Nut Processing Equipment

Find innovative nuts equipment and connect directly with world-leading technology suppliers

A fresh salad with a walnut oil dressing or a peanut butter sandwich? A bag of roasted cashews or a pack of almond cookies? The common thread among these tasty treats is nut processing equipment. Not all nut ingredients are indeed nuts, botanically speaking. But the machinery that transforms shelled fruits, legumes, and drupes into fried snacks or a paste is similar. As for the food products, there is a nut recipe for every mood and occasion.

Top picks for nut production

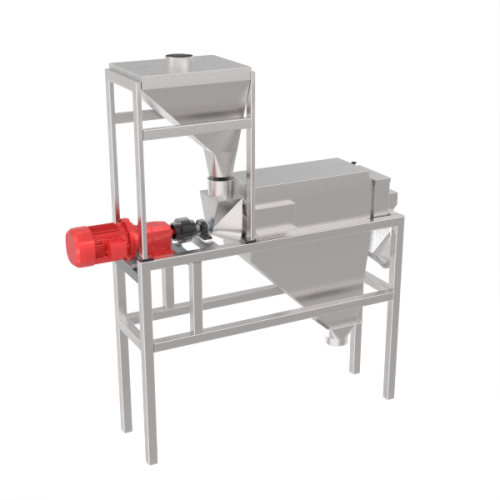

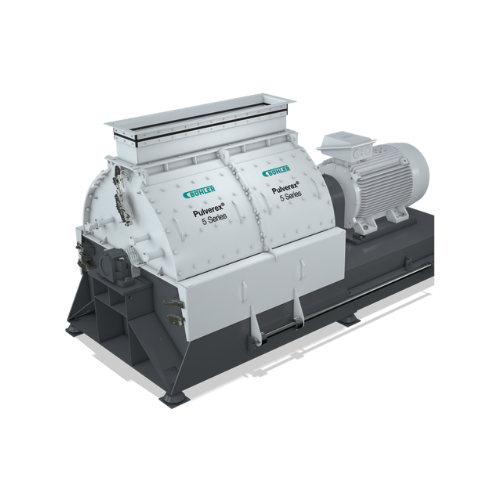

Nut and seed pre-grinder

When dealing with high-fat roasted nuts and seeds, achieving optimal particle size distribution can ...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

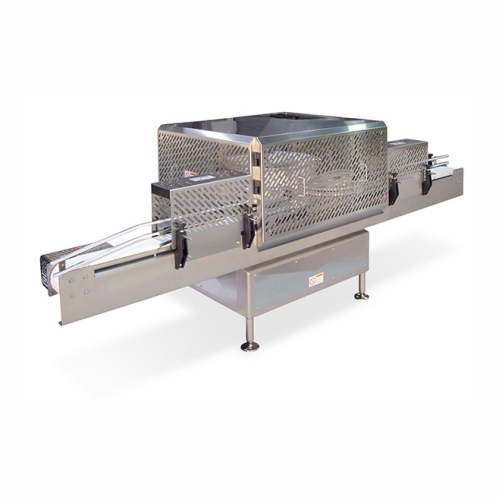

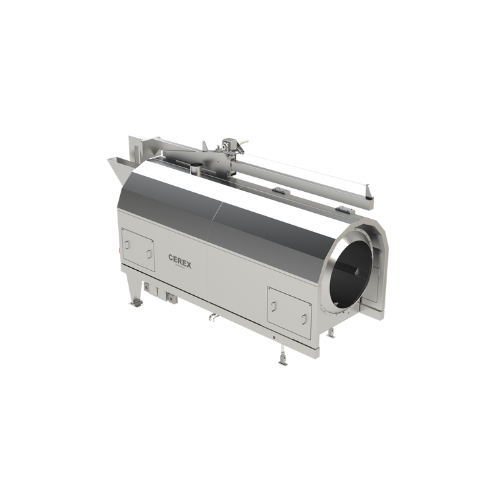

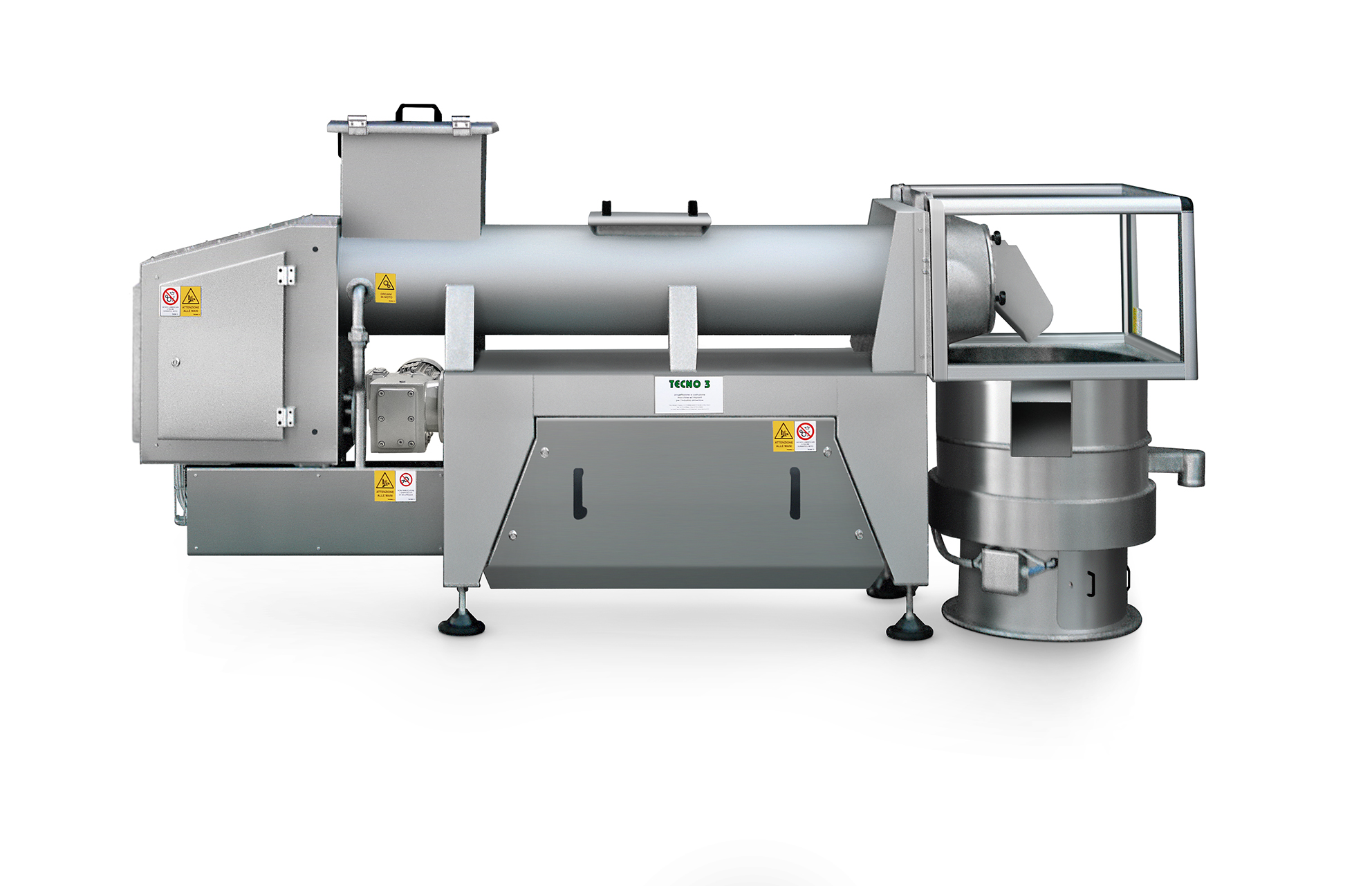

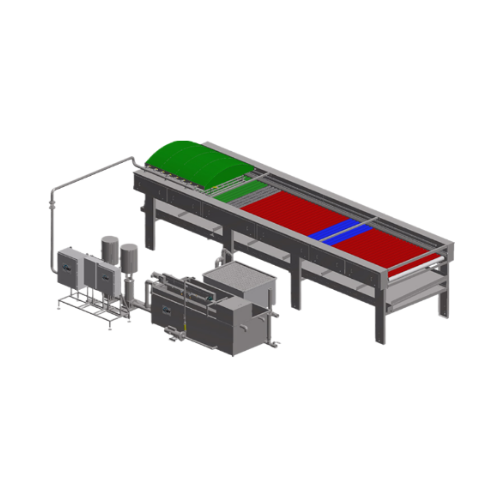

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Almond and apricot kernel blanching solution

Efficiently remove hulls from blanched almonds and apricot kernels to streaml...

Stories about nuts

An organic way of killing insects! MA concept, now available for 25 kg bags

From big bags to compact bags: use MAP in both

Taming the respiration and biological activity of cashews

Outsmarting the pistachio-greedy worm while storing your nuts

Modular design for a fast fryer plant startup

Say no to food waste. How to protect your hazelnuts from going rancid along the supply chain

#Changemaker: FIBC with brains

Cracking the code of fried peanuts: how to produce the tasty snack

Select your nuts process

What are you making?

Tell us about your production challenge

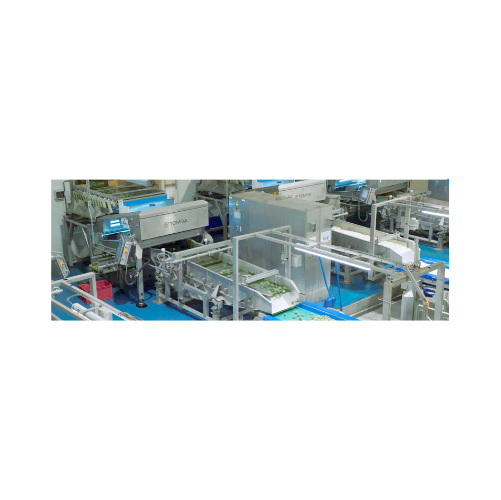

Precleaning technology is vital nut processing equipment

Harvested tree nuts bring plenty of contaminants into the plant. Before processing them, ensure that the nuts are free from surface pathogens and foreign objects.

Separate the nuts from hollow shells, stems, and other materials using screens of different mesh dimensions. A series of sorters will then calibrate the valuable nuts into equal sizes. Subject the nuts to high-pressure air blowers to rid them of debris and small particle residues.

Add moisture to protect nuts from breakage during processing

Drying the nuts makes them easier to crack. Heating the cleaned lots in a cabinet dryer hardens the shells and facilitates hulling.

But reduced water content makes the meat more brittle and could decrease yield at the end of the processing line. An effective technique is moistening the nuts to soften them and applying gentle heating to harden the shells. The processed nuts can be dried thoroughly after the hulling step is performed.

Accurate hulling is a tough nut to crack

The hulling operation is a delicate step during processing. Nut cracking machinery risks damaging the kernels, leading to wastage or poor quality.

Nut varieties, from peanuts to walnuts, have different shell structures that require specific equipment configurations. The cracking process is performed in two steps. Pre-awning technology first applies gentle pressure to weaken the shell before a second line completes the cracking. Empty hulls are blown into a collection bin and separated from the nuts.

Blanche the nuts to prepare them for peeling

Nuts can be peeled, mainly for further processing, like hazelnuts for chocolate spreads or almonds for marzipan.

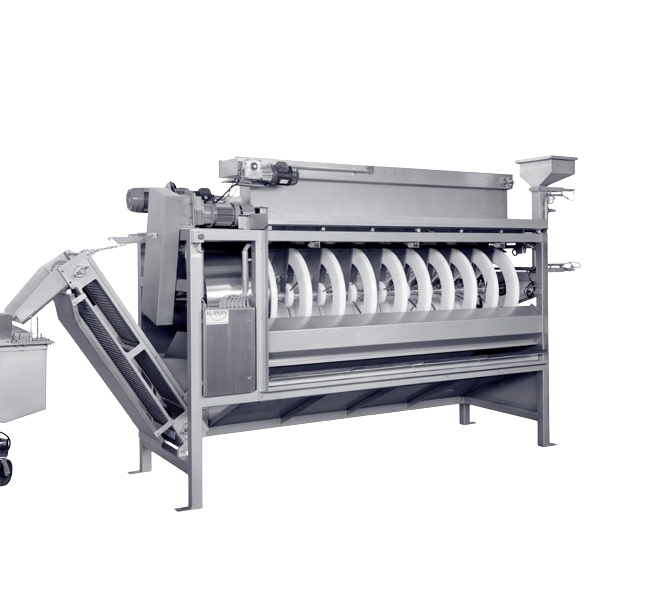

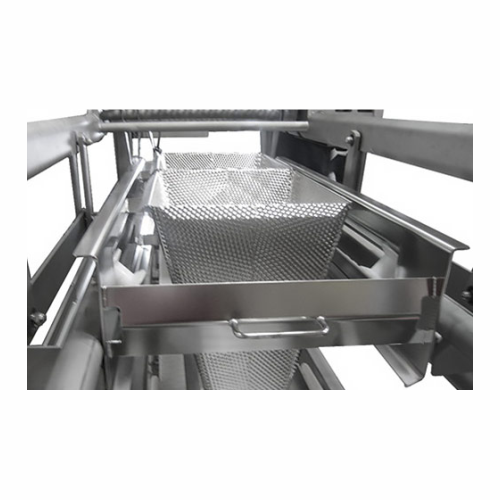

Blanche the kernels to relax the skins. Blanching technology subjects the processed nuts to scalding water for a brief period before submerging them in cold water. Finally, pass the nuts through the revolving rolls of a peeler to skin them.

Neutralize enzymes to prolong the shelf life of nuts

Enzymes in the nuts protect them from insect attacks, but they slow down digestion when consumed by humans. Moreover, these proteins accelerate the chemical breakdown of the kernels. Inactivate the enzymes to extend the shelf life of nuts and promote good digestion.

