Fruit Pulp Processing Equipment

Find innovative fruit pulp equipment and connect directly with world-leading technology suppliers

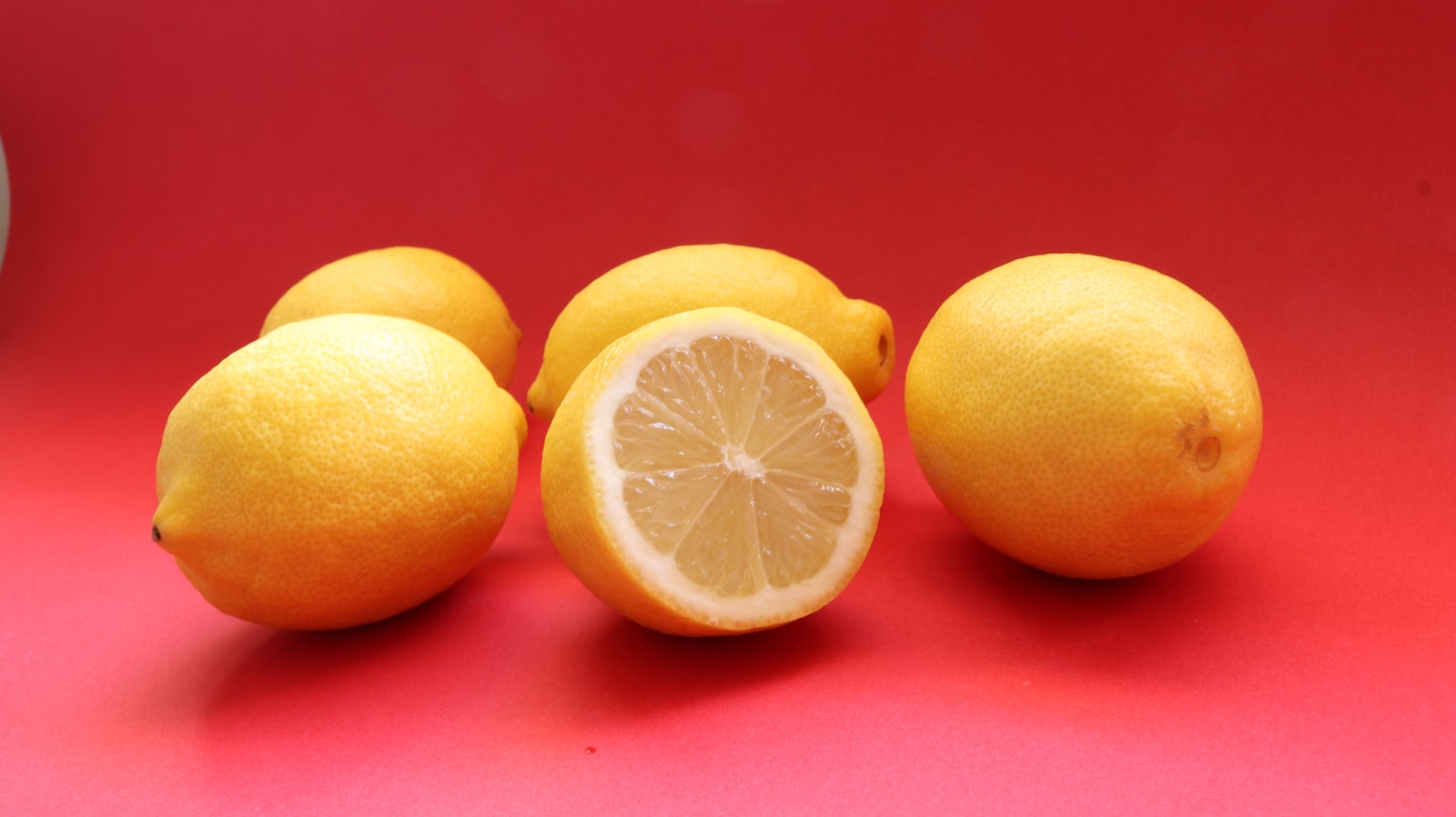

Fruit pulp is a mass of pressed fresh fruit not meant for immediate consumption. Production of fruit pulp avoids wasting food and preserves the flavors and nutrient value of the fruit product. Processed fruit pulp is an ingredient in beverages, sauces, baby foods, jellies, smoothies, and bakery products. Tradition and manufacturing procedures dictate the distinction between fruit juice, puree, and pulp. Still, naming and labeling are complex and depend on regulations, type of fruit, texture, consistency, preservation methods, and sugar or solid content (measured in Degrees Brix). Depending on your desired output, there are various fruit pulper machines for different stages of production that make the process quicker and more efficient.

Top picks for processing fruit pulp

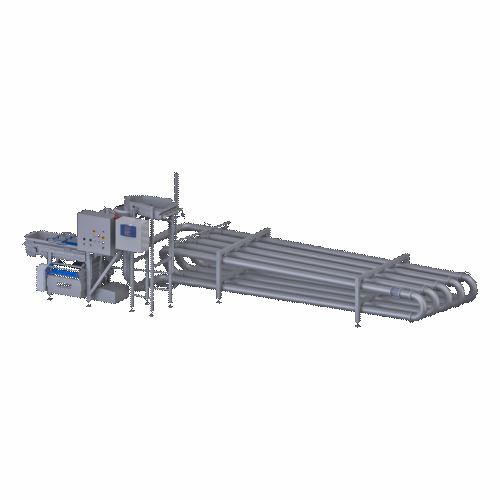

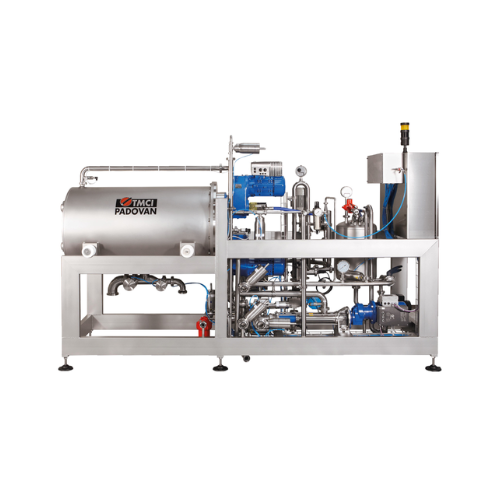

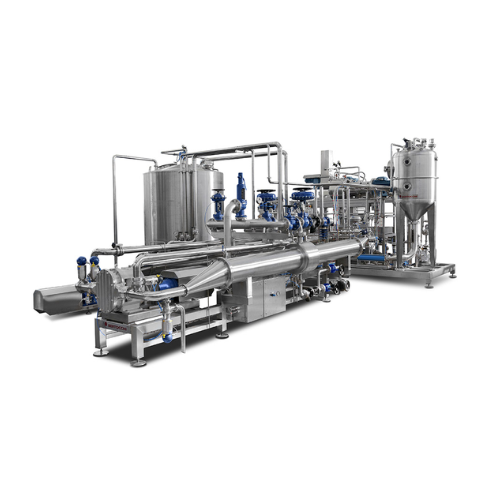

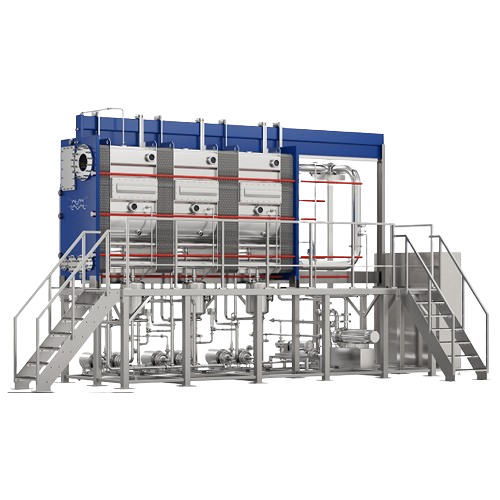

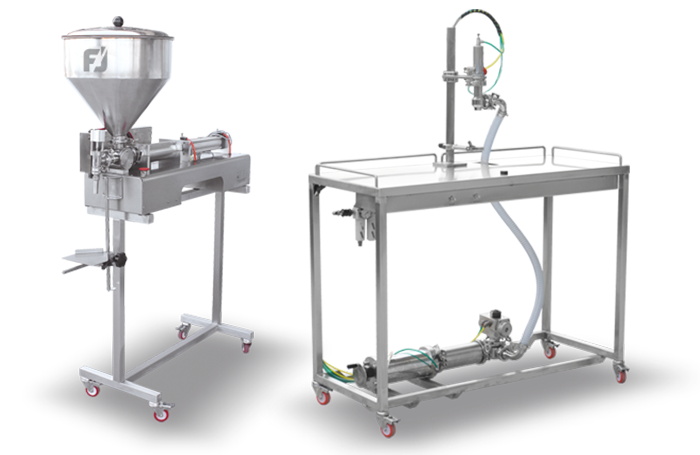

Cold extraction and deaeration system for fruit and vegetable purees

Ensure high-quality fruit and vegetable purees wit...

