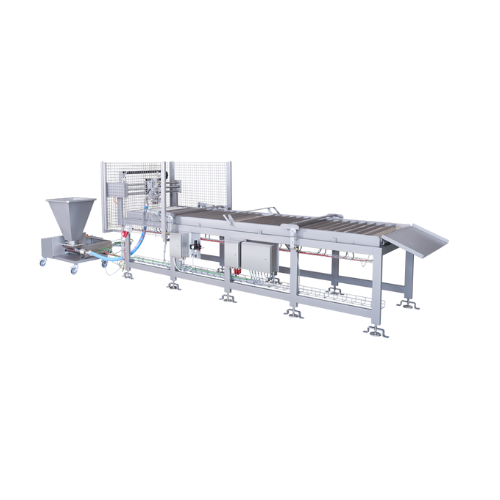

Commercial meatball roasting tunnel

Achieve consistent roasting of diverse products, from meatballs to grilled tofu, while freeing up your workforce for more strategic tasks with this high-capacity tunnel system.

Roasts and Flips Processed Foods Continuously

The FS 5000 and FS 7000 Roaster Tunnels from JOM Rustfri are engineered to automate the roasting process for high-volume food production facilities. These industrial roasting machines ensure precise cooking through automatic dosing, flipping, and conveying of products like meatballs and roasted vegetables. The roasters feature a touch screen for intuitive operation and offer a stepless adjustment of roasting time, allowing tailored cooking to meet specific product requirements.

With a roasting capacity of up to 280 kg per hour and processing 3500–4000 units per hour, the FS 7000 caters to large-scale production demands. Constructed from stainless steel, it includes removable Teflon cloths for easy maintenance and cleaning. The integration of an automatic oil doser and temperature regulation ensures consistent product quality, while compressed air supply and power requirements are designed to support seamless operation. Customization options allow you to adapt the system to fit your specific production line needs. The machine is ideal for food processing companies, meat processing facilities, and industrial kitchens specializing in ready-to-eat meals and snack foods.

Benefits

- Increases production efficiency by handling up to 4000 units per hour with minimal human intervention.

- Enhances product consistency through precise temperature control and stepless time adjustments.

- Lowers operating costs by reducing labor needs with fully automated roasting and flipping processes.

- Improves product quality with consistent oil dosing and adjustable product turning.

- Facilitates easy maintenance and cleaning with removable Teflon cloths and stainless steel construction.

- Applications

- Cooked food products, Meat products, Meatballs, Processed foods, Snack foods, Roasted foods, Ready-to-eat meals

- End products

- Cooked sausages, Roasted fish fillets, Fried chicken nuggets, Roasted nuts, Grilled tofu slices, Roasted chickpeas, Pre-cooked meatloaf, Roasted burger patties, Roasted vegetables

- Steps before

- Product preparation, Size determination, Thickness measurement

- Steps after

- Oil dripping, Product conveyance to tray, Cooling, Quality inspection, Packaging

- Input ingredients

- meatballs, raw food items

- Output ingredients

- roasted meatballs, golden brown food items, excess oil in drip tray

- Market info

- Machine Dimensions

- FS 5000

- FS 7000

- 5800 x 1600 x 1700 mm

- Roasting Capacity

- FS 5000

- FS 7000

- Up to 280 kg per hour

- Units Per Hour

- FS 5000

- FS 7000

- ca. 3500 – 4000 pcs/hour

- Power Supply

- FS 5000

- FS 7000

- 3 x 400V + PE, 130 kW 190 A

- Compressed Air Supply

- FS 5000

- FS 7000

- 600 litres/min. 8 bar

- Dosing Valves

- FS 5000

- FS 7000

- 2 pcs

- Dosing Pumps

- FS 5000

- FS 7000

- 2 pcs

- Standard Molds

- FS 5000

- FS 7000

- D70, 15 pcs

- Automation level

- Automatic

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual / CIP

- Stepless adjustment of roasting time

- Yes

- Automatic turning station

- Yes

- Roasting capacity

- 140–280 kg per hour

- Number of units per hour

- 1500–4000 pcs/h

- Automatic oil doser

- Yes

- Dosing method

- Automatic

- Abrasion resistance

- High

- Biological compatibility

- Food-safe materials

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel

- Machine footprint

- 4220 x 1600 x 1450 mm (FS 5000)

- Machine footprint

- 5800 x 1600 x 1700 mm (FS 7000)

- Roasting pan size

- 3520 x 1000 x 20 mm (FS 5000)

- Roasting pan size

- 5100 x 1250 x 20 mm (FS 7000)

- Container size

- 1 x 100 litres (FS 5000)

- Container size

- 2 x 100 litres (FS 7000)

- Control panel type

- Wall mounted electrical cabinet 1200 x 1000 x 300 mm

- Material

- Stainless steel

- Roaster Tunnel Size

- Custom size available

- Control Panel Type

- Touch screen

- Roasting Time Adjustment

- Stepless adjustment

- Built Material

- Stainless steel

- Product Molds

- Custom mold sizes available