Dosing equipment

Find innovative dosing equipment and connect directly with world-leading technology suppliers

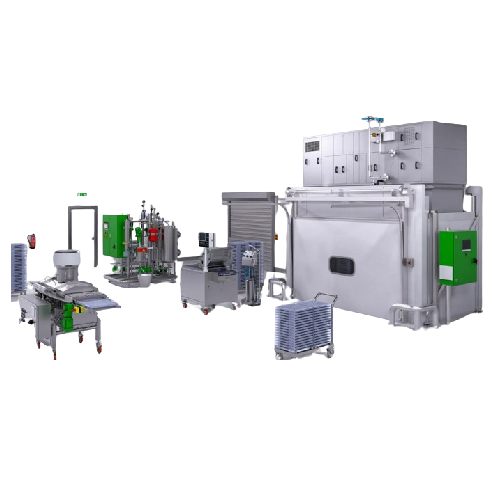

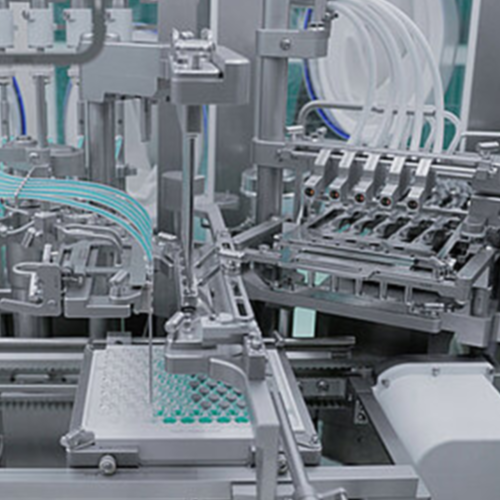

Dosing systems are a line of hoppers, feeders, filling machines, and checkweighers that operate in sync to dispense materials accurately. Dosing is an essential feature of the packaging process, whether you’re filling shampoo bottles or tea bags. But dosing equipment is critical for formulations, too, particularly in the pharmaceutical and chemical industries. Imprecise dosing may cause quality degradation in the best-case scenario. In the worst scenario, it creates serious health risks.

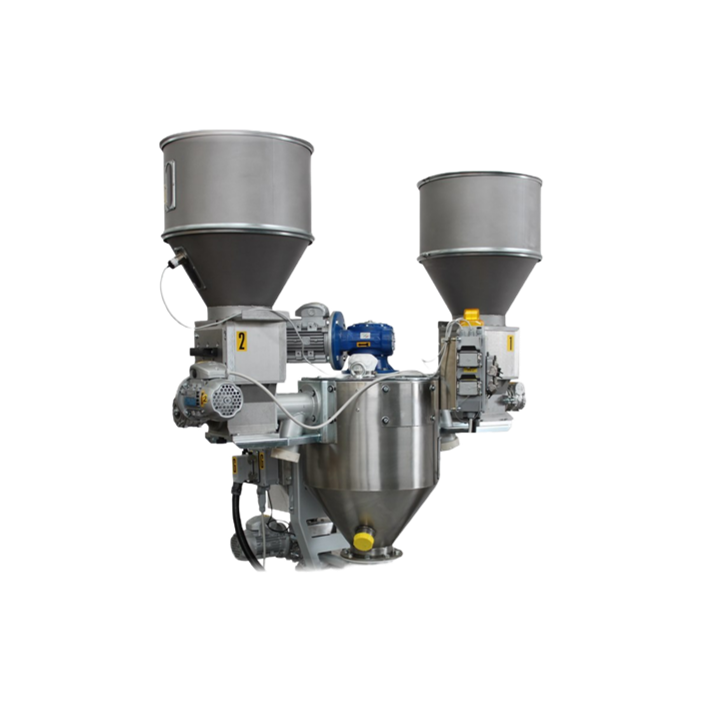

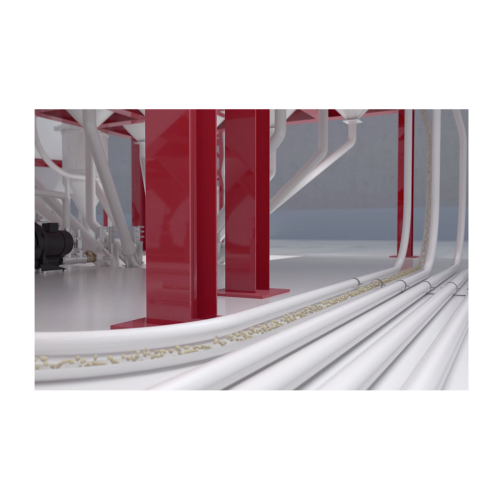

Volumetric dosing technology integrates into continuous lines

Volumetric dosing pumps the material at steady intervals. Based on the dispersion principle, volumetric dosing equipment relies on a pre-calculated timeframe to move the mixture.

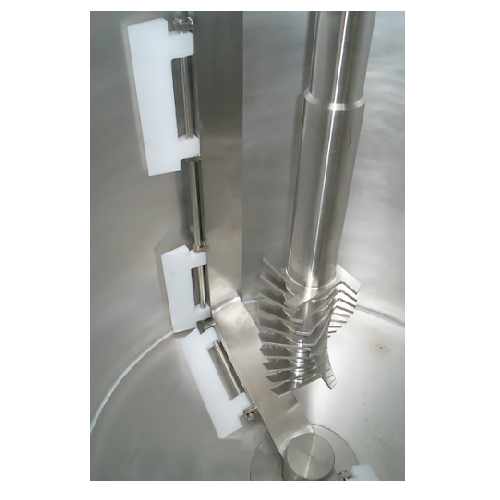

For example, if a drug in a liquid phase takes 10 seconds to reach the desired concentration, your dosing system will be configured to displace the mixture at that rate. Volumetric dosing technology is suitable for continuous processes. However, the revolving screws that move the mixture may subject the ingredients to unwanted pressure or fluidization.

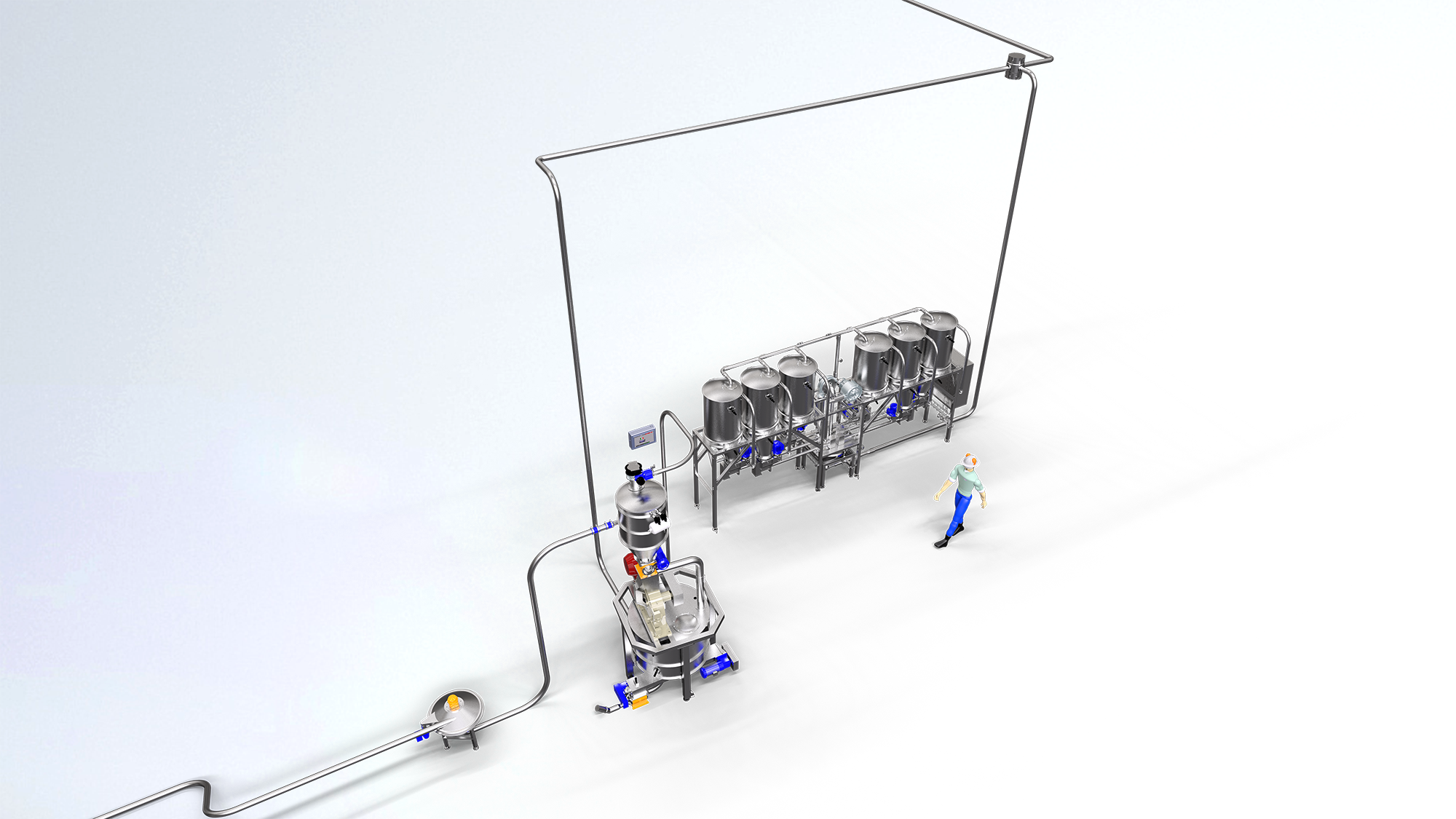

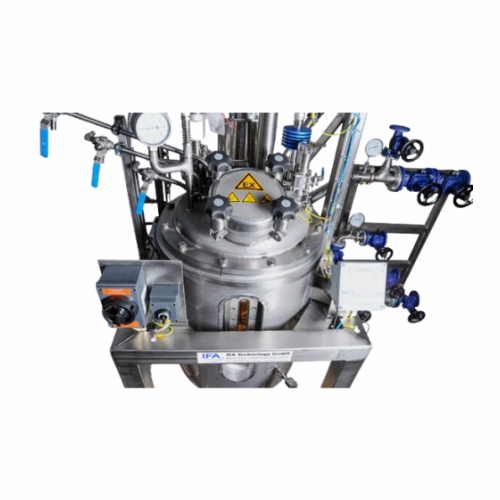

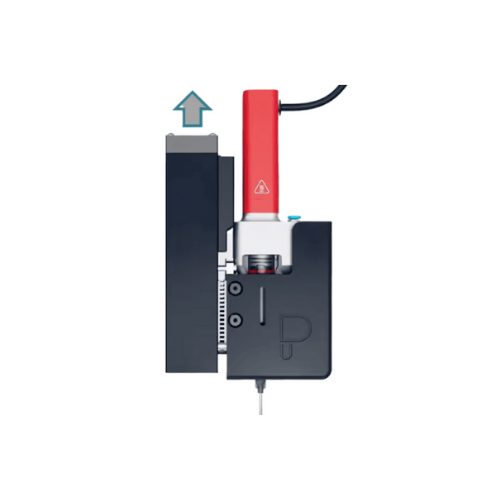

Use gravimetric dosing equipment when accuracy is more pressing

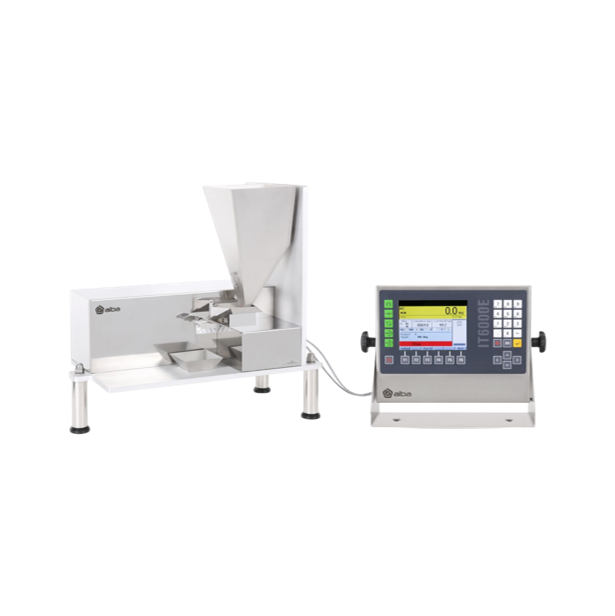

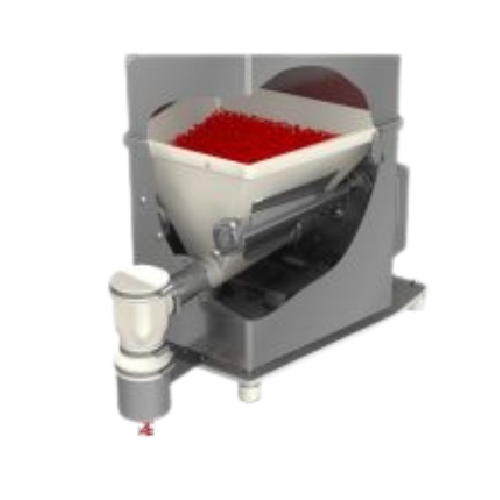

The gravimetric dosing technique is also known as loss-in-weight system because the feeder determines the dose based on the change in load. This mechanism is self-calibrated, and the dosing can be as accurate as the sensitivity of the check weigher unit, down to the slightest gram.

One of the drawbacks of gravimetric solutions is that the process must be stopped during refilling, so the dosing equipment typically fits batch production.

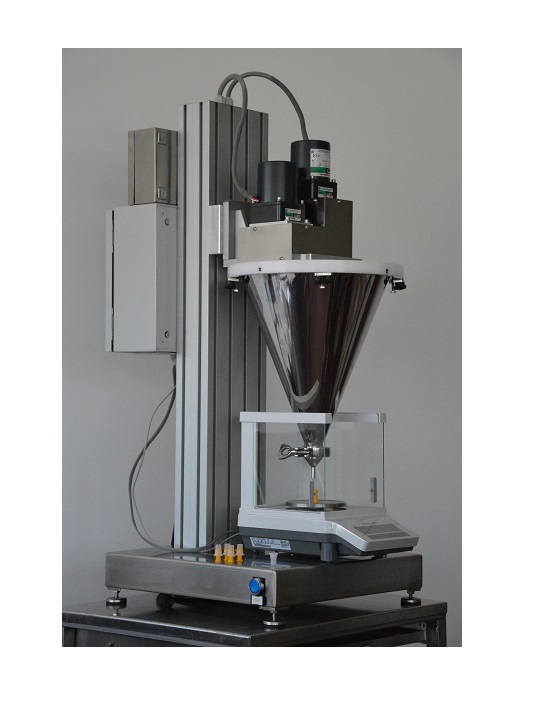

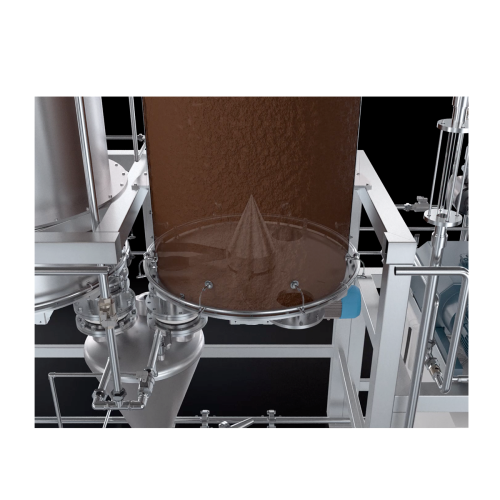

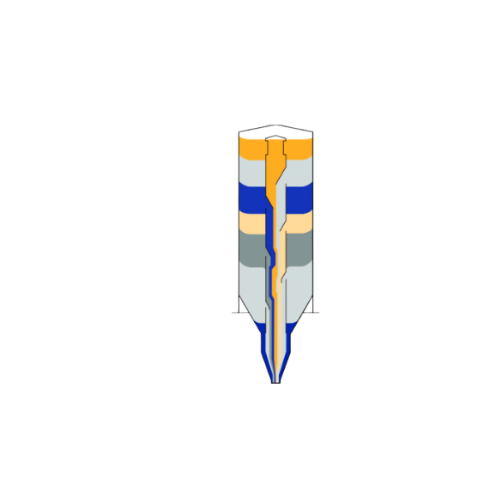

Microdosing solutions are suitable for highly-concentrated materials

Some product formulations are especially sensitive to the concentration of ingredients. Pharmaceutical formulations with high-potency API, for example, risk destabilizing the composition if not properly dosed.

The finer the particles of the material, the higher their concentration. Microdosing solutions account for these subtle changes by applying gravimetric methods to ultra-light masses counted in milligrams.