Soaking the lot in water breaks down the phytic acid content and neutralizes the enzymes. This process also helps release nutrients producing higher-quality nuts, especially if you’re packaging raw nuts.

Try alternative coatings to mix up the flavors

Coat the nuts to give them a surprising final taste. Place the roasted nuts in a coating machine where a rotating drum agitates the individual kernels as the sprayer sprinkles the coating ingredient on them.

Everybody knows the salted peanut and the sugar-coated pecans. But alternative coating ingredients create new complex flavors, such as coconut-coated cashews or caramel-coated walnuts.

Use frying technology to produce oil roasted nuts

Nut snacks owe their popularity to their texture. Roasting boosts the crunchiness and crispiness of nuts.

There are two ways of nut roasting: dry roast and oil roast. The first method involves placing the processed nuts in a cooking cabinet or roaster without additives. Oil roasting is usually performed in a fryer, immersing nuts in oils at high temperatures as they absorb the fats.

Which nuts technology do you need?

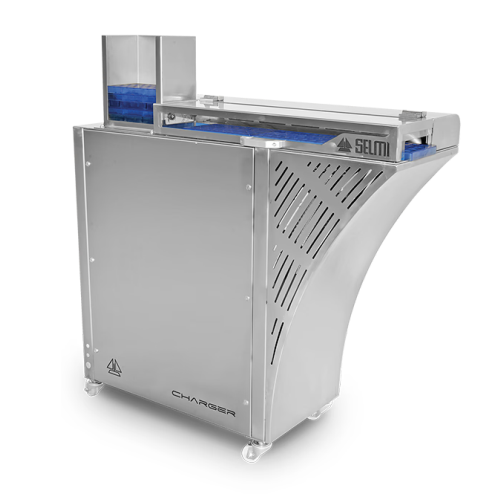

Nuts dosing system for chocolate drops

Effortlessly create consistently accurate chocolate-covered nut products with precis...

Coating solution for nuts and dried fruits

Easily apply multiple layers of chocolate to nuts, coffee beans, and more, achi...

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

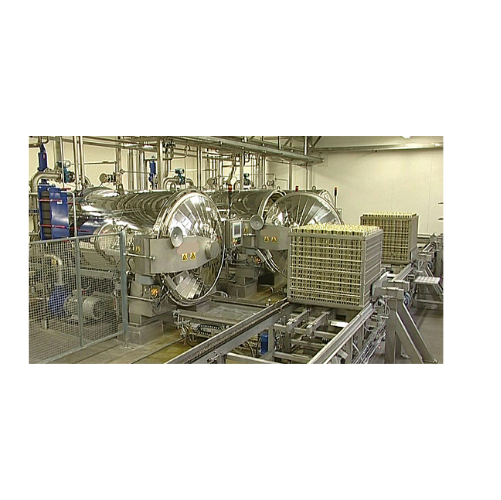

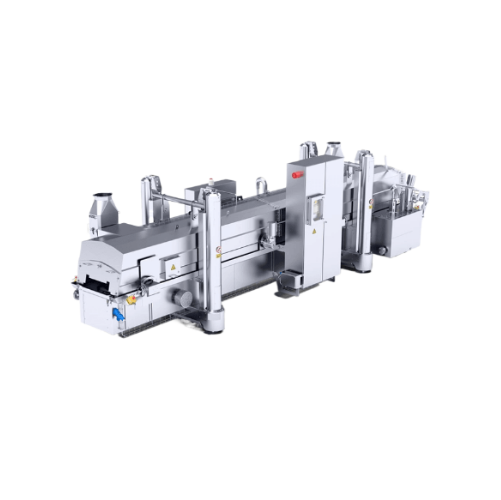

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

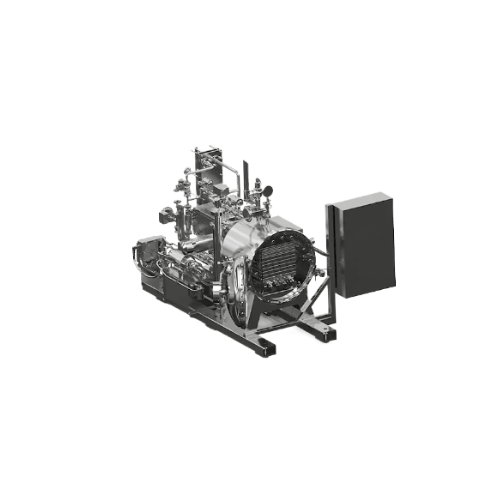

Nut roasting process with halved energy consumption

Achieve significant energy savings while maintaining high-quality roa...

Nut plasticizer for production cuts

Enhance cutting precision and minimize nut breakages with continuous conditioning, prov...

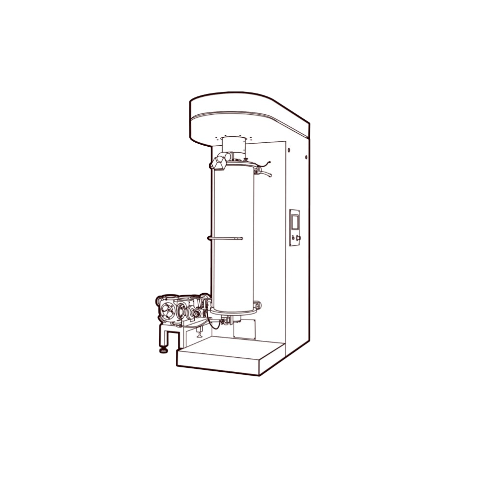

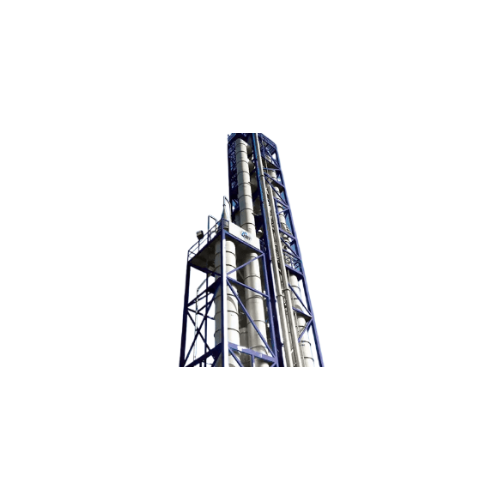

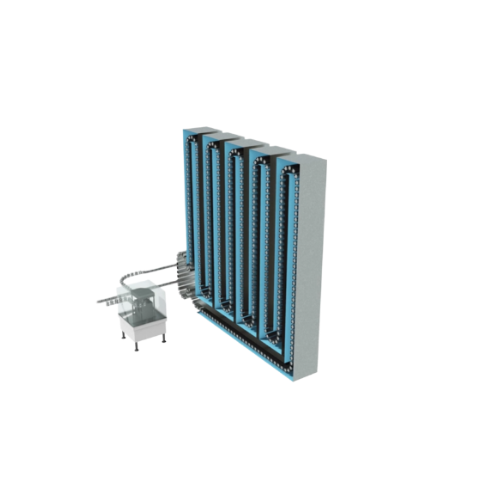

Vertical nut dryer

Achieve precise moisture control for nuts with a vertical dryer that optimizes space and adapts seamlessly...

Destoner for nuts and seeds

Efficiently separate heavier particles like stones from a wide range of food products, including...

Nut dicing machine

Efficiently transform whole nuts into uniform cubes with precision cutting technology, ideal for creators ...

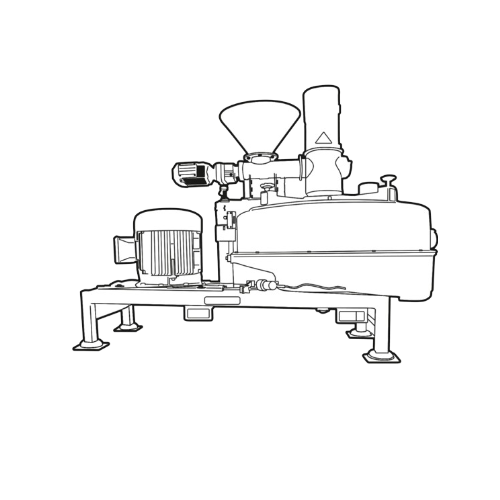

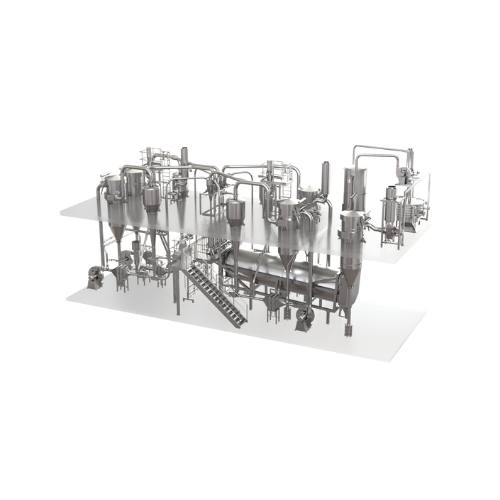

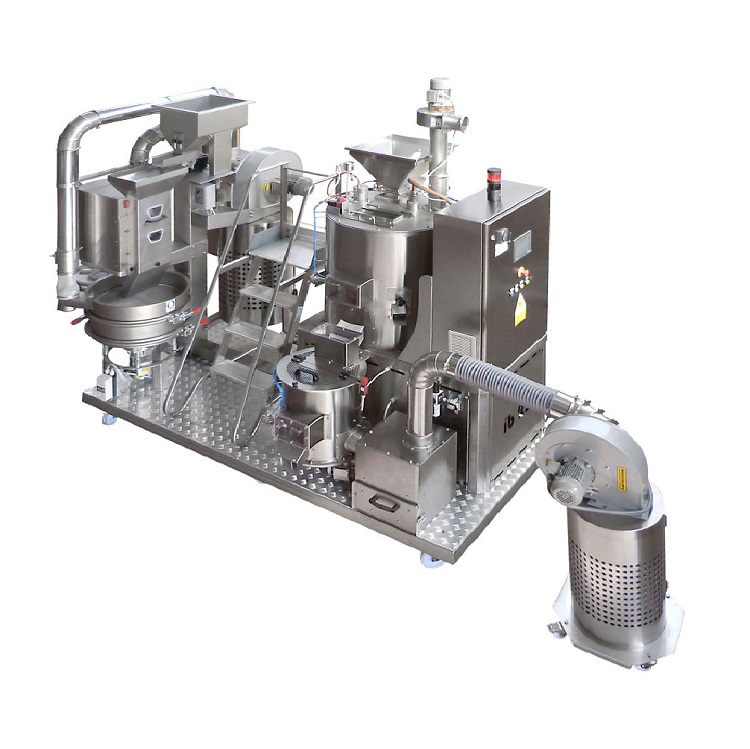

Nuts flour production system

Enhance your nut processing efficiency by transforming whole nuts into fine, consistent flour w...

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

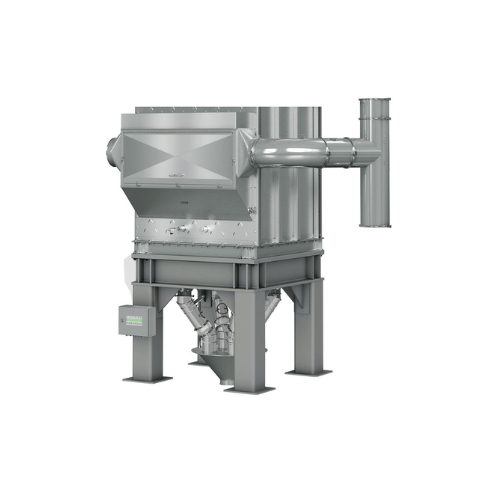

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

Peanut peeler for efficient skin removal

Ensure consistent peanut quality by efficiently removing skins with adjustable-spe...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Nut roaster for consistent and high-capacity processing

Achieve uniform roasting and elevate your nut processing with pre...

Nut roasting system

Achieve perfectly roasted and seasoned nuts with precision control over roasting, coating, cooling, and g...

Cutting mill for dry sample comminution

Achieve precise comminution of dry materials, from plastics to dried plants, with e...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Nut and seed pre-grinder

When dealing with high-fat roasted nuts and seeds, achieving optimal particle size distribution can ...

Pre-grinder for roasted nuts and seeds

Maximize efficiency in creating smooth nut and seed spreads with this pre-grinding s...

Cocoa nibs pre-grinder for high fat seeds and nuts

Enhance your processing line with high-speed pre-grinding designed to ...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

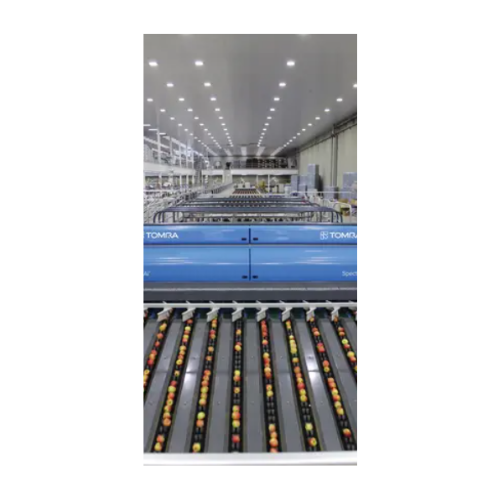

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Optical sorter for grains, coffee, nuts, and plastics

Ensure consistent product quality and minimize waste with advanced ...

Optical sorter for nuts or dried fruits

Ensure maximum food safety and quality by efficiently sorting and removing shells, ...

Ball mill for chocolate, cocoa, and nut products

Optimize your grinding processes and achieve perfect product consistency ...

