Nutraceuticals Manufacturing Equipment

Find innovative nutraceuticals equipment and connect directly with world-leading technology suppliers

Eating is more than just nutrition, but we have found ways to increase the nourishing power of our foods. Nutraceuticals manufacturing, from vitamin C powder and probiotics to omega 3 oil, is a concentration of natural ingredients and health supplements that complement our diets. While dietary supplements are not quite haute cuisine, the process of extraction and purification is no less a blend of science and art.

Technology picks for nutraceutical production

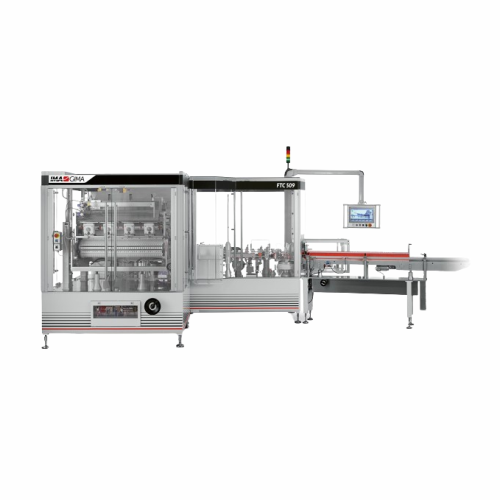

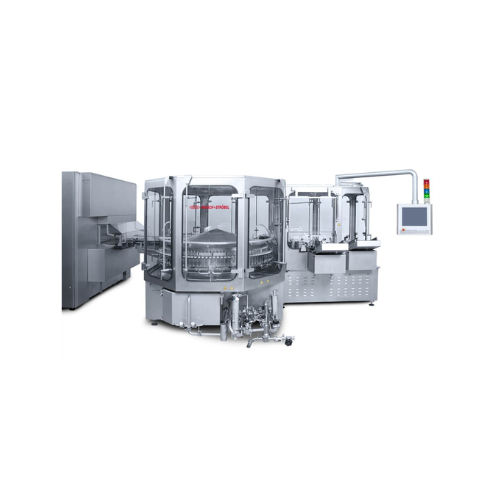

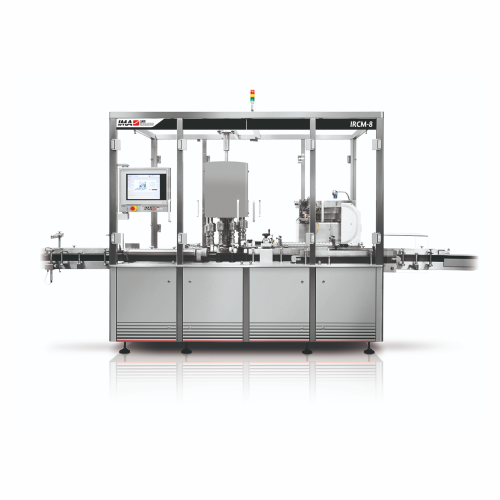

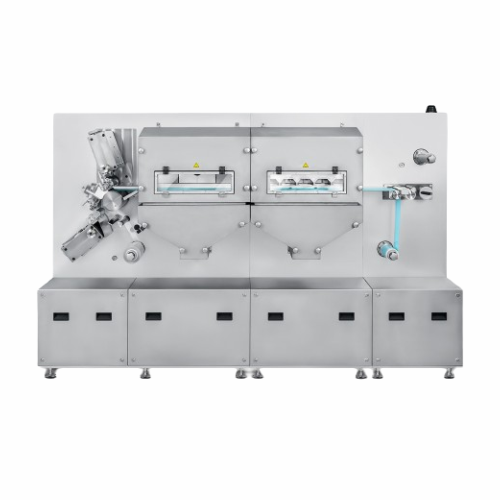

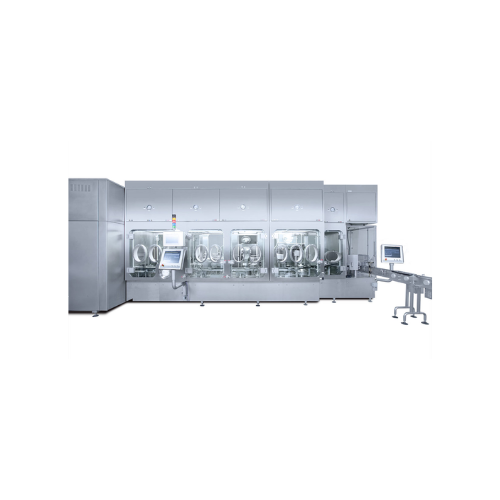

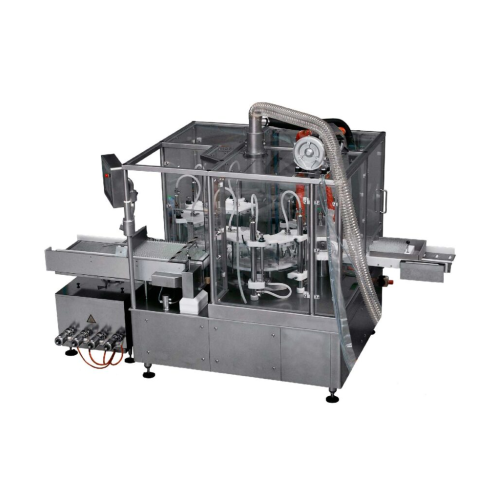

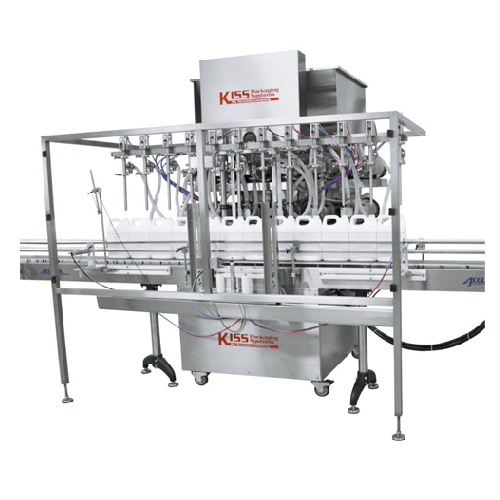

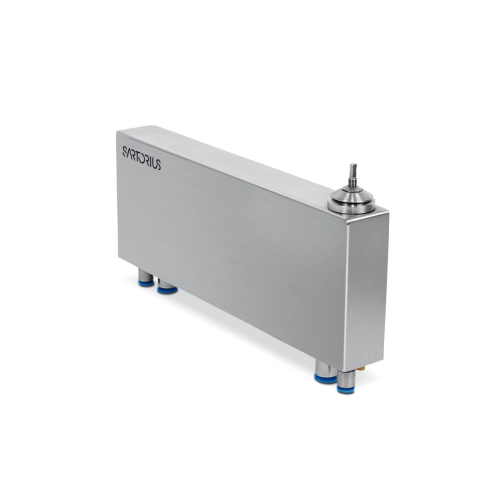

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

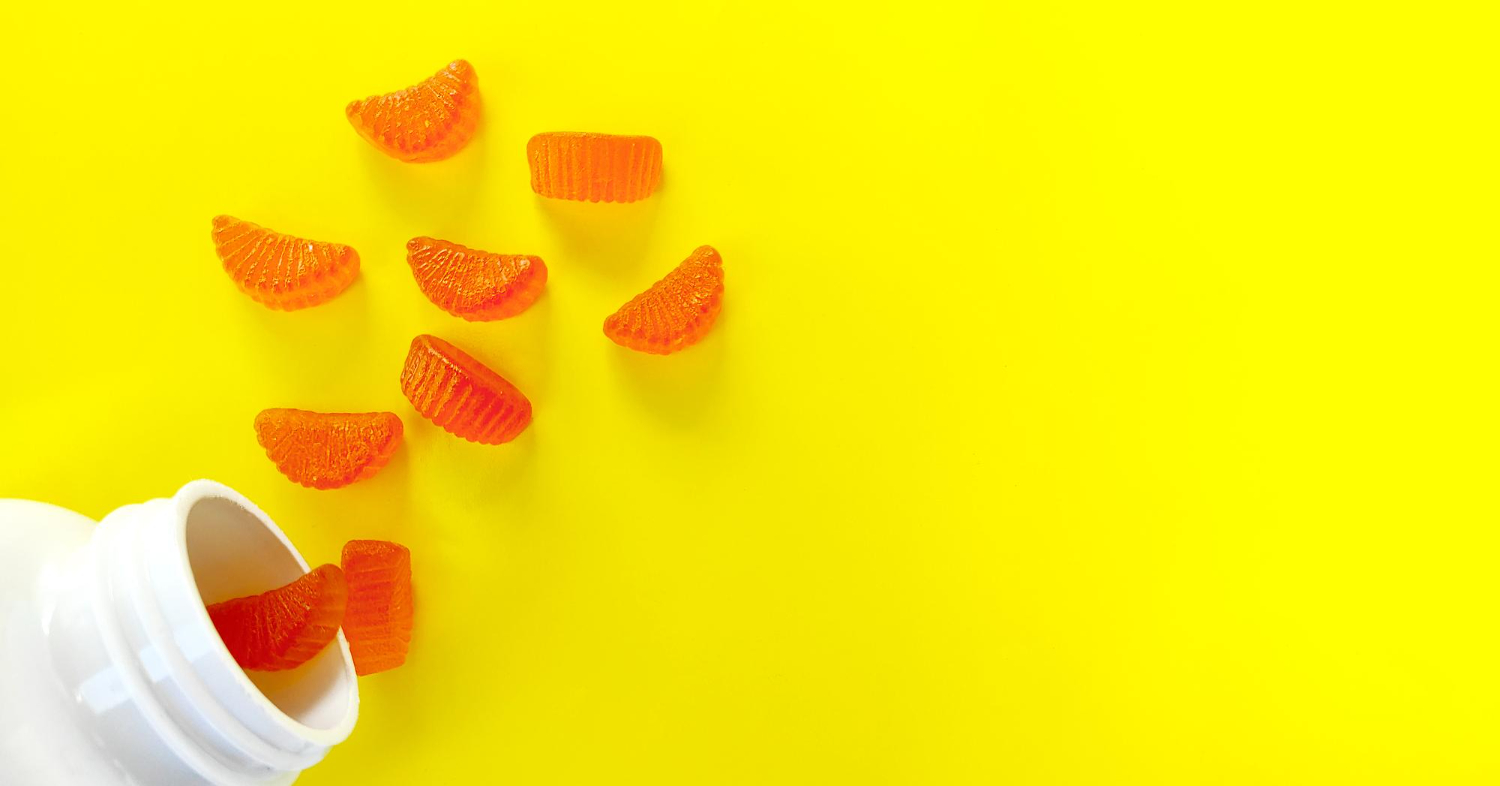

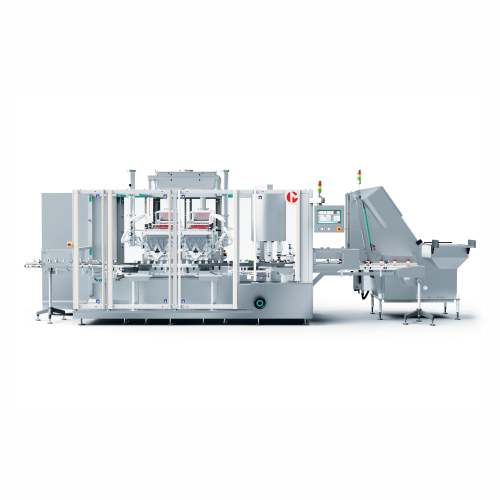

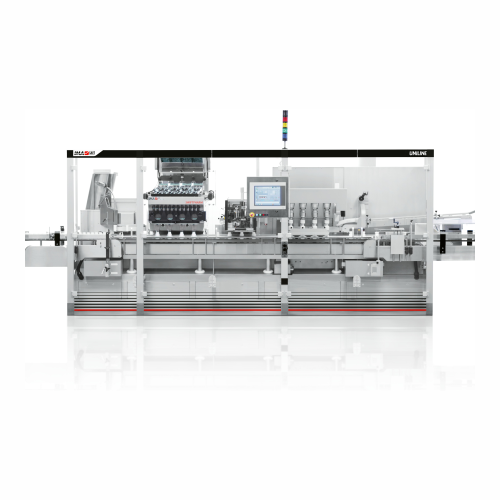

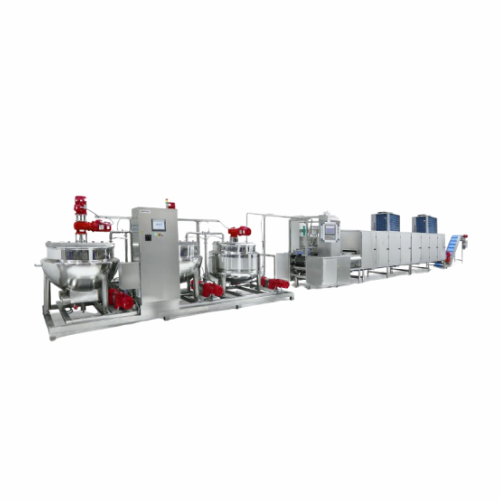

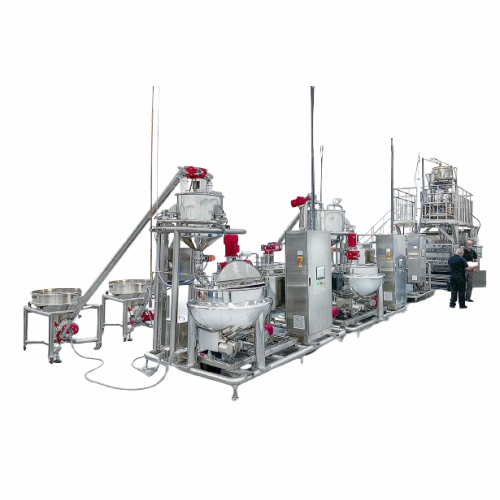

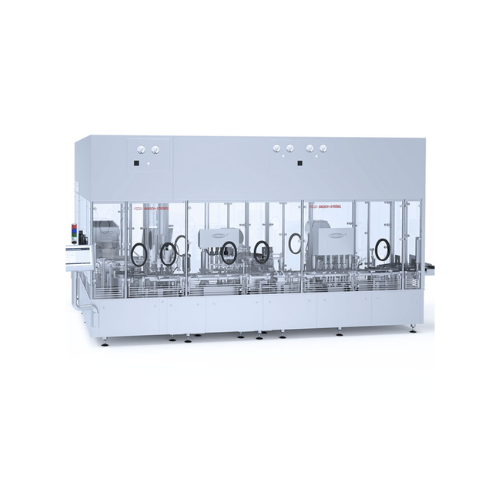

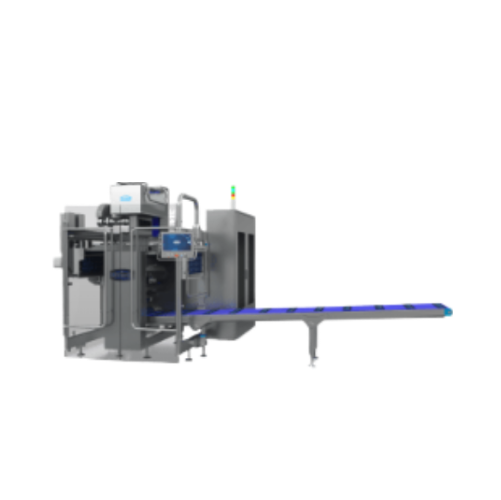

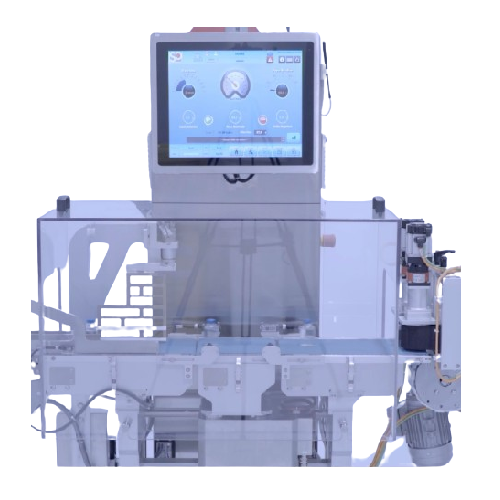

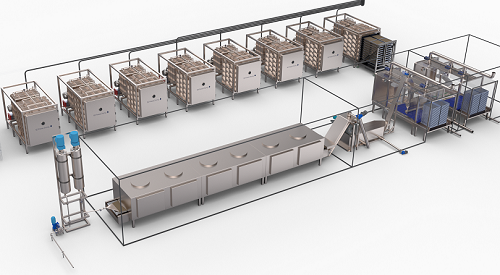

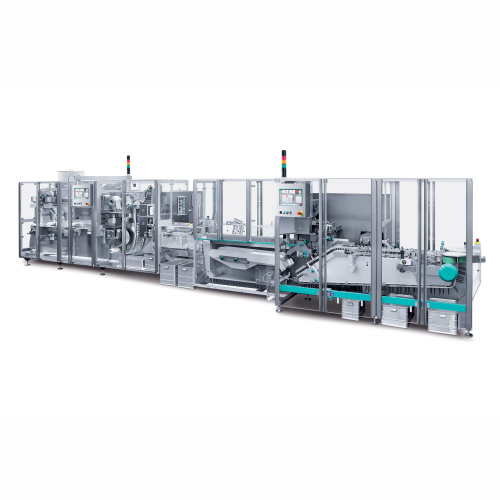

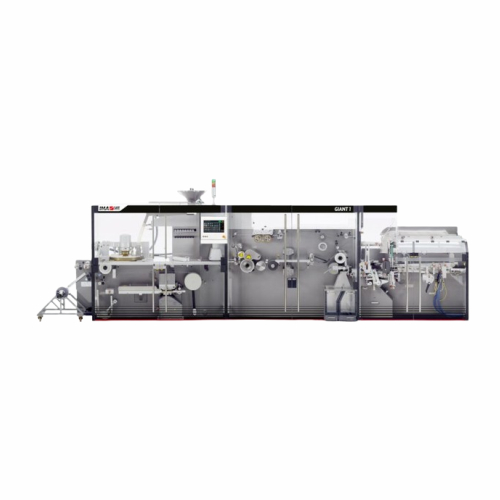

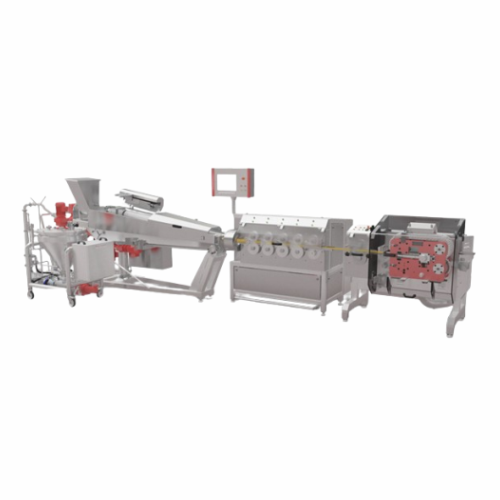

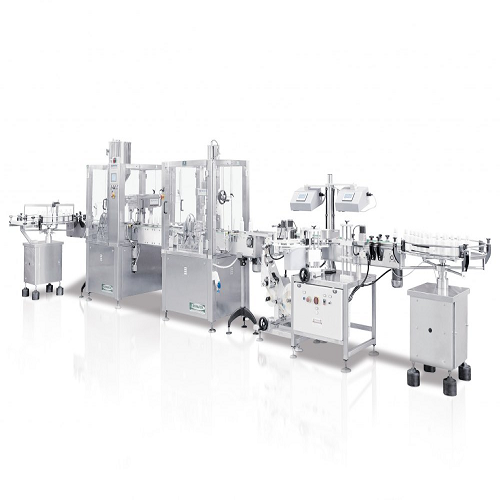

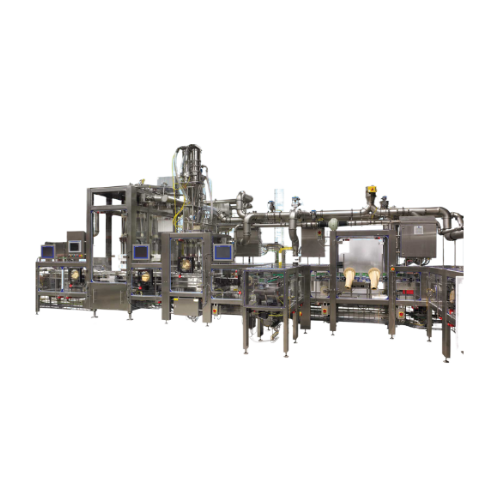

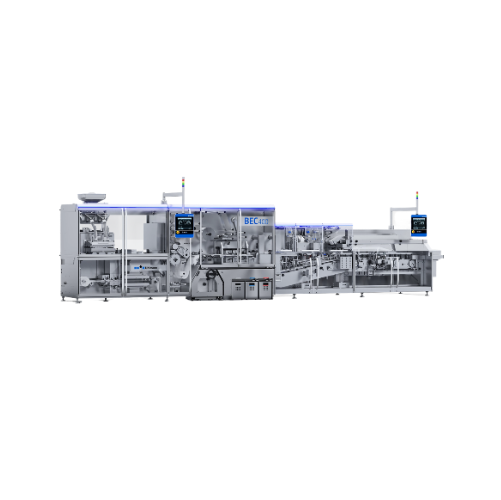

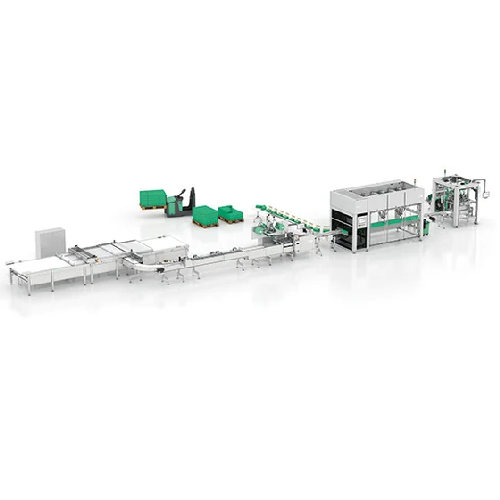

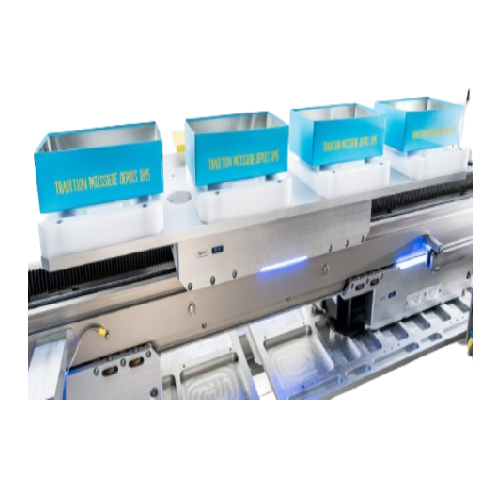