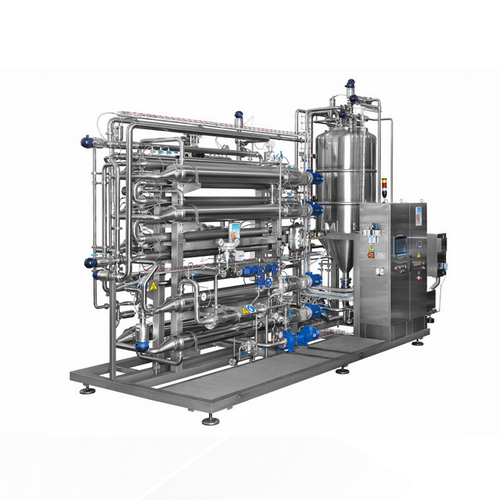

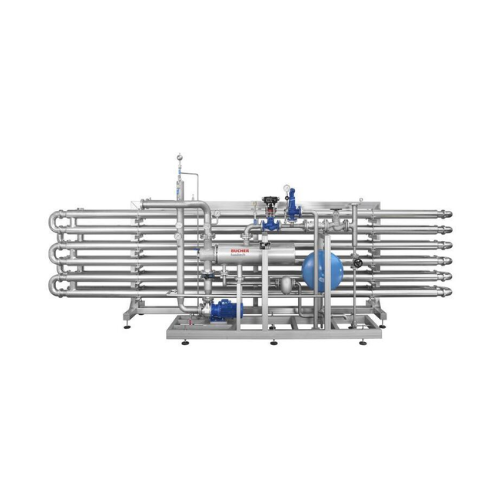

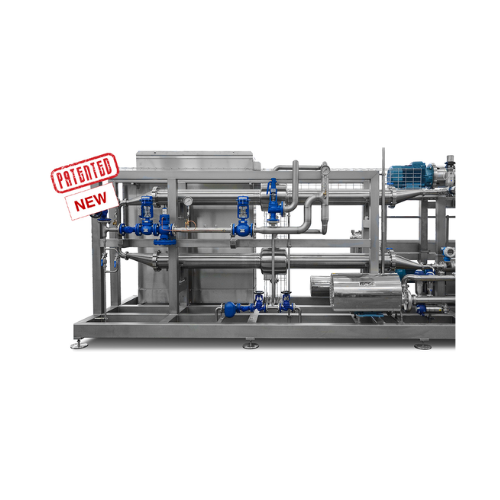

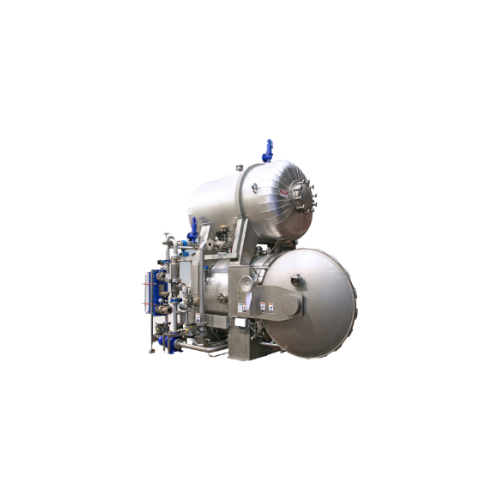

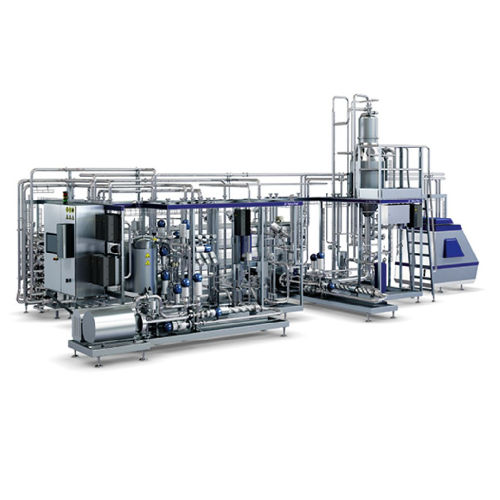

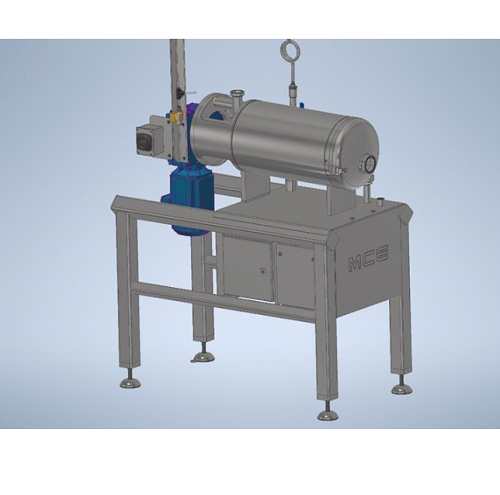

Aseptic sterilizers for fruit concentrates and pulp

Optimize your fruit processing by maintaining product quality and she...

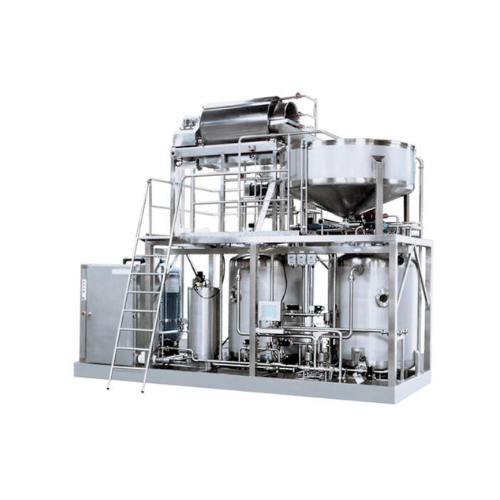

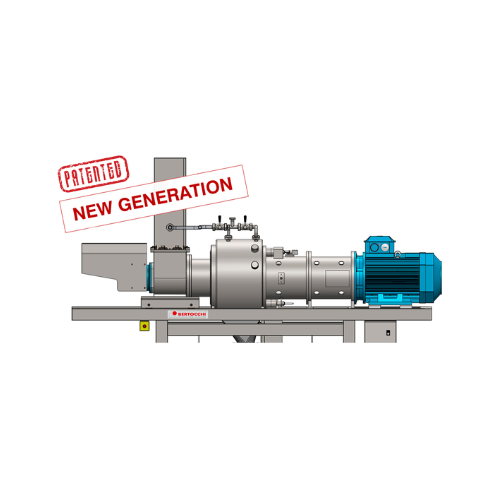

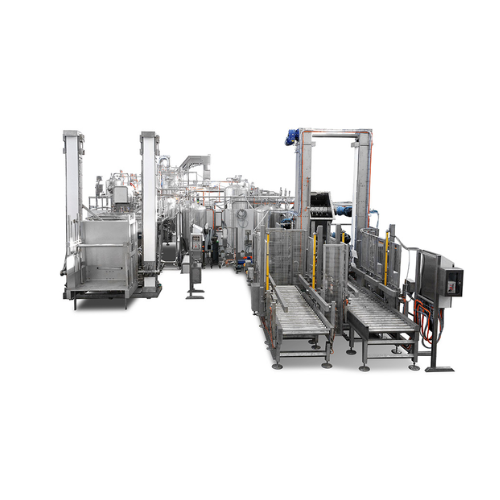

Evaporator for pulpy juice concentration

Achieve efficient concentration with reduced energy consumption, thanks to innovat...

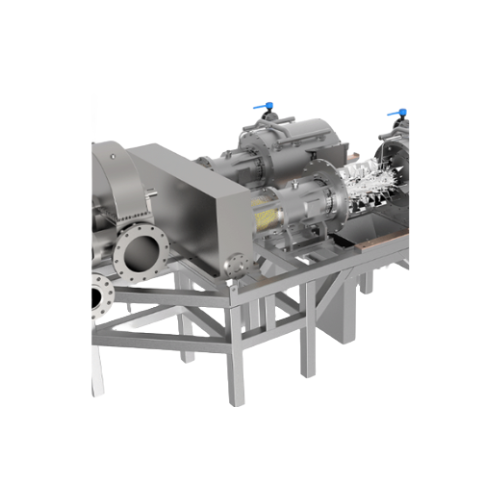

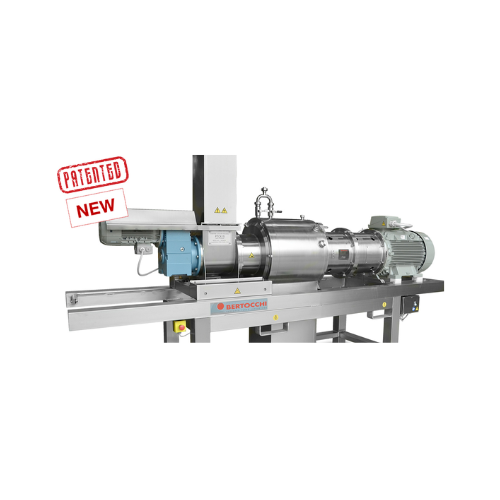

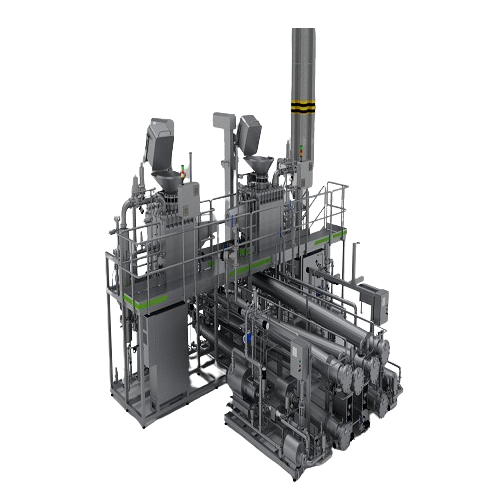

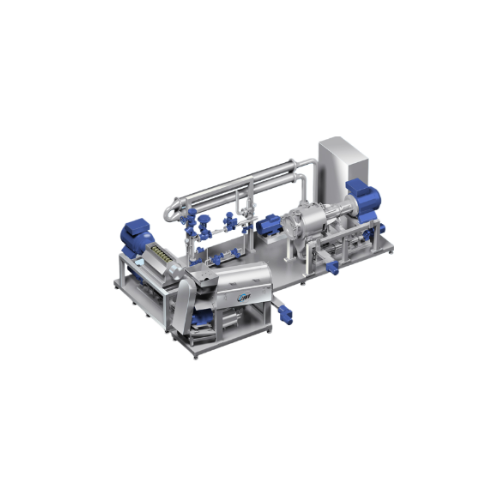

Depulper for efficient fruit and vegetable juice extraction

Streamline your juice production with equipment designed for...

Stories about fruit pulp

#Changemaker: clean even the stickiest products from your pipes by using air

#Changemaker: detect & reject truly low-density foreign bodies in your pumpable foods

From granulated to invert sugar: the liquid therapy to prevent crystals in your jam processing line

Clean up your label, drying fruit extracts without using carriers

#Changemaker: FIBC with brains

Inspect all types of tomatoes with speed up to 100 tons per hour.

Tell us about your production challenge

Fruit pulp extraction

As a natural product, sorting by quality control for ripeness and removal of foreign bodies is vital, and grading by appearance is important to the end user. Fresh fruits, like berries, can be frozen as such, or further processed into purees and concentrate.

The production steps and technology to process fruit pulp depend on the fruit type, scale of production, and desired end product. Typically fruits, such as grapes, are first washed, sorted, and inspected. Afterward, they are peeled and chopped or cut into pieces. Finally, the pulp or fruit juice is extracted, sieved, beat via rotation, and refined to create a more delicate pulp. The pulp can be pasteurized, homogenized, or further concentrated. Some manufacturers will process the seeds to be removed or extracted from the pulp. Whilst others keep the seeds in the pulp depending on what the end fruit pulp product will be.

The most common types of fruits used for making fruit pulp products include apple pear, strawberries, mango pulp, pineapple, peach, and guava.

Producing Jams & Jellies

Jams and Jellies require a minimum of 45 percent by weight in fruit pulp, juice, or pieces. Pectin is needed to set the gel and acid is added to reduce the pH level to 3.1. This process is related to concentration, as the juice is partially concentrated and sugar is added to increase the solids level to above 65 percent. Hot filled with pectin and acid makes jellies and jams reasonably shelf stable.

