Cheese Making Equipment

Find innovative cheese equipment and connect directly with world-leading technology suppliers

A cheeseboard demonstrates the different possibilities that milk and dairy can take. There are hundreds of recognized cheese recipes worldwide, but the main ingredients remain the same: milk, fermenters, salt, and time. Cheese manufacturers combine these elements to craft unique flavors, aromas, and textures. Advanced cheese making equipment provides better control over these elements to create ever more diverse cheeseboards.

Innivative cheese processing equipment

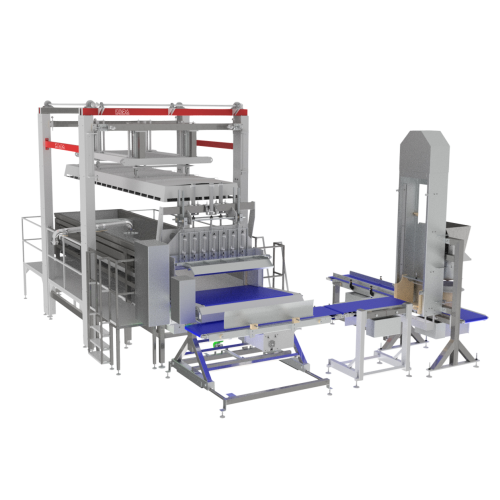

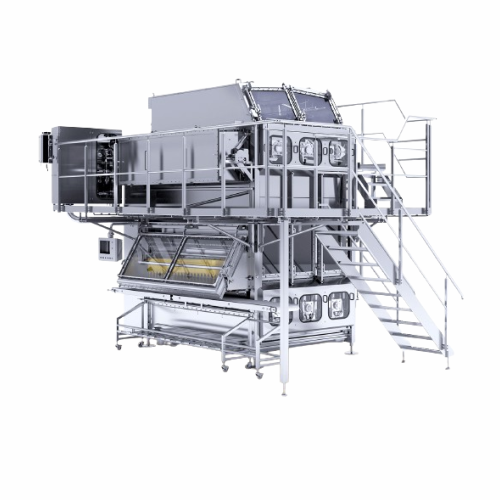

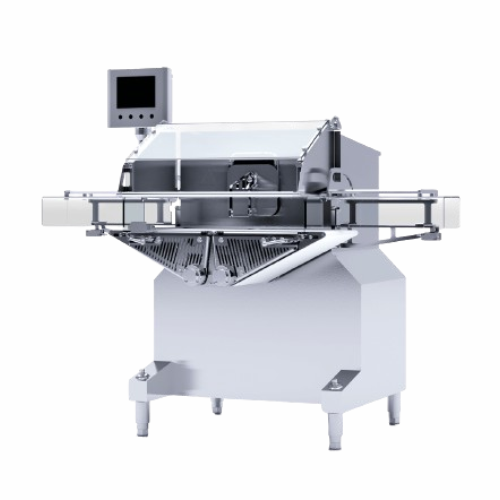

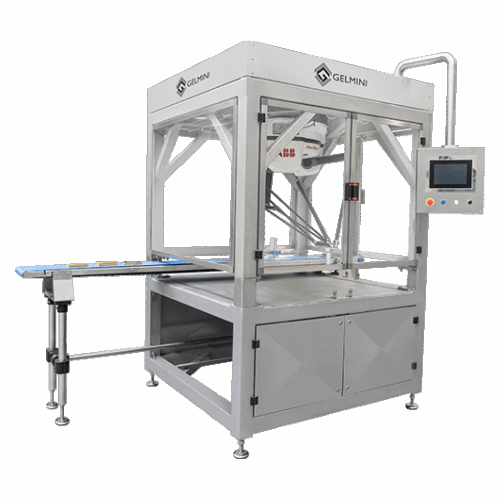

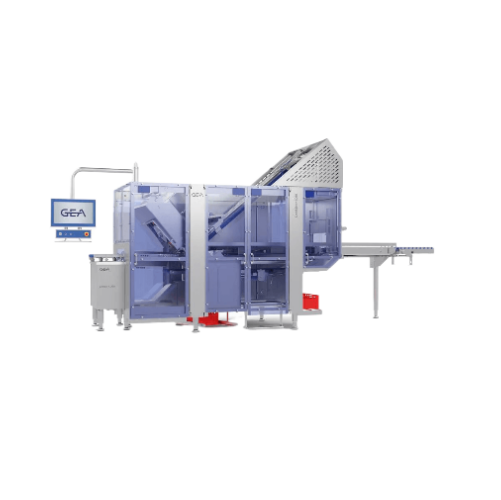

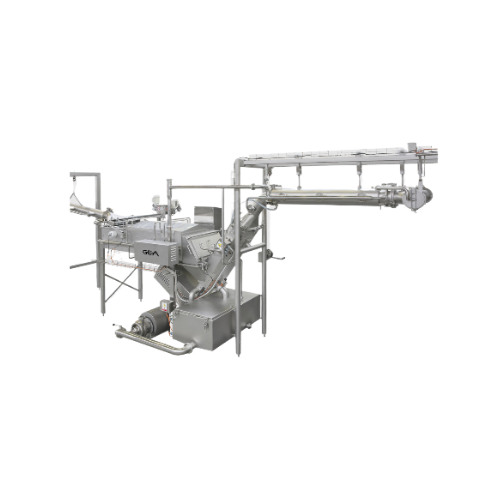

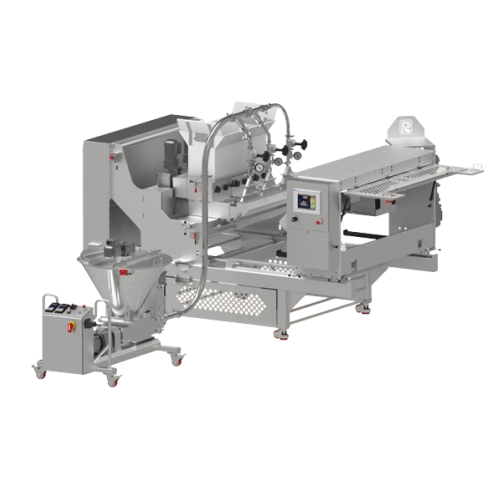

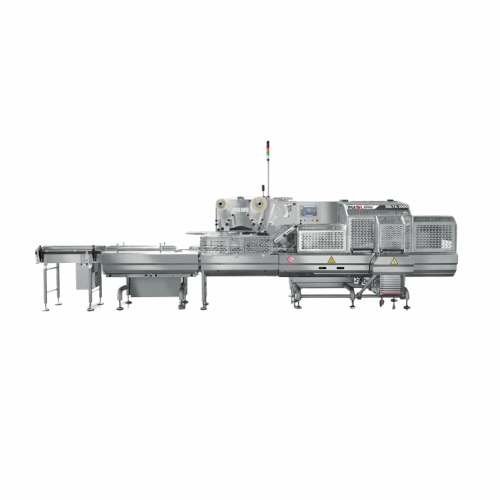

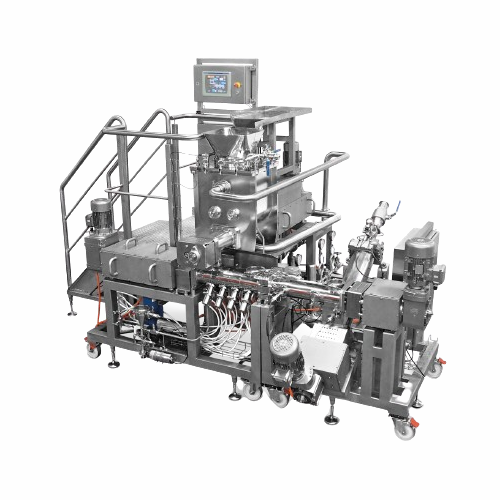

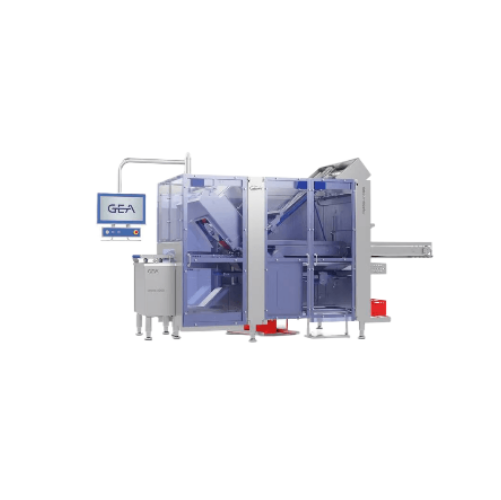

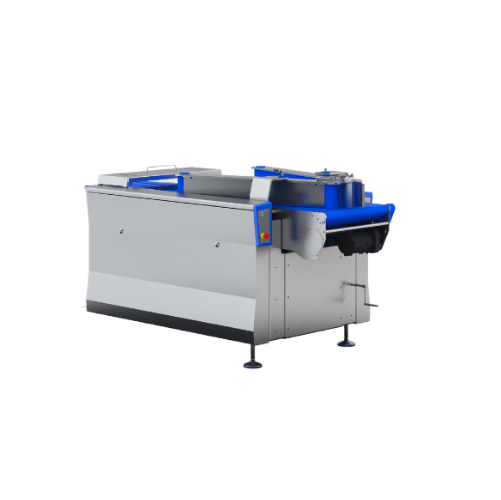

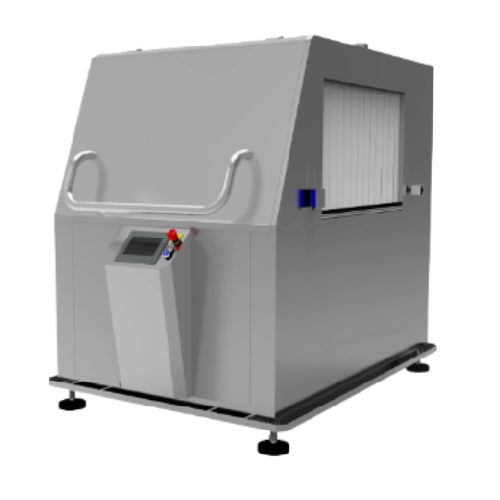

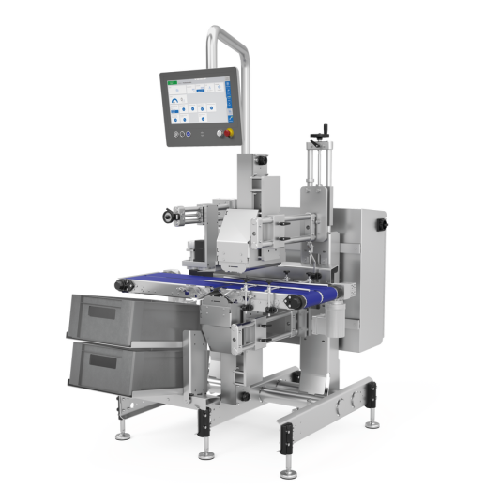

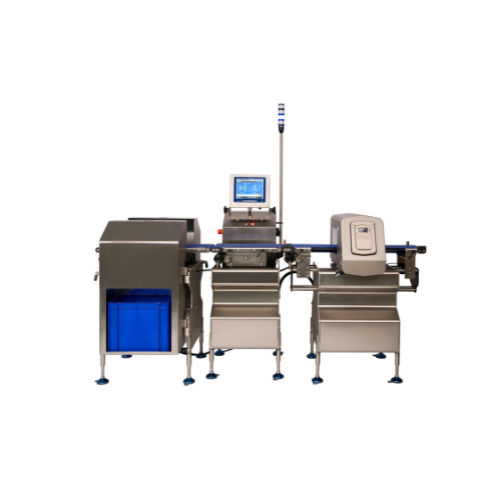

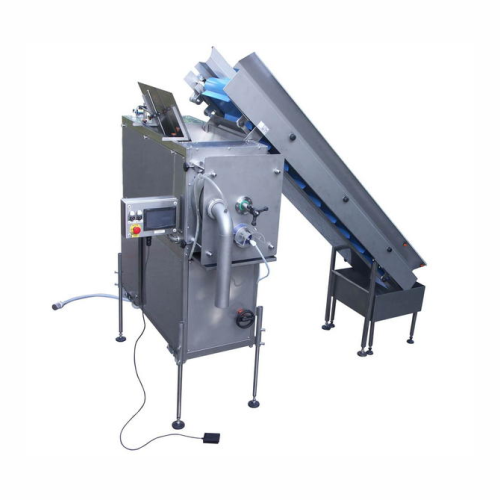

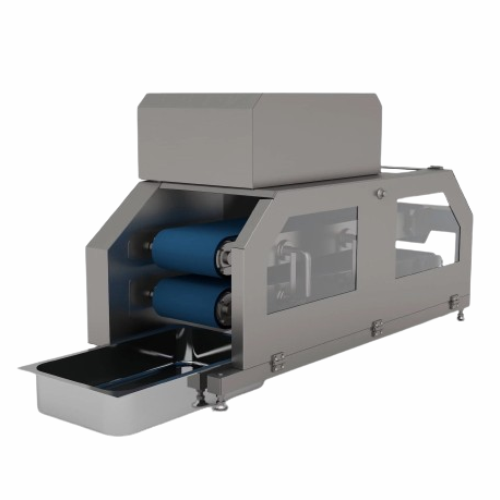

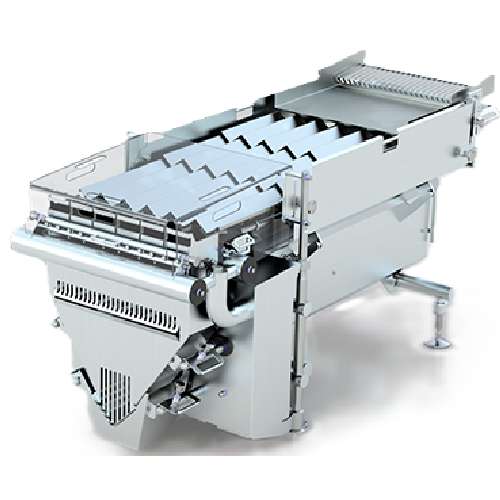

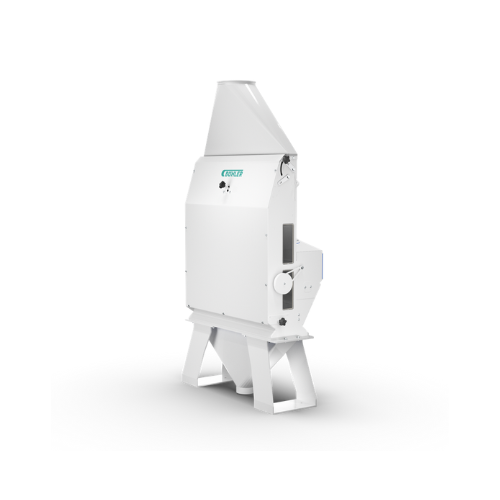

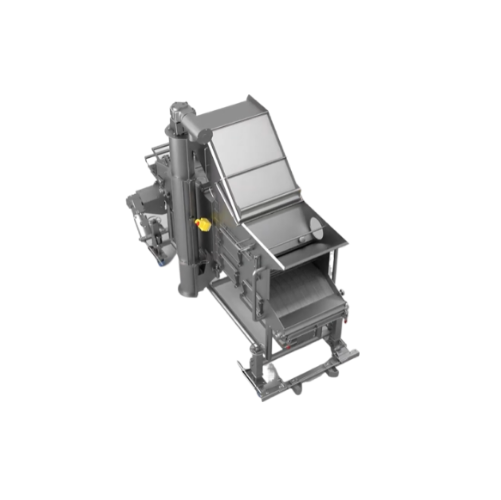

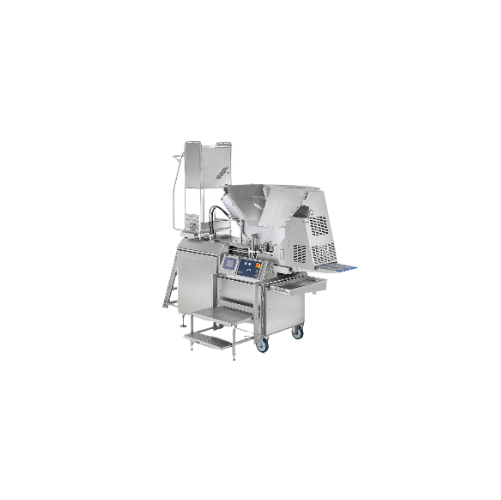

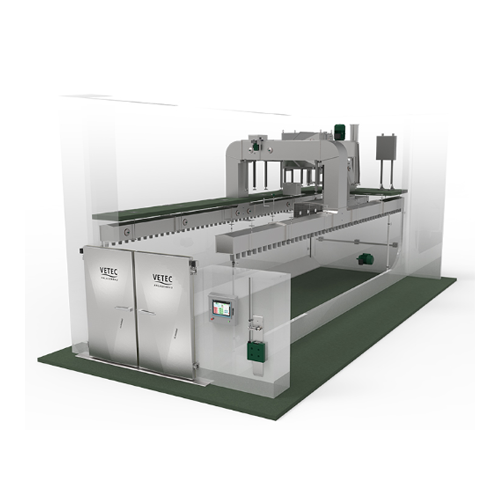

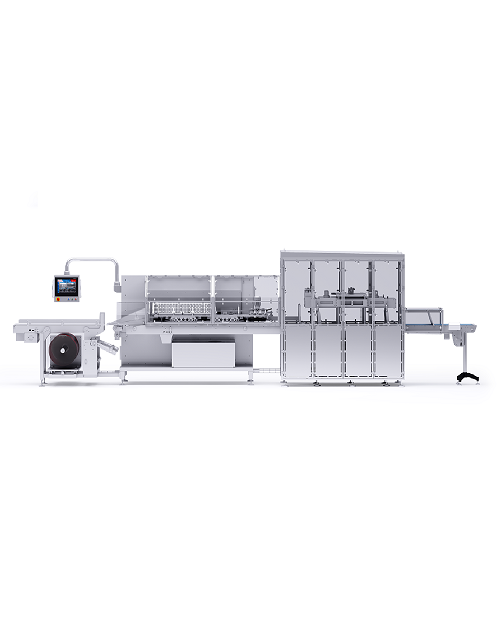

Automatic cheese derinding system for rectangular cheeses

For cheese processors seeking effortless precision, this machi...

