Extraction Equipment

Find innovative extraction equipment and connect directly with world-leading technology suppliers

Industrial extraction equipment unlocks the valuable compounds hidden away in natural materials. Automated extraction equipment is applied in the pharmaceutical and cosmetic industries to extract active compounds from medicinal plants or herbs. For example, extracting cannabinoids from cannabis plants. But the process is also fundamental to the food industry, recovering various components like aromas, oleoresins, and proteins. Considerations for selecting suitable extraction technology include the type of plant material to be processed, the extract's heat sensitivity, and the production volume.

Separate liquid substances with two-phase extraction equipment

Liquid-liquid extraction (LLE) separates immiscible solvents and is used to purify compounds. This type of extraction is typically performed with one aqueous phase and one organic phase with minimal solubility in water, such as diethyl ether or dichloromethane.

Industrial equipment for liquid-liquid extraction contacts the two phases together to trigger the separation of layers.

Increase the contact between phases to obtain higher liquid-liquid extraction

The higher the contact, the more efficient the process. Extraction technology, therefore, is usually fitted with a mixing device to facilitate interaction between the phases.

Industrial liquid-liquid extraction equipment is mainly used in the pharmaceutical and chemical industries to recover active ingredients. But it is also applied to the food sector to purify edible oils and wash out undesired compounds.

Use liquid-solid extraction equipment to pressure molecules out of a matrix.

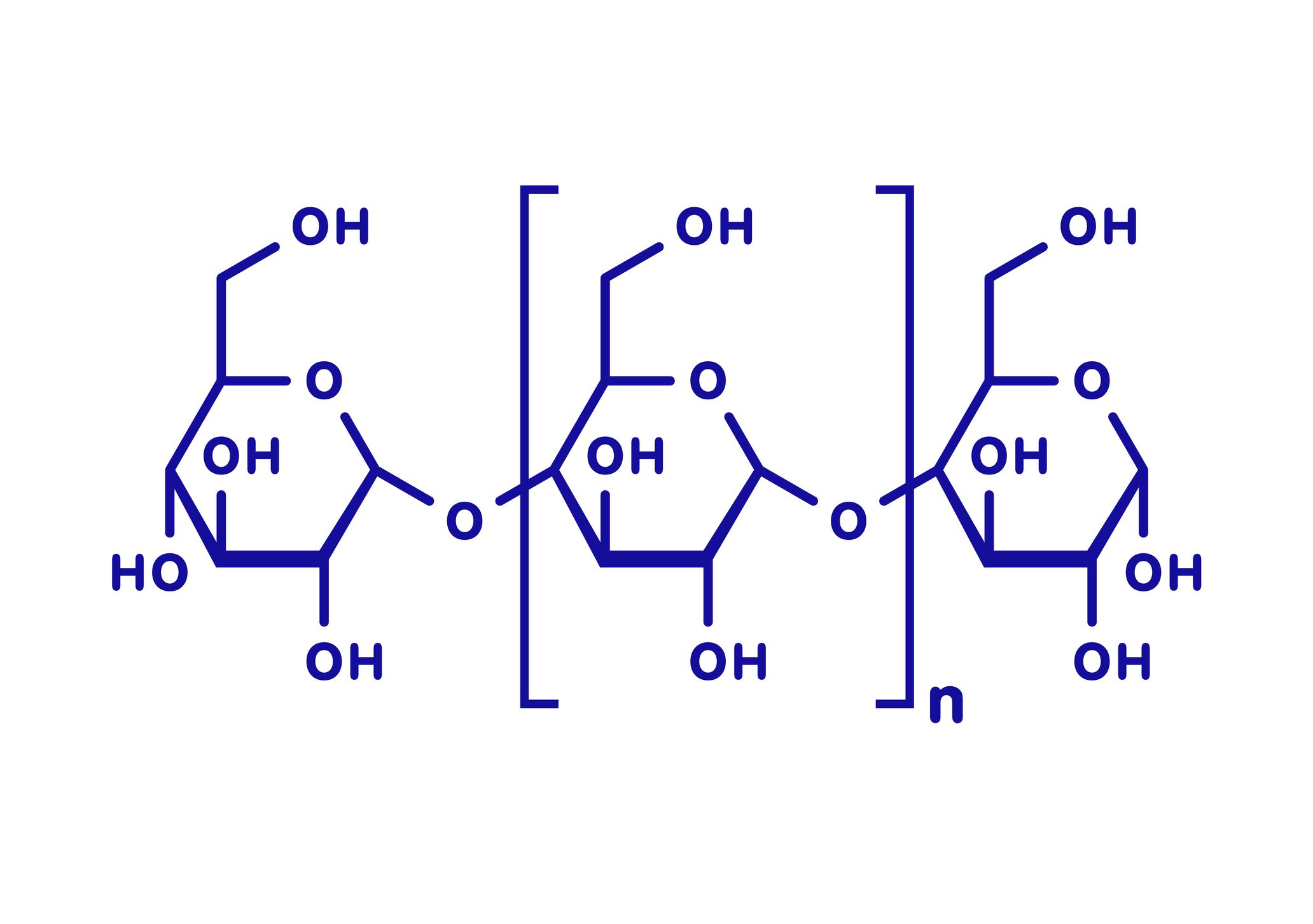

The liquid-solid extraction (LSE) method separates nonvolatile components like glycerin, salt, and sucrose. It is also a solution for capturing finely dispersed substances in solids, such as caffeine in coffee.

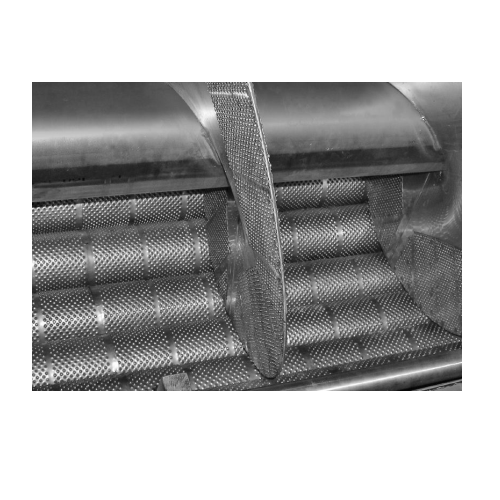

Solid-liquid extraction equipment mixes solvents to pressure cells out of an insoluble solid matrix. The traditional techniques include maceration and percolation, but newer technologies apply supercritical fluids and accelerated solvent extraction principles to achieve higher yields.

Non-conventional extraction equipment reaches higher temperatures for increased efficiency

Like traditional extraction methods, non-conventional systems are based on diffusion to cleave the bioactive compounds from the solid matrix. The solvents decrease the granulometry of the solid and increase the affinity towards the compounds. But newer technologies facilitate diffusion by applying higher temperatures non-aggressively.

Industrial extraction equipment in this category includes ultrasound-assisted extraction (UAE), ultrasonic extraction (USE), and microwave-assisted extraction (MAE).

Temperature control is critical in essential oil extraction

Many of the components in essential oils and CBD oils become unstable at high temperatures, so extraction equipment for this application is specially designed to preserve the compounds.

Traditional hydrodistillation systems heat the plant until its molecules are released into the vapor and captured in a condenser. Advanced extraction technology, such as microwave-assisted systems, rupture the raw material without subjecting the ingredients to extreme heat.

Rapid extraction systems remove the gradient of pressure to accelerate the liquid outflow

Rapid solid-liquid dynamic extraction (RSLDE) proposes a novel approach. Instead of relying on diffusion or osmosis, the extraction system creates a negative gradient of pressure between the cell wall and its surrounding area.

This “active process” causes the liquids to flow out of the solid matrix with lower resistance than passive techniques.