Vacuum concentration during boil down and rapid filling and cooling dramatically increases jelly quality and is favored over steam kettles when it comes to fruit pulp processing. Low-calorie fruit jelly is even more difficult to manufacture and store. Gel systems that require less sugar therefore usually need to be refrigerated after opening.

Processing Baby Food

Babies and young children until the age of 3, need specialized food and nutrition when they first begin eating. The food must be mushy yet nutritious, preserved well, and conveniently packed. Starting with smooth fruit- and vegetable-based purees, children slowly progress onto a mixed family diet. Healthy organic produce and products that prioritize low environmental impact are gaining territory quickly.

There are strict regulations on composition (protein, carbohydrate, fat, mineral substances and vitamins) and use of toxic pesticides on cereals and fruit and vegetables. In addition, producers must comply with extra safety standards for the hygiene, using food additives and contaminants and safe packaging.

Preserve and pack your fruit products

Aseptic processing is a technique where thermally sterilized liquid products are packaged into previously sterilized containers under sterile conditions to produce shelf-stable products that do not need refrigeration. With a Hot-fill solution, a sterilized sauce will be filled in non-sterile packaging. Only high-acid products can go without refrigeration. Another technique would be retort processing where non-sterile products are filled into non-sterile packaging and sterilized in an autoclave with pressurized steam.

Are you looking for a bulk solution to fill into large aseptic drums or containers? Or would you like to fill into containers, bottles, jars, cans, pouches, or even sachets? You need to make sure to keep your sauce safe and fresh from fill through end use. From small-scale stainless steel autoclaves for jars to high-speed aseptic pouch filling, there is enough choice for every product and production scale.

Which fruit pulp technology do you need?

Helicoid heat exchanger for grape mash and fruit pulp

Enhance your beverage processing with a heat exchanger designed for...

Fruit pulping system for juice production

Optimize your fruit and vegetable juice production with a pulping system that en...

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Industrial destoning solution for stone fruits

Efficiently separate stones from fruit pulp to enhance your production line...

Transport screw conveyor for pomace

Efficiently convey and discharge fruit pomace with a transport screw conveyor designed ...

Secondary solids recovery system for citrus pulp

Optimize your juice yield and enhance efficiency with a streamlined four-...

Industrial screw press for juice extraction

For juice manufacturers aiming for optimal yield and efficiency, this screw pr...

Aseptic sterilizers for fruit concentrates and pulp

Optimize your fruit processing by maintaining product quality and she...

Contact freezer

Frozen food manufacturers may require pre-freezing processes as part of their production steps before conveyin...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Food product smoothing system for dairy and purees

Achieve unparalleled texture and fineness in viscous food products wit...

Tangential filtration system for wine production

Achieve precise filtration, purification, and concentration of compounds ...

Aseptic storage tanks for high efficiency applications

Ensure consistent aseptic storage and efficient handling of variou...

Horizontal plates d.e. filter for wine and vinegar

Optimize filtration and purification across liquids with precision, en...

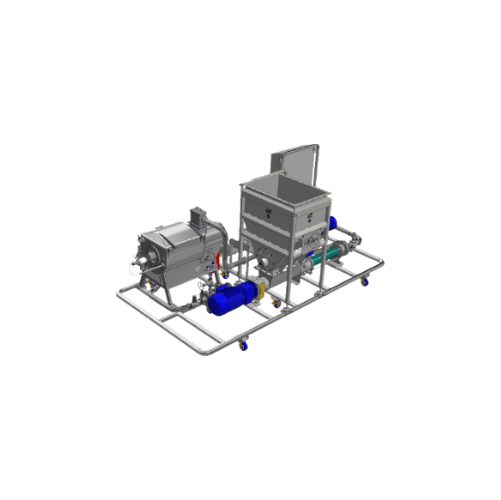

Pilot system for high-viscosity product processing

Efficiently handle high-viscosity or large particle products with this...

Vegetable and fruit peeling and washing

Efficiently wash and peel a wide range of fruits and root vegetables in one seamles...

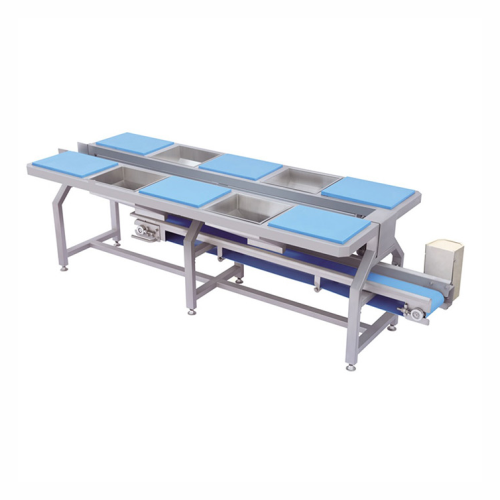

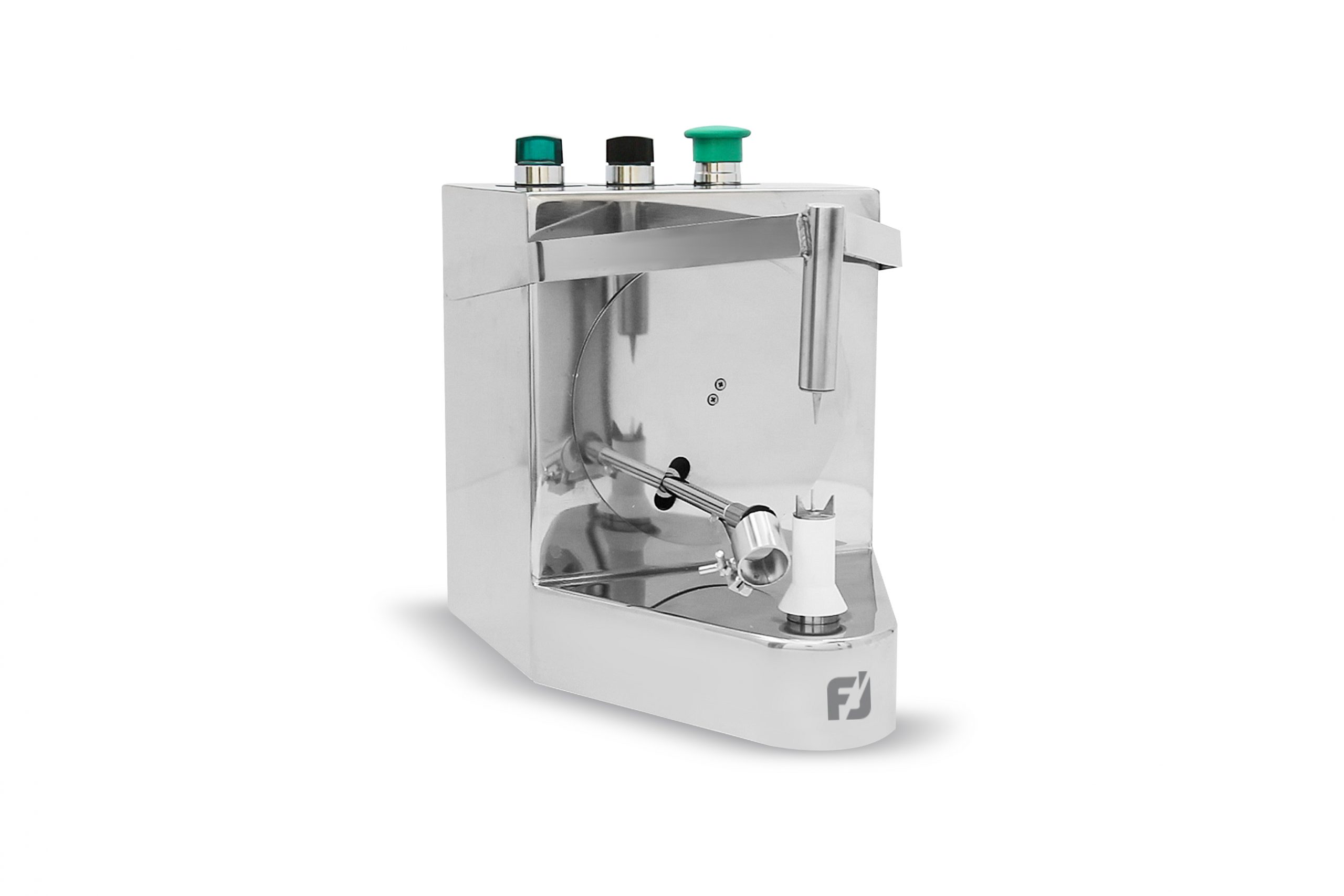

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

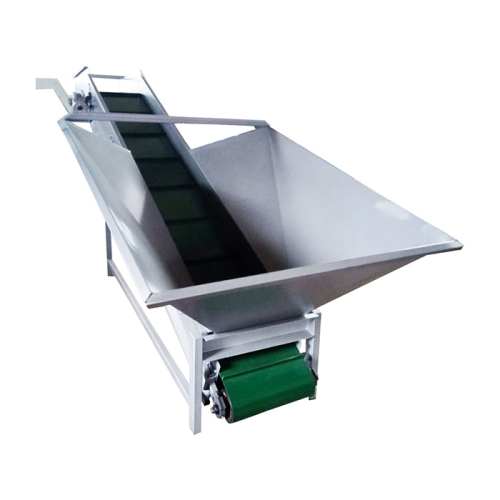

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-p...

Multifunction vegetable fruit slicing solution

Streamline your food processing with a machine that effortlessly slices, di...

Vegetable and fruit dicer for commercial use

Efficiently transform a variety of produce into precise cubes, slices, or shr...

Vegetable and fruit shredder for medium-sized operations

Enhance your vegetable and fruit processing efficiency with this...

Apple coring and wedge slicing solution

Streamline your apple processing with precise coring and slicing to meet diverse pr...

Juice product deaerator

Ensure high-quality filling without foam formation through efficient deaeration, perfect for manufact...

Industrial vegetable and lettuce spin-dryer

Achieve consistent, gentle drying for a wide range of food products with seven...

Industrial raisin washing system

Achieve thorough cleaning and separation for small, high-density food products with this in...