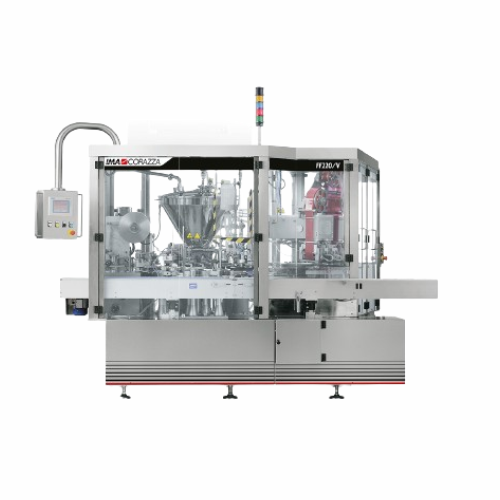

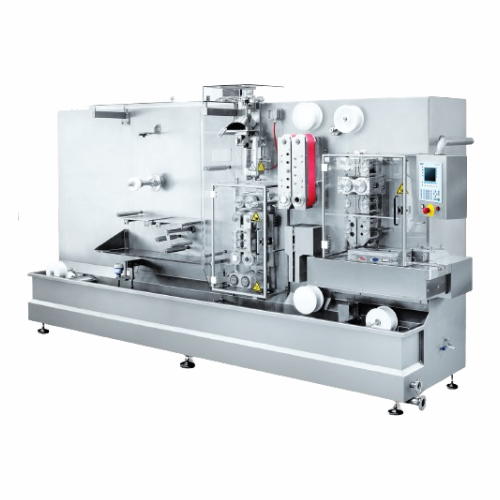

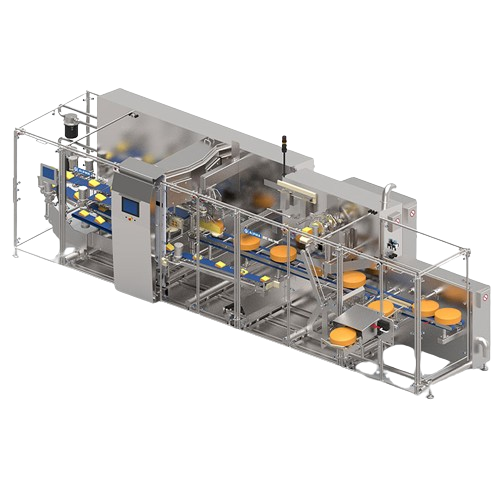

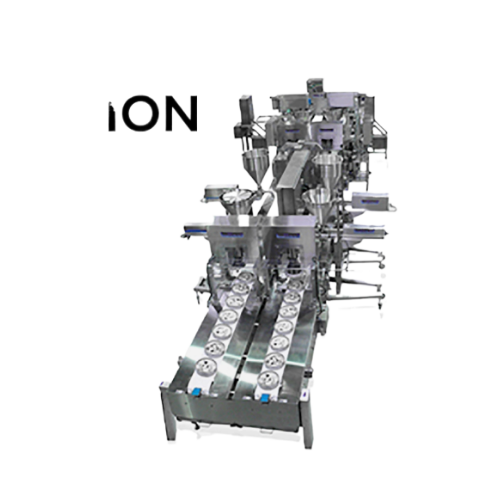

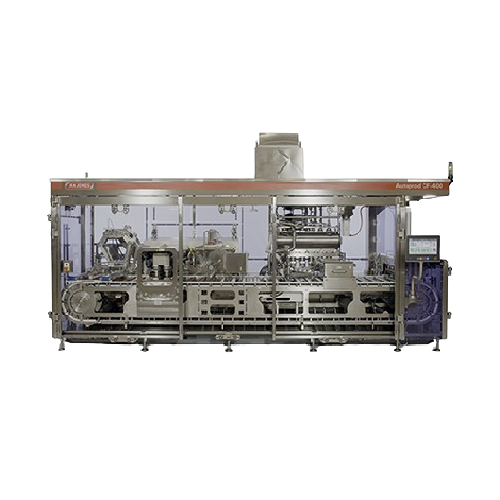

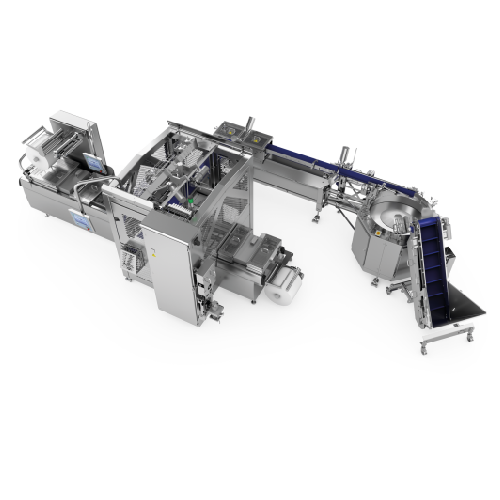

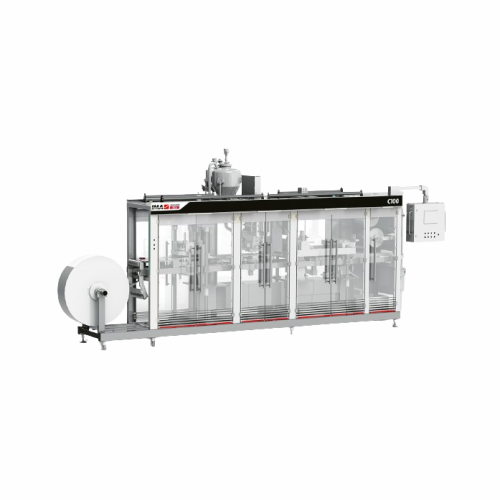

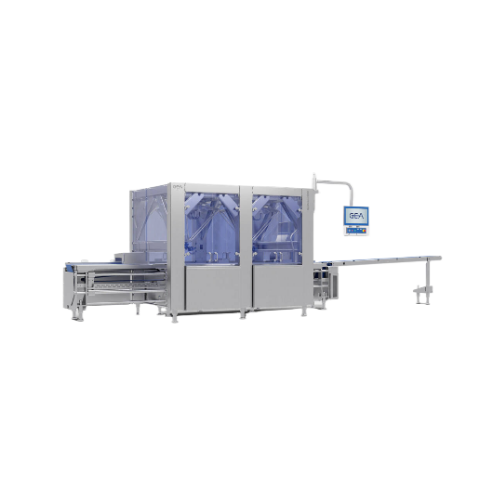

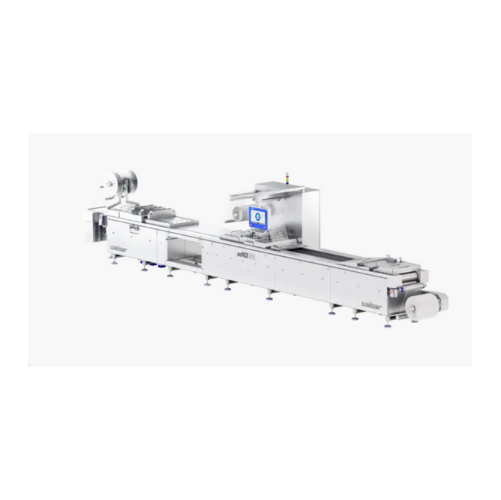

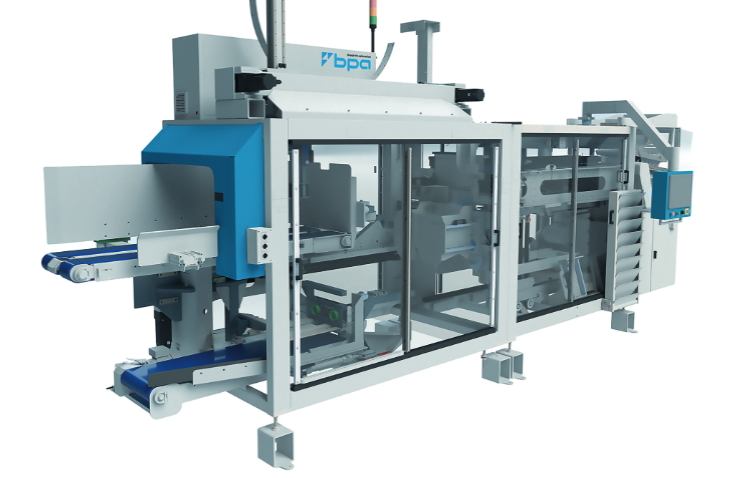

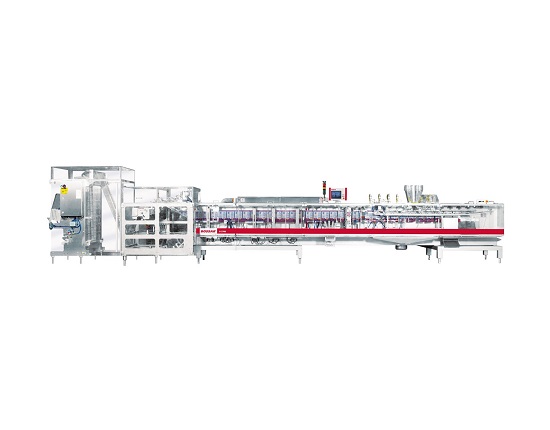

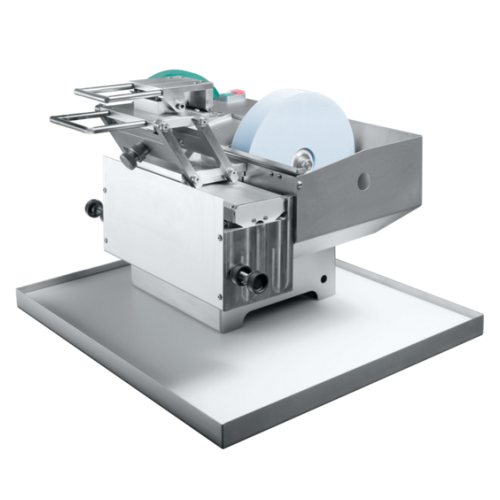

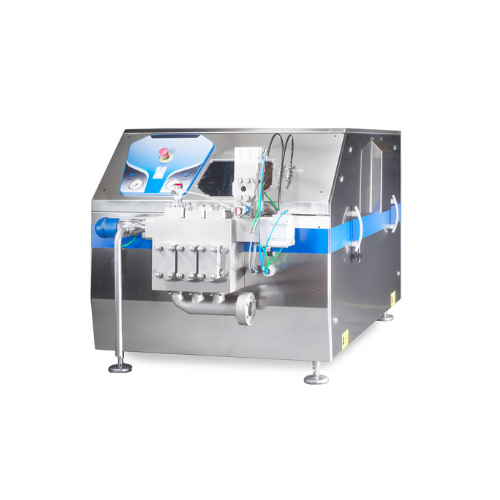

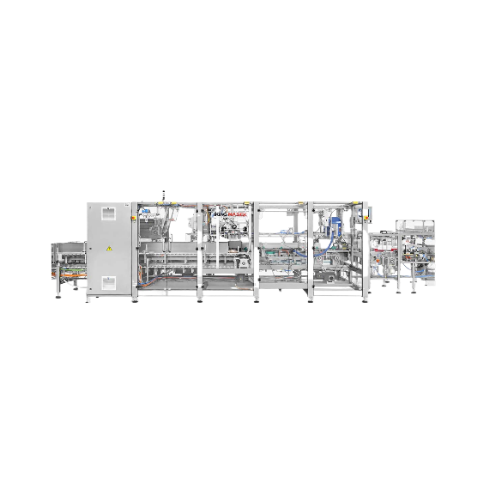

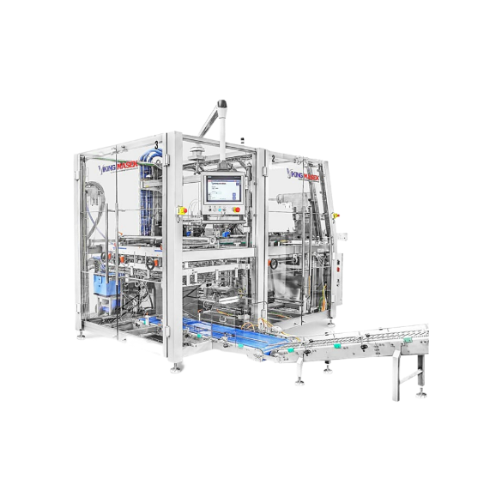

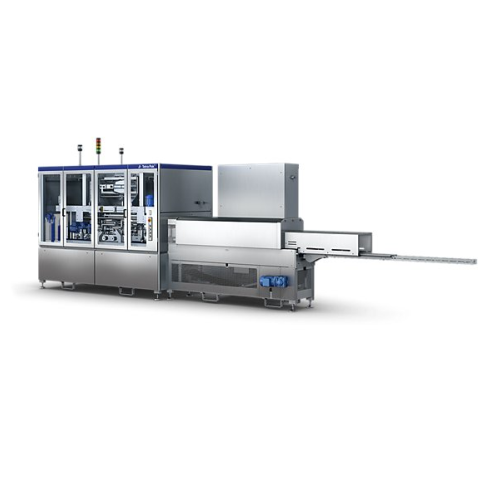

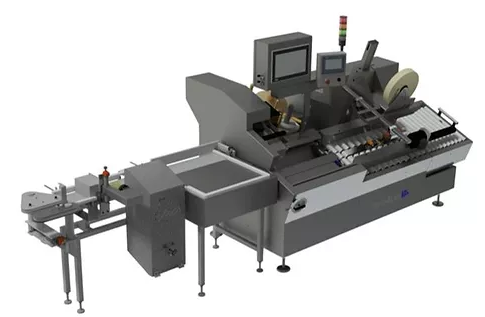

Automatic packaging for small cheese products

Effortlessly package a variety of cheese shapes and sizes with quick format ...