Retain nutrients in fruit and veg juices with industrial cold press technology

Cold press extraction equipment applies pressure to separate the juices or oils from the fibrous materials. It is typically used to extract the liquids from fruit and vegetables, but it is also a pressing solution for seeds and nuts.

The technology does not involve cooling in the process, but it gets its name because it prevents the build-up of heat. Other mechanical juicers such as centrifuges expose the raw foods to oxygen and heat, deteriorating the nutrition value as a consequence. Cold treatment preserves the bioactive compounds in the extracted liquids. At the same time, however, this same technique does not eliminate the natural macrobacteria in fresh foods. Cold pressed product, therefore, have a shorter shelf life.

What are you making?

Agar-agar

Algae

Aloe vera gel

Alternative medicine

Alternative proteins

Antibodies

Antioxidant supplements

Apple concentrate

Apple juice

Aromas

Avocado oil

Bakery ingredients

Beetroot juice

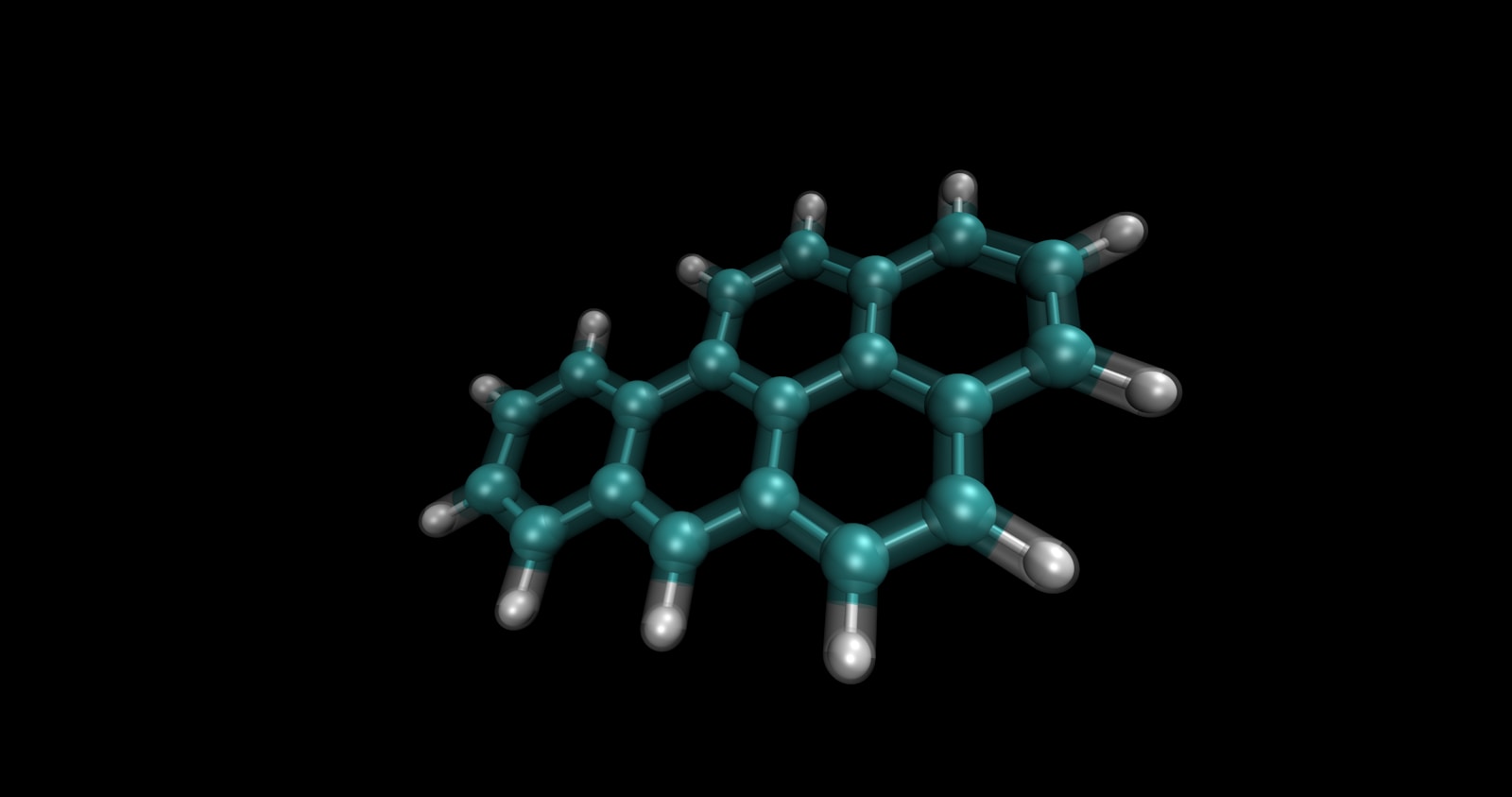

Benzene

Beverage ingredients

Bioactive compounds

Biofuel

Biologics

Botanical extracts

Broth

Caffeine

Cannabis distillate

Cannabis extracts

Cannabis oil

Canola meal

Canola oil

Caramel

CBD oil

Celery juice

Chamomile oil

Chinese traditional medicine

Chlorella powder

Citric acid

Citrus Fruit

Clarified grape juice

Cocoa butter

Coconut cream

Coconut milk

Coconut oil

Coconut water

Coffee extracts

Coffee powder

Cold-pressed juice

Cold-pressed olive oil

Collagen peptides

Collagen supplements

Cooking oil

Corn oil

Cottonseed meal

Cottonseed oil

Decaffeinated coffee

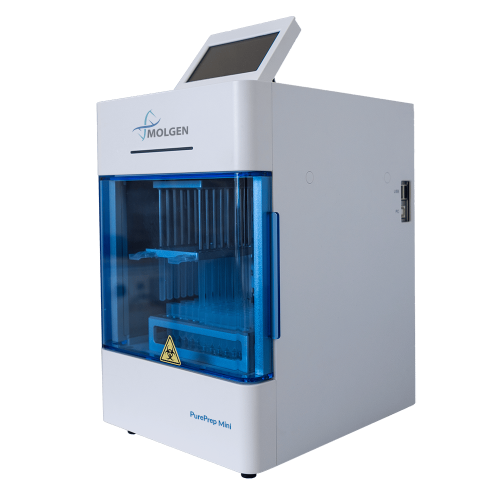

Dna

Dyes

Echinacea extract

Elderberry extract

Eucalyptus oil

Extra virgin olive oil

Extracts

Fatty acids

Fermentation broths

Fine chemicals

Fish by-products

Fish oil

Fish oil capsules

Flavor enhancers

Flavor extracts

Flavoring agents

Flavors

Flower extract

Food colorants

Food flavorings

Food ingredients

Fragrance compounds

Fragrance oils

Fragrances

Fruit concentrate

Fruit juice

Gelatin sheets

Gelatine

Ginkgo extract

Ginseng extract

Grape Juice

Ground coffee

Halloumi

Hemp seeds

Herbal medicines

Herbal supplements

Herbal tinctures

Hydrocarbons

Hydrocolloids

Hydrometallurgy

Infusions

Lavender oil

Lecithin

Lemon concentrate

Lemon essential oil

Lemon juice

Lemons