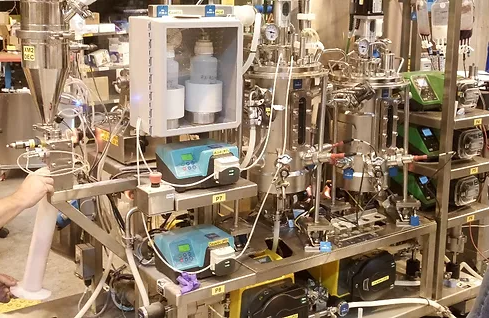

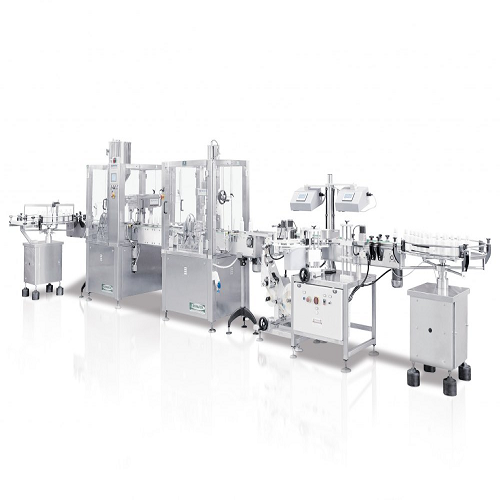

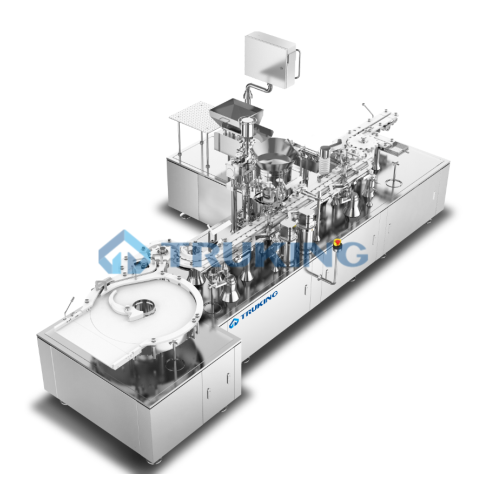

Integrate a flow meter with the dosing system for liquid materials

Dosing equipment products are set up differently from technology made for powder dosing. Besides a dosing pump that moves the liquid at pre-defined intervals, the machinery integrates a flow meter to measure the quantity of liquid dispersed.

Some liquids, like beverage mixtures or cosmetic formulations, may develop air bubbles that alter the dosing process. The sensor system in a flow meter detects these distortions before the liquid is pumped into the filling station or further processing.

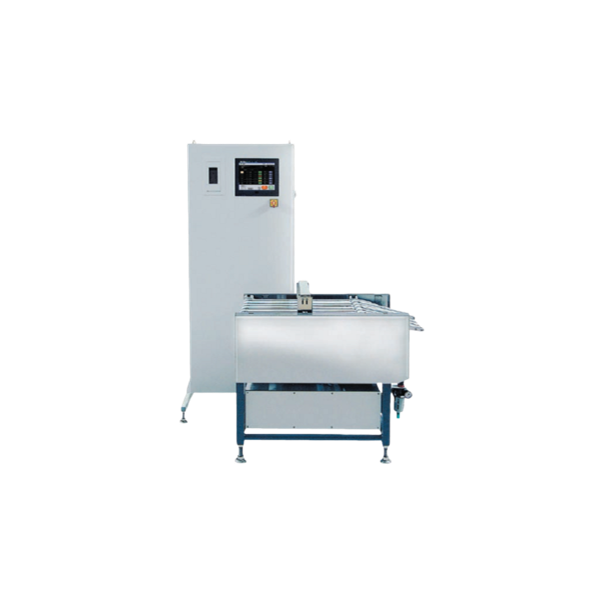

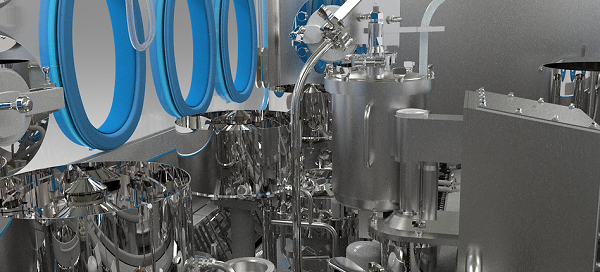

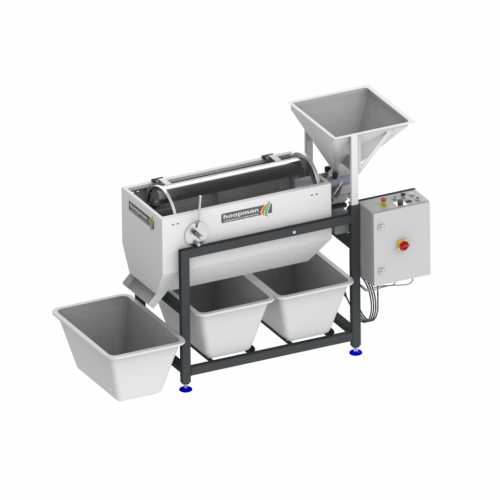

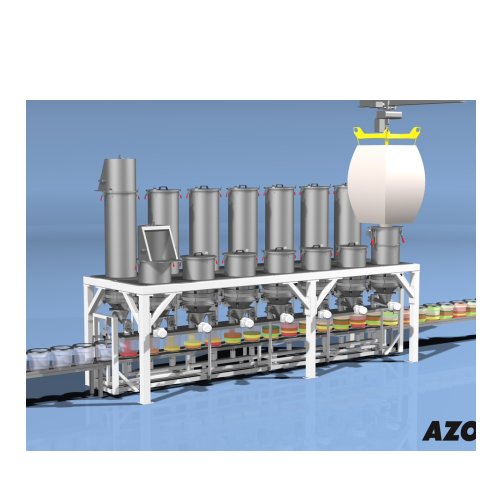

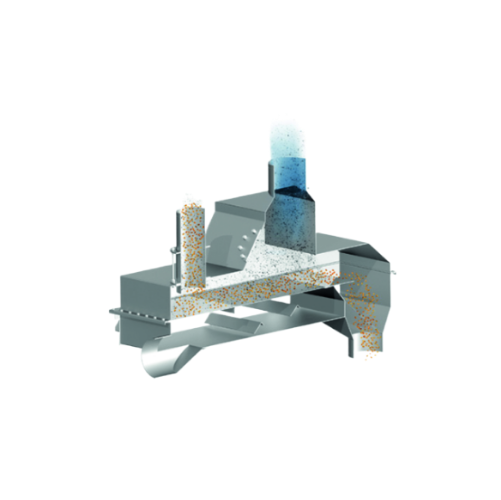

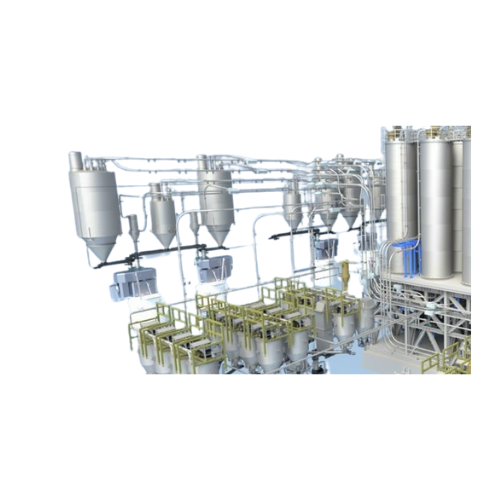

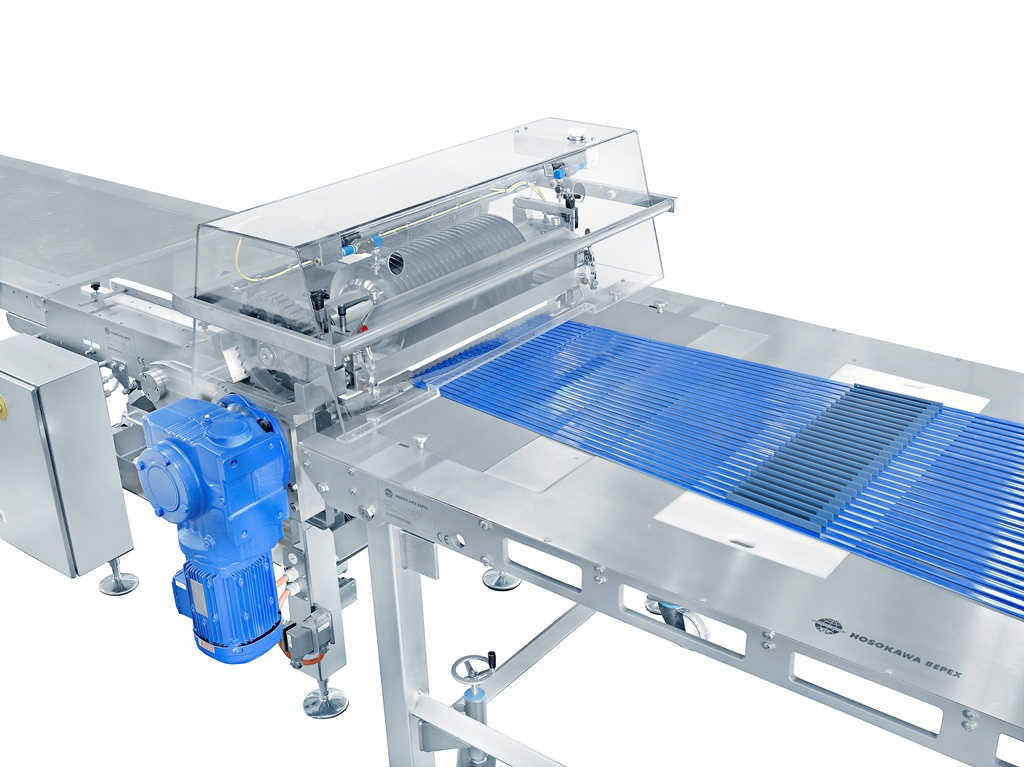

Combine gravimetric and volumetric techniques to dose powders

Flowability is a primary challenge when manufacturing powder products. Dosing systems for powders must ensure that particles do not stick to the equipment and maintain a steady flow. While volumetric technology drives the material homogeneously, it lacks the self-regulating calibration of gravimetric methods.

Combining the two techniques, integrated dosing systems overcome the flowability problem without compromising dosage accuracy. At the same time, this solution allows continuous processing.

What are you making?

Active pharmaceutical ingredients (API)

Almonds

Ampoules

Antibiotics

Batter

Battered nuts

Beer

Bioplastics

Black pepper

Cannabis candy

Cannabis edibles

Cannabis seeds

Caramel

Carbon black

Cement

Chewable tablets

Chewing gum

Chili powder

Coffee capsules

Cold and flu tablets

Concrete additives

Concrete admixtures

Concrete mixtures

Corn nuts

Crackers

Cultivated meat

Curry powder

Cytotoxic drugs

Decaffeinated coffee

Deoderant

Dough

Dragees

Dry pet food

Dyes

Electrolyte drinks

Enteric Coated Tablets

Extruded aquafeed

Fabric softener

Face powder

Feed premixes

Fishmeal powder

Flax seeds

Floating pellets

Fondant

Food preservatives

Fruit puree

Ground cinnamon

Gummy Bears

Hard gelatin capsules

HPMC capsules

Ink

Laundry detergent

Licorice

Lip gloss

Lithium-ion batteries

Lotions

Margerine

Marmalade

Masterbatches

Mealworm protein

Medical gummies

Mineral water

Mixed nuts

Molasses

Mozzarella

Muesli

Multi-layer tablets

Nut butter

Ointment

Omega 3 oil

Ophthalmics

Pastries

Peanut butter

Peanuts

Pelleted feed

Pharmaceutical cartridges

Pharmaceutical granules

Pineapples

Pistachios

Popcorn

Potato chips

Powder detergent

Powder for suspensions (PFS)

Powdered drink mixes

Pre-filled Syringes

Pretzels

Probiotics

Protein powder

Recycled plastic

Salami

Serums

Shampoo

Shrimp crackers

Silicone

Slow sinking pellets

Solvents

Sulphur

Sunscreen

Tea

Toner

Truffle balls

Truffle cream

Tubes

Uncoated tablets

Vaccines

Veterinary tablets

Vials

Vitamin C

Vitamin gummies

Waffles

Water for injection

Wet pet food

Whey protein

Dosing pumps

Gravimetric Dosing Systems

Industrial checkweighers

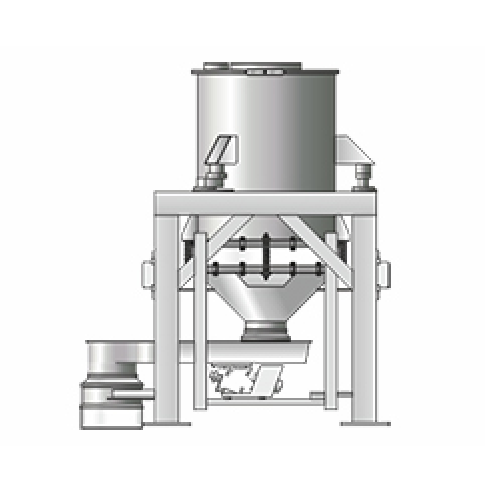

Industrial hoppers

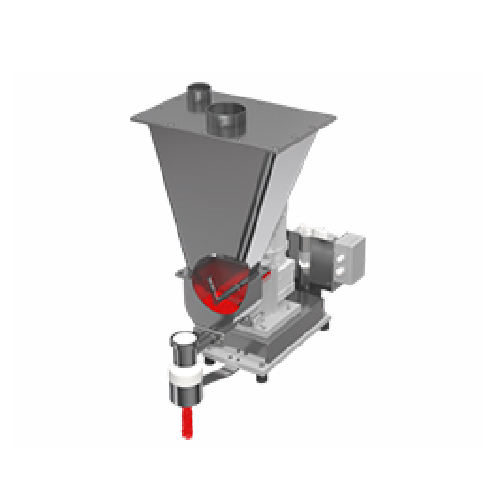

Loss-in-weight feeders

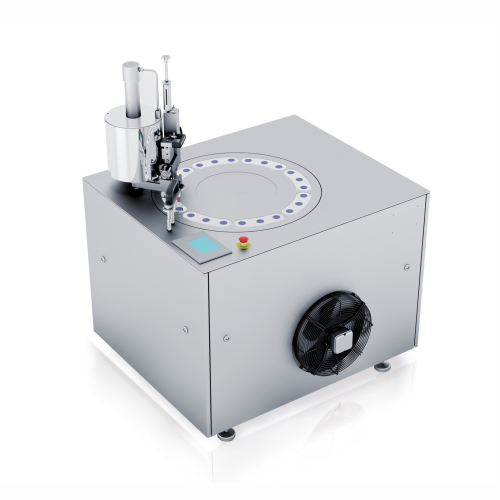

Micro dosing systems

Microdosing systems

Mono-dose strips filling machines

Multi piston depositors

Piston depositors

Pneumatic dosing machines

Powder auger fillers

Rotary dough feeders

Rotary feeders

Screw feeders

Twin screw feeders

Twin shaft feeders

Volumetric dosing systems

Volumetric feeders

Volumetric fillers

Which dosing technology do you need?

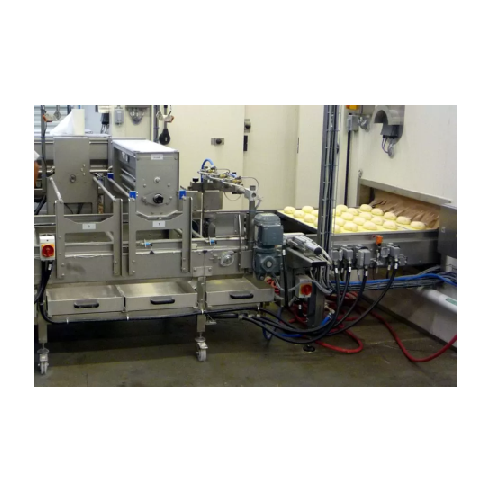

Automated milk dosing system for dairy production

Ensure precise milk allocation for diverse cheese types with this robus...

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Nuts dosing system for chocolate drops

Effortlessly create consistently accurate chocolate-covered nut products with precis...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Dosing system for chocolate tablets

Enhance your confectionery production with a versatile solution for precise dosing and ...

High accuracy micro dosing system

When handling diverse ingredients, precise dosing is crucial to ensuring consistent produ...

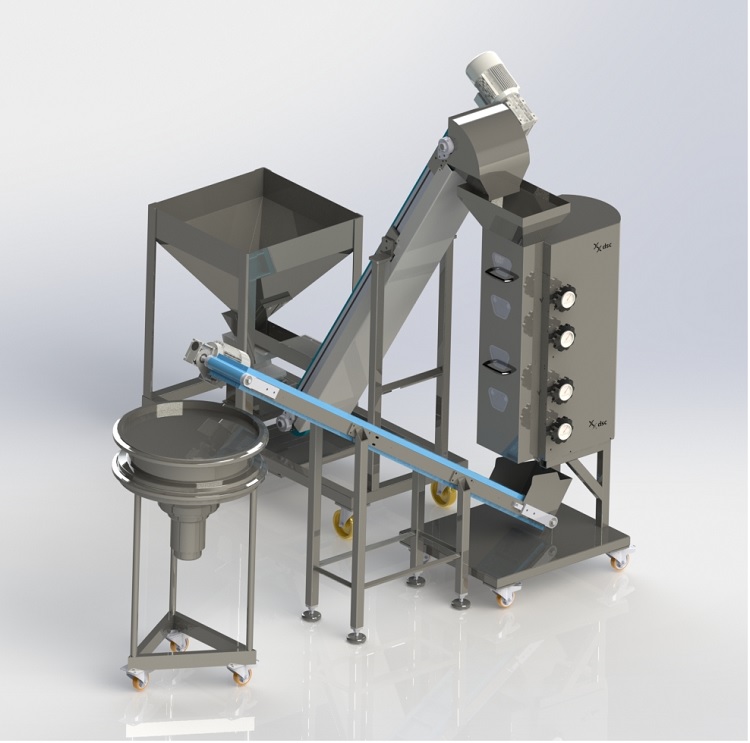

Micro-ingredient dosing system for animal feed production

Optimize your feed formulation accuracy with precision dosing,...

