Modular system for chocolate drops production

Enhance your chocolate production with a versatile machine that forms and cools a variety of chocolate shapes and sizes efficiently, ensuring seamless integration into your existing production line for optimal flexibility and customization.

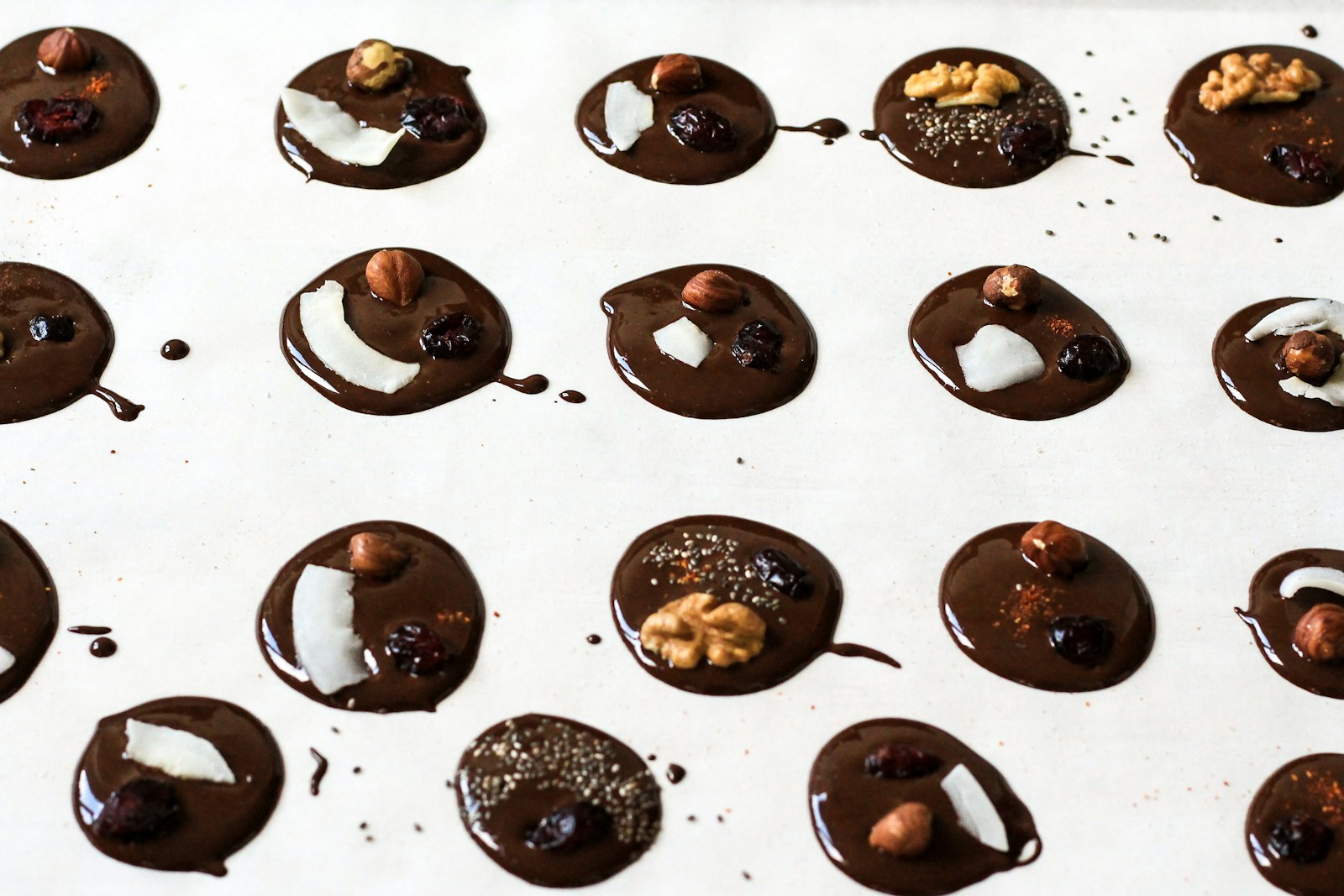

Forms and Cools Chocolate Drops and Decorations

The NRJ DROPS from Prefamac Chocolate Machines is a modular system tailored for producing chocolate drops and decorative patterns. Its unique design allows seamless integration into your production line, handling forming, cooling, and decorating processes efficiently. With its customizable execution in pearled stainless steel, the NRJ DROPS caters to diverse applications like chocolate pearls, nut clusters, and zigzag chocolate decorations. Available in widths of 400, 800, 1200, and 1600 mm, it meets various production scales. The PLC-controlled system simplifies operation, allowing rapid changeovers by adjusting a single parameter, ensuring uninterrupted production as long as the chocolate type remains consistent. Prefamac’s focus on continuous operation and tailored solutions ensures that the NRJ DROPS adapts to your production needs, offering robust flexibility for future expansions.

Benefits

- Maximizes production flexibility with modular design for various chocolate formats.

- Reduces changeover time to zero, enhancing operational efficiency.

- Supports future expansion, maintaining investment value with modular enhancements.

- Customizable configurations provide tailored solutions, optimizing integration into existing lines.

- Built with durable pearled stainless steel for longevity and hygiene in food production.

- Applications

- Nut clusters, Biscuits, Snacks, Confectionery, Sweets, Chocolate

- End products

- Chocolate pearls, Zigzag patterned chocolate decorations, Flat chocolate drops, Nut and chocolate clusters, Moulded confectionery, Chocolate drops, Decorative chocolate patterns

- Steps before

- Chocolate melting, Mixing, Tempering

- Steps after

- Cooling, Packaging, Decorating

- Input ingredients

- chocolate

- Output ingredients

- chocolate drops, pearled chocolate, customized chocolate patterns, flat chocolate drops

- Market info

- Prefamac is known for manufacturing high-quality chocolate processing equipment, including tempering, enrobing, and cooling machines. The company is recognized for innovative and custom-engineered solutions tailored to the confectionery industry, emphasizing precision, efficiency, and reliability.

- Capacity

- Determined by desired output and machine width

- Machine Width

- 400, 800, 1200, 1600 mm

- Automation

- PLC-controlled

- Cooling Adjustment

- Variable based on application

- Material

- Pearled stainless steel

- Changeover Time

- 0 (no switching time with same chocolate type)

- Electricity

- 220-240V 50Hz or 380-420V 50Hz

- Customizability

- Tailor-made based on customer requirements

- Drop Formation

- Flat or patterned

- Changeover time

- Reduced to 0

- Automation level

- PLC

- Batch vs. continuous operation

- Batch

- Customization

- Tailor-made

- Cooling option

- Variable based on application

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- End Product Variety

- Multiple Sizes/Formats

- Machine Width

- 400, 800, 1200, 1600 mm

- Material

- Pearled Stainless Steel

- Customization

- Tailor-made

- Cooling Flexibility

- Determined by applications

- Control System

- PLC-controlled

- Output Configuration

- Flexible Formats

- Changeover Time

- Reduced to 0

- Cooling Adaptability

- Based on user needs

- Control panel type

- PLC

- Machine width options

- 400, 800, 1200, 1600 mm

- Material

- Pearled stainless steel

- Changeover flexibility

- Parameter Entry

- Cooling configuration

- Customizable based on application

- Product output customization

- Variety in drop sizes and weights

- Future application extension

- Modular upgrades