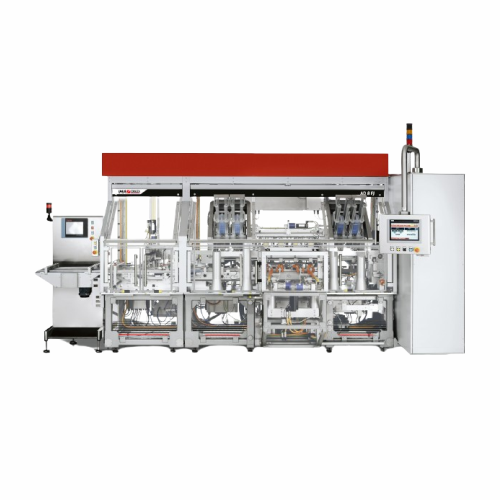

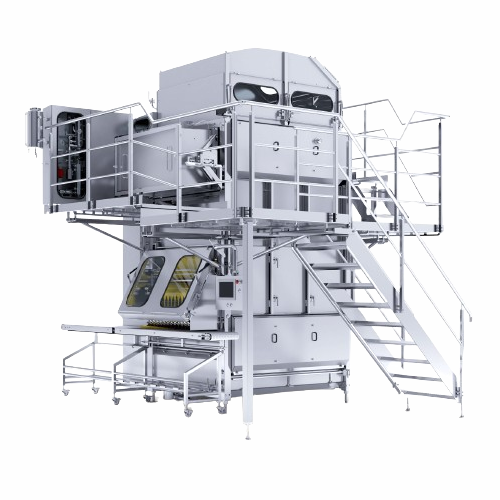

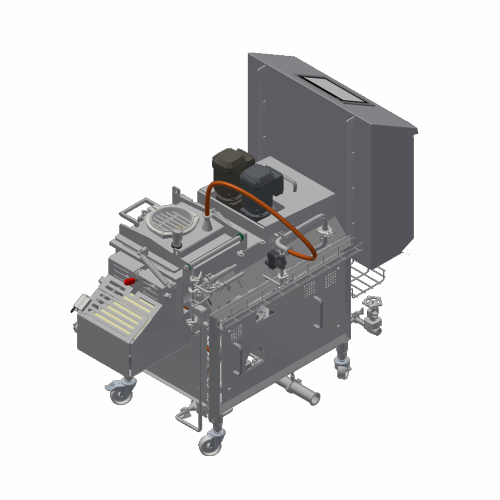

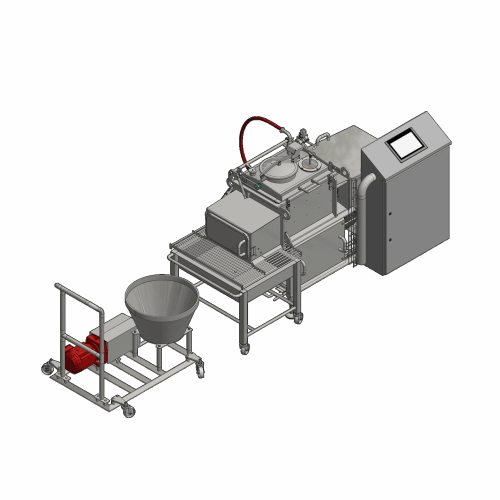

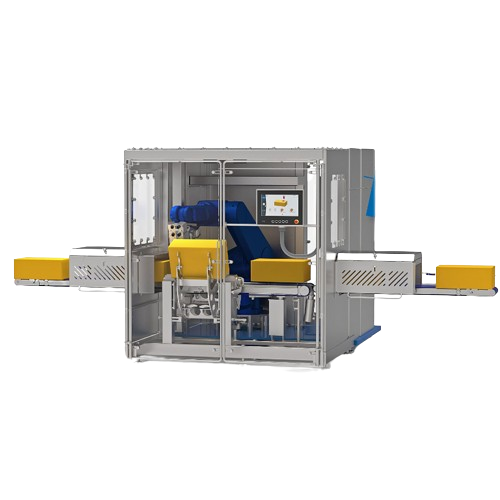

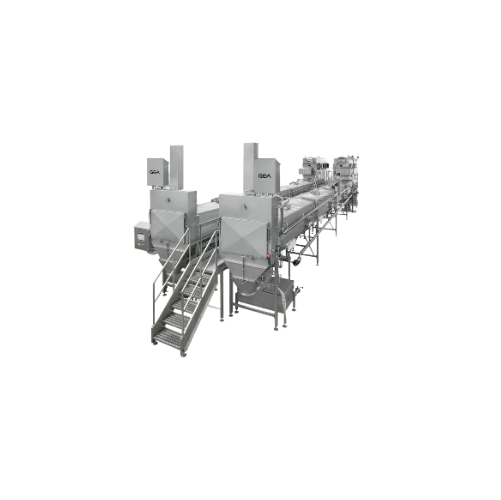

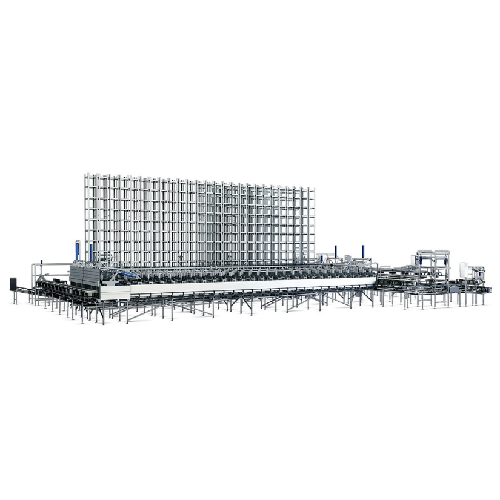

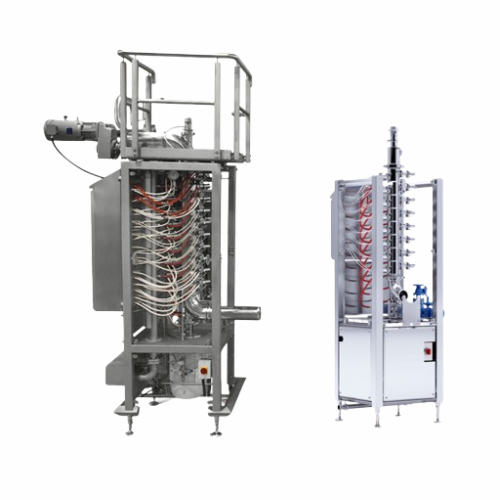

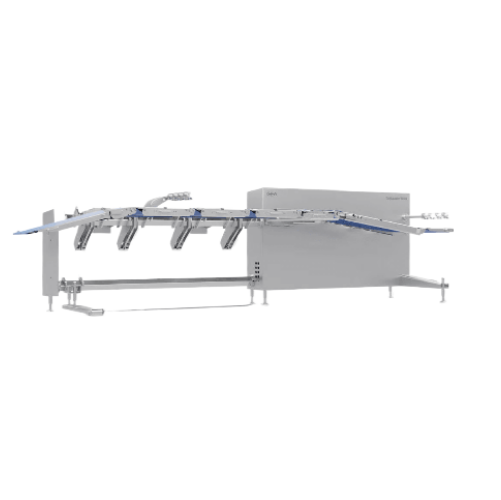

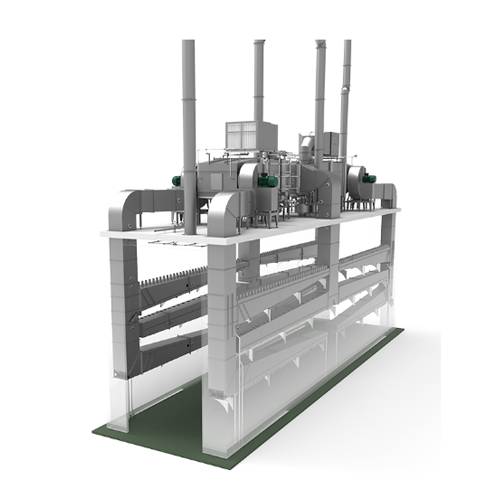

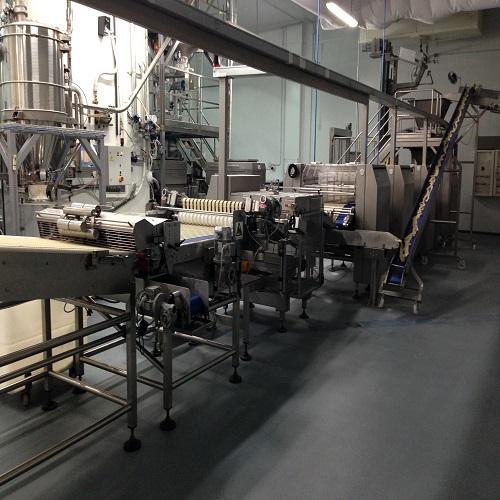

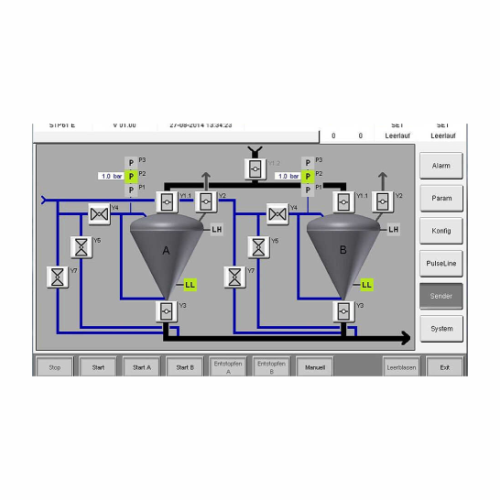

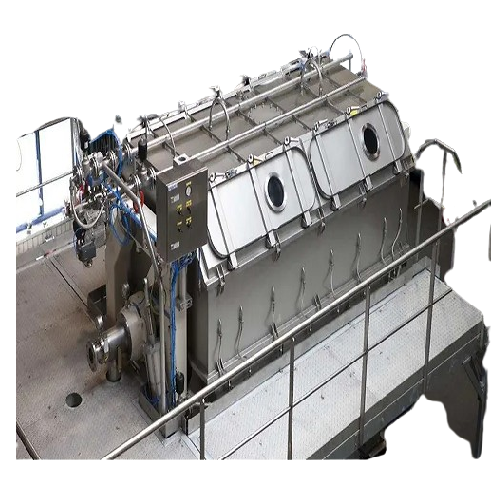

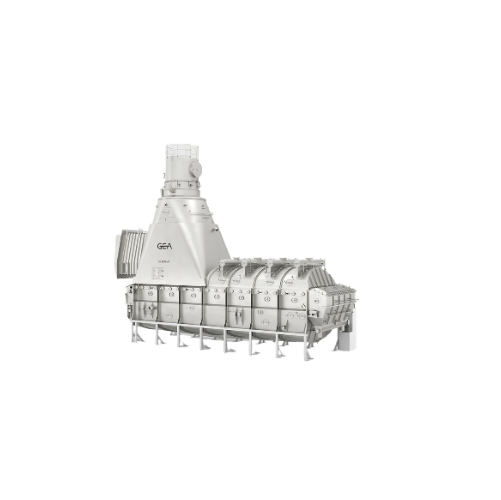

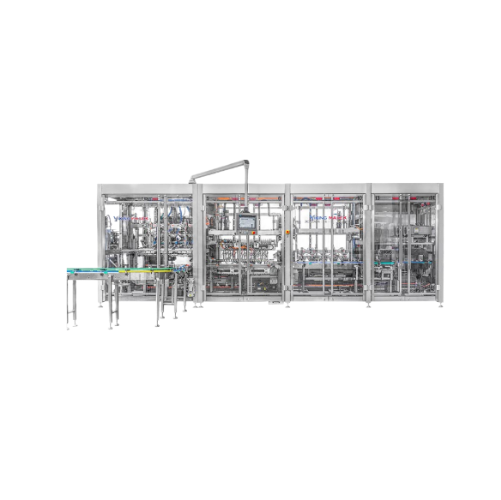

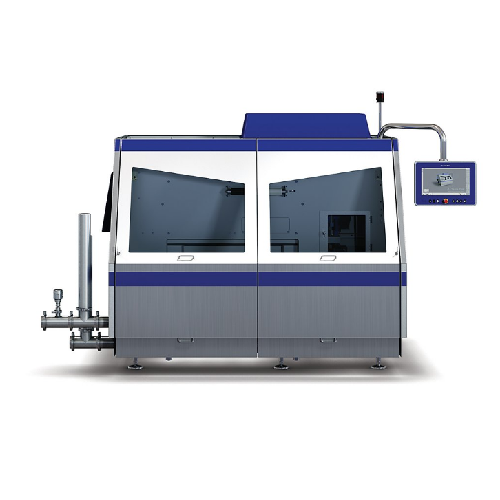

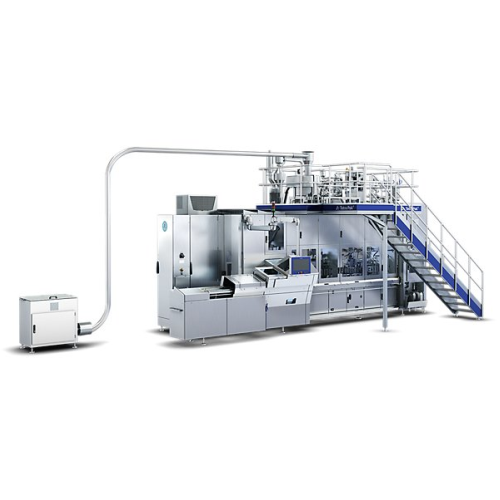

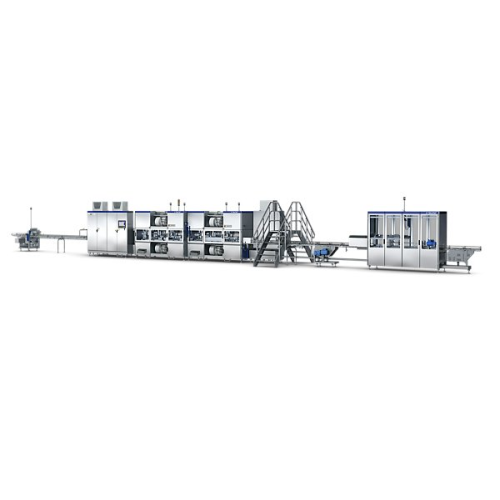

Automation system for cheese processing

Optimize your cheese production line with seamless integration to ensure consistent...