Vacuum pressure macro dosing system for dry syrups

Ensure precise dosage and minimal powder spillage with a high-speed va...

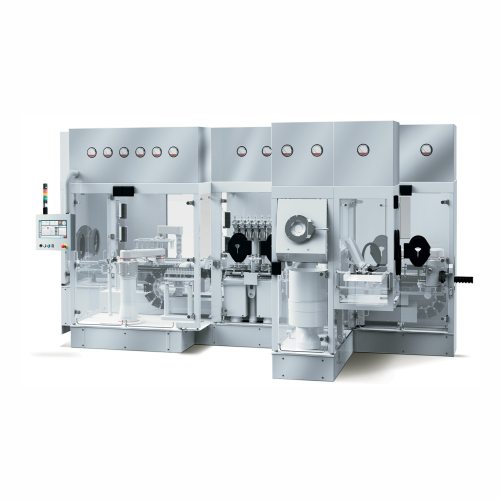

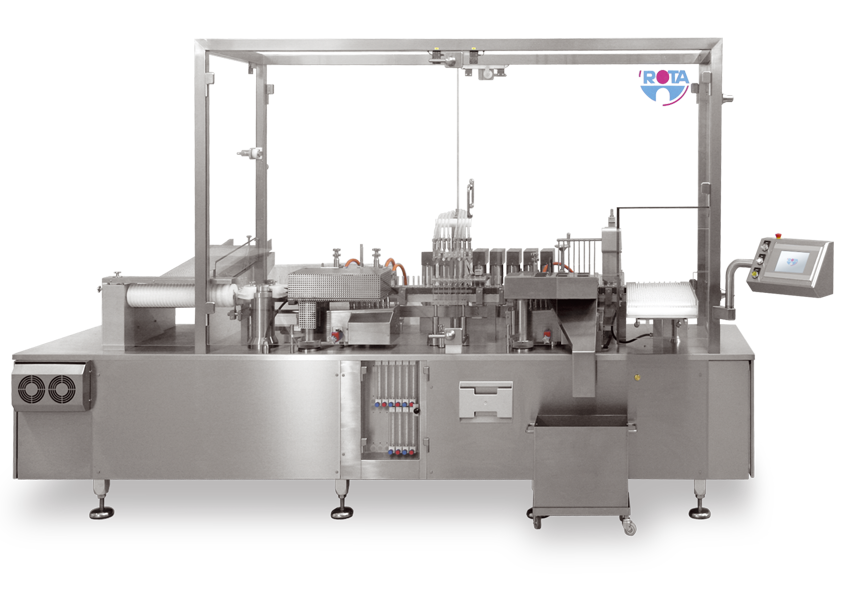

Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powder...

Continuous motion micro dosing system for nutraceutical powders

Streamline your powder processing with a high-speed, con...

Dual dosing and topping system for bakery products

Enhance your bakery’s production efficiency with advanced dosing...

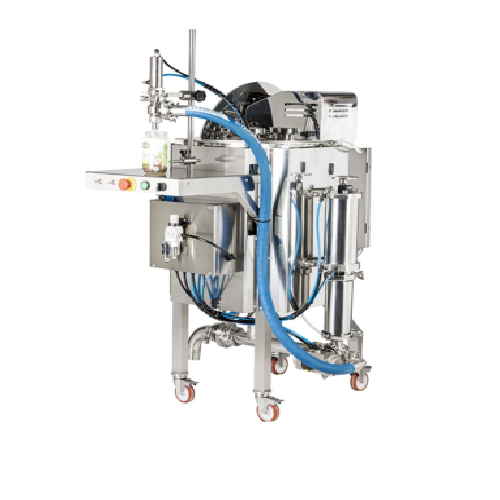

Professional dosing system for creams and sauces

Streamline your production with precise dosing of creams and sauces, tail...

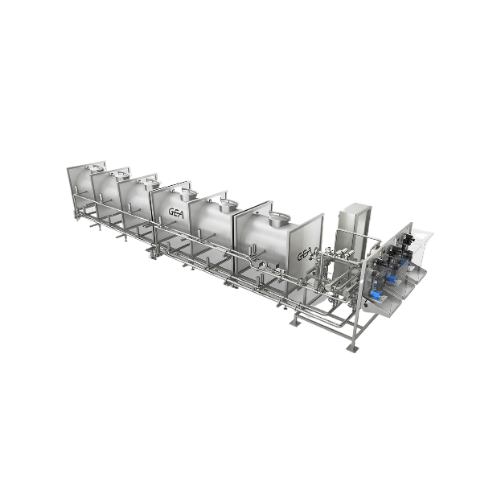

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Automatic dosing and packing system for cabbage and sauerkraut

Streamline your vegetable processing line with a robust, ...

Intelligent pre-dosing system for fruit juices

Optimize your beverage production by minimizing fruit piece damage and ensu...

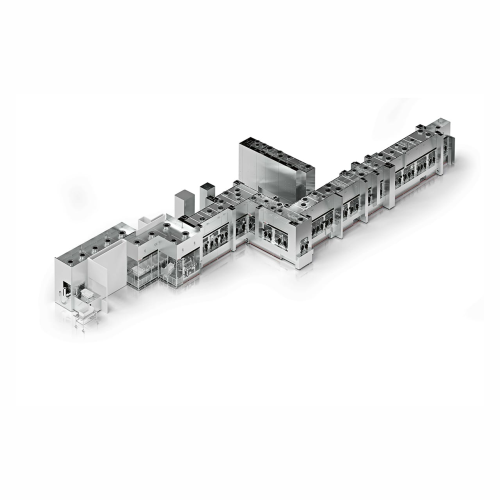

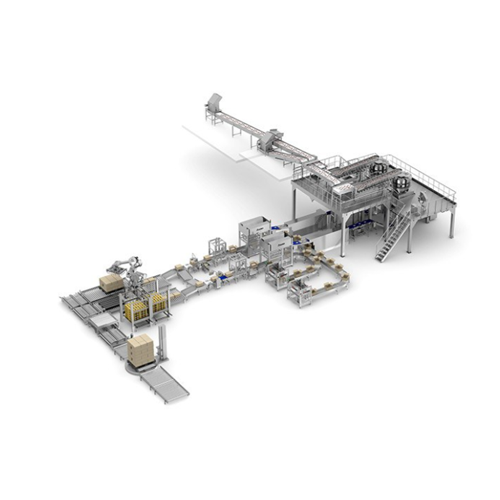

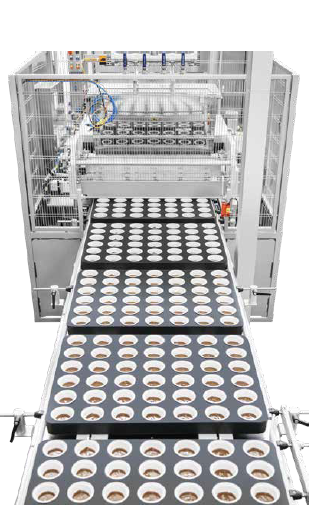

Dosing and tray handling lines for ready meals

Ensure precise dosing and seamless tray handling for a variety of ready mea...

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

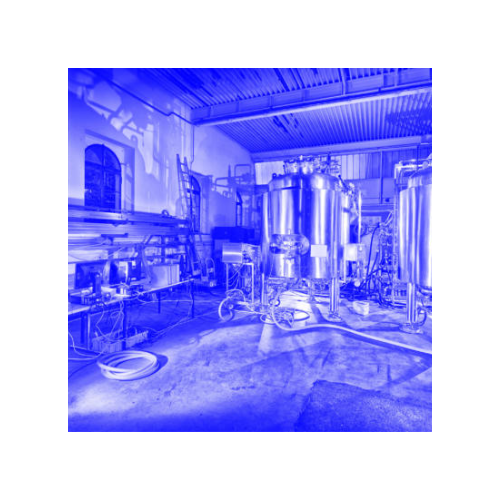

Dosing and blending system for beverage production

Enhance your beverage production with a flexible system capable of pre...

Hot-fill dosing system for soups and sauces

Efficiently dose hot soups, sauces, and porridges while ensuring workplace saf...

Hot-fill dosing system for soups and sauces

Ensure precise and efficient dosing of hot and cold liquid foods with integrat...

Automatic hot-fill dosing system for soups and sauces

Ensure consistent portioning and minimize occupational risks when h...

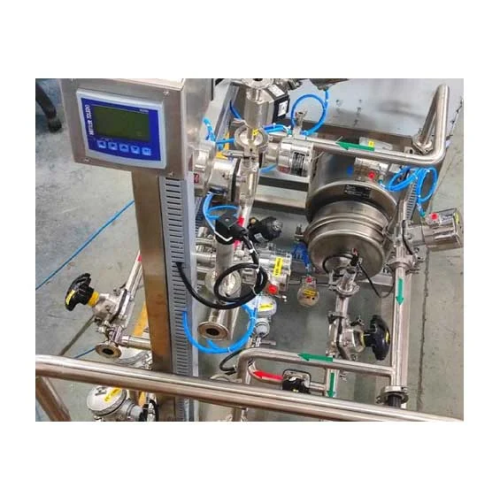

In-line additive dosing systems for beverages

Ensure precision and safety in beverage production by integrating in-line do...

Co2 dosing system for effervescent beverage bottling

For beverage manufacturers requiring precise carbonation, this solut...

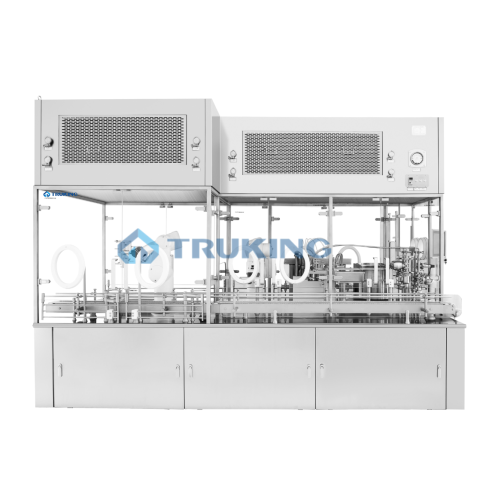

High speed powder dosing and stoppering for antibiotics

Address the threat of antibiotic-resistant bacteria with precisio...

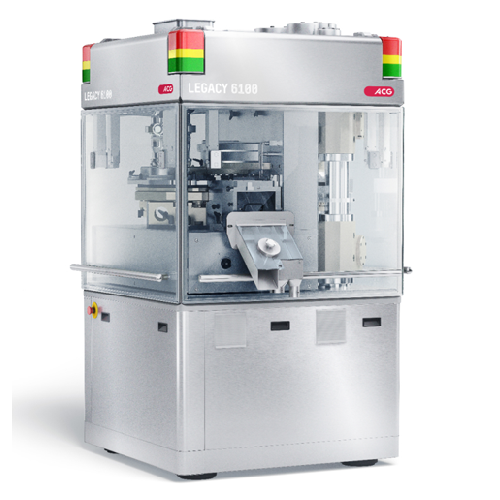

Pharmaceutical powder dosing system

Ensure precise dosing and contamination-free filling with this machine designed for eff...

Table-top capsule filler for micro-dosing

Achieve precise micro-dosing for pharmaceutical powders and pellets with a user-...

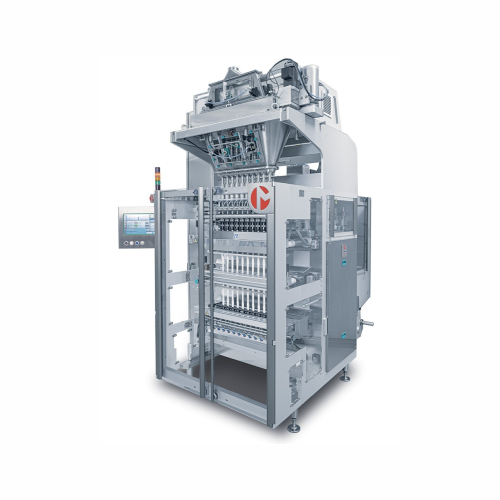

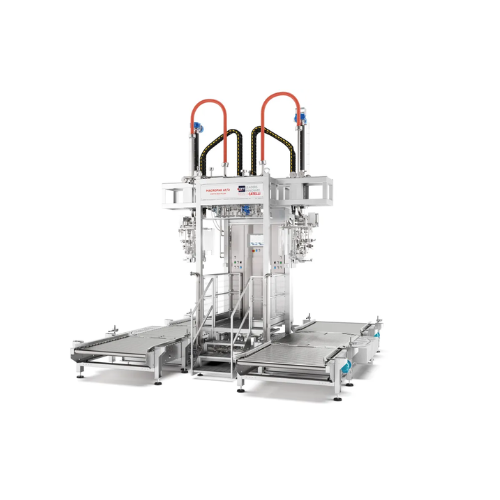

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Capsule filler for multi-product dosing

Achieve precision and flexibility in capsule filling with a system designed for hig...

Dosing and wrapping solution for pasty products

Achieve precise dosing and efficient wrapping of pasty products with high-...

Soup cube dosing and wrapping system

Ideal for high-speed production, this system precisely doses and wraps soup cubes, enh...

Cheese portioning dosing and wrapping solution

Effortlessly streamline cheese portioning with high-speed dosing and wrappi...

High speed cheese dosing and wrapping solution

Achieve precise dosing and efficient wrapping of cheese portions with versa...

High-speed dosing and wrapping for butter and margarine

Achieve precision in butter and margarine packaging with a high-s...

Butter portion dosing and wrapping system

Efficiently manage butter portion packaging with a compact system designed for p...

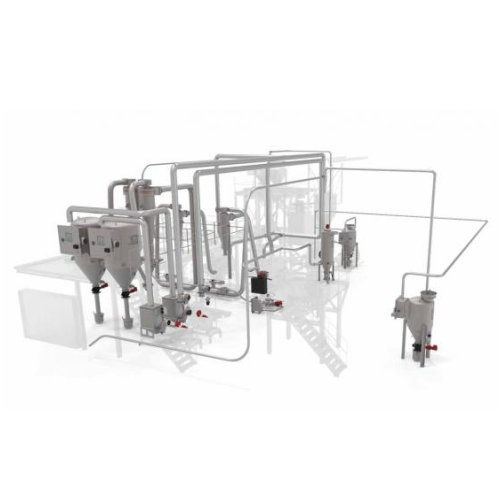

Green coffee storaging and dosing system

Optimize your coffee production with a flexible and modular solution designed for ...

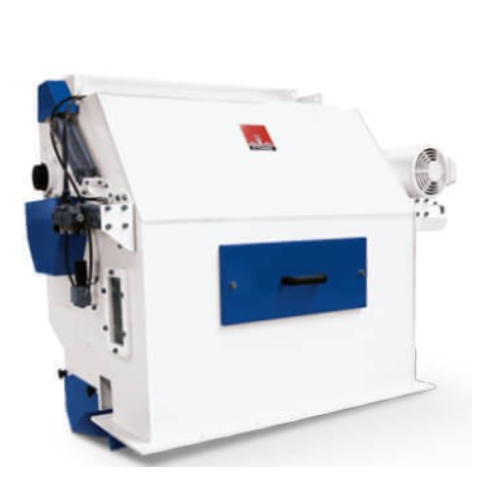

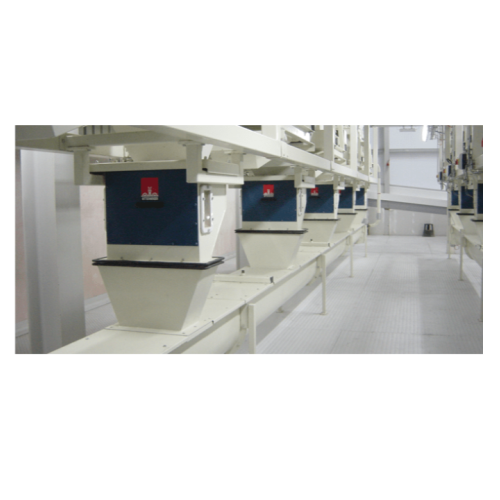

Gravimetric dosing systems for precise material measurement

Achieve precise material measurement with gravimetric dosing...

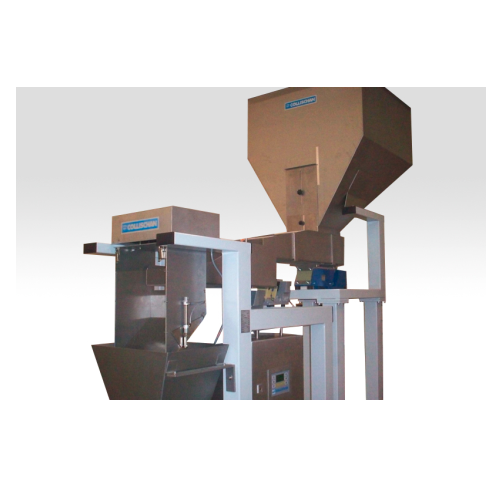

Powder dosing system for big-bags

Efficiently dose and fill various powdered materials directly from big-bags into your pro...

Double-stage rotary weigh feeder for precise powder dosing

Ensure consistent dosing and precise weighing of challenging ...

Rotary indexing table for dosing and assembly

Optimize production efficiency with a compact rotary indexing table that str...

