Seed Processing Equipment

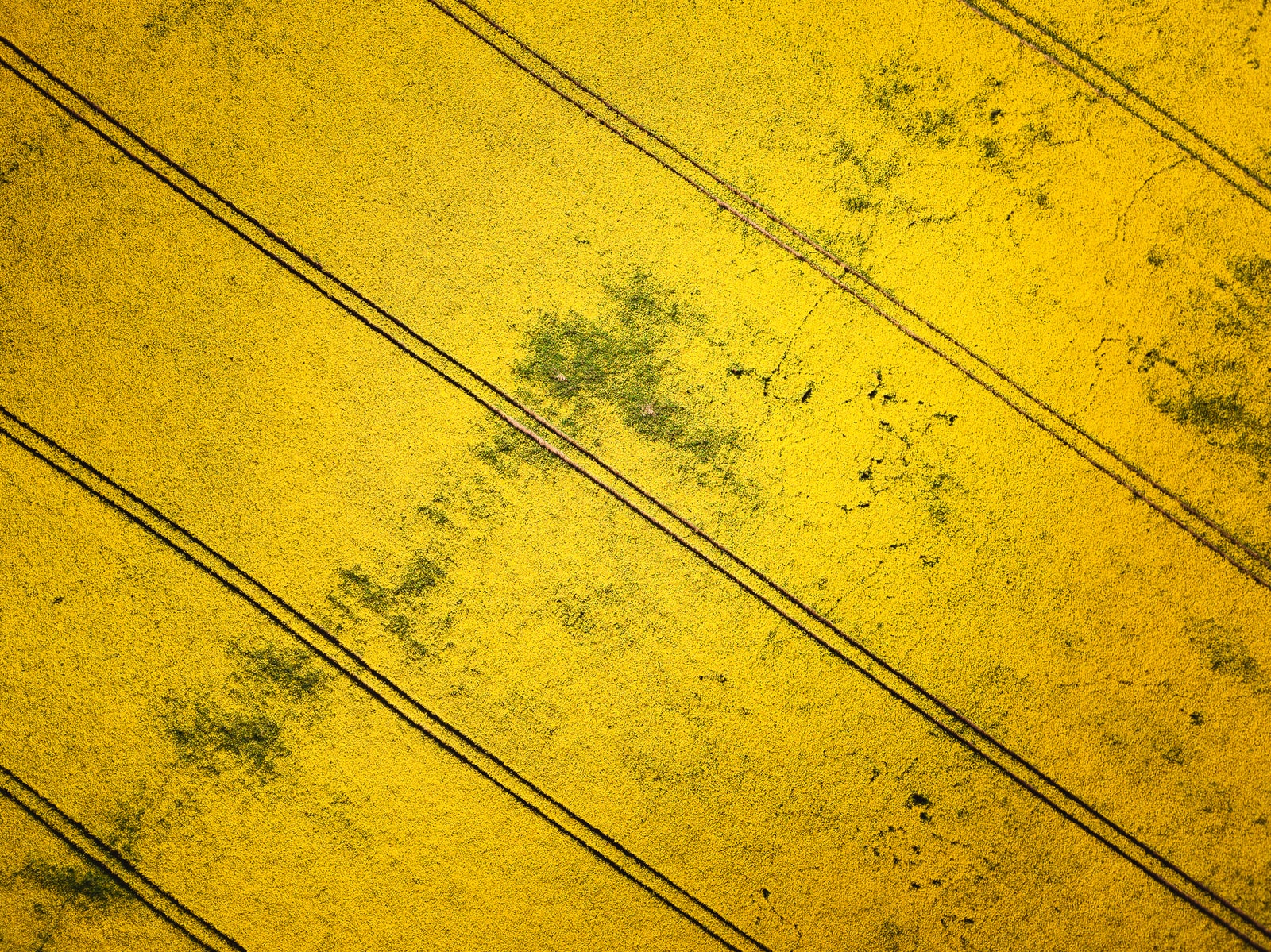

Find innovative seeds equipment and connect directly with world-leading technology suppliers

Whether for personal consumption or agricultural purposes, you process seeds to make them clean and maximize yield. Seed processing equipment includes the steps of polishing, threshing, separation, sorting, and drying. Some cases require additional processes. For example, the extraction of the seed from fruits or vegetables. Or, pressing the seed to extract oil.

Top picks for seed processing

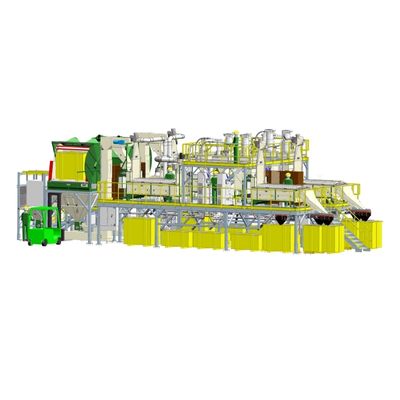

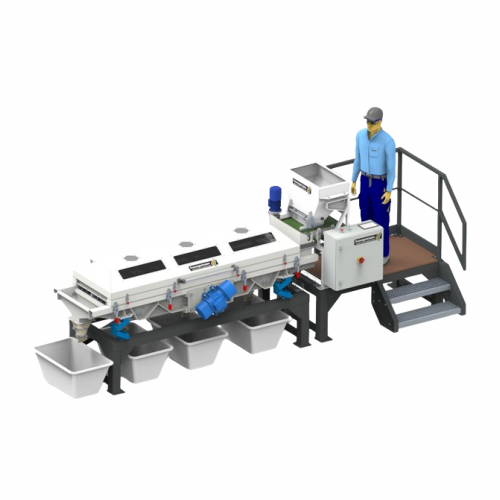

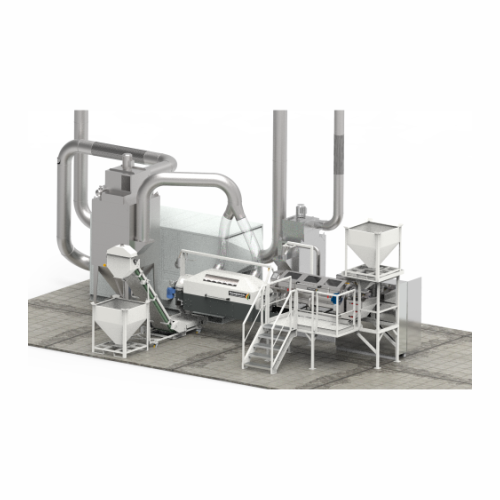

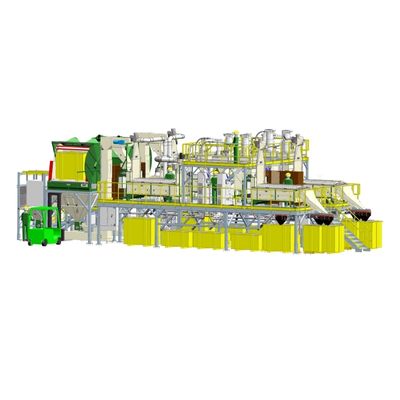

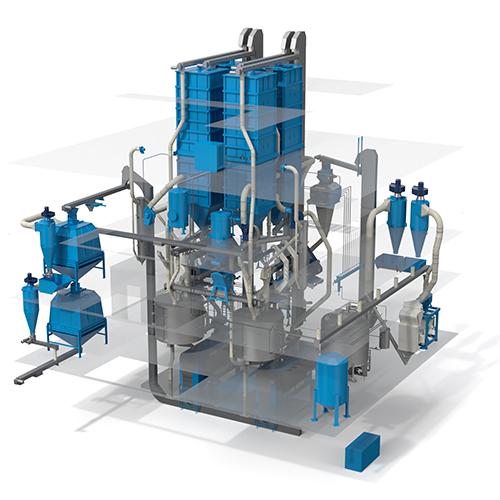

Automatic processing line for field crop seeds

The quality of field crops (ROW crops) is determined by their seeds. The br...

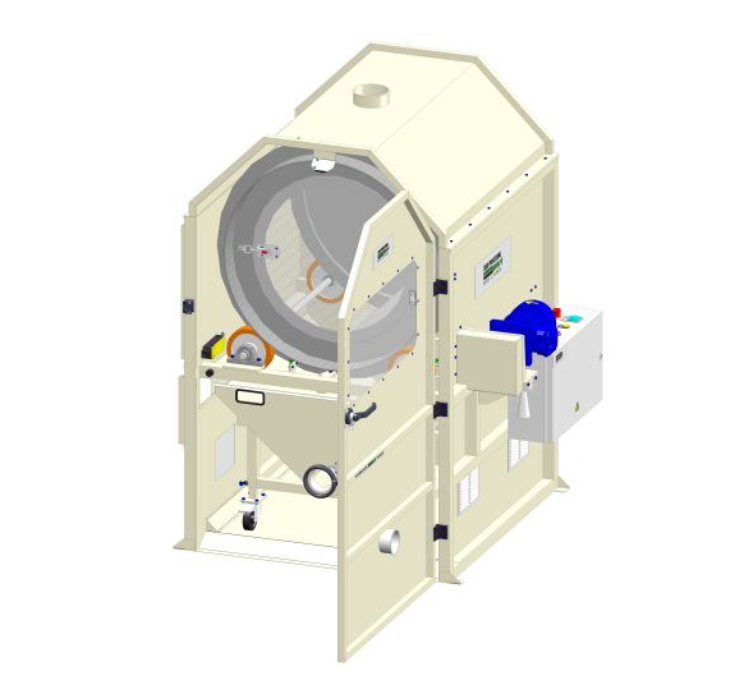

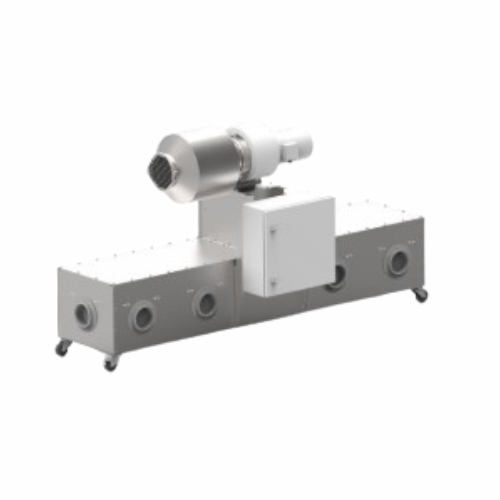

Air Seed Cleaning Machine

Cleaning of seeds is a vital step when getting the most of your crop. For this you need a speciali...