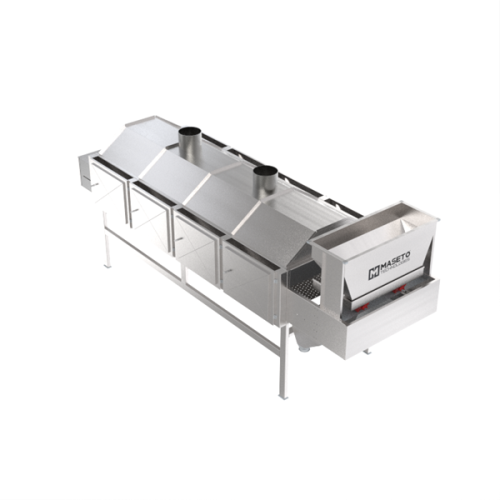

Vertical chestnuts dryer

Achieve optimal moisture removal for chestnuts with precise hot air cycling, perfect for converting ...

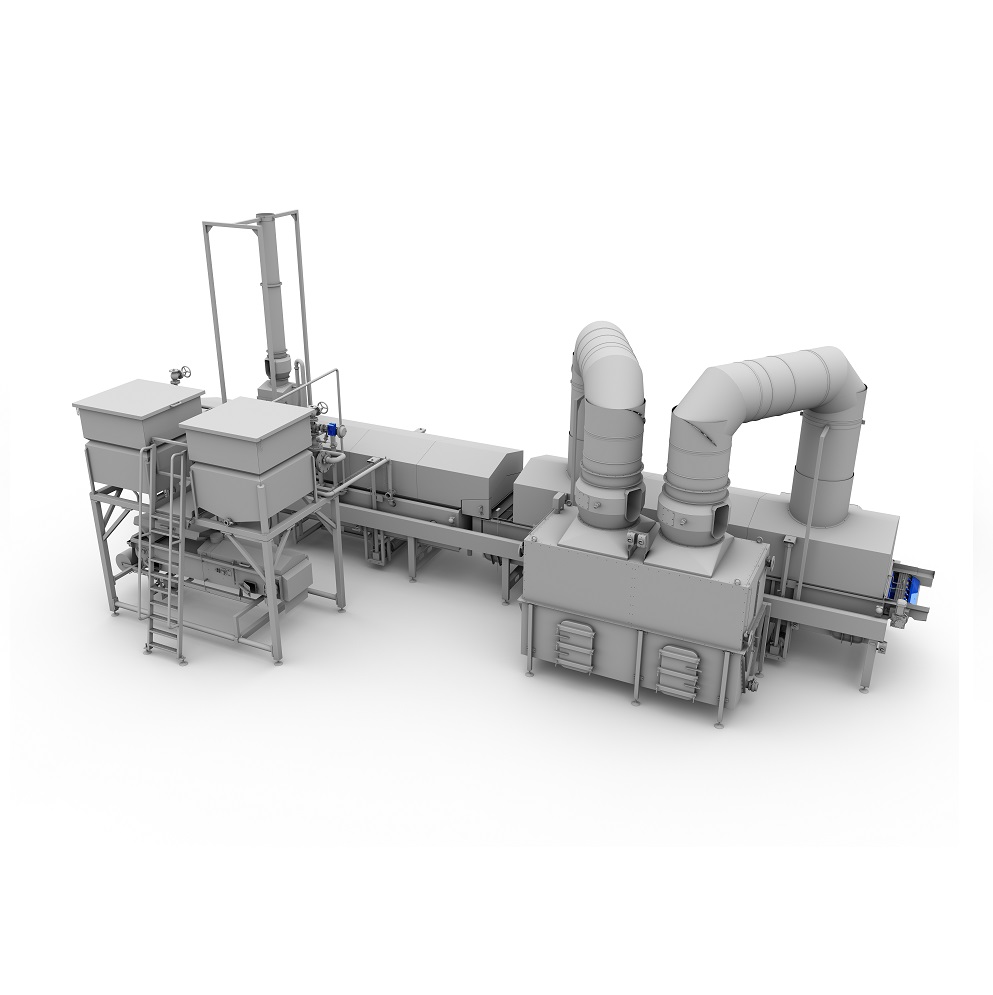

Chestnut processing line for fresh market

Efficiently transform raw chestnuts into polished, fresh market-ready products w...

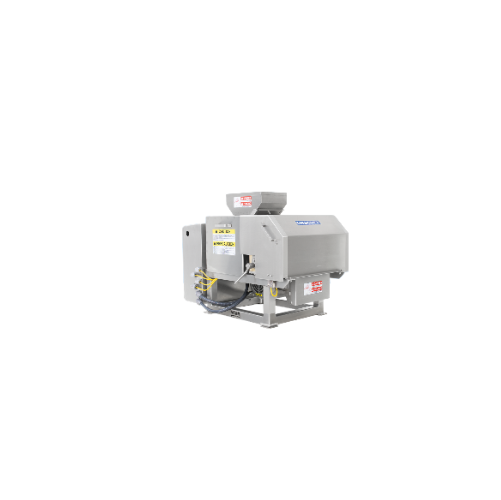

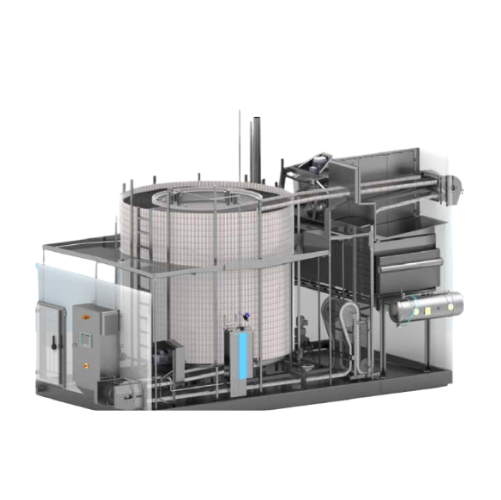

Chestnut sterilisation system for parasite control

Ensure pest-free chestnuts with precision-controlled hot water sterili...

Chestnuts steam peeling system

Efficiently transform raw chestnuts into ready-to-freeze products with a continuous steam pee...

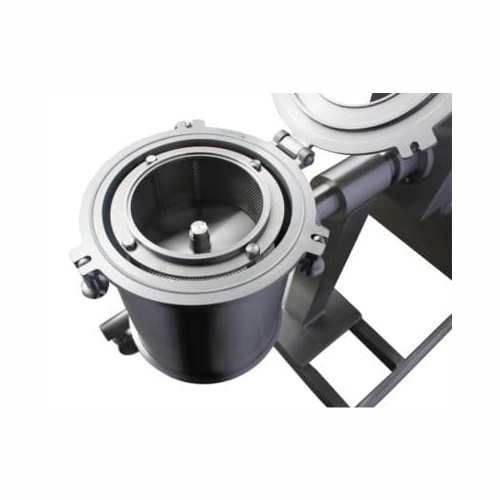

Centrifugal separator for reworking chocolate and chopped hazelnuts

Efficiently separate chocolate from chopped hazelnu...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

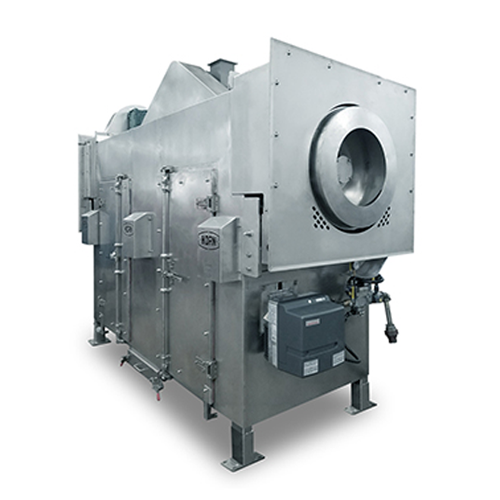

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Rotary oven for japanese peanuts

Achieve uniform coating and optimal roasting for Japanese-style peanuts with precise temper...

Split peanut blancher for snack food processing

Efficiently transform roasted or dried peanuts into perfectly blanched pro...

Granulator for nut processing

Efficiently transform various nut varieties into uniform, sharp-edged granules while minimizin...

Nut butter mill for snack food processing

Efficiently transform various nuts into smooth, spreadable butters with precisio...

Granulator for nut meats and cookies

Optimize your processing line with precision granulation, slitting, and scarifying of ...

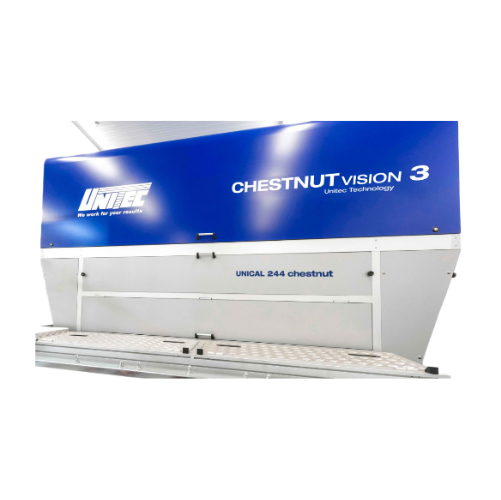

Chestnut sorting and grading system

Optimize chestnut processing with advanced sorting technology that ensures precise size...

Hazelnut sorting and quality selection system

Optimize your hazelnut processing with a system designed to detect defects a...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Optical sorter for nuts, dried fruit, and Iqf

Ensure flawless quality control by efficiently sorting, grading, and ejectin...

Optical sorter for nuts and dried fruit

Enhance sorting precision by effortlessly identifying and removing foreign material...

Food sorting system for nuts and dried fruit

Streamline sorting processes by removing visual irregularities, defects, and ...

Wet almond peeling machine for nut processing

Enhance your nut processing efficiency by achieving up to 98% peeling rate w...

Industrial almond slicer for nut processing

Achieve precise nut slices with adjustable thickness, perfect for enhancing pa...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Pine nut threshing system

Efficiently separate pine nuts from cones without damage, streamlining your nut processing operati...

Nut coating machine for snack food processing

Enhance your snack and confectionery production with a nut coating machine t...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Lebanese pine nut shelling and separating system

Ensure precision in your nut processing line with a system designed to ef...

Small scale cashew nut processing plant

Optimize your nut processing with our comprehensive cashew line, designed to stream...

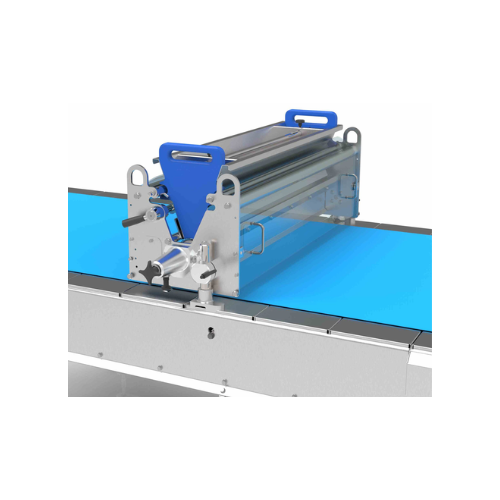

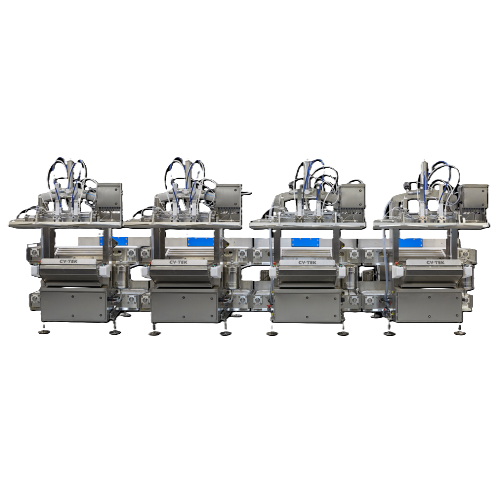

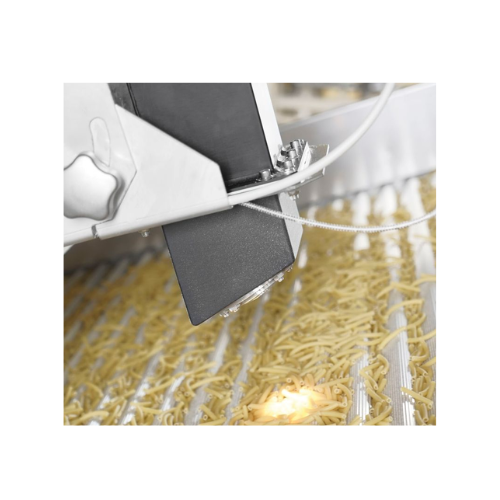

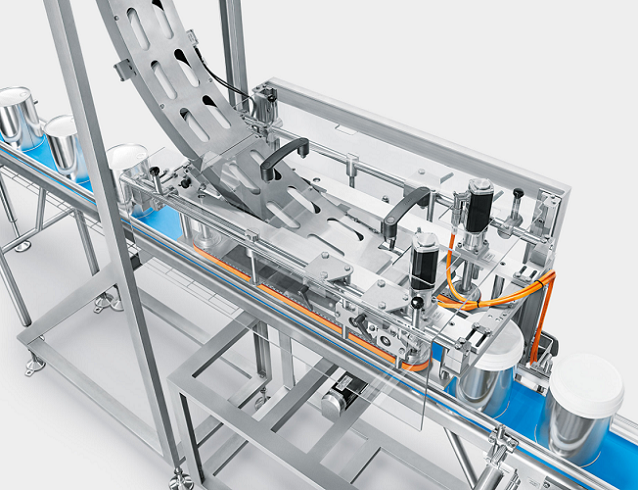

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Forming system for cereal bars and nut mixes

Effortlessly transform diverse ingredients like cereals and nuts into precise...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Industrial nut crusher for dried fruit processing

Optimize your nut and dried fruit processing by reducing them to precis...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Coffee, dried nuts, and cocoa beans roaster

Achieve precise and customizable roasting for a variety of beans and nuts with...

Industrial roaster for coffee, nuts, and cocoa beans

Optimize your roasting processes with a versatile solution designed ...

