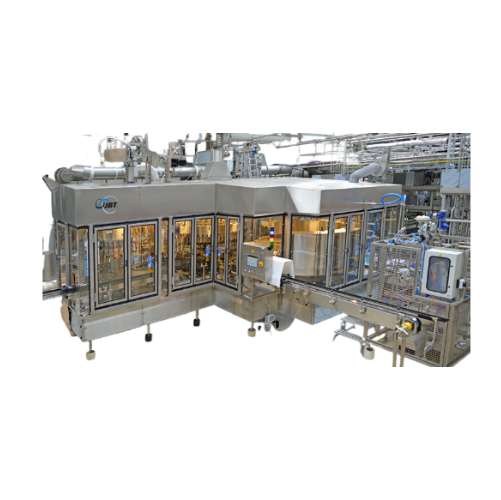

Rotary level filler for low to high viscosity liquid products

Ensure precise fill levels and enhance production efficiency with a rotary level filler designed for seamless integration into continuous, high-speed bottling lines, accommodating a wide range of viscosities from water to thick sauces.

Ensures Precise Liquid Filling and Leveling

The Level Filler from JBT, ensuring uniform filling for your diverse liquid packaging needs, integrates seamlessly into high-speed production lines. Specially designed with vacuum filling technology, it prevents drips and reduces product waste. Ideal for chemical producers, beverage companies, and pharmaceutical manufacturers, this machine efficiently handles products such as almond milk, cough syrup, and salad dressings. Equipped with an optional CIP system, it supports quick cleanup, maintaining hygiene standards. Its PLC-controlled mechanism allows easy automation, while the neck support system optimizes the use of lightweight bottles, minimizing material costs. Constructed from durable materials, the filler is ready for the rigorous demands of industrial use, ensuring compliance with stringent quality standards.

Benefits

- Ensures consistent product quality with precise fill levels and minimal product waste.

- Increases production efficiency with quick changeovers and high-speed operations.

- Enhances cleanliness and safety with optional CIP system, reducing contamination risks.

- Lowers production costs using lightweight bottle compatibility to minimize material expenses.

- Integrates smoothly into existing lines, supporting continuous operations and reducing setup time.

- Applications

- Personal care, Beverages, Soups, Sauces, Dairy alternatives, Oils, Chemical, Dressings, Industrial, Seasonings, Juices, Dairy, Pharmaceutical

- End products

- Liquid detergent, Tomato soup, Vegetable oil, Bottled water, Apple juice, Barbecue sauce, Orange juice, Almond milk, Cough syrup, Soy milk, Oral rinse, Shampoo, Marinara sauce, Salad dressing

- Steps before

- Bottle pre-heating, Bottle rinsing

- Steps after

- Capping, Sealing

- Input ingredients

- plastic bottles, glass bottles, low viscosity products, medium viscosity products, high viscosity products, juices, dairy products, personal care products, pharmaceutical materials, oils, soups, sauces, seasonings, dressings

- Output ingredients

- filled plastic bottles, filled glass bottles, precisely filled products, drip-free filled products

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Filling method

- Rotary level filling

- Filling speed

- High-speed

- Filling volume

- Gallons or Liters

- Product Viscosity Range

- Low to high viscosity

- Neck support system

- Included for lightweight bottles

- Optional CIP system

- Available

- Changeover time

- Quick bottle format change over

- Cleanability

- Improved with new valves

- Cost efficiency

- Lowest cost per unit produced

- Optional CIP system

- CIP / Manual

- Filling speed

- Faster filling

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Adapts to lightweight bottles

- Compact footprint

- Reduced footprint

- Discharge method

- Drip-free filling

- Footprint

- Compact

- Monoblock integration

- Possible with capper/sealer

- Changeover

- Quick bottle format change over

- Valve type

- New filling valves

- Support system

- Neck support system for lightweight bottles