Cold oil press for seeds

With a cold oil press, you can optimize the process of extracting oil from a wide variety of oil see...

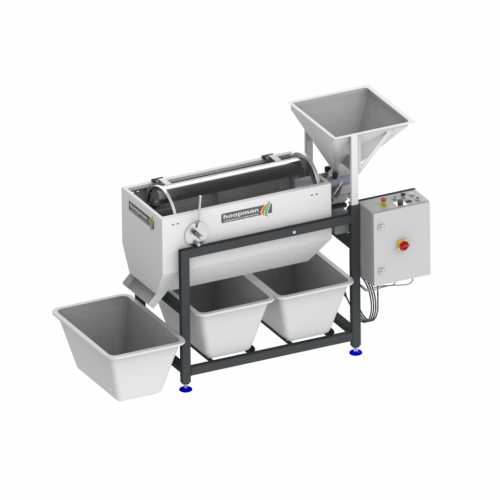

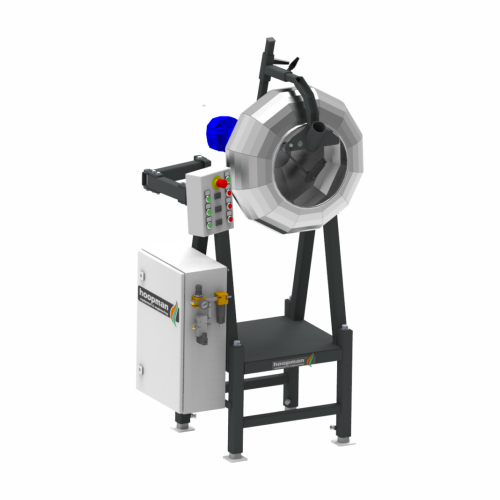

Crop and Vegetable Seeds Polisher

One way to improve crop and vegetable seed germination performance can be found in the fi...

Stories about seeds

An organic way of killing insects! MA concept, now available for 25 kg bags

#Changemaker: When soil is a scarce resource, go soilless

Give birch afforestation a head start with clean seeds

Stop treating pests to oilrape stock: treat your seed lot instead

Removing the seed of doubt from corn breeding

Extraction of tomato seeds – take care of your red gold

Sweet teamwork: processing the sugar beet seed

How to separate seeds from hemp crop

Freeze drying microencapsulated hemp seed oil

Select your seeds process

Tell us about your production challenge

The cross-pollination trick: hybrid seeds for improved performance

You can use hybrid seed processing to improve the crops characteristics. This is done to achieve better yield, uniformity, and create resistance to plant diseases. Hybrids are more expensive due to the careful selection of plants for cross-pollination. But also, the time required to grow and produce seeds.

You produce hybrid seeds through cross-pollination of two specific, but different varieties. Usually to combine the desired characteristics in each of them. For example, one tomato plant may withstand longer times with less water. While the other produces tomatoes vigorously. By crossing both varieties, you can get hybrid seeds from the resulting tomato. These seeds may turn to plants that are able to withstand longer times with less water while producing tomatoes vigorously. However, the next generation of seeds produced by hybrid plants will consistently have the same desired characteristics. Therefore, you can engineer the seed to your desired output of your crop.

Seed processing to pellet tiny and irregular-shaped seeds

Whether your seed is a hybrid or regular, you probably need to pellet them first. Small and irregular-shaped seeds are difficult to handle when sowing them in equal spaces. So they are pelleted to a size that can easily be seen and handled for further seed processing. Pelleting starts by applying a wetting agent to the seed in a rotating drum. Then you add a mix primarily composed of clay. which gradually coats the seed as the drum continues to rotate. This is done until it achieves the desired size. For quality control, you separate the samples of pelleted seeds according to size. By straining them through metal screens or a gravity separator (also called an aspirator), before you subject them to dissolvability and durability tests. These tests ensure the coating dissolves easily in water. But, is durable enough to withstand fragmentation during shipping. Before this process occurs, the seeds need to be cleaned with an Air cleaner machine. But, polishing the seeds is also a process needed to improve germination success.

Getting strong seeds: treatments to prevent diseases

Seeds undergo treatments to prevent diseases and keep away pests. Chemical seed treatment typically consists of applying pesticides, fungicides, insecticides, etc. Using specialised equipment, you usually apply these chemicals as dust or film coatings. And in some cases, as pellets. You can also apply other substances to make the seed strong. Substances such as growth stimulants and other micronutrients. Most treated seeds also come in different coated colors. This is used as an indicator that the seeds are chemically treated and are not to be consumed or used as feeds.

Which seeds technology do you need?

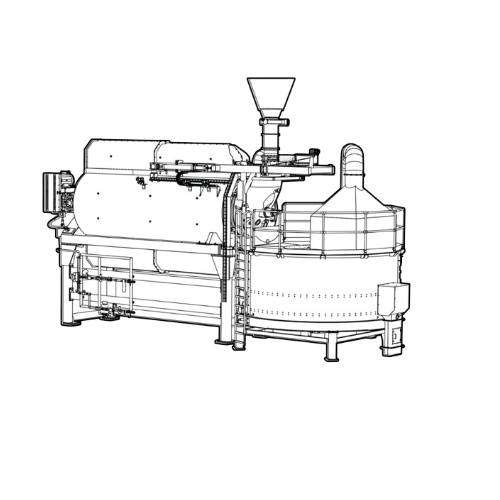

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

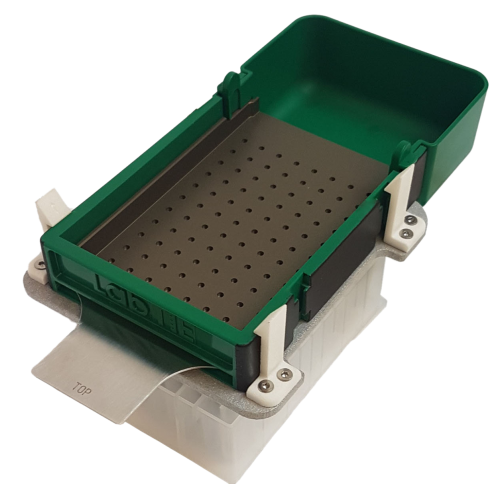

Accurate seed dispenser for lab use

Streamline your seed handling process with a versatile dispenser capable of quickly and...

Sesame seed dryer

Optimize your sesame processing with efficient moisture removal, ensuring desired quality and consistency f...

Destoner for nuts and seeds

Efficiently separate heavier particles like stones from a wide range of food products, including...

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

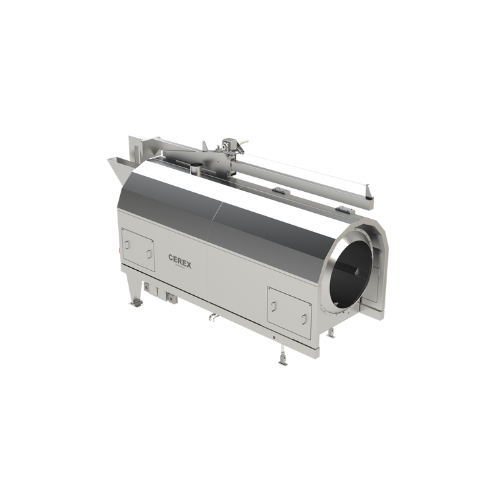

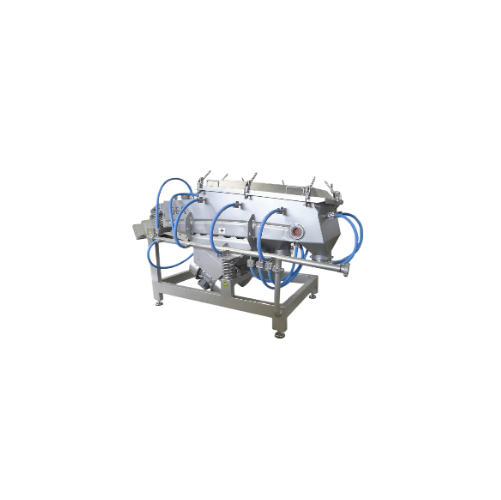

Cylinder sieving system for seed and pellet calibration

Simplify your seed and pellet calibration with a rotary cylinder ...