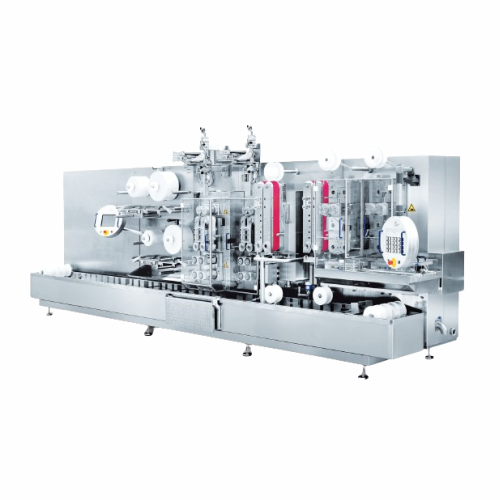

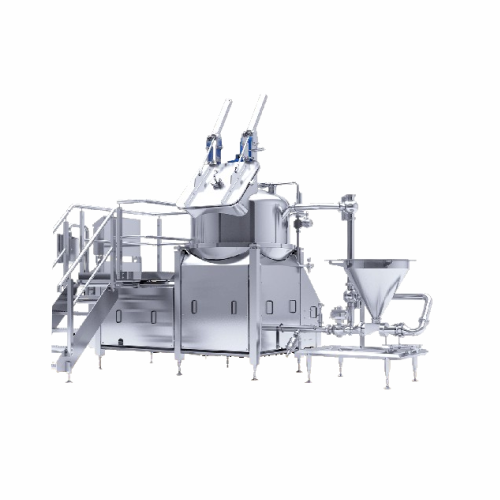

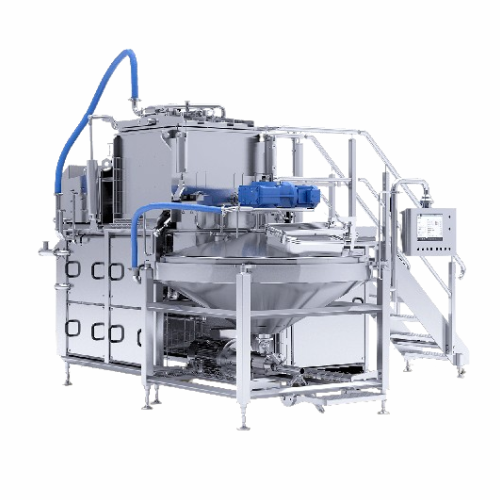

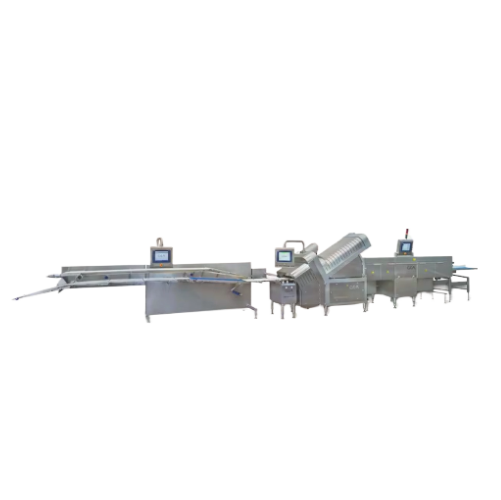

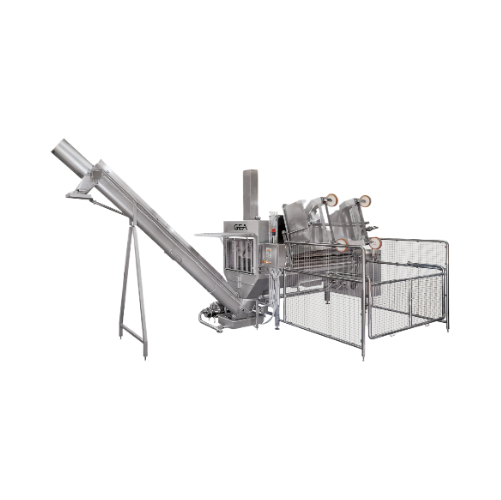

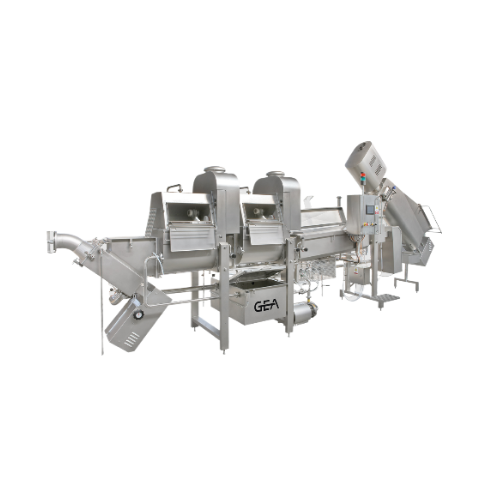

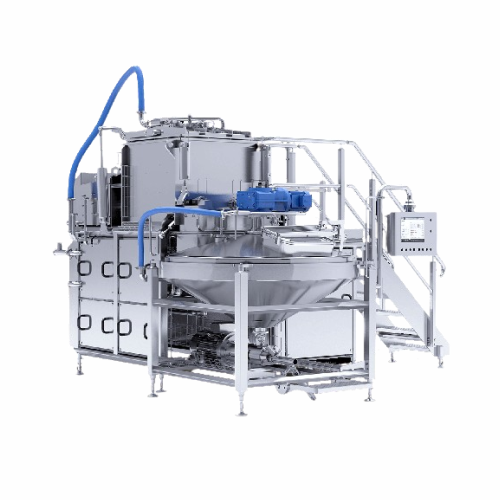

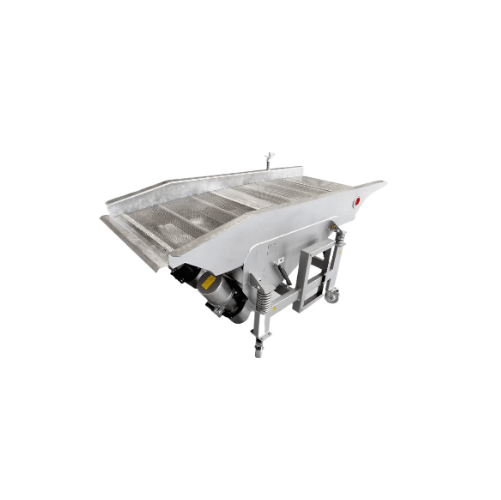

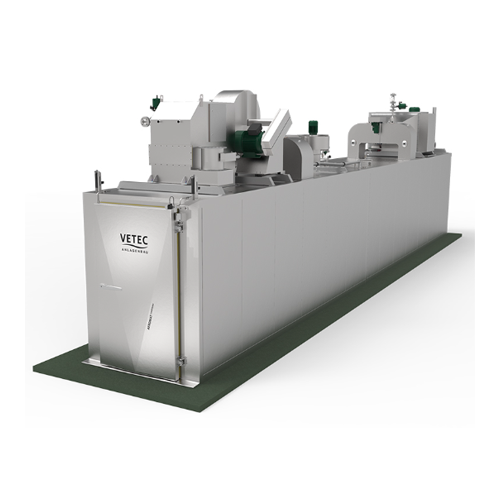

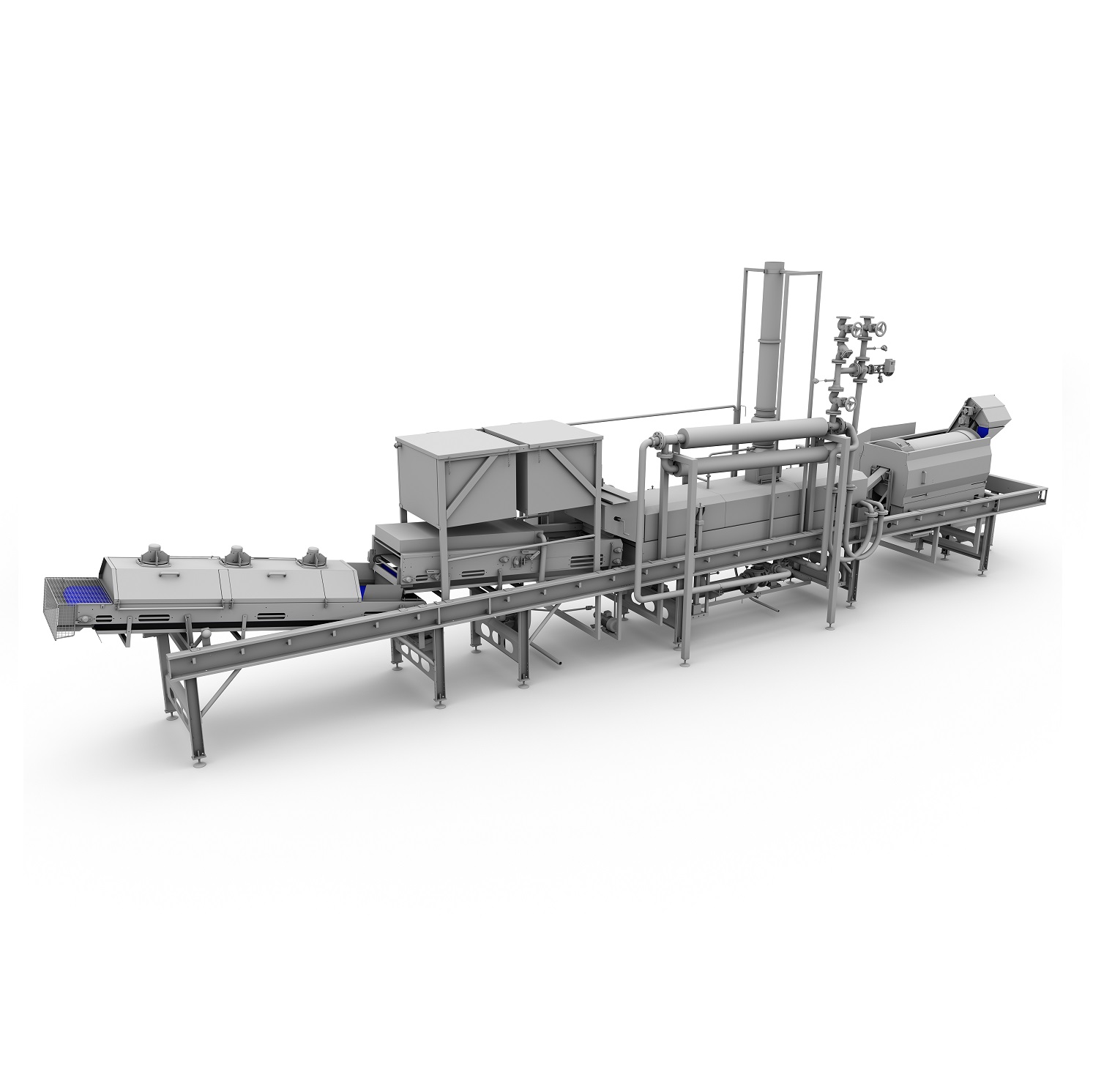

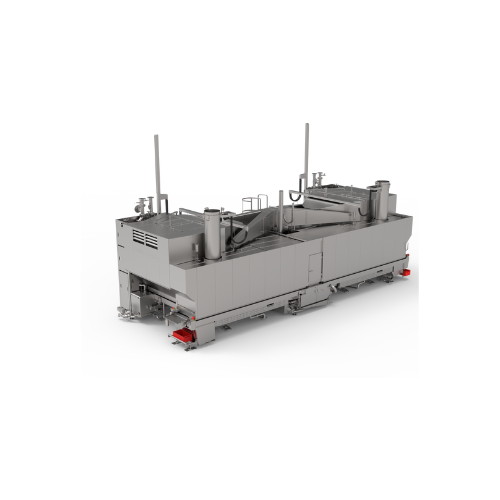

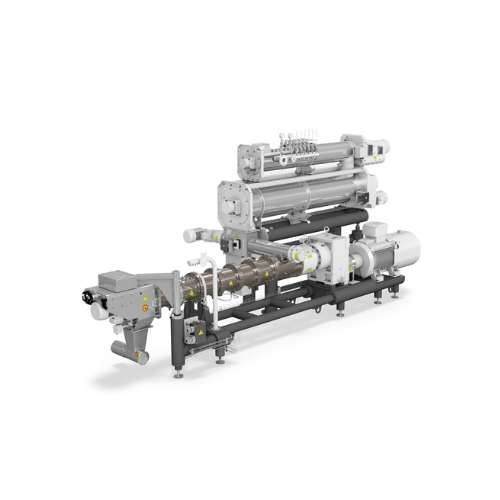

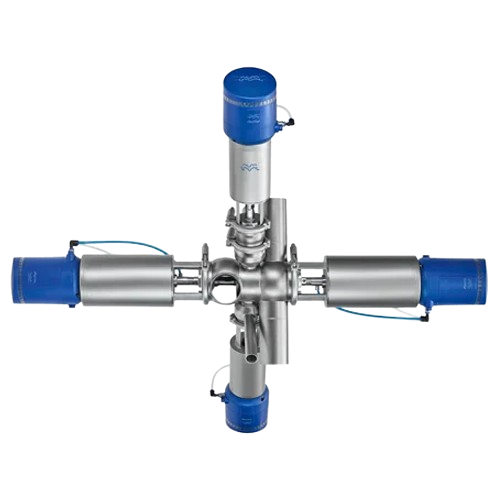

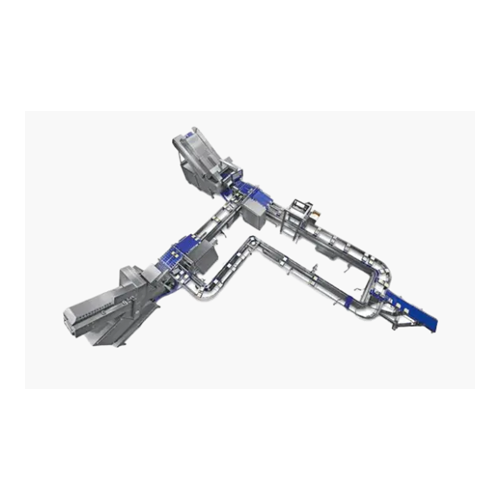

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Select your cheese process

What are you making?

Brie cheese

Bocconcini

Burrata

Blue cheese

White cheese

Vegan cheese

Swiss cheese

Shredded cheese

Scamorza

Provolone

Ricotta

Processed cheese

Pasta filata cheese

Parmesan cheese

Paneer

Mascarpone

Kashkaval

Grana padano cheese

Gouda cheese

Hard cheese

Feta cheese

Curd cheese

Cream cheese

Analogue cheese

Cottage cheese

Cheese wheels

Cheese sticks

Cheese slices

Cheese shreds

Mozzarella

Cheese Blocks

Halloumi

Plant-based cheese

Grated cheese

Cheese spread

Tell us about your production challenge

Combine fermenters and salt to transform milk into cheese

Cheese demonstrates the different possibilities that milk can take. There are hundreds of recognized cheese recipes worldwide, but the main ingredients remain the same: milk, fermenters, salt, and time. Cheese manufacturers combine these elements to craft unique flavors, aromas, and textures. Advanced cheesemaking equipment provides better control over these elements to create ever more diverse cheeseboards.

Ferment milk with cultures that can handle the processing temperature

During fermentation, bacteria consume the lactose content in milk and convert it into lactic acid. This process of acidification reacts with the casein, causing it to curdle.

The right starter culture depends on the type of cheese you want to produce. A mesophilic culture is best suited for making a cheese that forms in moderate heating (between 30°C and 39°C), such as gouda or cheddar. Hard cheeses like parmesan and challerhocker require thermophilic bacteria that can withstand temperatures up to 55°C.

Substitute animal-derived protease with lab-grown rennet

Much of the characteristic texture of cheese can be traced back to the curdling process. Traditional cheese makers added biological rennin taken from nursing ruminants to break down the protein in acidified milk.

