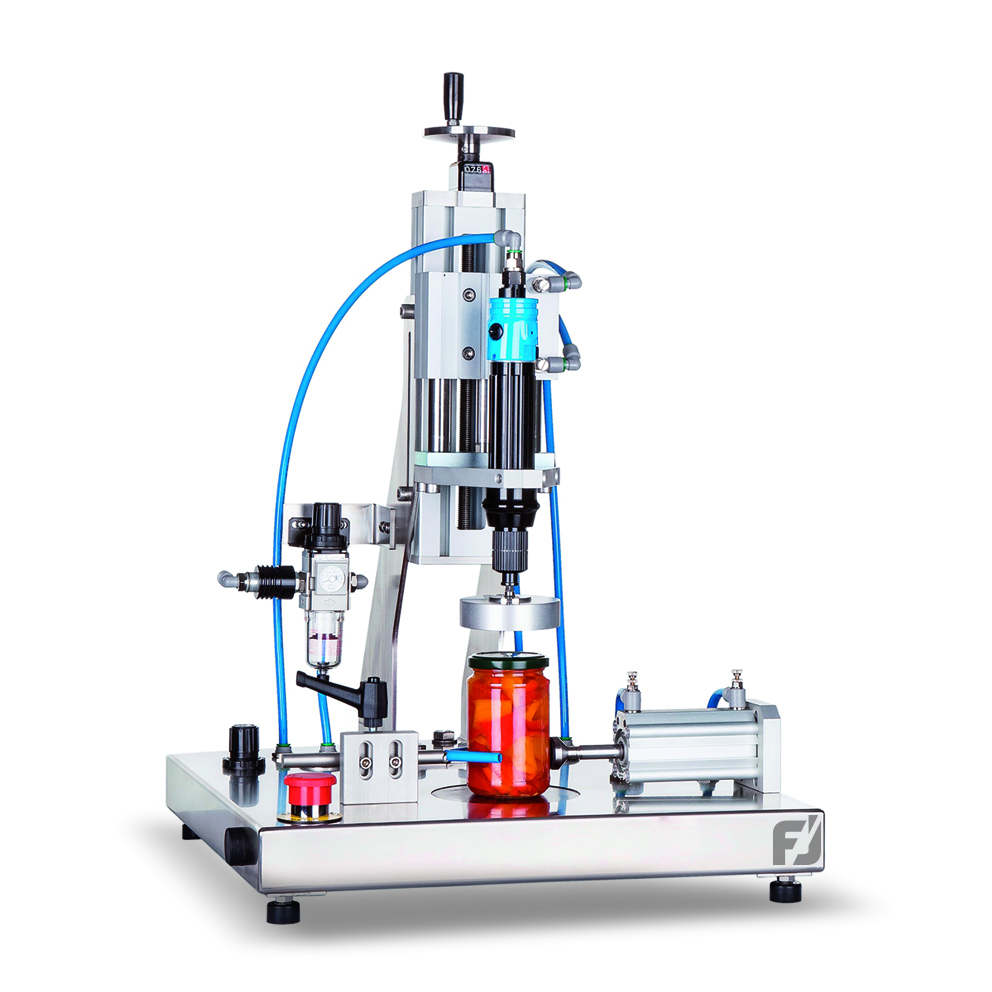

Semi-automatic capper for twisting and screwing metal and plastic caps

Effortlessly achieve precise cap tightening with...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

Automatic capping system for varied cap types

Enhance your packaging line efficiency with a high-speed capping machine des...

Vertical form, fill and seal packaging system for small bags

Maximize efficiency with small bag portioning for food and ...

Jam kettle for preserve and marmalade production

Ensure consistent flavor and texture in your jams and marmalades with pre...

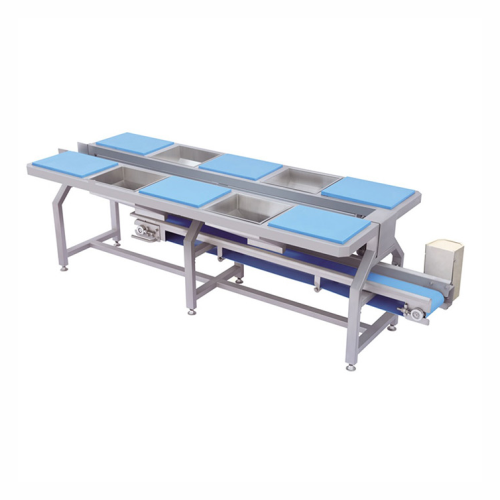

Dosing and tray handling lines for ready meals

Ensure precise dosing and seamless tray handling for a variety of ready mea...

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

Counter-rotating blender for cosmetic and pharmaceutical mixing

Achieve precise mixing and homogenizing of complex formu...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

Counter-rotating agitator for high viscosity products

Achieve seamless heat transfer and precise mixing with a counter-ro...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

Forming, filling and sealing solution for cups

Maximize production efficiency and flexibility with a high-output machine d...

Traysealer for modified atmosphere packaging - food products

Optimize your packaging line with this semi-automatic trays...

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Traysealer for food packaging with rotating table

Enhance your packaging line efficiency with a traysealer that simultane...

Multifunctional batch cooker for various food products

Optimize your production line with a versatile batch cooker design...

Lump-free emulsifier and steam batch cooker for processed cheese

Achieve consistent, lump-free processed cheese and crea...

R&d scale steam cooker for small batch processing

Optimize your R&D with a steam cooker that replicates large-scale ...

Multifunctional batch processing system for processed cheese

Enhance your production line with a sophisticated batch pro...

Batch processing system for processed cheese and various food products

Optimize your food production line with a multif...

