Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes with a high-speed duplex system, ideal for streamlining your packaging process while maintaining precision and quality control.

Fills and Seals Preformed Pouches

The Viking-7SU-240 by Viking Masek is an automatic rotary pouch machine optimized for high-speed packaging operations across a variety of industries, including food, beverage, health, and pharmaceuticals. This duplex model operates on a two-lane system, filling and sealing preformed pouches with precision at speeds up to 80 cycles per minute. Its dual gripper stations eliminate center grippers, enhancing stability and reducing cycle time. Ideal for products like sauces, frozen vegetables, and snack bars, the machine integrates seamlessly into production lines with its PLC control and touch screen operation. It offers advanced features such as servo-driven Allen Bradley control, comprehensive production parameter memory, and pouch presence detection to prevent wastage. The Viking-7SU-240 enhances energy efficiency and minimizes downtime with its cooling station, automatic deoxidizer feeding, and two-step sealing process for clean seals, particularly on liquid products. With the availability of proprietary options like Viking’s robotic pick and place system, multi-head scales integration, and extensive safety features, this machine delivers unparalleled flexibility and reliability. Compliance with industry standards is ensured through built-in quality control systems, including checkweighers and metal detection. Additionally, it supports CIP design for efficient cleaning, reducing risks of contamination and ensuring product integrity.

Benefits

- Increases efficiency with speeds up to 80 cycles per minute, enhancing overall production throughput.

- Minimizes product waste through pouch presence detection, ensuring only filled pouches proceed to sealing.

- Reduces operational costs with energy-efficient servo-driven controls.

- Enhances product safety and quality with integrated quality control systems like metal detection and checkweighers.

- Facilitates quick changes and minimal maintenance downtime with comprehensive CIP and parameter memory features.