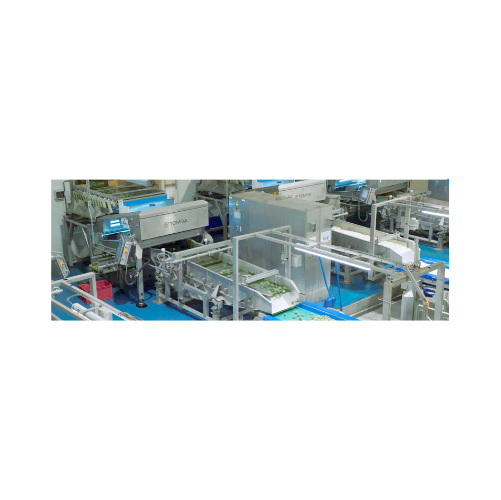

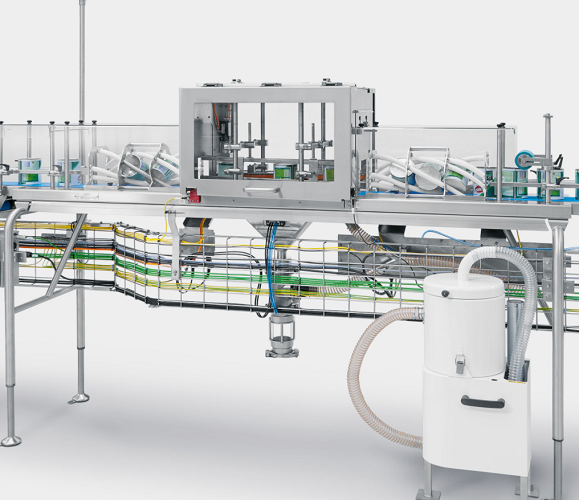

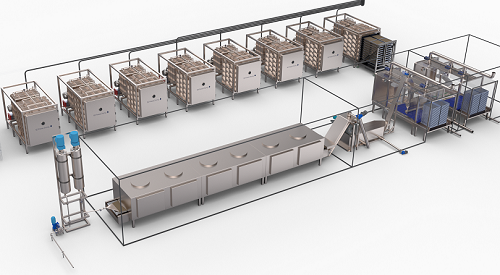

Fruit processing and packaging line

Streamline your fruit and vegetable processing with this semi-automatic system designed...

Manual melon chunk cutter

Transform your melon processing with a compact tabletop cutter, designed for efficient chunking an...

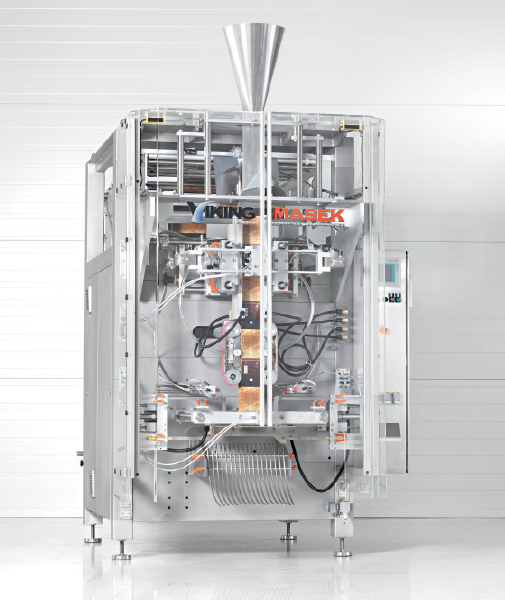

Vertical form, fill and seal packaging system for small bags

Maximize efficiency with small bag portioning for food and ...

Germ reduction system for leafy greens and produce

Optimize your processing line with a flexible germ reduction solution ...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

Manual vegetable and fruit grid cutter

Effortlessly transform small-sized fruits and vegetables into decorative and functio...

Stationary belt press for fruit juice extraction

Achieve optimal juice yield from fruits and vegetables through precise co...

Washing and grinding system for fruit and vegetables

Efficiently wash and grind fruits and vegetables to streamline your ...

Mobile batch blower washing unit for salads and vegetables

Ensure your produce is hygienically clean and ready for furth...

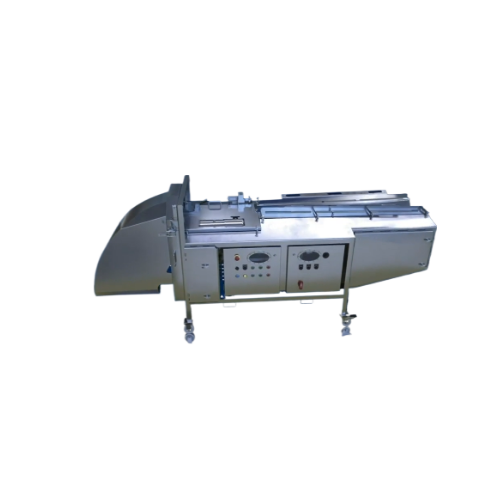

Industrial belt cutting system for vegetables and fruits

Achieve precise and high-capacity cutting for various food produ...

Industrial fruit drying cabinet

Efficiently transform fresh produce into long-lasting, nutrient-dense snacks with precise dr...

Juice bottle and bag-in-box filling systems

Streamline your juice production with versatile filling solutions that accommo...

Fruit bin tipper for processing intake

Efficiently transfer fruits and vegetables from standard bins into your processing l...

Mobile juice processing units

Transform your fruit harvest into fresh, pasteurized juices directly on-site, ensuring optimal...

Natural fiber preparation for packaging

Achieve efficient packaging solutions by preparing natural fibers into high-quality...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

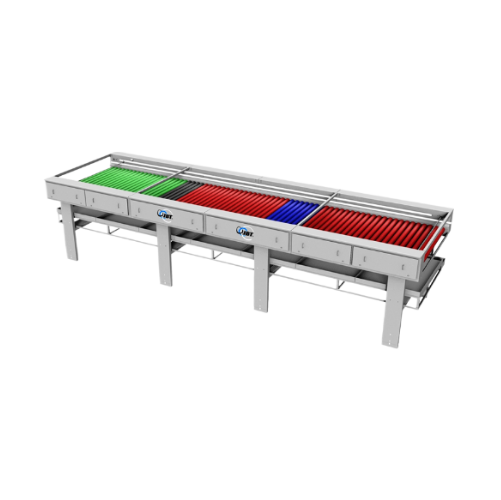

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

Food drying system for diverse products

Achieve precise moisture control and versatile drying for your diverse product line...

Industrial evaporators for multi-product processing

Optimize your production line with customized evaporators designed fo...

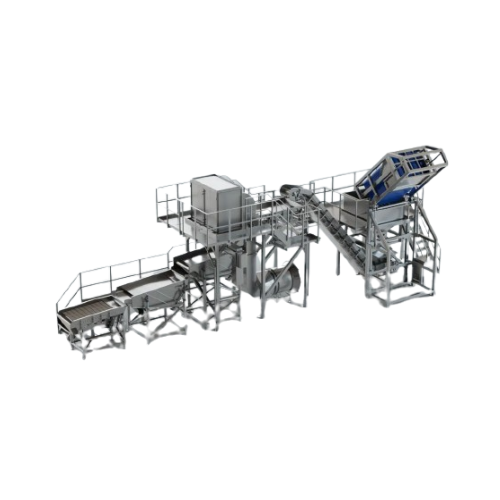

System for receiving, sorting, and destoning fruit

Enhance your fruit and tomato processing efficiency with an integrated...

Aseptic sterilizer for fruit-based products

Ensure product safety and extend shelf life with advanced sterilization techno...

Industrial dicer and peeler for fruit processing

Achieve seamless integration in your processing line with a dicing and pe...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Fruit juice pre-concentrator

Enhance your juice concentration process with a system that increases brix levels efficiently, ...

Enzymatic inactivators for fruit juice extraction

Optimize your fruit juice extraction process by ensuring precise contro...

Evaporator for pulpy juice concentration

Achieve efficient concentration with reduced energy consumption, thanks to innovat...

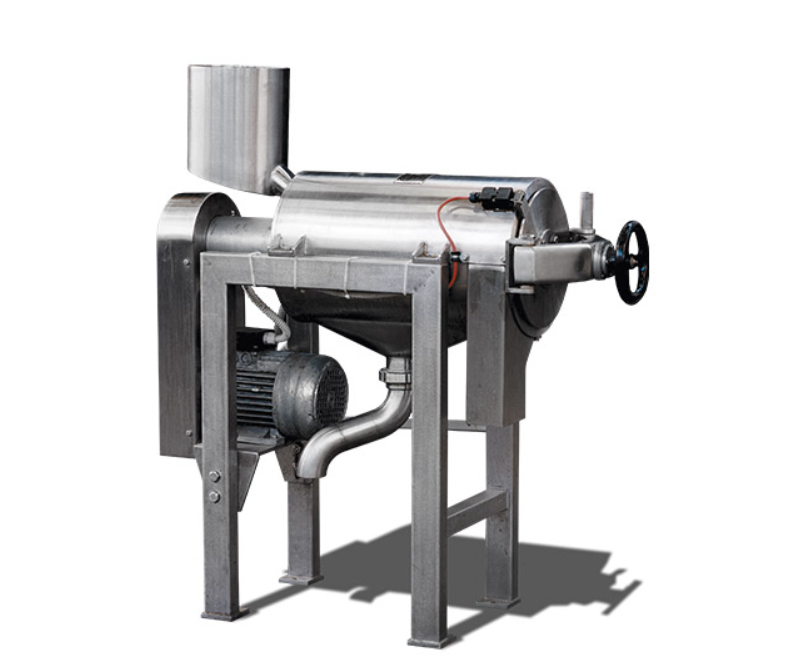

Juice extractor for fruit and vegetable processing

Maximize juice yield and enhance pulp quality with high-performance ex...

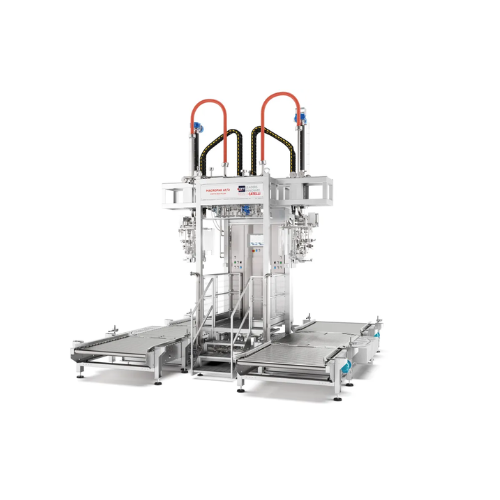

Aseptic filler for large bags

Ensure safe and sterile packaging of liquid and slurry products in large formats with this ase...

Sterilizer for liquid and viscous products

Effortlessly process and sterilize diverse liquid products, from concentrated j...