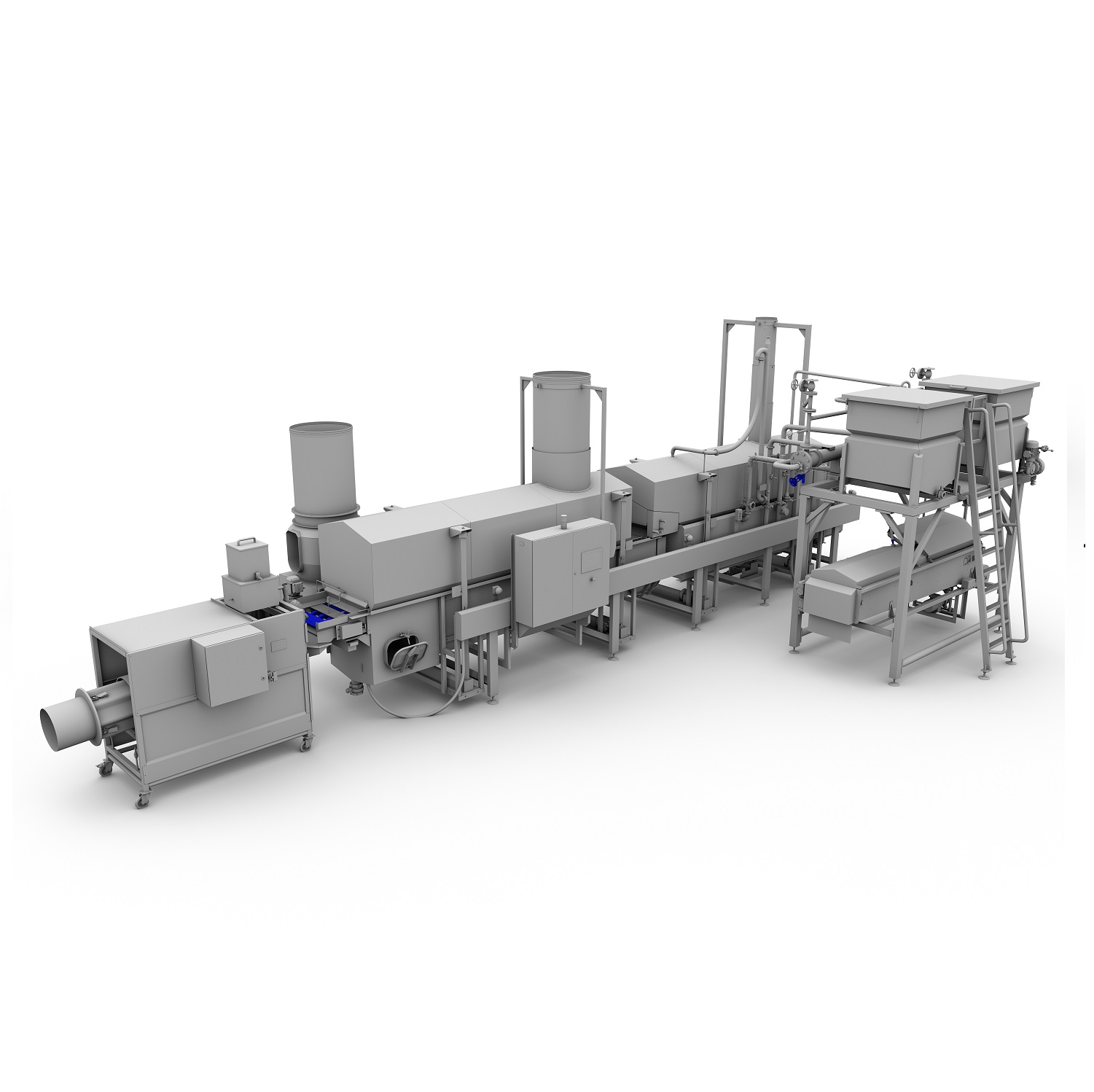

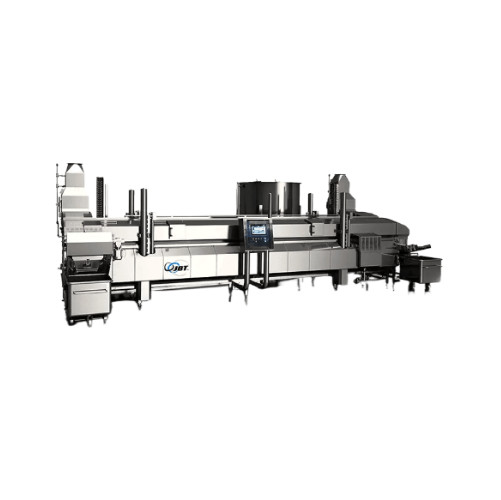

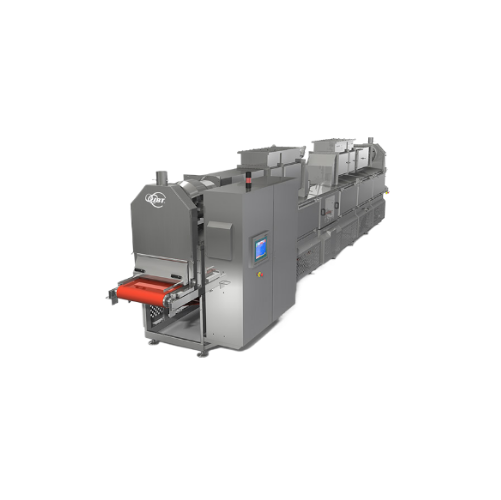

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

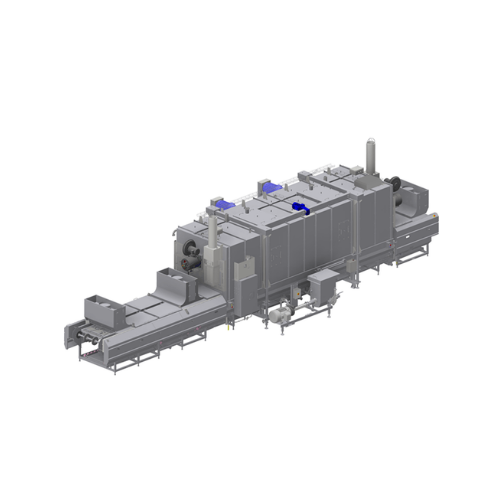

Peanut frying line

Fried peanuts are a very popular snack around the world. If you are looking to start a nut processing plan...

Continuous, automatic coating machine for peanuts

If you are in the peanut processing industry, bringing out delicious va...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

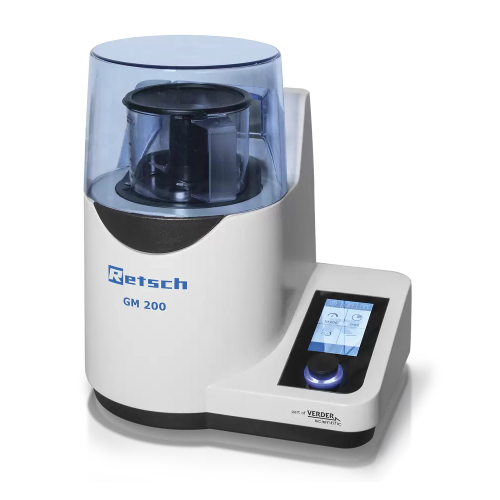

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Compact cylindrical roaster for beans, nibs and nuts

Roasting times and temperature can vary depending on the type of pro...

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

Nut roaster

Nut roaster that guarantees a high-quality roasting of nuts and seeds with a batching capacity of 40 and 120 kg, d...

Topping depositor for pizzas and baked goods

Enhance your production line’s efficiency by uniformly adding both dry ...

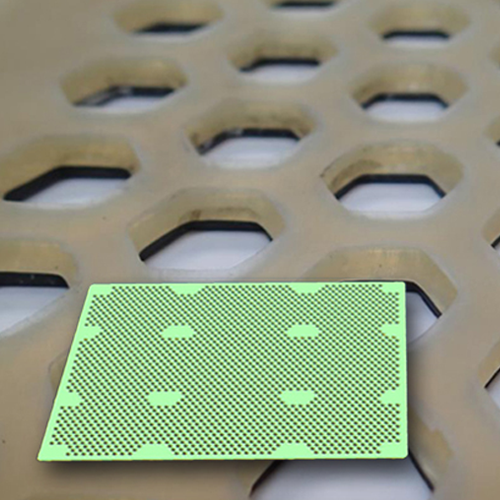

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

Chocolate decoration system for pralines and biscuits

Achieve intricate chocolate patterns and uniform coatings on confec...

Modular system for chocolate drops production

Enhance your chocolate production with a versatile machine that forms and co...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

Precision chocolate production from cocoa nibs

Achieve ultra-fine chocolate textures by utilizing stone conching to bring ...

Linear vibratory weigh filler for fragile food products

Achieve precise and gentle filling of fragile food products with ...

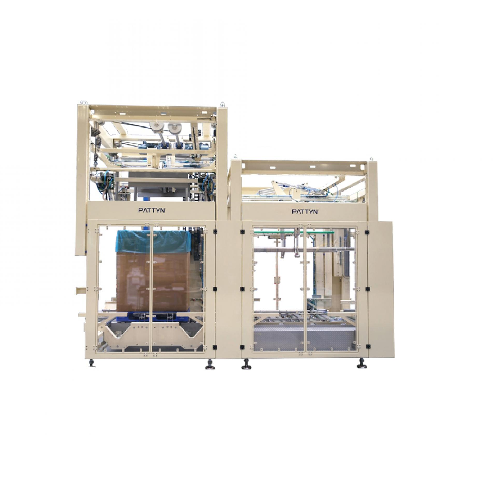

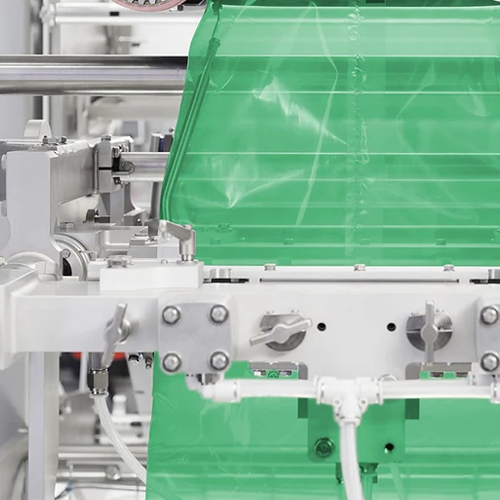

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

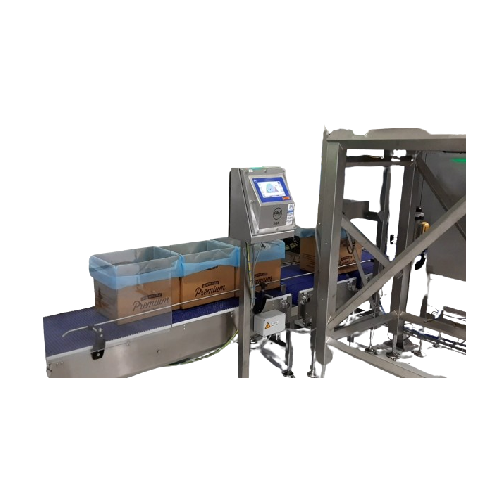

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

Almond hulling system for soft and semi-hard shells

Efficiently hull almonds with soft or semi-hard shells to streamline ...

Sesame seed roaster

Achieve consistently roasted sesame seeds and nuts with optimal moisture control, designed to enhance fla...

Sesame seed dryer

Optimize your sesame processing with efficient moisture removal, ensuring desired quality and consistency f...

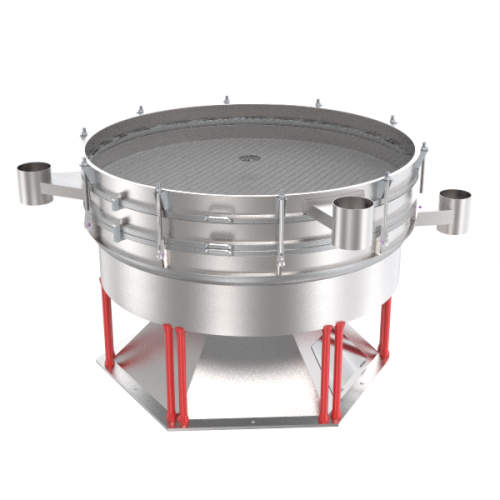

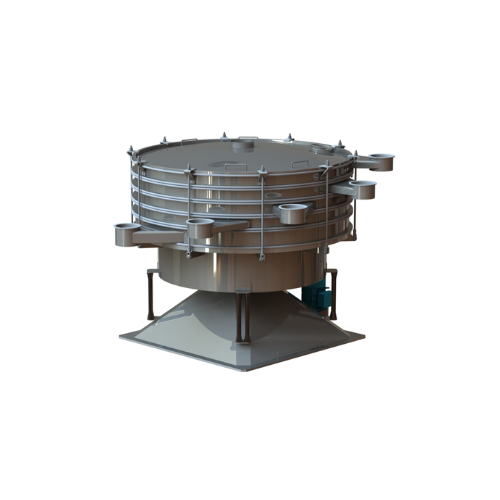

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

Cooling system for heat-treated products

Efficiently reduce temperatures of high-heat products to protect quality and textu...

Horizontal tray dryer for moisture removal

Ensure consistent product quality in nut and olive processing by efficiently re...

Industrial pistachio peeler

Efficiently remove the interior hull from pistachios with mechanical friction, ensuring high-qua...

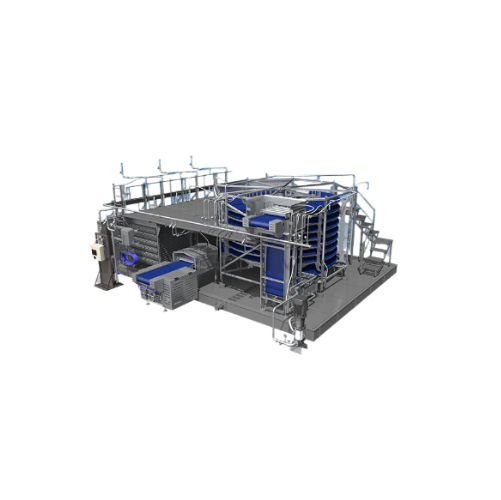

Almond and apricot kernel blanching solution

Efficiently remove hulls from blanched almonds and apricot kernels to streaml...

