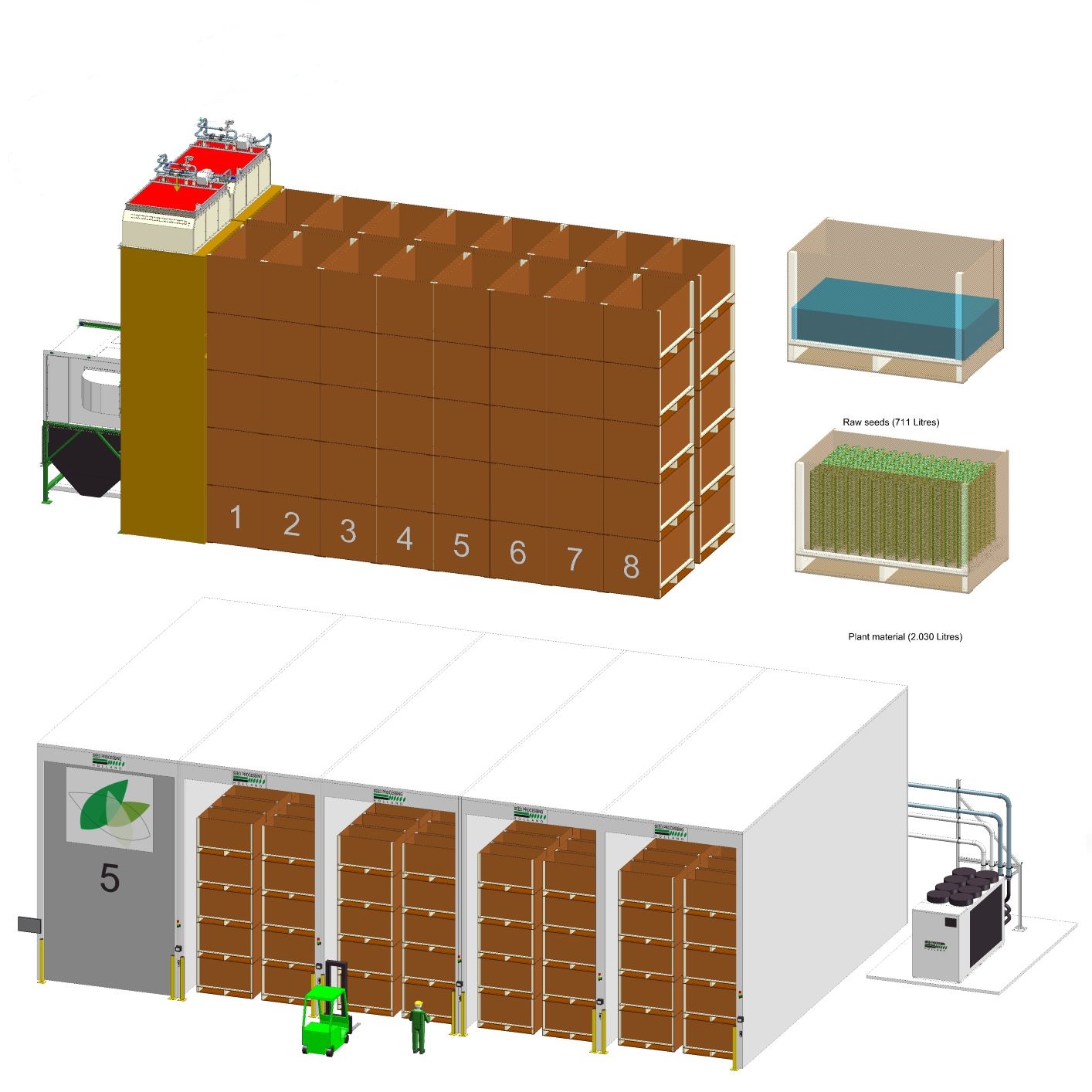

Conditioned Box Dryer

Seeds that are harvested are dried as part of their initial process of cleaning. Having huge quantities of seeds for drying in a single batch may take more time when done in ambient conditions since factors for drying involve the speed, temperature, and humidity of the air. The seeds can be dried under the desired conditions by controlling these factors, using a system that provides a more environmental-friendly operation.

Drying harvested seeds in a controlled environment

The DBM-SP02 Conditioned Seed Box Dryer from Seed Processing Holland is a seed drying system that controls a closed environment’s speed, temperature, and humidity. These are controlled via a touchscreen control display. The system consists of wooden boxes with mesh bottoms; these boxes are placed in cells and can be stacked or placed next to another cell. This allows the system to accommodate around 16,000 kg of seeds or around 800 m³ of plants in 400 pcs of drying boxes. Drying containers are also available in different sizes and the system can dehumidify at a rate of around 100 liters per hour depending on the desired temperature and humidity phase during the process. Dehumidification of the system is also available in different capacities.

The machine uses a heat pump installation whose design allows it to save 25 to 50% of energy, delivering an efficient drying process. More heat pumps can be added, depending on the volume of seeds to be treated. Moreover, the central heat pump system recovers surplus energy from one drying process and re-uses it in the following one. This operation accelerates the drying speed while also granting energy and cost savings.

Benefits

- High capacity (400 boxes with approx. 16,000kg of seeds/ 800m³ of plants)

- Consistent drying quality through automated controls

- Easy condition readout and adjustment through a touchscreen display

- High dehumidification capacity (up to 100 liters per hour)

- Heat pump provides more sustainable solution that saves energy and increases the drying pace