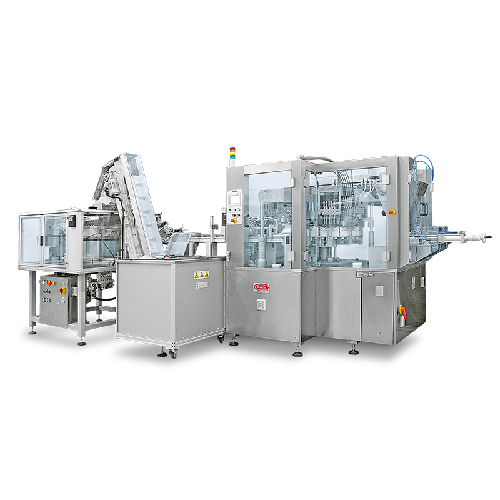

Automatic mono-dose strip filling system

Optimize your liquid product packaging with a multi-functional system designed for precise filling and sealing of mono-dose units, ensuring consistency and efficiency in high-speed operations.

Fills and Seals Liquid Monodose Units

The N500 from TGM – TECNOMACHINES s.r.l. is engineered to enhance filling and sealing processes for liquid monodose units and cartridges in pharmaceutical and cosmetic industries. This high-precision machine integrates automatic loading and multi-dose product handling, accommodating simultaneous filler operations with its versatile system. With a throughput of up to 1800 cartridges per hour, the N500 ensures efficient production for single-dose cough syrups to anti-aging serums. It supports seamless integration into existing production lines with advanced PLC control and automatic loaders. Its energy efficiency, derived from optimized motor controls, and construction from corrosion-resistant materials, ensures durability and reduced operational costs. Compliance with industry standards like GMP makes it suitable for regulated industries. The machine’s design facilitates easy cleaning and maintenance, featuring CIP systems for minimal downtime. Customization options are available, backed by engineering support to tailor the machine to your specific requirements.

Benefits

- Increases production efficiency by processing up to 1800 cartridges per hour.

- Ensures precise dosage and product consistency with high-precision filling and sealing.

- Reduces operational costs through energy-efficient motor control.

- Facilitates easy integration into existing lines with automatic loading capabilities.

- Complies with GMP standards, ensuring regulatory compliance for pharmaceutical applications.

- Applications

- Personal care, Liquid formulations, Syringes, Nutraceuticals, Monodose units, Cosmetics, Cartridges, Dispensers, Pharmaceuticals

- End products

- Nasal spray dispensers, Eye drop cartridges, Face cream single-use packs, Pre-filled insulin syringes, Disposable antiseptic cartridges, Monodose probiotic sachets, Anti-aging serum monodose strips, Energy shot supplements, Moisturizing lotion portable units, Omega-3 liquid supplement dispensers, Tanning lotion monodose pouches, Single-dose cough syrup, Vitamin d monodose vials, Disposable sterile wound care liquid applicators, Liquid foundation monodose packs

- Steps before

- Ingredient preparation, Mixing, Emulsification

- Steps after

- Sealing, Packaging, Labeling

- Input ingredients

- mono-dose plastic strips, 5 single-dose units, multiple products

- Output ingredients

- filled mono-dose strips, sealed mono-dose units, up to 1800 cartridges per hour

- Market info

- TGM - TECNOMACHINES srl is known for manufacturing customized, engineered-to-order packaging machinery, specializing in designing and producing high-quality, efficient equipment tailored to specific customer needs in various industries.

- Capacity

- 1800 cartridges/hour

- Automation

- Automatic loader

- Filling capability

- Mono-dose plastic strips

- Product versatility

- Handles 5 different products simultaneously

- Sealing system

- Special sealing system for optimal results

- Automation level

- Automatic loader

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP

- Energy efficiency

- High efficiency

- Versatility

- Handles five different products simultaneously

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Mono-dose plastic strips

- Filling purpose

- Mono-dose units

- Tank shape and size

- Mono-dose plastic strips

- Feed/Discharge method

- Automatic loader for mono-dose strips

- Control panel type

- Touchscreen HMI

- Integration Possibilities

- Industry 4.0 compatibility