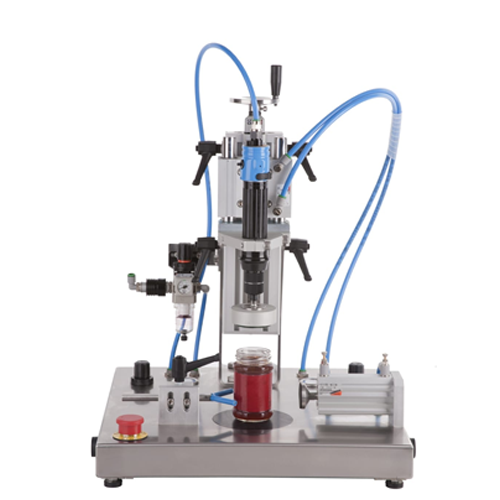

Pneumatic bottle capping solution

Efficiently secure a variety of bottle caps with ease, using a pneumatic system that accommodates diverse container sizes and offers adjustable torque for precise closure, enhancing your production line’s adaptability and speed.

Caps and Closes Containers Efficiently

The Pneumatic Bottle Capper Machine from Adelphi Manufacturing is an adaptable solution for diverse packaging needs. It excels in versatility with manually adjustable torque settings, ranging from 0.3NM to 4NM, allowing precise capping across multiple bottle sizes and cap types. Specializing in chemical, cosmetic, food, and pharmaceutical applications, this machine efficiently handles a variety of products such as essential oils and lab test reagents. With a throughput of up to 500 containers per hour, it seamlessly integrates into existing production lines, whether operating in automatic, semi-automatic, or manual modes. Constructed from hygienic stainless steel and aluminum, it offers robust performance and low maintenance requirements, ideal for environments demanding cleanliness and durability. The compact, portable design ensures easy integration and relocation within facilities, offering engineering support for tailored solutions.

Benefits

- Increases packaging efficiency with a capacity of up to 500 containers per hour.

- Minimizes operational costs through low maintenance and durable construction.

- Enhances production versatility by accommodating various cap sizes with adjustable torque.

- Ensures product integrity with hygienic materials and easy cleaning.

- Offers flexibility and ease of use in both manual and semi-automatic operations.

- Applications

- Personal care, Food, Veterinary products, E-liquid, Beverage, Household products, Oil, Cosmetics, Chemical products, Lube oil, Pharmaceutical products, Laboratory research

- End products

- Sauce bottles, Foundation bottles, Engine oil bottles, Nasal spray bottles, Lab test reagents, Chemical solvents, Essential oil bottles, Pet health supplements, Juice bottles, Shampoo bottles, Detergent bottles, E-liquid cartridges

- Steps before

- Bottle filling, Product labeling, Container alignment, Inspection of bottles

- Steps after

- Packaging, Quality control, Label application, Sealing

- Input ingredients

- bottles, containers, cap sizes

- Output ingredients

- capped bottles, closed containers, sealed twist-off caps

- Market info

- Speed

- Up to 500 containers per hour

- Torque range

- 0.3NM to 4NM

- Closure torque adjustment

- Manually adjustable through mechanical friction

- Cap size adaptability

- Wide range by changing the cap chuck

- Construction material

- Stainless steel and aluminium

- Automation level

- Manual

- Changeover time

- Adaptable

- CIP/SIP

- Manual Cleaning

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Air incorporation control

- Not specified

- Container type

- Various sizes and shapes

- Compact footprint

- Portable

- Control panel type

- Simple, Intuitive

- Construction Material

- Hygienic stainless steel and aluminium

- Cap Size Adaptability

- Wide range by changing cap chuck

- Maintenance

- Low Maintenance

- Cap chuck adaptability

- Multiple cap sizes

- Construction material

- Stainless steel and aluminium

- Torque adjustment

- Manually adjustable 0.3NM to 4NM

- Portability

- Robust and portable