Magnet for emulsion technology for lump-free blends

Achieve perfectly smooth and stable emulsions in a single pass with a...

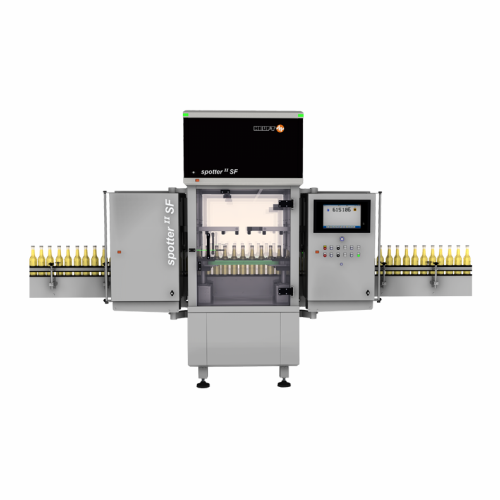

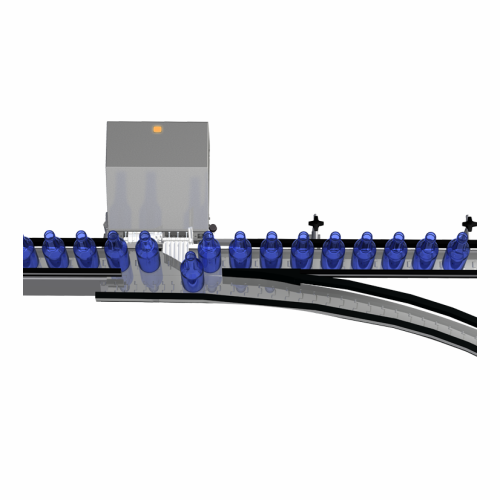

Closure inspection for beverage containers

Ensure the integrity of your bottled products with precision closure inspection...

Industrial nugget former for meat products

Efficiently shape and size a variety of meat and alternative products into nugg...

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel cooking kettle for food, pharma, and cosmetics

Efficiently streamline your production with versatile sta...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Industrial brine preparation system

Optimize your brine and marinade preparation with precise temperature control, efficien...

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

Tomato juice pre-concentrator

Achieve higher concentration levels with less energy use by utilizing accelerated juice circul...

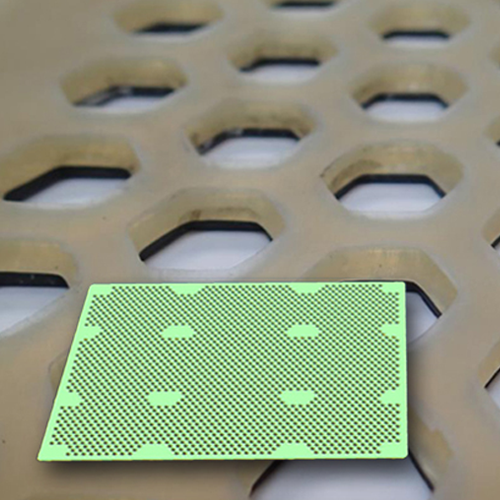

Enzyme inactivators for tomato processing

Efficiently inactivate enzymes to preserve nutritional value and organoleptic qu...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Production solutions for convenience foods

Effortlessly transform your innovative recipe ideas into consistent, high-quali...

In-line mayonnaise emulsifying system

Streamline your sauce and dip production with a system designed for efficient emulsif...

Electronic filling system for non-carbonated beverages

Optimize your bottling process with precision filling technology t...

Cooker for nougat and hard mixtures

Optimize the production of high-density mixtures like nougat and meat sauces with this ...

Medium-low density food cooker

Streamline your cooking process for medium-low density foods with precision-controlled mixing...

Planetary cooker for medium-high density mixtures

Achieve smooth, consistent textures with a planetary cooker designed fo...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Combination cooker-dosing kit for food packaging

Optimize your small-scale food production with seamless cooking-to-packag...

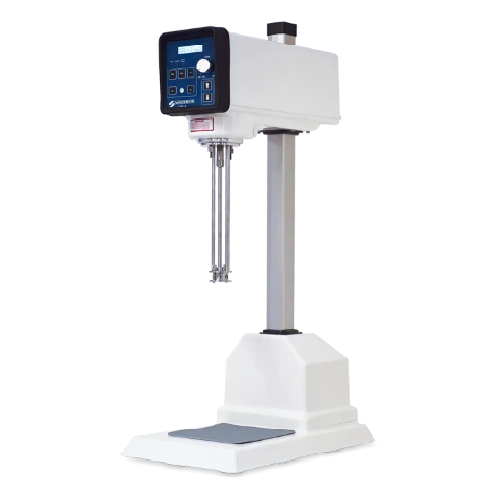

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Transfer hopper with stainless Pd pump for food processing

Eliminate spillage and maintain continuous flow with a positi...

Custom-designed work platform for safe operator access

Enhance operator safety and productivity by providing secure and h...

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Industrial cooking kettles for food processing

Optimize your production with versatile cooking kettles designed to handle ...

Precision size grader for tomatoes and round fruits

Ensure precise grading and sorting of tomatoes and round fruits to op...

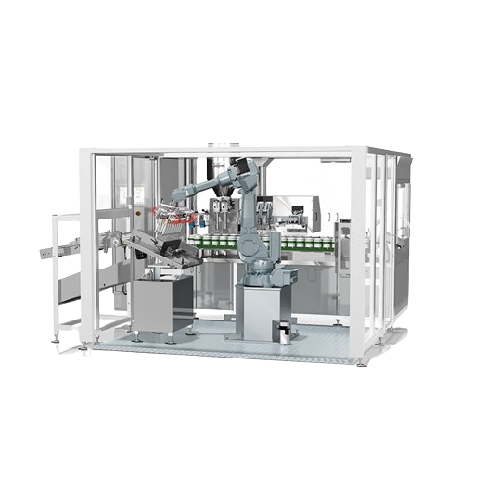

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handlin...

