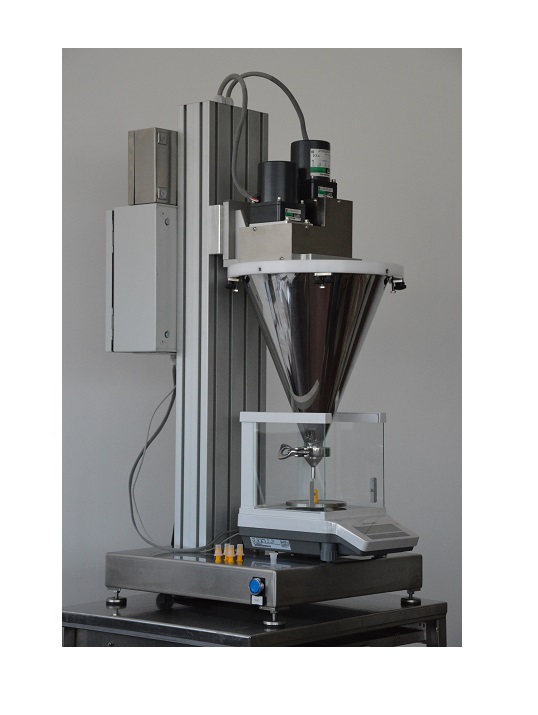

Semi-automatic powder dosing machine

Powders or granules are common dose types used in many pharmaceutical and nutraceutical products. However, small-scale or lab production volumes make fully automatic dosing solutions impractical and inefficient. In these scenarios, a purpose-designed semi-automatic machine for small batches with the flexibility to fill caps, bottles and jars is the ideal choice.

Machine for dosing powders into caps, jars, or bottles for small scale production

The PDS Semi-Automatic Powder Dosing Machine by Multigel is a highly flexible dosing solution for small-scale filling of a range of containers.

Based on the cochlea principle, the doser requires powder or compound granules to be manually added to the hopper. From there it is fed by gravity and the in-built mixing stirrer to the dosing unit.

Dosing is programmed by the operator using the easy-to-operate control panel. Parameters that can be set include dosage amount, dosage speed, and mixer speed.The hopper has a capacity of 5 litres, and a simple single adjustment is required to allow the machine to dose into containers of different sizes.

The PDS is constructed of stainless steel throughout, requires only a standard single-phase electrical outlet, and has a small footprint of 600mm x 500mm, allowing it to be positioned almost anywhere.

Benefits

- Compact powder doser designed specifically for lab and small-scale production

- All-stainless construction for longevity and easy maintenance

- Ability to dose into a wide range of sizes of bottles, jars, and containers for flexibility

- Full control of dosing parameters via a simple control panel

- Compact form factor means it can be installed anywhere, even the smallest labs