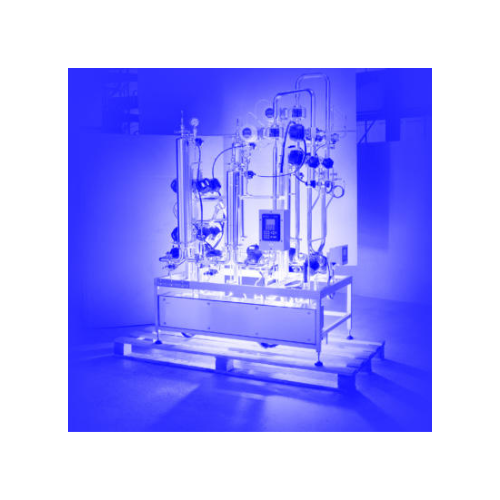

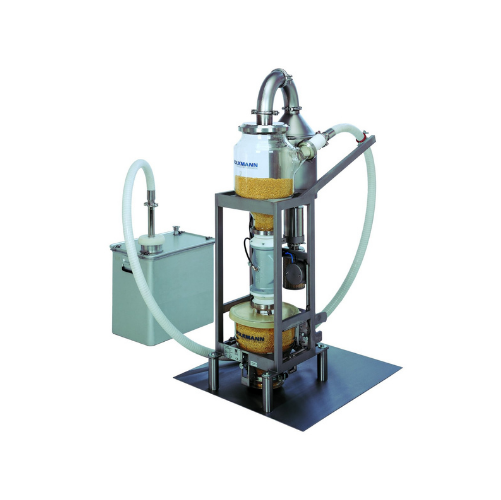

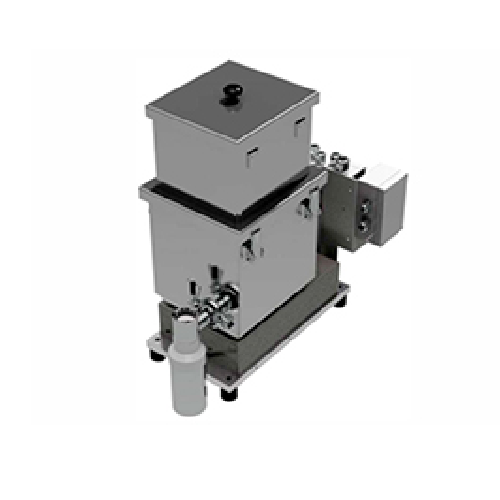

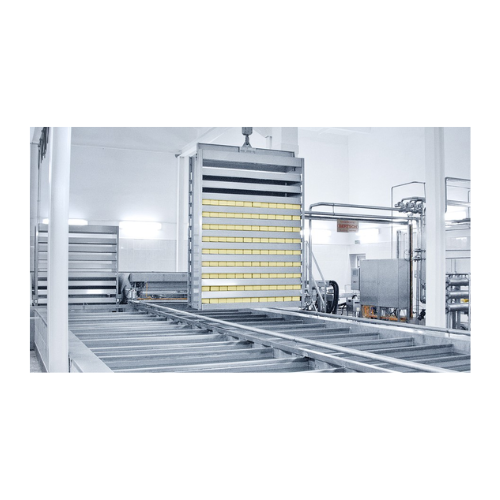

Powder dosing system for development and small batches

Streamline lab-scale pharmaceutical production with a versatile po...

Powder dosing machine for laboratory applications

Achieve precise powder dosing and streamline your R&D processes wi...

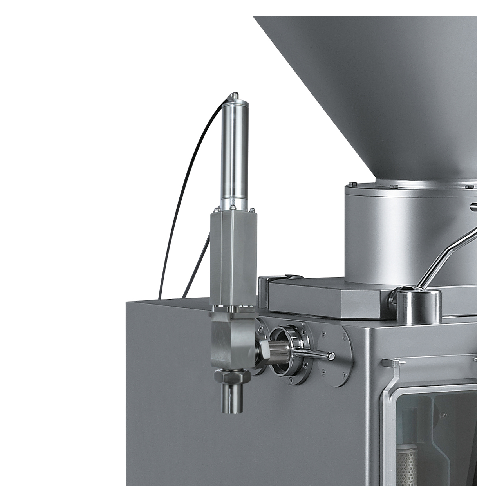

Auger dosing unit for powder dosing in pharmaceuticals

Ensure precise and flexible dosing of pharmaceutical powders with ...

Powder dosing for lab and galenics

Ideal for precise dosing needs, this compact lab device streamlines powder filling proce...

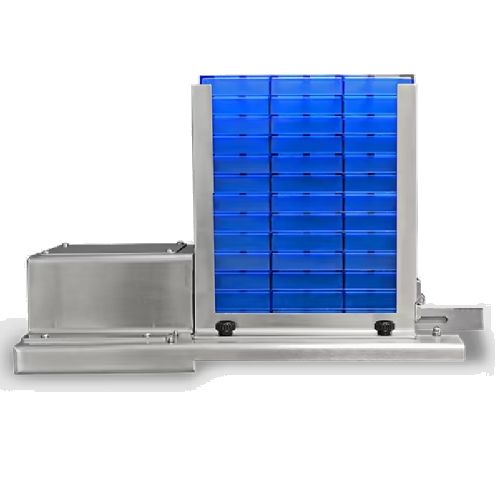

Micro-dosing system for inhalation blisters

Streamline your inhalation product production with precision micro-dosing, for...

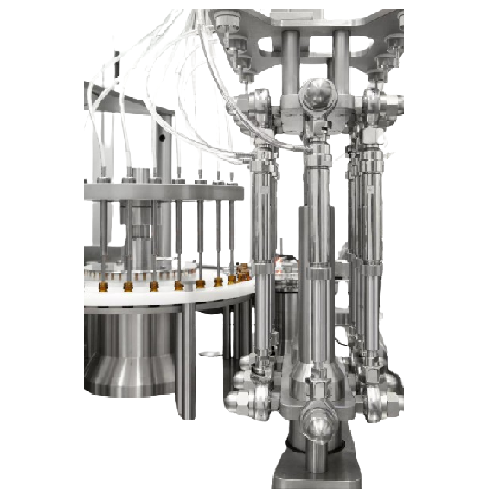

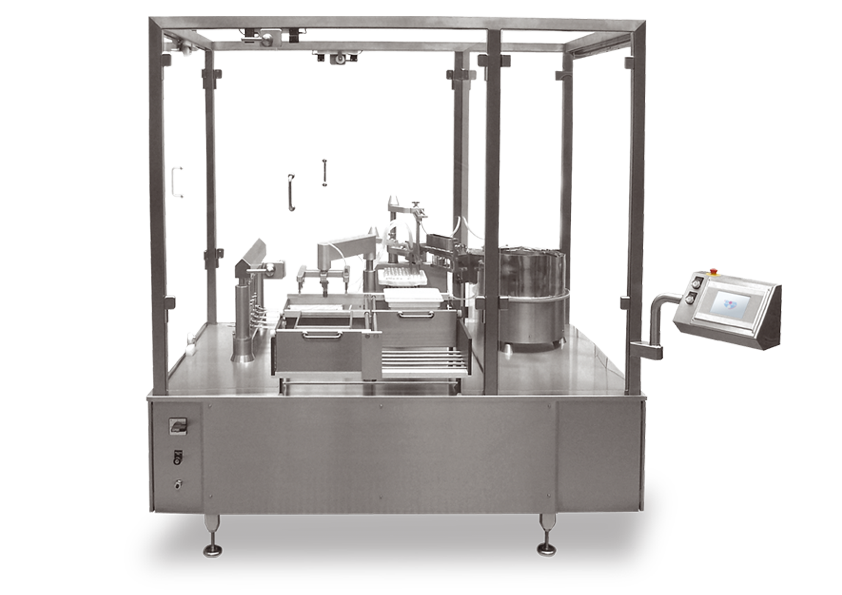

Liquid dosing and assembly platform for pharmaceutical products

Optimize your production line with a seamless solution f...

High-containment capsule dosing and filling system

Achieve precise dosing and optimal containment for pharmaceutical prod...

Semi-automatic powder dosing system

Achieve precise micro-dosing for pharmaceutical powders with a flexible system ideal fo...

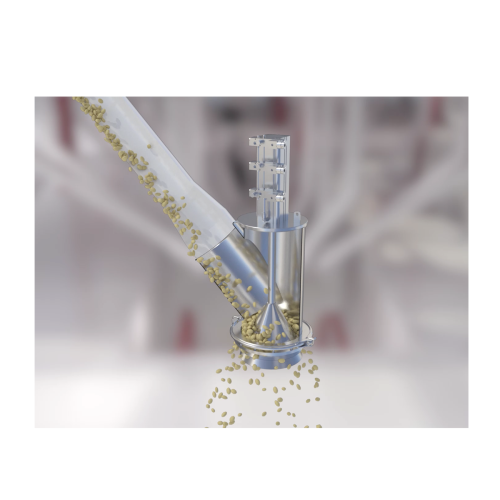

Lyophilized pellet dosing technology

Eliminate mechanical strain and static charge in your lyophilized pellet dosing proces...

High-accuracy rotary dosing valve for fine material feeding

Ensure precise dosage of fine powders and granules, enhancin...

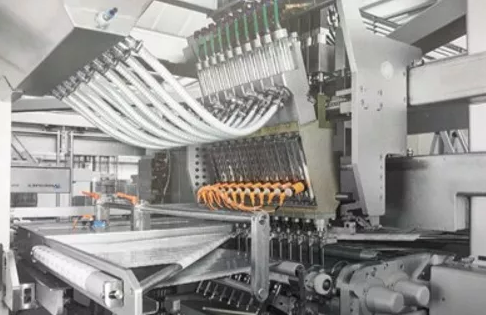

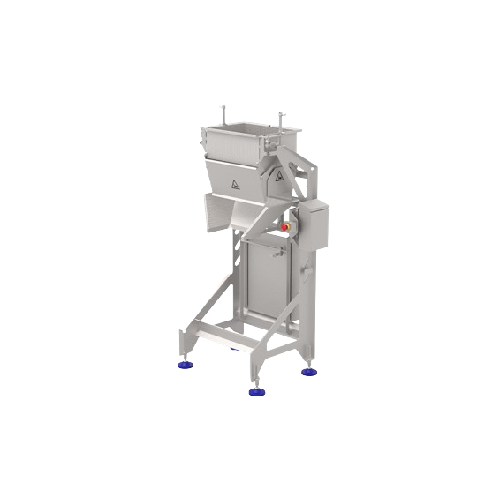

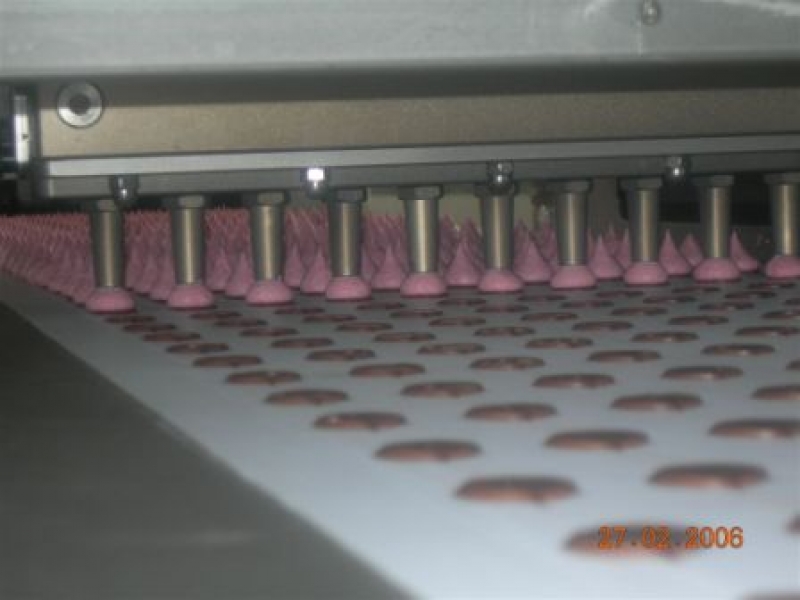

Depositing system for multi-lane dosing with vertical traversing

Achieve precision dosing and flexible portioning with t...

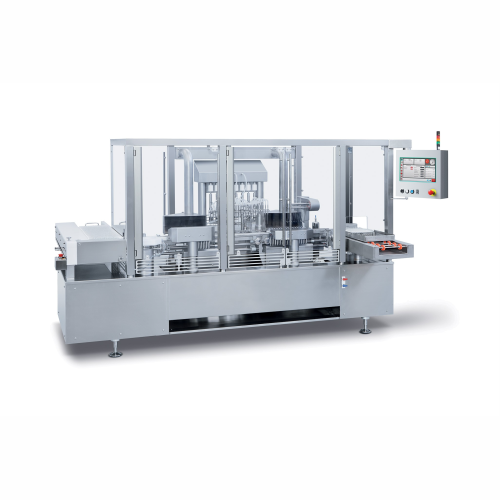

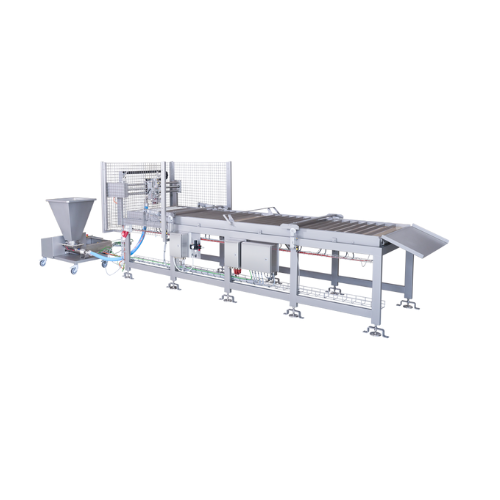

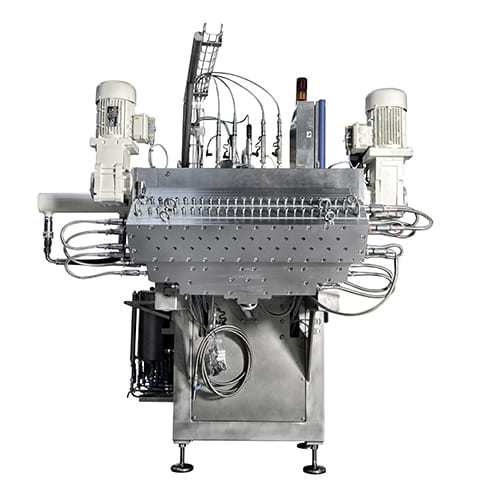

Automatic multi-lane dosing system for fluid to pasty products

Streamline your production with precise multi-lane dosing...

Precise dosing valve for pasty products

Achieve precise, gram-accurate dosing for a wide array of pasty and semi-viscous pr...

Dosing unit for automated mixing in of ingredients

Achieve precise ingredient integration for confectionery and nutraceut...

Additive mixing and dosing system for potato flakes

Achieve precise flavor and texture in potato flakes with this system,...

Servo-driven dosing and portioning system

Optimally dose and portion a wide range of food products with precise weight acc...

High precision dosing system for color, flavor, and acid

Achieve precision and reliability in dosing color, flavor, and a...

Precision ointment filling and dosing system

Achieve precise filling of liquid formulations with a versatile system capabl...

Carbonation system for Co2 dosing in beer production

Achieve precise carbonation in every beverage batch with seamless CO...

Automatic aroma and sugar dosing system for breweries

Effortlessly achieve consistent flavor profiles and precise sweetne...

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Liquid dosing system for powders and granulates

Achieve precise liquid addition with this dosing system, ideal for integra...

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

Combination cooker-dosing kit for food packaging

Optimize your small-scale food production with seamless cooking-to-packag...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

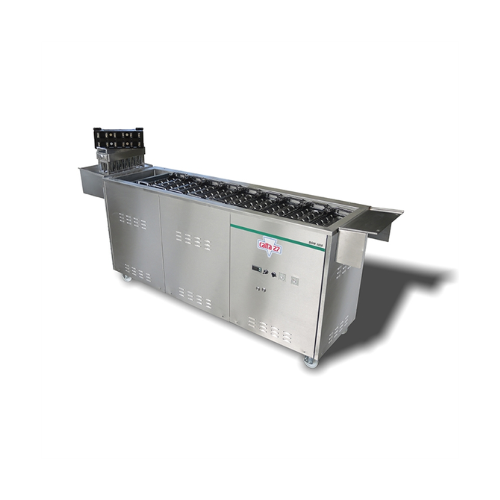

Semi-automatic dosing table for ice cream cups and bulks

Ensure consistent and precise dosing for various ice cream produ...

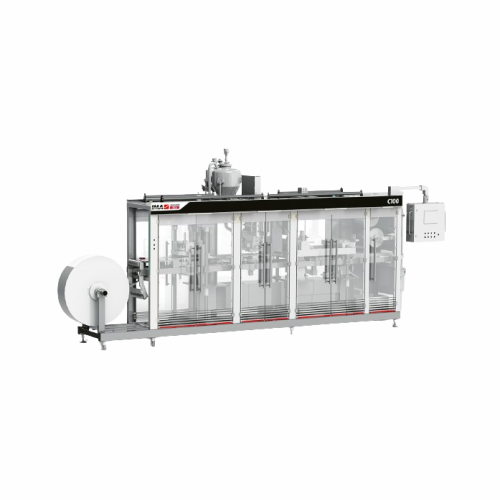

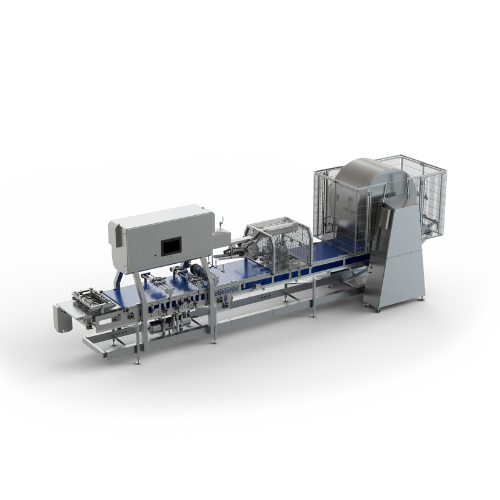

Continuous motion powder dosing system

Ensure precise dosing of pharmaceutical and nutritional powders with this continuous...