Robotic handling systems for beverage containers and bins

Streamline your container handling with precision-engineered r...

Sterilizers and pasteurizers for industrial food processing

Optimize thermal processing for viscous foods and beverages ...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

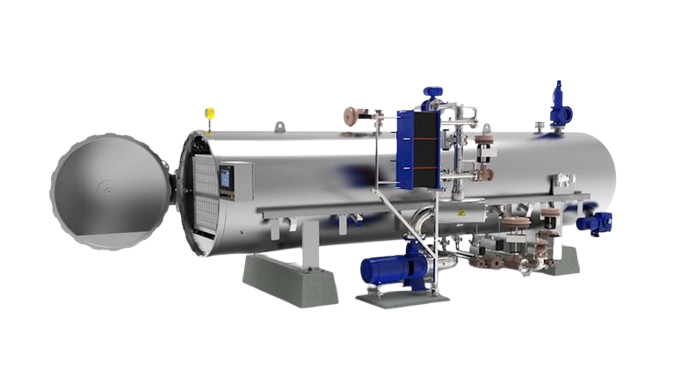

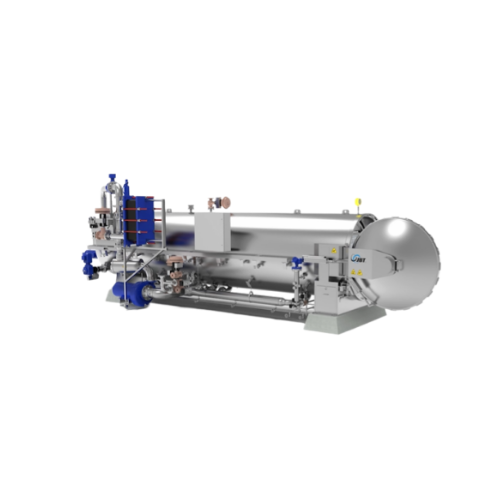

Batch retorts for food sterilization and pasteurization

Achieve optimal sterilization and pasteurization of packaged food...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

Clean-in-place systems for biotechnology and pharma

Ensure seamless transitions between production batches with efficient...

Horizontal evaporation bowl for fruit jams and purees

Optimize thermal exchange and preserve product integrity during jam...

Evaporator for juices and purees

Efficiently concentrate liquid products like apple juice, tomato puree, and chocolate sauce...

Evaporators for fruit and vegetable juices and purees

Optimize your juice and puree production with advanced evaporators ...

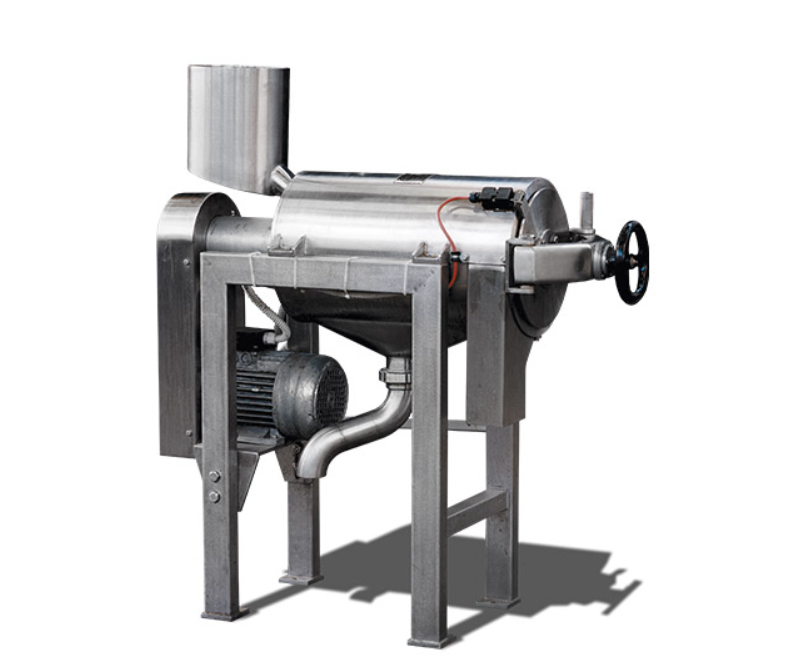

Hammer pulping system for fruit and vegetable processing

Optimize your fruit and vegetable pulping process with a high-sp...

Vacuum degasser for juices and purees

Enhance the quality of your liquid products with efficient degassing and flavor recov...

Pressure equipment directive (ped) compliant tanks

Achieve precise pressure regulation and safety with tanks designed to ...

Heater for enzymatic inactivation of fruit and vegetable pulp

Optimize your puree and concentrate production with effici...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Continuous cooker for vegetables and fruits

Optimize your production line with a continuous cooker designed to defreeze an...

Shelling mill for Iqf and frozen lumps

Precision-engineered for the seamless transition from frozen state to process-ready ...

Turbo extractor for puree and concentrate production

Enhance your puree and concentrate production with a turbo extractor...

Lumps melting system for chocolate and cocoa mass

Efficiently transform solid butter, grease, and chocolate into uniform ...

Drum blancher for continuous cooking and blanching

Optimize your production line with a continuous drum blancher, designe...

Fruit and vegetable washing solution with agitating action

Experience efficient dirt removal and product agitation for f...

Industrial frying system for sauté production

Optimize your culinary production with precise thermal exchange and adjustab...

