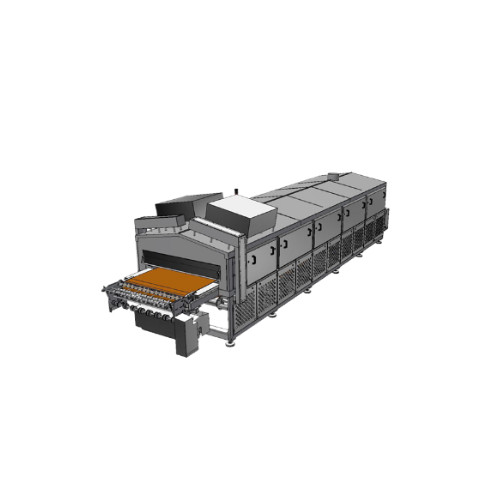

Continuous contact cooker for bottom crust treatment

Enhance dough product integrity with precise bottom heating, ensuring seamless product transfers and consistent crust formation for all dough-based bakery items.

Treats Bottom Crusts of Dough-Based Products

The Stein ProBake™ Contact Bottom Crust Treatment from JBT is a continuous contact cooker designed for dough-based bakery products. It employs bottom heating platens with a non-stick belt to ensure consistent under-sole formation, essential for optimal product transfer in bakery production lines. This system is ideal for applications including pizza bases, pie crusts, and croissants. The ProBake operates with precise temperature control, offering rapid processing with minimal internal cooking, akin to pan processing but with accelerated throughput. Available in stainless steel, it features models with usable belt widths of 600mm and 1000mm, customizable in modular cook lengths of 1.2 meters. The automatic belt tensioner, tracking system, and optional PLC controls facilitate seamless integration into existing bakery operations. Enhanced with an automatic belt wash and constructed to endure continuous operation, the ProBake supports efficient maintenance and cleaning processes.

Benefits

- Enhances product integrity and consistency with uniform heat distribution.

- Increases production efficiency through rapid processing and precise temperature control.

- Simplifies maintenance with automatic belt washing and tensioning systems.

- Integrates seamlessly with existing systems via modular design and optional PLC controls.

- Reduces material adhesion with non-stick belt technology.

- Applications

- Baked goods, Bread, Confectionery, Dough-based items, Pastries, Bakery products

- End products

- Baguettes, Brioche rolls, Flatbreads, Shortbread biscuits, Artisan bread, Croissants, Pie crusts, Pizza bases, Danish pastries, Puff pastry bottoms, Focaccia

- Steps before

- Dough Preparation, Mixing, Forming

- Steps after

- Topping, Cooling, Packing, Quality Control

- Input ingredients

- dough, bakery item

- Output ingredients

- bottom crust, prepared bakery item, under-sole for dough

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Automation

- PLC-controlled

- Usable Belt Width

- 600 mm

- Usable Belt Width

- 1000 mm

- Cook Length

- 1.2 meter modular design

- Material Construction

- Stainless steel

- Belt Speed

- Fast

- Heating Method

- Bottom heating platens

- Belt Material

- Non-stick

- Dwell Time

- Extremely short

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Automatic belt wash

- Changeover time

- Extremely short dwell time

- Energy efficiency

- Fast belt speed limits premature cooking

- Cleanability

- Stainless steel construction

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Temperature range

- Precise temperature control

- Usable Belt Width

- 600 mm, 1000 mm

- Cook Length

- Modular design in 1.2 meter lengths

- Material Construction

- Stainless Steel

- Control System

- Available with optional PLC controls

- Belt Type

- Non-stick belt

- Belt Features

- Automatic belt tensioner and tracking system

- Belt Wash

- Automatic Belt Wash

- Hood Enclosure

- Stainless steel hood enclosure

- Control panel type

- Optional PLC controls

- Belt width

- 600mm or 1000mm usable belt width

- Cook length

- Modular design in 1.2 meter lengths

- Belt wash system

- Automatic belt wash

- Belt tensioner and tracking system

- Automatic

- Hood enclosure material

- Stainless steel

- Customization of contact cooking surface

- Non-stick belt