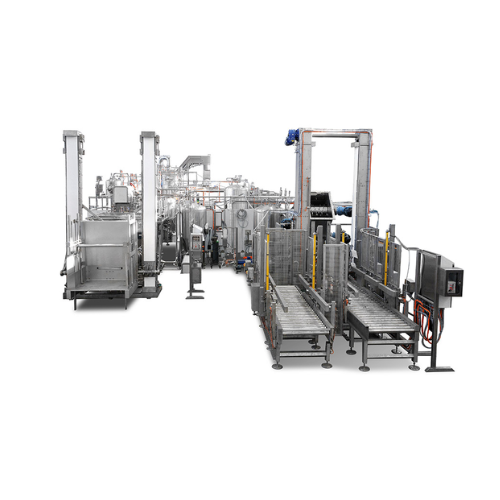

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expertly handles fresh, frozen, and aseptic ingredients, ensuring optimal quality and consistency in baby food and fruit or vegetable purees.

Processes and Mixes Fresh, Aseptic, and Frozen Ingredients

The MFS Line Multi Feeding System from Bertocchi Srl is designed to streamline the production of baby food and various fruit and vegetable purees by combining fresh, aseptic, and frozen ingredients into a consistent end product. Utilizing advanced feeding and mixing technology, this system ensures continuous controlled dosing and rapid defrosting, maintaining high product quality even with diverse input materials. It is equipped to process materials ranging from fresh fruits to aseptic purees and frozen blocks, integrating seamlessly into existing lines with its PLC and HMI systems for precise recipe management. With capacities of up to 8 tons per hour, the MFS Line supports high-speed, automated operations essential for large-scale production environments. Crafted from highly cleanable materials and featuring an integrated CIP system, it reduces downtime and maintenance efforts. Ideal for baby food manufacturers and puree producers, this system offers customizable configurations to meet specific production needs.

Benefits

- Enhances production efficiency by handling multiple ingredient types simultaneously.

- Reduces operational costs through automated dosing and mixing, minimizing manual intervention.

- Maintains high product quality with precise defrosting and controlled ingredient flow.

- Improves hygiene and safety with integrated CIP system for easy cleaning.

- Supports scalability with a capacity range of 1 to 8 tons per hour.

- Applications

- Vegetable puree, Aseptic products, Nectars, Baby food, Frozen products, Fruit puree

- End products

- Baby food purees, Pear puree, Frozen strawberry puree, Apple puree, Banana puree, Carrot puree, Spinach puree, Pumpkin puree, Peach nectars, Aseptic apricot puree

- Steps before

- Washing, Sorting, Destoning, Injection

- Steps after

- Cold Extraction, Frozen Extraction, Aseptic Packing, Mixing, Dosing, Liquefying

- Input ingredients

- fresh fruit, fresh vegetables, IQF fruits, IQF vegetables, whole fruits, whole vegetables, aseptic puree

- Output ingredients

- dosed mix of products, concentrate puree, single strength puree, hot packed puree, aseptic packed puree, baby foods, nectars

- Market info

- Bertocchi is known for manufacturing engineered-to-order industrial equipment, specializing in custom process solutions for the food and beverage industry. They have a strong reputation for innovation, quality, and reliability in producing machinery tailored to customer specifications.

- Capacity

- 1 to 8 t/h

- Automation

- PLC and HMI for managing recipes

- Defrost system

- Ultra rapid defrosting and melting

- Cleaning method

- Integrated CIP

- Dosing type

- Continuous controlled dosing

- Feed type

- Fresh and frozen fruit/vegetables, aseptic puree and frozen puree

- Feed System

- Multi Feeding System

- Flow Type

- Inline Continuous

- Automation Level

- PLC-controlled

- CIP/SIP Capability

- Integrated CIP

- Product Processing

- Cold or Frozen Extraction

- Defrost System

- Ultra Rapid Defrosting

- Dosing Control

- Continuous Controlled Dosing

- Cleanability

- Integrated CIP

- Machine footprint

- Custom

- Control panel type

- PLC and HMI

- Compact footprint

- Integrated CIP

- Discharge method

- Automatic

- Control panel type

- PLC and HMI