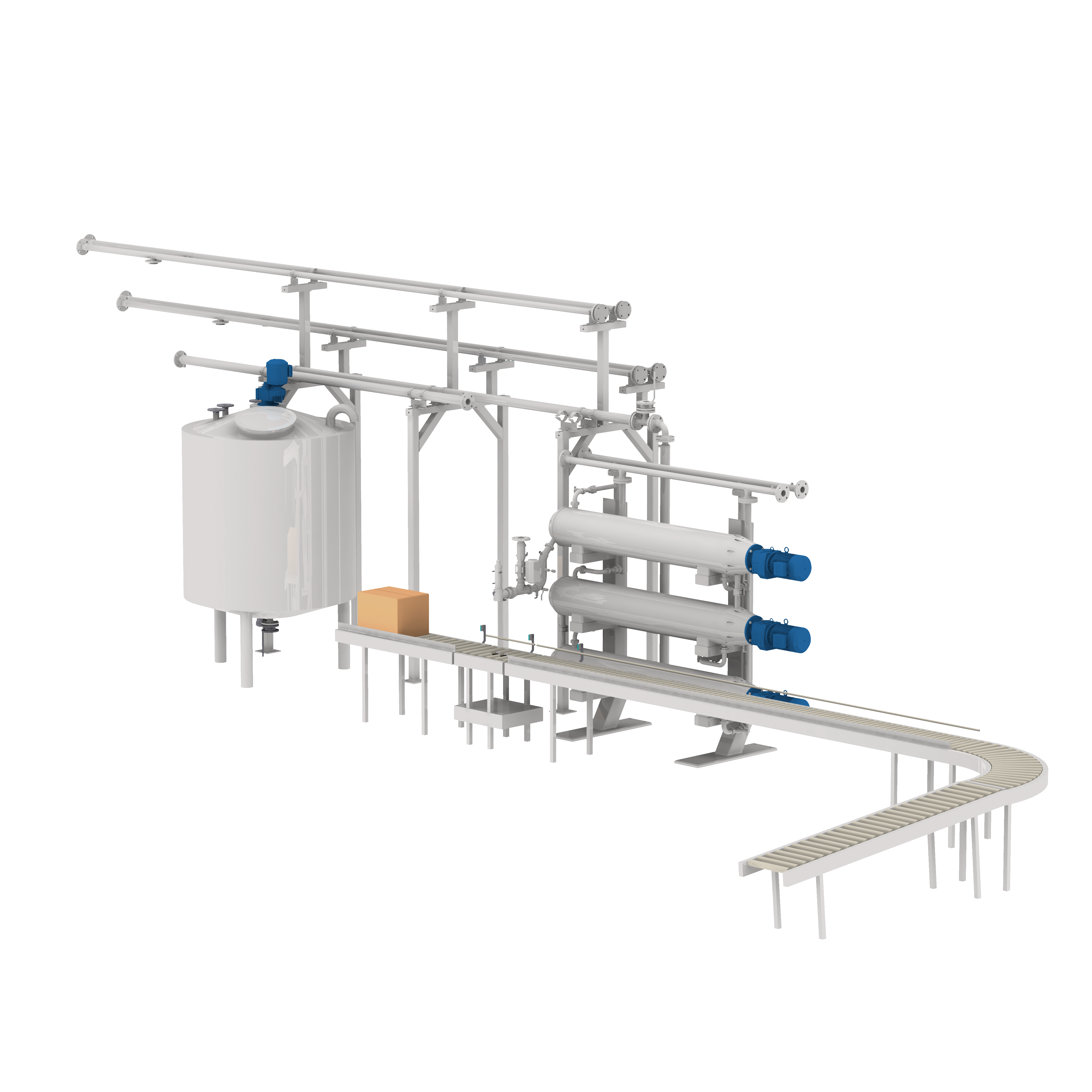

Pneumatic transport system for long-distance product conveyance

Efficiently convey solid and granular products across lo...

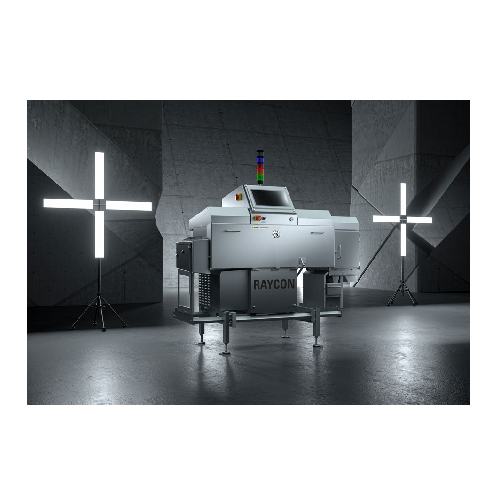

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

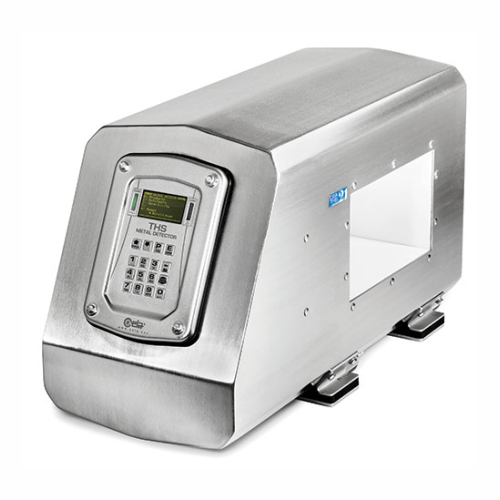

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

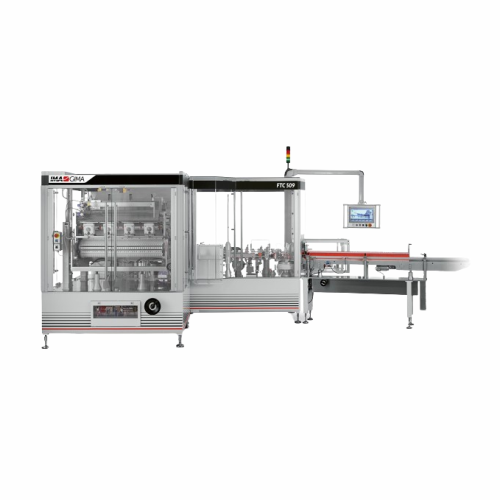

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

Pick and place robotic system for confectionery decoration

For food producers seeking precision in snack decoration, thi...

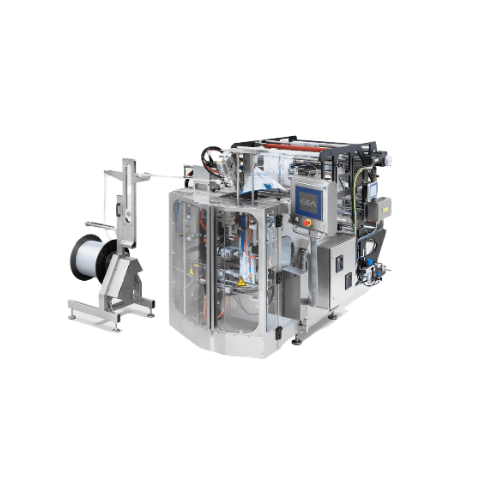

Vertical form, fill and seal packaging system for small bags

Maximize efficiency with small bag portioning for food and ...

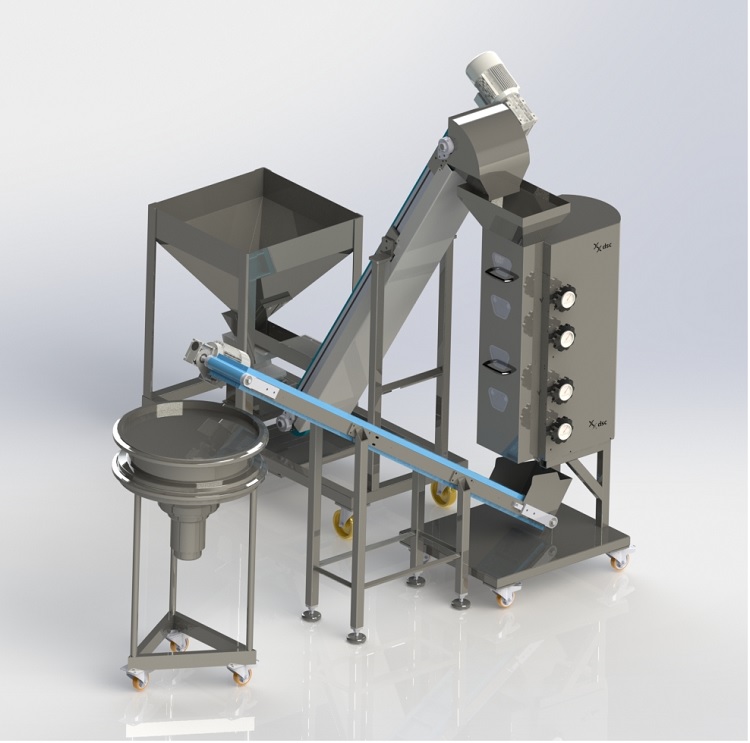

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

Snack food fryer with consistent thermal fluid heating

Achieve uniform frying with precise thermal fluid technology, ensu...

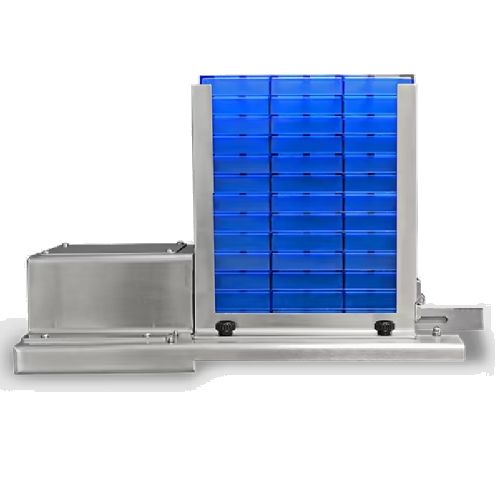

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

In-line seal checker for high-speed snack packaging

Ensure flawless package integrity with in-line leak detection, enhanc...

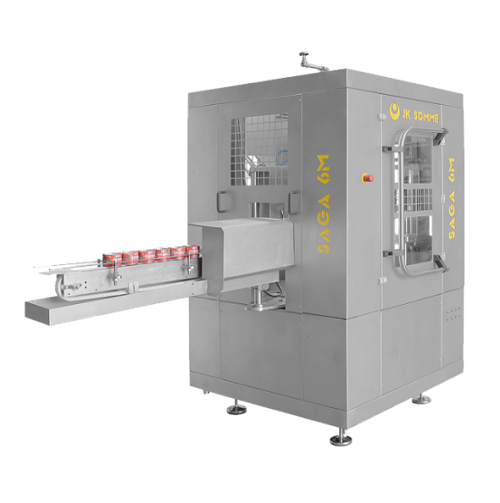

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

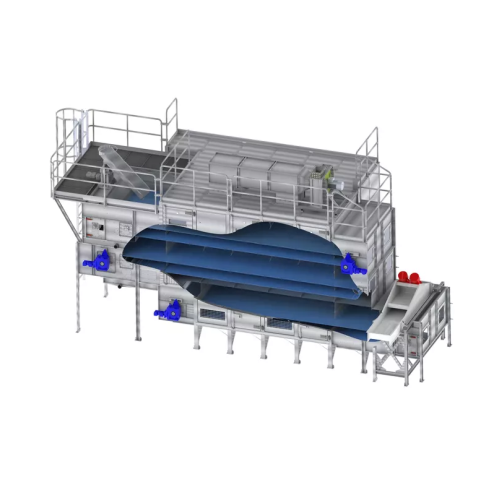

High volume rotary dryer roaster for continuous drying

Achieve uniform drying and roasting with a continuous, high-capaci...

Continuous paper filter for frying oil

Ensure oil clarity and enhance product quality by continuously removing ultra-fine p...

Oil curtain fryer for snack production

Enhance snack quality and shelf life by frying with rapid oil turnover and minimal o...

Ambient air cooling system for food products

Achieve precise cooling control with high-speed ambient air cooling systems, ...

Drum dryer for animal feed

Achieve efficient and uniform drying for a variety of products, from nuts to medicinal cannabis, ...

Rotary drum dryer for robust food products

Achieve uniform and gentle drying for sensitive and robust products alike with ...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

Continuous cocoa bean roaster

Achieve precise flavor profiles in cocoa and nut processing with a continuous roasting solutio...

Batch conche for chocolate making

Achieve optimal texture and flavor development in your chocolate with precise control ove...

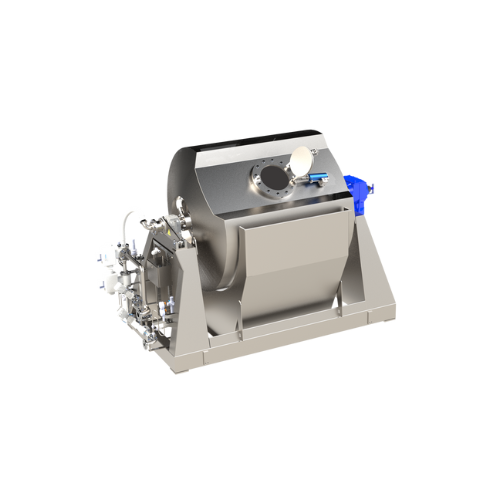

Double shaft batch mixer for chocolate production

Optimize your chocolate and confectionery production with precise mixin...

Pre-refiner for chocolate processing

Optimize pre-refining in chocolate and cocoa production with precise fineness control,...