Lignin

Limes

Lotions

Malt extract

Maltodextrin

Mango juice

Mango pulp

Marine algae

Meat and bone meal

Medicinal cannabis

Molasses

Molecular biology

Natural food colorants

Nectar

Nut oil

Oil

Oil and gas

Oilseeds

Ointment

Olives

Omega-3 capsules

Omega 3 oil

Organic acids

Organic chemicals

Organic pigments

Orphan drugs

Passion fruit juice

Pasteurized juice

Pasteurized milk

Pea protein isolate

Peaches

Pectin

Pineapples

Plant-based beverages

Plastic intermediates

Polysaccharides

Pomegranate juice

Precious metals

Protein powder

Rapeseed oil

Refill tablets

Refined sugar

Rice bran

Rice milk

Rose oil

Sea buckthorn oil

Seed oils

Sesame oil

Sodium chloride

Soluble coffee

Soy protein isolate

Soy protein powder

Soybean meal

Soybean oil

Starch derivatives

Stearic acid

Sugar

Sugar beet seeds

Sugar substitutes

Sunflower oil

Sunflower seeds

Sweeteners

Synthetic resin

Tangerine juice

Tapioca starch

Tea

Tea extracts

Tea tree oil

Technetium-99m

Technetium-99m radiopharmaceuticals

Terpenes

Thc distillate

THC

Thc oil

Tinctures

Tofu

Toluene

Tomato concentrate

Tomato juice

Tomato paste

Tomato seeds

Tomato soup

Traditional chinese medicine

Vanilla extract

Vegetable juice

Vegetable oil

Vegetable proteins

Virgin olive oil

Vitamins

Wheat gluten

Whey protein isolate

Whey protein powder

Wine

Which extraction technology do you need?

Separators for pharma extraction

Optimize your pharmaceutical extraction process with innovative centrifugal separation tech...

Pharma extraction clarifier

Achieve superior purity in pharma extraction with efficient separation of solids and liquids, se...

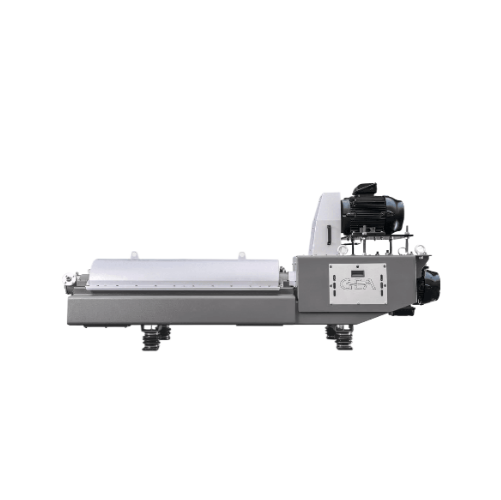

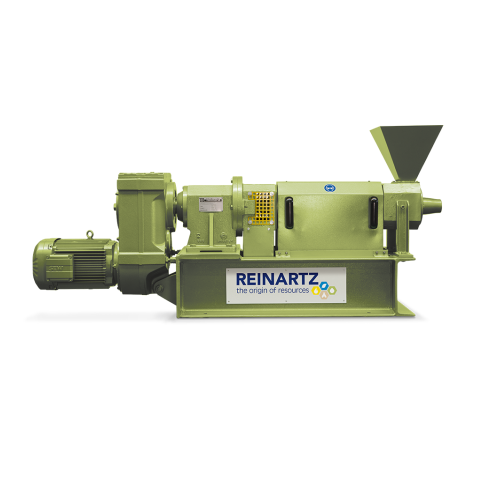

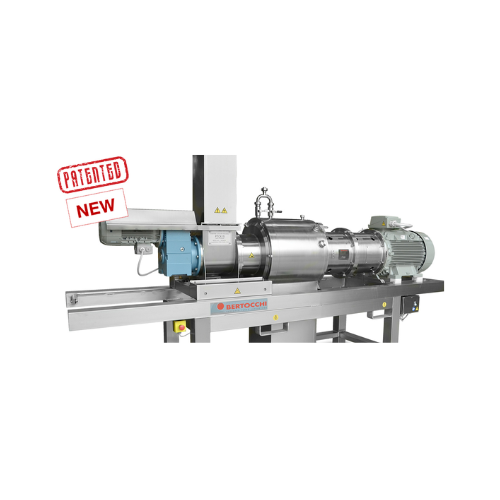

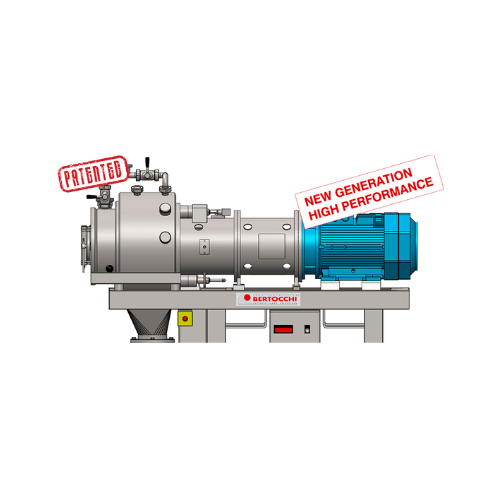

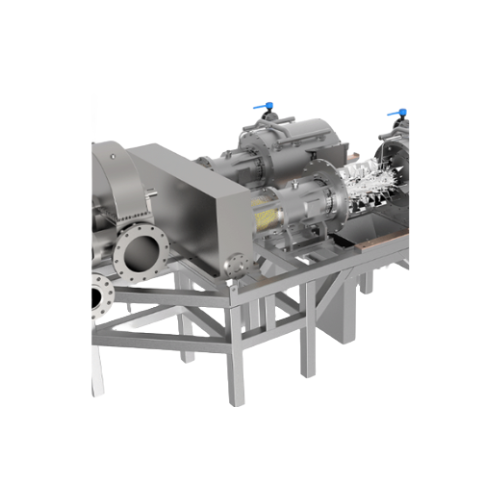

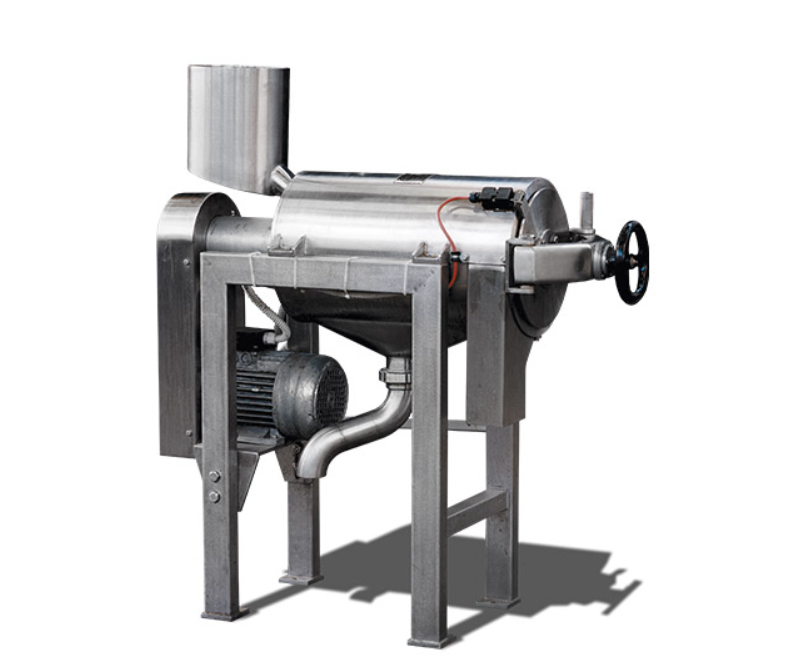

Screw press for mechanical oil extraction

Maximize protein extraction and oil yield with precision screw presses designed ...

Screw press for insect protein extraction

Address the rising protein demand with our screw press, designed to efficiently ...

Gas compressor for solvent recovery in hydrocarbon extraction

Need efficient, explosion-proof gas recovery for butane or...

Laboratory automation software for distillation and extraction

Optimize your distillation and extraction processes with ...