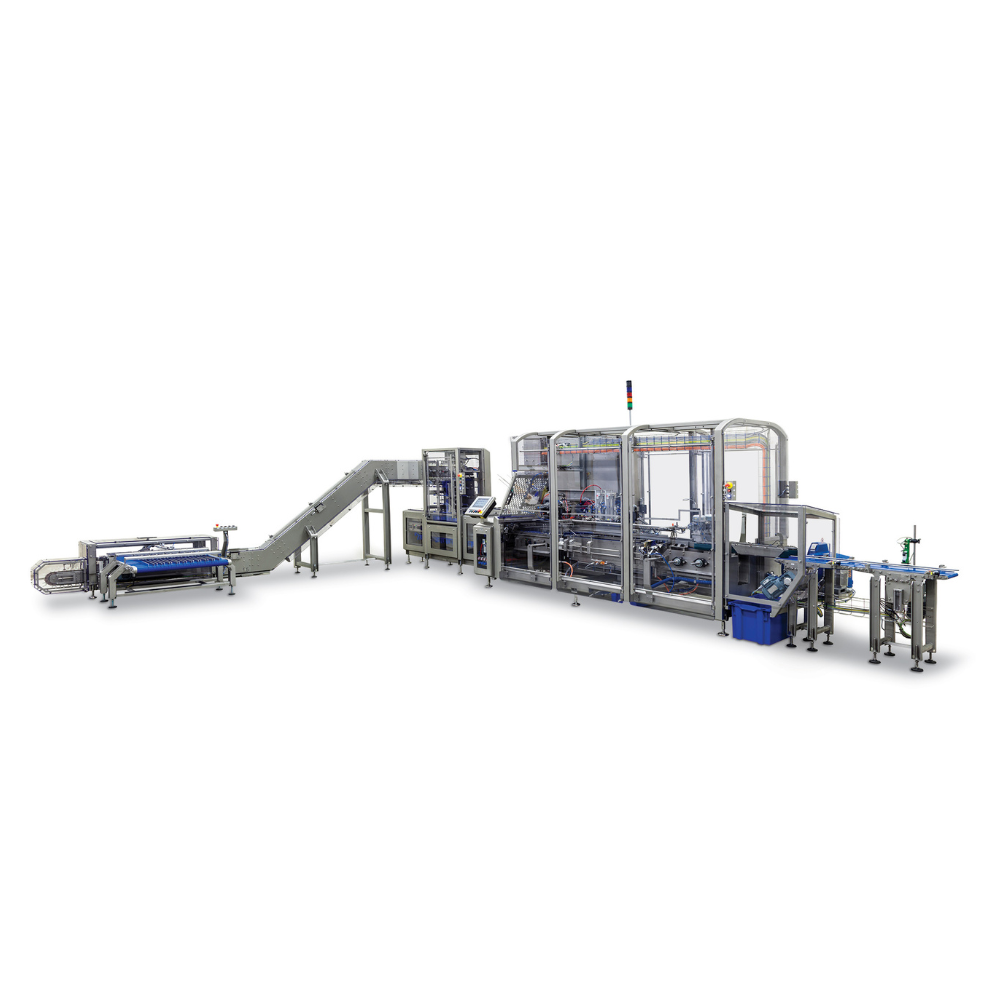

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

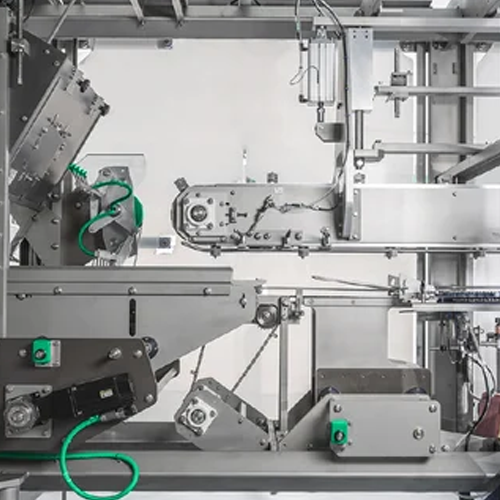

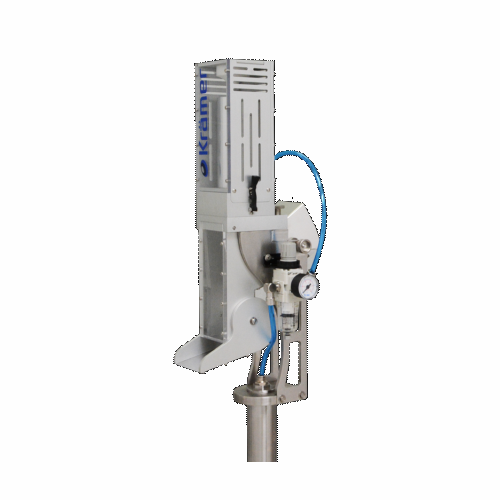

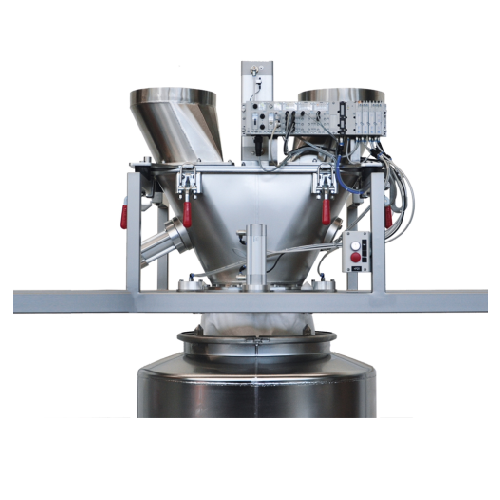

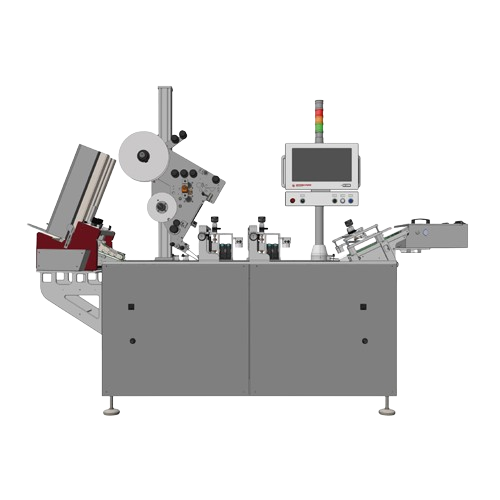

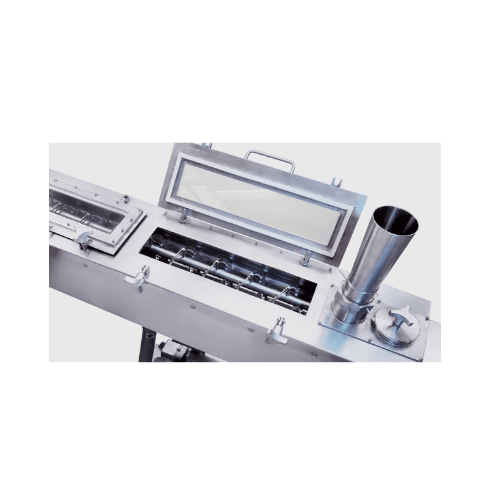

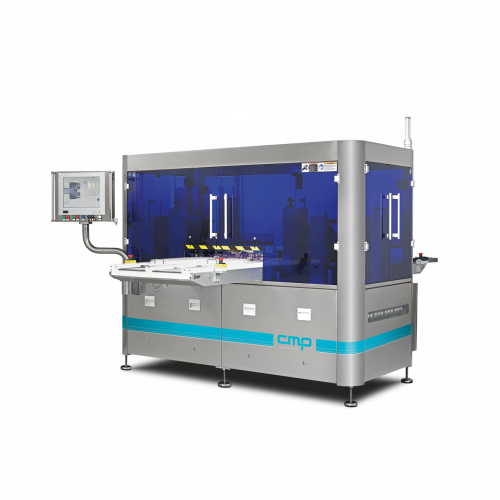

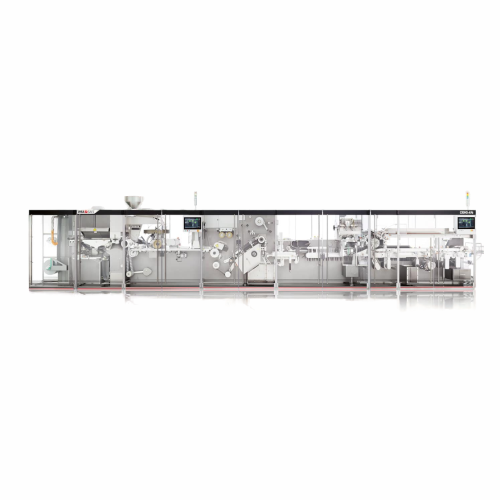

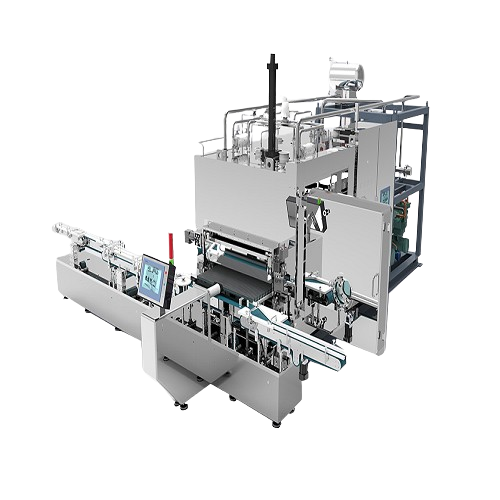

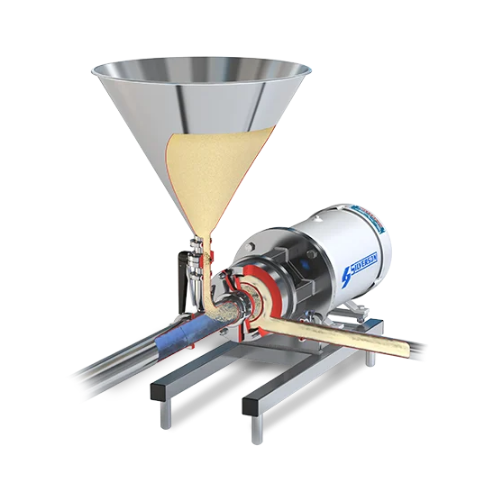

Continuous motion micro dosing system for nutraceutical powders

Streamline your powder processing with a high-speed, con...

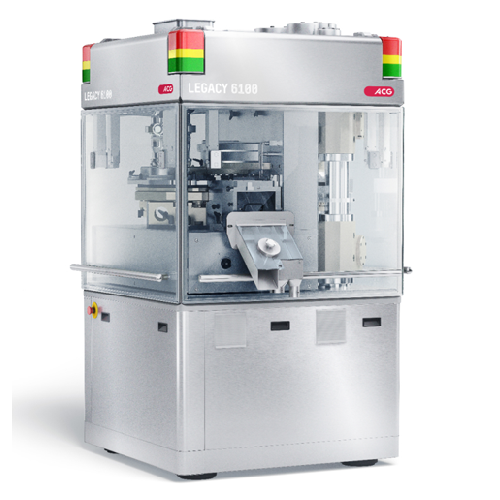

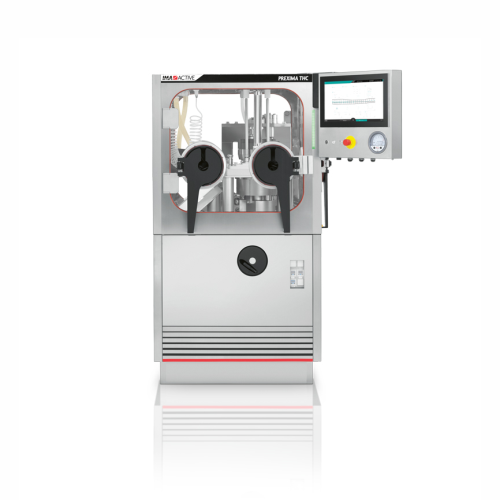

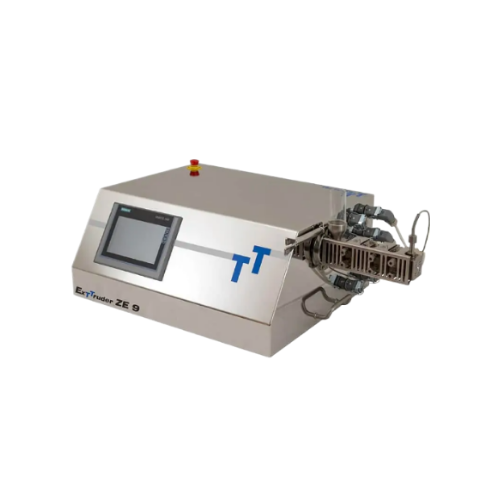

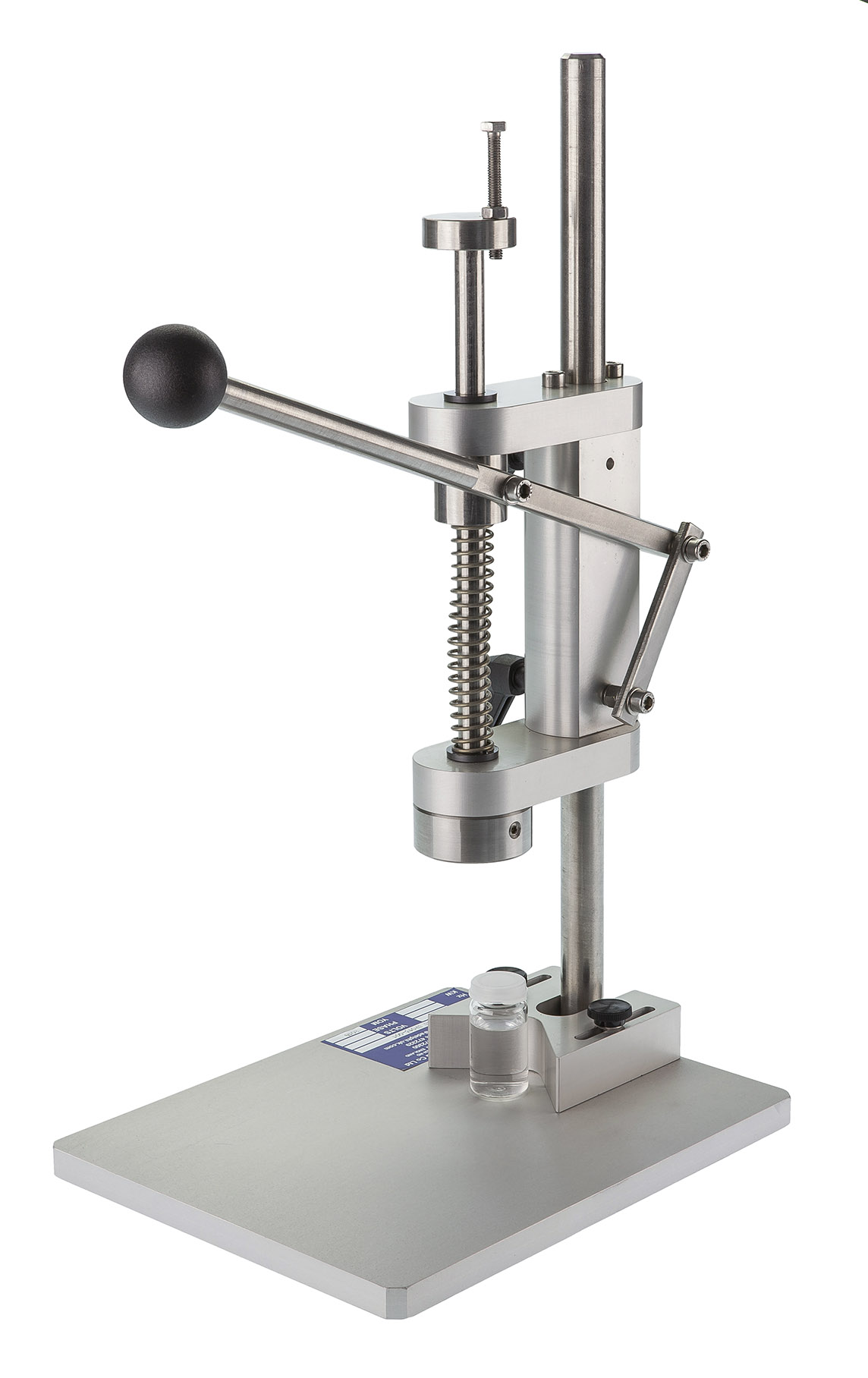

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Stories about nutraceuticals

Starchless gummy depositing for limited risk on cross-contamination

Discover the best mix for your blending application

Activate your candy game: from a nutraceutical idea to an active candy

How to turn a bag of sugar into a bag of scrumptious gummies

Find the perfect balance between sweets and wellness with vitamin candies

Keeping up with the trends: cartoning sustainable materials and utilizing AI all at once

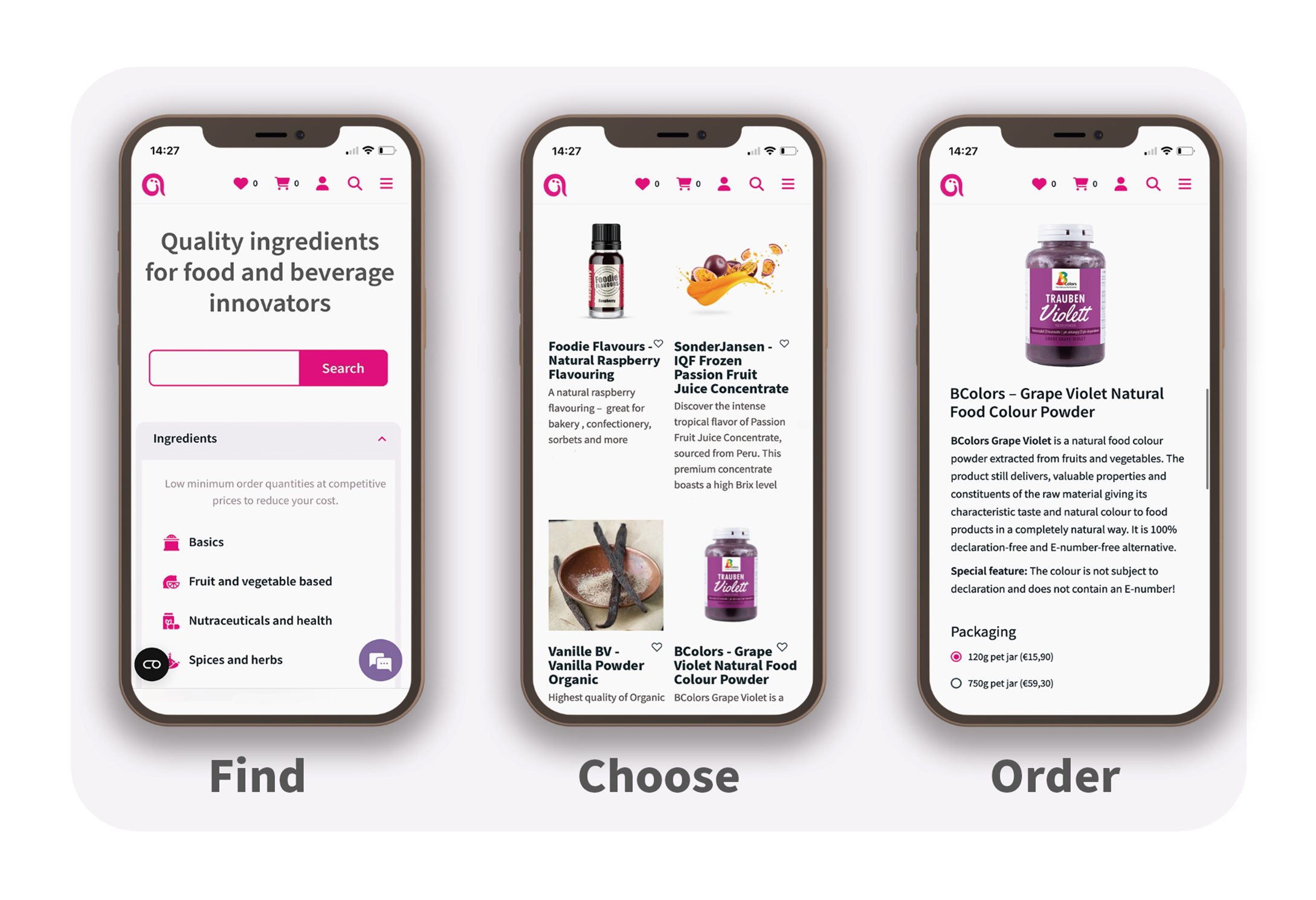

Order all your food Ingredients easily online at 1-2-Taste

Tech is [was] keeping vitamin gummy manufacturers from cutting starch

Two steps to stop formula deviation in CBD Gummies

Making chewable multivitamin tablets for kids

Unpacking the world of stick pack cartoning

The careful drying of herbal medicine

Keeping pharmaceuticals moisture free

Freeze drying microencapsulated hemp seed oil

What are you making?

