Vibratory collar for powder flow assistance

Struggling with sticky or poorly flowing powders during discharge? This vibratory collar enhances flow efficiency, ensuring precise powder handling in your production process.

Facilitates Effective Powder Discharge

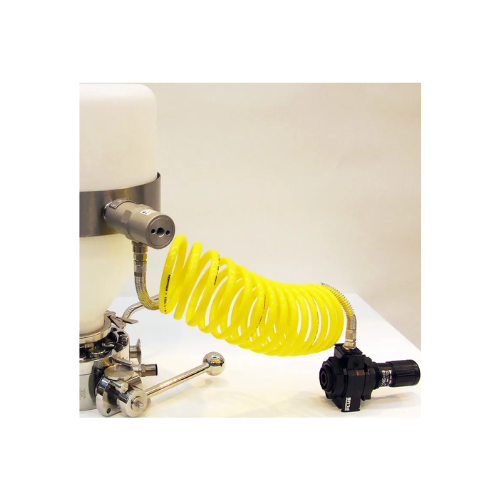

ChargePoint’s Vibratory Collar is a key tool for optimizing powder discharge in industries such as pharmaceuticals and fine chemicals. Designed to assist powder flow from rigid ChargeBottle® containers, it uses pneumatic power and a simple over-center latch system to securely facilitate powder release. This collar supports operations by enhancing the consistency of product flow, crucial for pharmaceuticals like tablets and APIs, or battery industry materials such as lithium-ion powders. Available in 25L and 10L sizes with durable 304 or 316L stainless steel construction, it offers flexibility and durability. The Vibratory Collar integrates seamlessly into existing production lines with options for manual or batch operations and is ideal for various scales of powder handling equipment.

Benefits

- Enhances powder flow to minimize bottlenecks and improve production efficiency.

- Lowers handling costs by enabling use across multiple containers.

- Facilitates operation flexibility with options for various container sizes.

- Built with corrosion-resistant materials suitable for rigorous industrial environments.

- Supports consistent powder discharge, crucial for maintaining product quality in pharmaceutical and chemical applications.

- Applications

- Fine chemicals, Battery industry, Nutraceuticals, Pharmaceutical powder, Pharmaceuticals

- End products

- Pharmaceutical tablets, Active pharmaceutical ingredients (apis), Vitamin supplements, Electrode materials, Herbal supplements, Lithium-ion battery powders

- Steps before

- Powder Storage, Container Filling

- Steps after

- Powder Discharge, Container Transfer

- Input ingredients

- poorly flowing powders, sticky powders, powder materials

- Output ingredients

- discharged powder, flow-assisted powder, extracted powder

- Market info

- Chargepoint Technology is known for its expertise in designing and manufacturing high containment and sterile transfer solutions for pharmaceutical and biopharmaceutical industries, particularly in powder containment and aseptic transfer systems.

- Power Source

- Pneumatically powered

- Container Compatibility

- 25L or 10L ChargeBottle

- Clamp Materials

- 304 or 316L Stainless Steel

- Grip Materials

- Rubber grip bonded to clamp

- Modular Clamp Design

- Yes

- Transfer Capability

- Multiple containers

- Latch Type

- Over center

- Optional Handle

- Yes

- Powder flow assistance

- Vibration

- Container adaptability

- Multiple sizes

- Secure attachment method

- Over centre latch

- Portability

- Transferable between containers

- Handling ease

- Optional handle

- Material handling capability

- Poor flowing powders

- Cost effectiveness

- Modular use across containers

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- ChargeBottle® M / MX

- Discharge method

- Pneumatic vibratory clamp

- Container Size

- 25L or 10L

- Clamp Material

- 304 or 316L Stainless Steel

- Grip Material

- Rubber grip bonded to clamp

- Handle Option

- Available for multiple size and weight containers

- Container Size Options

- 10L or 25L

- Material Options for Clamp

- 304 or 316L Stainless Steel

- Grip Material

- Rubber grip bonded to clamp

- Handles Option

- Available