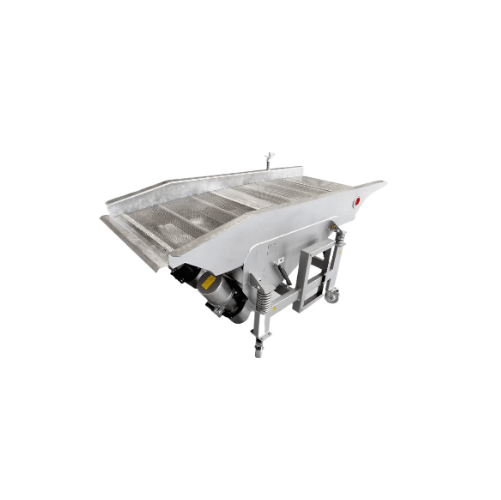

Vibrating calibration system for seed sieving

Streamline seed processing with a self-cleaning system that easily swaps sie...

Vibrating calibration system for seed samples

Ensure consistent seed quality by precisely calibrating small seed lots with...

Vibrating calibration system for seed sorting

Achieve precise seed sorting and calibration with high-speed, continuous ope...

Vibrating calibration system for accurate seed sieving

Optimize seed processing with an advanced vibrating calibration sy...

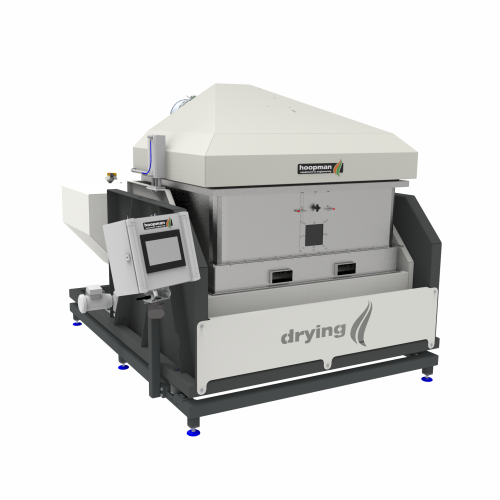

Continuous fluid bed drying system for seed coating

Elevate your seed coating operations with a continuous fluid bed dryi...

Belt elevator for seed transport

Optimize your production line with a customizable belt elevator designed to efficiently tra...

Seed containers with easy operable slide valve

Ensure complete seed emptying with specially designed containers, eliminati...

Single bucket elevator for seed handling

Optimize your seed processing efficiency by seamlessly transporting and splitting ...

Organic seed coating lines

Achieve optimal seed coating with a natural, biodegradable solution that minimizes energy use and...

Integrated coater and dryer for fragile seeds

When you need to gently coat fragile seeds like cucumber, melon, and beans, ...

Compact seed coating system for small production

Efficiently scale your seed processing with a reliable system designed fo...

High-capacity filmcoating system for seed treatments

Optimize seed enhancement processes with a modular, high-throughput ...

Seed conditioning and de-dusting system for lab use

When treating seeds, achieving precise de-dusting and curing is cruci...

Lab conditioner for de-dusting and curing film-coated seeds

Efficiently de-dust and cure your film-coated seeds with thi...

High capacity seed dedusting and conditioning system

Achieve optimal seed quality with a high-capacity system that seamle...

Seed drying system for large volume coated seeds

Achieve precise moisture control in your seed processing operations with ...

Cart drying system for non-threshed corn and seeds

Simplify your seed drying process with a flexible system designed for ...

Fluid bed drying system for seed pellets

Achieve precise moisture control and optimal seed conditioning with this fluid bed...

Fluid bed lab dryer for small seed lots

Efficiently dry and condition small seed lots with precise temperature control, ens...

Mobile fluid bed dryer for small seed lots

Dry your small seed lots efficiently and flexibly with a mobile fluid bed dryer...

Rotary seed coating system

Enhance seed coating precision with high-capacity rotary systems, minimizing damage and boosting ...

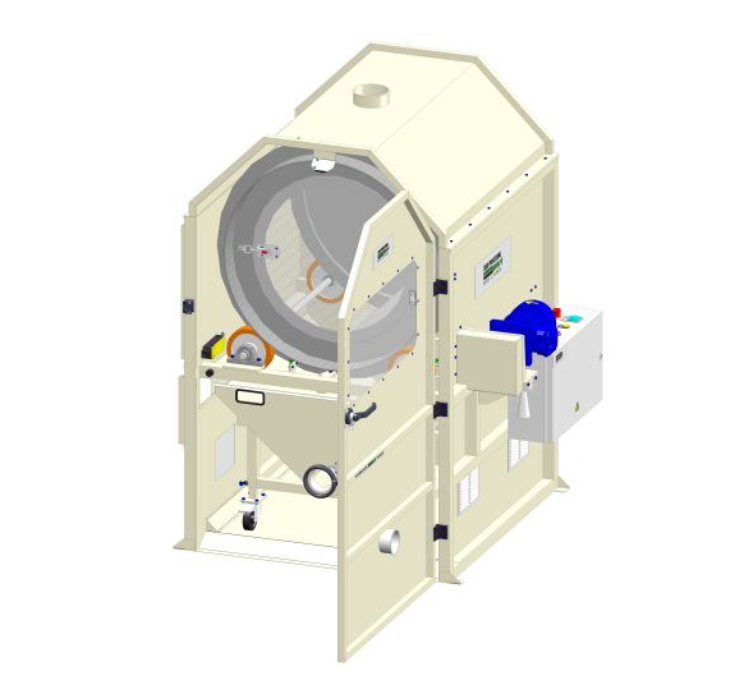

Steam-based seed disinfection system

Eliminate seed-borne pathogens with a steam-based technology that preserves germinatio...

Seed disinfection system for small seed lots

Streamline seed treatment with a powerful system capable of developing steam ...

Liquid treatment system for seed processing

For seed processors seeking enhanced seed quality, this liquid treatment syste...

Flexible seed rinsing and treatment station

For seed producers needing precise, controlled treatment, this rinsing station...

Seed disinfection and rinsing system

Optimize your seed processing by ensuring thorough disinfection and rinsing, maintaini...

Lab drumpriming system for seed treatment

Efficiently prepare liquid formulations with a reliable drumpriming system, ensu...

Flow testing system for seed coating evaluation

Ensure accurate seed flow assessment in coating processes, detecting chang...

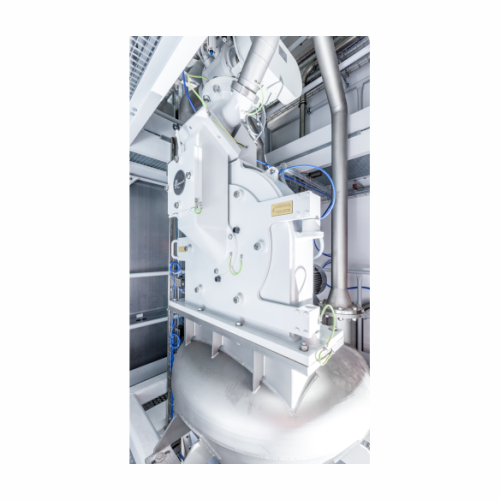

Integrated coater/dryer for seed treatment

Optimize seed coating and drying with a streamlined process that preserves seed...

Pelleting equipment for precision seed treatment

Achieve consistent and precise coating of seeds with exceptional control ...

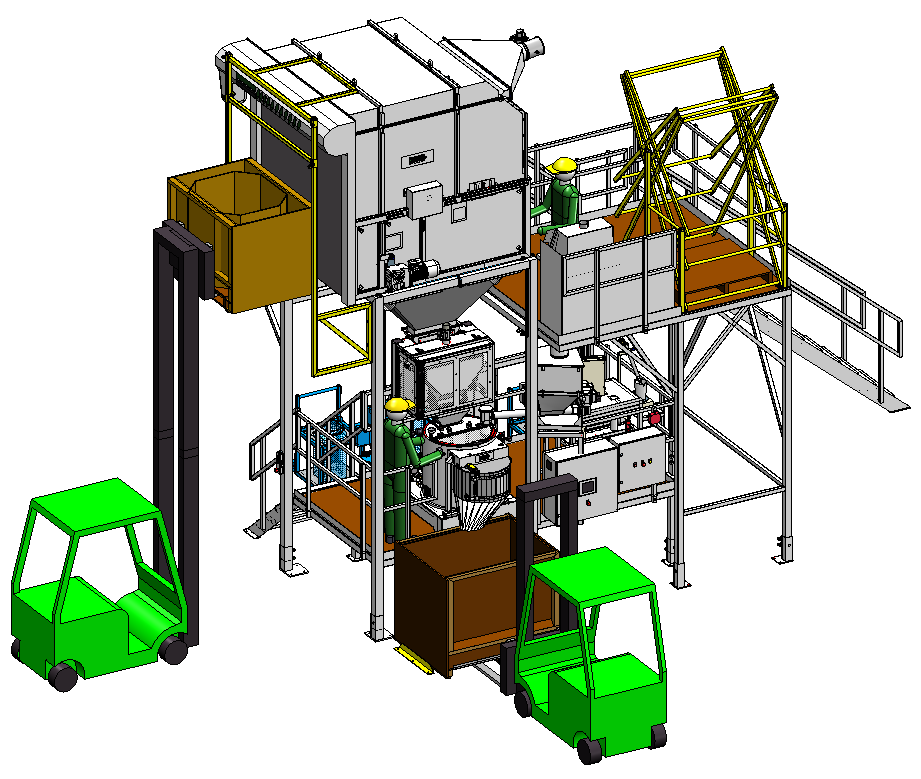

Seed counting and packaging system

Maximize your seed throughput with high precision counting and packaging technology, des...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Nut and seed pre-grinder

When dealing with high-fat roasted nuts and seeds, achieving optimal particle size distribution can ...