Bioactive compounds

Antioxidant supplements

Vitamin e supplements

Vitamin d3 supplements

Vitamin d supplements

Vitamin c supplements

Supplements

Sports nutrition

Protein supplements

Probiotic supplements

Omega-3 capsules

Nutritional drinks

Nutritional formula

Nutritional shakes

Nutritional supplements

Nut paste

Multivitamin supplements

Monomers

Mineral supplements

Iron supplements

Infant nutrition

Homeopathy

Herbal tinctures

Herbal supplements

Herbal medicines

Fish oil supplements

Dietary supplements

Collagen supplements

Collagen peptides

Coenzyme q10 capsules

Vitamins

Botanical medicine

Herbal Extracts

Infusions

Freeze dried berries

Spirulina powder

Agar-agar

Probiotics

THC

CBD gummies

CBD oil

Elderberry extract

Echinacea extract

Ginseng extract

Ginkgo extract

Hard gelatin capsules

HPMC capsules

Multi-layer tablets

Chewable tablets

Protein powder

Omega 3 oil

Vitamin C

Collagen powder

Hyaluronic acid

Vitamin gummies

Tell us about your production challenge

Convert solutions into solid fibers to facilitate solubility

In the nutraceutical industry, bioactive compounds that make the basis of most nutraceuticals typically have low aqueous solubility, leading to poor bioavailability. Electrospinning techniques can address this challenge.

The method and manufacturing process applies a high voltage the inclusion solution pumped through a needle. The electric field forces the droplet into a jet stretched to form a solid fiber. The ultrafine material can be woven into microcapsules that dissolve quickly.

Observe strict packaging regulations for nutraceuticals manufacturing process

Packaging is required to declare what dietary ingredients the nutraceuticals contain. The Supplement Facts panel must include measurable amounts of the 14 mandatory dietary ingredients.

The label must also carry warnings about daily intake limits in EU markets. And FDA limits for the US markets. In addition, as a manufacturer, you need to state that your product should not be considered a replacement for daily rations from foods. This is usually aligned by the Current Good Manufacturing Practice regulations, also known as CGMP, a practice enforced by the FDA.

Hemp is a core ingredient in nutraceuticals for livestock

Veterinary nutraceuticals form a vital component of integrative animal wellness. But not all ingredients used for human dietary supplements can be consumed by animals.

Hemp products are driving a trend in the veterinary supplements market, particularly livestock. Nutraceuticals manufacturing derived from low-THC cannabinoids are used in animal feed for their antioxidant and neuroprotective properties.

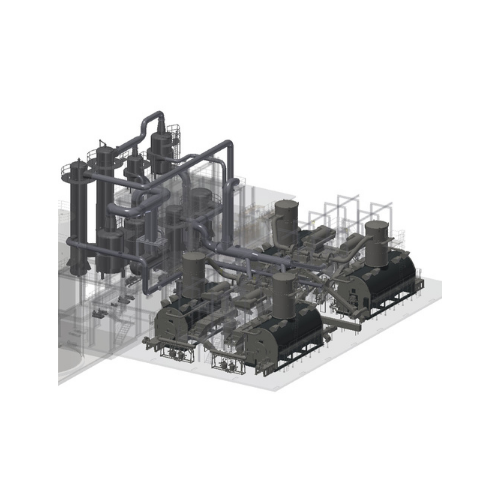

Nutraceuticals in a capsule-shaped nutshell

Nutraceuticals are health products that combine the benefits of food and pharmaceuticals. They can come in various forms, including capsules, tablets, powders, and beverages. Nutraceuticals manufacturing involves specialized equipment and processes to ensure high-quality products that meet regulatory requirements.

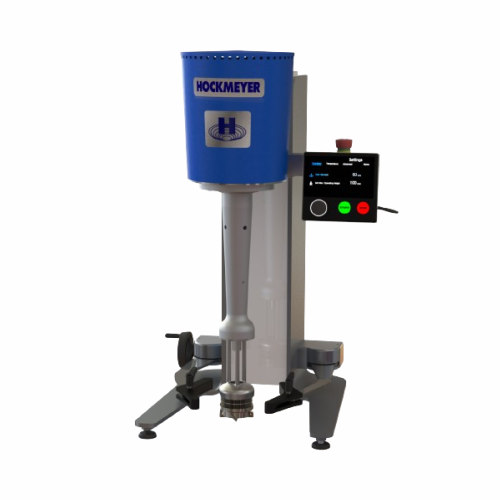

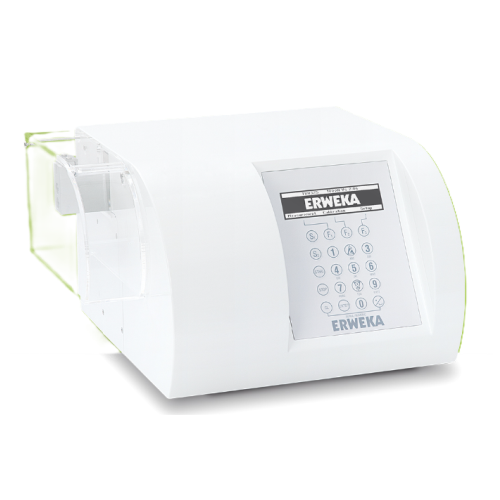

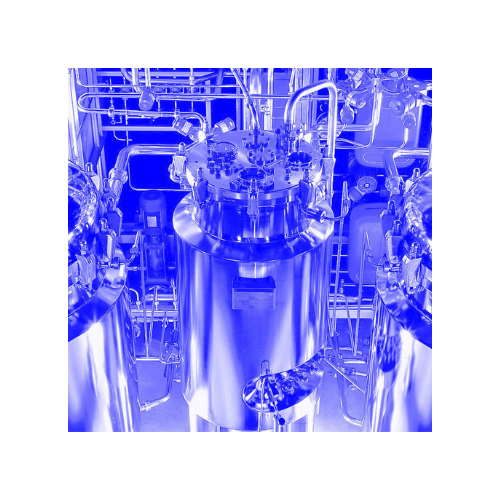

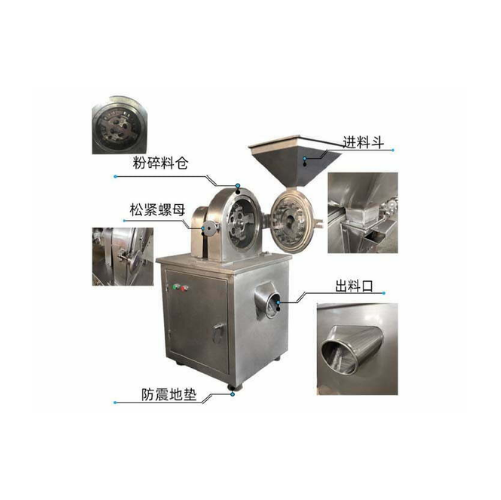

Companies can outsource manufacturing to contract manufacturers who offer private labeling, product development, and quality control services. Equipment such as capsule filling machines, tablet presses, powder mixers, mixing tanks, pasteurizers, and bottling machines are used. Quality control equipment tests the raw materials, in-process products, and finished products. Product development and proper storage and packaging are critical to maintain product quality, particularly for nutraceutical beverages.

Which nutraceuticals technology do you need?

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

Continuous motion micro dosing system for nutraceutical powders

Streamline your powder processing with a high-speed, con...

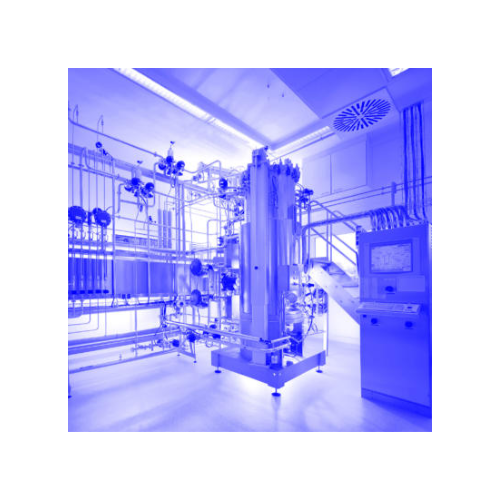

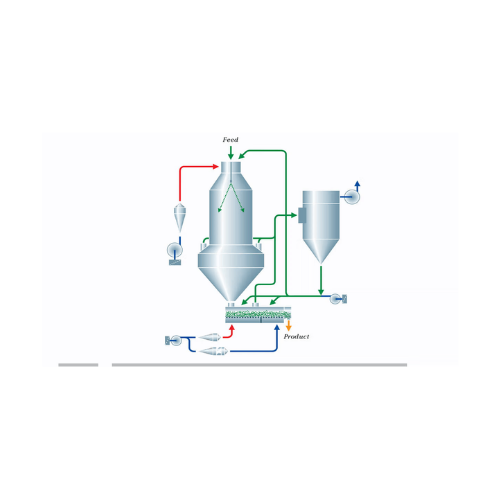

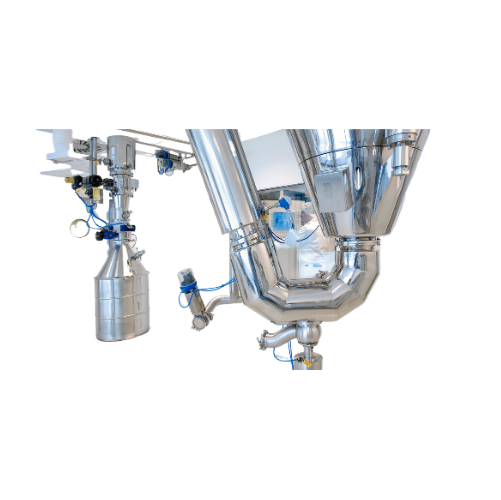

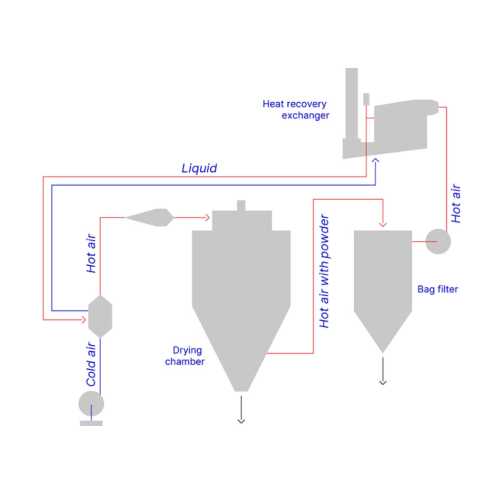

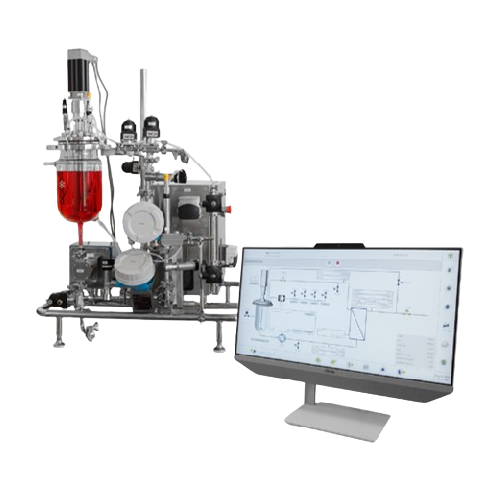

Pilot spray dryer for high-value proteins and nutraceuticals

Optimize powder development with precise pilot-scale spray ...

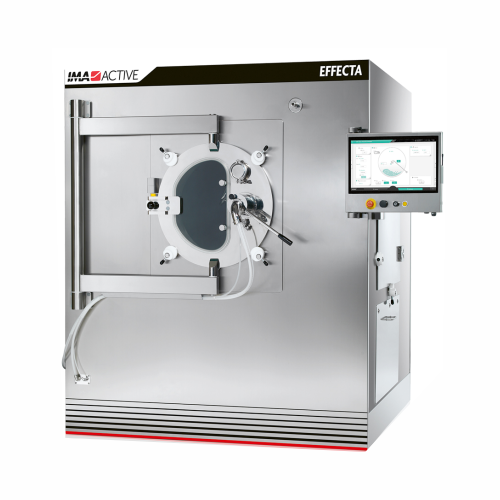

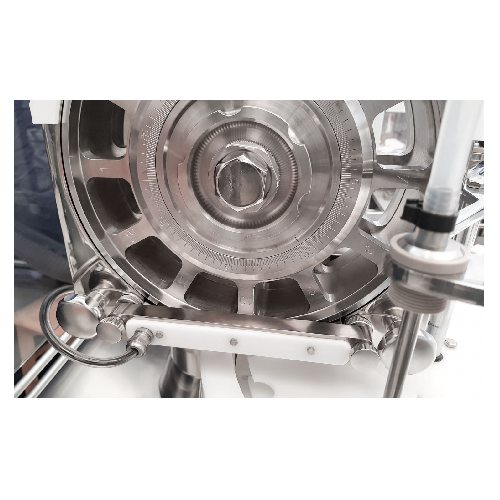

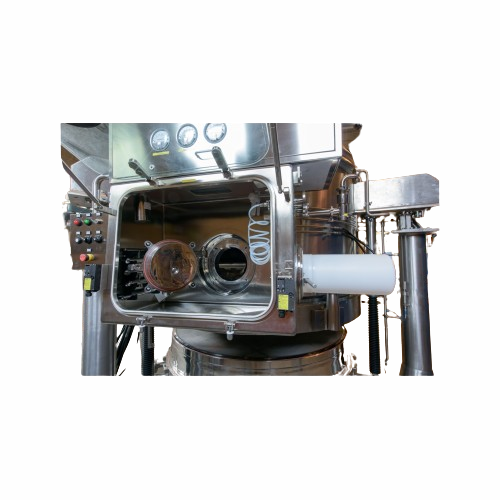

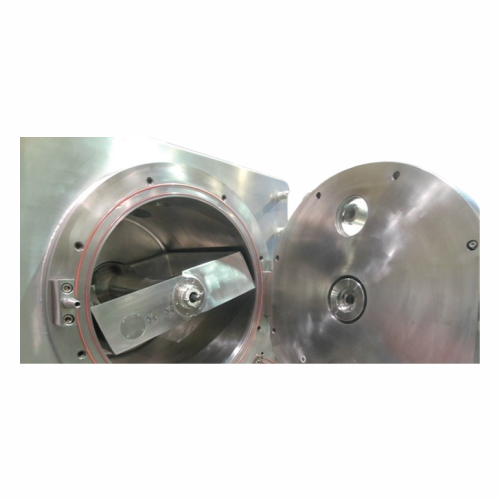

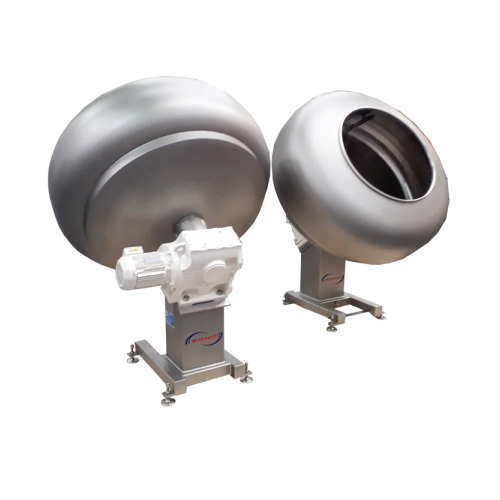

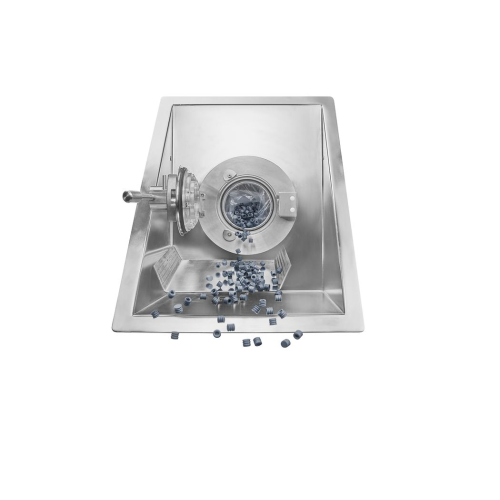

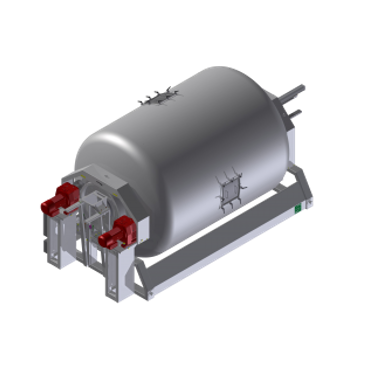

Tablet coating pan for pharmaceutical and nutraceutical industries

Enhance coating efficiency with a versatile solution...

Solid/liquid extractor for high-yield functional nutrient extraction

Maximize extraction efficiency and elevate product...