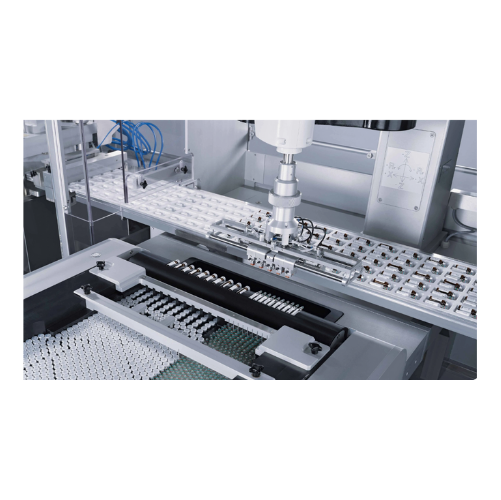

Compact automated nucleic acid extraction system

Quickly automate nucleic acid purification to reduce hands-on time and mi...

Apron extractor weigh feeder for large-scale material extraction

Achieve precise material dosing and metering under chal...

Laboratory filter-reactor for chemical synthesis and extraction

Optimize your chemical processes with a versatile filter...

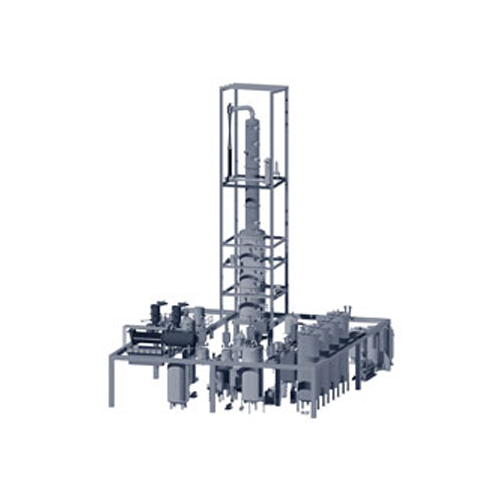

Packed and tray columns for distillation, absorption, and extraction

Enhance your production line with columns designed...

Enzymatic inactivators for fruit juice extraction

Optimize your fruit juice extraction process by ensuring precise contro...

Portable ethanol extraction processing lab

Accelerate your extraction process with a fully portable and compliant lab solu...

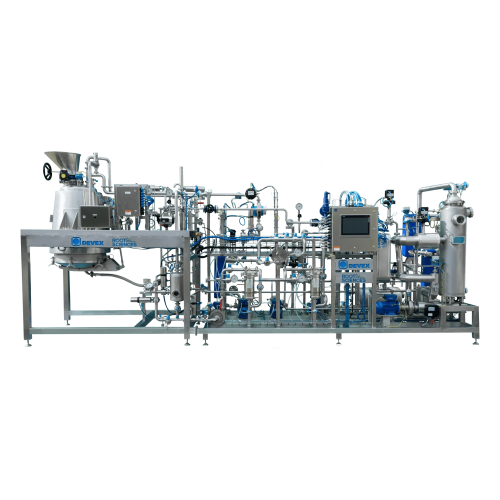

Extraction plant for natural essences and active ingredients

Optimize your extraction processes with a versatile system ...

Filtration skid for ethanol extraction of cannabis and hemp oil

Enhance the clarity and color of your ethanol-extracted ...

Inline chillers for ethanol extraction

Streamline your ethanol extraction process by quickly chilling alcohol to optimal te...

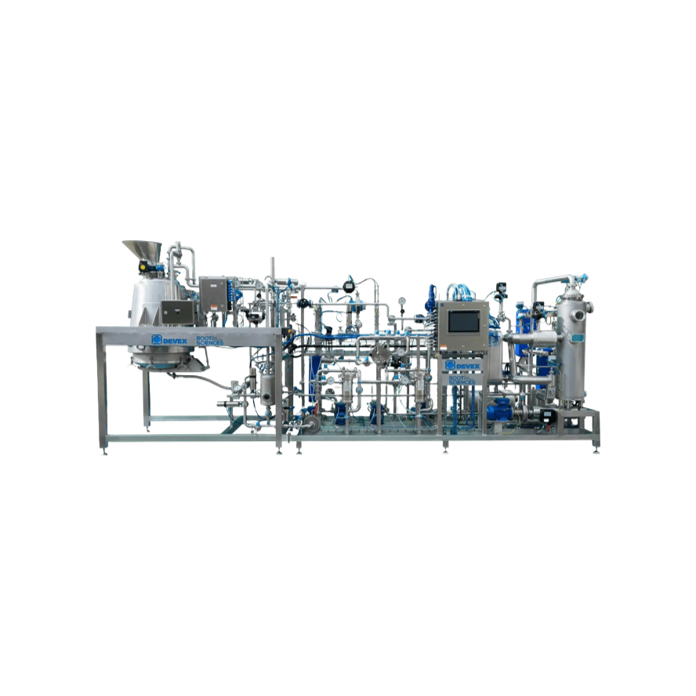

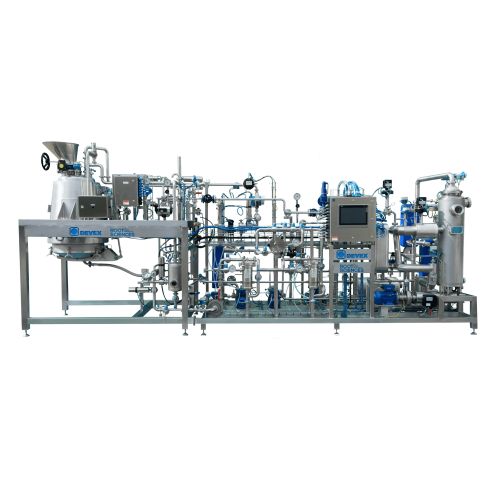

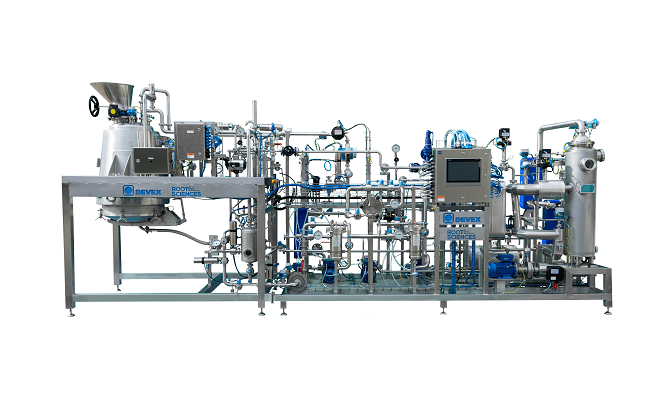

Ethanol alcohol extraction system for botanical compounds

Achieve high-purity extractions efficiently with a closed-loop...

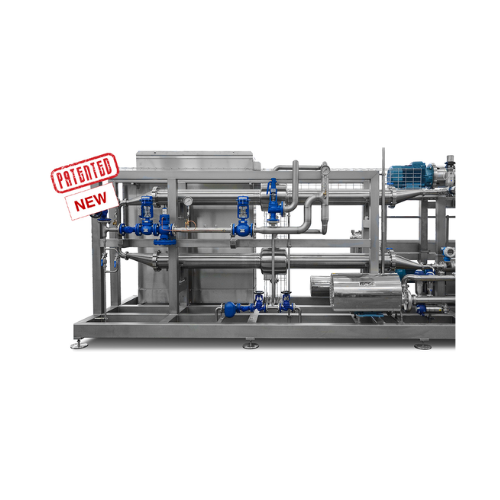

Liquid/liquid extraction mixer-settler plant

Optimize your extraction processes with a highly efficient mixer-settler syst...