Pre-grinder for roasted nuts and seeds

Maximize efficiency in creating smooth nut and seed spreads with this pre-grinding s...

Cocoa nibs pre-grinder for high fat seeds and nuts

Enhance your processing line with high-speed pre-grinding designed to ...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

Seed conditioning system for soybeans and rapeseed

Streamline your oilseed processing by efficiently conditioning and deh...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Corn seed sorting solution

Ensure precision in sorting and grading corn with optical and infrared technologies, enhancing pr...

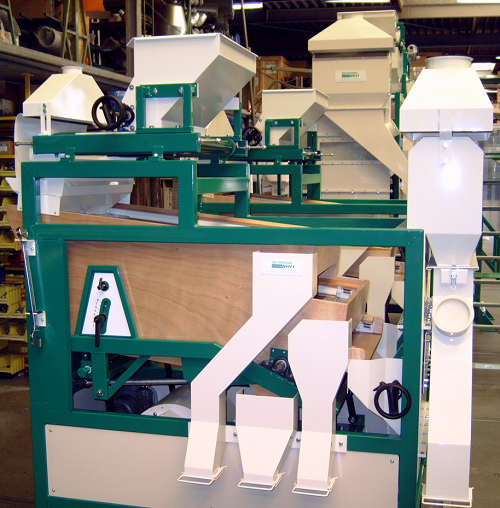

Automatic processing line for field crop seeds

The quality of field crops (ROW crops) is determined by their seeds. The br...

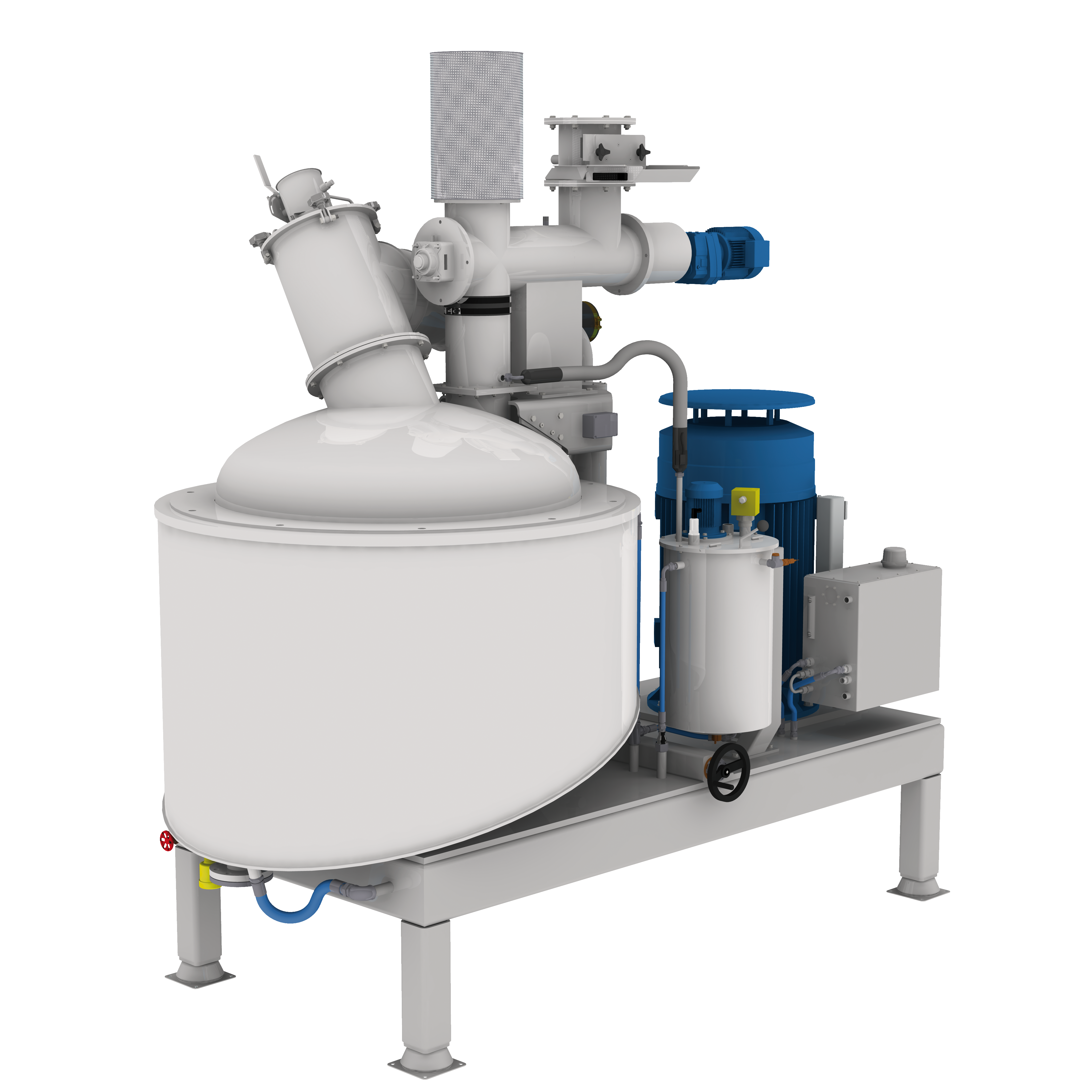

Rotary Seed Dryer Coater

Large-volume vegetable and field crop seeds manufacturers may prefer a fully automated coating and d...

Rotary Seed Pelleting Machine

When pelleting large batches of seeds like flower, vegetable, or agricultural types, it is imp...

Seed Gravity Separator

In large-scale production, separating quality seeds from empty seeds and other debris – such as ...

Seed Belt Grader

Large volume seed producers require high-capacity grading equipment to separate the good seeds from the bad o...

Tomato seed extraction machine

Although it’s the safest method, extracting tomato seeds manually can be time-consuming...

Seed extraction machine

The supply of high quality seeds is essential as it significantly contributes to the success of every...

Seed disinfection machine

It’s essential to disinfect seeds to eliminate bacterial infections and to protect them from these...

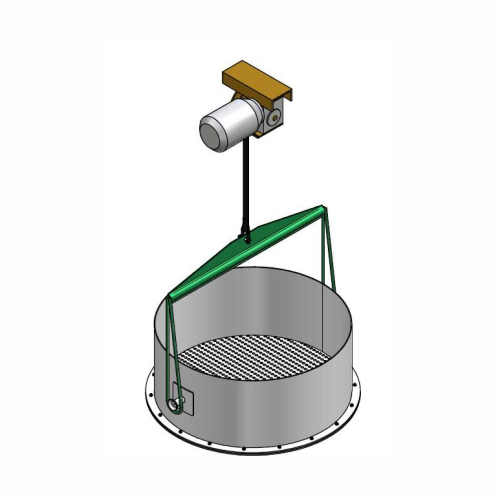

Seed Centrifuge Small

When drying extracted, disinfected, or primed seeds, the process can be very long, as they have high wa...

Conditioned seed drying machine

It’s essential to dry moist seeds before you process and store them. Seeds with too high or ...

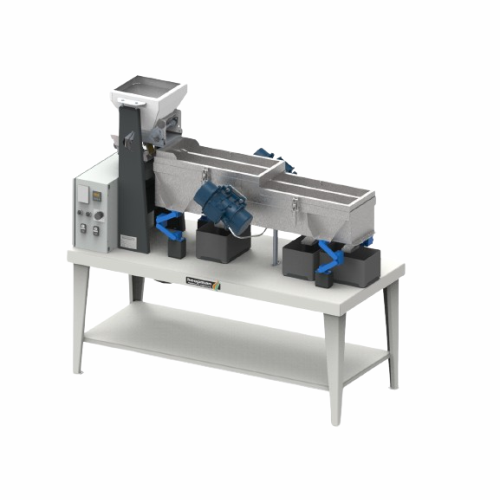

Laboratory Seed Brushing Machine

Breeding stations work daily to improve seed sow ability; but if seeds are not cleaned prop...

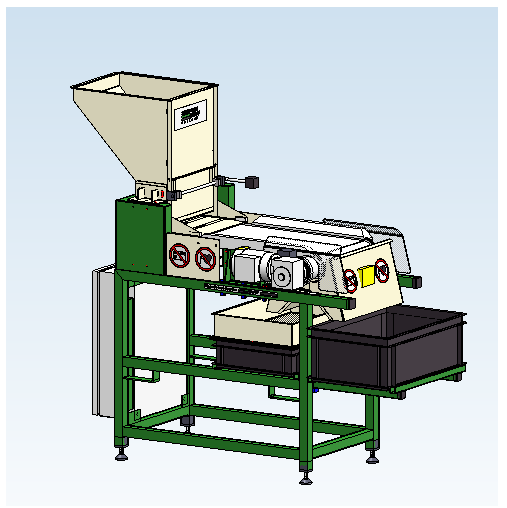

Crop and Vegetable Seeds Polisher

One way to improve crop and vegetable seed germination performance can be found in the fi...