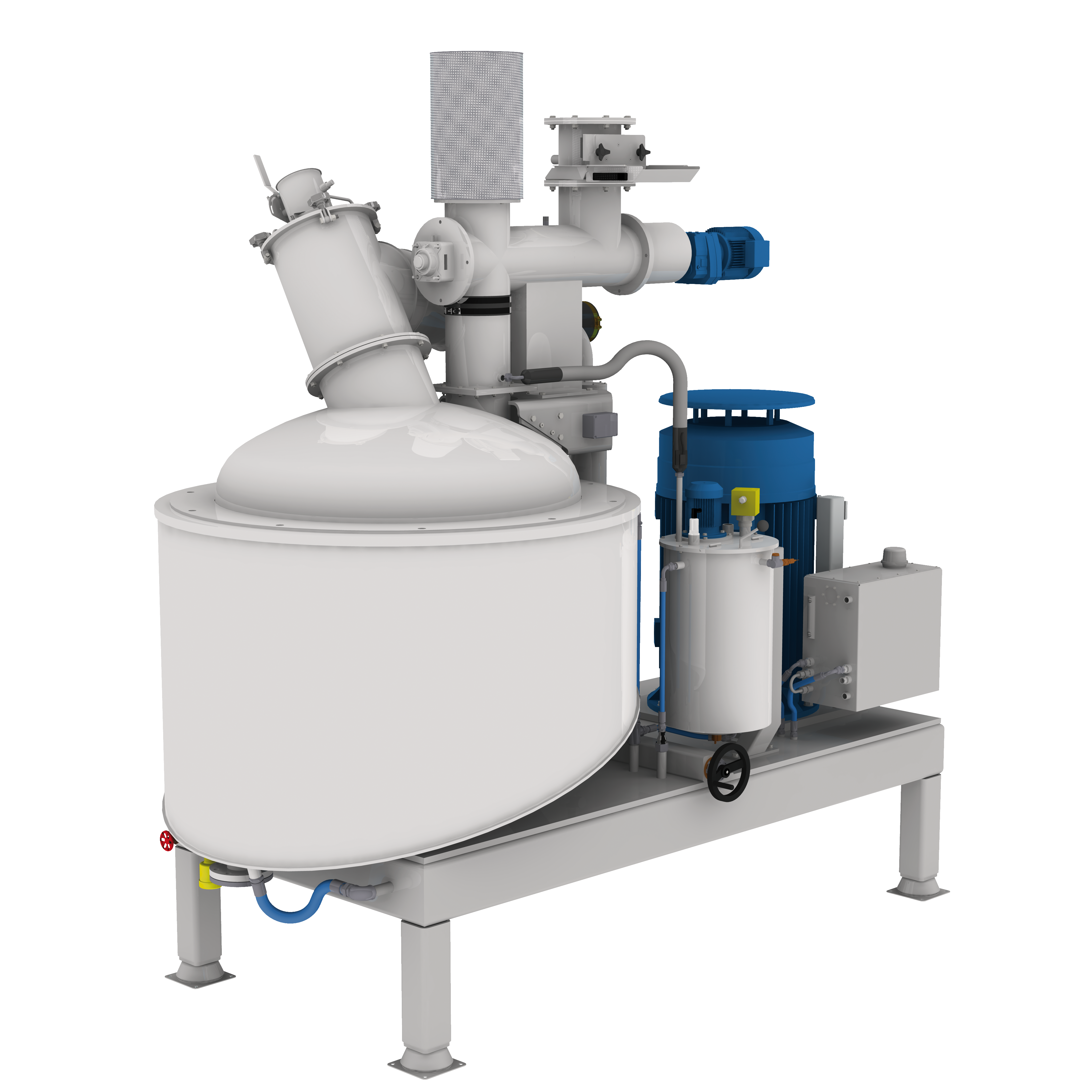

Cocoa nib grinding system

Optimize your cocoa and nut processing with precision grinding to achieve a pumpable mass, ensurin...

Spindle mill for fine and super fine grinding of cocoa liquor

Achieve precision in grinding cocoa liquor and nut pastes ...

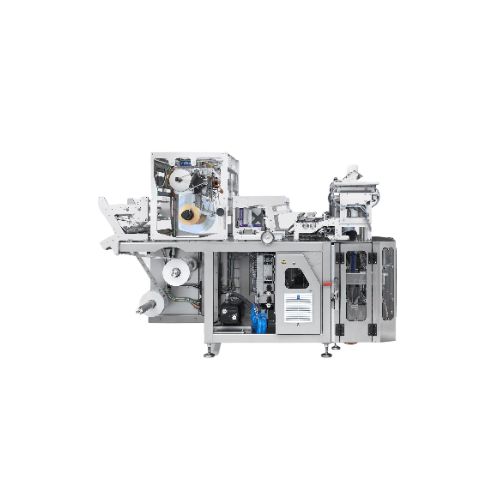

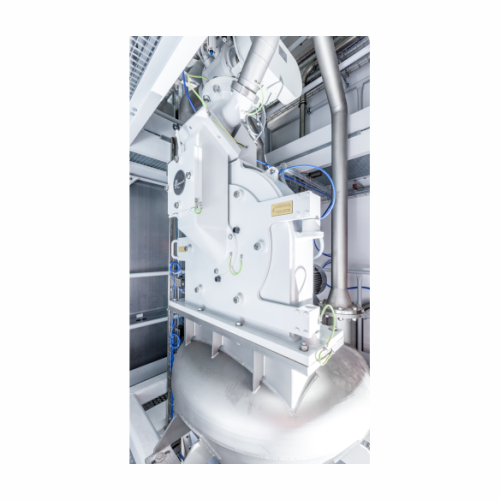

Modified atmosphere packaging for bulk bins

Achieve ultra-low oxygen levels and preserve product quality during bulk proce...

Product unscramblers for industrial automation

Efficiently organize and orient jumbled products for seamless integration w...

Continuous butter toffee processing system

Achieve precise caramelization and nut integration while maintaining the perfec...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

Single-zone toasters for raw grain processing

Optimize your cereal and snack food production by achieving consistent toast...

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

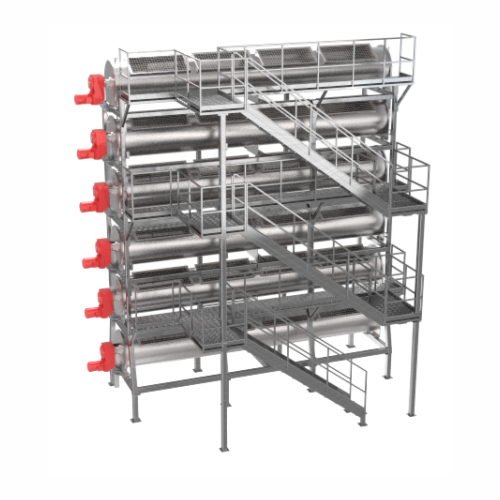

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

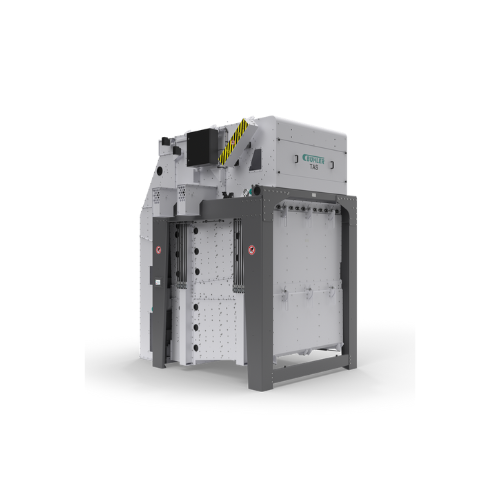

Industrial screeners for grain product processing

Optimize your cereal production line with specialized industrial screen...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Optical sorter for frozen fruit and vegetable processing

Enhance your processing line’s efficiency with high-speed ...

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and ...

Optical sorter for coffee beans

Achieve precise color differentiation and advanced foreign matter detection, optimizing your...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

Cooling tunnel for cream-filled wafer blocks

Ensure your wafer products maintain optimal texture and integrity with a stat...

Winnowing system for cocoa processing

Achieve precise cocoa separation with a high-efficiency winnowing system designed for...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Vibration batch dryer for difficult solids

Ensure efficient drying of complex solids prone to sticking and shape irregular...

Single lane collator for packaging room

Streamline your packaging operations by efficiently collating, counting, and aligni...

Modular rotary oven for snack food processing

Optimize flavor infusion and moisture control in snack production with a mod...

Retractable spiral chute for bulk material handling

Enhance the integrity of your products by gently transferring bulk ma...

Spiral chute for gentle product handling in limited space

Optimize your snack and nut production by minimizing product d...

Industrial bagging system for high-speed processing

Optimize your packaging line with this engineered-to-order bagging sy...

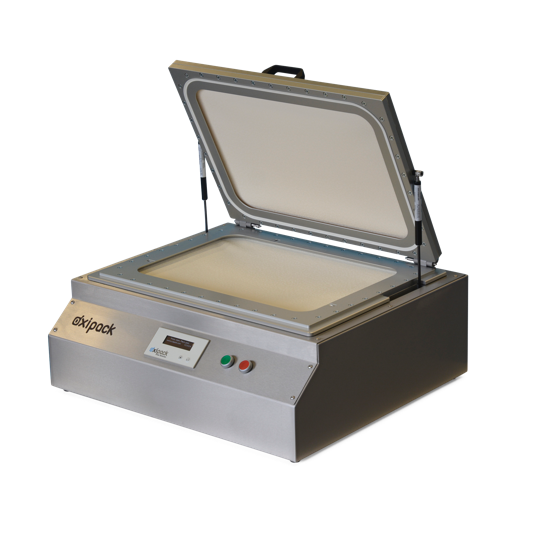

Semi-automatic tray sealing solution

Streamline your production line with a versatile tray sealing solution that enhances p...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Semi-automatic tray sealer for ready meals

Achieve optimal freshness with consistent sealing, maximizing shelf life for va...

Automatic tray sealer for high-speed food packaging

Optimize your production line with a high-capacity tray sealing solut...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Automatic tray sealing system for high-speed packaging

Experience seamless high-speed packaging with this versatile tray ...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

Bench mounted tray sealer with gas flush

Optimize your production line with a compact tray-sealing machine designed for pre...

Linear conveyor tray sealing

Experience unparalleled flexibility and efficiency in tray sealing with high-speed integration,...

High throughput tray conveyor system

Looking to streamline your tray sealing process? This modular conveyor system integrat...

High-speed tray sealer for food

Enhance your packaging line’s efficiency with a high-speed, in-line tray sealer design...

Industrial high speed tray sealer

Enhance your production line efficiency with precision sealing capabilities, accommodatin...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

In-line tray sealer for high-speed packaging

Optimize your packaging line with a high-speed solution that accommodates mul...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

High-capacity tray sealer for poultry, meat & seafood

Optimize your high-speed packaging line with this large-capacity tr...

Automatic tray sealer for high-speed packaging

Streamline your packaging line with an in-line tray sealer that adapts to t...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

Automatic inline tray sealer for food packaging

Streamline your packaging process with high-speed, reliable tray sealing t...

Automatic tray sealing system

Optimize your packaging line with versatile tray sealing technology that accommodates various ...

Heat exchanger for high viscosity products

For processors handling high viscosity products or those with fiber content, th...

Rotary atmospheric sterilizer for high acid canned foods

Optimize your canning process with uniform heat penetration and ...

Rotary pressure sterilizer for canned food products

Streamline your canning operations with continuous high-speed sterili...

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their ...

Low energy suction system for food processing retorts

Optimize your sterilization process with innovative suction technol...

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

Citrus juice extractor for industrial juice production

Maximize juice yields while preserving exceptional quality with ou...

Direct heated immersion fryer for convenience food processing

Achieve superior temperature control and minimize oil cons...

Industrial bin scrubbing system for fresh produce

Enhance food safety and operational efficiency with a bin scrubbing sys...

Brush bed system for fresh produce cleaning and waxing

Optimize your fresh produce processing with this advanced brush sy...

Heated flooder for sanitation in fresh produce processing

Optimize your fresh produce processing with a heated flooder, ...

Single pass dryer for fresh produce

Optimize your fresh produce processing with a continuous drying solution that enhances ...

Smart dryer system for fresh produce

Optimize your fresh produce drying process while ensuring consistent quality and effic...

Structure supported spiral freezer for food products

Optimize your high-speed production with a versatile spiral freezer ...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Forced circulation evaporator for tomato and fruit paste

Optimize your high-viscosity tomato and fruit paste production w...

Hybrid evaporator for highly viscous tomato concentrate

Achieve superior concentration and energy efficiency with a versa...

Granular filler for wide mouth containers

Ensure precise filling and minimize product loss with this granular filler, expe...

Batter mixer for small to medium food production lines

Achieve precise, consistent batter mixing with our semi-automated ...

Batter applicator for meat and fish

Achieve consistent and uniform batter coverage on diverse food products, enhancing the ...

Automated clipped netting system for meat packaging

Enhance your packaging line with a system designed for rapid and prec...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Industrial chopper/blender for frozen fruit processing

Efficiently transition frozen fruits and concentrates into a manag...

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

X-ray scanner for bulk material inspection

Ensure product safety and minimize downtime by intercepting foreign contaminant...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Topload cartoning system for efficient product packaging

Streamline your packaging line with this compact system that com...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Sleeve cartoners for ready meals and salads

Optimize your packaging line with a high-speed sleeve cartoner designed to eff...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Inline mechanical homogenizer for food processing

Achieve precise particle size and uniform texture in your emulsions and...

Slicer for food processing applications

Efficiently achieve precise cuts and textures for a variety of food products, enhan...

Industrial slicer for precise food cuts

Maximize your food processing efficiency with an industrial slicer that offers unpa...

Industrial dicer for small to intermediate size ranges

Boost your production capacity with a versatile dicing solution th...

