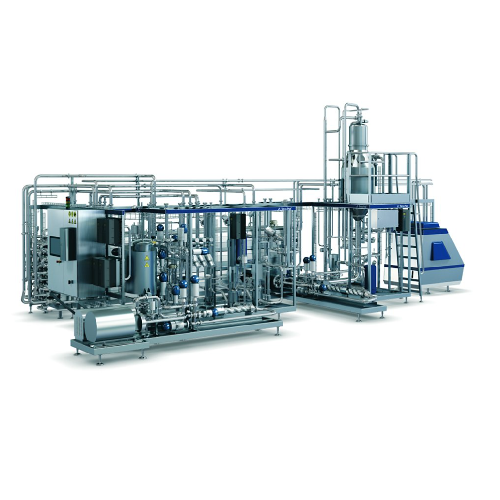

Efficient pasteurizer for prepared foods

Achieve precise heat treatment and reduce product waste with a modular pasteurization solution optimized for diverse prepared foods, from sauces to desserts, ensuring consistent quality and efficiency in your production line.

Executes Pasteurization and Heat Treatment Efficiently

The Tetra Pak® Pasteurizer PFC is an investment-efficient solution for versatile pasteurization and heat treatment of liquid prepared foods. It employs a flexible heat exchanger configuration, accommodating both tubular and plate heat exchangers, to handle a variety of viscosities ranging from smooth desserts to sauces. Designed for high operational efficiency, it supports continuous processes with automation options that tailor to your operational needs, offering integration with the Tetra PlantMaster system for comprehensive monitoring.

Capable of processing 3,000 to 30,000 liters per hour, it meets the demands of large-scale production and reduces product waste significantly through precise automated emptying and filling. The modular design accelerates setup and adaptation for new product lines, reducing time-to-market by up to 20%. Manufacturers can benefit from low total cost of ownership with potential yearly savings between €17,000 – 35,000 on product waste alone. Constructed with durable materials, the pasteurizer minimizes maintenance efforts and downtime. Ideal for producers of fruit preparations, baby food, sauces, and more, it ensures product quality and safety, complying with industry standards for food processing.

Benefits

- Optimizes product yield with precise automated filling and emptying, significantly cutting waste and saving costs.

- Accelerates time-to-market with a modular design that speeds up production line integration by up to 20%.

- Enhances process flexibility, allowing seamless adaptation for a diverse range of product viscosities and formulations.

- Lowers energy consumption and operational costs through efficient heat exchanger configurations tailored to specific product needs.

- Ensures consistent product quality and safety with comprehensive automation options and integration capabilities.

- Applications

- Ketchup, Sauces, Spreads, Soups, Infant formula, Jams, Smooth desserts, Dips, Fruit preparations, Dressings, Tomato products, Tomato paste, Baby food, Prepared foods, Soy sauces

- End products

- Hummus, Vegetable purees, Creamy ranch dressing, Blueberry yogurt, Tomato bisque, Cilantro lime dressing, Almond butter, Chocolate pudding, Pomodoro sauce, Vegan cheese sauce, Strawberry preserves, Spicy salsa, Apple compote, Fruit jam, Organic ketchup

- Steps before

- Mixing, Blending, Ingredient Preparation

- Steps after

- Filling, Packaging, Cooling

- Input ingredients

- ketchup, tomato paste, soy sauces, smooth desserts, fruit preparations

- Output ingredients

- prepared food products, high viscous products, low viscous products

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 3, 000 - 30, 000 l/h

- Temperature range

- Up to 140°C

- Automation

- Flexible degree of automation

- Modular Design

- Speeds up introduction of new products by 20%

- Heat Exchanger Configuration

- Flexible (Tubular and Plate)

- Automation level

- Manual / PLC / SCADA

- Flexible heat exchanger set-up

- Tubular / Plate

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP

- Changeover time

- Speeds up by 20%

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed method

- Flexible heat exchanger setup

- Discharge method

- Automated and optimized emptying

- Compact footprint

- Modular equipment design

- Control panel type

- Flexible degree of automation

- Flexible heat exchanger set-up

- Tubular and plate heat exchangers

- Modular equipment design

- Speeds up product introduction by 20%

- Flexible degree of automation

- Stand-alone, full line, or integrated system