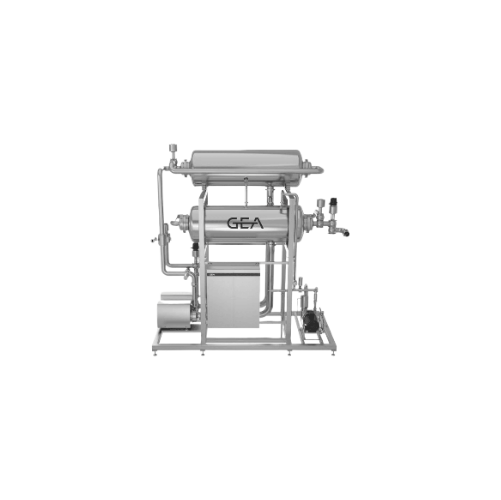

Solid/liquid extraction system for industrial applications

Optimize your solid-liquid extraction needs with a compact mu...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

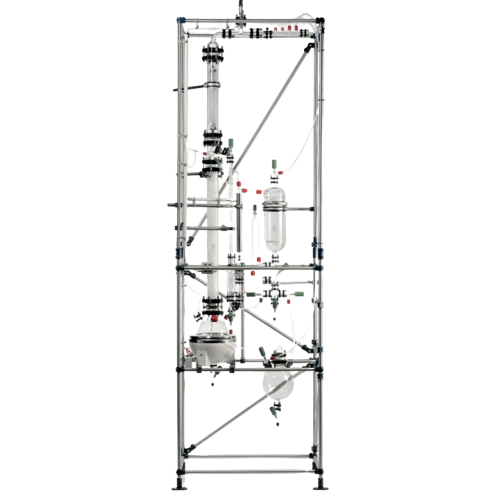

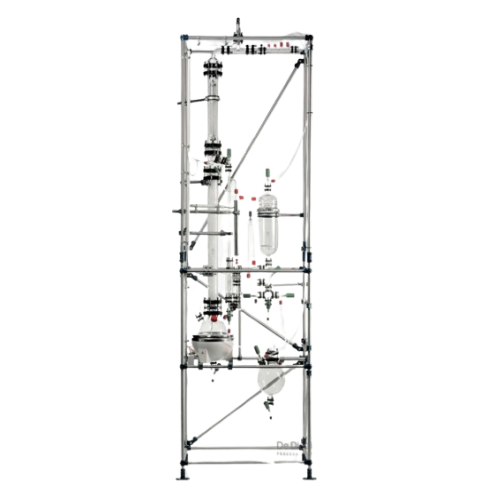

Solid/liquid extraction unit for process development

Optimize your extraction processes with flexible operation modes for...

Oil presses for oilseed extraction

Ensure efficient oil and protein extraction with specialized presses, enabling optimal s...

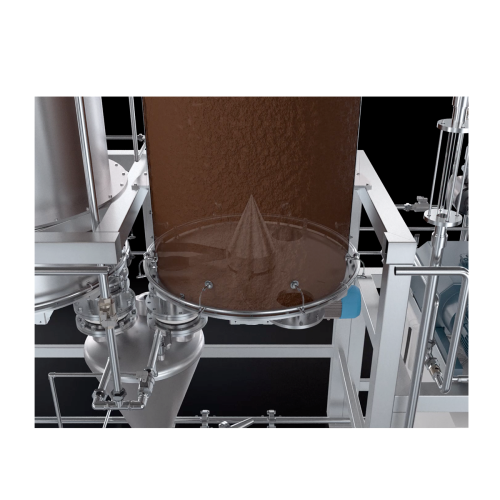

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

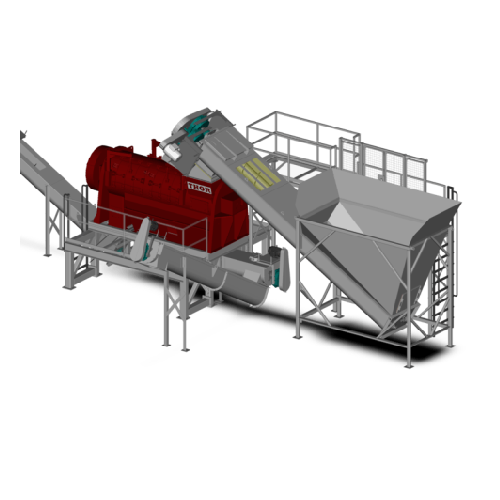

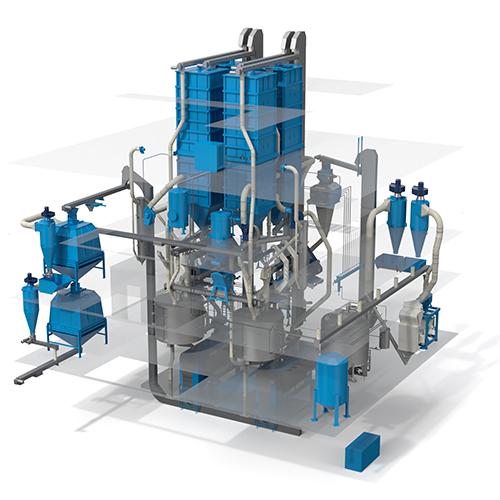

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

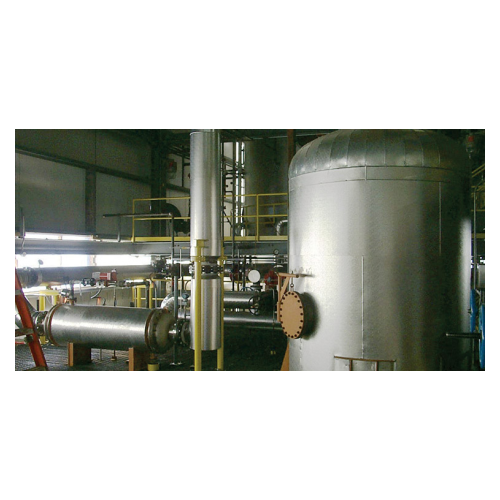

Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process whi...

Dust particulate extraction system

Ensure safe containment and minimize airborne particulates in your production line with ...

Multitasking extraction system

Effortlessly manage complex extractions with high-speed, reliable results, ensuring sample in...

Recirculating chiller for evaporation and extraction

Streamline your laboratory processes with a chiller that efficiently...

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Hydraulic press for juice extraction from apples

Optimize juice yield and purity with a robust hydraulic pressing system, ...

Fruit juice extraction technology for Nfc and freshly squeezed juices

Optimize your juice production with advanced extr...

Frozen extraction turbo extractor for fruit and vegetable purees

Efficiently transform frozen fruits and vegetables into...

Cold extraction system for fruits and vegetables puree

Optimize your fruit and vegetable puree production with a versatil...

Frozen extraction line for fruit and vegetable purees

Overcome challenges of processing frozen fruits and vegetables effi...

Cold extraction deaeration system for fruit and vegetable purees

Achieve superior puree quality with our system that ens...

Turbo extractors for tomato and fruit hot extraction

Optimize your fruit and vegetable processing with high-capacity turb...

Cold extraction and deaeration system for fruit and vegetable purees

Ensure high-quality fruit and vegetable purees wit...

Cold extraction turbo extractor for fruit and vegetable puree

Optimize your processing line with continuous cold extract...

Solid/liquid extractor for high-yield functional nutrient extraction

Maximize extraction efficiency and elevate product...