Large-capacity commercial food dehydrator

Achieve precise dehydration for a wide range of food items with unmatched consis...

Jumbo twin gear slow masticating juicer for high-yield juice extraction

Achieve optimal nutrient retention and extended...

Food dehydrator with Bpa-free trays

Effortlessly retain nutrients while creating a variety of dehydrated snacks using dual ...

Food dehydrator with Bpa-free plastic trays

Achieve precise dehydration for fruits, vegetables, and snacks with advanced t...

Vacuum sealing system for glass jars with metal lids

Efficiently vacuum seal glass jars with metal lids to transform pres...

Industrial hard cheese grater

Optimize your food preparation process with high-speed grating, perfect for transforming hard ...

Belt sorter for potatoes and leafy vegetables

Enhance the precision and efficiency of your sorting process with a system d...

Advanced fruit sorting platform

Optimize your operations with a cutting-edge sorting solution designed to enhance product in...

Advanced food sorter for tomatoes and peaches

Achieve precise sorting and defect removal for a variety of food products, e...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Blizzard sorter for Iqf fruits and vegetables

Optimize your frozen food production with a compact sorter that seamlessly r...

Color sorter for small fruits

Optimize your production line with a high-speed color sorting solution that enhances quality c...

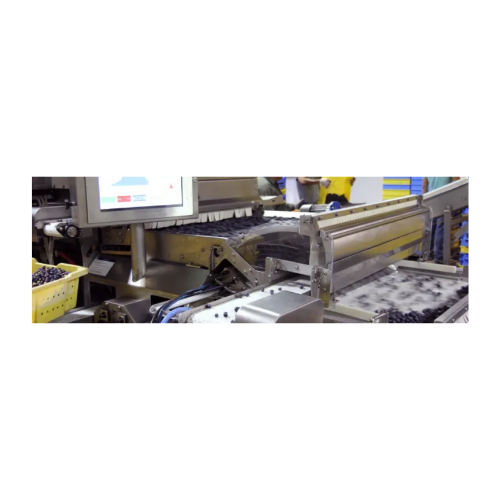

High-speed filling system for cherries and blueberries

Streamline your packaging process with a system designed for rapid...

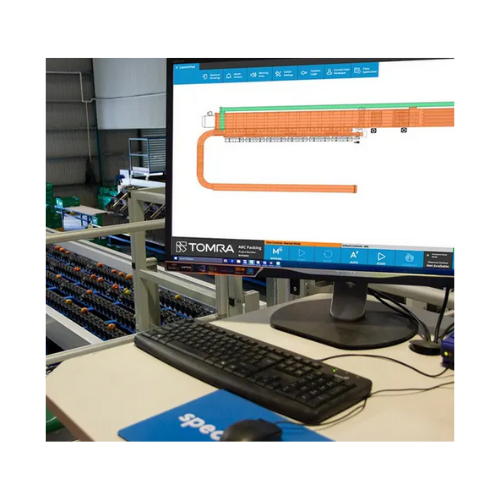

Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and r...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

14 head multihead weigher for dry products

Achieve precise and rapid weighing for a variety of dry, free-flowing products ...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

Ingredient doser for ice cream with large inclusions

Achieve precise and uniform inclusion of fruits, nuts, and candies i...

Dry ingredient blending solution for confectionery and bakery products

Achieve seamless integration of dry inclusions i...

Vibration sieving machine for removing droplets or oil

Enhance your production line by efficiently removing surface liqui...

Continuous roller cleaning system for food production

Enhance your food processing efficiency with this high-speed soluti...

Automatic cereal bar production line

Efficiently transform diverse ingredients into consistent, high-quality cereal bars wi...

Almond sheller

Streamline your nut processing operations with a high-efficiency shelling machine designed for precision cracki...

Hydraulic oil press for efficient oil extraction

Streamline your oil production with a hydraulic oil press that ensures hi...

Jujube grading machine for round and oval fruits

Optimize your fruit and vegetable processing with precise size sorting, e...

Garlic peeling equipment for industrial applications

Achieve optimal peeling efficiency with this garlic and nut peeling ...

Fully automatic electric heating frying system

Streamline your frying operations with a versatile system that not only sav...

Small deoiling machine for potato chips production

Enhance your snack production line with rapid deoiling and dewatering,...

Caramel treats production line

Enhance your snack production with a comprehensive solution for crafting caramel treats, effi...

Airflow grain puffing machine

Unlock the potential of versatile snack production with precision-engineered airflow puffing t...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Electrostatic drum flavouring system for food industry

Enhance the consistency of your food products with precise flavour...

Electrostatic drum flavoring system for food processing

Enhance your snack production efficiency with a system designed t...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Industrial enrobing solution for quality coatings

Achieve high-quality coatings for pralines, bars, and pastries with a c...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Vertical tunnel for cooling and moulding chocolate

Efficiently manage chocolate temperature control and molding precision...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Refiner for spreadable cream and chocolate

Achieve optimal texture and consistency for your spreadable creams and chocolat...

Professional chocolate tempering system for artisan chocolatiers

Achieve precise chocolate tempering with quick changeov...

Chocolate tempering solution for small scale production

Efficiently temper chocolate for diverse confectionery creations ...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Industrial cocoa nib grinder for bean to bar production

Streamline your chocolate production with this versatile grinder,...

Professional chocolate tempering solution for large workshops

Enhance your chocolate production efficiency with a machin...

Chocolate truffle enrobing system

Enhance your chocolate production with a machine that delivers precision enrobing for tru...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Optical sorter for fruit and vegetables

In fresh vegetable and fruit production, product quality is key to ensure a longer ...

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Continuous cocoa bean roasting line

When you are processing chocolate, after the conditioning and fermenting of cocoa, the ...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Optical sorter for dried and frozen fruits

Dried fruits, frozen fruits, frozen vegetables and nuts present a challenge for...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Food processor for making fruit jams for pastries

In a bakery environment fruit jams are often used for the decoration or...

Multi-functional food processor for a high sugar percentage pastes production

For the development and production of hi...

Vacuum cooker for concentrating sauces and purees

When producing high quality prepared food, concentrating products for s...

2-way diverter valves for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

Dense phase conveyor for normal wearing materials

Dense phase pneumatic conveying is used for powders, granules, and grai...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

Shop coffee bean grinder

Do you want to grind your beans on-site at your coffee shop, but are you limited for space? Bench-to...

Small batch filter press for oil seeds

Getting a high-quality oil filtration can be a challenging task, with a filtration ...

Cold oil press for seeds

With a cold oil press, you can optimize the process of extracting oil from a wide variety of oil see...

Basic mixer for granular foods

Straightforward blending solution for mixtures of beans, nuts, berries & powdered foods, ...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...

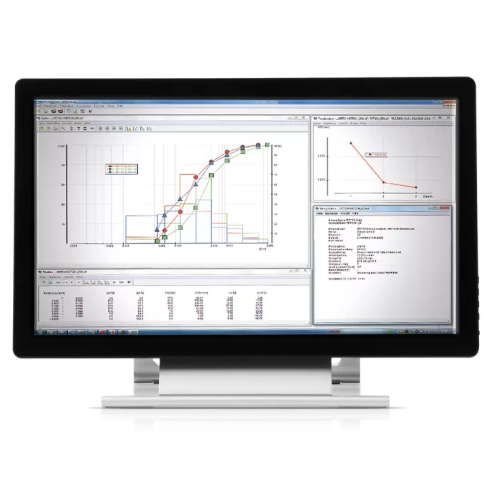

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

Mortar grinder for reproducible sample preparation

Achieve precise and consistent material preparation with this mortar g...

Electromagnetic sieve shaker for quality control

Achieve precise particle size distribution with this advanced electromagn...

Mesh sieves for laboratory particle size analysis

Ensure precise particle size control for a wide range of materials with...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

Industrial Xl bag sealer for large pallet containers

Eliminate manual handling and ensure perfect seals for bulk packagin...

Sesame peeling system

Enhance your seed processing with a sesame peeling system that reduces water usage and eliminates chemi...

Sesame seed washing system

Eliminate the bitterness and impurities from sesame seeds efficiently, setting the stage for high...

Metal detector for conveyorized applications

Enhance your production line by ensuring product safety with advanced metal d...

Conveyorized food metal detector for high-care environments

Ensure food safety with advanced metal detection tailored fo...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

Checkweigher for high-care food environments

For facilities needing precision and hygiene, this high-care checkweigher ens...

High-care food processing combination system with metal detection

Optimize your high-care food environment with a robus...

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Rotationally symmetric product rolling machine

Achieve precision shaping of chocolate balls, candy drops, and more with ou...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

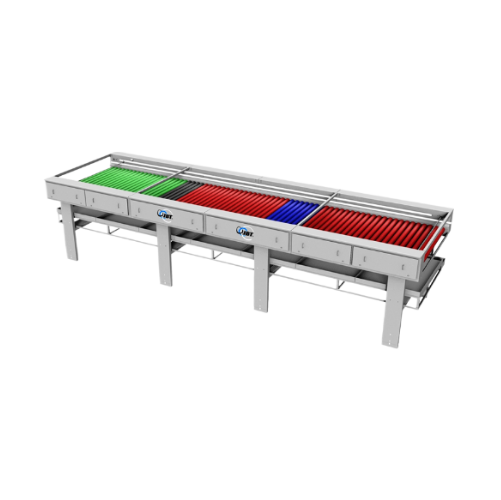

Industrial transfer conveyor system

Efficiently transport and sort diverse food products with precision, ensuring seamless ...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

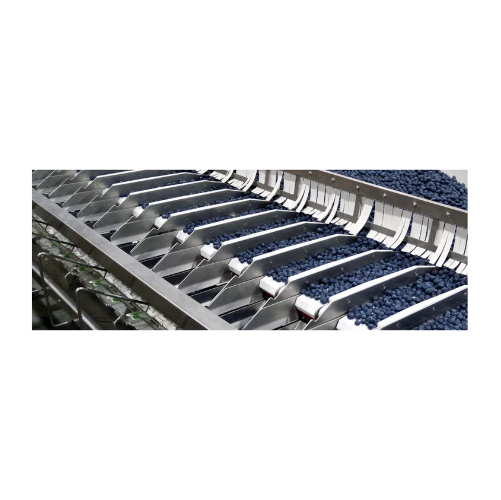

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

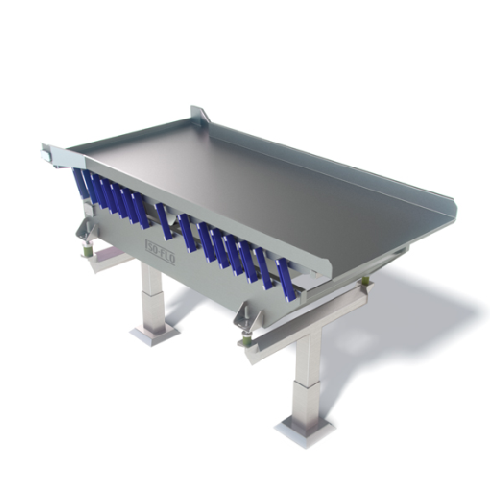

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Automatic defect removal for french fries

Maximize yield and enhance quality in potato strip production with precision cut...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

Potato chip production slicer feeder

Ensure optimal slicing and consistent chip quality with a feeder that delivers a stead...

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this...

Oil cooling module for industrial fryers

Quickly cool frying oil to prevent thermal shock and maintain oil quality, allowin...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tra...

Food drying system for diverse products

Achieve precise moisture control and versatile drying for your diverse product line...

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

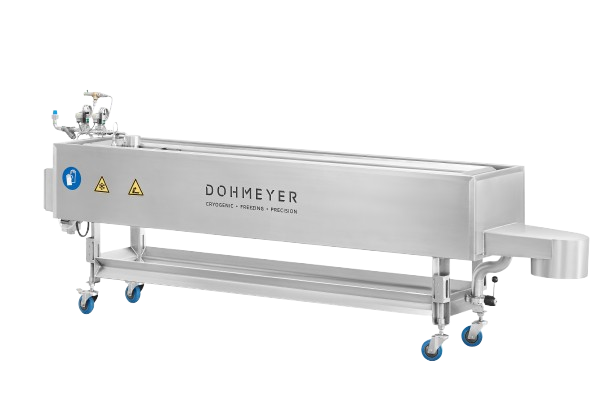

Cryogenic immersion bath for rapid freezing

Achieve rapid and intense cooling by immersing products in liquid nitrogen, id...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Granola drying solution

Optimize your granola production with modular drying technology that ensures precise moisture control...

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

Wafer block cooling tower

Optimize your confectionery production with seamless wafer cooling, ensuring precise temperature c...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Multi-pass pet food dryer for consistent moisture content

Achieve precise moisture control and enhanced product quality ...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

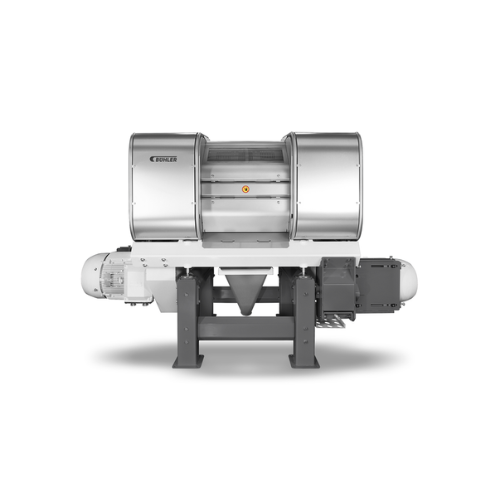

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

Commercial pasta press for diverse ingredients

Optimize your pasta production with a flexible solution capable of handling...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

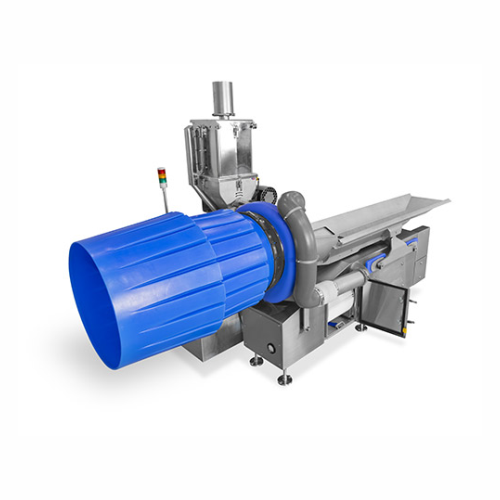

Impact dehuller for sunflower, soybean, and cottonseed

Enhance oil extraction efficiency with a dehulling solution that g...