Vertical bowl for cooking, degassing, and concentration of fruits and vegetables

Optimize the cooking, degassing, and ...

Sterile cooling system for fruit preparations

For manufacturers seeking aseptic conditions, this cooling system ensures ra...

Scraped surface sterilizer for high viscosity liquid products

Optimize your production of high viscosity liquids with a ...

Industrial jam processing line for fresh fruit or puree

Streamline your jam production with a versatile line capable of p...

Ketchup production line

Optimize your sauce production with advanced equipment designed to ensure consistent blending, precis...

Turbo extractor for tomato and fruit puree processing

Optimize your production line with high-capacity turbo extraction f...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Drizzler for precise food decoration

Transform ordinary dishes into visually stunning creations with a precise drizzling sy...

Pneumatic dosing system for dense and semi-dense products

For precise dosing of dense and semi-dense liquids, this pneum...

Pneumatic dosing system for dense and semi-dense products

Easily handle dense and semi-dense products with precision dos...

Cleaning system Cip for internal equipment maintenance

Ensure optimal hygiene and production efficiency with this portabl...

Ultra-clean vertical bag filler for viscous and particle-containing products

Streamline your viscous product packaging...

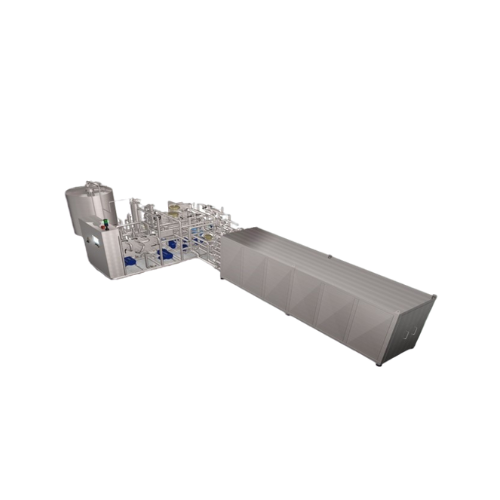

Aseptic cooking line for industrial food processing

Achieve seamless aseptic cooking and filling for diverse food product...

Industrial shear pump for high-viscosity food applications

Optimize your high-viscosity food processing with a shear pum...

Linear filler for preformed containers

Streamline your packaging process with a compact solution that ensures precise filli...

Rotary filler for preformed containers

Ensure microbiological safety and extended shelf life for your liquid products with ...

Scraped-surface heat exchanger for industrial fruit processing

Optimize your production with this advanced scraped-surfa...

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Tank for jelly and liquid preparations

Optimize your food processing line with a versatile solution that efficiently blends...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Flexible bag-in-box filler for liquid and viscous products

Optimized for flexibility and efficiency, this bag-in-box fil...

Bag-in-box filling solution for non-aseptic products

Maximize your production line’s efficiency with a high-speed f...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Aseptic vacuum cooker-cooler for jams and marmalade

Ensure your fruit-based products retain vibrant color and taste while...

Inline wet mill for mayonnaise emulsions

Eliminate the challenges of achieving stable, uniform emulsions in your sauces and...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Cooling tunnel for Pet container hot fill cooling

Ensure product integrity with a cooling tunnel that swiftly reduces PET...

Bottle corking system for high-volume production lines

Streamline your bottling line with precise and reliable cork inser...

Industrial crate washing system

Optimize your production line with a solution that ensures pristine cleanliness of crates an...

Compact digital bench weighing scale for food processing

Ensure precise portioning with this compact and durable digital ...

Industrial water belt cooler for fresh produce

Ensure consistent cooling for various food products with a system designed ...

Industrial melt tanks for butter and chocolate

Reduce manual labor and elevate safety in your production line with a melt ...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Electric bin tipper system for food processing

Achieve consistent product flow and minimize manual handling with this adva...

Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a sy...

Industrial hot water heating system

Optimize your production line’s efficiency with precise water temperature control...

Ohmic heat exchanger for high viscosity foods

Optimize the thermal processing of heat-sensitive foods with precise ohmic h...

Tomato steam pressure peeler

Efficiently peel and process large volumes of tomatoes while maintaining product quality with a...

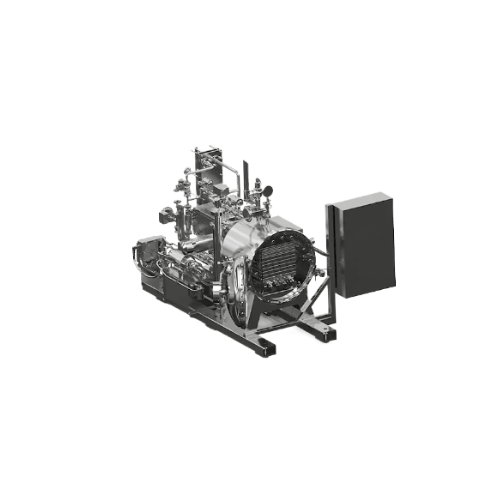

Pilot rotary retorts for laboratory sterilization

Optimize your prototype testing with precision thermal simulations to p...

Gentle can handling ejector for rotary cooker

Achieve seamless can transfer and sterilization with reduced damage during h...

Heat exchanger for liquid and semi-liquid foods

Optimize your heating and cooling processes with superior heat transfer ef...

Low energy suction system for food processing retorts

Optimize your sterilization process with innovative suction technol...

Steam water spray retort for shelf-stable food processing

Ensure uniform heat distribution and precision control in ster...

Agitating batch retort for food sterilization

Ensure superior heat distribution and precise control in your sterilization ...

Coil heat exchanger for dairy and beverage processing

Quickly sterilize and retain product quality with this coil heat ex...

