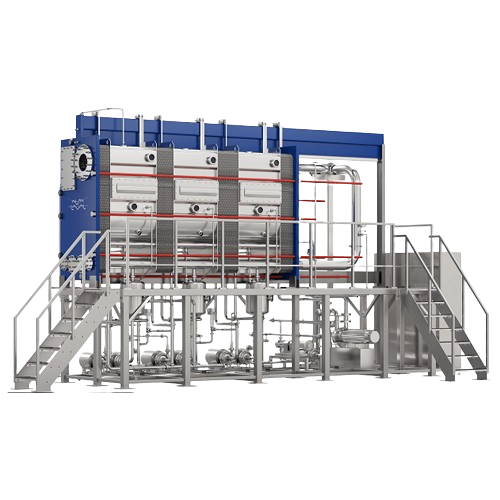

Climbing film plate evaporator for food industry

Efficiently concentrate heat-sensitive liquids while minimizing product exposure to heat, enhancing quality, and reducing energy use.

Concentrates and Separates Liquid Products Efficiently

The AlfaVap Inline from Alfa Laval is a climbing film plate evaporator designed to maximize efficiency in concentrating heat-sensitive, low-to-medium viscosity products. Its modular design supports applications in the food, beverage, and herbal supplement industries by effectively reducing product exposure to heat, which is crucial for maintaining quality in products like fruit juices and protein hydrolysates.

This system utilizes a multi-effect evaporation process, allowing production capacity to expand without increasing energy consumption. Its compact skid-based design ensures easy integration into existing production lines, minimizing the need for extensive restructuring. Operating continuously and at high speed, the AlfaVap Inline is engineered for energy efficiency, reducing steam consumption.

Constructed from high-quality materials, it offers durability and corrosion resistance, essential for processing aggressive liquids. The system’s vapor-liquid separation vessel ensures precise separation, enhancing the quality of the end product, such as orange juice concentrate and ginseng tonic beverage. With options for various configurations and engineering support, the AlfaVap Inline fits seamlessly into any production environment.

Benefits

- Enhances product quality by minimizing heat exposure.

- Lowers operational costs with reduced steam consumption.

- Integrates flexibly into compact spaces, optimizing factory layout.

- Facilitates easy maintenance with accessible modular design.

- Supports sustainable practices by decreasing carbon footprint.

- Applications

- Sugar, Functional foods, Protein hydrolysates, Herbal extracts, Ginseng extract, Sweeteners, Fruit juices

- End products

- Ginseng tonic beverage, Collagen peptides, Cane sugar syrup, High fructose corn syrup, Stevia extract, Orange juice concentrate, Apple juice concentrate, Botanical supplement tinctures

- Steps before

- Purification, Mixing, Heating

- Steps after

- Cooling, Concentration, Packing

- Input ingredients

- fruit juices, sugar, sweeteners, herbal extracts, protein hydrolysates

- Output ingredients

- concentrated liquid, ginseng extract, concentrated fruit juices, concentrated sugar, concentrated sweeteners, concentrated herbal extracts, concentrated protein hydrolysates

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Evaporator Type

- Rising film plate evaporator

- Product Viscosity

- Low to medium

- Fouling Tendency

- Low to medium

- Modularity

- Modular process skid

- Retention Time

- Reduced to minutes

- Space Requirement

- Ultra-compact footprint

- Material Usage

- Less steel used

- Energy Efficiency

- High, reduced steam consumption

- Height Comparison

- Lower than comparable evaporators

- Foundation Requirement

- Smaller concrete foundation

- Temperature Difference

- Operates with small temperature differences

- Installation Cost

- Reduced installation costs

- Working mechanism

- Climbing film plate evaporator

- Integrated steps

- Vapor-liquid separation

- Flow type

- Inline Continuous

- Retention time

- Reduced to minutes

- Steam consumption

- Reduced by increasing effects

- Product exposure to heat

- Minimized by up to five times

- Modular design

- Process skid

- Temperature difference

- Small, for increased effects

- Maintenance

- Easy access, minimal maintenance

- Product Types

- Fruit Juices, Sugar, Herbal Extracts, Protein Hydrolysates

- Compact Installation

- Reduces Installation Costs

- Machine footprint

- Ultra-compact

- Height

- Lower than comparable systems

- Weight

- More lightweight than comparable evaporators

- Foundation requirement

- Smaller concrete foundation

- Installation space

- Fits into tight spaces

- Structure

- Modular process skid

- Feed method

- Dual inlet at the bottom

- Discharge method

- Outlet at the top for vapor, outlet at the bottom for liquid in vapor separator

- Modular design

- Yes

- Compact footprint

- Ultra-compact

- Process skid

- Modular

- Integration possibilities

- Fits into existing structures

- Energy efficiency

- Low steam consumption

- Retrofitting

- Reduces installation costs