Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and real-time product tracking, enhancing efficiency and ensuring traceability from harvest to the point-of-sale.

Monitors and Optimizes Production Line Efficiency

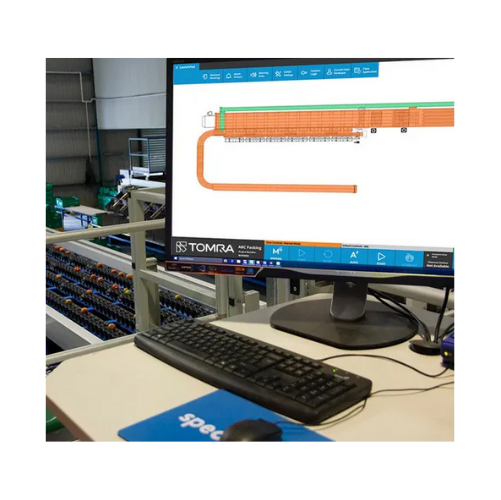

The SmartLine Supervisory Control and Product Tracking System from TOMRA is designed to revolutionize your food processing and agricultural operations. By leveraging the power of the industry-leading Wonderware® software by Aveva, this system offers a comprehensive approach to managing production lines with precision. Central to its functionality is the SCADA-based control, which allows for real-time monitoring and data acquisition, enhancing decision-making and operational efficiency.

SmartLine supports a wide range of applications, accommodating the complexities of processing fruits, nuts, dried fruit, potatoes, seafood, seeds, grains, vegetables, confectionery, coffee beans, and pet food. Whether you’re producing fruit juices, potato chips, or packaged seafood, this system ensures that each step—from sorting and speed optimization to final packaging—is tightly controlled and traceable.

The Adaptive Rate Controller is a highlight, offering dynamic infeed speed adjustments to optimize the sorting process, effectively handling large volumes of product. Meanwhile, the FreshTracker system provides unmatched traceability, pinpointing product issues down to the picker and field, which minimizes the risk of complete recalls.

Integration is seamless, with capabilities for automation and supervisory control, making it suitable for continuous and high-speed operations. The system enhances both line efficiency and accountability while being adaptable to specific customer needs. With TOMRA’s global service support, you can ensure minimal downtime and continuous optimization of your production line.

Benefits

- Enhances operational efficiency by optimizing production line speed and tracking precision.

- Minimizes product recall risk through comprehensive traceability and problem identification.

- Improves decision-making with real-time data acquisition and situational awareness.

- Reduces manual intervention and associated costs with automated control and monitoring.

- Facilitates seamless integration into existing systems for continuous, high-speed operations.

- Applications

- Seafood, Grains, Dried fruit, Potatoes, Protein, Pet food, Confectionery, Nuts, Coffee beans, Vegetables, Seeds, Fruit

- End products

- Whole grain flour, Canned meat, Seed mixes, Canned vegetables, Confectionery chocolates, Frozen seafood packs, Potato chips, Fruit juices, Roasted coffee beans, Packaged dog food, Mixed dried nuts, Dried cranberry snacks, Packaged fresh potatoes

- Steps before

- Harvesting, Sorting

- Steps after

- Processing, Packaging, Point-of-sale

- Input ingredients

- large fruit, field potatoes, fresh pack potatoes, frozen potato products, potato specialties, fruits, vegetables, nuts, seeds, grains

- Output ingredients

- processed fruits, packaged products, batch reports, traceability data, line performance information

- Market info

- TOMRA is known for its expertise in sensor-based solutions for resource productivity, particularly in recycling, food sorting, and mining industries, offering advanced technology to improve resource recovery and efficiency, enhancing sustainability and operational performance.

- Line Control System

- SCADA

- Software Platform

- Wonderware® by Aveva

- Automation

- AI-driven

- Infeed Speed Adjustment

- Autonomous

- Product Tracking

- Full traceability from harvest to point-of-sale

- Data Contextualization

- High

- Working mechanism

- SCADA-based system

- Integrated steps

- Supervisory control

- Data acquisition

- Automation level

- Autonomous adjustment through AI

- Batch vs. continuous operation

- Continuous

- Traceability system

- From harvest to point-of-sale

- Decision support

- Situational awareness concepts

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Control panel type

- Touchscreen interface

- Discharge method

- Automated discharge

- Feed/discharge method

- Roller elevator and sorter system

- Control panel type

- SCADA