Vegetarian rennet is manufactured by genetically modifying bacteria to cause them to produce a protease equivalent to that found in young mammals. The rennet inactivates the casein leading the milk to coagulate and whey to drain out.

Cut the curdles to increase their surface area

Cutting technology is critical to cheese production. After solidifying, the milk is cut into smaller curdles to let out more whey. Cheesemaking equipment slices the curds down in different directions, increasing their surface area with each cut.

The smaller the pieces, the more whey they lose, so harder cheeses are cut down more finely. Softer cheeses retain more moisture, and the coagulant is kept in larger pieces.

Pass the curds through whey treatment to remove unwanted protein

Every cheese style has its processing method. A pecorino will be cooked and stirred to release as much water content. A mild cheese like fontina is washed repeatedly to move out moisture.

But whatever the technique, the curd is finally subjected to whey treatment to drain the protein. Cheesemaking equipment like presses and compactors force the liquid to ooze out. The byproduct is collected and processed into whey protein for separate applications.

Select cheesemaking equipment for salting according to the product consistency

Many cheese recipes include herbs and spices, such as dried mint in halloumi or habañero chilies in pepper jack. All cheese formulas, however, contain salt.

Salt is not a taste-enhancer as much as a preserving agent, halting fermentation. In hard cheeses, salt is sprayed onto the mix during milling. The curdles are further reduced before being compacted into ripening molds.

In the case of fresh cheeses, salting is done in a brine system. The curdles are placed in the saline solution containing calcium chloride, non-iodized salts, and vinegar to soak in the minerals. The processing equipment required to produce cheese usually remains the same, even if the type of cheese you want to make will be different. Typically the equipment is stainless steel and consists of a cheese press, cheese vats, tanks, homogenizers, heat exchangers and mixers.

Which cheese technology do you need?

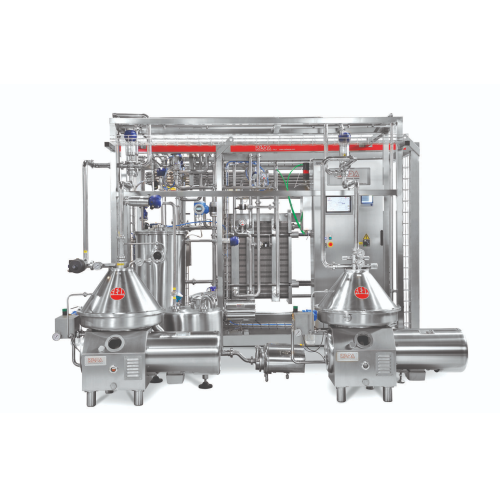

Separator for double cream fresh cheese

Optimize your dairy production with a high-performance centrifugal separator, desig...