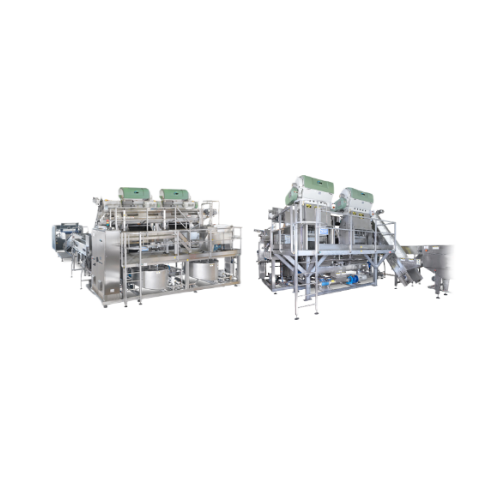

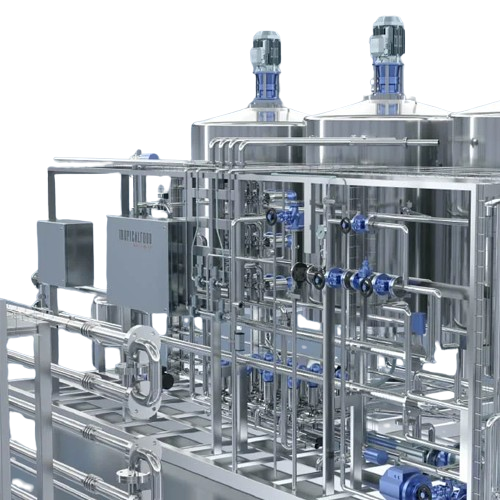

Plant-based protein extraction technology

Achieve optimal purity in plant-based milk, yogurt, and cheese production with c...

Decanter centrifuge for protein extraction

Efficiently enhance your recovery of valuable proteins and fats with customizab...

Olive oil extraction system for extra virgin olive oil

Enhance the quality of your extra virgin olive oil production with...

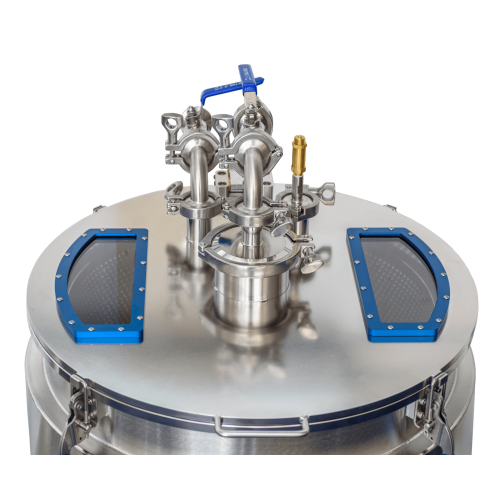

Winterization reactor for botanical extraction

Achieve precise temperature control and efficient separation during winteri...

Ice water extraction system for solventless extract production

Optimize your plant-based extraction processes with a mod...

Decarboxylation package for botanical extraction

Optimize decarboxylation and reaction processes with precise temperature ...

Dual-jacketed reactor for botanical extraction winterization

Optimize your production with precise temperature control a...

D-limonene extraction system for citrus processing

Enhance your citrus processing capabilities by efficiently extracting ...

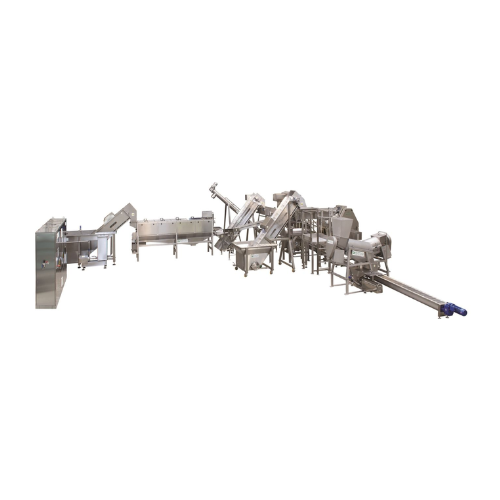

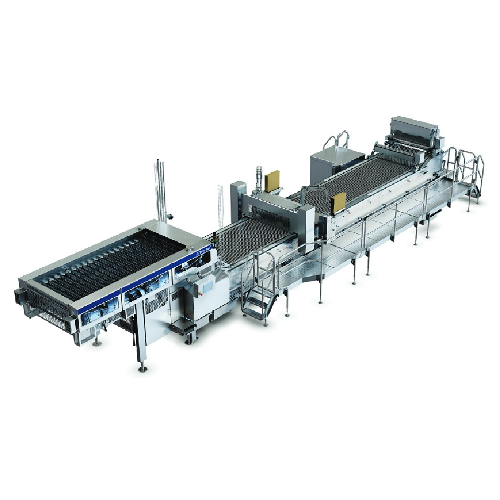

Industrial extraction line for fruits and vegetables

Optimize your fruit and vegetable processing with a highly flexible ...

Citrus juice extraction system

Optimize your citrus juice processing with a compact, flexible system that efficiently extrac...

Industrial coffee extraction system for high yields

Maximize coffee yield and quality with precision-controlled extractio...

Centrifugal separator for pharmaceutical extraction

Optimize your extraction process with precision centrifuging that enh...

Decanter for plant-based beverage extraction

Ensure high-yield extraction and optimal purity from plant-based ingredients ...

Solid-wall bowl separators for pharma extraction

Optimize your extraction processes with precision solid-wall bowl separat...

Pectin extraction decanter centrifuge

Achieve precise separation and maximize yield in pectin and plant extract processing ...

Fruit treatment lines for juice and pulp extraction

Optimize your juice production line by efficiently extracting, proces...

Industrial screw press for juice extraction

For juice manufacturers aiming for optimal yield and efficiency, this screw pr...

Industrial citrus juice extraction system

Streamline your juice production with a versatile system that efficiently extrac...

Depulper for efficient fruit and vegetable juice extraction

Streamline your juice production with equipment designed for...

Essential oil extraction from citrus fruit peel

Optimize your citrus fruit essential oil extraction process with a versati...

Industrial filter drum for whey extraction

Streamline your cheese production with a rotary drum filter designed to efficie...

Multi-fruit extraction line for mango, guava, and passion fruit juice

Optimize your fruit processing with high-yield ex...

Pineapple juice extraction line

Streamline your pineapple processing with a complete solution designed to efficiently transf...

Apple, pear, and kiwi juice extraction line

Achieve high-yield juice production from apples, pears, and kiwis while retain...

Aroma recovery system for natural juice extraction

Maximize aroma recovery in your juice production with a fully automate...

Rapid cold brew coffee & tea maker with vacuum extraction

Achieve smooth, bold cold brews with less bitterness and enhan...

Single-pass tea extraction system

Achieve consistent, high-quality ready-to-drink tea extraction with a streamlined, semi-c...

Continuous soya extraction unit

Enhance your plant-based beverage production with a unit that maximizes protein yield and re...

Double decanter for plant-based beverage extraction

Maximize protein yield and enhance extraction efficiency in your plan...

Single-pass extraction system for tea

For tea producers seeking consistent, high-quality extraction, this semi-continuous s...

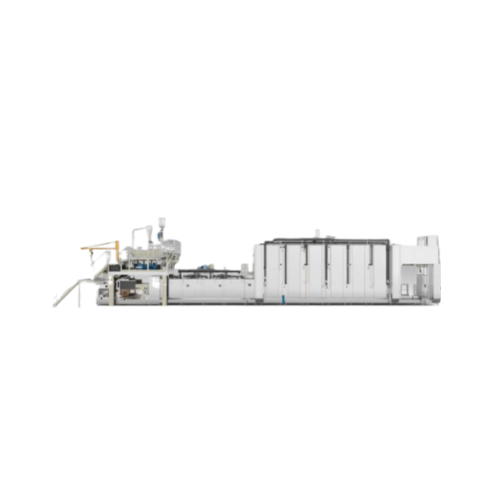

Continuous soya protein extraction system

Optimize plant-based milk yield and reduce waste with a versatile extraction sys...