Uht sterilizer for dairy and high-viscosity products

Optimize your production of dairy alternatives and fruit-based drink...

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Cold break system for tomato processing

Enhance product quality and consistency in liquid processing by utilizing precise t...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

Knocker conveyor for fresh produce processing

For processors dealing with mixed produce, this conveyor effectively separat...

Preparation line for fresh produce

Streamline your fresh-cut processing with this efficient preparation line, facilitating ...

Rotary level filler for low to high viscosity liquid products

Ensure precise fill levels and enhance production efficien...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

Granular filler for wide mouth containers

Ensure precise filling and minimize product loss with this granular filler, expe...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Industrial brine mix and chill system

Streamline your production with a versatile system that seamlessly blends and chills ...

Uht plant for aseptic product treatment

Ensure optimal product quality and production safety with versatile UHT solutions f...

Microparticulation unit for whey protein processing

Enhance your dairy and food formulations with optimized whey protein ...

Rotary vacuum fillers for liquid and semi-liquid food products

Achieve precise filling of a wide range of liquid and sem...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Rotary piston fillers for pumpable products

Optimize high-speed production lines with precision filling for diverse liquid...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

Turnkey plant solutions for industrial applications

Enhance your production line with seamless integration and optimized ...

Industrial brat pan for ethnic food manufacturing

Enhance your culinary production with a versatile brat pan designed for...

Horizontal flat pouching for top-cap pouches

For manufacturers aiming to streamline pouching operations, this high-speed h...

Horizontal flat pouching system for up to 180ml capacity

Optimize your packaging process with a high-speed solution desig...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

Solid-liquid in-line mixer for chemical product manufacturing

Effortlessly integrate and disperse high-solids content in...

Energy-saving cooling tumbler for industrial kitchens

Optimize food quality and texture with a versatile cooling tumbler ...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Industrial buffer tank for temperature and texture control

Achieve precise temperature control and optimal texture with ...

Multifunctional industrial food mixer

Efficiently handle complex food processing tasks from mixing to homogenizing with a m...

Viscous and liquid product processor

Optimize your production of viscous slurries and liquid formulations with a versatile ...

Single piston food filler

Achieve precise portioning and consistent product flow with a versatile solution perfect for handl...

Industrial depositor for automated recipe management

Effortlessly streamline your production with precise depositing cont...

High speed pneumatic depositor for bakery applications

When depositing batters, creams, and sauces, achieving consistent ...

Food spraying solution for various products

Streamline your food processing with a versatile sprayer that handles everythi...

Industrial food depositor for large volume applications

Efficiently handle diverse food textures with precise portion con...

Industrial food portioning system

Optimize your production flow with precision portioning equipment designed to handle a di...

Food grade transfer pump for semi-solid products

Streamline your production with a high-speed transfer pump designed for s...

Industrial food filling and depositing equipment

Optimize your production line with precise, gentle depositing and filling...

Layered food production line

Effortlessly streamline your production of layered foods with versatile technology that pumps, ...

Dual or triple lane food depositor

Enhance your production efficiency with a depositor that seamlessly handles a variety of...

Multipiston food filling machine

Experience precise and versatile portion control with high-speed, servo-driven piston depos...

Large portion depositor for food production

Achieve precision and efficiency in depositing large portions with versatile s...

Industrial food spraying and flocking system

Reduce waste from single-use canisters in food production while achieving pre...

Bakery batter depositor for efficient, consistent depositing

Enhance your bakery production with precision depositing fo...

Compact depositor for viscous and liquid products

Easily transition between depositing viscous and liquid products with p...

Multi piston depositor for automated bakery filling

Optimize your bakery production with precise portioning and filling, ...

Compact food depositor for direct container use

Streamline your depositing process with a versatile solution that handles ...

High-speed piston depositor for food applications

Achieve precise portioning and rapid depositing of diverse food product...

Industrial depositors for flowable food products

Enhance your production line’s efficiency with precision depositing...

Pneumatic Rp depositor for bakery and food plants

Optimize your production line with a high-speed depositor designed to d...

Single piston food depositor

Achieve precise portion control for diverse food products, from soups to chunky fillings, with ...

Industrial food portioning depositor

Optimize portioning precision and streamline your production with this advanced deposi...

Compact food filling and portioning solution

Ideal for facilities needing precise portioning, this versatile filling machi...

Tabletop food depositor for portion control

Streamline your food production with precise portion control, reducing waste a...

Semi-automated depositor with handheld nozzle

Maintain portion precision and reduce ingredient waste with a versatile depo...

Single piston food depositor for temperature-sensitive environments

Optimize your production with a versatile depositor...

Compact food transfer pump

Effortlessly maintain your production flow with a compact transfer pump designed to handle a wide...

Bakery transfer pump for smooth and chunky products

Ensure consistent product quality with this transfer pump that gently...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

Batch evaporators for fruit juice and tomato concentration

Achieve high-quality fruit and tomato concentrates while pres...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

Vertical slow juicer for producing cold pressed juice

Achieve optimal juice quality and versatility with low-speed crushi...

Cold press juicer for tough vegetables

Effortlessly handle tough produce with this twin gear, cold press juicer, designed f...

Glass personal blender for nutrient preservation

Experience enhanced flavors and nutrient retention with advanced vacuum b...

High-speed blender for commercial use

Designed for high-performance blending tasks, this solution integrates vacuum technol...

Single-serving blender for home use

Create smooth, nutrient-rich beverages and culinary delights effortlessly, whether you&...

In-line filling and closing system for pre-formed containers

Looking to enhance production efficiency with a solution th...

Semi-automatic filling and closing system for pre-formed containers

Streamline your packaging process with reliable sem...

Glass jar filling system for processed cheese

Streamline your production line with a robust, high-speed filling solution d...

