Separators for recovering plasma and meal from animal blood

Optimize protein recovery and transform animal blood into high-value supplements with specialized separators that streamline both the plasma and meal production processes, ensuring efficient and hygienic operation for diverse processing needs.

Extracts Plasma and Meal from Animal Blood

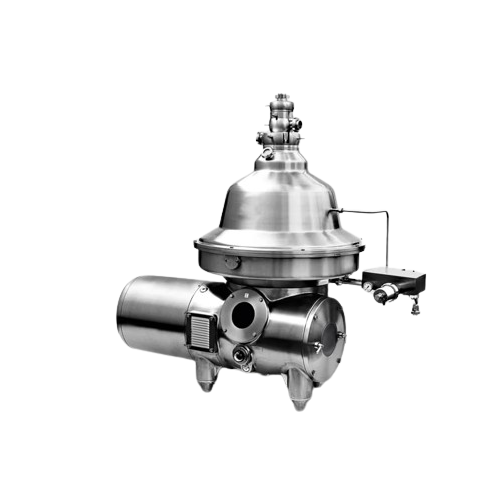

The GEA plasmaprime is a centrifugal separator designed to optimize plasma and meal recovery from animal blood, catering to both small-scale abattoirs and large-scale professional blood processors. This system employs a robust centrifuging process to separate valuable proteins, enhances throughput efficiency with capacities ranging from entry-level to high-performance operations, and can process both liquid and powdered outputs. Its hygienic design ensures food-grade quality, with all contact parts constructed from stainless steel for durability and corrosion resistance. Automation features include fully automated operation and cleaning, with seamless integration into existing production lines, offering maximum efficiency and reduced manual intervention. Suitable for diverse industries, such as food, agriculture, and pharmaceuticals, the separator supports a range of protein recovery applications, delivering high-value protein supplements and animal feed products. Offering customization options, this equipment ensures adaptability for various processing requirements, backed by engineering support from GEA’s expertise in advanced separation technology.

Benefits

- Enhances resource efficiency by maximizing protein recovery from animal blood.

- Minimizes labor with fully automated operation and cleaning processes.

- Ensures food safety with stainless steel construction and food-grade materials.

- Integrates seamlessly into existing production lines for streamlined operations.

- Adapts to various processing needs with customizable configurations and engineering support.

- Applications

- Food, Protein recovery, Nutraceuticals, Beverage, Animal blood processing, Agricultural by-products

- End products

- Animal feed supplements, Protein concentrate from animal blood, Blood meal, High-value protein supplements, Blood plasma powder

- Steps before

- Collection, Anticoagulant Addition, Transportation

- Steps after

- Blood Plasma Processing, Blood Meal Production, Drying

- Input ingredients

- animal blood, blood with anticoagulant

- Output ingredients

- blood plasma, blood concentrate, plasma powder, blood meal

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- Small scale to full scale processing

- Automation

- Fully automatic or manual operation

- Material of construction

- Stainless steel

- Cleaning method

- Fully automatic cleaning

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- 3A Sanitary Standards

- Yes

- FDA compliance

- Yes

- FDA materials

- Yes

- CE marking

- Yes

- EHEDG certification

- Yes

- Machine footprint

- Compact footprint for easy integration

- Material construction

- Stainless steel

- Discharge method

- Fully automatic

- Hygienic design

- Food-grade standards

- Control panel type

- Intuitive and easy to operate

- Cleaning feature

- Fully-automatic cleaning

- Control panel type

- PLC Touchscreen

- Integration possibilities

- Easy integration with existing systems

- Capacity options

- Entry-level to high-capacity

- Automation

- Manual to Fully-automatic

- Design features

- Hygienic design for food-grade plasma

- Operation flexibility

- Suitable for small to large scale operations

- Cleaning system

- Fully-automatic cleaning