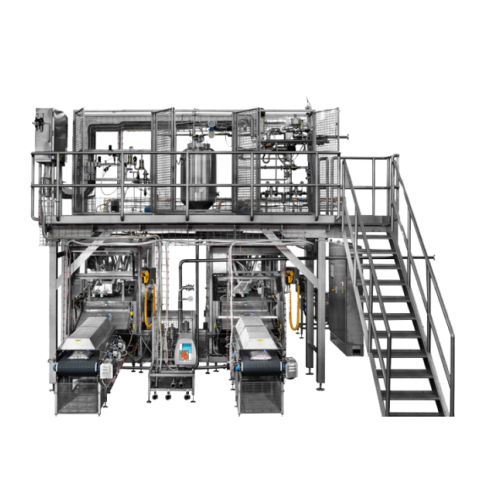

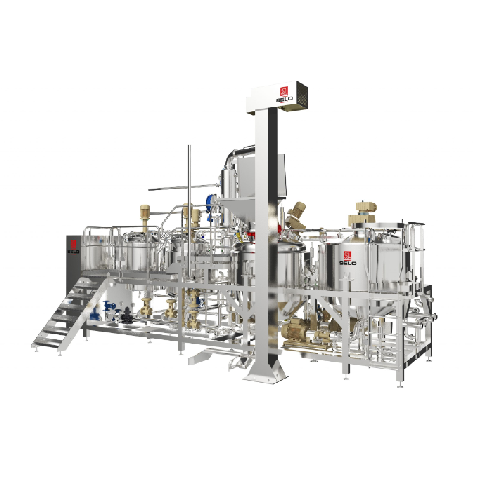

Aseptic treatment and filling for concentrates and purees

Optimize your processing line with a compact solution that com...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

Fruit processing system for jams and marmalades

Optimize your fruit-based product manufacturing with equipment designed fo...

Cleaning and sterilization system for food factories

Ensure optimal hygiene and safety in your production line with advan...

Concentrate drum emptying system

Efficiently extract every drop of fruit concentrate from your drums with precision and ease...

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

Fluidized bed freezer for fruits and vegetables

Efficiently freeze fruits and vegetables without clumping, thanks to advan...

Precision size grader for tomatoes and round fruits

Ensure precise grading and sorting of tomatoes and round fruits to op...

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handlin...

Industrial spiral freezing system

Optimize your food processing line with a reliable spiral system, designed to efficiently...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and ...

Robotic depalletizers for bins

Efficiently optimize your warehouse space while ensuring precise and adaptable material handl...

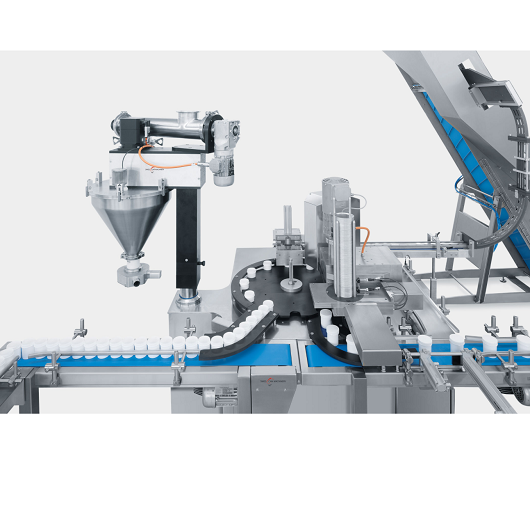

Vibratory rotary filler for accurate filling in food packaging

Achieve precise and efficient filling of diverse solid pr...

Pre-cleaning system for Iqf berries

Ensure the purity of your IQF berries with advanced pre-cleaning technology that expert...

Fruit strigger for Iqf berries

When processing IQF berries, achieving precise stem and flower removal ensures superior quali...

Industrial water chiller for efficient cooling

Achieve precise temperature control and efficient heat transfer with this w...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Crushing mill for berries and stone fruits

Optimize your juice production by achieving the finest mash from berries and st...

Mash heater for core fruits and berries

Improve juice extraction and color yield in your fruit processing line with this in...

Tubular falling film evaporator for fruit juice concentrates

Optimize your fruit juice concentration process with seamle...

Grinding mill for apple and pear mash

Optimize your fruit and vegetable processing with a high-speed, energy-efficient grin...

Cross-flow filtration for wine and fruit juice

Achieve high-quality filtration and purification for liquid and slurry prod...

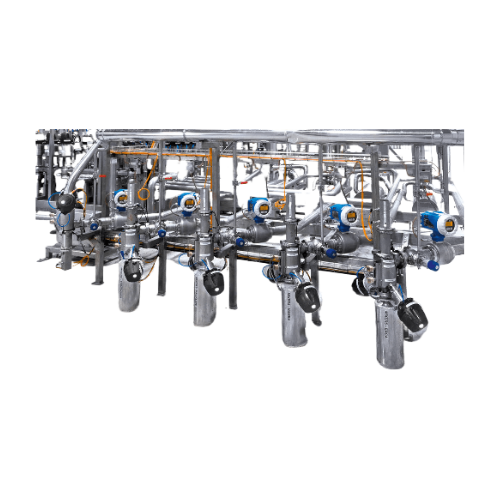

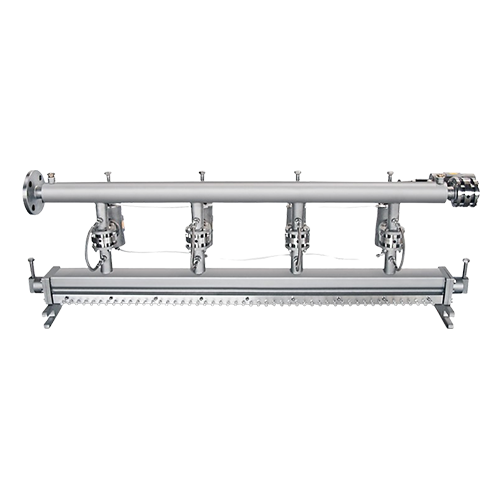

Industrial Cip system for fruit juice production lines

Ensure optimal hygiene and operational efficiency with advanced CI...

Citrus brush washer

Ensure optimal cleanliness of citrus fruits with a mechanical washer that combines rotating brushes and t...

Grinding mill for apples and pears

Optimize juice yield with tailored grinding for a variety of fruits and vegetables, ensu...

Adsorber for haze stabilisation in clear fruit juices

Achieve precise haze stabilization and debittering in fruit juices ...

Horizontal evaporation bowl for fruit jams and purees

Optimize thermal exchange and preserve product integrity during jam...

Evaporator for juices and purees

Efficiently concentrate liquid products like apple juice, tomato puree, and chocolate sauce...

Evaporators for fruit and vegetable juices and purees

Optimize your juice and puree production with advanced evaporators ...

Hammer pulping system for fruit and vegetable processing

Optimize your fruit and vegetable pulping process with a high-sp...

Vacuum degasser for juices and purees

Enhance the quality of your liquid products with efficient degassing and flavor recov...

Chestnut processing line for fresh market

Efficiently transform raw chestnuts into polished, fresh market-ready products w...

Heater for enzymatic inactivation of fruit and vegetable pulp

Optimize your puree and concentrate production with effici...

Continuous cooker for vegetables and fruits

Optimize your production line with a continuous cooker designed to defreeze an...

Shelling mill for Iqf and frozen fruit lumps

Effortlessly process frozen fruit and vegetable conglomerations into shelled ...

Shelling mill for Iqf and frozen lumps

Precision-engineered for the seamless transition from frozen state to process-ready ...

Turbo extractor for puree and concentrate production

Enhance your puree and concentrate production with a turbo extractor...

Sterile cooling system for fruit preparations

For manufacturers seeking aseptic conditions, this cooling system ensures ra...

Ultrafiltration for fruit juices and nectars

Optimize your juice and nectars production with precise ultrafiltration, ensu...

Diatomaceous earth pressure filter for fruit juices and soft drinks

Achieve exceptional clarity and taste in your bever...

High solids crossflow filter for fruit juices and nectars

Eliminate the challenges of suspended solids in beverage produ...

Deaeration system for fruit juices and soft drinks

Enhance your beverage quality by efficiently deaerating and carbonatin...

Microfiltration system for fruit juice and soft drinks

Ensure optimal purity and flavor retention in your beverages with ...

Plate flash pasteurizer for fruit juices and soft drinks

Ensure the purity and safety of your beverages with precision th...

Cleaning in place for fruit juices and soft drinks

Ensure maximum hygiene and reduce downtime in your beverage production...

Desulphurizer for fruit juices and nectars

Enhance beverage quality by efficiently removing sulphur dioxide from fruit jui...

Apple processing equipment for juice and puree production

Efficiently process apples and pears into high-quality juice a...

Avocado processing plant for puree and oil extraction

Optimize your avocado processing with a complete system designed fo...

Dicing solution for fruits and vegetables

Optimize your ready-prepared food production line with a versatile cutting solut...

Industrial jam processing line for fresh fruit or puree

Streamline your jam production with a versatile line capable of p...

Industrial depitter for stone fruits

Effortlessly process stone fruits into smooth purees and nectars with a continuous, co...

Smoothies production line for fruits and vegetables

Optimize your smoothie production with a line designed for efficient ...

Industrial cutter for big fruits and vegetables

When dealing with large fruits and vegetables, precise chopping to prepare...

Industrial liquefying and crunching solution for frozen fruits and vegetables

Efficiently transform frozen produce int...

Turbo extractor for cold extraction of fruit and vegetable purees

Achieve high-yield, efficient cold extraction of frui...

Frozen extraction turbo extractor for fruit and vegetable purees

Efficiently transform frozen fruits and vegetables into...

Cold extraction system for fruits and vegetables puree

Optimize your fruit and vegetable puree production with a versatil...

Washing and sorting line for fruits and vegetables

Efficiently achieve pristine fruit and vegetable cleanliness while enh...

Line for production of fruit and vegetable purees by cold extraction

Streamline your puree production with innovative c...

Frozen extraction line for fruit and vegetable purees

Overcome challenges of processing frozen fruits and vegetables effi...

Cold extraction deaeration system for fruit and vegetable purees

Achieve superior puree quality with our system that ens...

Cold extraction system for fruit and vegetable purees

Optimize fruit and vegetable puree processing with cold extraction,...

Cold extraction line for fruit and vegetable purees

Enhance puree quality with minimal thermal stress through a seamless ...

Cold extraction and enzymatic deactivation for fruit and vegetable purees

Enhance your puree quality with advanced col...

Turbo extractors for tomato and fruit hot extraction

Optimize your fruit and vegetable processing with high-capacity turb...

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expert...

Cold extraction and deaeration system for fruit and vegetable purees

Ensure high-quality fruit and vegetable purees wit...

Cold extraction turbo extractor for fruit and vegetable puree

Optimize your processing line with continuous cold extract...

Aseptic cooking line for plant-based products

Enhance your production efficiency and product quality with an advanced doub...

Aseptic filler for bag in drum or box

Enhance product shelf life and maintain quality without preservatives by employing as...

Fine screen for municipal and industrial wastewater treatment

Streamline wastewater treatment with a reliable, self-clea...

Two-phase decanter centrifuge for olive oil production

Achieve optimal clarity and yield in olive oil extraction with a h...