Vacuum sealing system for glass jars with metal lids

Efficiently vacuum seal glass jars with metal lids to transform pres...

Electric tomato squeezer for large-scale production

Optimize your tomato processing with this high-capacity electric sque...

Tomato squeezer for efficient fruit and vegetable pressing

Streamline your fruit and vegetable processing with a versati...

Tomato squeezer for efficient food processing

Efficiently transform raw tomatoes and other fruits into smooth sauces and p...

Electric tomato squeezer for family and small community use

Ideal for crafting homemade sauces and preserves, this elect...

Multifunctional cooking kettle for commercial kitchens

Optimize your batch cooking processes with an all-in-one solution ...

Cooking kettles for efficient industrial food preparation

Optimize your cooking processes with these versatile kettles d...

Large capacity cooking kettle for industrial kitchens

Optimize your cook-and-chill production with a versatile cooking ke...

Commercial cooking kettles for cook-and-chill food production

Transform your cook-and-chill processes with kettles that ...

Integrated stirring cooking kettles for commercial kitchens

Streamline your culinary operations with innovative cooking ...

Industrial cooking kettle for heating, stirring, and chilling

Streamline your kitchen operations with a versatile cookin...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

Commercial food mixers for versatile culinary applications

Streamline your food production with mixers and kneaders desi...

High-volume industrial blender for large-scale food processing

Effortlessly blend and transfer high-volume liquid produc...

Direct Uht treatment for liquid foods

Optimize aseptic production with advanced UHT technology to preserve nutritional valu...

Food pasteurizer for prepared foods

Optimize your prepared food production with precise temperature control and automated o...

Ingredient dissolver for small batch processing

Optimize your mixing processes with a versatile dissolver designed for eff...

High shear mixer for dairy and beverage applications

When creating complex formulations like sauces or dairy spreads, ach...

Coiled heat exchanger for high viscosity products

Efficiently handle high-pressure, viscous product heating and cooling w...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Industrial homogenizer for liquid food applications

Achieve unparalleled product consistency and quality with high-speed ...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Evaporator for dairy products

Need efficient moisture removal in diverse dairy and food applications? This falling film evap...

Powder feeder for consistent and accurate dosing

Ensure precise powder dosing with high hygiene standards to maintain prod...

Liquid ingredient reception tank

Optimize your liquid processing with versatile tanks designed for efficient storage and han...

Indirect Uht treatment for high viscous products with particles

Optimize your production line with a unit that ensures h...

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with cont...

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

Efficient pasteurizer for prepared foods

Achieve precise heat treatment and reduce product waste with a modular pasteurizat...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

High shear mixer for emulsification and powder dissolving

Achieve seamless mixing and emulsification for high and low vi...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Ice cream mix preparation solution

Achieve efficient, continuous ice cream and dairy product mixing with low-energy consump...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

Batch dissolver for sugar or dextrose

Efficiently dissolve crystalline substances like sugar and dextrose with precision, e...

Contherm scraped-surface heat exchanger for viscous food products

Optimize your heating and cooling processes for stick...

Tubular heat exchanger for food products

Achieve precise temperature control and energy efficiency with this innovative tub...

Cleaning-in-place system for food and beverage processing equipment

Effortlessly manage the cleaning of diverse process...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

Blending tank for food preparations

Optimize your production line with a tank designed for efficient blending and storage o...

Liquid sugar storage tank

Ensure seamless liquid sugar management in your production line with advanced storage solutions de...

High-speed form and seal machine for retortable food packages

Streamline your production with a machine engineered for h...

Compact filling system for retortable carton packages

Simplify your production of ready meals and soups with a space-savi...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Semi-automatic capping machine for aluminium screw caps

Ensure consistent cap application across diverse container format...

Manual system for filling and capping jars

Ideal for efficiently handling liquid and semi-dense products, this manual syst...

Pneumatic syringe dosing system

Streamline your liquid dosing process with precision and efficiency, ensuring each applicati...

Filling solution for various container types

This versatile filling solution optimizes liquid packaging by accommodating a...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Automatic line for filling and capping spouted pouches

Streamline your production line with high-speed filling and cappin...

Inline blender for liquid ingredients

Optimize your production line with seamless liquid blending, enhancing flavor consist...

Tomato paste processing line

Streamline your tomato processing with our comprehensive production line, ensuring high-quality...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Cryogenic mixer for frozen fruits and vegetables

Enhance frozen food quality with rapid, uniform mixing and precise temper...

Cascading water sterilizer for optimized food preservation

Reduce sterilization times significantly while preserving foo...

Cascading water autoclave for food sterilization

Streamline your food sterilization process with an energy-efficient autoc...

Colloid mills for shearing and mixing in food processing

Optimize your liquid formulations with precise colloid mills, en...

Scraped surface heat exchangers for high viscosity products

Ideal for continuous processing, these heat exchangers effic...

Food processing scraped surface heat exchanger

Enhance your production line with precise temperature control and continuou...

Vertical scraped surface heat exchanger for food processing

For continuous production that demands consistent texture an...

Deaerator for liquid food products

Enhance product quality by efficiently removing air and preserving vital aromas in liqui...

Medium torque top entering mixer for industrial applications

Optimize your mixing and blending operations with precise t...

Scraped surface heat exchanger for high-viscosity products

Designed for handling high-viscosity products, this system en...

Industrial cooking kettle for diverse food processing needs

Optimize your food processing with a versatile kettle design...

Tilting agitator for cooking and mixing processes

Enhance cooking efficiency and product consistency with this versatile ...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Process tanks for mixing, cooking, and cooling applications

Efficiently tackle viscous product challenges with advanced ...