Air Seed Cleaning Machine

Cleaning of seeds is a vital step when getting the most of your crop. For this you need a speciali...

Machine For Sizing Seeds

Seeds coming from the same plant might have different sizes and shapes. The germination percentage o...

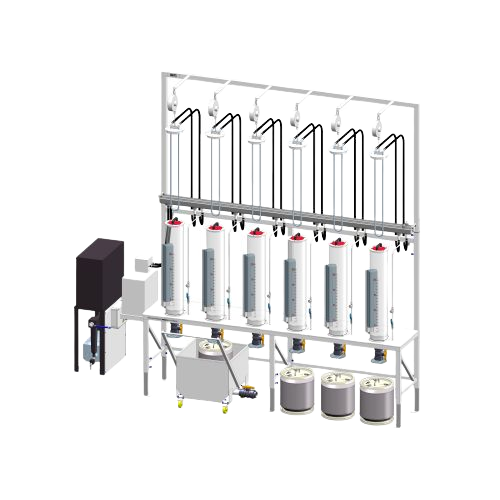

Seed priming equipment

Seed priming is a controlled hydration technique in which seeds are soaked in water or low osmotic pot...

Thermogradient table for seed tests

Seed germination performance relies on factors such as seed type, cleanliness level, an...

Seed threshing machine

After threshing seeds from plant material, various cleaning steps still have to be done to ultimately ...

Magnetic Seed Separator Machine

It is challenging to separate seeds with cracks or holes from undamaged seeds. The way to do...

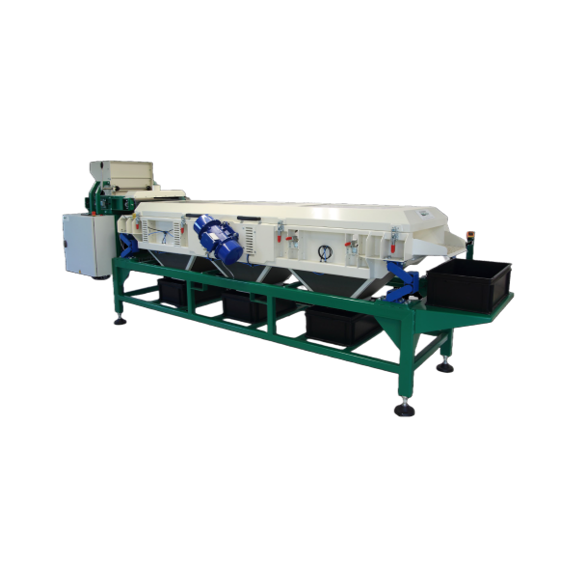

Air screen seed cleaning machine

The quality of seeds and grains starts to deteriorate once they have been harvested. Thus, ...

Seed storage cabinet

The proper storage of seeds is essential in conserving their vitality, and to maintain germination power...

Seed Coating Machine With Integrated Dryer

Seed coating, also known as seed dressing, refers to the covering of seeds with...

Seed Pelleting Machine

Seed pelleting or encrusting is the addition of materials like powders and liquids to seeds to increas...

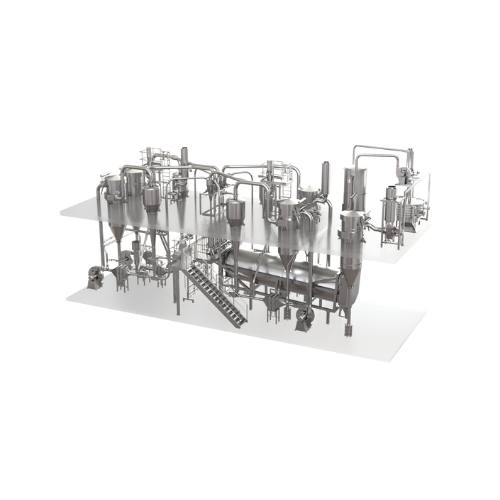

Oilseeds preparation plant

When producing customized flakes, pressed cakes, or other oilseed products, the oilseed preparati...

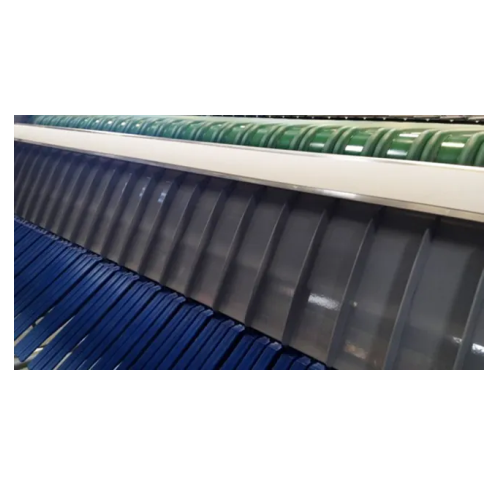

Small batch filter press for oil seeds

Getting a high-quality oil filtration can be a challenging task, with a filtration ...

Cold oil press for seeds

With a cold oil press, you can optimize the process of extracting oil from a wide variety of oil see...

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

Sesame peeling system

Enhance your seed processing with a sesame peeling system that reduces water usage and eliminates chemi...

Automatic sieve for pellet separation

Efficiently separate and clean seeds and pellets, ensuring product integrity from sta...

Material container emptying device

Efficiently unload and empty material containers with adaptable mounting options, ensuri...

Modular system for liquid treatment protocols

Streamline your seed treatment process with a versatile system capable of ha...

Priming cabinet for liquid matrix protocol development

Optimize your seed enhancement process with a versatile priming sy...

Liquid matrix priming unit

Ensure seed vitality and improve germination rates with advanced liquid matrix priming, designed ...

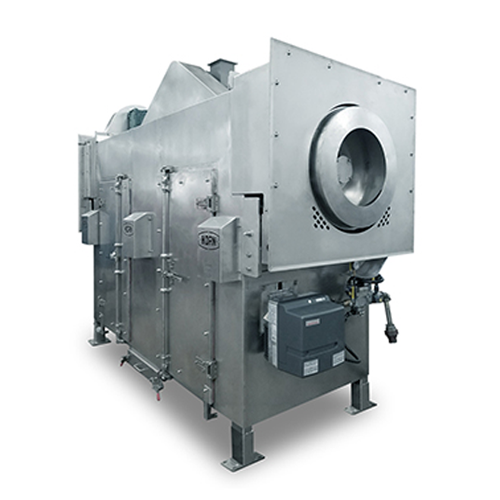

High volume rotary dryer roaster for continuous drying

Achieve uniform drying and roasting with a continuous, high-capaci...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

Indented separator for grain quality control

Achieve precise grain length separation with an adaptable indented separator,...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Modular rotary oven for snack food processing

Optimize flavor infusion and moisture control in snack production with a mod...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Grain separator for removing foreign materials

Ensure high-quality grain processing by efficiently removing foreign materi...

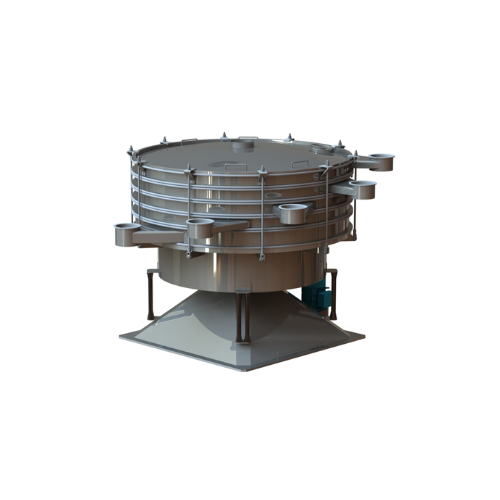

High capacity grain sifter

Efficiently separate and clean a variety of grain types with minimal space requirements, ensuring...

Classifier for flour, semolina, and pulse factories

Optimize grain processing with a high-capacity classification solutio...

Color sorter for small fruits

Optimize your production line with a high-speed color sorting solution that enhances quality c...

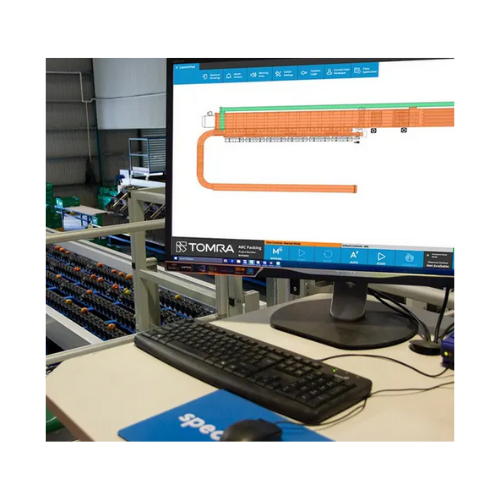

Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and r...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Hydraulic oil press for efficient oil extraction

Streamline your oil production with a hydraulic oil press that ensures hi...