Climbing film plate evaporator for food industry

Efficiently concentrate heat-sensitive liquids while minimizing product e...

Forced circulation evaporator for high viscosity liquids

Optimize your production by efficiently concentrating viscous an...

Decanter centrifuge for olive oil processing

Optimize olive oil production by achieving higher oil clarity and reduced wat...

Aseptic vacuum cooker-cooler for jams and marmalade

Ensure your fruit-based products retain vibrant color and taste while...

Benchtop mixer for lab-scale product development

Easily scale up your formulations with precise and repeatable lab-scale m...

Fruit pieces handling for juice production

Achieve perfect fruit piece integration in juice with a system designed to prev...

Citrus brush washer for fruit cleaning

Ensure your produce is impeccably clean with a brush washer designed to efficiently ...

Multifunctional washer for fruits and vegetables

Achieve impeccable cleanliness in your food processing line with a versat...

Industrial extraction line for fruits and vegetables

Optimize your fruit and vegetable processing with a highly flexible ...

Pump for products with large particulates

When handling products with large particulates, maintaining integrity is paramou...

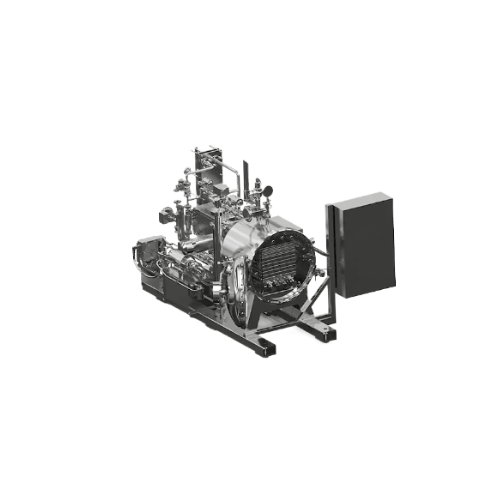

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

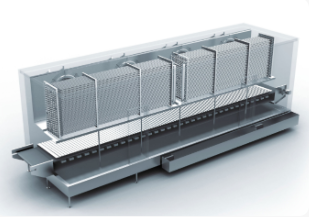

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Laboratory pulp saturation analyzer for citrus processing

Ensure accurate dryness levels of citrus pulp with a reliable ...

High speed fruit and vegetable juicer

Optimize your production with a high-capacity juicer designed to efficiently process ...

Thermal treatment system for tomato purees

Eliminate pectin enzyme activity and prevent syneresis in your purees and conce...

Juice extractors for variety of fruits and vegetables

Streamline your juice and puree production with advanced extraction...

Screw finishers for citrus processing

Optimize your production line with screw finishers designed to efficiently separate l...

Paddle finishers for fruit and vegetable processing

Optimize your processing efficiency with robust paddle finishers desi...

Vegetable and fruit processing skid

Optimize your fruit and vegetable processing with a compact skid that seamlessly integr...

Knocker conveyor for fresh produce processing

For processors dealing with mixed produce, this conveyor effectively separat...

Industrial bin scrubbing system for fresh produce

Enhance food safety and operational efficiency with a bin scrubbing sys...

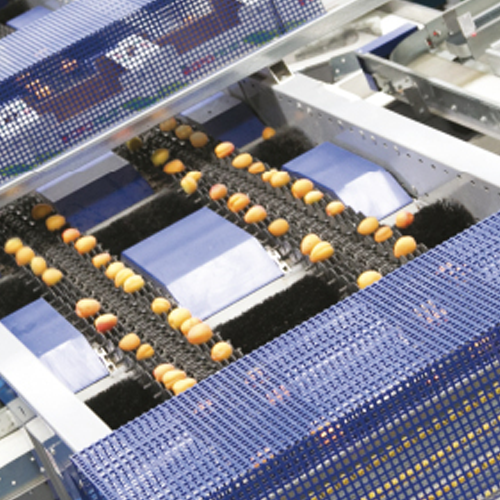

Brush bed system for fresh produce cleaning and waxing

Optimize your fresh produce processing with this advanced brush sy...

Single pass dryer for fresh produce

Optimize your fresh produce processing with a continuous drying solution that enhances ...

Forced circulation evaporator for tomato and fruit paste

Optimize your high-viscosity tomato and fruit paste production w...

Evaporator for citrus juice concentrate

Optimize juice concentration and reduce thermal damage with advanced short-time eva...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

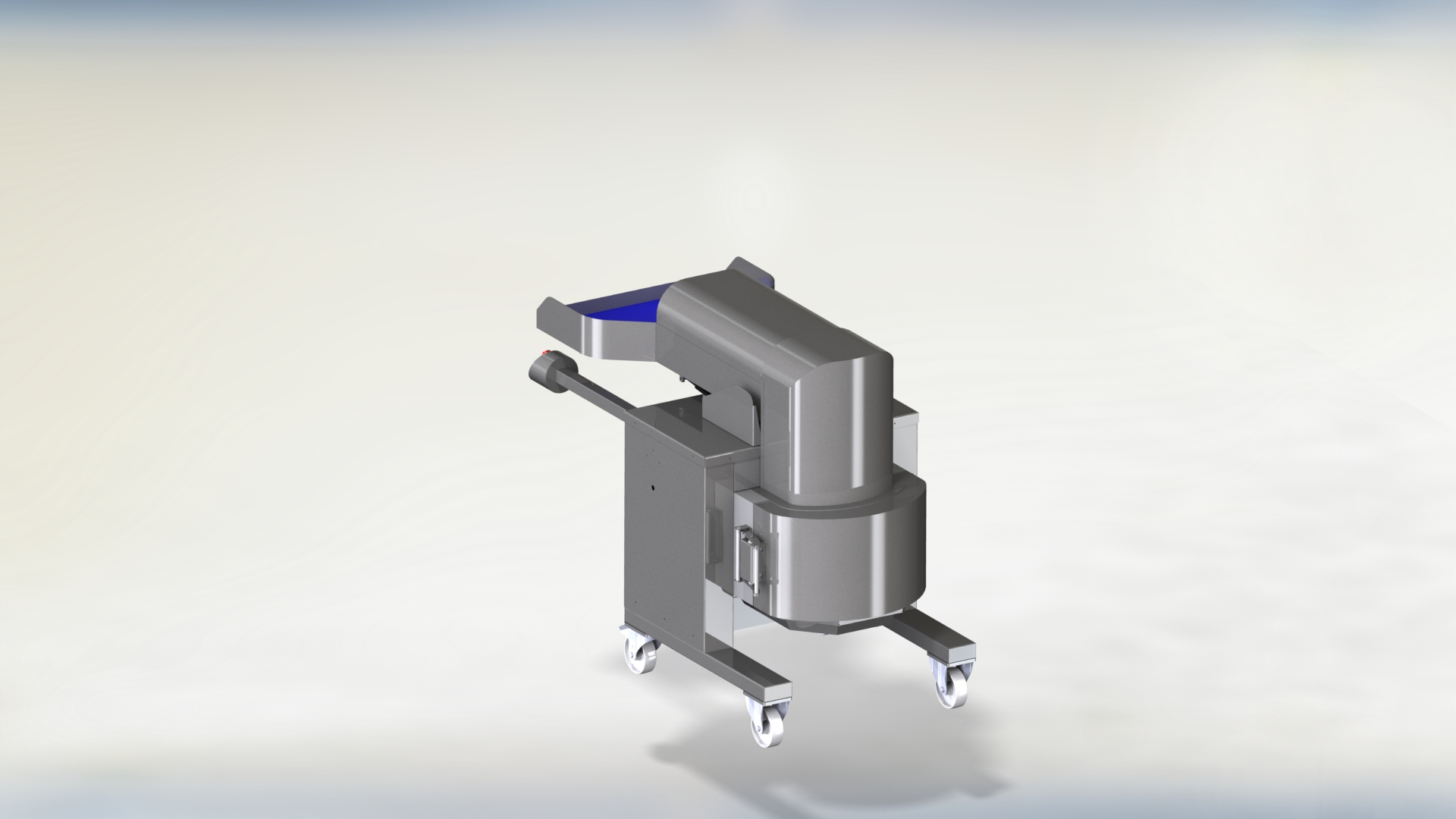

Industrial chopper/blender for frozen fruit processing

Efficiently transition frozen fruits and concentrates into a manag...

Industrial chopper blender for thawing frozen products

Quickly transform frozen produce into pumpable liquids, optimizing...

Industrial-scale chopper and blender for frozen juice processing

Eliminate lengthy thaw times for frozen concentrates wi...

3a certified product recovery system for food and pharmaceuticals

Optimize your production line with a system designed ...

Iqf tunnel freezers for berries

Maximize product quality with advanced fluidization technology, ensuring consistent freezing...

Clarifying decanter for starch recovery

Ensure optimal dewatering and separation of starch, pulp, and fibers with this high...

Vacuum juicing for fruits and vegetables

Achieve superior juice quality with minimal oxidation and maximum nutrient retenti...

Fruit treatment lines for juice and pulp extraction

Optimize your juice production line by efficiently extracting, proces...

Industrial fruit juice extractor

Maximize juice yield from a wide range of fruits and vegetables with precise extraction and...

Industrial fruit washing and loading hopper system

Streamline your juice production by ensuring optimal fruit preparation...

Depulper for efficient fruit and vegetable juice extraction

Streamline your juice production with equipment designed for...

Industrial fruit elevator crusher

Maximize juice yield and streamline processing with efficient fruit crushing and elevatio...

Flash pasteuriser for high-quality fresh juice

Achieve superior juice quality and extended shelf life with precision paste...

Food freeze dryer for bulk materials

Achieve efficient and uniform drying of fruits, herbs, and other materials with advanc...

Industrial multifiller for fruit and vegetable salads

Need to efficiently fill diverse containers with fruit and vegetabl...

Shaftless spiral conveyor for waste water treatment

Efficiently handle challenging materials like de-watered sludge and s...

Vertical screw separator for slurries

Efficiently separate solids from liquids in diverse slurry applications, ensuring opt...

Horizontal screw press separator for pomace yield optimization

Enhance your production line by efficiently separating so...

High-capacity food processor slicer

Enhance your production line with precise cutting capabilities and reduced cleaning tim...

Automatic bin dumper for various fruits

Streamline your fruit and vegetable processing with our self-adjusting bin dumpers,...

Bin fillers for fruit packing

Achieve precise and gentle handling of fruits and vegetables with flexible bin fillers that se...

Automatic palletizer for fruit and vegetable crates

Optimize your fruit and vegetable handling with efficient palletizati...

Avocado sorting and processing systems

Ensure consistent quality and maximize yield in your avocado production with precisi...

Water purification systems for fruit processing plants

Ensure high-quality fruit products with pristine water through adv...