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

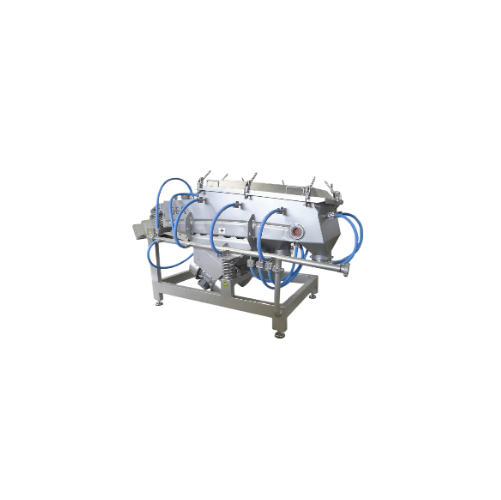

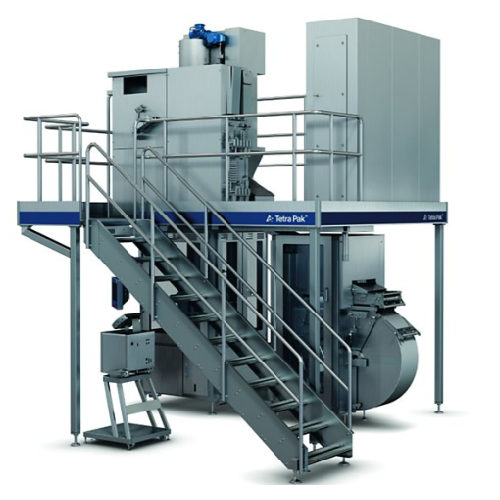

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

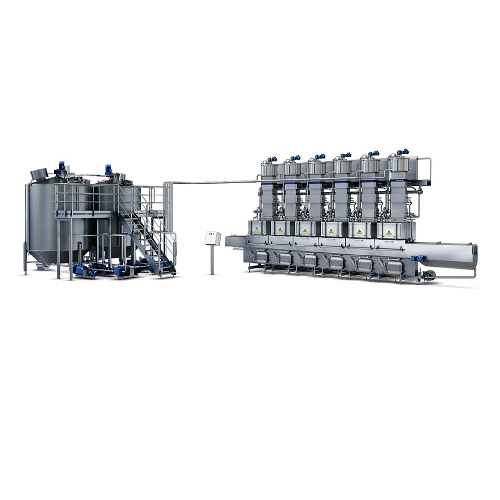

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

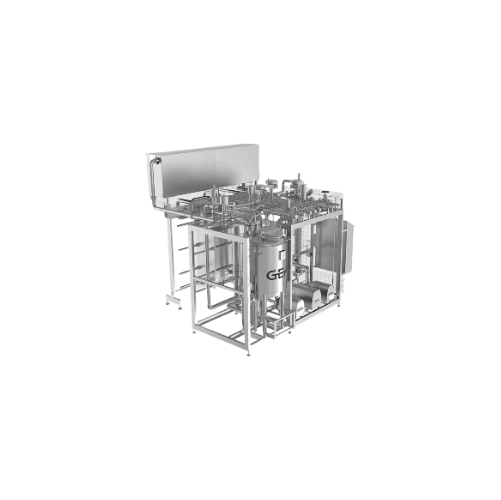

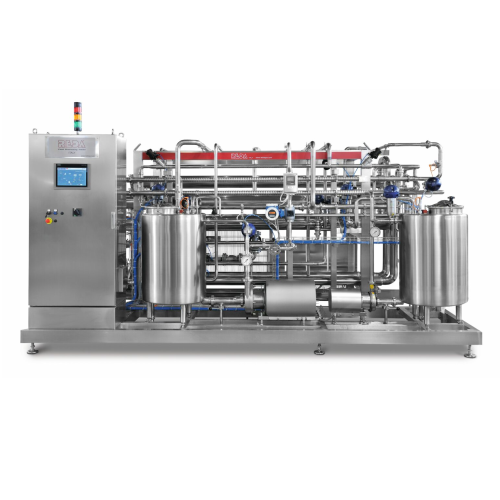

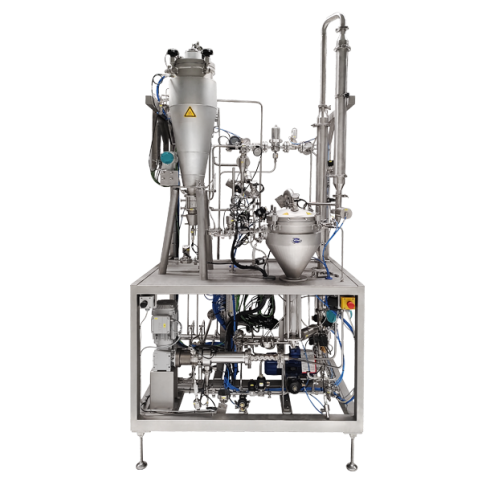

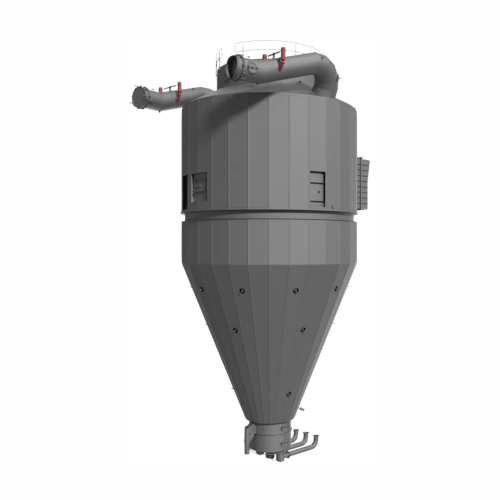

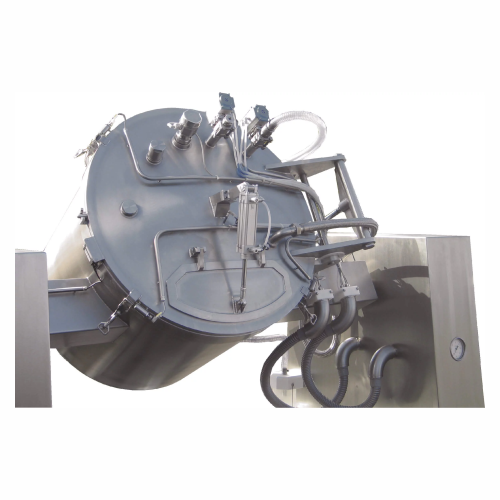

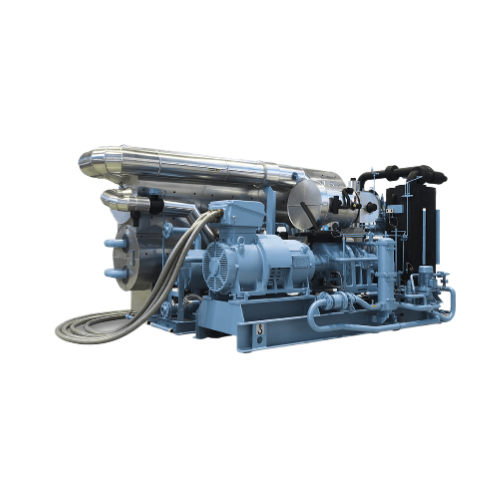

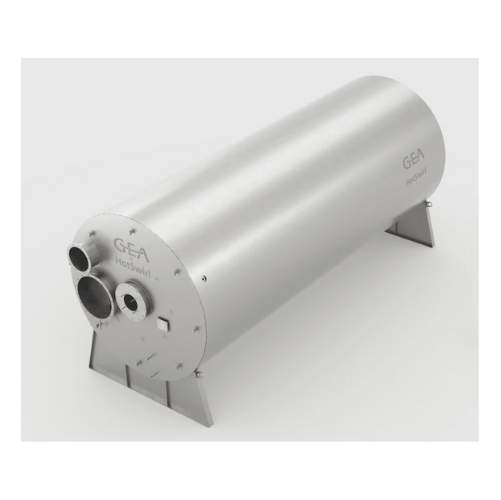

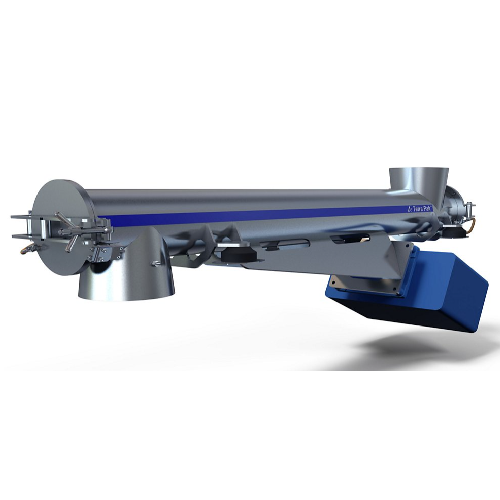

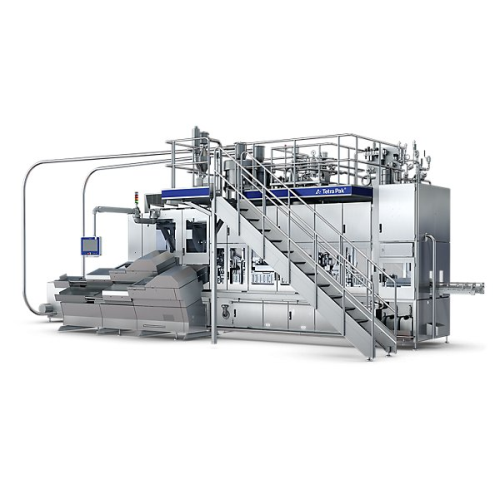

Continuous ultra-high temperature processor for processed cheese

Ensure precise thermal treatment and enhanced flavor re...

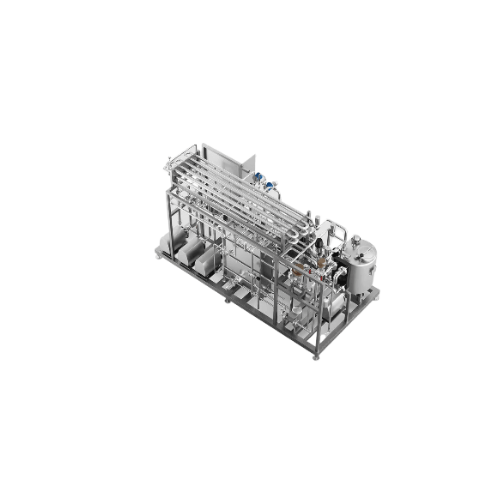

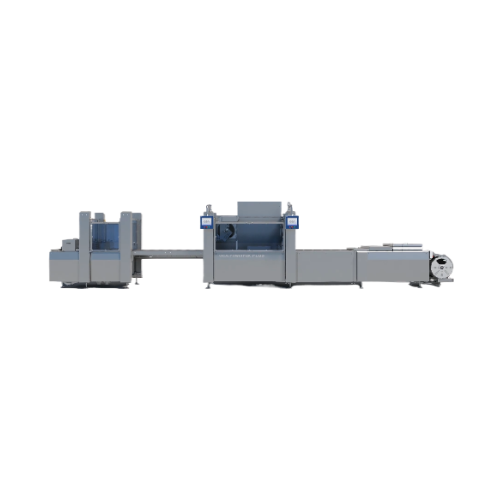

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

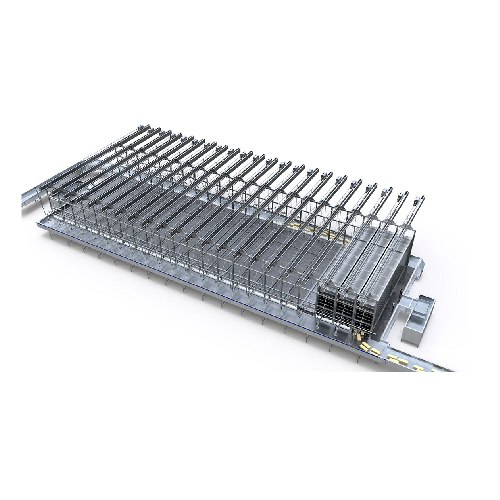

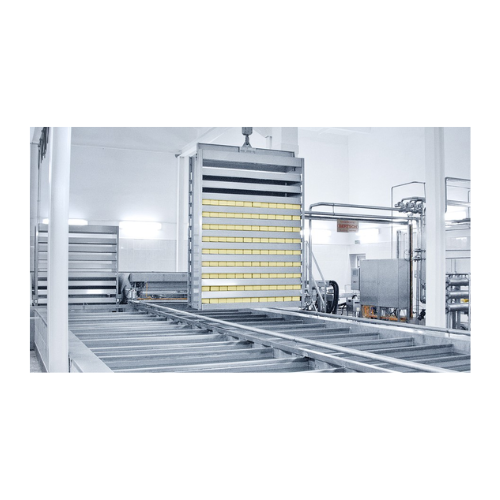

Mechanized systems for hard cheese molding rooms

Optimize your cheese production with advanced systems designed to streaml...

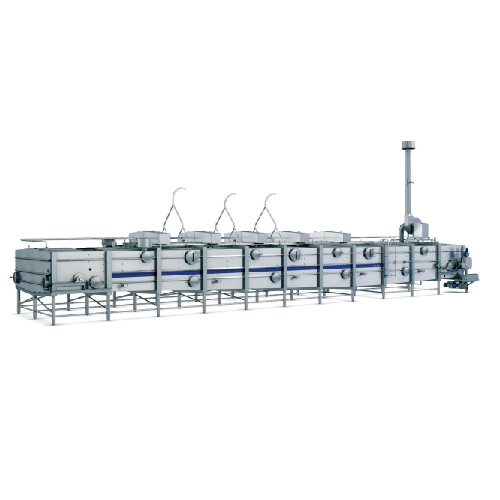

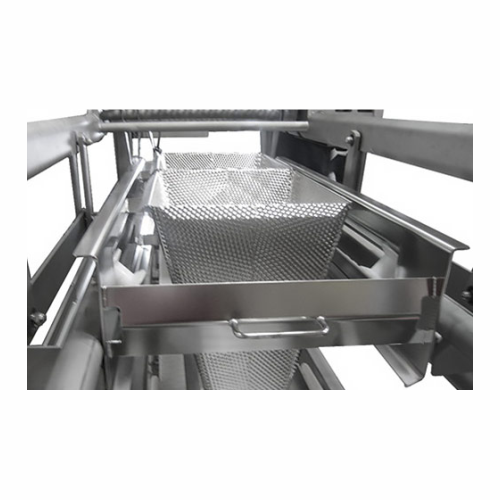

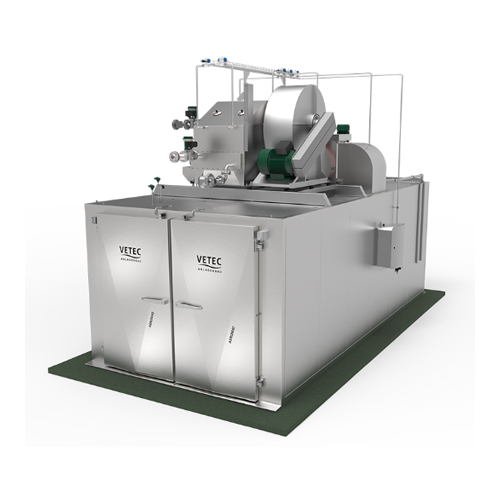

Cheese brine immersion salting system

Ensure consistent flavor and quality in cheese production by immersing blocks and whe...

Conditioners for cheese aging warehouses

Ensure precise temperature and humidity control in cheese aging warehouses to main...

Milk cream separation system for cheese production

Enhance your cheese production efficiency by seamlessly integrating a ...

Dynamic salting system for cheese production

Ensure even and efficient salting for soft and semi-hard cheeses with a dynam...

Multipurpose coagulation vats for cheese production

Streamline your cheese production process with multipurpose coagulati...

Curd drainers and portioners for cheese production

Enhance your cheese production with precise curd draining and portioni...

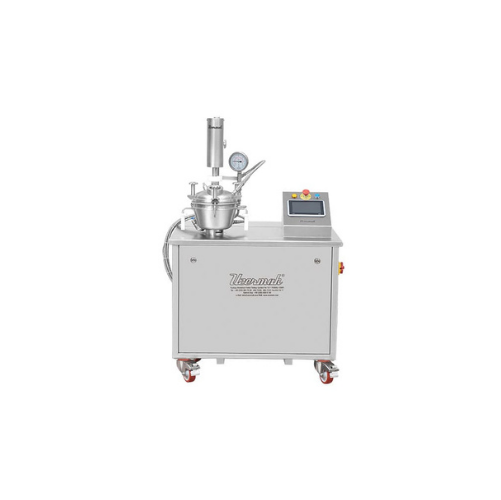

Mini dairy system for small-scale cheese production

Optimize your dairy production with a compact system designed for tra...