- Applications

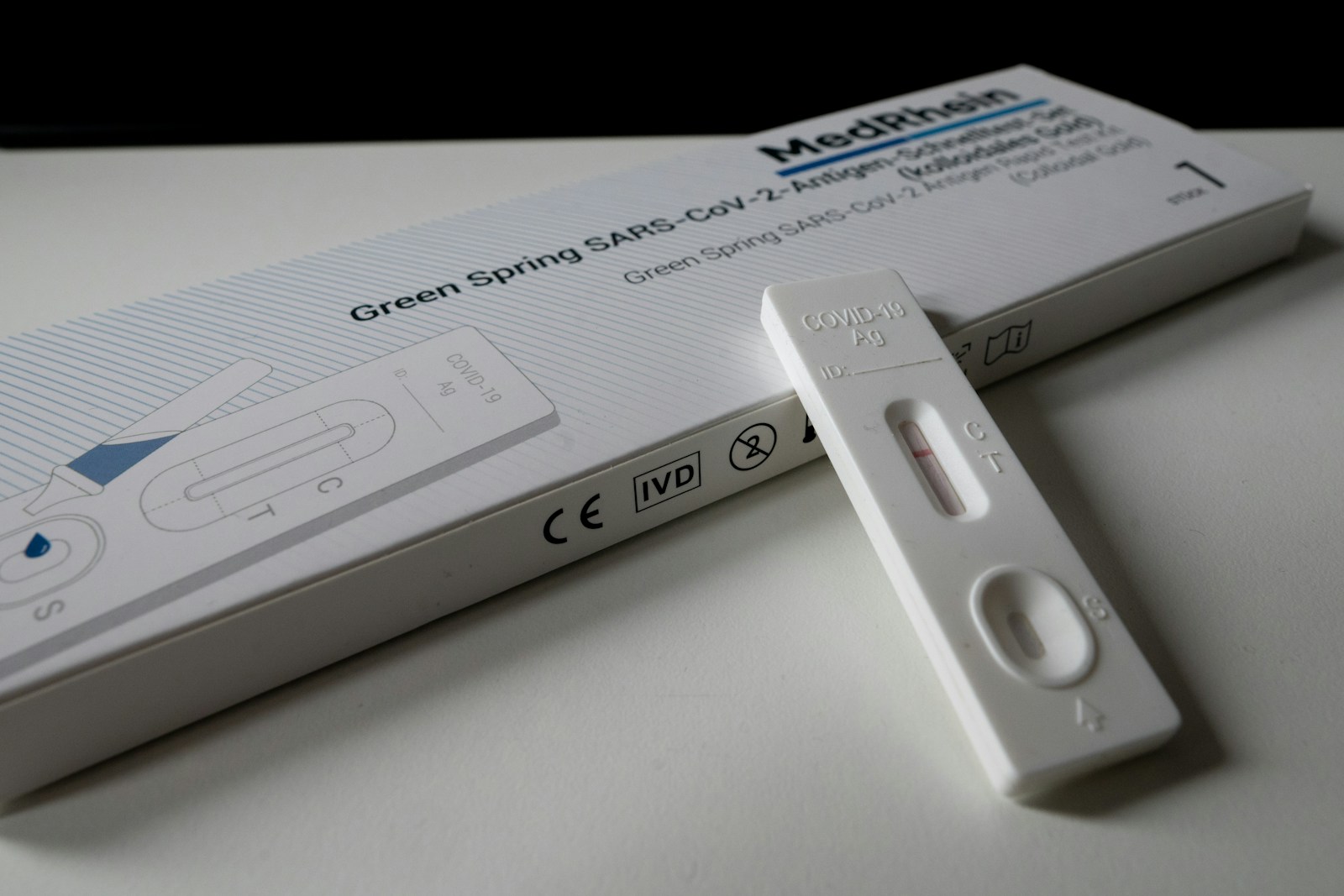

- Treats, Medical devices, Snacks, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Powders, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Vegetables, Poultry, Medical

- End products

- Spaghetti, Sauces, Lentils, Diced fruits, Mozzarella cheese, Espresso beans, Chicken pieces, Jasmine rice, Face masks, Cannabis gummies, Chocolates, Fish fillets, Fruit juices, Syringes, Nutritional supplements, Frozen vegetables, Snack bars, Ground beef, Gummy candies, Dog treats, Organic salad mix, Multivitamin pills, Fish oil capsules, Mixed nuts, Pet kibble, Covid-19 test kits

- Steps before

- Multi-head weighing, Volumetric filling, Auger filling, Product sorting

- Steps after

- Bag sealing, Cooling, Quality control, Date coding, Bag rejection, Collating discharge

- Input ingredients

- preformed pouches, Cannabis edibles, liquid products, powders, cereal, snacks, fresh fruit, vegetables, meat, poultry, fish, pet food, candy, pasta, beans, rice, natural foods, organic foods, cheese, pills, capsules, medical devices, supplies, medical testing kits

- Output ingredients

- filled pouches, sealed pouches, packaged cannabis edibles, packaged liquid products, packaged powders, packaged snacks, packaged fresh fruit, packaged vegetables, packaged meat, packaged poultry, packaged fish, packaged pet food, packaged candy, packaged pasta, packaged beans, packaged rice, packaged natural foods, packaged organic foods, packaged cheese, packaged pills, packaged capsules, packaged medical devices, packaged medical testing kits

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 80 bpm

- Bag Size

- Min 100 mm W x 120 mm L / Max 240 mm W x 350 mm L

- Number of Stations

- 7

- Number of Lanes

- 2

- Bag Gripping Range

- 100-240 mm

- Maximum Bag Length

- 350 mm

- Electrical Requirements

- 3-Phase, 480V, Approx. 10 Kw, 60Hz

- Compressed Air

- Approx. 1, 00NL/min, 8kgf/cm²

- Automation

- PLC control with touch screen operation

- Control Platform

- Servo-driven Allen Bradley

- Sealing Temperature

- Adjustable

- Filling Volume

- Adjustable

- Cooling option

- Cooling station for liquid products

- Cleaning method

- Clean-in-place design

- Date coding

- Emboss, hot stamp, inkjet or thermal transfer

- Quality control

- Checkweigher, metal detector, X-ray inspection

- Dust collection

- Dust suction nozzles and dust collector

- Bag rejection system

- Yes

- Network Connectivity

- Ethernet connectivity

- Working mechanism

- Rotary premade pouch machine

- Integrated steps

- Filling, Sealing, Cooling

- Automation level

- PLC control with touch screen operation

- CIP/SIP

- Clean-in-place design

- Batch vs. continuous operation

- Continuous

- Cooling option

- Cooling station for liquid products

- Cleaning method

- CIP

- Bag deflation method

- Wire guide or push bars

- Bag detection system

- Pouch presence detection – no filling, no sealing

- Dense materials handling

- Yes/No

- Temperature resistance

- -10°C to 80°C

- Pouch material compatibility

- Plastic/foil/paper

- Sealing material compatibility

- PE/PP/PA/PET

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Gas flush compatibility

- Yes/No

- Discharge method

- Rotary

- Bag gripping range

- 100-240 mm

- Maximum bag length

- 350 mm

- Control panel type

- PLC control with touch screen operation

- Integration possibilities

- Can be integrated with multi-head scales, volumetric fillers, and auger fillers

- Cooling option

- Cooling station for liquid products

- Bag handling system

- Proprietary Viking robotic pick, place bag infeed system

- Safety features

- Fully interlocked safety guards

- Date coding options

- Emboss, hot stamp, inkjet or thermal transfer

- Cleaning capability

- Clean-in-place design

- Data connectivity

- Ethernet connectivity