Persimmon sorting and grading system

Streamline your persimmon processing with advanced sorting and grading that ensures pr...

Plum sorting and grading system

Enhance your fruit processing efficiency with our advanced solution that precisely sorts and...

Sour cherry sorting and grading system

Optimize fruit processing with precision sorting technology that ensures the highest...

Industrial fruit bin washing system

Optimize your fruit and vegetable processing with a high-speed bin washing system that ...

Brushing systems for agricultural produce

Enhance the precision and efficiency of fruit and vegetable processing with vers...

Automatic crate fillers for fruit packing

Elevate your fruit packing efficiency with precision crate fillers, designed to ...

Grapefruits sorting & grading system

Achieve unparalleled precision in grapefruit processing by eliminating manual selectio...

Mandarin and clementine processing sorting and grading system

Optimize your citrus operations with advanced processing s...

Grading and sorting solutions for apricots

Optimize your fruit production with precise grading and sorting technologies de...

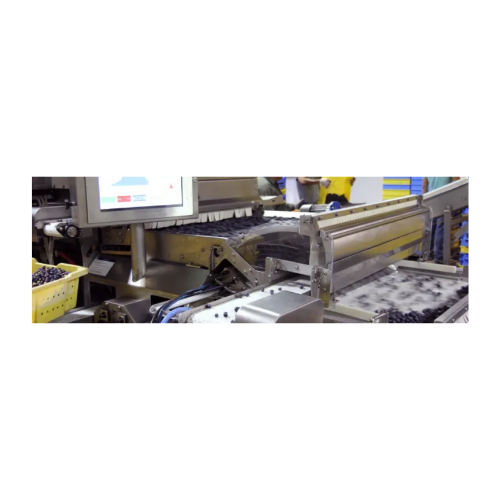

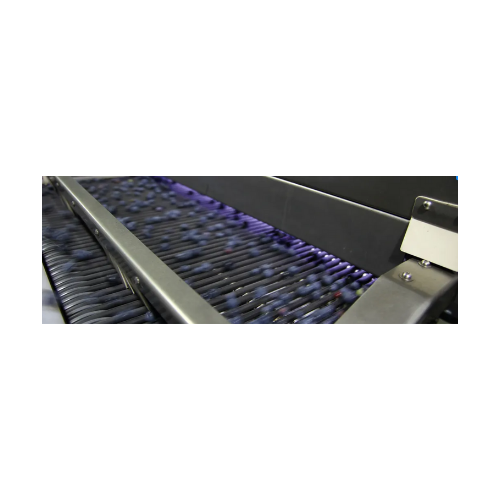

Blueberry sorting for consistent quality control

Ensure your blueberries meet market standards with precise sorting and gr...

Parfait production line equipment

Optimize your dessert production with advanced depositing technology, perfect for creatin...

Industrial food filler for precise depositing over conveyors

Optimize your food production line with a versatile filler ...

Horizontal flow wrapper for packaging trays and punnets

Optimize your packaging process with an adaptable flow wrapper, p...

Forced circulation fruit juice concentrator

Optimize your fruit juice production with advanced forced circulation technolo...

Multi-fruit extraction line for mango, guava, and passion fruit juice

Optimize your fruit processing with high-yield ex...

Small-scale fruit processing line for juices and sauces

Streamline your small-scale production with a versatile line that...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...

Multifruit processing line for tropical and temperate fruits

Optimize your fruit processing operations with a versatile ...

Nectar formulation line for fruit juices

Optimize your fruit-based product lines with a seamless process that integrates hi...

Peach, plum, and apricot juice processing line

Optimize your fruit processing capabilities with a multifunctional solution...

Pineapple juice extraction line

Streamline your pineapple processing with a complete solution designed to efficiently transf...

Aseptic filler for fruit juice and dairy products

Ensure sterile, high-speed filling of liquids and creams with precision...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

Banana purée production line

Maintain banana pulp quality by processing in a nitrogen atmosphere, ensuring fresh, oxidation-...

Batch evaporators for fruit juice and tomato concentration

Achieve high-quality fruit and tomato concentrates while pres...

Automatic banana peeling solution

Struggling with banana oxidation during puree production? This solution ensures swift, hi...

Falling film concentrators for low viscosity fruit juices

Achieve high concentration levels in fruit and dairy products ...

Acai berry processing line

Enhance your acai berry production efficiency with an automated line that transforms traditional ...

Apple, pear, and kiwi juice extraction line

Achieve high-yield juice production from apples, pears, and kiwis while retain...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Food dehydrator with Bpa-free trays

Effortlessly retain nutrients while creating a variety of dehydrated snacks using dual ...

Cabinet Food dehydrator

Achieve precise drying control with dual fan technology, ensuring even airflow and optimal nutrient p...

Tomato squeezer for efficient fruit and vegetable pressing

Streamline your fruit and vegetable processing with a versati...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Professional food dehydrator for fruits and vegetables

Enhance your culinary creations with precise dehydration technolog...

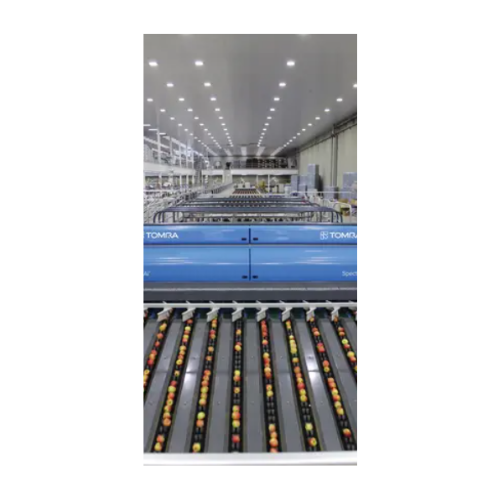

Advanced fruit sorting platform

Optimize your operations with a cutting-edge sorting solution designed to enhance product in...

Dry bin filling for delicate fruit

Achieve gentle, high-throughput filling of delicate fruits with minimized manual interve...

Soft fruit sorter for packing lines

Enhance your production line’s efficiency by accurately sorting and removing unwa...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Blizzard sorter for Iqf fruits and vegetables

Optimize your frozen food production with a compact sorter that seamlessly r...

Cherry singulation system

Effortlessly streamline cherry processing with a system that ensures gentle handling and superior ...

Color sorter for small fruits

Optimize your production line with a high-speed color sorting solution that enhances quality c...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

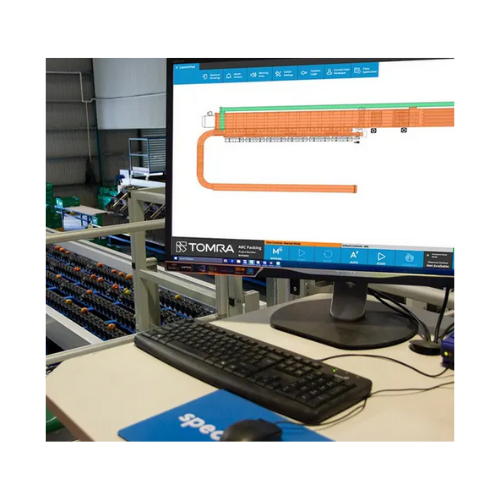

Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and r...

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with cont...

Blueberry pre-grading system

Optimize your blueberry sorting by automating the removal of clusters and unwanted berries, enh...

Blending tank for food preparations

Optimize your production line with a tank designed for efficient blending and storage o...

Vibration sieving machine for removing droplets or oil

Enhance your production line by efficiently removing surface liqui...

Spiral fruit juicer for apples and oranges

Enhance juice production efficiency by seamlessly integrating this spiral fruit...

Industrial strawberry and blueberry washer

Ensure your soft fruits remain intact and impurity-free with this specialized w...

Industrial passion fruit juicer for efficient juice extraction

Achieve complete separation of passion fruit components w...

Mango juice production line

Streamline your mango juice production with a complete solution that efficiently transforms fres...

Jujube grading machine for round and oval fruits

Optimize your fruit and vegetable processing with precise size sorting, e...

Bubble type fruit and vegetable washer

Ensure your produce is impeccably clean and damage-free with our bubble-type washing...

Date palm processing line for jujube cleaning and drying

Optimize your date and fruit production with our line that ensur...

Vegetable and fruit air drying production line

Efficiently dry fruits, vegetables, and vacuum-packed goods while maintaini...

Dual-motion rectangular separator for pulp and paper industry

Optimize your production line with a versatile separation ...

Fruit washer for efficient cleaning and sanitizing

Effectively clean and sanitize a range of buoyant and non-buoyant frui...

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Vacuum juice extraction for various soft-pulp fruits

Achieve superior fruit juice quality by maintaining the integrity of...

Jam production line

Optimize your jam production with our sophisticated line that ensures high capacity, consistent quality, ...

Flaker for frozen meat and food blocks

Efficiently transform solid blocks of frozen foodstuffs into precise cuts and flakes...