Intermittent motion powder dosing and capping system

Ensure precise powder dosing and secure capping in one seamless step...

Dosing unit for semi-automatic filling and packaging extension

Streamline your filling operations with this dosing unit,...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Micro-dosing system for animal feed additives

Achieve precise and consistent feed formulation with high-precision micro-do...

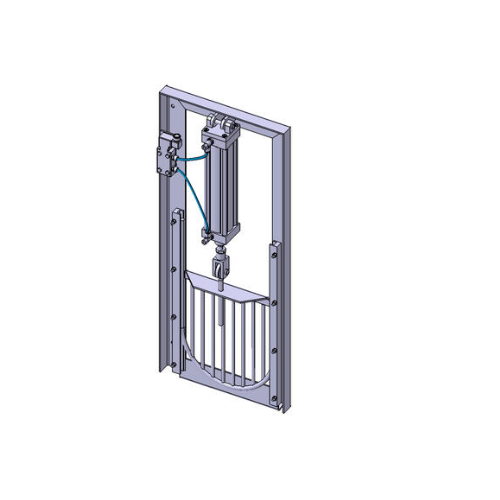

Pneumatically controlled dosing slide for pome fruit silos

Ensure consistent and controlled fruit discharge in your proc...

Claryfing agent dosing station for beverage production

Ensure precise clarifying agent dosing in beverage production with...

Crunching and dosing solution for frozen fruits and vegetables

Streamline your processing line with a versatile system d...

Advanced powder dosing system for continuous production

Achieve precise powder integration into your liquid processes, en...

Dust-tight docking for dosing units to bulk solids containers

Ensure seamless, dust-free transfer and dosing of bulk sol...

Cost-effective dosing container for minor ingredients automation

Optimize your production by streamlining ingredient han...

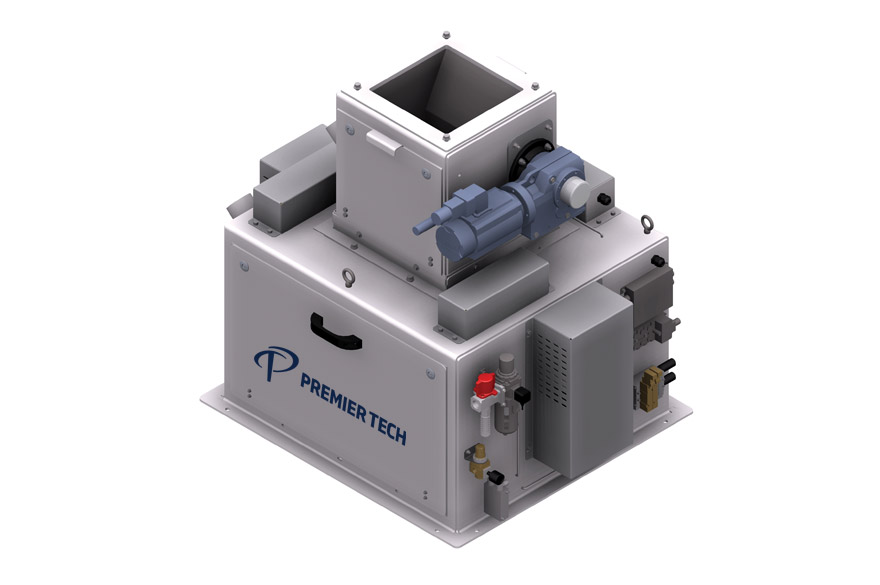

Precise dosing system for bulk materials

Ensure precise bulk material dosing with minimal dust, seamlessly switching betwee...

Accurate dosing for powder products

Ensure precise dosing and consistent flow of bulk powders in your production line to en...

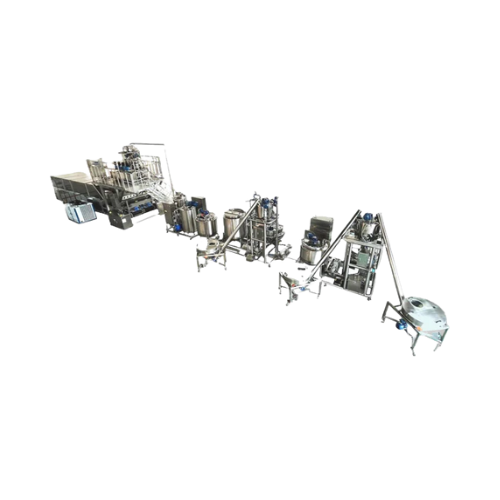

Feeding, dosing, weighing and mixing system for granulate

Achieve precise granulate mixing and rapid color changes with ...

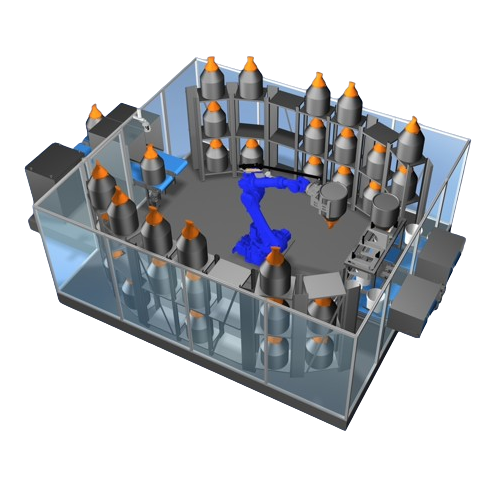

Robotic dosing system for accurate micro quantities

Achieve precise and reproducible micro dosing of challenging raw mate...

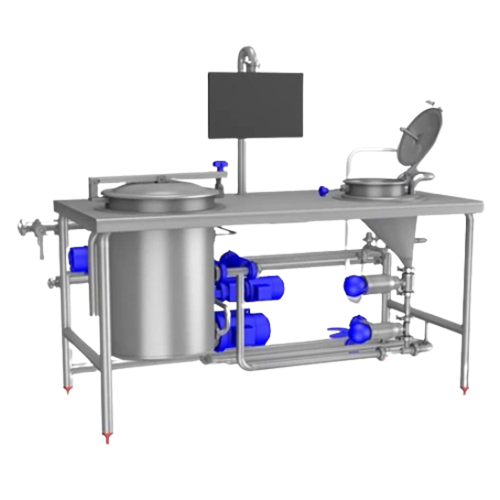

Water mixing and dosing unit for dough production

Achieve precise dough temperature control effortlessly, ensuring consis...

Pneumatic dosing system for dense and semi-dense products

For precise dosing of dense and semi-dense liquids, this pneum...

Pneumatic dosing system for dense and semi-dense products

Easily handle dense and semi-dense products with precision dos...

Modular dosing system for brewing and beverage industry

Ensure precise formulation of beverages by seamlessly integrating...

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

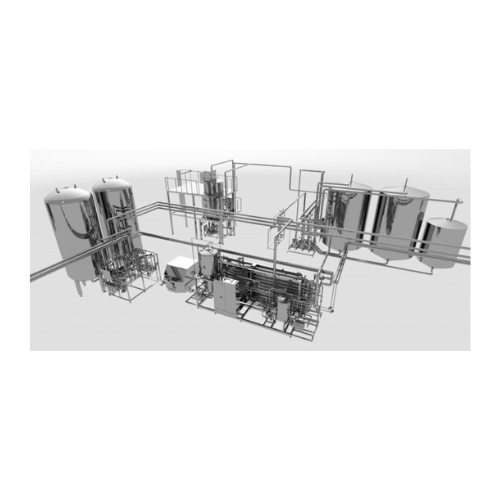

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

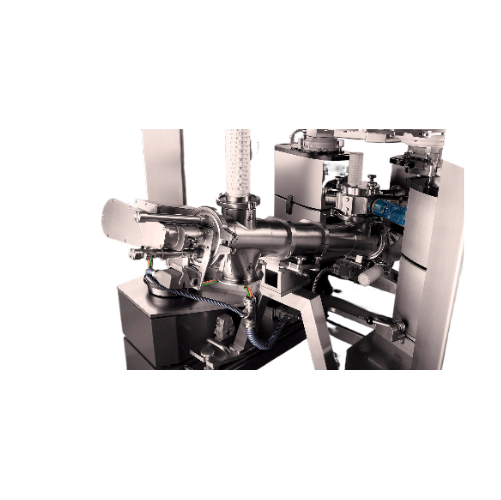

Continuous dosing and blending for pharmaceutical powders

Optimize your pharmaceutical production with precise dosing an...

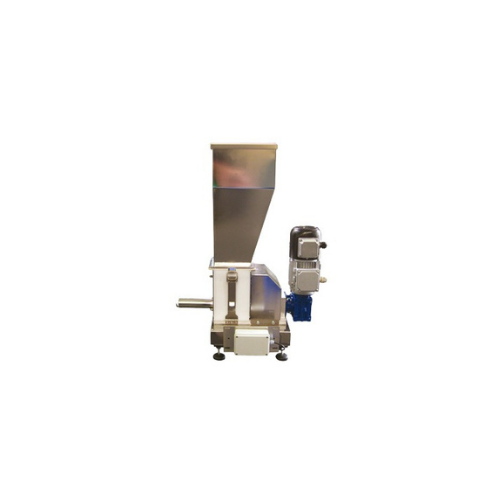

Industrial screw pump for dosing hard fillings

Enhance precision and efficiency in dosing hard fillings with a robust scre...

Creamy filling dosing system

Effortlessly dose creamy fillings into your production line with precision, ensuring chunk size...

Aseptic liquid dosing system

Ensure precise, sterile dosing of aseptic liquid products, enhancing product integrity and exte...

Precise discharge and dosing module for silos and containers

Ensure seamless material flow and accurate dosing with adva...

Industrial discharge and dosing module

Optimize material flow and prevent blockages in silo discharge and dosing processes,...

Liquid additive dosing system for industrial mixers

Achieve unparalleled precision in liquid ingredient integration with ...

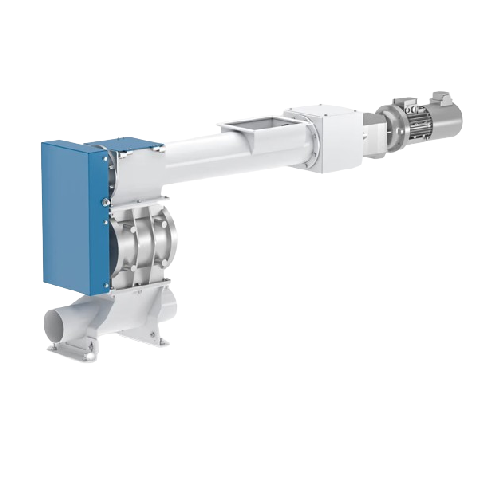

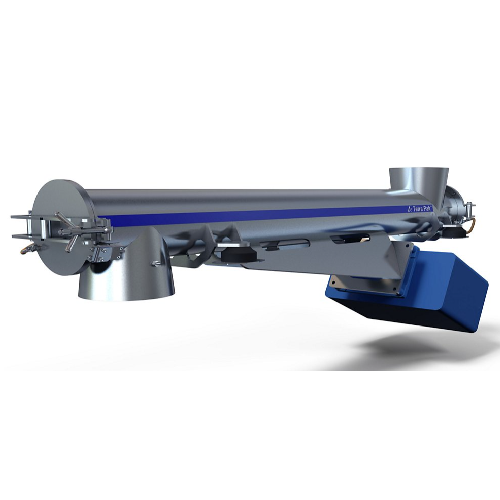

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Industrial lye dosing system with peelboard

Ensure consistent, high-quality lye coating for baked goods with a rapid, modu...

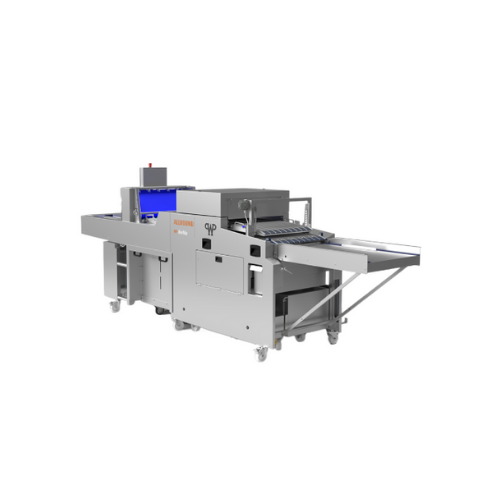

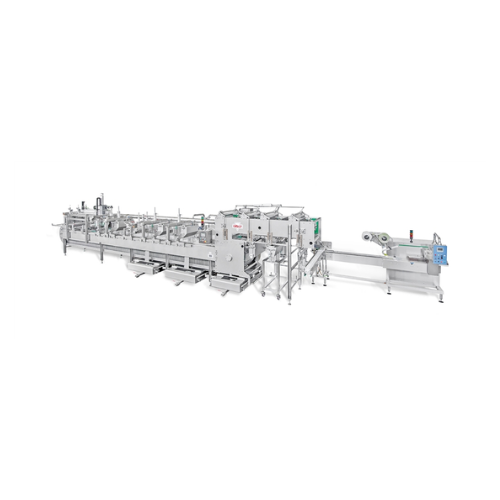

Automatic lye dosing system for pretzel production

Enhance your bakery’s efficiency with a lye dosing system that e...

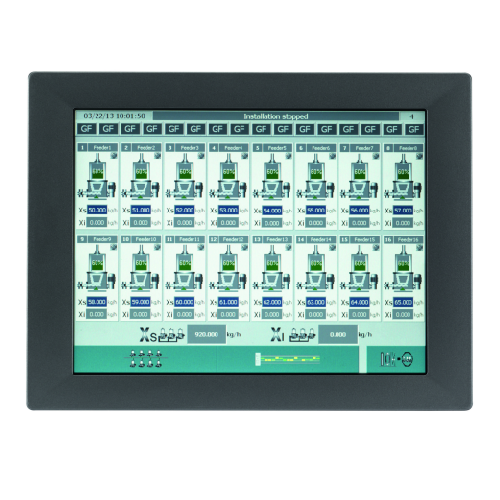

Batch-control system for dosing, mixing, and weighing processes

Enhance your process control by automating dosing, mixin...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Vibratory feeder for dosing powders and bulks

Ensure precise feeding of powders and bulk materials with a system that inte...

Dosing pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with flexibility in dosing volu...

Modular dispenser for dosing adhesives and abrasive media

Streamline your production line with a modular dispenser desig...

Hygienic dispenser for precise dosing in food and cosmetics

Achieve precise dosing and application of high-viscosity liq...

Dosing and filling pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with compact, hygi...

Pressure sensor for viscous fluid dosing applications

Ensure precise dosing and fluid analysis in high-viscosity applicat...

Pressure monitoring solution for dosing processes

Optimize your production line by ensuring precise pressure monitoring, ...

Modular 2-component dosing system for industrial applications

Ensure precise and adaptable dosing solutions with a modul...

Dosing and filling pump for hygienic applications

Optimize your production line with this dosing and filling pump, design...

Fluid and paste dosing systems for industrial applications

Achieve precise dosing and mixing for high-viscosity liquids ...

1-component industrial dispenser for precision dosing

Achieve unparalleled precision in microdispensing across diverse ap...

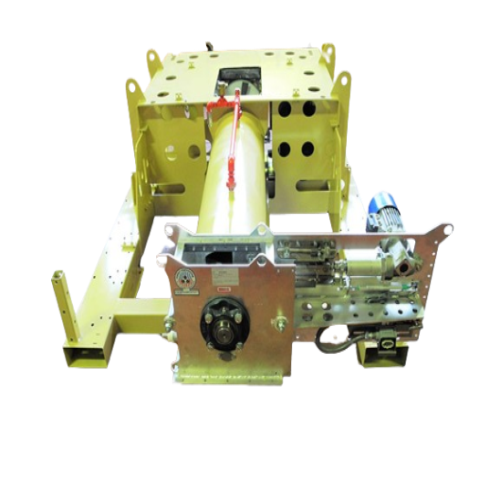

High-precision dosing systems for aerospace applications

Achieve unmatched precision and reliability when dosing complex ...

Food transfer and dosing pumps for bakeries

Enhance efficiency in food processing with pumps designed for precise transfer...

Dosing scale for accurate raw material weighing in feed recipes

Ensure precise feed formulation by weighing raw material...

