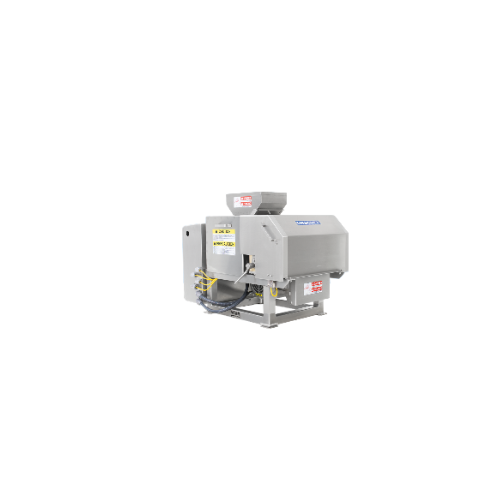

Granulator for nut meats and cookies

Optimize your processing line with precision granulation, slitting, and scarifying of nuts, cookies, and fruits, enhancing product quality and reducing waste through efficient size reduction and continuous operation.

Processes Nut and Bakery Products into Granules

The Model N Granulator from Urschel Laboratories is designed for food processors and bakery manufacturers seeking precise granulation and scarification capabilities. Operating on a continuous feed system with its adjustable gate, feed roll, and stripper plate, this machine ensures consistent particle sizes and minimal fines, ideal for producing nut granules, cookie crumb toppings, and scarified dried fruits. Equipped with a robust 3/4 HP motor, it integrates smoothly into pre-processing or processing stages, supporting industries like confectionery, nut processing, and frozen foods. The Model N’s simplified design facilitates easy cleaning and maintenance, essential for maintaining stringent hygiene standards. With flexible material handling features, it accommodates varying product dimensions, all while contributing to efficient energy use.

Benefits

- Ensures precise product sizing with minimal fines, enhancing end-product quality and consistency.

- Continuous operation maximizes production efficiency by reducing stoppages.

- Simplified design allows for quick cleaning and maintenance, minimizing downtime.

- Adjustable components accommodate diverse product sizes, supporting varied processing needs.

- Energy-efficient operation contributes to lower operational costs.

- Applications

- Cookies, Fruits, Nuts, Crackers, Vegetables

- End products

- Scarified peas, Pistachio bits, Pecan pieces, Walnut fragments, Cookie crumb toppings, Scarified raisins, Almond granules, Cracker meal, Scarified blueberries, Scarified cranberries

- Steps before

- Purification, Drying, Dehydration, Grinding

- Steps after

- Packing, Coating, Size Grading, Quality Control

- Input ingredients

- nut meats, cookies, crackers, frozen vegetables, dehydrated vegetables, rehydrated vegetables, frozen fruits, dehydrated fruits, rehydrated fruits, capsules

- Output ingredients

- granulated nuts, granulated cookies, granulated crackers, scarified vegetables, scarified fruits, slitted products

- Market info

- Urschel is known for its expertise in precision cutting technology and manufacturing industrial food processing equipment, especially cutting machines. It has a strong reputation for quality and innovation in delivering engineered-to-order solutions for the food processing industry.

- Motor Power

- 3/4 HP (.56 kW)

- Dimensions

- Length

- Net Weight

- 450 lb (204 kg)

- Cut Size Range

- Granulations 3/32 to 3/8" (2.4 to 9.5 mm)

- Adjustable Components

- Adjustable Gate, Feed Roll, Stripper Plate

- Operation Type

- Continuous

- Working Mechanism

- Granulating, scarifying, slitting

- Continuous Operation

- Yes

- Adjustable Components

- Gate, feed roll, stripper plate

- Easy Clean-up

- Simplified design for maintenance

- Uninterrupted Production

- Continuous operation

- Operation Type

- Continuous

- Particle Size Adjustment

- Through gate, feed roll, and stripper plate

- Cleanability

- Easy cleanup and maintenance

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Nuts

- Almonds, Pecans, Pistachios, Walnuts

- Confectionery

- Cookies, Crackers

- Fruits

- Blueberries, Cranberries, Raisins

- Vegetables

- Peas

- Machine footprint

- 40.30" x 26.57" x 30.21" (1024 mm x 675 mm x 767 mm)

- Net Weight

- 450 lb (204 kg)

- Adjustable components

- Gate, Feed Roll, Stripper Plate

- Control panel type

- None

- Adjustable gate

- Yes

- Adjustable feed roll

- Yes

- Adjustable stripper plate

- Yes

- Granulation size range

- 3/32 to 3/8" (2.4 to 9.5 mm)