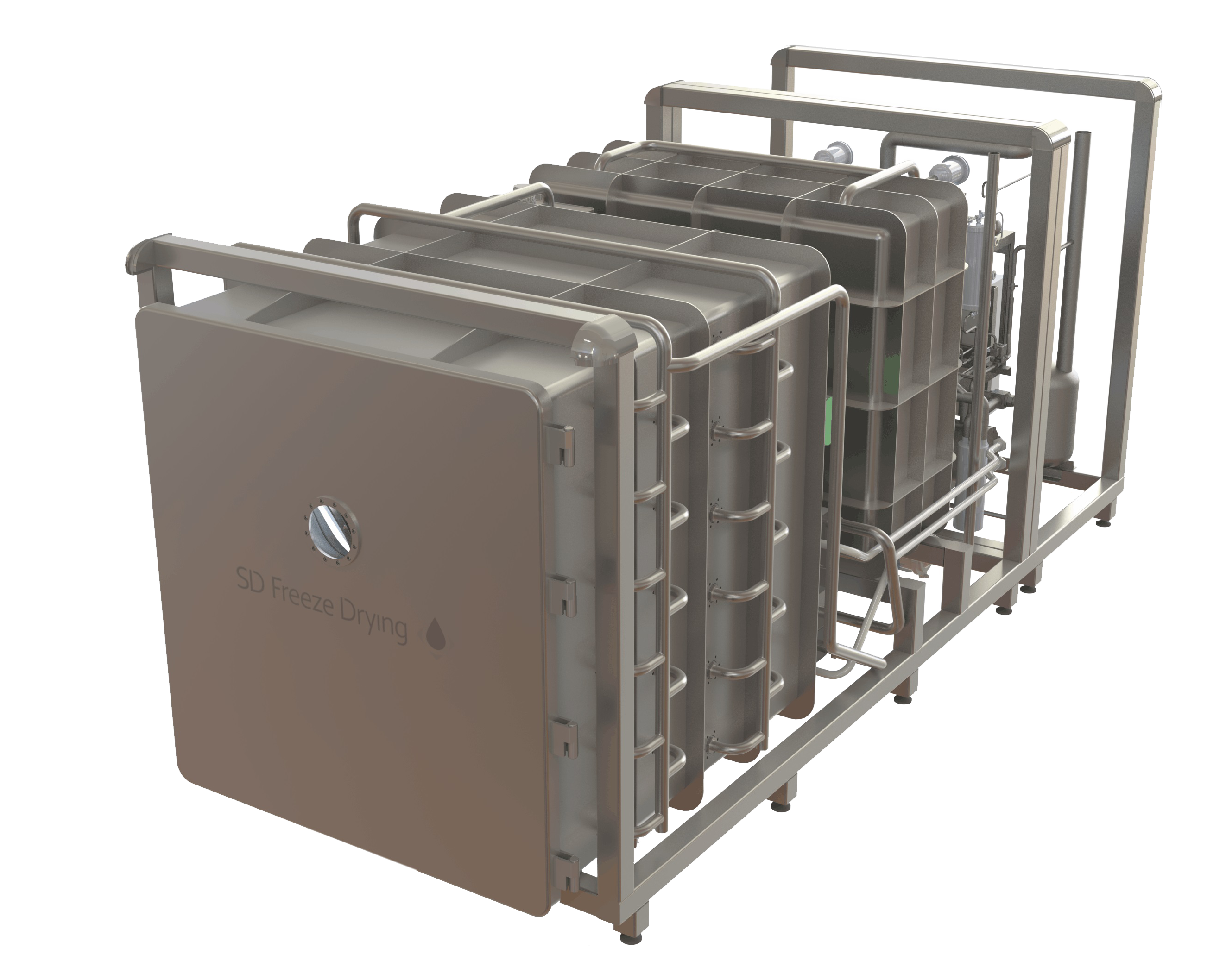

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

IQF (Individual Quick Freezing) freezer

Food products such as berries and fries in large volumes may tend to stick and form...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Tomato seed extraction machine

Although it’s the safest method, extracting tomato seeds manually can be time-consuming...

Industrial jam vacuum cooker

In a production setup of agri-food preserves, sauces, and other condiments, vacuum cooking at 5...

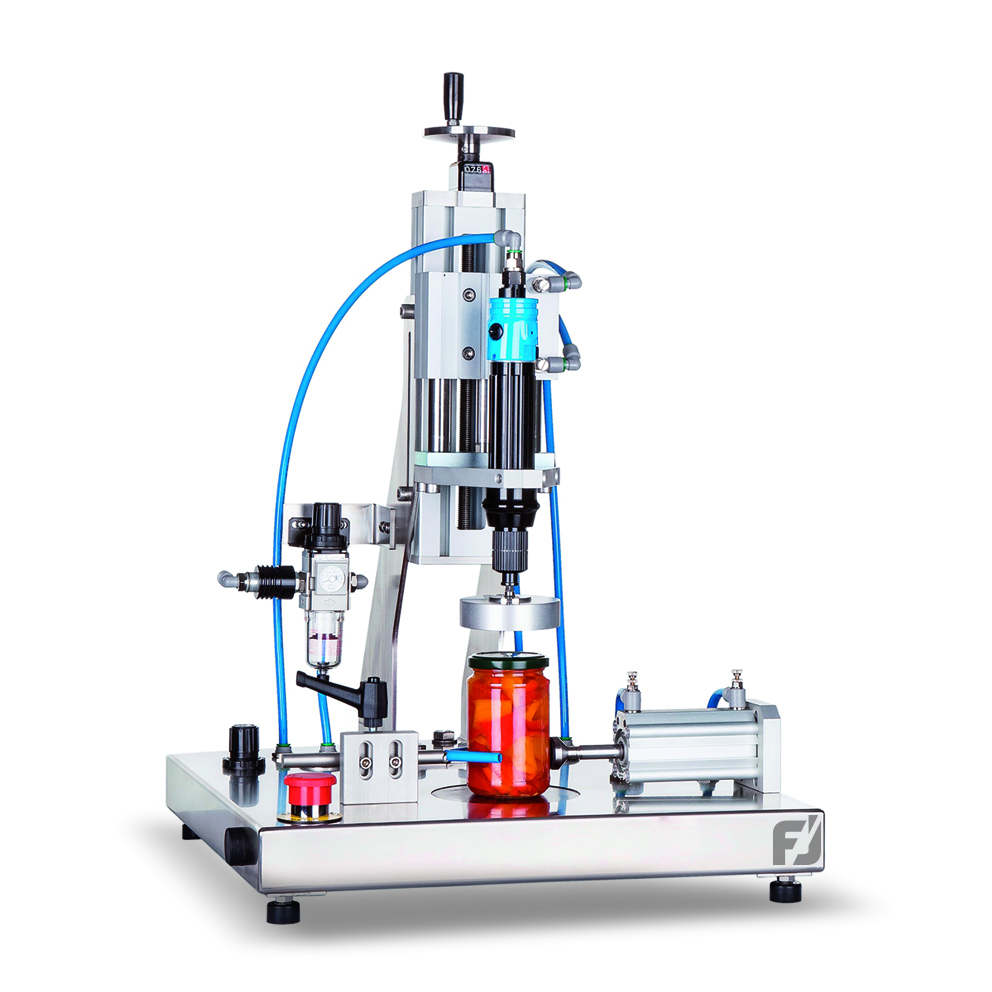

Capping Machine for Jars

In production lines that involve sterilization processes, jars that are not properly capped may expl...

Semi-Automatic Volumetric Liquid Filling Machine

Filling containers manually with liquid and viscous products is the metho...

Small Scale Industrial Jam Cooker

Production of marmalades, jams, fruit concentrates, and sauces requires multiple steps. T...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Optical sorter for fruit and vegetables

In fresh vegetable and fruit production, product quality is key to ensure a longer ...

Industrial washing machine for fruits and vegetables

The effective fruit and vegetables’ initial preparation for producti...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

Automatic Peeler Machine For Fruits and Vegetables

Manually peeling fruits and vegetables can be tedious. Especially in l...

Vegan Sauce Processing System

Having a multipurpose machine allows one to perform different tasks like cooking, frying, brai...

Industrial washer for plastic crates

In the food production sector, hygiene regulations are getting stringent by the day. E...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Craft Beer Pasteurizer

Pasteurization of craft beers in breweries is very important to ensure the maintenance of taste and ex...

Licorice cooker

When producing liquorice and other sticky or viscous food products, during the cooling or heating process, com...

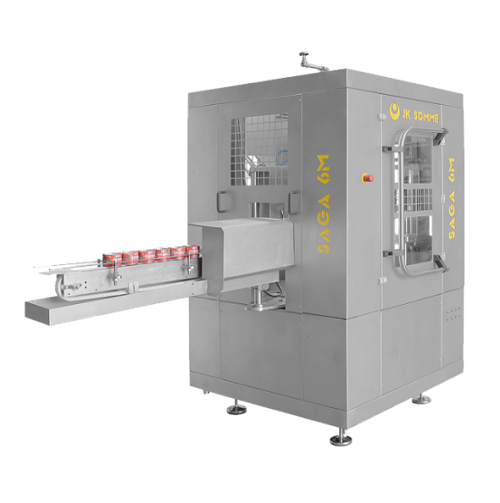

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Jam pasteurizer with temperature control

Microorganisms and pathogenic forms in fresh fruit jams can shorten storage time. ...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Ionized air system for cleaning of baby food cans

When producing canned food products, especially those for infant...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Industrial potato washer

Washing potatoes or other vegetables can be a time consuming task for large restaurants or other foo...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

High-clean FFS machine for butter in mini portions

With the production of dairy products such as butter in mini portions ...

High pressure processing machine for juice

High-pressure processing (HPP) is one of the technologies in the manufacturing ...

Continuous cocoa bean roasting line

When you are processing chocolate, after the conditioning and fermenting of cocoa, the ...

Entry-level vertical cartoner for frozen food

When it comes to frozen food, selecting quality packaging is fundamental for...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Industrial IQF freezer for fruits and vegetables

As people become more health aware, frozen fruits and vegetables have bec...

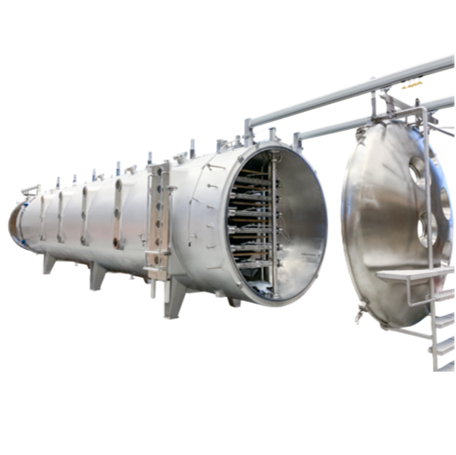

Industrial freeze-dryer for fruits

Freeze-drying is a complex and delicate process. If you are searching the market for a f...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Inline syrup room

The beverage industry requires high-quality syrup. Soft drinks, fruit juices, still drinks, ice tea, flat o...

Flash pasteurizer for beer

The food and beverage industry are faced with constant challenges. Contamination and cross infect...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand forming machine for creamy mixtures

Turn your ingredients mixture into strands and slabs for further processing int...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Air knife dryer for pouches

Flexible pouch packaging is a popular choice for many consumer food products. Before final print...

Autoclave for canned food

Sealing and cooking products in cans, pouches or other containers is a very popular method of pres...

Optical sorter for dried and frozen fruits

Dried fruits, frozen fruits, frozen vegetables and nuts present a challenge for...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Continuous vacuum belt dryer

For gently drying liquid concentrates into granulates or powders, a vacuum drying solution is t...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Food processor for making fruit jams for pastries

In a bakery environment fruit jams are often used for the decoration or...

Multi-functional food processor for a high sugar percentage pastes production

For the development and production of hi...

Vacuum cooker for concentrating sauces and purees

When producing high quality prepared food, concentrating products for s...

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

Declumping machine for dried fruit or frozen vegetables

Breaking up dried fruit neatly, without damage, requires gentle a...

Cold oil press for seeds

With a cold oil press, you can optimize the process of extracting oil from a wide variety of oil see...

Basic mixer for granular foods

Straightforward blending solution for mixtures of beans, nuts, berries & powdered foods, ...

Hygienic open-mouth bottom-up baggers

Here are the open-mouth baggers that are specially designed for hygienic bagging of p...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Short path evaporators

With short path distillation, a substantial decrease of boiling temperature is obtained by reducing th...

Continuous cooker for hard caramels

Continuously cook ingredients for your hard caramel-based product. This is a three-stag...