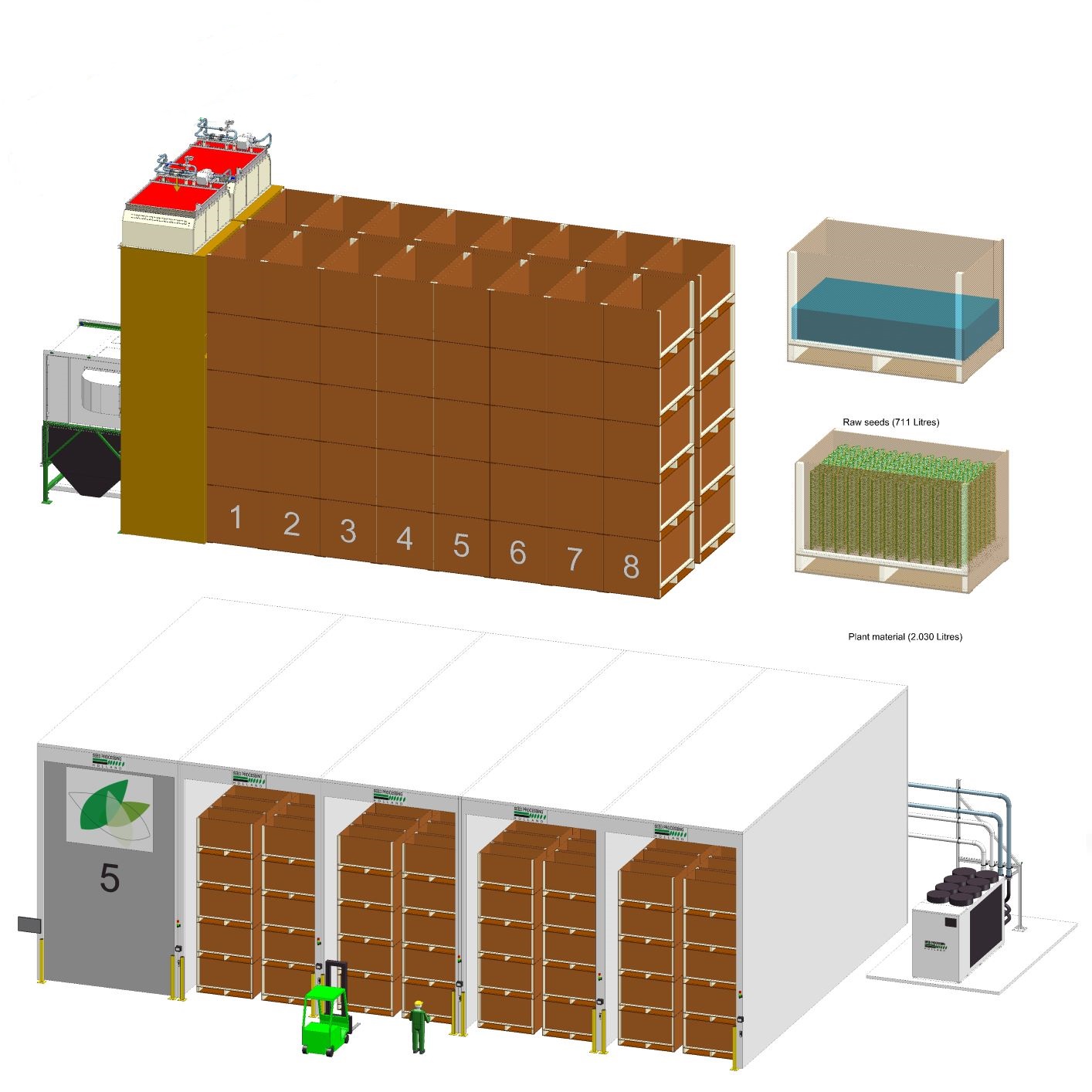

Conditioned Box Dryer

Seeds that are harvested are dried as part of their initial process of cleaning. Having huge quantities...

Semi-automatic extraction machine

When extracting seeds from fruit or vegetable crops, it is best to consider a flexible de...

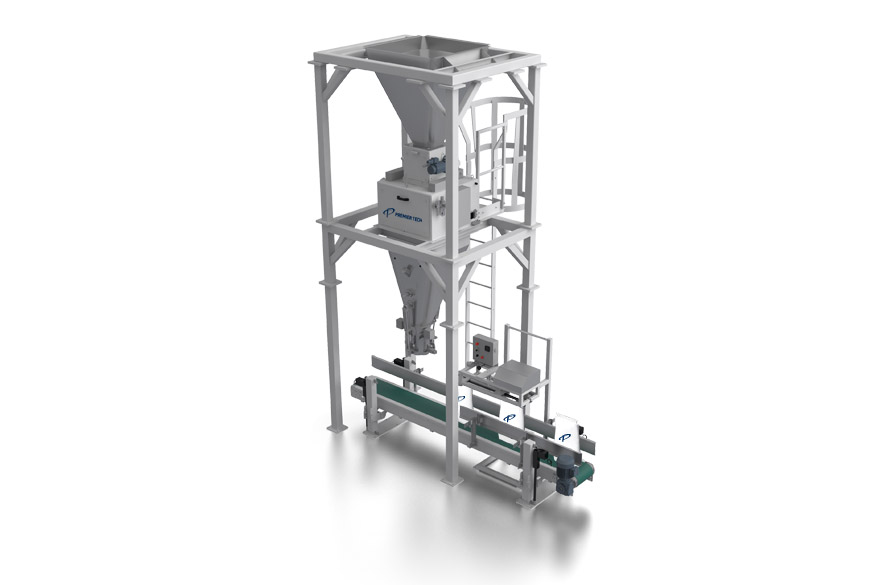

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

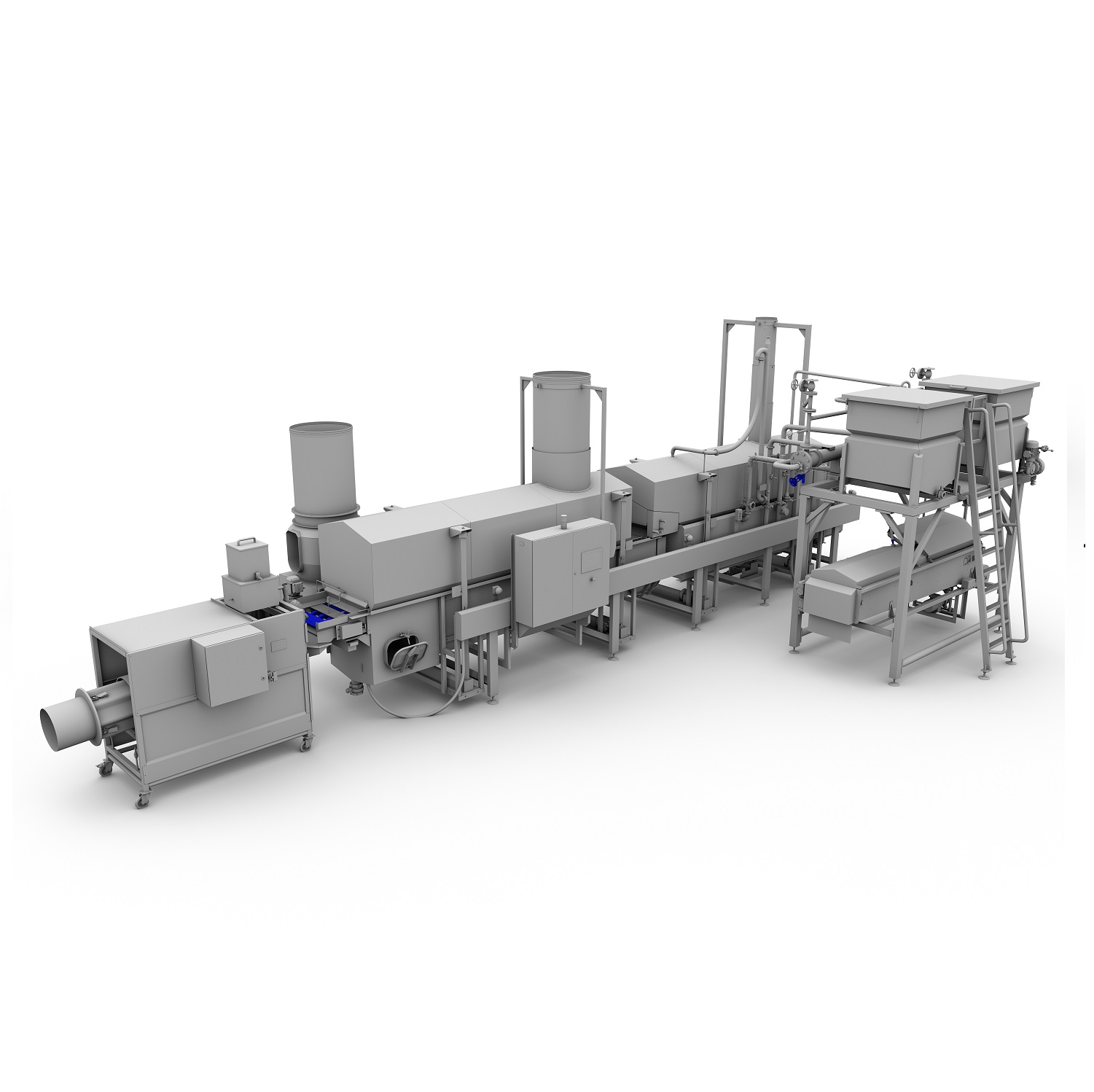

Peanut frying line

Fried peanuts are a very popular snack around the world. If you are looking to start a nut processing plan...

Germination Cabinet For Commercial Growing

Each variety of seed has its optimum growing conditions including temperature, ...

Continuous cocoa bean roasting line

When you are processing chocolate, after the conditioning and fermenting of cocoa, the ...