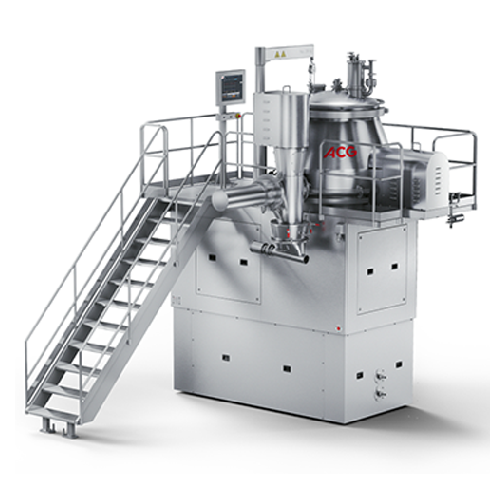

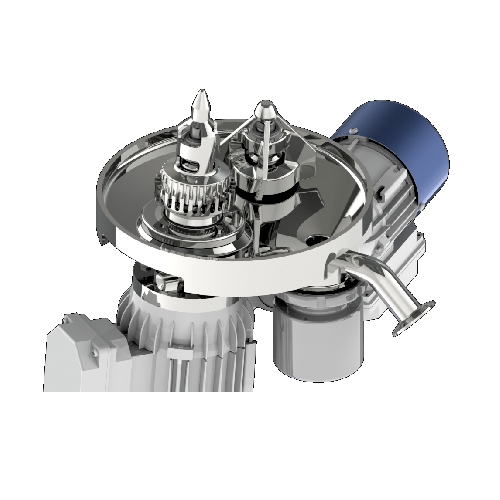

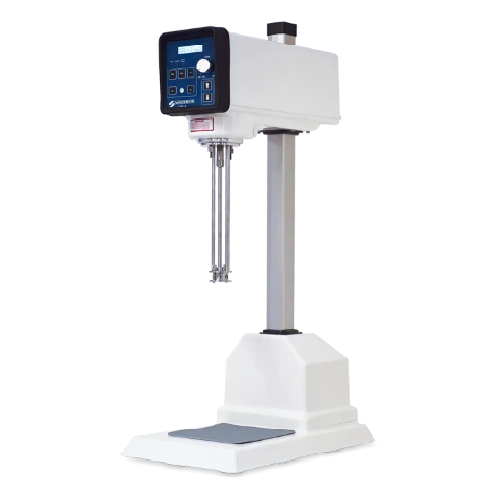

High-shear mixer granulator for pharma and nutraceuticals

Optimize your batch and high-speed production with a powerful ...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

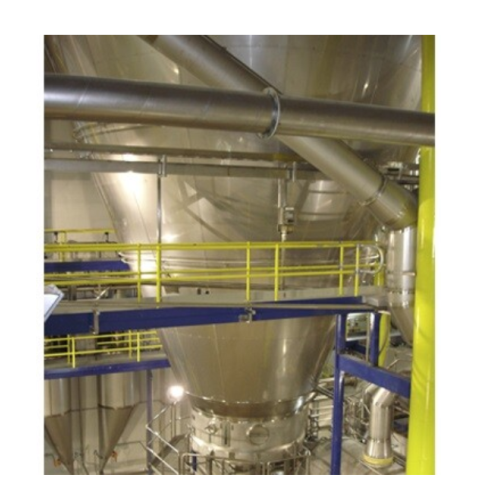

Spray dryer for nutritional and dairy powders

Achieve precise particle size and optimal drying of nutritional and dairy po...

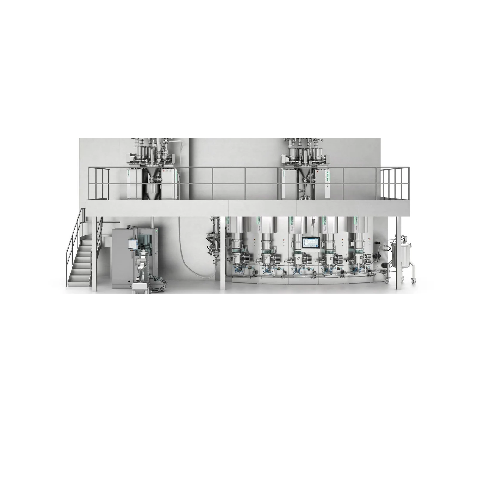

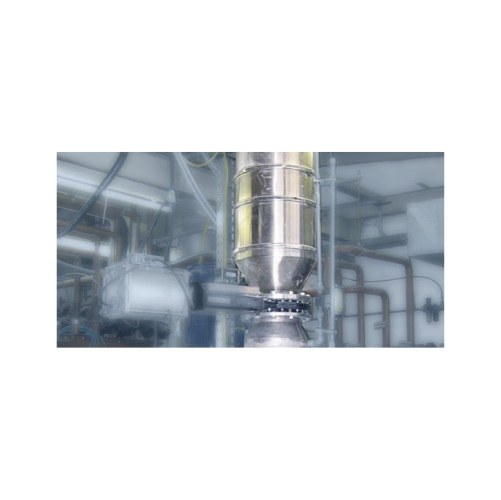

Spray drying system for nutritional powders

Enhance production efficiency and product quality with a versatile spray dryin...

Spray dryer for nutritional powders

Ensure precise moisture control and enhance powder quality in nutritional products with...

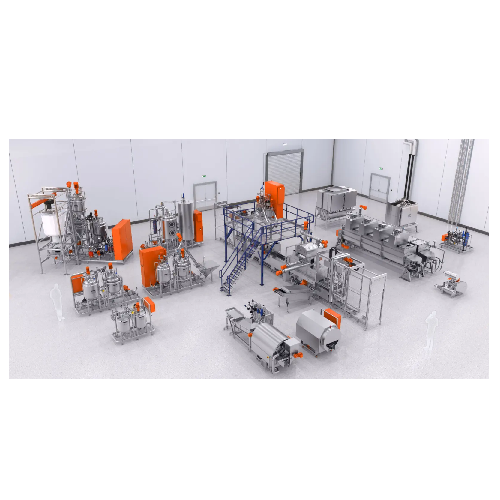

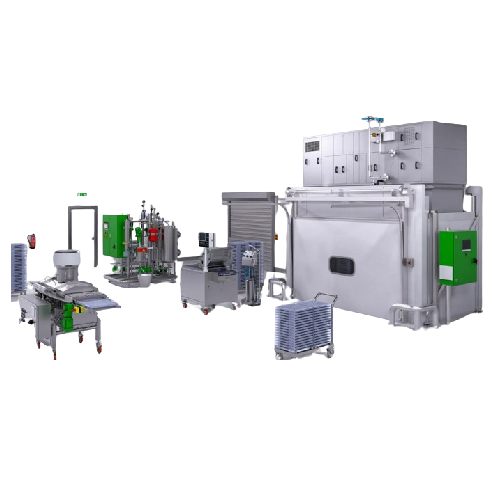

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

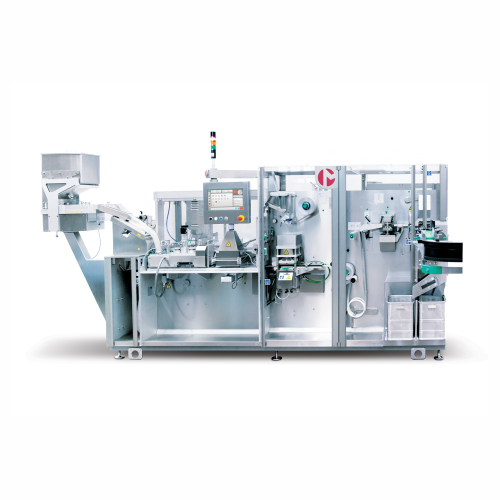

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

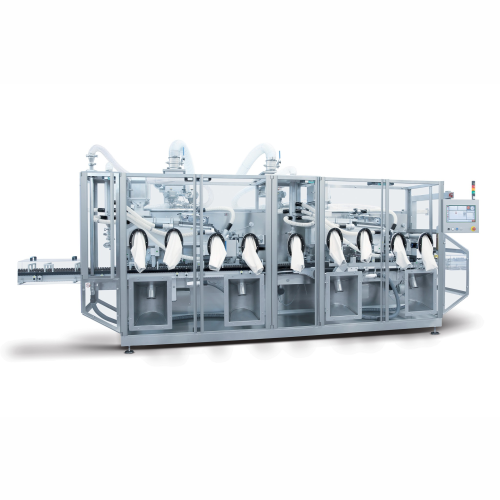

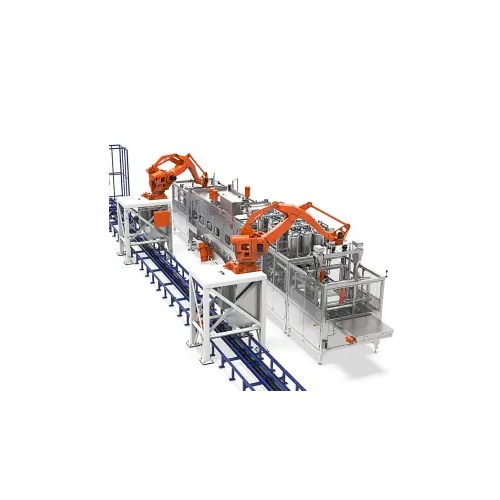

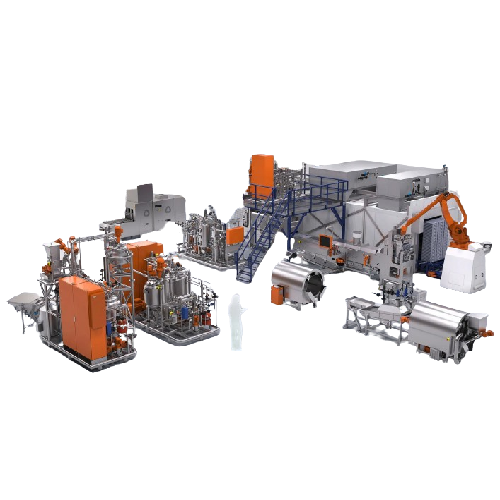

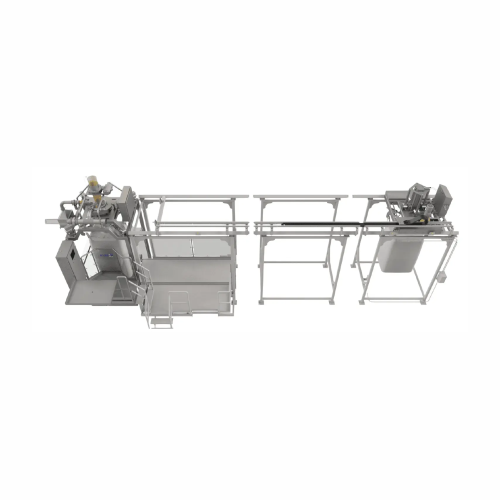

Robotic production line for gummies and nutraceuticals

Streamline your gummy and nutraceutical production with a versatil...

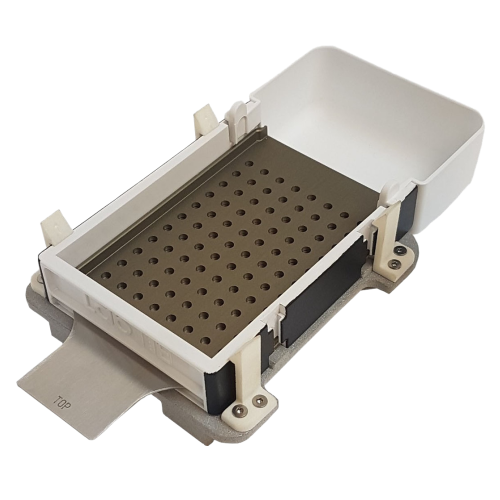

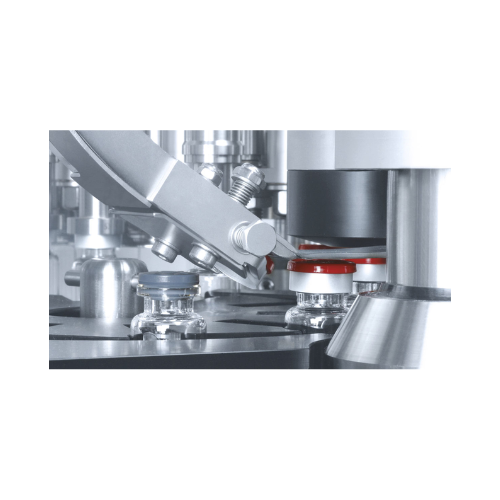

Capsule filling for nutrition and health products

Optimize your production line with advanced capsule filling capabilitie...

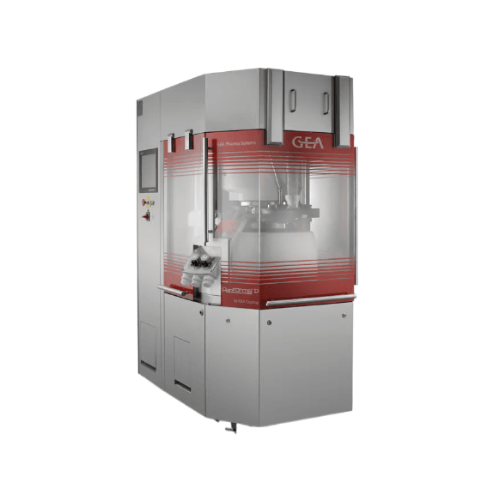

Capsule filling for pharmaceuticals and nutraceuticals

Enhance your capsule production capabilities with modular filling ...

Nutraceutical products processing and packaging

Streamline your nutraceutical production with versatile equipment capable ...

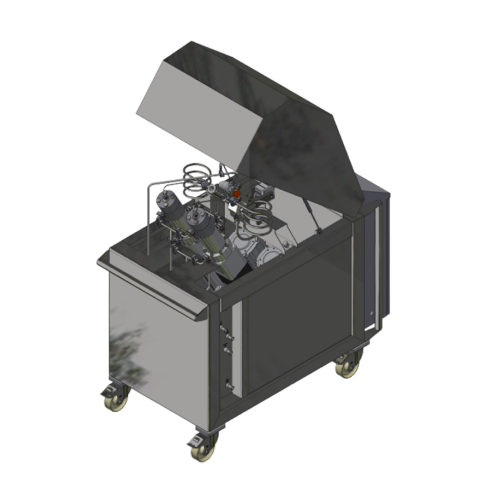

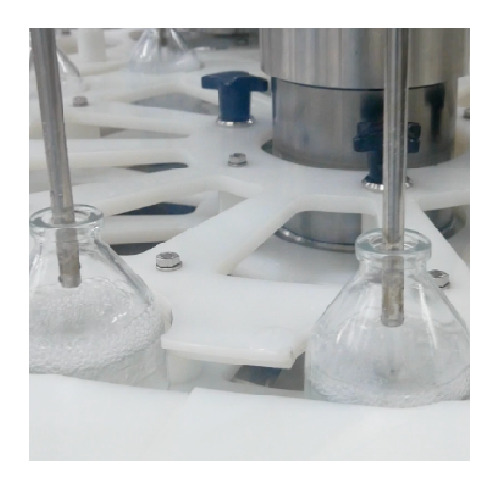

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

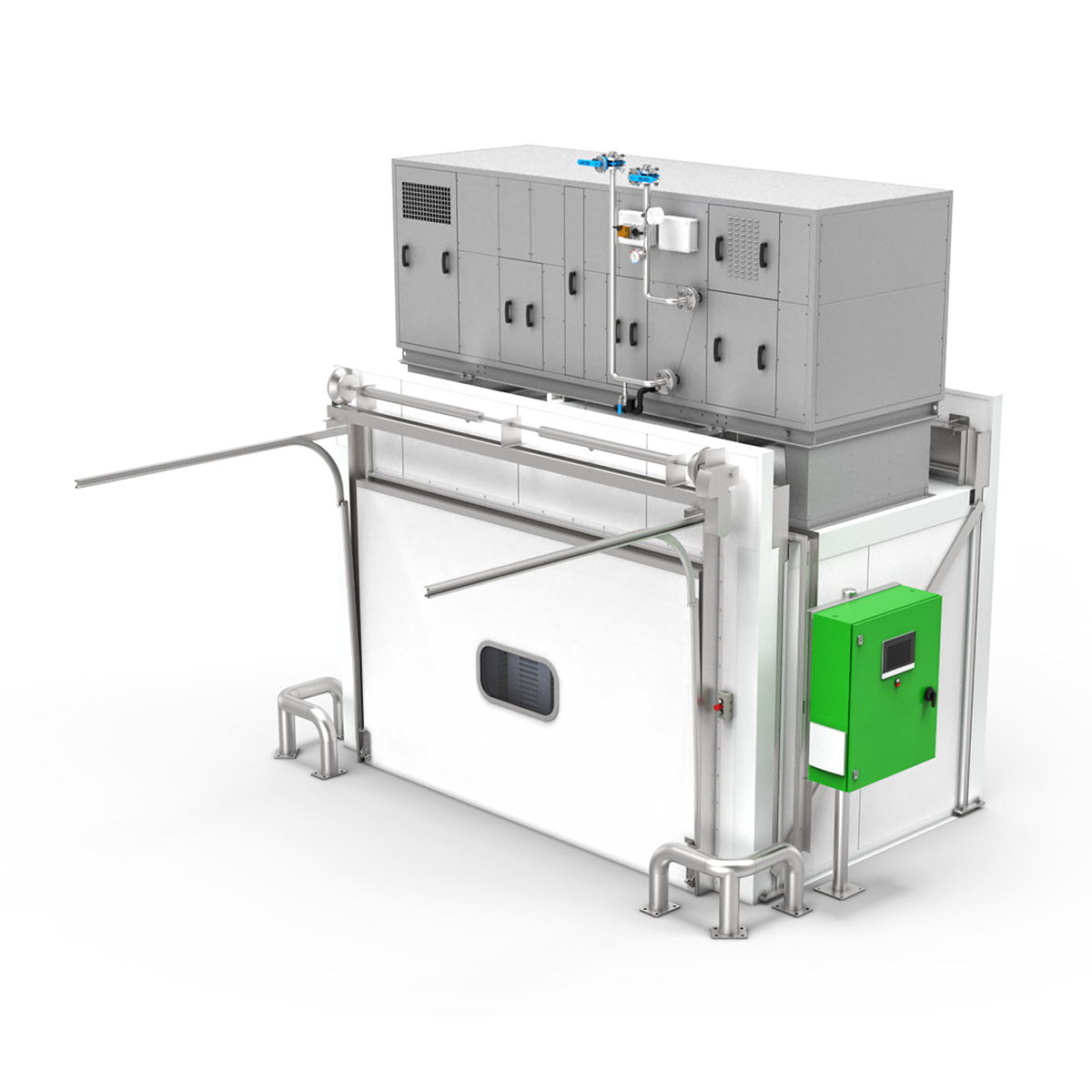

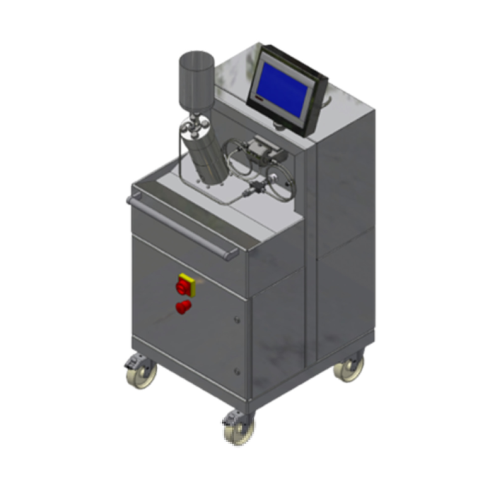

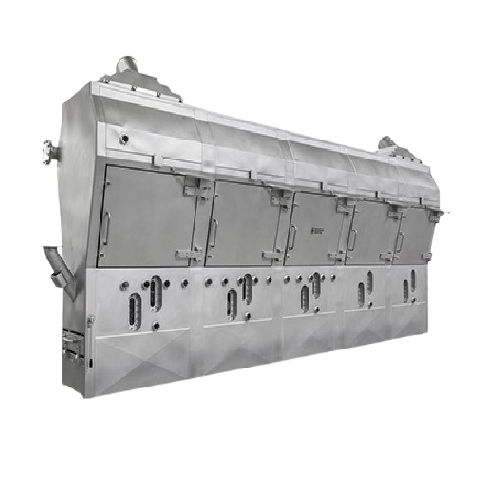

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

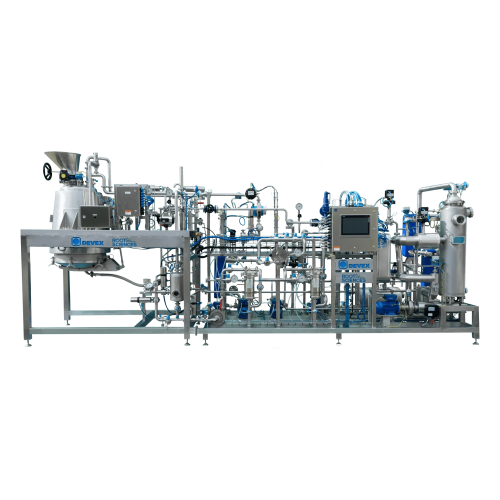

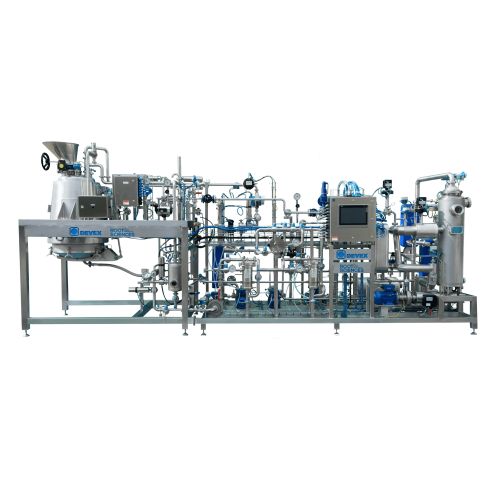

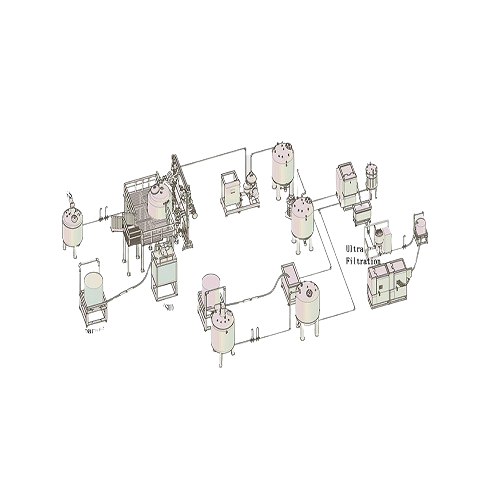

Whey processing line

Streamline whey processing by transforming byproducts into high-value proteins, catering to diverse nutr...