Plant-based beverage extraction system

Maximize yield and product quality in plant-based and dairy beverages with high-effi...

Industrial passion fruit juicer for efficient juice extraction

Achieve complete separation of passion fruit components w...

Screw oil press for edible oil extraction

Optimize your oil extraction process with this screw oil press, designed to effi...

Hydraulic oil press for efficient oil extraction

Streamline your oil production with a hydraulic oil press that ensures hi...

Vacuum juice extraction for various soft-pulp fruits

Achieve superior fruit juice quality by maintaining the integrity of...

Cold pre-fermentation system for wine extraction

Enhance your wine’s flavor profile with rapid extraction of color, ...

Organic material extraction for recycling

Achieve high-efficiency organic material separation for versatile end products l...

Solventless cannabis extraction system for large-scale operations

Optimize your large-scale cannabis, hemp, or hops pro...

Solventless extraction for cannabis and hemp

Achieve iceless hash production with a precision-engineered system that optim...

Solventless cannabis extraction system

Optimize solventless extraction of cannabis and hemp with precise agitation and filt...

Cold processed ethanol extraction system

Streamline your extraction process by integrating an all-in-one system that combin...

Hydrocarbon extraction system for cannabis extraction

Achieve high-efficiency extraction with precise solvent control, op...

Hydrocarbon extraction system for cannabis and hemp

Streamline your extraction process with a versatile system capable of...

Hydrocarbon extraction system for cannabis industry

Optimize your extraction process with cutting-edge technology designe...

Hydrocarbon extraction equipment for cannabis and hemp processing

Optimize your extraction processes with a high-capaci...

Hydrocarbon extraction system for cannabis

Optimize your cannabis concentrate production with a flexible hydrocarbon extra...

Advanced rosin press for solventless extraction

Enhance your extraction capabilities with precision-controlled pressure an...

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

High capacity cannabis cryo-ethanol extraction line

Boost extraction efficiency with high-capacity cryo-ethanol technolog...

Semi-automatic extraction machine

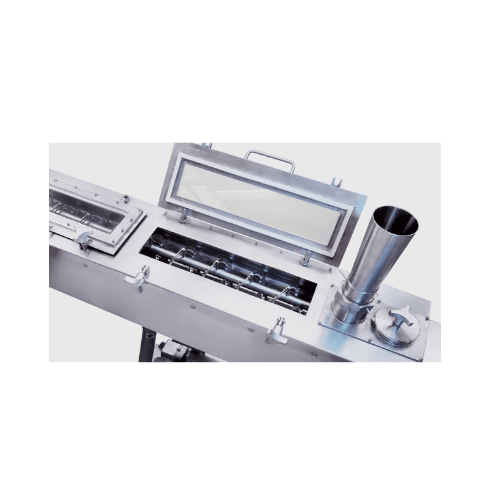

When extracting seeds from fruit or vegetable crops, it is best to consider a flexible de...

Tomato seed extraction machine

Although it’s the safest method, extracting tomato seeds manually can be time-consuming...

Seed extraction machine

The supply of high quality seeds is essential as it significantly contributes to the success of every...

Sunflower oil extraction plant

Extracting sunflower oil using an organic solvent, usually hexane, has a big environmental im...

Ultrasonic barbell for extraction

Conventional extraction methods are time-consuming, labour-intensive and can sometimes be...

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

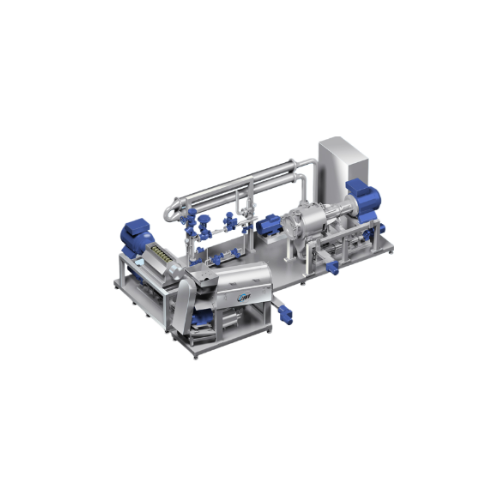

Continuous Multistage Centrifugal Extractor

When working with complex liquid-liquid separations, when handling pharmaceuti...

Monostage Centrifugal Extractor for Solvent Recovery and Purification

When separating immiscible liquids, speed and pre...

Cold press for extracting vegetable oils

Efficiently extract high-quality oils from diverse seeds while preserving vital nu...

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

Thermovinification plant for grape juice

Optimize color and tannin extraction while reducing energy use by up to 35% with t...

Citrus fruit juicing system

Efficiently extract and refine citrus juices and oils with a streamlined system designed to hand...

Buffer tanks for powdered or granulated solids storage

Enhance your production line with buffer tanks designed for precis...

Industrial coffee roaster for high-capacity coffee production

Enhance your coffee production line with high-speed roasti...

Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma...

Top discharge centrifuge for chemical manufacturing

Achieve precise filtration and separation with top discharge centrifu...

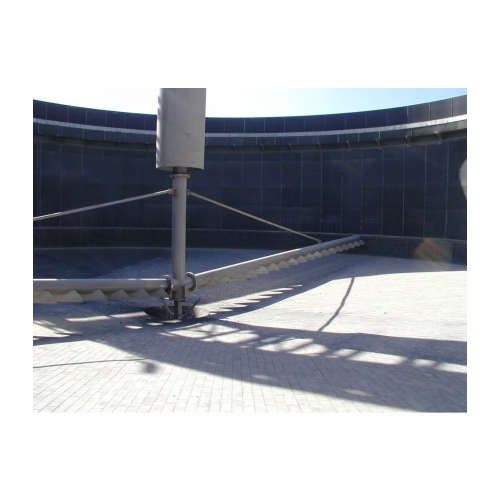

Industrial scraper for settling processes

Efficiently manage continuous sludge removal and sedimentation within your clari...

High capacity molding line for stick ice cream

Transform your frozen dessert production with an advanced molding line desi...

Tomato juice extractor

Achieve optimal juice extraction with efficient separation and minimal waste—ideal for producers aimin...

Evaporator for pulpy juice concentration

Achieve efficient concentration with reduced energy consumption, thanks to innovat...

Juice extractor for fruit and vegetable processing

Maximize juice yield and enhance pulp quality with high-performance ex...

Pulsed electric field system for olive oil processing

Enhance extraction efficiency and product quality with this advance...

Falling film evaporator for botanical oil separation

Optimize your ethanol recovery and botanical oil production with hig...

Thermovinification system for red wine production

Optimize your vinification process with a complete thermovinification s...

Grape stem extractor for winemaking

Efficiently remove grape stems to enhance quality in winemaking and streamline your pro...

Supercritical Co2 fluid purification system

Optimize your extraction process with our supercritical CO2 fluid purification...

12l solid/liquid extractor for pilot plant solutions

Optimize your extraction processes with a versatile extractor that a...

Semiautomatic lu-177 production and dispensing plant

Optimize your radiopharmaceutical production with an advanced system...

Continuous distillation columns for spirits production

Optimize your spirits production with advanced distillation column...

Impact dehuller for sunflower, soybean, and cottonseed

Enhance oil extraction efficiency with a dehulling solution that g...

Citrus juice extractor

Achieve unparalleled juice purity and essential oil separation with a system that elevates your fruit ...

Hydrocarbon recovery unit for chemical plants

Maximize your hydrocarbon capture and reuse with an advanced recovery unit t...