Scraped surface heat exchanger for high viscosity products

When dealing with complex formulations, achieve efficient hea...

Buffer tanks for high viscosity fluids

Optimize your production line with buffer tanks designed to efficiently store, agita...

Crystallization and pin-working equipment for food processing

Optimize your food product quality with precise crystalliz...

Industrial dissolver for liquid-solid mixing applications

Optimize your production line with an industrial dissolver tha...

Horizontal mixers for industrial food production

Enhance your production efficiency by achieving uniform mixing of diverse...

Industrial fat melter for food and pharma applications

Optimize your production line with an advanced solution designed t...

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

Sanitary high shear mixers for pharmaceutical production

Achieve unparalleled hygiene and efficiency in your mixing proce...

Filler for yoghurt and white cheeses

For manufacturers seeking efficient, versatile filling for products like yoghurt and s...

Versatile rotary filler-capper for liquid products

Optimize your liquid product production with a versatile solution that...

Aseptic filling technology for dairy products

Ensure product integrity and extend shelf life with a high-speed aseptic fil...

Mayonnaise production line

Streamline your high-capacity mayonnaise production with precise mixing, emulsifying, and pasteur...

Automated mayonnaise and dressing production line

Ensure the consistent quality of your mayonnaise, dressings, and sauces...

Semi-automatic weight filling system for liquid products

Achieve precise and versatile liquid filling performance with th...

Yoghurt and dairy desserts filling solution

Maximize efficiency in filling and sealing multi-product dairy desserts and be...

Ketchup manufacturing line

Streamline your sauce production with precision-engineered efficiency, allowing for seamless reci...

High-speed moisture analyzer for liquid and pasty samples

Ensure precise moisture analysis with rapid microwave drying, ...

Aseptic tank for liquid food storage

Store and maintain the sterility of low and high acid liquid foods while ensuring prod...

Pasteurization solution for food liquids

Extend the shelf-life of your liquid products while maintaining their quality with...

Uht sterilization solution for liquid food products

Enhance your liquid food processing with reliable UHT sterilization, ...

Vacuum process system for food product mixing and emulsifying

Optimize your production of sauces, dressings, and condime...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

Energy-saving cooling system for vegan products

High-viscosity products like hummus or chunky pasta sauces must be cooled ...

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

Semi-automatic filler

When you are a small or a medium-sized manufacturer the manual filling processes might often lead to in...

Industrial jam vacuum cooker

In a production setup of agri-food preserves, sauces, and other condiments, vacuum cooking at 5...

Small Scale Industrial Jam Cooker

Production of marmalades, jams, fruit concentrates, and sauces requires multiple steps. T...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Jam pasteurizer with temperature control

Microorganisms and pathogenic forms in fresh fruit jams can shorten storage time. ...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Pilot ultrasonic extractor

In the herbal medicine industry, an ultrasonic extractor is a valid alternative to conventional e...

Batch vacuum mixer for emulsion-based products

The production of creams or ointments can be either be a water in oil (w/o)...

Pre-made cup filler for salad dressings

Pre-made cup fillers are mostly used by food companies to assist in the mass produc...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Flash pasteurizer for beer

The food and beverage industry are faced with constant challenges. Contamination and cross infect...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Wet Wipes Packaging Machine

Sachet packaging is a convenient and popular wrapping method for a wide range of products in the...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Autoclave for doypack pouches

The self-standing Doypack and other similar pouch products are a very popular method of packag...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Industrial sous vide cooker

High temperatures, oxidation and evaporation from long sessions of conventional cooking can impa...

Industrial pressure cooker

Optimizing production processes and human resources to reduce energy consumption and save time an...

Multifunctional cutting and dispersing machine

When processing alternative proteins or making products such as smoothies a...

Industrial pizza production line for bases and toppings

Optimize your pizza production with versatile equipment designed ...

Industrial dough laminator for croissants and pastries

Achieve consistently light and flaky products with precision lamin...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Food product smoothing system for dairy and purees

Achieve unparalleled texture and fineness in viscous food products wit...

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Powder and liquid mixing system for food and life sciences

Achieve rapid and homogeneous dissolution of large quantities...

Laboratory homogenizer for viscous products

Achieve ultra-fine textures and improved consistency in pasty and semi-pasty p...

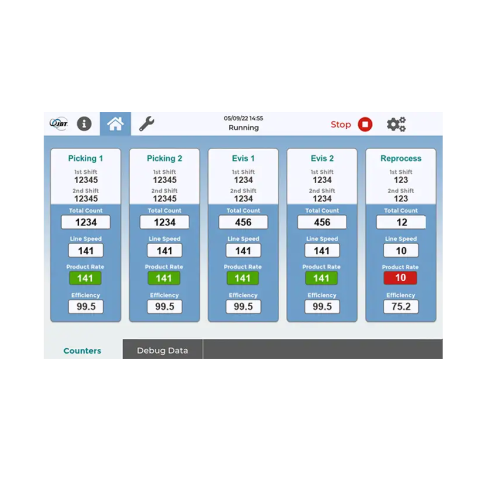

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Batch processing systems for industrial applications

Optimize batch production with versatile systems that enhance energy...

Cip cleaning systems for food and beverage industry

Optimize your cleaning operations with seamless Clean-in-Place and St...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Aseptic storage tanks for high efficiency applications

Ensure consistent aseptic storage and efficient handling of variou...

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Vacuum packaging system for high-volume operations

Optimize your packaging line with high-speed vacuum sealing for divers...

Vacuum packaging system for food products

Optimize your packaging process with high-speed vacuum technology designed to pr...

In-line production of fine emulsions

Achieve homogenous emulsions with precise control, reducing the risk of lump formation...