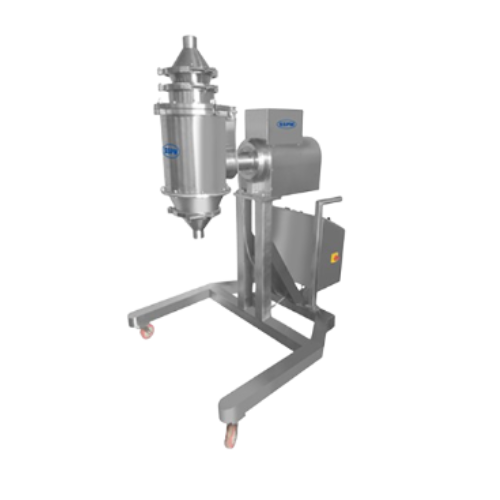

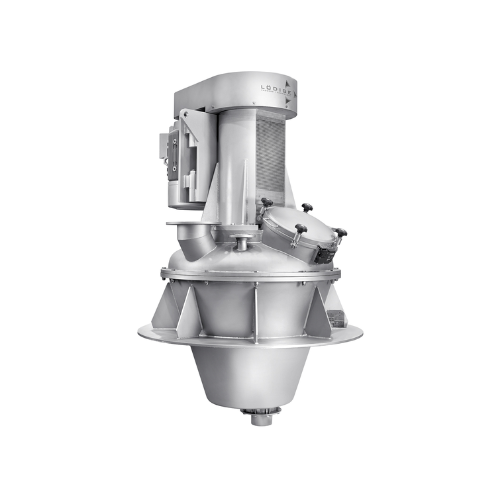

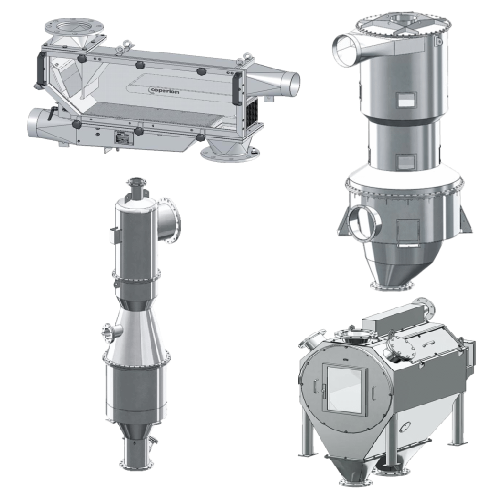

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Lab-scale milling and processing platform

Effortlessly transition from lab-scale research to full production with a versat...

Conical mill for high-capacity powder milling

Optimize your powder milling process with efficient conical milling systems ...

Atex compliant milling equipment for explosive atmospheres

Ensure operator safety and process integrity with milling equ...

Deagglomeration and delumping system

Ensure product integrity and streamline operations by effectively breaking down agglom...

Soya protein isolate production line

Ensure the highest protein purity with this comprehensive production line designed to ...

Indoor microalgae cultivation technology

Enhance sustainability and productivity in microalgae cultivation with a vertical ...

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Vacuum cold trap for lab applications

Ensure efficient separation and purification in biopharmaceutical applications with t...

Vacuum cold trap for efficient purging and drying

Optimize your laboratory’s efficiency by integrating high-perform...

Heating mantle system for round bottom glassware

Optimize your lab’s heating and stirring processes with a snug-fit system...

Dry scroll vacuum pumps for laboratories and manufacturing

Ensure a clean, oil-free environment with advanced dry scroll...

Moisture analyzer for precise and reliable measurements

Ensure precise moisture control in high-value products like lyoph...

Food processing blower systems

Optimize your production line with precise air handling and moisture control to ensure qualit...

In-situ fiber optic Uv-vis spectrometer for dissolution studies

Optimize drug formulation by obtaining real-time, in-sit...

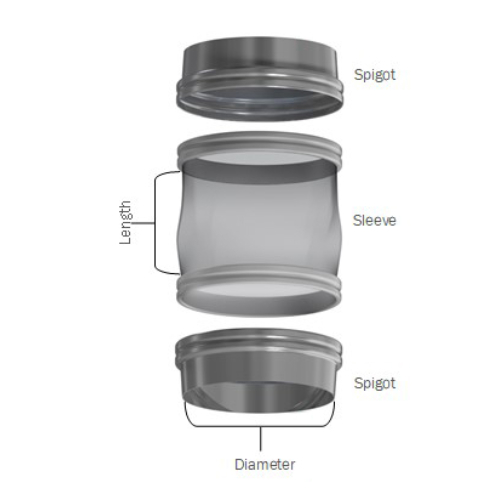

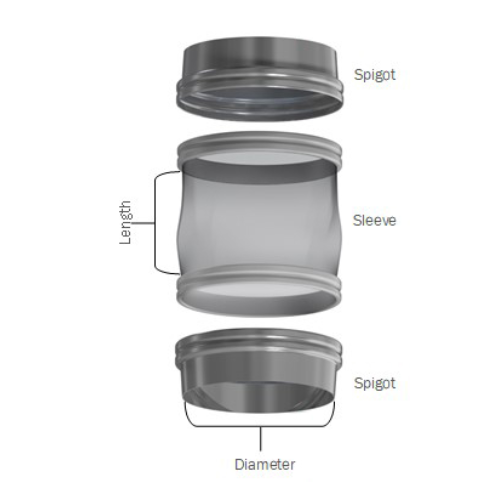

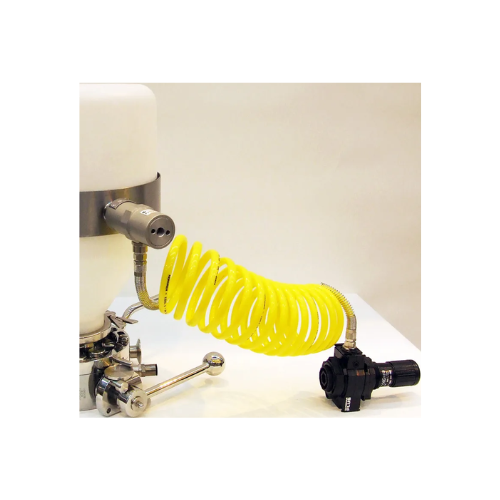

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

Flexible connector system for bulk powder processing

Eliminate leaks and enhance hygiene in your powder processing line w...

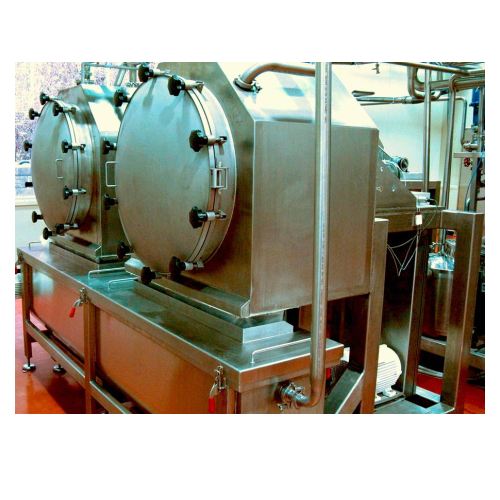

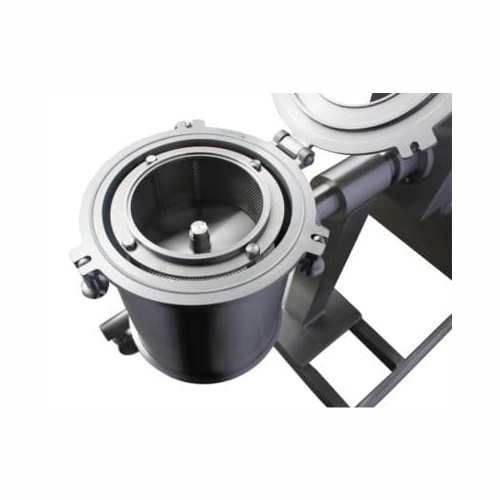

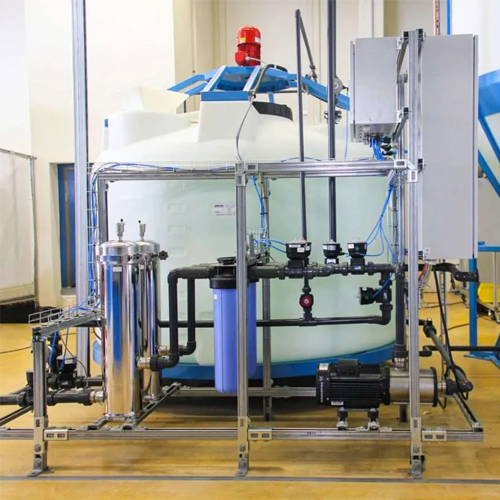

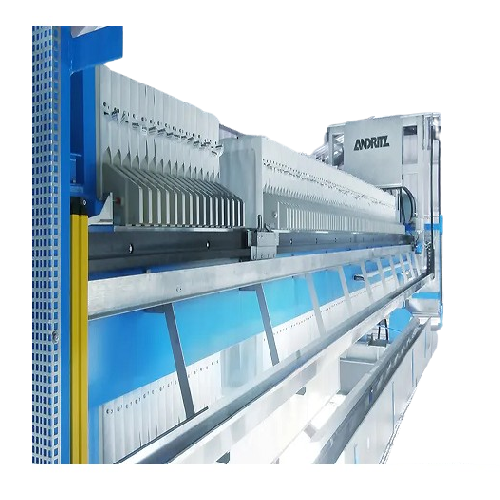

Tangential filtration system for wine production

Achieve precise filtration, purification, and concentration of compounds ...

High-speed capsule filling system

Maximize production efficiency with high-speed capsule filling designed for precise dosin...

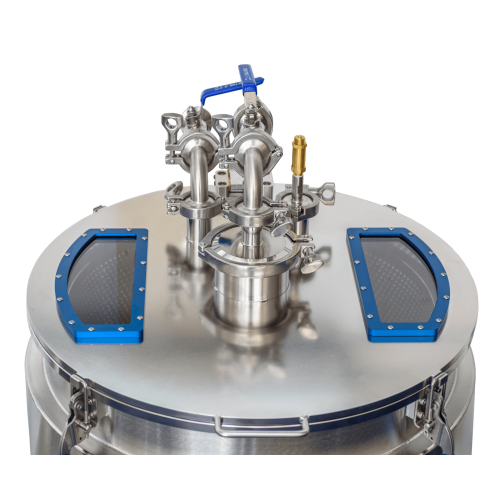

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

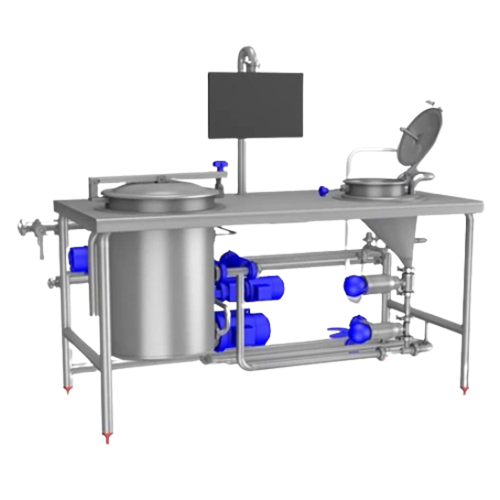

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

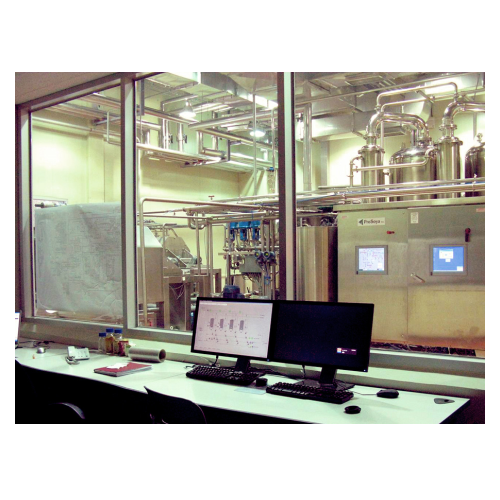

Lab Uht/htst system for r&d activities

Optimize your R&D with a versatile, modular system allowing precise control ove...

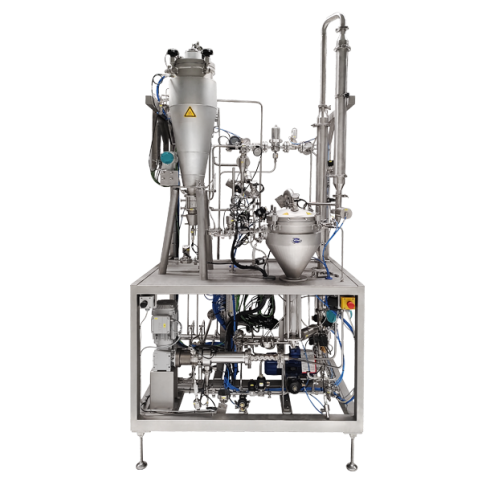

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

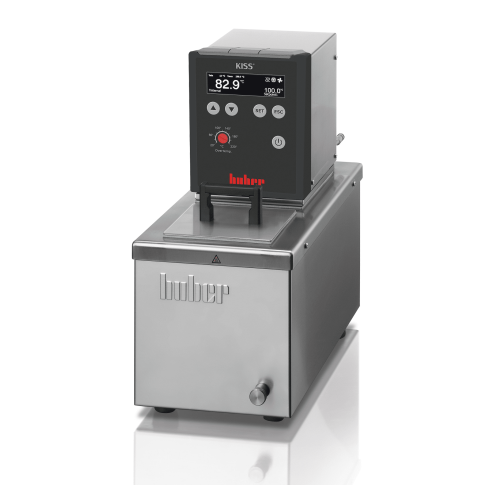

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

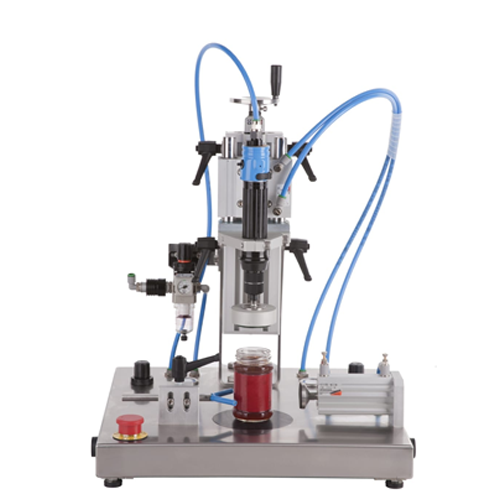

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

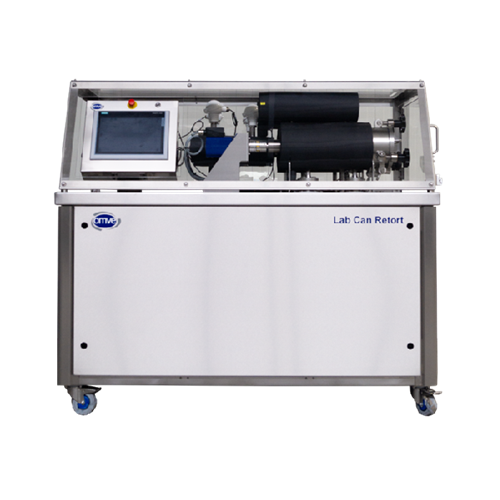

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Cleaning in place unit for lab and pilot equipment

Streamline your lab and pilot-scale cleaning processes with a mobile, ...

Fully automated cleaning in place unit for food processing plants

Enhance food safety and streamline operations with a ...

Batch deaerator for reduced oxidation in liquid processing

Optimize product shelf life and quality by efficiently removi...

Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powder...

Bench-top carbonation system for postmix drink production

Achieve precise carbonation in small batches with a reliable b...

Carbonation and filling system for Pet and glass bottles

Optimize your beverage production with precise carbonation, fill...

Lab powder dispenser for precision measurements

Effortlessly streamline your lab’s powder dispensing tasks with a ve...

Flexible powder recipe formulation system

Streamline your batch production with efficient, dust-tight formulation and blen...

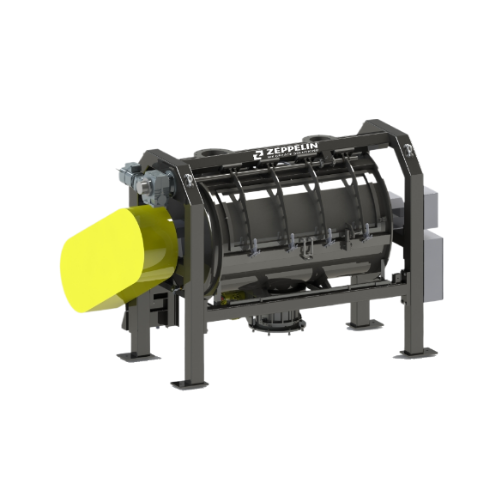

Ibc blender for industrial powder mixing

Streamline your powder mixing with rapid batch changeovers and reduced cleaning do...

Powder packing module for consistent flow

Enhance your production efficiency with streamlined powder packing that ensures ...

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

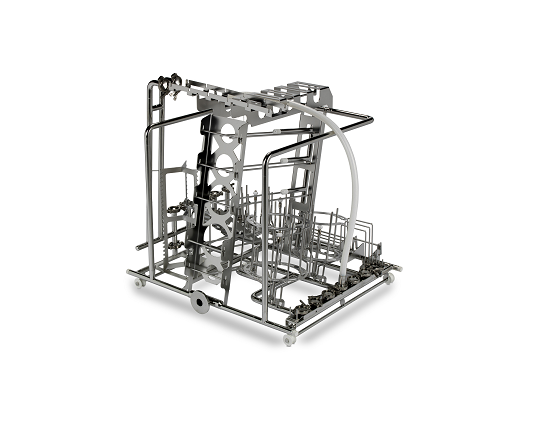

Ibc cleaning equipment for hygienic powder handling

Optimize cleaning efficiency and maintain hygiene standards with a ve...

Small powder recipe formulation system

Streamline the formulation of diverse powder recipes with seamless integration into ...

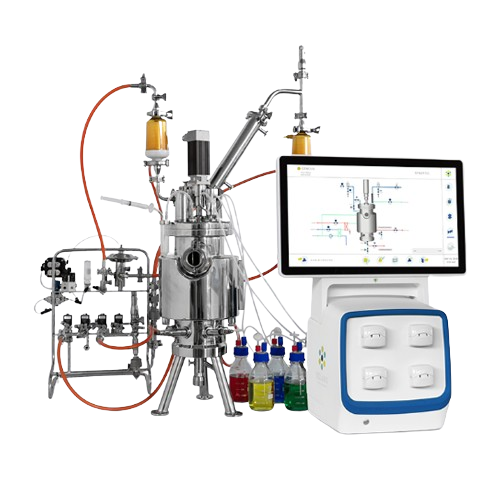

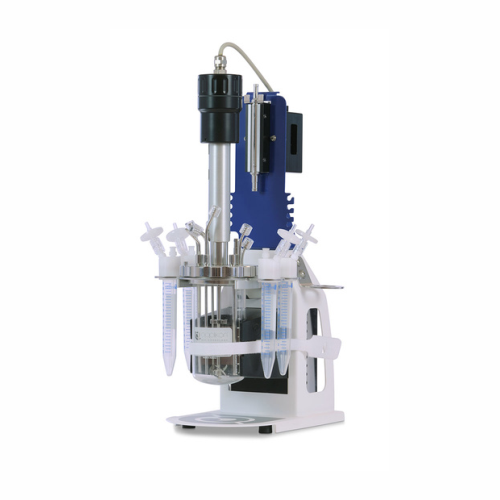

Small scale fermentor/bioreactor for multi-condition bioprocessing

Explore diverse fermentation conditions with precisi...