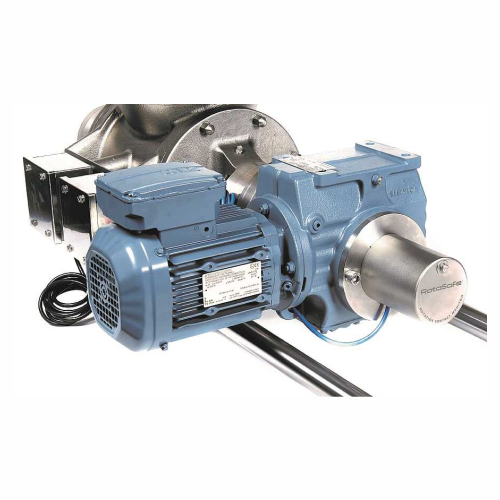

Rotary lobe pump for curds transfer in cheese production

Ensure gentle handling of delicate curds with rotary lobe pumps ...

Bottom valve for cheese vats

Enhance your cheese production efficiency with a flush-mounted bottom valve, designed for optim...

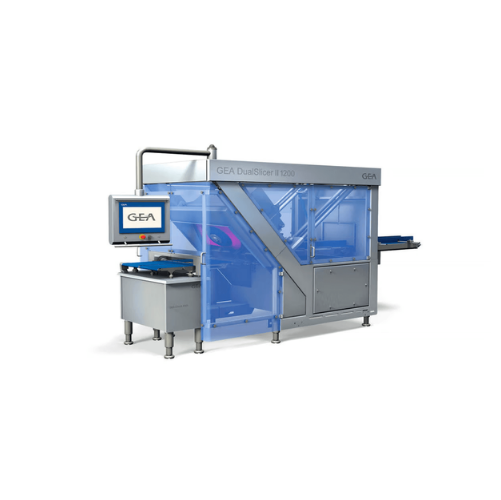

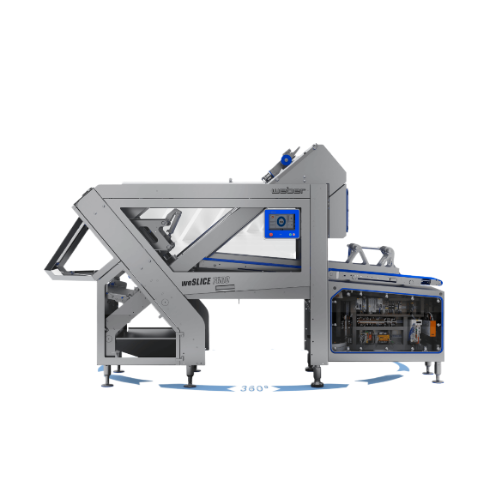

High-precision slicing for cheese and sausage products

Experience unparalleled slicing precision and efficiency with high...

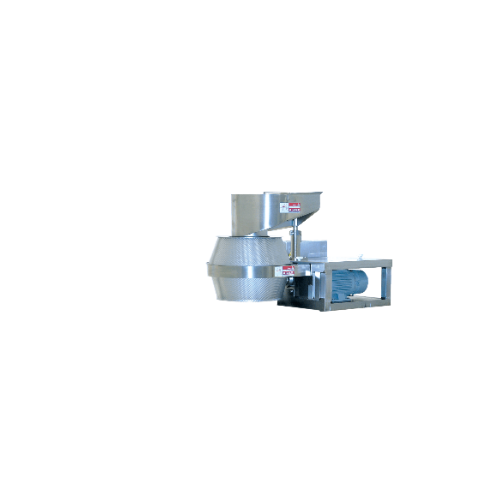

Professional grater for parmesan and hard cheeses

Enhance your processing line with a robust grater designed to efficient...

High-volume cheese cutting solution

Achieve unmatched precision in cheese processing with a high-volume cutting solution de...

Cheese belt for continuous production

Enhance your cheese production with a fully enclosed, adjustable belt system designed...

Cottage cheese vat for efficient curds production

Maximize cheese yield while minimizing curd damage with this advanced v...

Cheese blockformer for dairy industry

Achieve consistent cheese block quality and seamless curd fusion through precision en...

Curd table for cheese production

Streamline cheese production with effective curd separation, precise salt mixing, and relia...

Cheese vat for consistent curd size and low whey fats

Improve your cheese production with equipment designed for uniform ...

Tray packing for square and rectangular cheese portions

Optimize your cheese packaging line with high-speed tray forming ...

Cartoning system for triangular cheese portions

Streamline your cheese packaging process with precision-oriented cartoning...

Cheese portioning dosing and wrapping solution

Effortlessly streamline cheese portioning with high-speed dosing and wrappi...

High speed cheese dosing and wrapping solution

Achieve precise dosing and efficient wrapping of cheese portions with versa...

Cartoning solutions for processed cheese products

Optimize your cheese production line with a cartoning solution that ens...

Flow wrapper for processed meat and cheese

Optimize wrapping efficiency and hygiene in your meat and cheese packaging line...

Cartoning solution for cheese portions

Optimize your cheese packaging with a flexible cartoning solution designed to accomm...

Wrap-around cartoner for processed cheese portions

Streamline your cheese packaging with high-speed wrap-around cartoning...

High-speed cheese slice wrapper

Achieve unparalleled efficiency with the high-speed wrapping machine that securely packages ...

Lump-free emulsifier and steam batch cooker for processed cheese

Achieve consistent, lump-free processed cheese and crea...

Processed cheese slice wrapper

Effortlessly wrap individually-portioned cheese slices with precision and uniformity, ensurin...

Pilot unit for processed cheese slices

Perfect for R&D and small-scale production, this adaptable unit offers high fle...

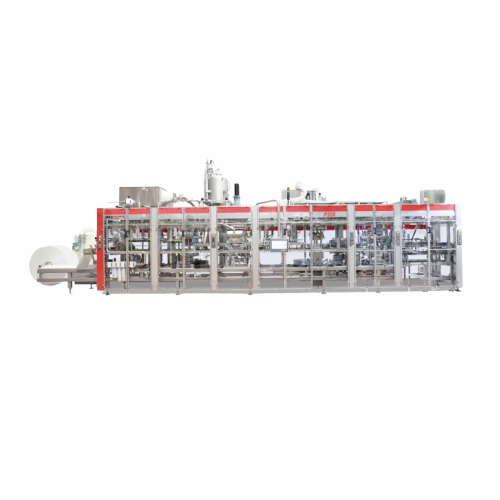

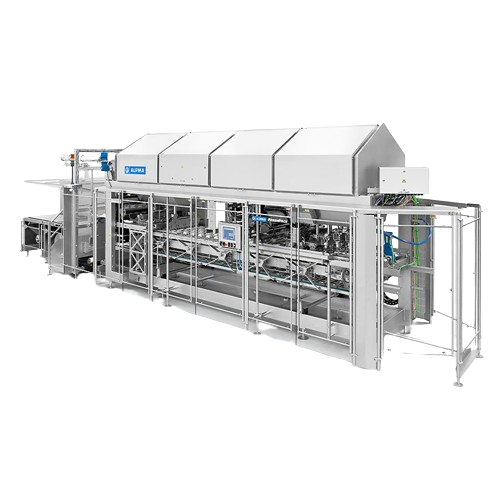

Processed cheese slice production system

Reduce recontamination risks in cheese production with a system designed for high-...

Cheese forming and slicing system

Optimize your cheese production with high-speed, precision forming and slicing, ensuring ...

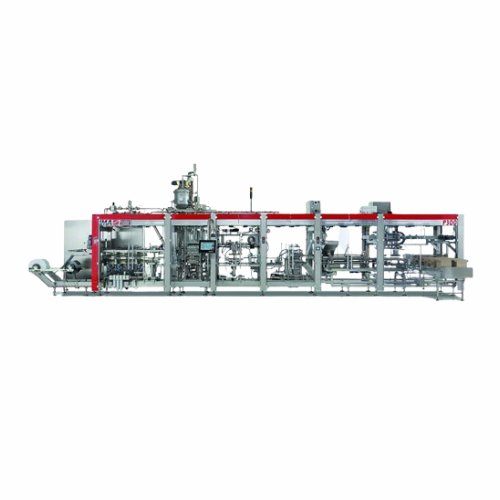

Individually wrapped processed cheese slice production line

Efficiently produce consistent, individually-wrapped cheese ...

Separating packed cheese products from packaging

Efficiently separate individual cheese portions from packaging, reducing ...

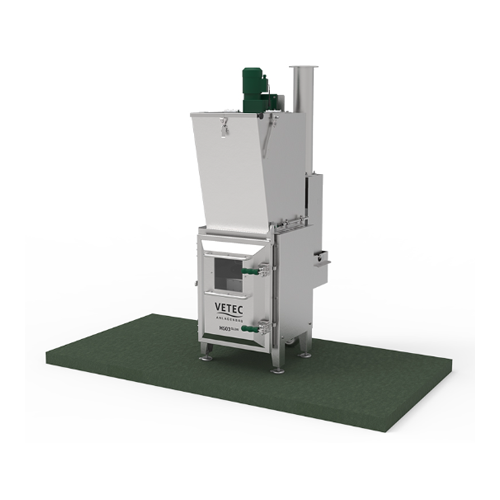

Cheese and butter block grinder

Efficiently transform frozen cheese and butter blocks into manageable sizes for continuous p...

Cheese packaging system for mixed cheese types

Optimize your cheese production line by seamlessly integrating a system des...

Processed cheese stick cutter

Achieve precise and consistent cheese stick production with a machine designed to streamline f...

Cheese ribbon cutting solution

Achieve precise and efficient cheese ribbon cutting with high-speed operations, ensuring perf...

Automatic cheese stack and grouping system

Efficiently stack and group cheese slices to streamline your production line an...

Processed cheese slice forming system

Effortlessly produce high-quality Slice-on-Slice cheese slices, cubes, shreds, and st...

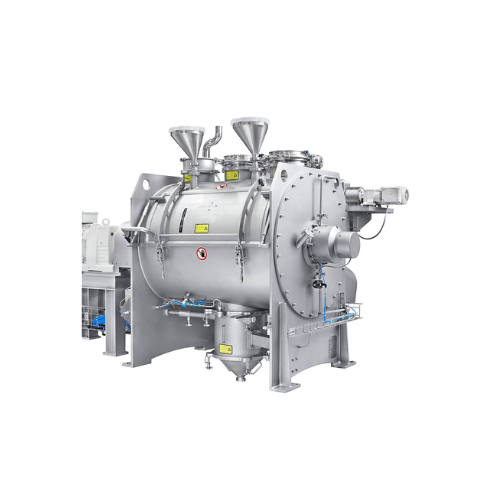

Multifunctional batch processing system for processed cheese

Enhance your production line with a sophisticated batch pro...

Batch processing system for processed cheese and sauces

Optimize your food processing line with a versatile batch process...

Batch processing system for processed cheese and various food products

Optimize your food production line with a multif...

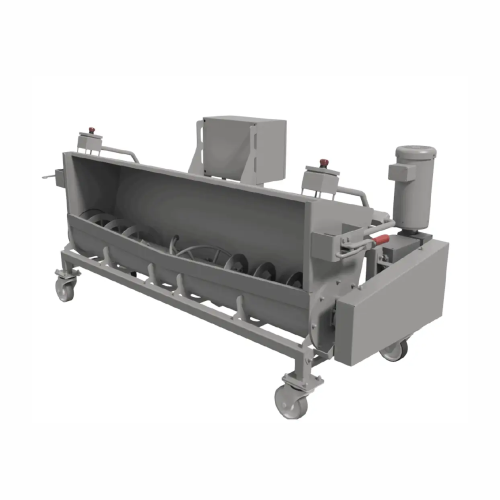

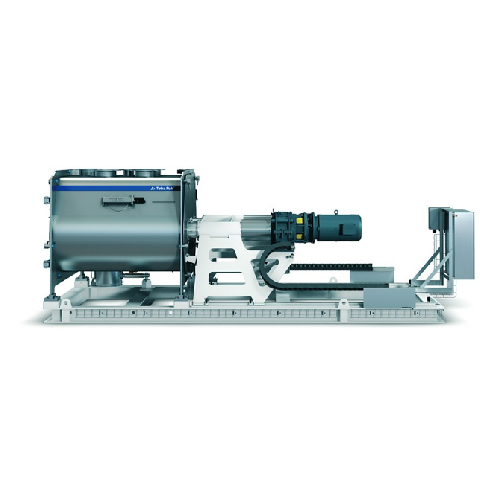

Twin ribbon blender for processed cheese and meat products

Achieve seamless blending and consistent feeding for large-sc...

Cheese grinder for fine cheese grinding

Achieve optimal protein emulsification and minimize waste with this high-capacity g...

Cheese cube and shreds production line

Achieve precision cutting for cheese products while seamlessly integrating forming a...

Vertical cheese portioning system

Achieve precise and customizable cheese portioning with a system that adapts to various s...

Semi-automatic cheese portioning solution

Enhance your cheese processing capabilities with a versatile portioning solution...

Automatic foil unpacking system for cheese

Streamline your cheese production with cutting-edge technology designed to repl...

Double cheese shredder for soft, semi-hard and hard cheeses

Optimize your cheese production with a robust shredding solu...