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

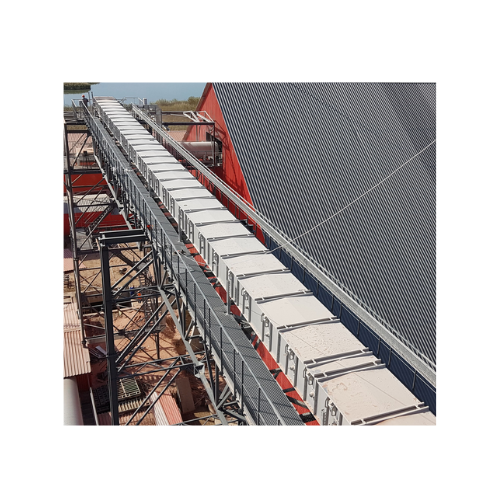

Enclosed belt conveyor for grain handling

Optimize your material transportation and ensure dust-free operations with this ...

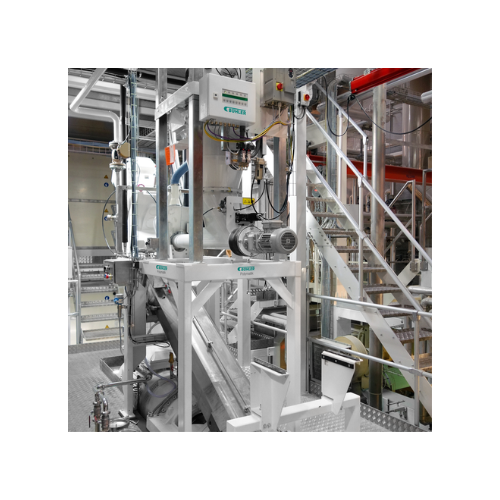

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Vertical conveyor for bulk materials

Optimize your handling of bulk materials with a cost-effective solution that ensures h...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Cracking mill for oilseeds and feed processing

Maximize your production efficiency with advanced cracking and milling solu...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Automatic fasteners packaging system

Streamline your fastener packaging process with a system that automates sorting, dosin...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Stir fryer for industrial food production

Streamline your culinary operations with this innovative stir fryer, designed to...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Sanitary static blender for food and beverage

Optimize your mixing process with low shear, energy-efficient blending desig...

Citrus brush washer for fruit cleaning

Ensure your produce is impeccably clean with a brush washer designed to efficiently ...

Compact digital bench weighing scale for food processing

Ensure precise portioning with this compact and durable digital ...

Bi-directional frame scale for industrial weighing

Achieve precise product accumulation and streamlined batch processing ...

Industrial weight tracking system for injected products

Optimize your production line by accurately tracking product weig...

Flat belt product transfer conveyor for food processing

Efficiently streamline your production line with a hygienically d...

Twin lane separator for automated tray sealing

Optimize your production line with this conveyor system designed to effortl...

R&d vessels for research and development centers

Optimize your R&D operations with versatile vessels designed to hand...

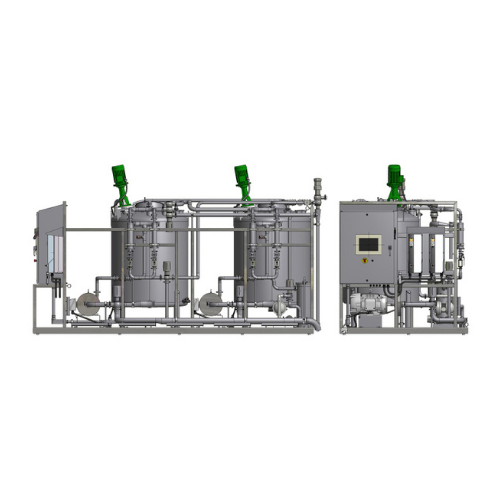

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

Custom fabricated industrial tanks

Optimize your production with these industrial tanks, designed to handle a diverse range...

Two-stage defect removal system for citrus juice

Ensure your juice production achieves maximum yield and purity with a two...

D-limonene extraction system for citrus processing

Enhance your citrus processing capabilities by efficiently extracting ...

Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a sy...

Industrial clean-in-place (cip) system

Ensure seamless cleaning and sanitation in your production line with innovative CIP ...

Industrial hot water heating system

Optimize your production line’s efficiency with precise water temperature control...

Pump for products with large particulates

When handling products with large particulates, maintaining integrity is paramou...

Ohmic heat exchanger for high viscosity foods

Optimize the thermal processing of heat-sensitive foods with precise ohmic h...

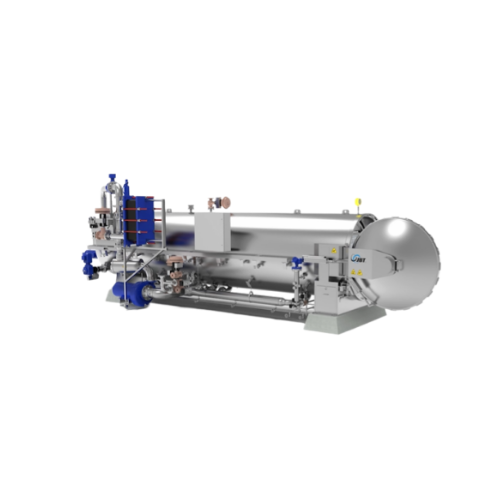

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous ...

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

Pilot rotary retorts for laboratory sterilization

Optimize your prototype testing with precision thermal simulations to p...

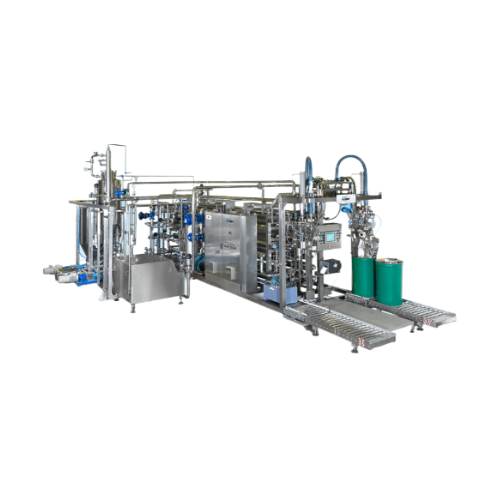

Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing syst...

Heat exchanger for liquid and semi-liquid foods

Optimize your heating and cooling processes with superior heat transfer ef...

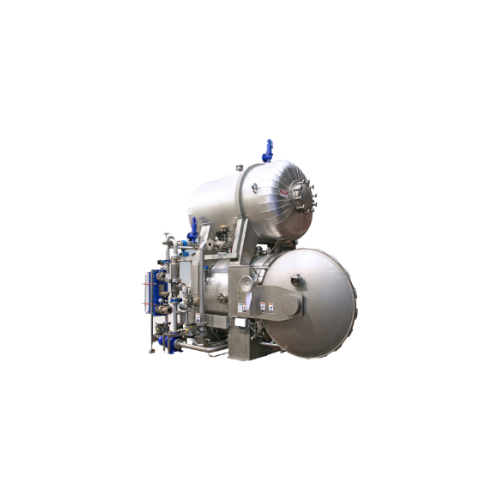

Agitating batch retort for food sterilization

Ensure superior heat distribution and precise control in your sterilization ...

Industrial retort for food sterilization

Achieve uniform sterilization and cooling in your batch production processes while...

Automated batch retort system for food sterilization

Optimize your sterilization process with seamless transportation fro...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Contact cooker for browning and searing

Optimize your cooking process with continuous heat transfer technology that enhance...

Chargrill and bar marker for protein searing

Enhance product appearance and taste with precision searing and grill marking...

Industrial conduction and convection cooker for proteins and vegetables

Enhance your production line with advanced cook...

High speed fruit and vegetable juicer

Optimize your production with a high-capacity juicer designed to efficiently process ...

Screw finishers for citrus processing

Optimize your production line with screw finishers designed to efficiently separate l...

Laboratory fryer for food product development and small runs

Ideal for perfecting culinary creations, this fryer facilit...

Centrifugal hot oil filter for frying applications

Enhance oil quality and extend usability with this advanced centrifuga...

Conveyorized thermal fluid immersion fryer for coated food products

Optimize frying processes with precise heat control...

High pressure washer for citrus and avocados

Achieve perfect cleanliness in your fruit and produce processing with a syste...

Industrial fryer for meatballs and vegetarian food

Enhance your production with a versatile industrial fryer that offers ...

Self-stacking belt for industrial freezers

Enhance your production line with advanced self-stacking belt technology, desig...

Compact spiral freezer for food processing

Enhance your production efficiency and hygiene standards with a compact, self-s...

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, o...

Spiral freezer for frozen food production

Optimize your product’s shelf life and quality with advanced freezing tech...

Industrial spiral freezer for high-volume food processing

Optimize your production line with a modular spiral freezer th...

Spiral freezer for high-volume food products

Achieve rapid, sanitary freezing with this spiral system, designed to handle ...

Industrial spiral freezer for high-volume processing

Optimize your high-volume food production with a robust spiral freez...

Impingement freezer for thin product freezing

Optimize your freezing process with advanced airflow, ensuring quick and uni...

Iqf freezer for fruits and vegetables

Achieve perfect individual quick freezing with fluidization technology, ensuring deli...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Vacuum filler for low viscous products

Achieve precise vacuum filling for liquid and granule products while effectively eli...

Spiral freezer for bakery and confectionery

Maximize space and efficiency while preserving the quality and freshness of di...

Economy breading applicator for granular coatings

Achieve consistent coating uniformity with a conveyorized breading syst...

Automatic tempura batter mixer for poultry and seafood

Enhance the consistency and quality of your tempura coatings while...

Batter applicator for poultry, meat, and seafood

Achieve precise batter application with adjustable submerger controls, en...

Breading applicator for poultry, meat & seafood products

Improve your production line with versatile breading and predust...

Breading applicator for high-volume poultry processing

Achieve uniform coating with precision hydraulics, ensuring every ...

Electric breading applicator for high-volume food production

Enhance coating precision and ensure dust containment with ...

Flour and crumb feeders for breading and pre-dusting processes

Optimize your breading and pre-dusting operations with ad...

Breading applicator for poultry, meat & seafood

Ideal for optimizing your coating line, this applicator efficiently handle...

Industrial chopper blender for thawing frozen products

Quickly transform frozen produce into pumpable liquids, optimizing...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

Industrial refrigeration reciprocating compressor

Optimize your refrigeration systems with advanced reciprocating compres...

Rotary sifter for bulk material separation

Eliminate foreign particles and ensure precise grain size verification with a h...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Mechanical homogenizer for fine cutting and emulsifying

Achieve precise particle size control and consistent texture in y...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Brushing systems for agricultural produce

Enhance the precision and efficiency of fruit and vegetable processing with vers...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Steam peeler for vegetables and fruits

Optimize your food processing with a versatile steam peeling solution that efficient...

Steam peeler for vegetables

Optimize your peeling process with a versatile steam peeler that minimizes waste and enhances th...

Dry bin filling for delicate fruit

Achieve gentle, high-throughput filling of delicate fruits with minimized manual interve...

Small fruit sorter for sensitive cherry varieties

Optimize your packhouse throughput and consistency with advanced sortin...

Soft fruit sorter for packing lines

Enhance your production line’s efficiency by accurately sorting and removing unwa...

Cherry singulation system

Effortlessly streamline cherry processing with a system that ensures gentle handling and superior ...

Industrial steam peeler for potatoes

Optimize peeling efficiency while minimizing waste and energy usage with this high-spe...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

Corn seed sorting solution

Ensure precision in sorting and grading corn with optical and infrared technologies, enhancing pr...

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

Modular packing system for multihead weighing

Streamline your production with a versatile multihead system designed for pr...

multihead weigher for dry products

Optimize your production line with precise weighing for dry products, ensuring high-spee...

Automatic onion peeling system

Efficiently peel and prepare onions with precision using this high-speed, fully automatic sys...

Industrial cereal popcorn making solution

Enhance your snack production with a versatile solution designed for creating a ...

Garlic splitting and peeling line

Streamline garlic processing with this high-speed line designed to efficiently split, pee...

Chili powder milling machine

Transform raw spices into finely milled powders effortlessly with this high-speed grinding solu...

Industrial food drying oven

Achieve efficient dehydration and heat curing with precision control, ensuring uniform drying ac...

Cocoa bean peeling solution

Enhance your cocoa and coffee production with efficient peeling, reducing waste and ensuring hig...

Continuous fryer for high-capacity industrial frying

Achieve consistent high-capacity frying with this continuous mesh be...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

Electrostatic drum flavouring for uniform coating

Achieve precise and uniform flavor distribution on snack products with ...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

X-ray inspection system for unpackaged bulk products

Ensure product purity and safety in high-speed production lines with...

Simultaneous chocolate dosing solution

Achieve high-precision chocolate and ganache filling in a single step with this effi...

Sieve for bean to bar chocolate filtering

Ensure consistency and safety in your chocolate production by eliminating impuri...

Cocoa bean winnower

Transform roasted cocoa beans into nibs efficiently, ensuring precise separation of cocoa from its shell,...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in ...

Chocolate enrobing, moulding, and cooling tunnel

Optimize your chocolate production with this advanced tunnel, designed fo...

Wall chocolate fountain for continuous chocolate flow