Industrial washing and sterilizing system for ampoules and vials

Ensure the highest hygiene standards in your liquid for...

Blister thermoforming for Pvc/alu

Effortlessly mold and seal blister packs for a range of solid products, optimizing packag...

Strip packing for solid products

Ensure consistent quality and precision in packaging solid products with this advanced stri...

Rigid tube filling and capping system for tablets

Streamline your tablet production with an efficient solution that preci...

Electronic counting and filling system for vials

Efficiently streamline the packaging of solid dosage forms with a cutting...

Counting and capping solution for tablets and capsules

Streamline your tablet and capsule production with a high-speed so...

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

Pharmaceutical powder and granule metal detection system

Ensure the integrity of your pharmaceutical and nutraceutical pr...

Pharmaceutical metal detector for tablets and capsules

Ensure contaminant-free tablets and capsules with advanced detecti...

Pharmaceutical metal detector for powder and granule inspection

Ensure product integrity by efficiently detecting metal ...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Powder handling systems for battery production

Optimize your battery production with a versatile powder handling system th...

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

Empty capsule sorting system

Streamline your capsule production by efficiently removing empty and defective capsules, ensuri...

Vertical vibratory tablet deduster for pharmaceutical tablets

Ensure optimal cleanliness and quality assurance for table...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety ...

Capsule polisher for pharmaceutical production

Enhance capsule quality and safety by effectively polishing, dedusting, and...

Capsule polisher for pharmaceutical capsules

Ensure your capsules are free from dust and perfectly polished with a solutio...

2-way diverter for tablet and capsule filling

Ensure precision in tablet and capsule filling with seamless batch switching...

Tablet and capsule diverter

Streamline your tablet and capsule production with precise container filling and flexible config...

Dense phase pressure conveying system for fragile powders

Ensure gentle handling and long-distance transport of fragile ...

High pressure homogenizer for pharma applications

Achieve precise particle size reduction and stability in liquid formula...

High pressure homogenizer for lab applications

Achieve precise control over droplet size and consistency in high-viscosity...

Industrial ultrasonic liquid processor for high volume applications

For large-scale liquid formulations, achieving cons...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

Ultrasonic liquid processor for feasibility testing and procedure optimization

Optimize your liquid formulations by en...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

Table top tablet and capsule counter

Effortlessly ensure precise tablet and capsule counts with solutions that seamlessly i...

Electronic tablet counter for tablets and capsules

Optimize your production line with precise counting solutions for a wi...

Medium speed blister packaging solution for pharmaceuticals

Optimize medium-speed tablet blister packaging with seamless...

Integrated counting system for tablets and capsules

Streamline your packaging line with a highly versatile system that se...

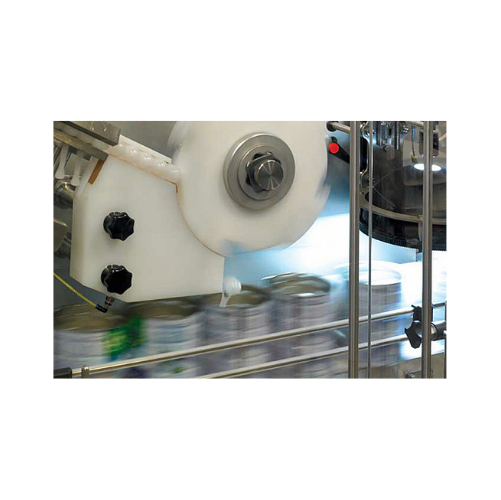

Labelling solution for cylindrical containers

Achieve precise and efficient labelling for cylindrical containers with a sy...

High-precision slat counter for tablet bottling

Optimize your tablet bottling with a low-energy, high-speed counter design...

Capsule filler for pharmaceutical applications

Need precise capsule filling for pharmaceuticals and nutraceuticals? This s...

Table-top capsule filler for micro-dosing

Achieve precise micro-dosing for pharmaceutical powders and pellets with a user-...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Lifting column for drums and containers

Streamline your production with lifting columns designed for precise handling, blen...

Capsule banding system for tamper-evident sealing

Ensure tamper-evident integrity for capsules by utilizing a precise ban...

Blister packaging solution for small/medium batches

Achieve high production efficiency with frequent changeovers for your...

Cone mill for particle size reduction

For precise particle size reduction, the cone mill offers flexible screening options ...

Capsule filler for multi-product dosing

Achieve precision and flexibility in capsule filling with a system designed for hig...

Pure steam generation and distribution system

Ensure reliable sterilization with pure steam that’s free from contami...

Wfi cooler

Ensure precise temperature control and contamination-free dispensing for high-value liquid formulations with this a...

Water for injection storage and distribution system

Ensure the integrity and sterility of injectable solutions with this ...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Mid-capacity film coating solution

Enhance your seed coating and biofuel pellet production with a customizable turn-key sol...

Lab and pilot scale immersion mill

Maximize process efficiency with a compact immersion mill designed for precise milling, ...

Lab-scale disperser and immersion mill

Achieve precise dispersing and milling with rapid changeover capabilities, ideal for...

Laboratory vacuum milling for fine particle size reduction

Streamline your lab and pilot processes with high-speed vacuu...

Powder feeder for consistent mixing in pan coating processes

Ensure precise dosing and mixing of pharmaceutical powders ...

Pharmaceutical filter dryer

Achieve precise moisture control and efficient drying of sensitive materials with this advanced ...

Vertical pilot plant centrifuge for pharmaceutical applications

Ensure precise separation and optimal scaling in your la...

Lab machine for producing portion packs

Efficiently form, fill, seal, and punch portion packs in laboratory settings with c...

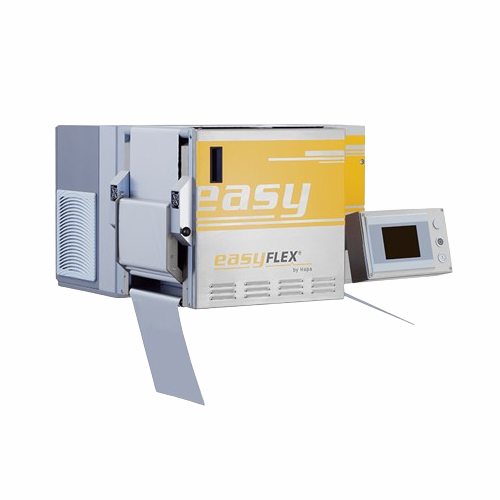

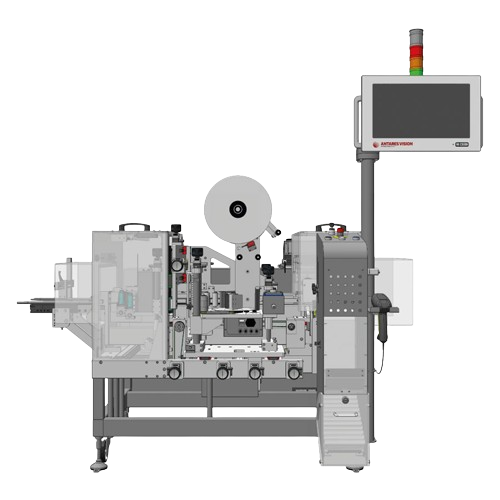

Uv flexographic printing system for blister-lidding foils

Achieve precise and consistent single-color prints on blister-...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

Waste powder recovery cyclone for pharmaceutical processes

Efficiently recover up to 99.9% of waste powder from oral sol...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

Tablet storage and transport containers

Ensure the safe and gentle handling of tablets during storage and transport, minimi...

Hygienic vacuum conveyor for pharmaceutical and food industries

Optimize your material handling process with a vacuum co...

Rotary crushing valve for lump breaking

When handling bulk solids, effective pre-breaking and sizing are crucial to ensure ...

High-accuracy rotary dosing valve for fine material feeding

Ensure precise dosage of fine powders and granules, enhancin...

Split butterfly valve for sterile powder transfer

Ensure safe and sterile transfer of powders with unparalleled containme...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Industrial container and drum handling solution

Effortlessly maneuver and position heavy containers such as IBCs and drums...

Conical mill for particle size reduction

Achieve precise particle size control and reduce thermal stress on materials with ...

Empty capsule transfer system

Ensure seamless capsule filling operations by eliminating manual handling and preventing produ...

Filled capsule conveyor system for pharmaceutical production

Ensure gentle and efficient conveying of filled capsules in...

Over-driven conical mills for precise particle size reduction

Achieve consistent particle size reduction with minimal he...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Industrial drum tumblers for uniform batch processing

Achieve precise mix uniformity in your batches with drum tumblers, ...

Pharmaceutical size reduction shredder

Achieve fast, efficient material size reduction with this shredder, enabling seamles...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

Adjustable weighing system for raw materials

Optimize your confectionery and nutraceutical production with precise weighin...

Pre-cooking and final cooking for candy production

Optimize your candy production with a versatile cooker designed to han...

Dosing unit for automated mixing in of ingredients

Achieve precise ingredient integration for confectionery and nutraceut...

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small ...

Powder and oil coating system for gummies

Enhance your gummy production with precise powder and oil coating, achieving con...

Sugar coating system for gummies

Achieve a flawless sugar coat on up to 240,000 gummies per hour, seamlessly integrating int...

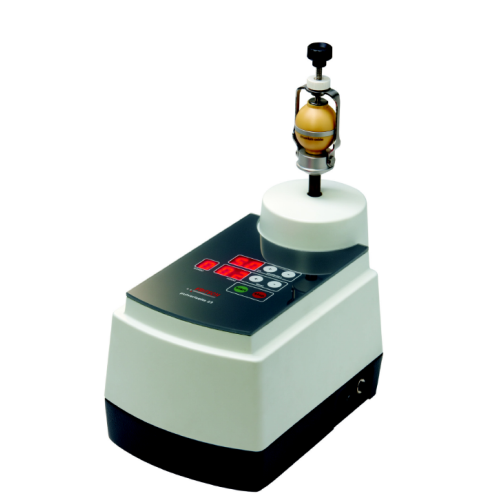

Portable water activity meter for gummy production

Ensure consistent gummy quality and extended shelf life by precisely m...

Gummy counter for gusseted bags

Optimize your gummy production line with precise counting and packaging into re-sealable gus...

Small automatic gummy line

Streamline your gummy production with a compact system designed to deliver precision deposits and...

High-capacity gummy production system

Optimize your gummy production with a starchless system that deposits up to 240,000 g...

Turnkey bioreactor system for cell culture

Streamline your bioprocessing with a complete cultivation system; ideal for pro...

Tablet coater for precision pan coating

Achieve precise coating control for pharmaceuticals and nutraceuticals, accommodati...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

Laboratory film coating system for development and clinical batches

Achieve precision in tablet coating with a versatil...

Laboratory and pilot scale pan coater

Maximize coating efficiency in tablet production with this advanced pan coater, offer...

Portable pan coater for pilot scale tablet coating

Achieve uniform tablet coating with interchangeable pans and anti-mark...

High shear granulation mixing system

Optimize your powder granulation process with a system designed for precise control ov...

Pilot High shear granulator for wet granulation

Achieve consistent particle sizing and superior homogeneity in your powder...

High shear lab granulation system for powder processing

Achieve precise granulation and consistent mixing of powders with...

Mini High shear granulator for wet granulation

Optimize your powder granulation with precision and flexibility, ensuring c...

High shear wet granulation line

Achieve consistent and uniform granules with energy-efficient wet granulation designed to op...

Fluid bed granulator for industrial granulation

Optimize your production efficiency with versatile fluid bed granulation, ...

Fluid bed system for granulation and coating

Optimize your production with a multi-purpose fluid bed system designed for e...

Tablet coating system for aqueous, solvent, and sugar films

Achieve precision coating with flexible application capabili...

Roller compaction system for dry granulation

Achieve precise densification and consistent powder granulation with a system...

Dry granulation system for powder compaction

Achieve consistent sheet hardness and increased density in powdered materials...

Benchtop roller compacting system

Achieve precise powder densification and uniform dry granulation with this compact system...

Pilot blender for small batch powder blending

Optimize your R&D processes with this versatile mobile blender, ideal f...

Laboratory fluid bed granulator and coater

For researchers and manufacturers requiring precise control in drying, granulat...

Development fluid bed system for feasibility studies

Explore precise granulation and coating capabilities for small batch...

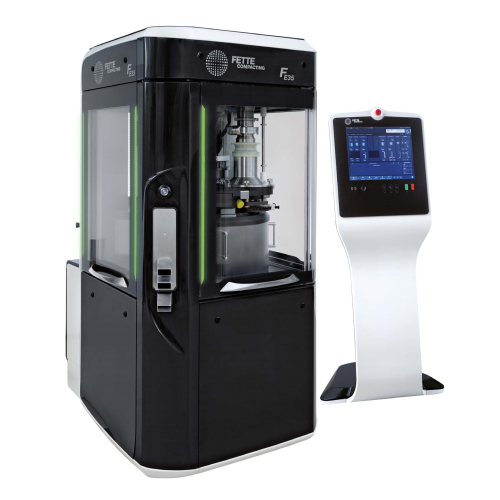

High-capacity tablet press for pharmaceutical production

Achieve precise compression and consistent tablet density with a...

Industrial tablet press for high output production

Achieve precise control and efficient production with advanced rotary ...

High performance tablet press for large batches

For manufacturers aiming to boost tablet production without sacrificing pr...

Tablet coating solution

Achieve precise tablet coating with uniformity and efficiency, tailored for diverse tablet types, ens...

Closed loop granulator for pharmaceutical production

Streamline your production with a fully automated closed-loop system...

High shear mixer granulator for efficient wet granulation

Achieve consistent and precise granule formation with high she...

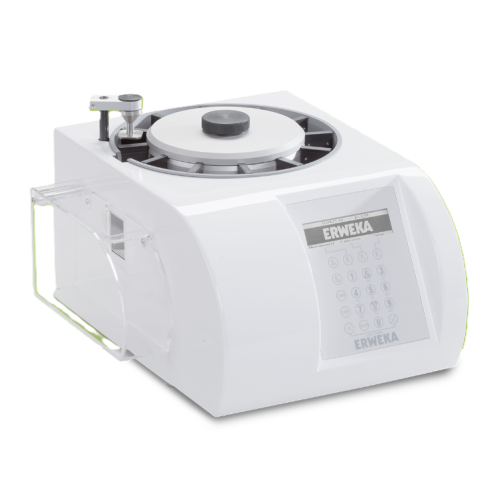

Tablet hardness and combination tester

Ensure consistent tablet hardness and precision across multiple parameters with this...

Double cone mixer for free flowing powders and granules

Achieve uniform blending of powders and granules with precision, ...

V-mixer for solid bulk material blending

Achieve precise and uniform mixing of sensitive powders with gentle treatment, ide...

Pelletizer for pharmaceutical and biotech applications

Achieve precise pellet formation with adjustable pan angles and li...

Industrial liquid filler for small to medium volume operations

Ensure accuracy and efficiency in liquid formulation with...

Double roll crusher for laboratory applications

Optimize material processing with a double roll crusher designed for preci...

Apparent bulk density tester for granules and powders

Ensure accurate formulation by determining the apparent bulk densit...

Dissolution testing software for compliance and efficiency

Ensure data integrity and streamline compliance with a robust...

Automatic dissolution testing for sustained release dosage forms

Effortlessly simulate pH changes for accurate dissoluti...

High volume dissolution tester for pharmaceutical research

Achieve precise dissolution testing of tablets across two bat...

Microalgae photobioreactors for bioenergy production

Optimize your microalgae’s growth and conversion processes wit...

Continuous mixer for industrial powders and liquids

Achieve precise and efficient mixing of solids and liquids with minim...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

Fast screen exchange grinding solution for medium-hard products

Maximize your milling efficiency with a solution that al...

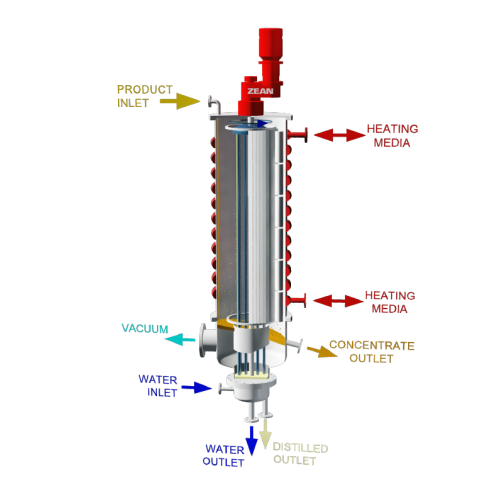

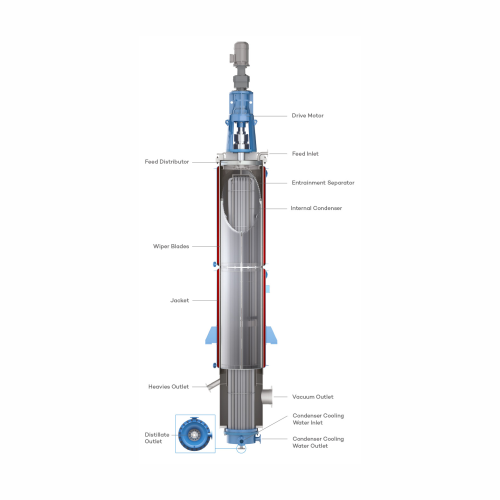

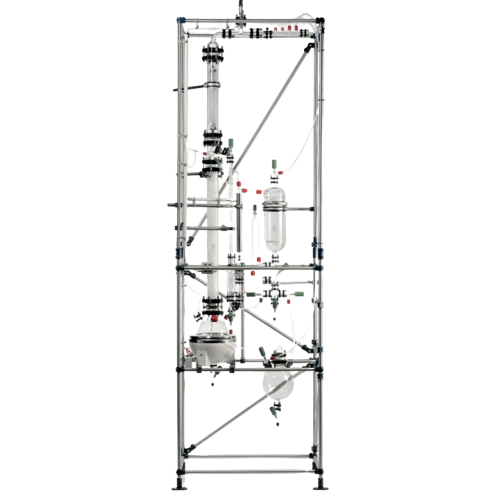

Short path evaporator for high vacuum distillation

Achieve high-efficiency separation and purification of sensitive compo...

Benchtop laboratory powder blender

Perfect for R&D labs needing precise, small-batch powder blending and mixing, this ...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Oil presses for oilseed extraction

Ensure efficient oil and protein extraction with specialized presses, enabling optimal s...

Oil and fat refining system

Ensure high-quality oil and fat production by efficiently removing contaminants such as phosphat...

Continuous deodorizing for oils and fats

Achieve optimal purity and flavor in oils and fats with advanced continuous deodor...

Industrial oil degumming process

Achieve optimal oil purity and maximize yield with this advanced system designed to streaml...

Oil neutralizing technology for chemical refining

Achieve optimal purity and yield in oil processing with precise control...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

General purpose freeze dryer for small commercial batches

Maximize your production line’s flexibility with this ve...

Continuous vacuum dryer for protein products

Achieve precise moisture control and maintain product functionality with low-...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

Mineral oil absorption system for solvent vapor recovery

Optimize solvent recovery and reduce atmospheric emissions with ...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process whi...

Seed hull removal and condition system

Optimize your seed processing efficiency by effectively removing hulls and foreign m...

Linear tablet and capsule counter

Ensure precise and efficient bottle filling with a cutting-edge counting system that guar...

In-motion bottle filling system for pharmaceuticals

Boost your production efficiency with our high-speed bottle filling s...

Mini laboratory mixer for tabletops

Optimize your lab’s mixing precision with this compact tabletop bin mixer, design...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

Robot manipulator for intermittent motion machines

Optimize your pharmaceutical packaging line’s efficiency and pre...

High speed blister packaging for pharmaceuticals

Need efficient packaging with quick format changeovers for various capsul...

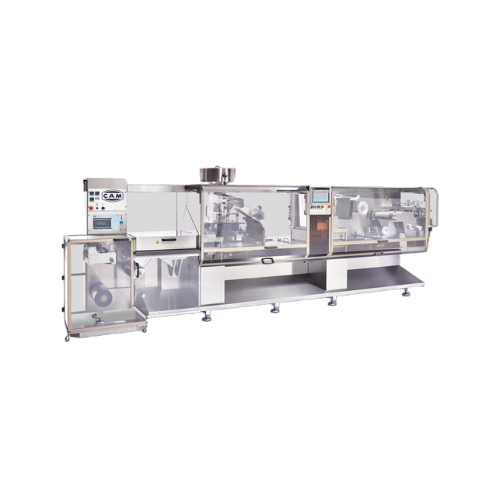

Intermittent motion horizontal cartoner for large products

Simplify your packaging process with a solution that ensures ...