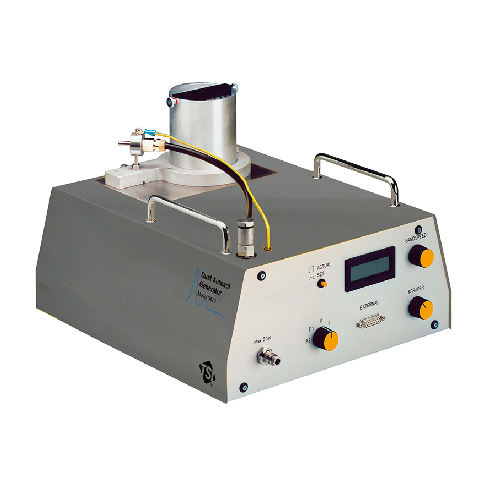

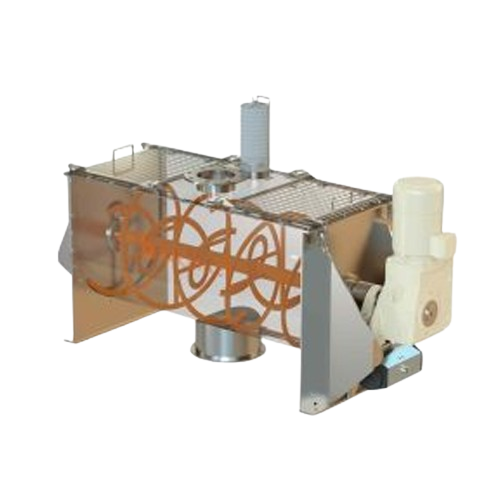

Dust aerosol generator for stable dosing and calibration

When precision is non-negotiable, this equipment disperses and d...

Twin screw feeder for dosing bulk solids

Ideal for precise bulk solids dosing, this twin screw feeder ensures consistent fl...

Volumetric single-screw feeder for fine dosing

Achieve precise and consistent dosing of fine powders and granules with a c...

Quick change volumetric and gravimetric single-screw dosing device

Simplify your dosing process with a quick-change sin...

Gas dosing system for experimental chemistry

Achieve precise gas dosing and regulation for laboratory and industrial chemi...

Gdl and rennet dosing solution for white cheese production

Optimize white cheese production by dramatically reducing aci...

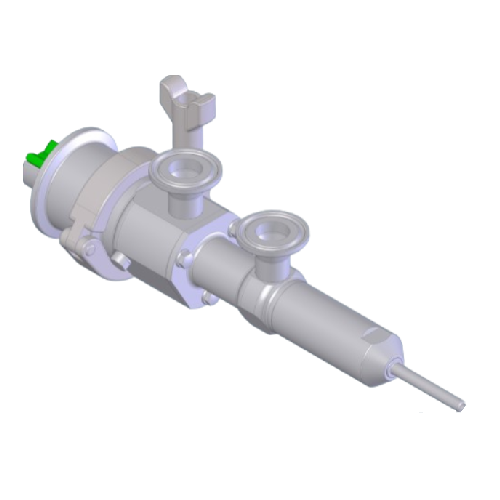

Inline white cheese rennet dosing unit

Optimize your cheese production with precise rennet dosing, ensuring consistent and ...

Cheese salt dosing unit

Optimize your cheese production with precise salt dosing, ensuring consistent flavor and quality in e...

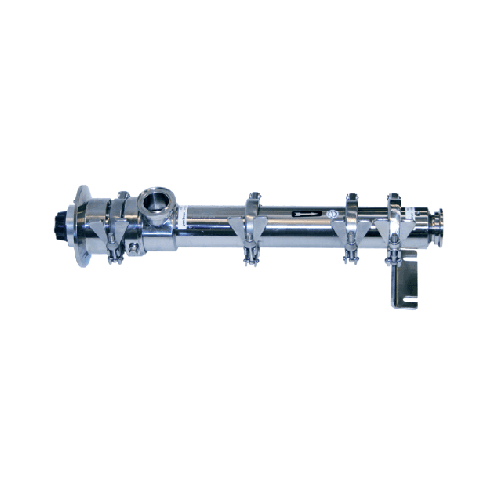

Aseptic dosing unit for enzymes and vitamins

Efficiently integrate precision ingredient dosing for enzymes and vitamins in...

Aseptic dosing system for heat-sensitive ingredients

Enhance product quality and reduce ingredient waste by precisely inj...

Powder feeder for consistent and accurate dosing

Ensure precise powder dosing with high hygiene standards to maintain prod...

Aseptic dosing unit for in-line ingredient addition

Optimize your production with precise aseptic dosing, minimizing ingr...

Aseptic dosing unit for sensitive ingredients

Ensure the stability of heat-sensitive ingredients with precise in-line dosi...

Pneumatic dosing syringes for precise liquid dispensing

Achieve precise and reliable liquid dosing with pneumatic syringe...

Manual dosing and capping for semi-dense products

Enhance your production line efficiency by seamlessly integrating manua...

Pneumatic syringe dosing system

Streamline your liquid dosing process with precision and efficiency, ensuring each applicati...

Automated ingredient weighing and dosing system

Streamline your production process with precise and consistent ingredient ...

Dosing screw system for precise ingredient management

Achieve unparalleled precision in formulating mixtures with our dos...

Batch ingredient dosing system for high-accuracy weight control

Achieve precise weight measurement for multi-ingredient ...

Microbatch dosing for precision ingredient measurement

Achieve precise ingredient dosing with our MicroBatch system, desi...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Dosing system for bakery and convenience food

Achieve precise dosing and filling of liquids and slurries with this versati...

Dosing system for packaging lines

For producers looking to optimize their packaging lines, this dosing system offers precis...

Simultaneous chocolate dosing solution

Achieve high-precision chocolate and ganache filling in a single step with this effi...

Dosing feeder for coffee production

Streamline your coffee production with precision control, ensuring consistent packing l...

Vertical dosing valve for accurate food portioning

Ensure precision in portioning liquid and semi-liquid food products wi...

High precision dosing system for liquid media

Producing confectionery and bakery products implies mixing large amounts of ...

Accurate multiple dosing system for powders

Dosing multiple powders in a batch process is time inefficient, especially whe...

High-speed powder dosing system

Balancing speed and accuracy in powder dosing is crucial to fulfilling production viability....

Powder micro-dosing system

Pharmaceutical powders in metered doses demand maximum filling precision. This is particularly ch...

Powder dosing system

Dosing of powder products must be done in a continuously controlled manner to provide a precise amount o...

Fast gravimetric powder microdosing 50 - 200 g

Micro-dosing powders of high-value food or chemical products can be challen...

Gravimetric powder microdosing 2 - 100 g

Powders and granules are commonly dosed for the manufacturing of pharmaceuticals, ...

Gravimetric powder microdosing 0.400 - 2 g

If you need to process high value food, pharmaceuticals or chemicals, there is ...

Macro ingredient dosing system

Traditional dosing systems do not have a very long operational life and are hard and expensiv...

Exchangeable silo dosing system

Rarely used bulk ingredients, like grains, agricultural feed or silage, can get spoilt if th...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

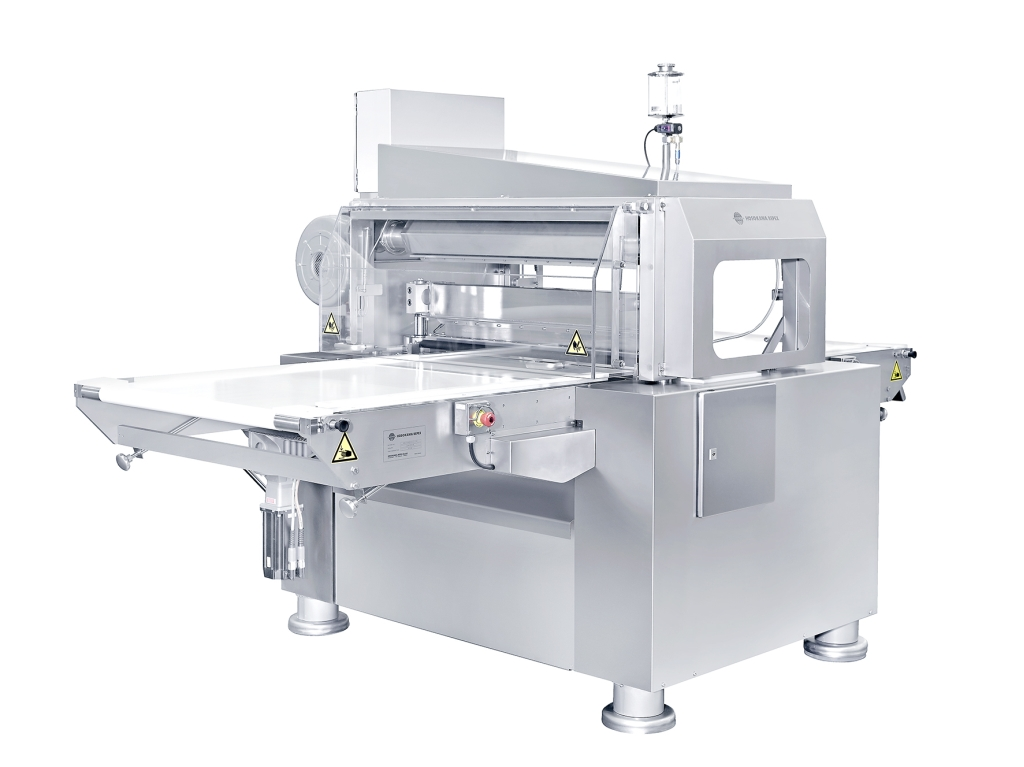

Cake batter dosing machine

High precision machines are essential to ensure a consistent dough mix pours into a mould. The fi...

Semi-automatic powder dosing machine

Powders or granules are common dose types used in many pharmaceutical and nutraceutica...

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

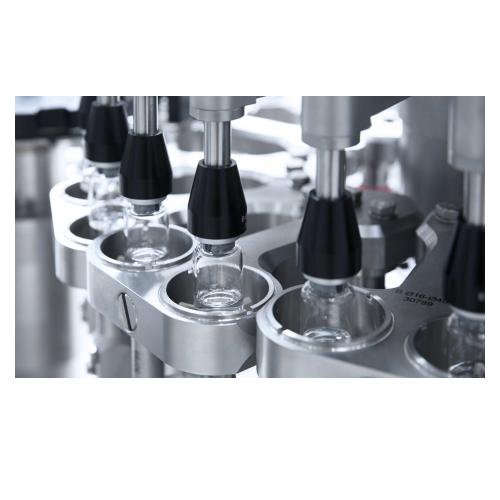

Microdosing machine for sterile powders

Fill sterile pharmaceutical powders into vials under aseptic conditions with a spee...

Dosing machine for nonfree-flowing powders

Fill poorly flowing powders, dry syrups and similar substances into various gla...

Continuous butter maker for industrial butter production

Streamline your butter production with a system designed for sea...

Continuous butter production system

Efficiently transform cream into versatile butter products, ensuring consistent quality...

Mixing system for beer mix beverages

Enhance your beverage offerings with precise mixing and dosing systems designed to pro...

Lobe depositors and extruders for filled and decorated cookies

Optimize your bakery production with precision depositing...

Topping depositor for pizzas and baked goods

Enhance your production line’s efficiency by uniformly adding both dry ...

Volumetric piston depositors for cake and pie fillings

Achieve precise depositing and gentle handling of varied doughs an...

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

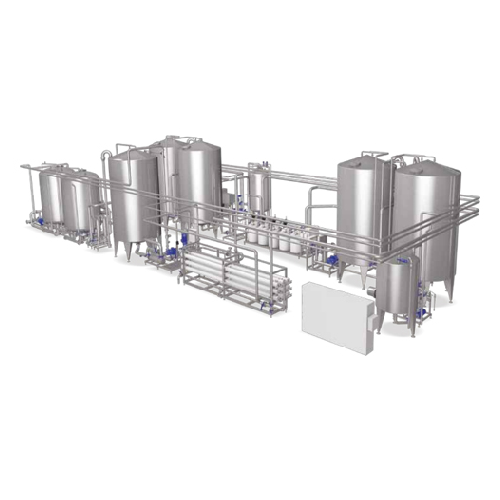

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

Automatic grinder/polisher for sample preparation

Streamline your sample preparation with a versatile grinder and polishe...

Refrigerated fermentation tank with cold water jacket

Enhance the precision of your cheese production with advanced therm...

Ultrafiltration system for brine regeneration

Optimize your cheese and brine processes with a versatile ultrafiltration sy...

Precise starter culture dosage system for dairies

Ensure precise integration of starter cultures into your cheese product...

Buttercream filling applicator for chocolates

Enhance your confectionery process with precision dosing and moulding to cre...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Linear belt vibratory weigh filler for solid chocolate

Optimize your chocolate production by minimizing product giveaway ...

Crossflow filter for wine and grape juice

Efficiently streamline your beverage filtration process with a versatile crossfl...

Crossflow filter for wine production

Optimize your wine and juice production with advanced membrane filtration, ensuring hi...

Vertical leaves pressure filter for wine and viscous liquids

Ensure optimal clarity and consistency in your liquid produ...

Roll feeders for consistent hammer mill supply

Ensure precise and controlled feedstock delivery to your hammer mill, effec...

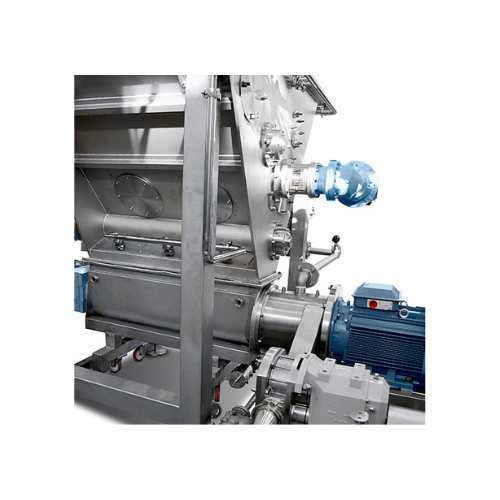

Continuous mixers for feed mill applications

Optimize your liquid incorporation process with continuous mixers that ensure...

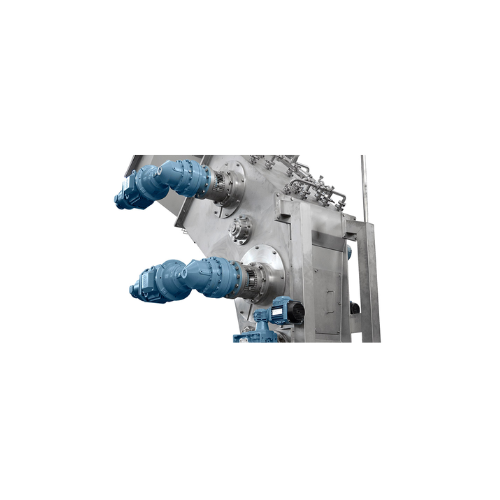

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

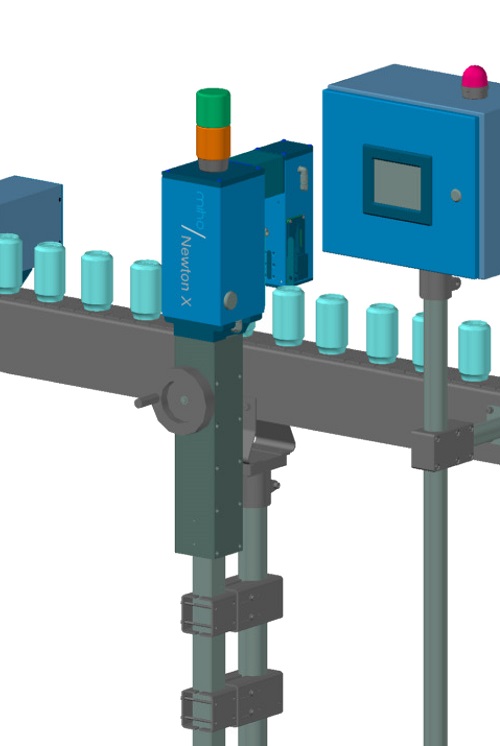

Inline and continuous weighers for accurate product flow management

Maintain precision and efficiency in your productio...

Screw conveyors for grain processing and feed mills

Optimize your production line with versatile screw conveyors, designe...

Batch weighers for large-volume powder and granulate weighing

Ensure precise ingredient dosing and streamline your produ...

Continuous coater for pellet and extrudate liquid addition

Efficiently enhance your feed products by uniformly adding li...

Capsule filling system with in-line weight control

Experience precise capsule filling with high-speed accuracy, designed ...

In-line production of fine emulsions

Achieve homogenous emulsions with precise control, reducing the risk of lump formation...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Fully automated cleaning in place unit for food processing plants

Enhance food safety and streamline operations with a ...

Wine washing system for bottling quality control

Ensure pristine wine quality by eliminating waste through innovative bott...

Filling and capping solution for oral liquid products

Achieve precise, high-speed filling and capping of oral liquids wit...

Oil and fat filling system for industrial use

Optimize your production line with this precise filling solution, designed t...

Compact dough depositor for artisan confectioneries

Ideal for crafting intricate and uniform pastries, this machine enhan...

Rotating nozzle depositor for pastry production

Optimize your pastry production with precise dosing and shaping capabiliti...

Depositing system for fixed deposited biscuits

Optimize your bakery production with a versatile depositing system designed...

Industrial muffin production line

Maximize your bakery’s efficiency with a high-performance line engineered for preci...

Industrial cream doser for pastry applications

Efficiently dose and fill a variety of bakery and confectionery mixtures wi...

Intermediate bulk containers for powder and materials handling

Optimize your material handling processes with containers...

Lipstick filling solution for high output production

Achieve precision and efficiency in lipstick production with advance...

Melting tank for cosmetic production

Achieve precise and consistent melting and dosing of cosmetic liquids, from face cream...

Cosmetic pencil filling system

Streamline your cosmetic production with high-speed filling and precise molding capabilities,...

Lipstick moulding system

Achieve precision and efficiency in your cosmetic production line with advanced moulding and dosing ...

Semi-automatic lipstick moulding system

Streamline your lipstick production with a versatile system that effortlessly mould...

Stickpack filling and closing system for pharmaceutical powders

Achieve precise dosing and secure packaging for pharmace...

Aseptic ampoule filling and sealing solution

Ensure precise dosing and secure sealing of sterile liquid pharmaceuticals in...