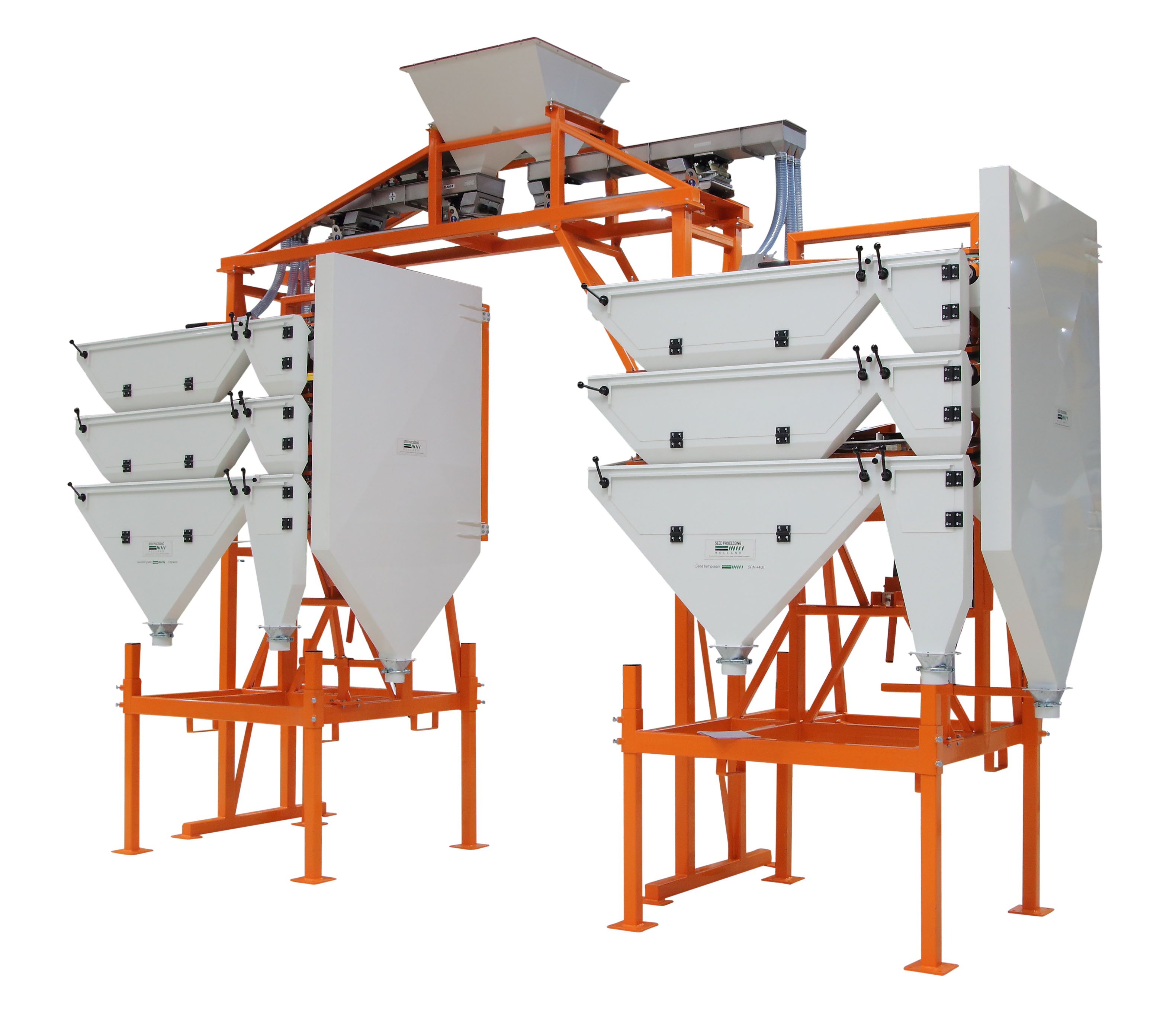

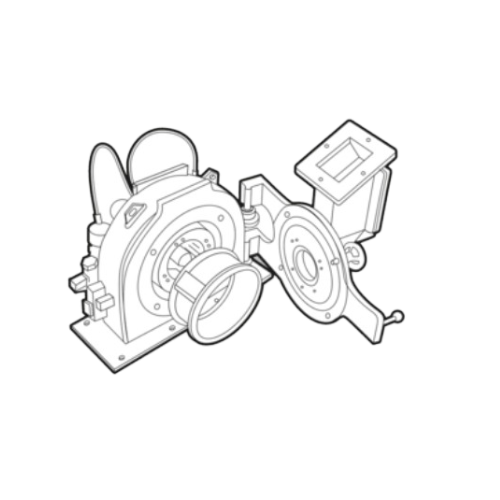

Macro ingredient dosing system

Traditional dosing systems do not have a very long operational life and are hard and expensiv...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

Counterflow pellet cooler

Food and feed industries require the highest standards of hygiene and sanitation. This entails fre...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Organic soybean oil press

In traditional soybean oil production, chemical solvents such as hexane are used to facilitate liq...

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Organic soybean oil pressing plant

Soybean oilseeds are usually processed through extraction methods using hexane or other ...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

Shop coffee bean grinder

Do you want to grind your beans on-site at your coffee shop, but are you limited for space? Bench-to...

Nut roaster

Nut roaster that guarantees a high-quality roasting of nuts and seeds with a batching capacity of 40 and 120 kg, d...

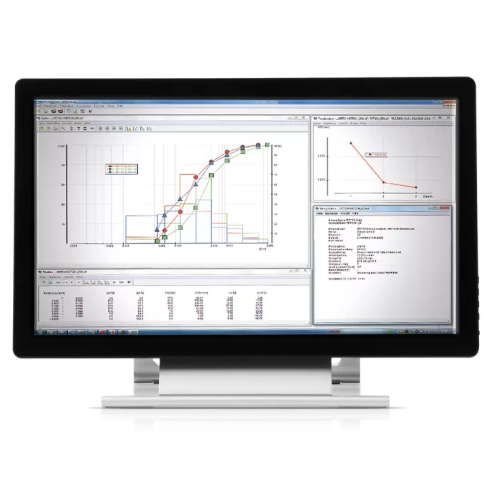

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

Electromagnetic sieve shaker for quality control

Achieve precise particle size distribution with this advanced electromagn...

Mesh sieves for laboratory particle size analysis

Ensure precise particle size control for a wide range of materials with...

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

Planetary ball mill for high throughput grinding

For precise material engineering, achieve efficient size reduction, homog...

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

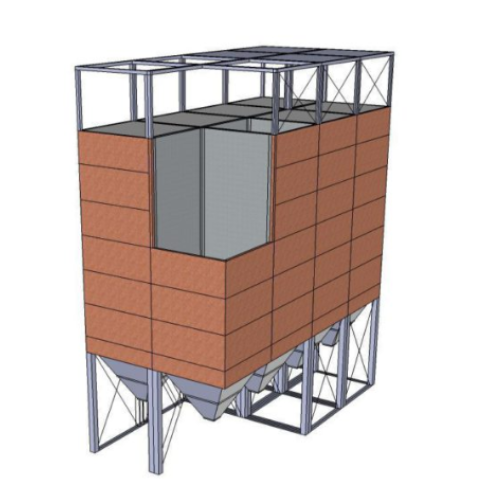

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

High accuracy micro dosing system

When handling diverse ingredients, precise dosing is crucial to ensuring consistent produ...

Nut roasting process with halved energy consumption

Achieve significant energy savings while maintaining high-quality roa...

Sweep auger for flat bottom silos

Optimize your grain storage operations with a fully automatic sweep auger designed to eff...

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

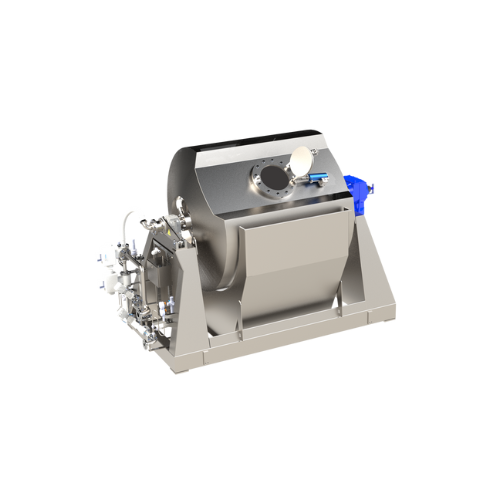

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

High precision weigher for small package weights

Achieve precise micro-dosing with unmatched accuracy at high speeds, opti...

Food drying system for diverse products

Achieve precise moisture control and versatile drying for your diverse product line...

Industrial malt roaster for specialty malts

Optimize malt roasting with precision control over heat distribution, ensuring...

Batch conche for chocolate making

Achieve optimal texture and flavor development in your chocolate with precise control ove...

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

Double shaft batch mixer for chocolate production

Optimize your chocolate and confectionery production with precise mixin...

Pre-refiner for chocolate processing

Optimize pre-refining in chocolate and cocoa production with precise fineness control,...

Single-zone toasters for raw grain processing

Optimize your cereal and snack food production by achieving consistent toast...

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

Granola drying solution

Optimize your granola production with modular drying technology that ensures precise moisture control...

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

Industrial screeners for grain product processing

Optimize your cereal production line with specialized industrial screen...

Fully automatic bagging station for granular products

Streamline your packaging line with a high-speed solution designed ...