Slat-type counting solution for pharmaceutical applications

Ensure precise tablet counts and efficient packaging with th...

Continuous motion powder dosing system

Ensure precise dosing of pharmaceutical and nutritional powders with this continuous...

Flexible spheronization kit for wet granulation pellets

Achieve precise pellet and granule formation with a versatile ben...

Variable density pellets extruder and spheronizer

Develop diverse pellet densities for enhanced drug formulation with pre...

High speed stick packaging solution

Optimize your packaging line with this high-speed vertical solution, designed to effici...

Compact rotary evaporator for laboratory distillation

Achieve efficient solvent removal and sample concentration with thi...

Supercritical fluid chromatography system for preparative separations

For complex substance formulations requiring rapi...

Laboratory spray dryer for organic solvent samples

Experience precise particle control and enhanced safety when convertin...

Nano spray drying system for pharmaceuticals and nanotechnology

Transform minuscule samples into submicron particles eff...

Recirculating chiller for evaporation and extraction

Streamline your laboratory processes with a chiller that efficiently...

Autoclavable glass fermentor for biotech research

Optimize your fermentation processes with a versatile benchtop solution...

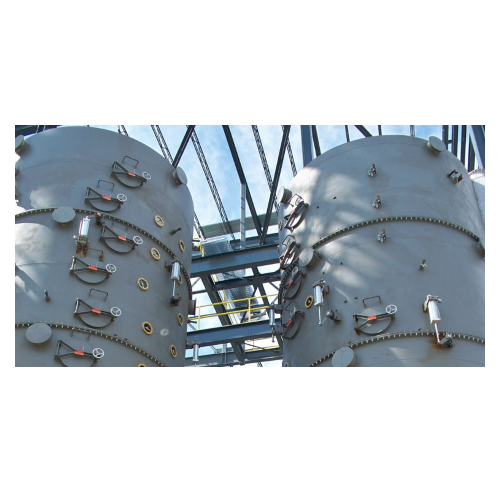

Industrial fermentors for large-scale bioprocessing

Enhance yield and consistency in fermentation processes with precise ...

Bioreactors for cell culture processes

Efficiently cultivate sensitive cell lines with customizable bioreactors designed to...

Lab-scale fermentors for microbial cultivation

Optimize microbial cultivation with lab-scale fermentors designed for preci...

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

Compact cleaning system for glass and plastic containers

Ensure exceptionally thorough cleaning and gentle handling of di...

Sampling unit for continuous sampling in industrial processes

The PRS sampling unit ensures precise and uncontaminated s...

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Big bag connection system for dust-free docking

Achieve dust-free docking and seamless discharging of bulk solids with an ...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Contamination-free docking system for bulk solids

Achieve contamination-free transfer of bulk powders and granules while ...

Efficient blister packing for pharmaceutical tablets

Streamline your production with a blister packing machine that enhan...

Integrated raw & auxiliary material pre-treatment system

Experience dust-free processing with an integrated system design...

Particle size control equipment for pharmaceutical applications

Achieve precise particle size control for diverse materi...

In-line conditioning system for buffer preparation

Optimize your buffer management with precise in-line conditioning, ens...

Customizable production freeze dryer for pharmaceuticals

Ensure precise moisture control and preservation with a versatil...

Softgel pre-dryer tumbler system

Ensure optimal shape and seam formation of softgel capsules with efficient oil removal, pav...

Gelatin melters for softgel production

Optimize your softgel production with a solution that ensures precise gelatin meltin...

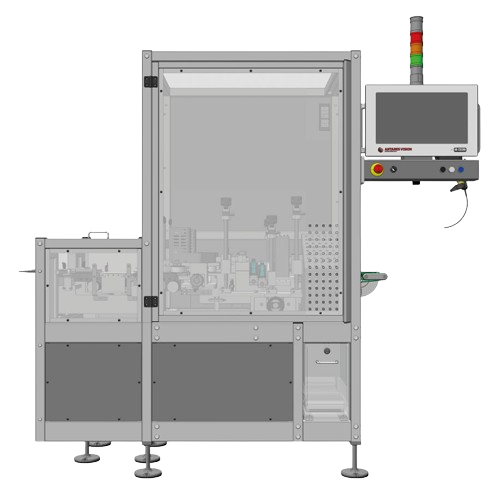

Serialization system for printing and verifying carton codes

Ensure accurate serialization with high-speed printing and ...

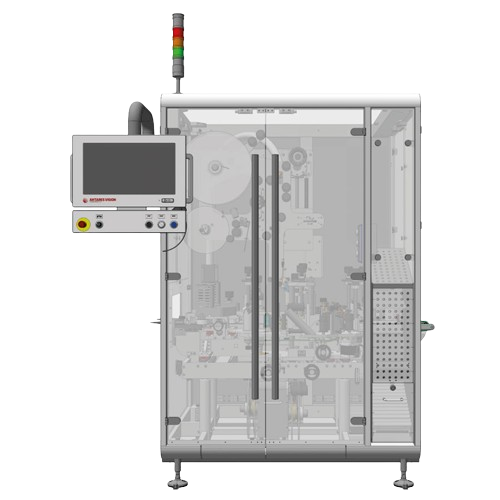

Print and verify cartons packaging systems

Streamline your packaging line with a versatile solution that prints, verifies,...

Serialization system for flat cartons

Ensure precise serialization of flat cartons with integrated printing and inspection....

Special purpose auger filling systems for diverse industries

For manufacturers handling precise dosing, our advanced aug...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Industrial grater and shredder for pharmaceutical and chemical applications

Optimize your production line with a versa...

Moist granulation system for pharmaceutical and chemical industries

Transform powdered materials into uniform granules ...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Lifting column for drums and bins

Optimize your powder handling operations with a versatile lifting solution designed for p...

Stainless steel pharma bin for powder containment

Ensure precise powder handling and containment with this stainless stee...

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

Capsule filling solution for small to medium batch sizes

Achieve precise and efficient capsule filling up to 3,400 units ...

Capsule filling system for pharmaceutical production

Efficiently fill and lock capsules of various sizes with exceptional...

Autoclave for sterilizing medical instruments and containers

Achieve reliable sterilization for a wide range of medical ...

Pharmaceutical large freeze dryer with vacuum pump

Preserve the integrity and potency of sensitive compounds with precisi...

Pharmaceutical freeze dryer for medium scale production

Ensure optimal preservation of active ingredients through precise...

Analytical balance for precise laboratory measurements

Achieve unparalleled precision and reliability in your lab’s...

Stainless steel crystallization reactor 100l

Optimize your crystallization and formulation processes with precision-contro...

50l jacketed glass reactor with explosion-proof motor

Enhance your reaction processes with precise temperature and pressu...

50l jacketed glass reactor for synthetic reactions

Achieve precise control over chemical reactions and material synthesis...

Dual-jacketed reactor for decarboxylation processes

Streamline your decarboxylation process with a dual-jacketed reactor ...

Dual-jacketed reactor for botanical extraction winterization

Optimize your production with precise temperature control a...

Large capacity jacketed glass reactor

Achieve precise control over temperature and vacuum conditions with this versatile re...

Single rotary tablet press for small and medium-batch production

Optimize your tablet production with precision compress...

Industrial bin washer for Ibc cleaning

Ensure your Intermediate Bulk Containers are contamination-free and ready for reuse ...

High-shear mixer granulator for small batches

Achieving consistent particle size and mix uniformity in pharmaceutical and ...

High-shear granulator for wet granulation

Achieve precise content uniformity with advanced high-shear granulation, designe...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

Double rotary press for high-volume tablet compression

Achieve high-speed, precision tablet compression with a machine th...

Single rotary tablet press

Streamline your tablet production with enhanced efficiency and precision, ensuring consistent tab...

Tabletop granulation system for small batches

Enhance R&D capabilities with this innovative solution designed for gra...

Versatile fluid bed combo for granulation and coating

Optimize lab-scale R&D with an adaptable fluid bed system, sea...

Advanced fluid bed for pharmaceutical granulation

Achieve precise granulation and drying for pharmaceutical powders with ...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid-bed drying and granulation system

Optimize your production line with high-speed batch processing for efficiently dryi...

Fluid bed granulator for pharmaceutical applications

Optimize your granulation and drying processes with advanced fluid-b...

Integrated granulation train for pharmaceutical processes

Achieve precise granulation, uniform mixing, and efficient dry...

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear...

High-shear mixer for small batch granulation

Enhance your production efficiency with a high-shear mixer designed for preci...

Liquid capsule filling for r&d and pilot-scale production

Optimize liquid capsule production with a compact machine that...

Liquid filling system for hard capsules

Easily fill two-piece hard capsules with liquids, pastes, and suspensions with prec...

High-speed capsule filler for large batch production

Achieve higher yields and reduce powder waste with a capsule filling...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

Fluid bed combo for granulation and coating

Achieve seamless granulation and coating with batch and high-speed operations,...

Fluid bed combo for top-spray granulation and wurster coating

Optimize your batch processing with a versatile system cap...

Fluid bed combo for granulation and coating

Streamline your manufacturing with a versatile fluid bed combo, integrating gr...

High-output blister packaging system

Maximize blister packaging efficiency with continuous-motion capabilities, ensuring su...

Continuous cartoning solution

Enhance your production line with efficient high-speed cartoning, designed to streamline packa...

Intermittent motion cartoning machine for blister packs

Optimize your packaging line with a space-efficient cartoning mac...

Capsule band sealer for liquid-filled hard capsules

Seamlessly seal liquid-filled hard capsules to enhance product integr...

Semi-automatic de-blistering solution for Pvc and alu blister packs

Streamline your packaging operations by swiftly rec...

Automatic capsule checkweigher for statistical weight control

Ensure precise weight control of capsules with automatic s...

Capsule de-dusting and polishing system

Ensure precision in capsule production with continuous de-dusting and polishing, en...

Empty capsule sorting system for pharmaceutical manufacturing

Expedite your capsule production with a high-speed system ...

Filled capsule elevator for seamless process integration

Efficiently streamline the transfer of filled capsules across va...

Automated powder and pellet product conveying system

Optimize your encapsulation process effortlessly with this fully aut...

Capsule sorter elevator for encapsulation processes

Ensure uninterrupted encapsulation by efficiently removing defective ...

Metal contamination detection for tablets and capsules

Ensure product integrity by detecting and separating metal particl...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Desiccant inserter for pharmaceutical containers

Prevent product degradation by efficiently inserting desiccants into cont...

High-speed container reject system

Ensure product integrity by swiftly rejecting non-compliant containers at speeds up to 3...

High-output tablet press for pharmaceutical production

Achieve high-speed, continuous production of precise and consisten...

Rotary tablet press for pharmaceutical industries

Optimize your tablet production with swift format changeovers and bi-la...

Rotary tablet press for small to medium scale production

Optimize your tablet production with a versatile rotary press, o...

Continuous direct compression line for pharmaceuticals

Optimize tablet production with a seamless system combining contin...

Disposable containment system for solid dosage material

Ensure safe and dust-free transfer of hazardous materials with ou...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

Pharmaceutical homogenization skid system

Achieve precise particle size reduction and efficient cell rupture with an auton...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Automated powder bag filling system

Streamline your powder packaging operations with a fully integrated system that automat...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

Fluid bed pellet coating solution

Achieve precise and uniform pellet coating with fluid bed technology for enhanced product...

Pharmaceutical fluid bed r&d processing

Ensure precise formulation and consistency in pharmaceutical and nutraceutical tabl...

Coffee extractor for optimal flavor preservation

Unlock the potential of your extracts with a continuous system that ensur...

Solid-wall bowl separators for pharma extraction

Optimize your extraction processes with precision solid-wall bowl separat...

Laboratory freeze dryer for small batch processing

Ensure precise moisture control and stability in sensitive samples wit...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

X-ray scanner for contaminant detection in packaging

Ensure your products remain contamination-free with advanced X-ray s...

X-ray and optical inspection system for product safety

Ensure the safety and integrity of your products with a single sys...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Large bottle blow/fill/seal packaging system

Achieve precise liquid filling and sealing for large-scale production with hi...

Blow/fill/seal packaging system for sterile liquid products

Streamline your liquid product manufacturing with high-speed...

Blow/fill/seal system for aseptic liquid packaging

Achieve efficient aseptic packaging with a system that combines blow m...

Blow/fill/seal packaging for large bottles

Need a high-speed solution for producing sterile liquid formulations in large v...

Automatic cap welding system for Lvp production

Optimize your parenteral and ophthalmic production line with a versatile c...

Insertion technology for sterile blow/fill/seal systems

Ensure sterility and precision in liquid pharmaceutical packaging...

Batch-type single shaft mixer for efficient discharging

Optimize your material mixing and discharging processes with a sy...

Containment system for product loading

Ensure safe handling of hazardous materials with this containment system, designed t...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

In-line mixer for solid-liquid blending

Efficiently combine powdered and liquid ingredients in real-time with high-shear pr...

Sachet packaging for pharmaceuticals

Streamline your pharmaceutical packaging with high-precision sachet solutions, ensurin...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Cartoning solution for pharmaceutical products

Ensure accurate and efficient packaging of pharmaceutical products with pre...

Turnkey stainless steel tanks

Optimize your liquid processing with versatile stainless steel tanks designed for efficient st...

Vitamin adding system for ground products

Ensure precise vitamin dosing in continuous production lines, enhancing nutritio...

Stainless steel craft tanks for biopharmaceuticals

Ensure precise temperature control and customized capacity for your fo...

Fully automatic hard capsule filling machine

Enhance pharmaceutical production with precise capsule filling, ensuring opti...

High-speed vacuum blender for commercial use

Achieve optimal blending with cutting-edge vacuum technology, ensuring vibran...

Hybrid laboratory extruders for reproducible scale-up applications

Easily switch between screw diameters to enhance fle...

Twin screw feeder for poorly flowing powders

Optimize your process with precision feeding for powders that easily clump or...

Spheronizer for extrudate strand reduction and rounding

Achieve precise pellet formation with a versatile system that cus...

Quick change feeding devices for industrial applications

Experience seamless product transitions with quick-change feedin...

Micronization for pharmaceuticals

Achieve ultra-fine particle size reduction for complex materials, essential when precisio...

Jet milling system for super fine particle size reduction

Achieve ultra-fine particle sizes with precision milling techn...

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Powder auger filler for precise weighing and depositing

Ensure accurate and efficient powder filling with this innovative...

Lab scale roller compactor for dry granulation

Achieve seamless scale-up from lab development to full-scale production wit...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

High accuracy hammer milling for precise particle size reduction

Achieve precise particle size control to enhance produc...

Pilot-scale milling and screening platform

Achieve precise powder consistency and integrity with flexible milling and scre...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Roller compactors for dry granulation

Optimize your powder processing with advanced roller compaction, ensuring consistent ...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Industrial powder milling solution

Achieve precise particle size control and improve material flowability with this advance...

Industrial-scale bioreactors for large-scale biomanufacturing

When producing at large volumes, efficient and reliable bi...

Pilot-scale bioreactors for bioprocess scale-up

Bridge the gap between experimentation and large-scale production with pil...

Industrial bag filter for powder collection efficiency

For producers seeking to enhance powder yield while minimizing emi...

Industrial bag filter for powder collection

Optimize powder yield and maintain strict hygiene with a high-capacity filtrat...

Freeze dryer for small batch scale-up in biotech and pharma

Optimize freeze-drying processes for small batches or high-v...

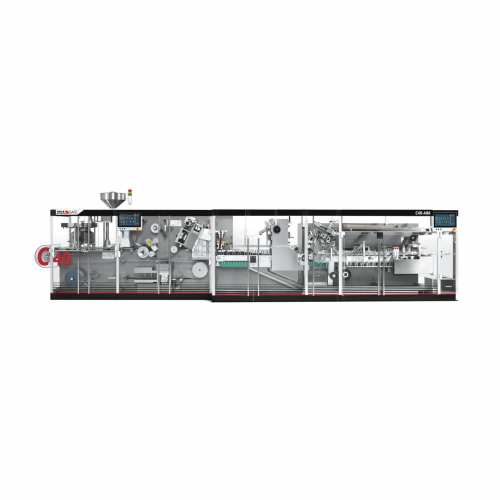

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automat...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

Robotic high capacity production line for gummies and jellies

Optimize your gummy and jelly production with a high-capac...

Cocoa bean processing line from cocoa pod to cocoa nibs

Streamline your cocoa production process by transforming raw coco...

Black garlic fermenter for garlic processing

Optimize your garlic fermentation process with precise temperature and humidi...

Tablet compression technology for pharmaceutical production

Enhance your production capabilities with advanced tablet co...

Capsule checkweighing system for pharmaceutical production

Ensure every capsule meets your precision weight standards wi...

Continuous manufacturing for pharmaceuticals

Achieve precision in oral solid dosage production with seamless continuous pr...

Fluid bed processor for pharmaceutical granulation and coating

Achieve superior granulation and coating of pharmaceutica...

High-shear mixer granulator for pharmaceutical production

Achieve optimal granulation with enhanced mixing efficiency, r...

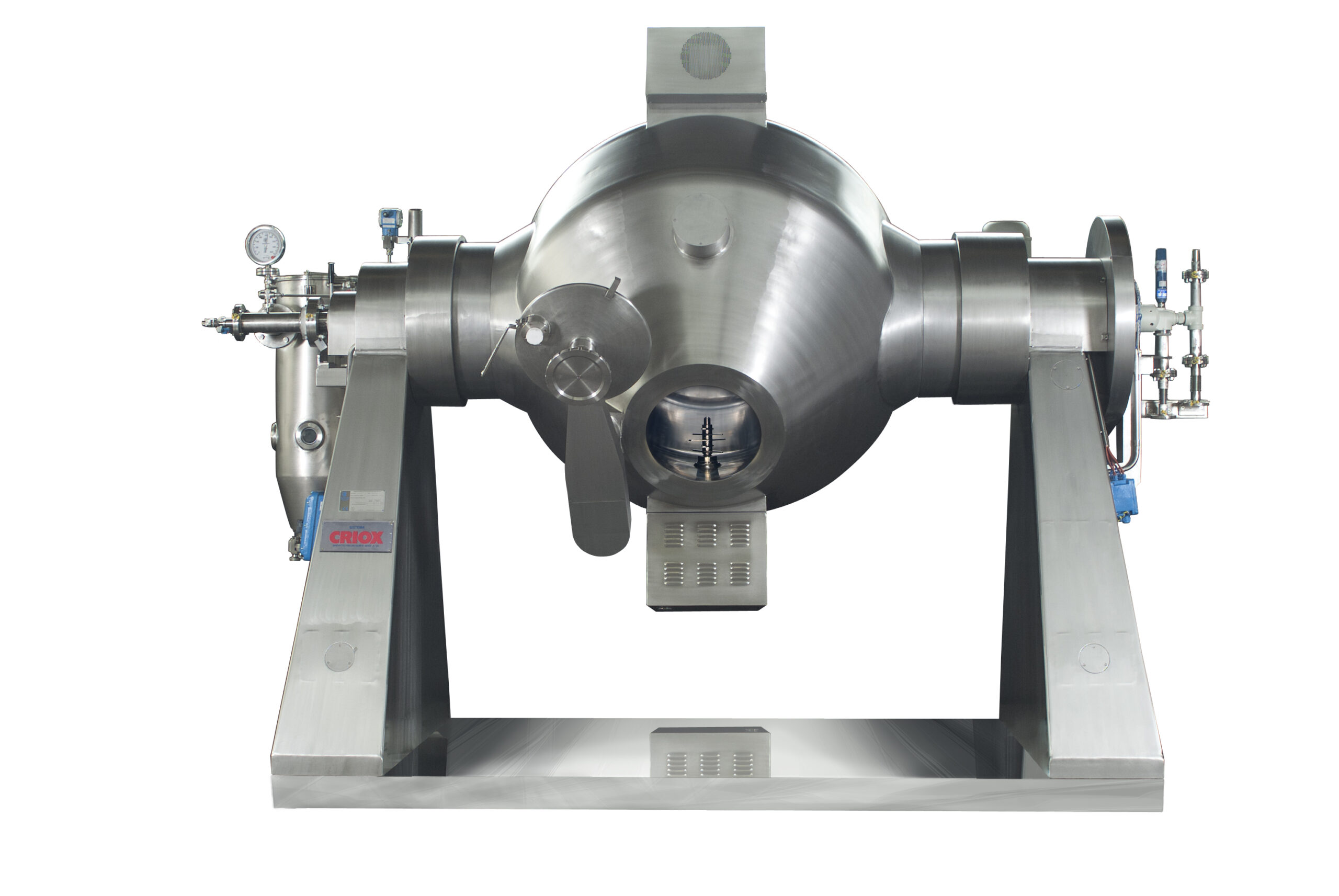

Pharmaceutical aseptic separator filter dryer

Achieve seamless filtration, washing, and vacuum drying in a single aseptic ...