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Hygienic buffer tanks for process optimization

Enhance your production flow with hygienic buffer tanks that ensure consist...

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

Lab Uht/htst system for r&d activities

Optimize your R&D with a versatile, modular system allowing precise control ove...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Bench-top blending vessel for small batch preparation

For small-batch liquid products, achieve precise mixing, heating, a...

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Fs closing devices for industrial packaging solutions

Streamline your packaging process with versatile closing devices, d...

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

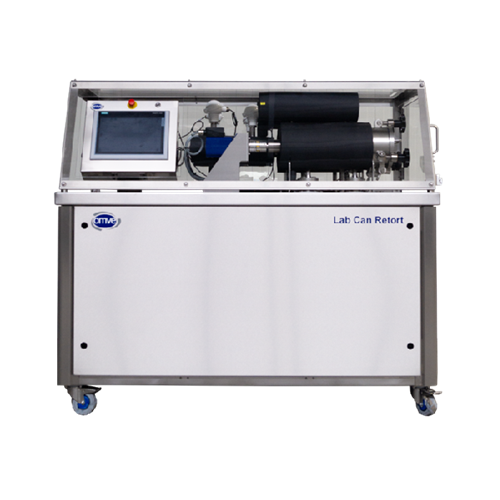

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Cleaning in place unit for lab and pilot equipment

Streamline your lab and pilot-scale cleaning processes with a mobile, ...

Fully automated cleaning in place unit for food processing plants

Enhance food safety and streamline operations with a ...

Batch deaerator for reduced oxidation in liquid processing

Optimize product shelf life and quality by efficiently removi...

Continuous deaeration solution for laboratory and pilot systems

Achieve superior product stability and minimize foaming ...

Crown cork sealer for liquid food packaging

Ensure reliable sealing for bottled beverages and dairy with a compact, table-...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Bench-top carbonation system for postmix drink production

Achieve precise carbonation in small batches with a reliable b...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Carbonation and filling system for Pet and glass bottles

Optimize your beverage production with precise carbonation, fill...

Carbonation and can seaming solution for beverages

Optimize your beverage production with a seamless integration that sim...

Sterile carbonation system for beverages

Achieve precise carbonation for both common and specialty beverages with this vers...

Medium-speed shrink wrapper and case packer for food industry

Optimize your packaging line with a combined solution that...

Medium-speed automatic shrink wrapping systems for food and dairy

Optimize your packaging line with this flexible shrin...

Robotic palletizer for row gripping

Optimize your palletizing efficiency with a robotic system designed for fast, continuou...

90-degree infeed palletizer

Achieve seamless integration and high throughput with a palletizer designed to optimize your pro...

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Pressurized fermenter for lab-scale fermentation

Achieve precise and controlled fermentation with this advanced pressurize...

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Mounting configurations for industrial agitators

Optimize your mixing processes with versatile agitators designed for effi...

Dished end for optimized mixing in small-volume vessels

When space constraints challenge vessel design, this solution eli...

Atmospheric fermenter for lab and pilot scale projects

Streamline your fermentation process with precise control over tem...

Convection oven for bakery production

Optimize your baking with precise temperature and humidity control, ensuring perfect ...

Inline marinating and coating for meat and poultry

Enhance product quality and consistency with an inline tumbler that si...

Cryogenic freezer for food processing

Achieve rapid, precise freezing for your diverse food production needs, ensuring qual...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic tunnel freezer for continuous food processing

Optimize product quality and retention with advanced cryogenic fr...

Cryogenic freezing systems for food processing

When you need precise and rapid freezing for diverse food products, these a...

Cryogenic food freezer

Achieve rapid and precise freezing for diverse food products, ensuring optimal texture and moisture re...

Cryogenic chilling for food processing

Optimize your food production line with cutting-edge cryogenic chilling solutions, d...

Cryogenic chilling for meat mixing and blending

Ensure precise temperature control during mixing and blending to prevent b...

Cryogenic freezer for food industry applications

Efficiently tackle high-speed freezing and chilling challenges with a ver...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixin...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

Food mixing and blending system

Enhance your production line with a versatile system designed for gentle processing needs, o...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Ultra high temperature treatment for small-scale production

Achieve extended shelf life and uniform product quality with...

Volumetric filler for liquid and viscous products

Achieve precise and adaptable filling for a wide variety of liquid and ...

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Two-component filling machines for food and beverage packaging

Streamline your filling process with precise two-componen...

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

Hydraulic juice press for fruit and vegetables

Streamline your juicing operations with this hydraulic solution, expertly d...

Highly scalable reactors for chemical synthesis

Optimize your production line with versatile reactors designed for seamles...

Laboratory dispersion reactor for 10l batch processes

Enhance precision and efficiency in lab-scale liquid formulations w...

Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures pre...

Transparent glass barrier coating for Pet bottles

Ensure the longevity of sensitive beverages and liquid foods with glass...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

Industrial magnetic agitator for homogenizing pharmaceutical products

Achieve precise dispersion and homogenization in ...

Standard batch mixer for salt and citric acid mixing

Achieve perfectly homogeneous blends of salts, sugars, and challengi...

High shear vertical mixer for dispersion and emulsification

Achieve seamless emulsification and homogenization in divers...

High-speed drift-dwell motion doypack forming system

Optimize your liquid packaging efficiency with a dual-motion system ...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Stick pack forming, filling, and sealing solution

Enhance packaging efficiency with a high-speed solution designed for pr...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Filling and sealing pre-formed cups solution

Ensure ultra-clean and aseptic processing for pre-formed cups with a fully en...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Packaging solution for small bottles and jars

Effortlessly seal and fill non-stackable containers, ensuring precision for ...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

Rotary filler for optimized production processes