Flat storage system for grain

Designed to accommodate various agricultural products, this flat storage system ensures effici...

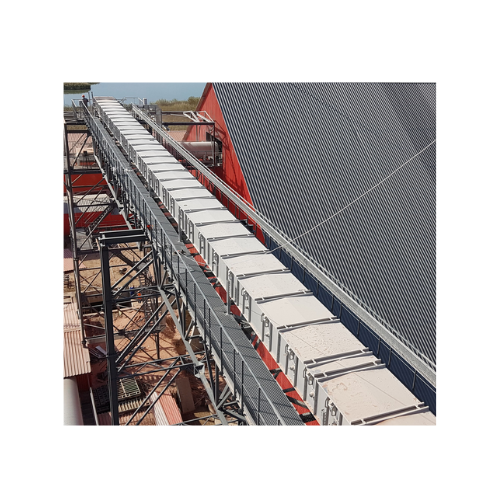

Enclosed belt conveyor for grain handling

Optimize your material transportation and ensure dust-free operations with this ...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

Sifter for pet food, fish feed, and animal feed

Achieve precise particle separation and enhance feed quality with this vib...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

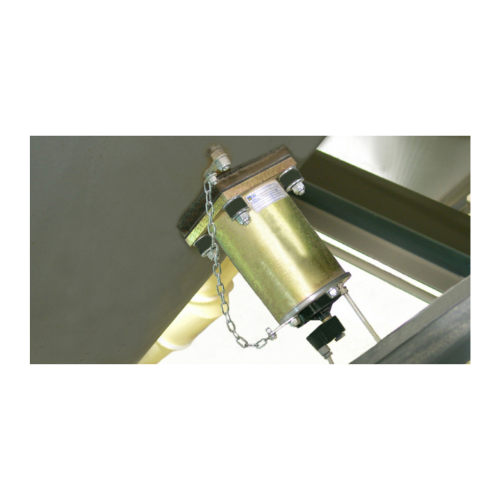

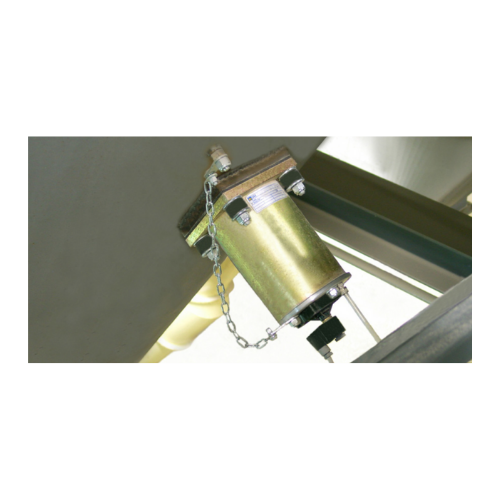

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Vacuum dissolver for high viscosity products

Optimize your production with a vacuum dissolver designed to efficiently prev...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Lab and pilot plant dissolver for dispersion and fine grinding

Achieve efficient dispersion and fine grinding in laborat...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Bucket elevator for grain and powder products

Efficiently transport bulk materials like grain and powder vertically with p...

Double story paddy sieve for rice cleaning

Efficiently cleanse and separate impurities from rice, lentils, and grains, ens...

Optical sorter for nuts, dried fruit, and Iqf

Ensure flawless quality control by efficiently sorting, grading, and ejectin...

Optical sorter for nuts and dried fruit

Enhance sorting precision by effortlessly identifying and removing foreign material...

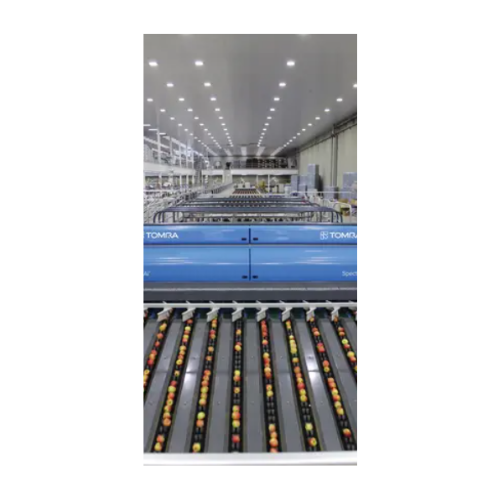

Advanced fruit sorting platform

Optimize your operations with a cutting-edge sorting solution designed to enhance product in...

Steam peeler for vegetables and fruits

Optimize your food processing with a versatile steam peeling solution that efficient...

Steam peeler for vegetables

Optimize your peeling process with a versatile steam peeler that minimizes waste and enhances th...

Dry bin filling for delicate fruit

Achieve gentle, high-throughput filling of delicate fruits with minimized manual interve...

Advanced food sorter for tomatoes and peaches

Achieve precise sorting and defect removal for a variety of food products, e...

Small fruit sorter for sensitive cherry varieties

Optimize your packhouse throughput and consistency with advanced sortin...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

Soft fruit sorter for packing lines

Enhance your production line’s efficiency by accurately sorting and removing unwa...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Blizzard sorter for Iqf fruits and vegetables

Optimize your frozen food production with a compact sorter that seamlessly r...

Cherry singulation system

Effortlessly streamline cherry processing with a system that ensures gentle handling and superior ...

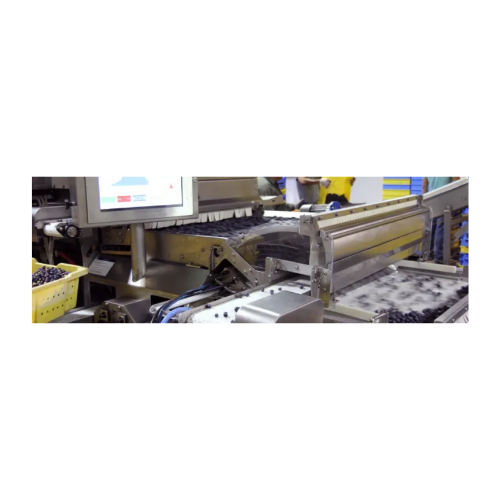

High-speed filling system for cherries and blueberries

Streamline your packaging process with a system designed for rapid...

Industrial steam peeler for potatoes

Optimize peeling efficiency while minimizing waste and energy usage with this high-spe...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

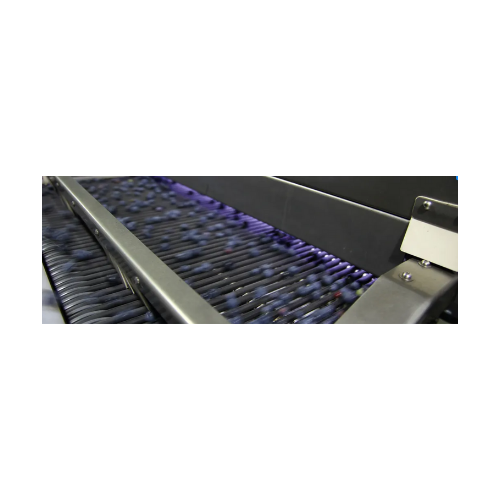

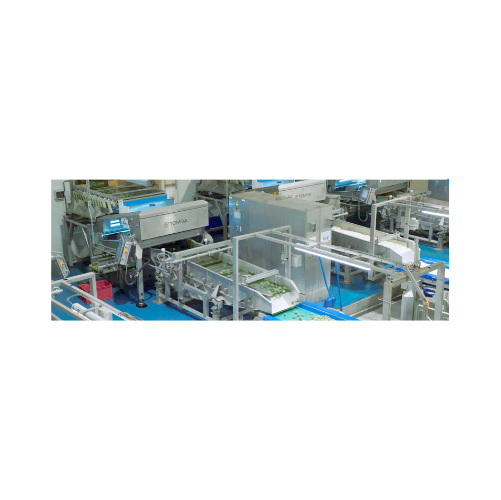

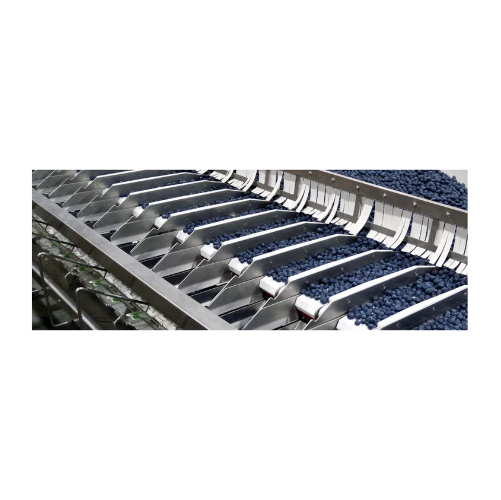

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

Coffee, dried nuts, and cocoa beans roaster

Achieve precise and customizable roasting for a variety of beans and nuts with...

Sanitary modular bulk silos for efficient storage

Maximize your storage capacity and streamline assembly with a modular s...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

Energy efficient steam dryer for feed products

Traditional drying technologies with low investment cost, such as hot air d...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Cabinet dryer for cannabis

If you need careful drying for products like pharmaceutical-grade cannabis buds then traditional ...

Cocoa liquor grinding line

After roasting and cracking chocolate beans (without husks), the following process is the grindin...

Infrared rotating drum steriliser

Sterilisation of foodstuffs is vital to maintain uncompromising standards of hygiene and ...