Lab Pharmaceutical aseptic separator

Achieve high-yield recovery and safe handling of potent pharmaceuticals with this asep...

Pilot pharmaceutical aseptic separator and dryer

Achieve high-yield recovery of potent compounds with a separator that com...

Pharmaceutical aseptic separation system

Achieve precise separation and efficient drying of pharmaceutical powders with an ...

Pharmaceutical aseptic separator tumble dryer

Streamline moisture reduction with precision: this solution accelerates dryi...

Microalgae cultivation infrastructure

The microalgae cultivation infrastructure streamlines your production with integrated...

Lab-scale microalgae cultivation system

Achieve precise control of microalgae cultivation with optimized growth conditions ...

Laboratory-scale microalgae cultivation system

Harness precise cultivation capabilities for microalgae with advanced photo...

Wet granulation system for pharmaceutical tablets

Optimize your tablet production with precise particle size reduction an...

Wet granulation process for pharmaceutical applications

Achieve consistent granule size and uniform mixing with advanced ...

Vacuum rated vibro sifter for pharmaceutical materials

Ensure precise separation of impurities and achieve consistent par...

Tablet de-dusting system for pharmaceuticals

Ensure the highest quality of your tablets by effectively removing excess pow...

High-speed sifting for safety screening in pharmaceutical production

Achieve precise particle sizing with a high-speed ...

Steam/electrical kettle for wet granulation processes

Achieve precise moisture content and uniformity in your granulation...

Material lifting system for dust-free transfer in pharma plants

Achieve seamless material transfer with reduced manual h...

Wet granulation co mill for pharmaceutical formulations

Optimize your manufacturing process with precise particle size re...

Bin washing station for pharmaceutical applications

Achieve reliable sanitation and enhanced efficiency with this tailore...

Instant infusion Uht for baby food or milk concentrate processing

Achieve exceptional product quality with ultra-short,...

Tubular ultra high temperature processing system for dairy products

Optimize your dairy processing with precise thermal...

Wet granulation cleaning system

Ensure optimal cleaning and purification within your production line with a system designed ...

Spray dryers for producing free-flowing dustless powders

Achieve consistent product quality with customizable spray dryer...

Aseptic storage tank for aseptic products

Ensure uninterrupted aseptic product storage with this advanced tank system, des...

Centrifugal atomizer for precise spray drying

Achieve precise control over particle size and moisture content with centrif...

Bottle induction seal integrity inspection

Ensure uncompromised product quality by accurately inspecting and verifying the...

Pilot-production freeze dryer for diagnostic kits and Api

Optimize your lyophilization process with this versatile freez...

Production freeze dryer for pharmaceutical manufacturing

Achieve precise lyophilization for sensitive products with custo...

Motorized cap torque tester for bottle closures

Ensure precise seal integrity and compliance with bottle cap torque measur...

Forming solution for candy and cereal bars

Achieve precision in bar production with a system that ensures minimal weight v...

Autoclavable photobioreactor for microalgae and bacteria cultivation

Optimize the growth of phototrophic organisms with...

Pilot industrial tangential flow filtration system

Enhance precision in filtration and separation processes with this sys...

Benchtop stirred fermenter for precise fermentation control

Optimize your fermentation and cultivation processes with pr...

Benchtop Sip fermenter for bioprocessing applications

Optimize your bioprocesses with precise control over fermentation a...

Autoclavable fermenters for small scale bioprocessing

Optimize your bioprocesses with configurable fermenters offering pr...

Benchtop electric mini fermenter for process development

Optimize your process development with a compact benchtop fermen...

Seaweed substrate ropes for cultivation

Enhance seaweed cultivation efficiency by providing an optimal growth substrate tha...

Rotary stoppering and capping for vials

Achieve precise and efficient stoppering, capping, and crimping for high-speed vial...

Rotary vial filling and stoppering system

For high-speed production of sterile injectable vials, this continuous motion ro...

Nested syringe filling and stoppering system

Optimize your syringe production with precise filling and stoppering, ensurin...

External washing and drying system for sealed vials

Ensure contamination-free packaging of liquid vials with this precise...

Automatic counting and capping system for tablets and capsules

Ensure precise tablet and capsule counting and seamless c...

Automatic syringe de-nester for pharmaceutical production

Streamline your syringe production line with high-speed de-nes...

Automatic vial capping system

Ensure precise capping and sealing for sterile vial production with a compact, high-speed solu...

Automatic labelling system for pharmaceutical vials

Ensure precise and efficient packaging for cylindrical containers wit...

Automatic labelling system for pharmaceutical vials and bottles

Optimize your bottle labelling process with precision al...

Automatic carton labelling and weighing system

Boost your carton packaging precision with a solution that seamlessly integ...

Automatic tamper-evident seal applicator

Ensure your product integrity and traceability in packaging lines with this soluti...

Automatic carton labeling system

Streamline your packaging line with a high-speed labeling system designed to ensure precise...

High precision pharmaceutical checkweigher

Ensure precise weight compliance in high-speed production lines with this advan...

Automatic blister packaging for pharmaceuticals

Experience precise blister packaging that ensures product integrity and qu...

Automatic bundling machine for cartons and bottles

Streamline your packaging line with a compact system that efficiently ...

Automatic capping solution for pharmaceutical vials

Cap your liquid formulations with precision and efficiency using this...

Automatic cartoning system for pharmaceuticals

Simplify your cartoning process with high-speed, continuous motion that boo...

Baby food production line

Ensure optimal safety and precision with this production line, designed for processing delicate ba...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Capsule printer for pharmaceutical applications

Experience precise dual-color printing with high-speed efficiency for caps...

Dual laser capsule marking system

Ensure precise and rapid laser marking of tablets and capsules with a dual-laser system, ...

Flatbed laser drilling for tablet manufacturing

Optimize your tablet production with high-speed laser drilling, ensuring p...

Combination ink printing and laser writing for high-speed production

Achieve precise ink printing and laser marking at ...

High-speed tablet laser drilling system

Achieve precise, high-speed drilling of solid dosage forms with a system capable of...

Co2 laser writer for soft gelatin capsules

Achieve precise and efficient laser marking on soft gelatin capsules and caplet...

Tablet and capsule ink print and laser marking system

Streamline tablet and capsule identification with a high-speed syst...

Tablet and capsule ink printer

Achieve precise and high-speed printing on tablets and capsules, ensuring clear product ident...

Co2 laser writer for gelatin capsules

Achieve high-speed laser marking on gelatin capsules and caplets with precision, ensu...

Tablet and capsule ink printing and laser writing solution

Maximize efficiency in marking and coding with a high-speed s...

Cannabis nanoemulsification system for high-precision production

Achieve rapid bioavailability and stable formulations i...

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

High capacity cannabis cryo-ethanol extraction line

Boost extraction efficiency with high-capacity cryo-ethanol technolog...

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

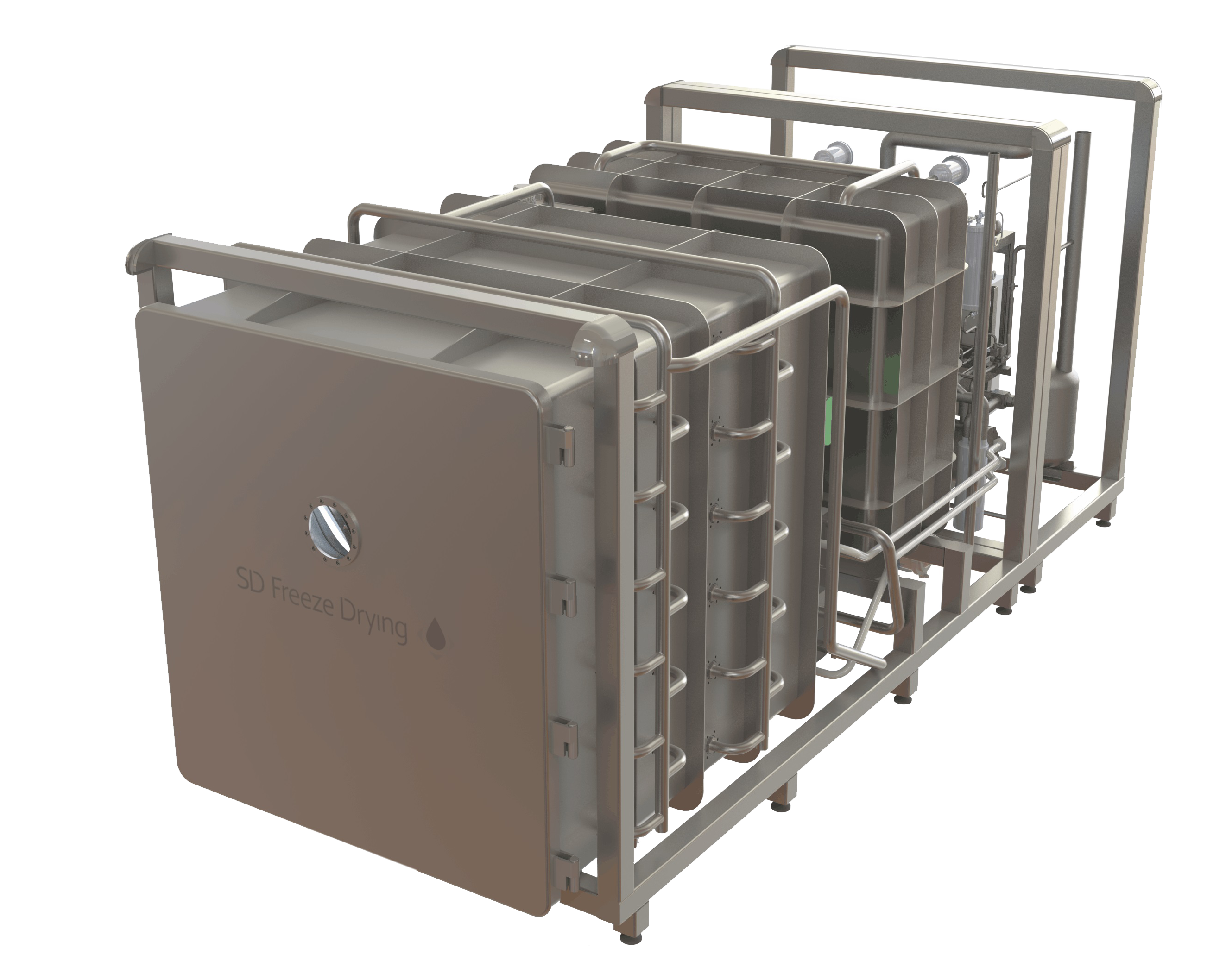

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Automatic filling line for solid doses

For medium-scale production of solid doses such as tablets, capsules, and softgels t...

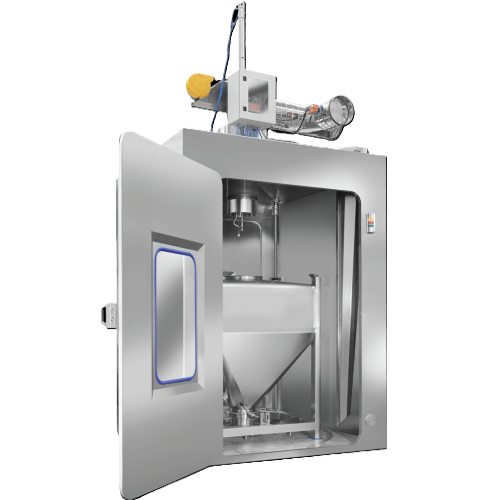

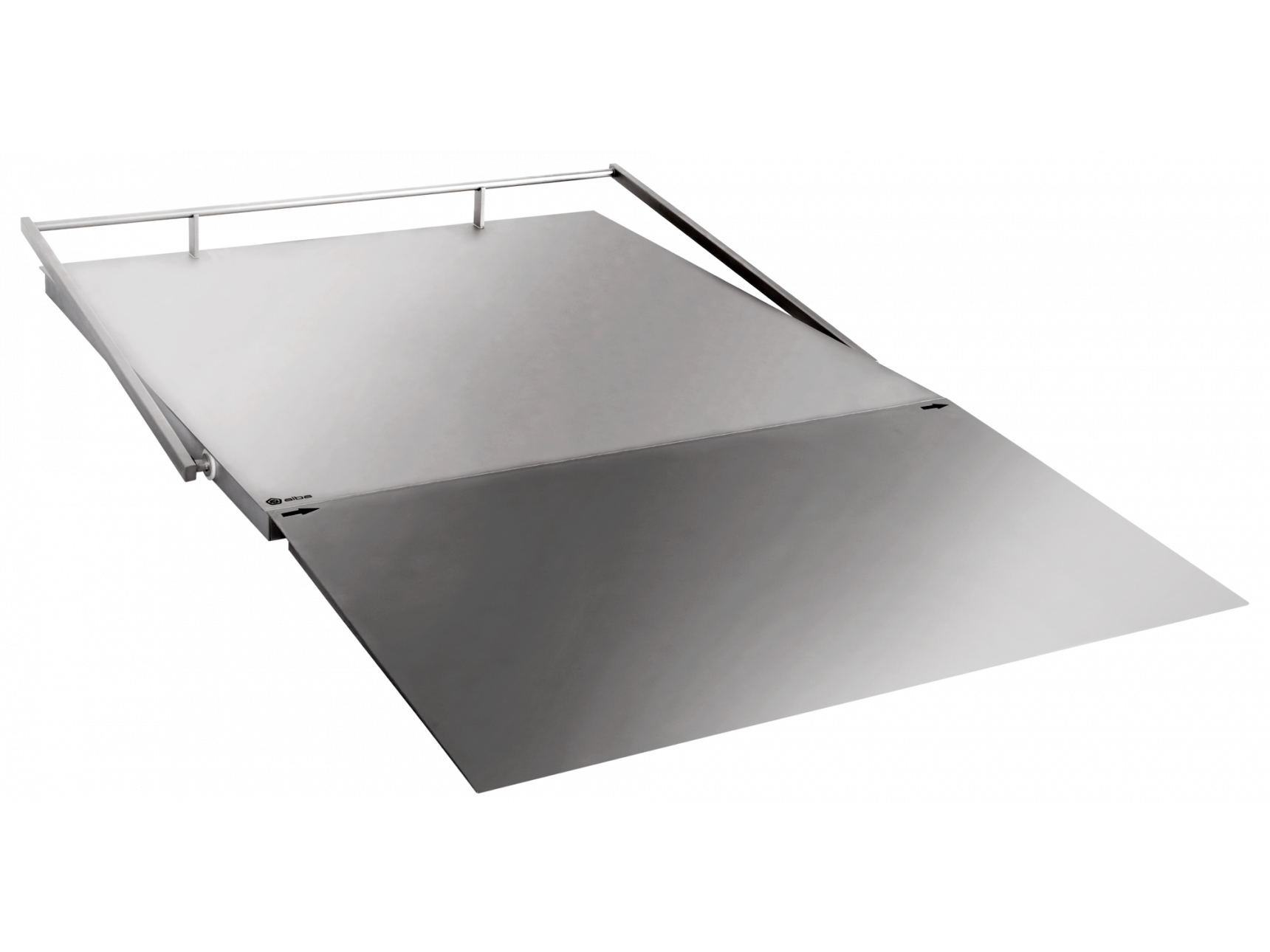

Bulk chamber washer

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

Microencapsulation system for your drug delivery system

Whether you want to improve the stability of nutrients, protect a...

High-speed small volume liquid filler

Fill liquid pharmaceutical, nutraceutical and cosmetic products in ampoules and bottl...

Separators for recovering plasma and meal from animal blood

Optimize protein recovery and transform animal blood into hi...

Separators for pharma extraction

Optimize your pharmaceutical extraction process with innovative centrifugal separation tech...

Pharma extraction clarifier

Achieve superior purity in pharma extraction with efficient separation of solids and liquids, se...

Clarifiers for pilot and lab scale applications

Ensure efficient separation and clarification at the pilot or lab scale wi...

Pharma separator for biopharma processing

Streamline your production with this advanced separator, designed to efficiently...

Centrifuge water saving unit for sustainable cooling

Reduce your cooling water consumption by 99.9% with this efficient s...

Horizontal batch centrifuge for chemical industry

Optimize your solid-liquid separation with a centrifuge designed for pr...

Planetary ball mills for fine grinding of materials

Optimize particle size and surface area in your samples with high-ene...

High-torque cutting mill for tough and fibrous materials

Tackle the toughest materials and ensure consistent particle siz...

Pressure and temperature monitoring system for ball mills

Ensure optimal grinding conditions and enhance product quality...

Ultrafine grinding solution for nanoparticles

Achieve ultrafine particle sizes with high-speed precision, ideal for labora...

Sample dividing solutions for laboratory applications

Streamline your lab’s precision in sample preparation with so...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Laboratory nutsche filter dryer for solid-liquid separation

Optimize your lab processes with a versatile benchtop filter...

Pilot scale nutsche filter dryer for solid-liquid separation

Achieve maximum product recovery and consistent quality wit...

Nutsche filter dryer system for small scale batches

Efficiently tackle filtration and drying challenges with a compact, m...

Cip systems for dairy production

Ensure consistent hygiene and sanitation levels in your production line with efficient, aut...

Pressure control monitor for laboratory vacuum systems

Effortlessly maintain precise vacuum pressure in your lab operatio...

Diaphragm vacuum pumps for laboratory applications

Optimize your lab processes with oil-free diaphragm vacuum pumps, ensu...

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

Gas compressor for solvent recovery in hydrocarbon extraction

Need efficient, explosion-proof gas recovery for butane or...

Laboratory heated circulator for precise temperature control

Achieve precise temperature control for your liquid formula...

Heated circulator for laboratory temperature control

Achieve precise temperature control for demanding applications like ...

Laboratory vacuum cold trap for extract purification

Optimize your vacuum purging and drying applications with this advan...

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

Digital stir controllers for laboratory applications

Achieve precise stirring and mixing control with this digital soluti...

Laboratory automation software for distillation and extraction

Optimize your distillation and extraction processes with ...

Storage silos and hoppers for food and dairy industries

Ensure optimal powder storage with solutions that enhance space e...

High-pressure homogenizer for small-scale production

Enhance your liquid formulations with precise particle size reductio...

Benchtop homogenizer for r&d labs

Optimize your lab processes with precision particle size reduction and efficient emulsifi...

Dissolution-absorption study system for drug formulations

Optimize drug formulations with precise in-situ dissolved subs...

High pressure homogenizer for cell disruption and nanoemulsions

Achieve precise particle size reduction and enhanced bio...

In-vitro dissolution-absorption assessment

Optimize drug formulation tests by combining dissolution and absorption measure...

Laboratory homogenizer for nanoemulsions and dispersions

Elevate your laboratory capabilities with a bench-top homogenize...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

In-line production of fine emulsions

Achieve homogenous emulsions with precise control, reducing the risk of lump formation...

Hygienic buffer tanks for process optimization

Enhance your production flow with hygienic buffer tanks that ensure consist...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Pilot system for high-viscosity product processing

Efficiently handle high-viscosity or large particle products with this...

Bench-top blending vessel for small batch preparation

For small-batch liquid products, achieve precise mixing, heating, a...

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Fs closing devices for industrial packaging solutions

Streamline your packaging process with versatile closing devices, d...

Small-scale in-container spray pasteurizer for laboratory use

Optimize your R&D processes with precise control over...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Continuous deaeration solution for laboratory and pilot systems

Achieve superior product stability and minimize foaming ...

Crown cork sealer for liquid food packaging

Ensure reliable sealing for bottled beverages and dairy with a compact, table-...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Carbonation and can seaming solution for beverages

Optimize your beverage production with a seamless integration that sim...

Sterile carbonation system for beverages

Achieve precise carbonation for both common and specialty beverages with this vers...

Pressurized fermenter for lab-scale fermentation

Achieve precise and controlled fermentation with this advanced pressurize...

Accurate powder filling solution

When precision is paramount, this solution offers exceptional accuracy, filling powders up ...

Automatic checkweighers for precise weight control

Ensure accurate weight compliance and enhance quality control with adv...

Vacuum preservation system for professional packaging needs

Enhance your food product longevity and quality with precise...

Pneumatic and electric lift for industrial mixing tanks

Enhance operational efficiency and safety with versatile lifts fo...

Cleaning-in-place (cip) systems for hygienic processing

Elevate hygiene standards in your liquid processing line with an ...

Gas pycnometer for precise density determination

Achieve accurate and reliable density measurements for a diverse range of...

Mounting configurations for industrial agitators