Turbo extractor for puree and concentrate production

Enhance your puree and concentrate production with a turbo extractor...

Apple processing equipment for juice and puree production

Efficiently process apples and pears into high-quality juice a...

Industrial depitter for stone fruits

Effortlessly process stone fruits into smooth purees and nectars with a continuous, co...

Turbo extractor for tomato and fruit puree processing

Optimize your production line with high-capacity turbo extraction f...

Foodec decanter centrifuge for food processing

Achieve high yields and clear liquid separation in your food processing lin...

Automated dry hopping system for large-scale beer production

Achieve seamless dry hopping with reduced oxygen pick-up, o...

Dry hopping system for medium size breweries

Enhance the aroma and flavor of your brews with a system that accelerates the...

Juice extractors for variety of fruits and vegetables

Streamline your juice and puree production with advanced extraction...

Modular oil recovery extractor for citrus essential oils

Achieve maximum yield and purity in citrus essential oil extract...

Citrus juice extractor for industrial juice production

Maximize juice yields while preserving exceptional quality with ou...

Rotary tablet press for abrasive powders

Achieve precise tablet sizing and bilayer production, even with abrasive powders, ...

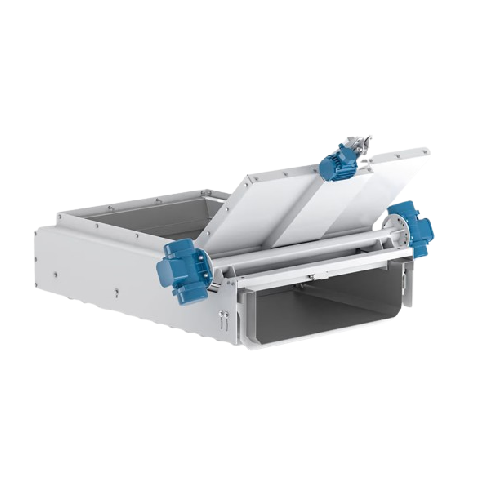

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Water deaeration system for beverages

Achieve ultra-low oxygen content in beverage water to enhance taste and prolong shelf...

Coffee extractor for optimal flavor preservation

Unlock the potential of your extracts with a continuous system that ensur...

Industrial fruit juice extractor

Maximize juice yield from a wide range of fruits and vegetables with precise extraction and...

Pulp separation system for citrus and pomegranate juices

Efficiently refine and separate pulp from juice to enhance produ...

Industrial citrus juice extractor

Achieve high-yield juice extraction with reduced oil content, delivering premium quality ...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...

Multifruit processing line for tropical and temperate fruits

Optimize your fruit processing operations with a versatile ...

Peach, plum, and apricot juice processing line

Optimize your fruit processing capabilities with a multifunctional solution...

Automatic banana peeling solution

Struggling with banana oxidation during puree production? This solution ensures swift, hi...

Coconut processing line for green coconut water and cream

Enhance your coconut processing with a fully automatic line th...

Horizontal slow masticating juicer for maximum juice yield

Optimize your juice extraction process with a slow masticatin...

Manual juice press for pomegranate and citrus

Effortlessly extract maximum juice from pomegranates and a variety of citrus...

Manual juicer for wheatgrass

Achieve nutrient-rich wheatgrass and produce juice without electricity, enhancing the freshness...

Cold press vertical slow juicer for fresh juices

Experience efficient juicing with a compact, slow-juicer system designed ...

Twin gear slow masticating juicer for vegetables and fruits

Achieve higher mineral content in your juices with this slow...

Manual citrus juice press

Effortlessly extract pure citrus and tomato juices with unmatched pressure, optimizing your yield ...

Citrus juicer for oranges, lemons, and limes

Effortlessly extract fresh citrus juices with a high-clearance design that pr...

Rotary moulder for ice cream production

Achieve high-speed, precise ice cream moulding with seamless integration into your ...

Hydrolysation tank for plant-based beverage production

Ensure optimal hydrolysis conditions for plant-based beverages wit...

High-precision decanter for plant-based beverages

Enhance your plant-based beverage production with a decanter engineered...

Industrial fruit juicer for high capacity processing

Optimize your extraction process with industrial-grade juicing that ...

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Rotating fermenters for wine making

Enhance your wine production with advanced fermenters designed for rapid extraction of ...

Vertical fermentation tanks for winemaking

Achieve optimal fermentation with vertical tanks designed for gentle must movem...

Edible oil processing solution

Optimize your production line with advanced pressing and dewatering technology, ensuring high...

Solventless terpene extractor for cannabis processing

Preserve the most volatile aromatic compounds during extraction, en...

Cannabis distillation system for high-potency extracts

Ensure your extracts achieve up to 99% cannabinoid purity with pre...

Pilot ultrasonic extractor

In the herbal medicine industry, an ultrasonic extractor is a valid alternative to conventional e...

Organic soybean oil press

In traditional soybean oil production, chemical solvents such as hexane are used to facilitate liq...

Organic soybean oil pressing plant

Soybean oilseeds are usually processed through extraction methods using hexane or other ...

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Separators for animal and fish by-products

Efficiently extract, purify, and recover valuable components such as high-quali...

Separators for recovering plasma and meal from animal blood

Optimize protein recovery and transform animal blood into hi...

Solid-wall bowl separator for chemical products

Optimize your separation and clarification processes with this high-speed,...

Craft brewhouse for medium to large breweries

Achieve unparalleled brewing flexibility and efficiency with a brewhouse tha...

Laboratory vacuum cold trap for extract purification

Optimize your vacuum purging and drying applications with this advan...

Nanofiltration and reverse osmosis for wine processing

Streamline your beverage production by effectively concentrating l...

Top discharge centrifuge for pharmaceutical production

Optimize your product yield and quality with precise filtration an...

Bag emptying system for bulk material handling

Streamline your material processing operations with a versatile solution de...

Processing plants for instant coffee production

Achieve optimal flavor retention and cost efficiency in instant coffee pro...

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and ...

Enzymatic inactivation system for fruits and vegetables

Achieve optimal product quality by maintaining vivid color, robus...

300l stainless steel dual-jacketed reactor for winterization

Enhance your extract processing with precision temperature ...

Secondary solids recovery system for citrus pulp

Optimize your juice yield and enhance efficiency with a streamlined four-...

Industrial dust collection system for food processing

Effectively capture and separate airborne dust particles from conti...

Point-of-sale orange juice juicer for freshly squeezed juice

Maximize your beverage offerings with a point-of-sale juice...

High corrosion-resistant vacuum systems for chemical industries

These high corrosion-resistant vacuum systems are design...

Vibrating extractor for silo and hopper product distribution

Ensure consistent product flow and precise distribution fro...

Industrial Long-cut pasta production line

Achieve superior long pasta quality with energy reductions up to 30%, featuring ...

Innovative brewing process for optimized wort quality

Revolutionize your brewing operations by optimizing subprocesses fo...

Cold press juicer for tough vegetables

Effortlessly handle tough produce with this twin gear, cold press juicer, designed f...

High-capacity ice cream stick production line

Maximize production efficiency with a high-speed, continuous ice cream moldi...

Degumming plant for edible oil refining

Achieve optimal purity and quality in edible oils through precise degumming process...

Cannabis distillate production system

Achieve high-purity cannabinoid distillates with continuous, high-volume processing t...

Solvent recovery and decarboxylation system

Enhance solvent recovery and streamline decarboxylation processes with an inno...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

Plug & play water to hydrogen generator

One of the highest volume industrial gases, hydrogen serves a wide range of applica...

Evaporator for manure fertilizer

Traditionally, liquid manure processing can lose some important nutrients. An efficient ful...

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...