Bottle filler and capper

Achieve precise liquid filling and secure capping with high-speed, intermittent motion, ensuring con...

High-speed vial filling and capping system

Ensure precise vial filling and secure capping with this high-speed rotary solu...

Stickpack filling and closing system

Optimize your stickpack production with precise dosing, uniform sealing, and seamless ...

Filling and stoppering system for nested syringes

Ensure aseptic precision in syringe and vial preparation with a high-sp...

Automatic sachet filling and sealing system for liquids and creams

Optimize your cosmetic and personal care production ...

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

Juice bottle and bag-in-box filling systems

Streamline your juice production with versatile filling solutions that accommo...

Industrial potato flake production line

Maximize yield and quality in potato processing by integrating advanced pre-cleanin...

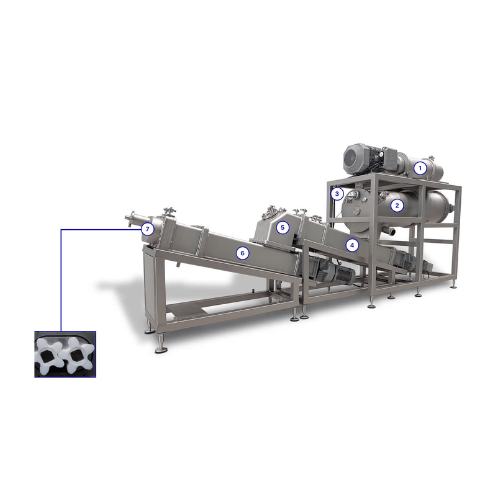

Pellet snack production line for industrial use

Streamline your snack production with a versatile pellet snack line that e...

Batch sugar dissolver for syrup production

Streamline your syrup production with precise control over sugar dissolution, w...

Wrap-around packer for cartons and trays

Effortlessly streamline your packaging process with a high-speed solution designed...

Pvpp beer stabilization system for breweries

Reduce beer hazing and extend shelf life with this advanced stabilization sys...

Commercial meatball roasting tunnel

Achieve consistent roasting of diverse products, from meatballs to grilled tofu, while ...

Bag dump station for handling solid foodstuffs

Efficiently manage manual dosing of solid foodstuffs and powders with this ...

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Big bag unloading station for solids handling

Optimize bulk solid ingredient handling with this station, designed to strea...

Micro ingredients loading station for solid additives

Optimize precision dosing and ensure smooth transfer of powdered in...

Buffer tanks for powdered or granulated solids storage

Enhance your production line with buffer tanks designed for precis...

Automated Cip system for small facilities

Ensure impeccable hygiene with a mobile cleaning system designed to efficiently ...

Cip cleaning system for pharmaceutical industry

Optimize cleanliness and ensure sterile conditions with this advanced CIP/...

Oxygen and carbon dioxide monitoring and elimination system

Achieve precise control over dissolved gases with a system t...

Wine recovery system for bottling processes

Streamline bottling operations by recovering and re-dosing valuable wine, redu...

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

Vertical intermittent motion stick packaging

Experience seamless packing for diverse products, from powders to dense paste...

Sterile bag filling and closing system

Ensure precision and sterility in multi-chamber bag filling for liquid and powder ph...

Powder filling and stoppering for antibiotic production

Tackle antibiotic resistance with precision powder filling and st...

Capsule filler for pharmaceutical applications

Need precise capsule filling for pharmaceuticals and nutraceuticals? This s...

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

Aseptic filling and stoppering solution for vials

Ensure precise aseptic filling and stoppering of vials with enhanced fl...

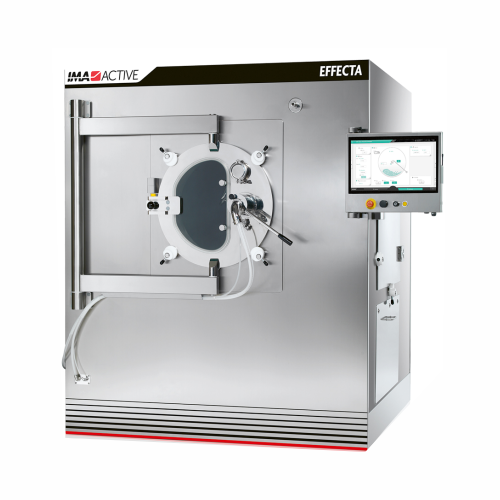

Tablet coating pan for pharmaceutical and nutraceutical industries

Enhance coating efficiency with a versatile solution...

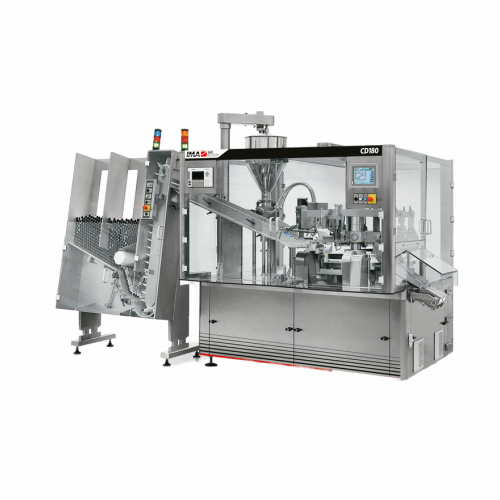

Automatic tubefiller for pharmaceutical tubes

Streamline your tube packaging process with this versatile solution, optimiz...

Automatic biscuit sandwiching equipment for high-volume production

Optimize your biscuit production line with high-spee...

Automatic sandwich biscuit production system

Elevate your biscuit production line with high-speed sandwiching capabilities...

Filling and wrapping system for pasty products

Achieve precise dosing and flexible wrapping of diverse pasty products, ens...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Automatic moulding and wrapping for butter and margarine

Looking to reduce packaging waste and increase dosing precision?...

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

Tub filling and sealing for pasty products

Experience high-speed, precision tub filling and sealing designed for pasty pro...

Cup forming, filling, and sealing solution

Optimize your cup production with a compact solution designed for precise formi...

Capsule filling and sealing system for coffee production

Achieve precise coffee capsule production with a machine that se...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

Capsule filling and sealing system for coffee

Optimize your capsule production with a system designed to enhance precision...

Roasted coffee weighing and blending system

Achieve precision and consistency in your coffee blends with cutting-edge weig...

Capsule filling and sealing for lab purposes

Streamline your lab-scale coffee capsule production with a compact solution d...

Capsule filling and sealing system for coffee products

Optimizing the precision of coffee and tea capsule production, thi...

Hard pod packaging system for coffee

Optimize your coffee production with a compact system designed for high-speed packagin...

Green coffee handling and conveying systems

Efficiently handle and convey green coffee beans to maintain product integrity...

Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma...

Packaging solution for small bottles and jars

Effortlessly seal and fill non-stackable containers, ensuring precision for ...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

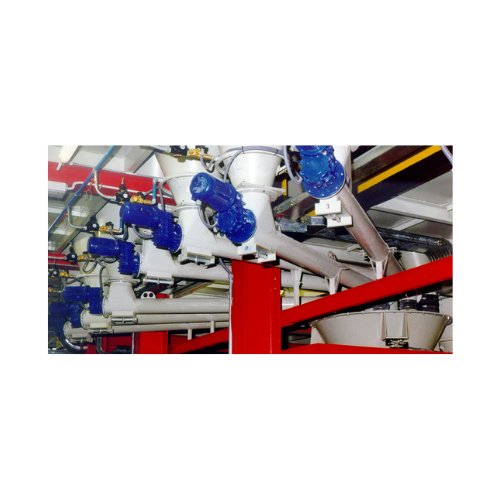

Pneumatic conveying systems for industrial applications

Efficiently transport bulk materials or liquids across your produ...

Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrat...

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Cylinder sieving system for seed and pellet calibration

Simplify your seed and pellet calibration with a rotary cylinder ...

Seed containers with easy operable slide valve

Ensure complete seed emptying with specially designed containers, eliminati...

Powder feeder for consistent mixing in pan coating processes

Ensure precise dosing and mixing of pharmaceutical powders ...

Automatic wafer batter preparation system

Optimize wafer production with precision dosing and homogeneous mixing, ensuring...

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

Seasoning mixing system for extruded snacks

Achieve consistent flavor profiles in your extruded snacks with this high-spee...

High flow rate extractor weigh feeder for cement and mining

Streamline high-capacity material flow and precise dosing of...

Apron extractor weigh feeder for large-scale material extraction

Achieve precise material dosing and metering under chal...

High-temperature extractor weigh belt feeder for clinker

Handle hot, abrasive products like clinker seamlessly with a rob...

Weigh belt feeder for low-density materials

Optimize high-volume feeding accuracy for light materials while reducing your ...

Powder belt feeder for accurate powder metering

Achieve precise powder metering with a specialized feeder that maintains d...

Rotary weigh feeder for high-volume powders

Ensure continuous and accurate high-volume powder dosing in your industrial pr...

Belt feeder for alternative fuels

Maximize fuel efficiency with this belt feeder designed for seamless dosing of alternativ...

High-speed conveyor belt scale for high-flow applications

Achieve precise continuous material flow with a robust belt sc...

High-speed industrial belt feeder for granular materials

Achieve precise and consistent material dosing in high-flow envi...

High-precision belt feeder for granular materials

Achieve precise material dosing and consistent flow in your continuous ...

Automated assembly system for lab diagnostics

Streamline your lab diagnostics production with a flexible assembly system, ...

Round motion assembly platform for inhalers

Achieve high-efficiency assembly and inspection of inhalers and diagnostic dev...

Servo-driven device assembly system

Achieve precise and flexible assembly of medical and pharmaceutical devices with a serv...

Production system for multi-chamber portion packs

Efficiently produce multi-chamber portion packs with high precision for...

Liquid filling system for medical and pharmaceutical products

Enhance your production capabilities with high-speed liqui...

Sterile filling system for Iv bags

Ensure precise and sterile filling of IV and infusion bags with flexible, semiautomatic ...

Dpi inhaler production system

Enhance your inhaler production with precision assembly and integrated dosing, filling, and ca...

Commercial blister filling solution for dry powder

Efficiently fill and seal blister packs with precision, ensuring consi...

Commercial capsule filling for small scale production

Efficiently fill and dose capsules with precision, ensuring flawles...

Capsule filling system for powder, pellets, and tablets

Optimize capsule production with rapid dosing changes, minimizing...

Containment capsule filling system for lab and small batch production

Designed to ensure maximum safety in pharmaceutic...

Versatile capsule filler for pharmaceuticals

Effortlessly switch between powder, pellet, and liquid dosing with this adapt...

Disc filler for dry powder inhalers

Optimize your dry powder inhaler production with precision micro-dosing for diverse pow...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

Split butterfly valve for sterile powder transfer

Ensure safe and sterile transfer of powders with unparalleled containme...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Flexible mixing system for meat and dairy products

This versatile mixing system delivers precise control over temperature...

High-precision depositing system for fluid and viscous fillings

Achieve precise and efficient dosing for diverse food pr...

Filling flow divider for food and pet food applications

Optimize your production line with precision filling flow divider...

Cutting valve for chunky food portioning

Achieve precise portioning of chunky products, reducing waste and increasing effic...

Cocoa sterilizing and alkalizing plant

Optimize cocoa product quality with a system engineered for precise sterilizing, alk...

Adjustable weighing system for raw materials

Optimize your confectionery and nutraceutical production with precise weighin...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Cheese shredding line for large volume production

Achieve seamless cheese processing with a fully integrated shredding li...

Lab nutsche filter for small scale filtration

Efficiently manage filtration and drying needs in fine chemical and pharmace...

High-precision volumetric feeder for bulk materials

Achieve precise bulk material flow with a solution that ensures consi...

High-precision gravimetric feeders for industrial bulk solids

Achieve unparalleled accuracy in your production line with...

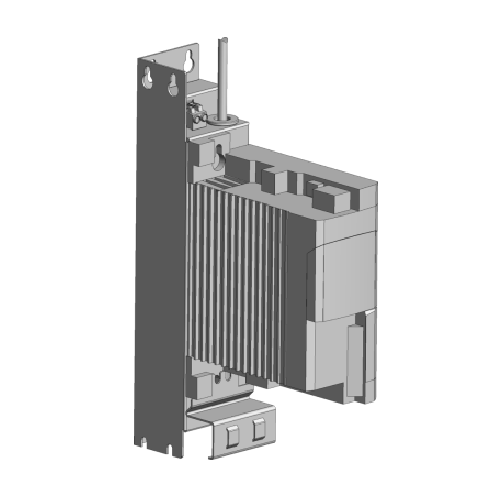

Universal controller for feeders in powder handling applications

Simplify and enhance your powder handling with precise ...

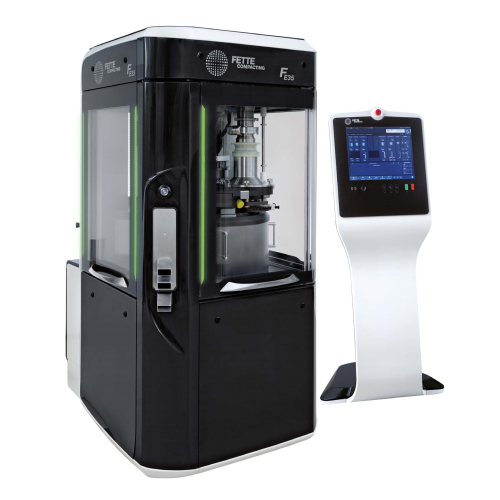

Continuous direct compression system for tablet production

Achieve seamless continuous direct compression by integrating...

High-capacity tablet press for pharmaceutical production

Achieve precise compression and consistent tablet density with a...

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Cip & Sip systems for pharmaceutical cleaning

Ensure effective cleaning and sterilization in production lines with customi...

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

Industrial liquid filler for small to medium volume operations

Ensure accuracy and efficiency in liquid formulation with...

Bread fermentation for rye sourdough

Transform leftover bread into high-quality rye sourdough with a mobile, plug-in fermen...

Wheat and spelt pre-dough system

Optimize your bakery production with a flexible system designed for rapid, lump-free mixing...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

Calibratable big bag filling station for dust-free operations

Ensure precise, dust-free filling of bulk bags with ergono...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

Electronic filling system for non-carbonated beverages

Optimize your bottling process with precision filling technology t...

Continuous wine flotation unit for must clarification

Enhance your must clarification process with a continuous flotation...

Continuous flotation units for wine clarification

Optimize your wine and juice production with our advanced flotation uni...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

Vacuum high shear mixer for medium to high viscosity products

Achieve flawless blending and air-free consistency in visc...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Product counting system for confectionery and food products

Achieve 100% counting accuracy and seamless integration in y...

Syringe dispensing system for nuclear medicine

Optimize your radiopharmaceutical workflows with a system designed to preci...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

Powder dissolution unit for beverage production

Achieve precise and rapid dissolution of powders like sugar and acids, opt...

Stickpack wrapper for lollipops

Enhance your confectionery line’s efficiency by wrapping up to 480 lollipops per minut...

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

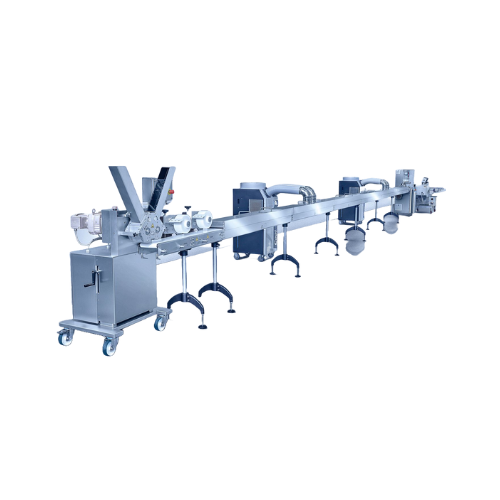

Processing line for spring rolls

Streamline your spring roll production with a compact machine designed to minimize downtime...

Vacuum filler for glass jars and cans

Ensure precise filling and equal headspace for your products with this vacuum filler,...

Vibratory rotary filler for accurate filling in food packaging

Achieve precise and efficient filling of diverse solid pr...

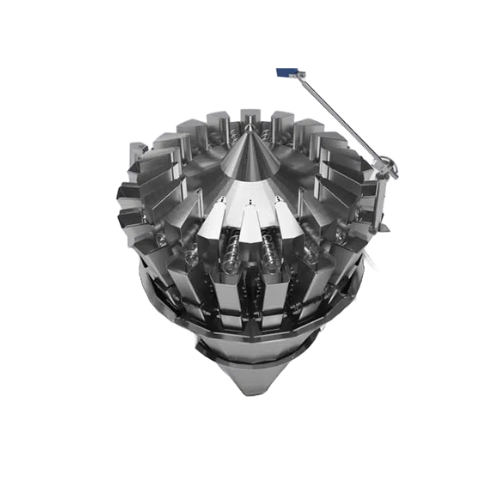

Multihead weigher with screw feeding for sticky products

Achieve exceptional precision and reduce giveaway costs in handl...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

High-capacity tubular screw conveyor for grain transport

Optimize your production flow with a robust solution that ensure...

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrati...

Hydration solutions for baked goods

Achieve consistent dough quality faster with a system that precisely hydrates and mixes...

Fully automatic bagging station for granular products

Streamline your packaging line with a high-speed solution designed ...

Automatic bagging station for powdery products

Streamline your packaging line with a reliable solution designed for high-s...

Automatic silo scale for grain processing

Enhance your grain handling operations with precision weighing and dosing, ensur...

