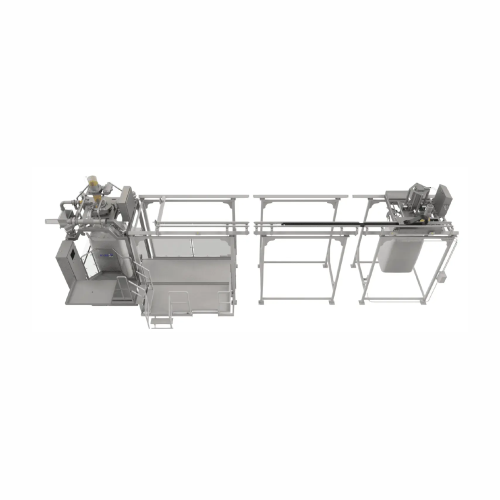

Bulk bag filler with integrated palletizing system

Optimize your powder packaging with a seamless system that fills and automatically palletizes bulk bags, enhancing hygiene and efficiency by removing forklift traffic from sensitive areas.

Fills and Palletizes Bulk Bags Efficiently

The RELCO® Bulk Bag Filler with Integrated Palletizing System is designed to revolutionize the way bulk powders are handled across multiple industries. This system uniquely combines filling and palletizing processes, addressing the challenge of maintaining sanitary conditions by eliminating wood pallets and forklift traffic in hygienic packaging rooms. It uses a motorized trolley system to transport filled bags from the packaging area to the warehouse, ensuring a seamless operation.

Ideal for applications such as dairy, food, beverage, pharmaceuticals, and more, it accommodates end-products from milk powder to automotive additives. It can achieve a throughput of 10 bulk bags per hour when paired with an appropriate feed system. The system is fully automatic, featuring stainless steel construction for durability and corrosion resistance, with all components housed in UL-listed NEMA 4 enclosures for safety and compliance with 3A standards and USDA guidelines.

The integrated PLC/HMI ensures precise control, while the configurable trolley system adjusts to various bag widths. The equipment also includes automatic pallet and slip-sheet presenters, minimizing manual intervention. Maintenance is straightforward, thanks to the robust stainless steel design, offering prolonged operational life while adhering to rigorous hygiene requirements.

Benefits

- Enhances hygiene by removing wood pallets and forklift traffic from sensitive areas.

- Increases production efficiency by filling and palletizing up to 10 bulk bags per hour.

- Improves operational safety with UL-listed NEMA 4 enclosures and comprehensive E-Stop systems.

- Extends equipment longevity with robust stainless steel construction offering corrosion resistance.

- Reduces manual handling through automatic pallet and slip-sheet presenting features.

- Applications

- Food, Sour gas, Environmental, Gas, Textile, Automotive, Beverage, Oil, Biogas, Metals refining, General industrial, Pulp, Mining, Paper, Life sciences, Dairy

- End products

- Metal powders, Beverage powders, Pulp refinement additives, Biogas substrates, Textile treatment chemicals, Automotive additive powders, Environmental treatment powders, Gas purification chemicals, Milk powder, Paper coating powders, Protein supplements, Pharmaceutical powders, Cheese powder, Refined oil powder

- Steps before

- Conveying, Manual Packaging, Automatic Packaging, Blending

- Steps after

- Palletizing, Load Accumulation, Warehouse Storage

- Input ingredients

- bulk bags, powder, packaging materials

- Output ingredients

- palletized bulk bags, packaged powder, slip-sheeted bulk bags

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Compliance,Certifications

- 3A Sanitary Standards

- Material

- Stainless steel construction

- Filling Rate

- 10 bulk bags/hour

- Automation

- PLC/HMI controlled

- Enclosure

- UL listed NEMA 4 stainless steel

- Transport System

- Trolley with four-axle drive system

- Bag Handling

- Automatic pallet and slip sheet presenters

- Automation level

- PLC-controlled

- Cleanroom compatibility

- Yes

- Trolley drive system

- Four-axle

- Bag handling

- Automatic release

- Hygienic design

- Sanitary applications

- Palletizing automation

- Automatic

- Airlock system integration

- Yes

- Filling rate

- 10 bulk bags per hour

- Cleanability

- Complies with 3A and USDA standards

- Corrosion resistance

- Stainless steel construction

- Biological compatibility

- Suitable for sanitary applications

- Footprint

- Compact for hygienic room

- Material

- Stainless steel

- Construction

- Robust stainless steel

- Discharge Method

- Trolley to pallet

- Frame Design

- Stainless steel chain conveyors

- Transport System

- Overhead trolley

- Trolley Features

- Four-axle drive system

- Trolley Hangs

- Adjustable for bag width

- Control panel type

- PLC/HMI

- Trolley drive system

- Four-axle

- Trolley width adjustment

- Automatic

- Trolley enclosure type

- UL listed NEMA 4 stainless steel