Tubular screw conveyor for grain transport

Efficiently discharge and dose raw materials with high precision, ensuring seam...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Commercial juice mixing station

Streamline your beverage production with precise mixing and dosing, ensuring consistently hi...

Industrial Cip system for fruit juice production lines

Ensure optimal hygiene and operational efficiency with advanced CI...

Vertical forced feeder for extruders

Enhance your extrusion process with a vertical forced feeder designed for precise dosi...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Automatic fasteners packaging system

Streamline your fastener packaging process with a system that automates sorting, dosin...

Mixer-pasteurizer-carbonator for soft drinks and juices

Optimize your beverage production with a versatile system that se...

Sterile media and buffer storage tanks

Ensure uninterrupted bioproduction with our tanks designed for secure storage and pr...

Media and buffer preparation solution for bioprocessing

Achieve seamless media and buffer preparation with precise dosing...

Aroma-batch blender for beverage production

Optimize your beverage formulation process with precise aroma dosing and effic...

Batch blenders for fruit juices and nectars

Achieve precise ingredient ratios and uniform mixing in beverage production wi...

Carbonators for fruit juice and soft drinks

Achieve optimal carbonation in your beverages with precise CO2 dosing equipmen...

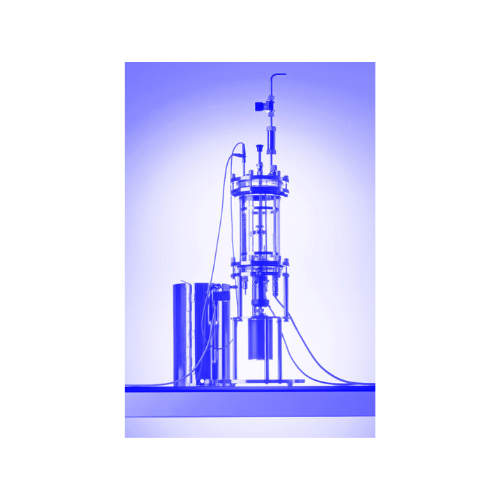

Lab-scale fermentors for microbial cultivation

Optimize microbial cultivation with lab-scale fermentors designed for preci...

Filter stations for sterile filtration in biopharmaceuticals

Ensure sterility and precision in your biopharmaceutical pr...

Formulation vessel for biopharmaceutical homogeneity

Achieve precise homogeneity in liquid formulations with vessels opti...

Ketchup production line

Optimize your sauce production with advanced equipment designed to ensure consistent blending, precis...

Juice reconstitution equipment for concentrated juice

Revolutionize your beverage production with advanced equipment desi...

Industrial liquefying and crunching solution for frozen fruits and vegetables

Efficiently transform frozen produce int...

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expert...

Combisys filling and closing system for pharmaceutical containers

Ensure precise filling and closing of pharmaceutical ...

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

Filling and closing solution for nested containers

Streamline your vial, cartridge, and syringe production with precise d...

Filling and closing system for nested containers

Optimize liquid formulation packaging with a high-speed system designed f...

Filling and closing solution for vials and stable bottles

Optimize vial and bottle processing with a seamless solution d...

Filling and closing system for cartridges

Enhance your cartridge production with precise filling and closing technology de...

Aseptic filling and closing for flexible Iv bags

Streamline your production line with high-speed aseptic filling and seali...

Filling and closing system for ampoules

Ensure precision and efficiency in your aseptic fill-finish operations with a compa...

Precise weighing solutions for small batch production

Streamline handling of diverse ingredient blends with precise dosin...

Batch automation system for fast and precise weighing

Achieve unmatched precision and speed in batch processing with this...

Automatic tube filling and closing system

Enhance production efficiency with a high-speed tube filling and closing system ...

Semi-automatic tube filling and closing system

Achieve precise filling and secure closing for diverse tube types, optimizi...

Contamination-free docking system for bulk solids

Achieve contamination-free transfer of bulk powders and granules while ...

Automatic minor components weighing system

Streamline precision in your production by automating the weighing of minor and...

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrat...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Automatic tube filling and closing system

Enhance your packaging efficiency with a high-speed tube filling and closing sol...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Aseptic filling isolator for small cgmp batches

Guarantee aseptic integrity for small-scale batches with this isolator, of...

Flexible bag-in-box filler for liquid and viscous products

Optimized for flexibility and efficiency, this bag-in-box fil...

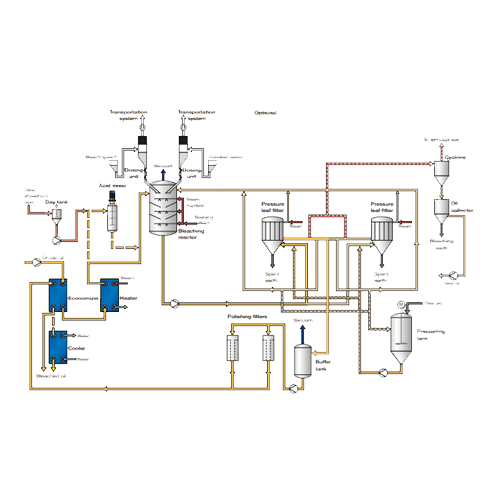

Bleaching systems for edible oil refining

Achieve clarity and stability in your edible oils with cutting-edge bleaching sy...

Mobile mixing system for beverages in breweries

Optimize blending and carbonation processes with a mobile solution that st...

Emulsion processing system for homogenizing solids into liquids

Achieve precision in emulsifying and homogenizing proces...

Digital doser system for plastics additive feeding

Achieve precise additive dosing for plastics, ensuring consistent qual...

High-precision analytical balance for laboratory use

Achieve precise measurements and ensure reliability in your laborato...

Single rotary tablet press

Streamline your tablet production with enhanced efficiency and precision, ensuring consistent tab...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Water remineralization system for mineral and flavored water production

Achieve precision in mineral content with a sys...

High-speed dough depositor and extruder

Streamline your high-speed dough processing with precise dosing and gentle handling...

Ingredient management system for beverage production

Efficiently manage a diverse range of solid and liquid ingredients t...

Versatile industrial water disinfection system

Ensuring optimal water disinfection is crucial for beverage manufacturers s...

Industrial water disinfection system

Ensure the microbiological safety of liquids by utilizing an advanced water disinfecti...

Industrial beverage preparation systems

Optimize beverage production with integrated systems designed for seamless mixing, ...

Fruit pieces handling for juice production

Achieve perfect fruit piece integration in juice with a system designed to prev...

Automatic chemical mixing system for postharvest treatment

Achieve precise chemical dosing and mixing for postharvest tr...

Continuous granulation and compression line for pharmaceuticals

Optimize your pharmaceutical production with a line that...

Continuous raw material distribution screw doser

Optimize your material flow with a screw doser designed for precise and c...

Loading box for granular products in production lines

Optimize your production line with a manual-to-continuous loading b...

Micro-ingredients doser for precise powder additives

Maintain precision and hygiene in your production line with a specia...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Circular distribution feeder for fragile product handling

Achieve precise dosing and reduced product damage with a versa...

Vibrating feeder for food and pharmaceutical industries

Optimize your production line with precision dosing and gentle ma...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Bulk packaging system for long cut pasta

Optimize your bulk packaging of long cut pasta with a high-speed, customizable sol...

High-speed packaging system for long-cut pasta

Achieve seamless high-speed packaging with enhanced accuracy and minimized ...

Lobe pump for soft fillings

Efficiently dose and feed soft fillings for food products with precision, ensuring smooth integr...

Pasta folding system for cannelloni production

Streamline your production by precisely folding pasta around filling to cre...

Single sheet former for fresh pasta production

Optimize your production line with a versatile machine designed to precisel...

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing ...

Modular batch mixing system for beverages

Streamline your beverage production with a flexible solution that manages comple...

Continuous in-line blender for home and personal care products

Achieve precision and flexibility in blending liquid mult...

Tumbling and massaging system for meat and poultry marination

Optimize your marination process with a system that ensure...

Standardization unit for cream fat or milk fat

Optimize your milk standardization process to achieve precise cream and fat...

Dry salt dosage system for curd cheese production

Streamline your cheese production with precise salt dosing, ensuring op...

Liquid salt dosage systems for pasta filata-type cheeses

Achieve precise salinity control and optimal temperature for you...

Powder feeding behavior characterization solution

Optimize your R&D with precise powder feeding behavior analysis, c...

Authentic homestyle bread solution

Achieve authentic homestyle breading on an industrial scale with a drum breader that ens...

Automated tempura batter mixer

Achieve consistent tempura batter quality with automated mixing control that ensures precise ...

Bottle filler for still and carbonated drinks

Maximize efficiency in your bottling process by seamlessly filling both stil...

Dairy waste reduction with evaporator product recovery

Transform dairy processing by efficiently recovering valuable low ...

Pharmaceutical extrusion and spheronization system

Achieve precise control over pellet size and uniformity with this adva...

Cip system for small to medium breweries

Ensure consistent craft beer quality with a modular cleaning solution that seamles...

Fillers for solid products

Optimize your production line with versatile fillers that ensure precise handling and packaging o...

Spice doser for powdered and free-flowing dry vegetables

Optimize spice and dried vegetable packaging with precise dosing...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Automated process controllers for industrial plants

Enhance your production line’s efficiency and adaptability with...

Technical plastics production system

Optimize your production line by integrating a versatile system capable of precise mix...

Turnkey plant solutions for industrial applications

Enhance your production line with seamless integration and optimized ...

Plant refurbishment services for industrial operations

Optimize your existing plant’s performance and extend its li...

Short base skirt silo for bulk material storage

Optimize your bulk material handling with adaptable discharge and rapid lo...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

Automated material flow system for starch processing

Streamline the handling of powdered starches with precise dosing, mi...

Industrial multi-chamber silos

Optimize spatial efficiency and streamline your production with versatile multi-chamber silos...

Process control for baked goods production

Enhance your production line with precise process control designed to optimize ...

Pta and Pet production systems

Maximize throughput while minimizing dust fines in your production of PTA and PET pellets wit...

Storage silo with long base skirt for processing industry

Optimize your bulk material storage with a silo that offers du...

Advanced plant engineering services

Optimize your production line with seamless integration of high-efficiency mixing, dosi...

Continuous material handling in compounding plants

Enhance your production line efficiency with advanced dosing, mixing, ...

Battery production facilities with precision weighing

Achieve maximum product purity and precision in your production pro...

Microfiltration systems for wine pre-bottling

Ensure product stability in pre-bottling by efficiently removing particles t...

Tubular screw conveyor for powdery and granular materials

Optimize your material handling processes with a versatile sol...

Tubular ribbon flight screw feeder for lime feeding

Experience uniform material flow and precise dosing with this special...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying des...

Integrated conveying and weighing system for bulk materials

Achieve precise material management with a solution that sea...

Closed powder handling loop for Eos metal Am printers

Effortlessly manage metal 3D printing powders with a solution that ...

Vertical mixing solution for bakery and snacking industry

Streamline your dough processing with robust and reliable spir...

Precision 2k dispenser for automated systems

Achieve precise mixing and dispensing of two-component materials with minimal...

Accurate pharmaceutical dispenser for high-viscosity fluids

Achieve precise liquid dosing with ease, designed to handle ...

Continuous mixing and filling system for viscous materials

Experience precise, pulsation-free mixing and filling of visc...

Fully automatic filling lines for liquids

Achieve precise dosing and filling of liquids with minimal cycle times using com...

Precision dispenser for high-viscosity fluids

Achieve unparalleled precision in dosing and application with a dispenser de...

3d print head for high-viscosity fluids and pastes

Enhance your 3D printing capabilities by reliably handling high-viscos...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Two component dispensing and meter mixing system for small quantities

Achieve precision and consistency in microdispens...

Automated precision spraying dispenser for high viscosity materials

Achieve precise spraying and consistent coating res...

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Sachet packaging for pharmaceuticals

Streamline your pharmaceutical packaging with high-precision sachet solutions, ensurin...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Stick pack packaging line for pharmaceuticals

Optimize your pharmaceutical production with stick pack packaging lines that...

Multi piston depositors for high-volume baking production

Optimize your high-speed production line with precision deposi...

Frozen chicken cut-ups packaging solution

Maximize your poultry packaging efficiency with a solution that seamlessly integ...

Vitamin adding system for ground products

Ensure precise vitamin dosing in continuous production lines, enhancing nutritio...

Nested fillers for vials, pre-filled syringes, and cartridges

Optimize your aseptic filling processes with precision dos...

Vial filling and stoppering system for aseptic production

Streamline aseptic production by integrating high-speed vial f...

Aseptic blow fill seal system

Ensure sterile, high-speed production of liquid pharmaceuticals by integrating a cutting-edge ...

In-line filling and closing system for pre-formed containers

Looking to enhance production efficiency with a solution th...

Glass jar filling system for processed cheese

Streamline your production line with a robust, high-speed filling solution d...

Table top extruder for customizable extrusion processes

Discover versatile extrusion capabilities for developing complex ...

Volumetric twin-screw feeder for poorly flowing powders

For manufacturers dealing with powders that clump or cake, this f...

Small-scale twin-screw feeder for powder handling

Perfect for precision in lab environments, this small-scale feeder effi...

Gravimetric twin screw feeders for pharma powders

Optimize feeding for challenging materials with dust and water-resistan...

Stuffing feeding device for extruders

Efficiently feed cohesive or lightweight powders into extruders to enhance product qu...

Twin-screw feeder for powders and micro-granules

Ideal for handling poorly flowing powders and granules, this advanced twi...

Volumetric single-screw feeders for free-flowing products

Achieve precise and continuous feeding of free-flowing powders...

Gravimetric single-screw feeder for free-flowing products

Optimize your dosing precision for powders and granulates with...

Ingredient doser for ice cream with large inclusions

Achieve precise and uniform inclusion of fruits, nuts, and candies i...

Ingredient doser for ice cream products

Ensure precise and consistent addition of ingredients like fruit pieces or cookie d...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Volumetric bottom filler for ice cream

Achieve precise distribution and inclusion integrity in moulded ice creams and froze...

Ice cream filler for consistent and efficient production

Achieve precision in ice cream production with a system that off...

Dry salting system for mozzarella production

Optimize mozzarella consistency with precise dry salting—achieving perfect sa...

Fresh cheese former for hygienic production

Streamline your cheese production with a hygienic and no-mould solution that s...

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this...

Automatic cleaning-in-place system for processing equipment

Streamline your cleaning operations with this cutting-edge s...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Autonomous ingredient dissolver for high volume dry ingredient mixing

Streamline your production by seamlessly mixing d...

Cleaning-in-place system for food and beverage processing equipment

Effortlessly manage the cleaning of diverse process...

Dual-line filler for tetra top packages

Maximize your production flexibility with a high-speed, dual-line filling solution ...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Manual monoblock for filling and capping spouted pouches

For those handling liquid or semi-dense products, this manual mo...

Feed hopper for volumetric feeders

Optimize product consistency while handling a variety of viscosities with this feed hopp...

Manual filling and capping for spouted pouches

Optimize your production line with a versatile solution for filling and cap...

Manual filler and capper for spouted pouches

Easily manage filling and capping for flexible pouches with precise volumetri...

Filling solution for various container types

This versatile filling solution optimizes liquid packaging by accommodating a...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Automatic line for filling and capping spouted pouches

Streamline your production line with high-speed filling and cappin...

Automated ingredient weigher for dairy production

Optimize your batching process with precise ingredient weight managemen...

Dry ingredient blending solution for confectionery and bakery products

Achieve seamless integration of dry inclusions i...

Batch mixer for homogeneous batter production

Ensure consistent batter quality by minimizing aeration during mixing, enhan...

Dry and liquid ingredient batch mixer for bakery applications

Achieve homogeneous mixing with precise heat control and e...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

Capsule filling for pharmaceuticals and nutraceuticals

Enhance your capsule production capabilities with modular filling ...

Continuous manufacturing for pharmaceuticals

Achieve precision in oral solid dosage production with seamless continuous pr...

Automated cup filling solutions for liquid and viscous products

Ensure precise and hygienic filling of dairy, baby food,...

Volumetric feeder for flowable ingredients

Ensure consistent and precise dosing of diverse materials in your production li...

Volumetric feeder for consistent ingredient flow

Achieve precise and consistent ingredient dosing in your production line ...

Single screw feeder with stirring agitator for powders and pellets

Ensure consistent mass flow and precise dosing with ...

Twin screw feeder with stirring agitator for poor flowing powders

Optimize your processing line with a highly adaptable...

Flash cooler for sweetened condensed milk production

Optimize cooling and slight evaporation processes in dairy productio...

Loss-in-weight feeder for flowable ingredients

Achieve precise ingredient delivery with this feeder, designed to handle a ...

Laboratory loss-in-weight feeder for powders or pellets

Achieve precise dosing for lab-scale trials with this versatile f...

Loss-in-weight feeder for liquids

Achieve precise and continuous liquid dosing with high accuracy, adapting seamlessly to y...

Loss-in-weight feeder for non-hygroscopic ingredients

Ensure precision in your dosing and weighing processes with this ad...

Single screw loss-in-weight feeder for powders and pellets

Ensure precise dosing and mixing in continuous automated oper...

Twin screw volumetric feeder for poor flowing powders

Struggling with poor flowing or floodable powders? This twin screw ...

Vibrating tray loss-in-weight feeder for grained ingredients

Achieve precise and continuous dosing of free-flowing solid...

Weigh-belt feeder for industrial processes

Efficiently manage material flow and precision with a dependable weigh-belt fee...

Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consiste...

Double screw batch feeder for poorly flowing powders

Effectively manage challenging powders with precise batch dosing and...