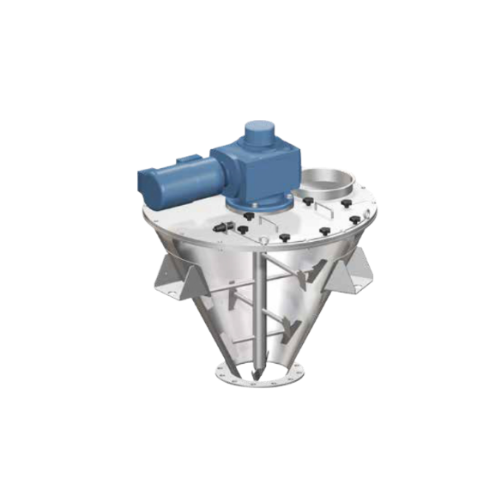

Mixing drum for shredded cheese

Optimize your dairy production line with this innovative mixing drum designed to effortlessl...

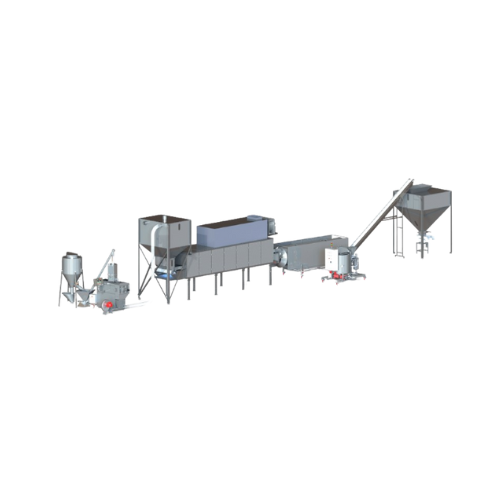

Cheese shredding line for large volume production

Achieve seamless cheese processing with a fully integrated shredding li...

Cheese cubing solution for further processing

Optimize your cheese processing efficiency by transforming whole cheese bloc...

Square and rectangular cheese cutter for bars and halves

Perfect for cheese processors needing precision, this machine ef...

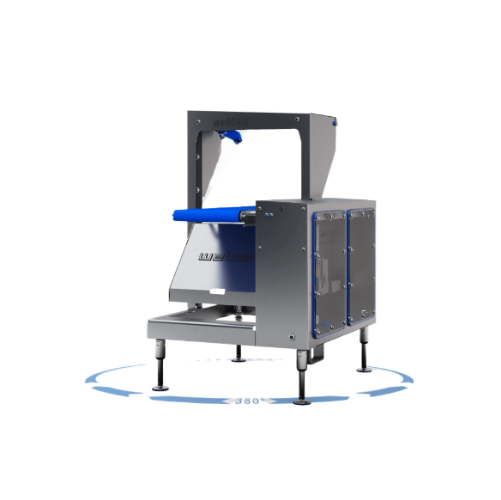

Automatic cheese slicer feeder

Optimize your cheese processing line with a fully automatic solution designed to streamline s...

Fully automatic slicer feeder for cheese bars

Enhance your cheese processing efficiency with high-speed slicing and sortin...

Automatic slicer feeder for large cheeses

Streamline your cheese processing with a system designed to seamlessly transform...

Cheese portion cutter

With ultrasonic precision, this semi-automatic cutter transforms cheese blocks into uniform portions an...

Cheese portion cutting solution

Achieve precise weight-based portions for cheese products, enhancing product consistency and...

Cheese shape cutter for custom designs

When producing cheese snacks, achieving precise and creative shapes quickly is essen...

Cheese shape cutter for animal, letter, and custom designs

Transform cheese slabs into creative shapes with precision, e...

Cheese snack cutter for various shapes and sizes

Streamline your cheese production with precision cutting for a variety of...

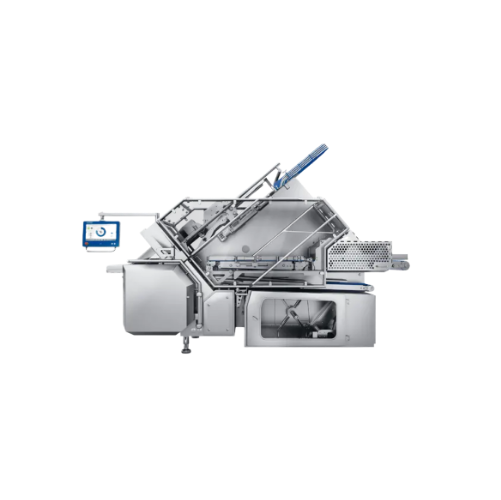

Automatic cheese derinding system for rectangular cheeses

For cheese processors seeking effortless precision, this machi...

Cheese shredding solution for soft, semi-hard, and hard cheeses

Maximize cheese processing efficiency with precise shred...

Automatic solution for unpacking foil-ripened cheese

Streamline your cheese processing with this fully automated solution...

Automated cheese unpacking and cutting line

Streamline your cheese production process with a fully automated system capabl...

Cheese portion thermoforming system for automation

Optimize your cheese production with precision portioning and efficien...

Cheese cutting machine for various cheese types

Optimize your cheese and meat processing line with high-speed, precise cut...

Disk cutter for round and block cheese

Achieve precise portioning for varied cheese formats with our versatile disk cutter,...

Automatic cutting machine for cheeses and cold cuts

Enhance production efficiency with precise, automated slicing and dic...

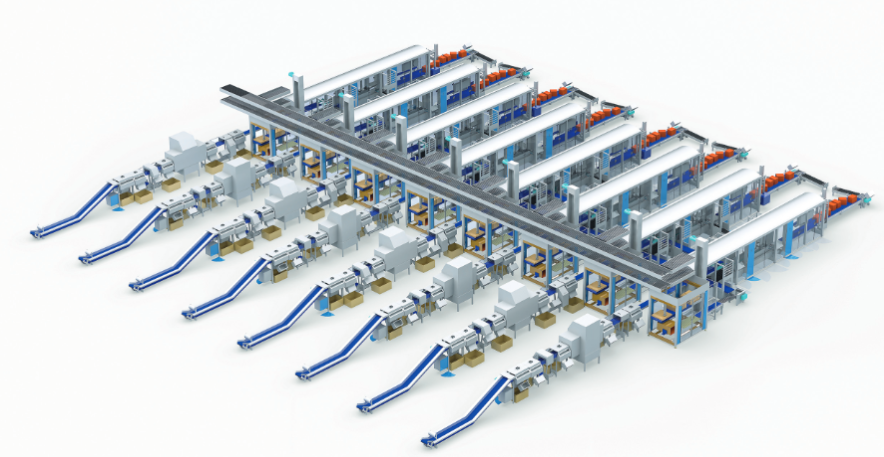

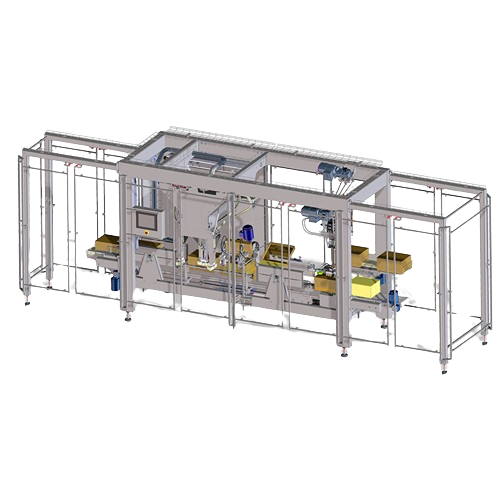

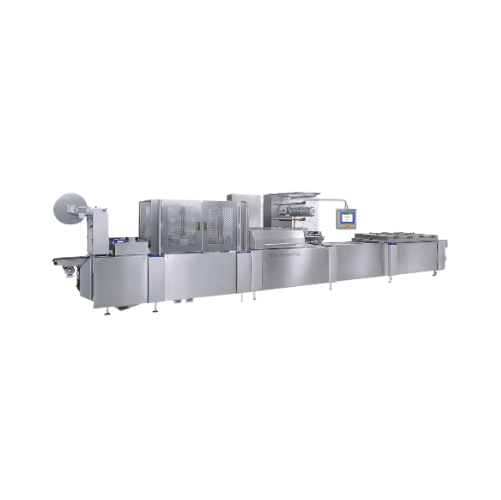

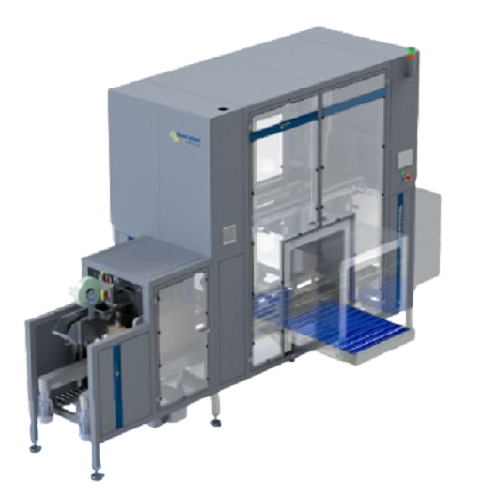

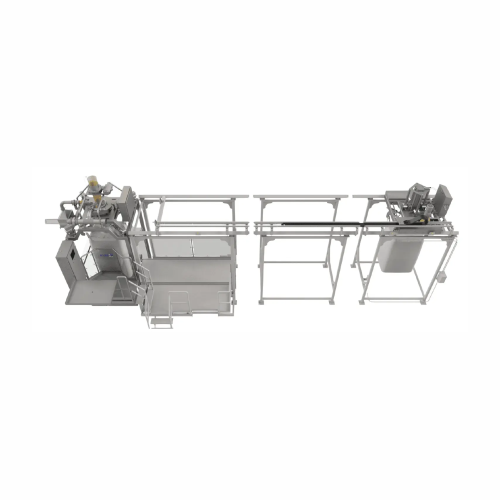

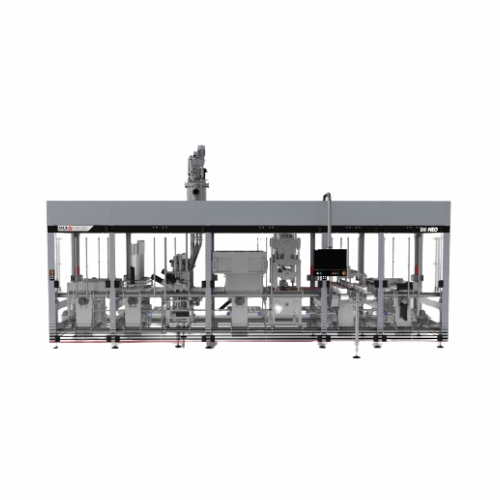

Automation system for cheese processing

Optimize your cheese production line with seamless integration to ensure consistent...

Wedge aligning robot for hard cheese

Streamline your cheese processing with precision and efficiency; this solution expertl...

Cheese dicer for precision cuts

Streamline your cheese processing with unparalleled precision and versatility, ensuring clea...

High-capacity cheese dicer with sanitary design

For high-volume cheese producers, achieving consistent cube cuts without p...

High-capacity shredder for cheese processing

Achieve impeccable cut accuracy and consistent shred dimensions for high-volu...

Cheese shredder for high-volume applications

Streamline your cheese processing with a high-capacity shredder designed to d...

Full block cheese shredder

Maximize your production line’s efficiency with a versatile shredder that seamlessly proces...

Automatic cheese washing system for dairy industry

Ensure your cheese production maintains optimal hygiene and efficiency...

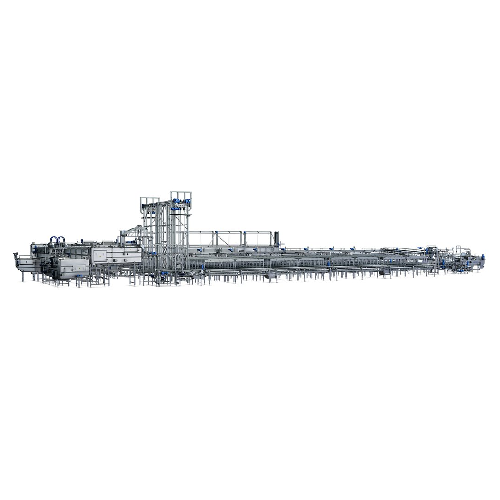

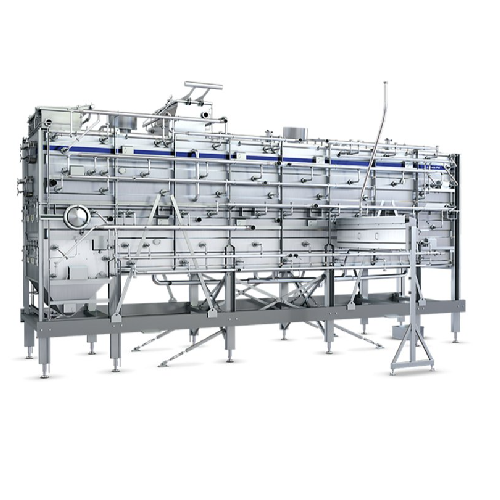

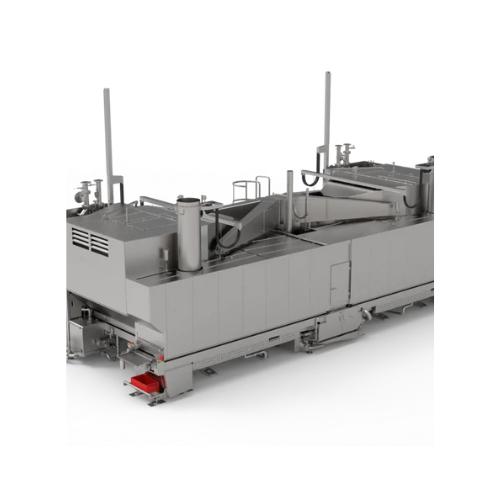

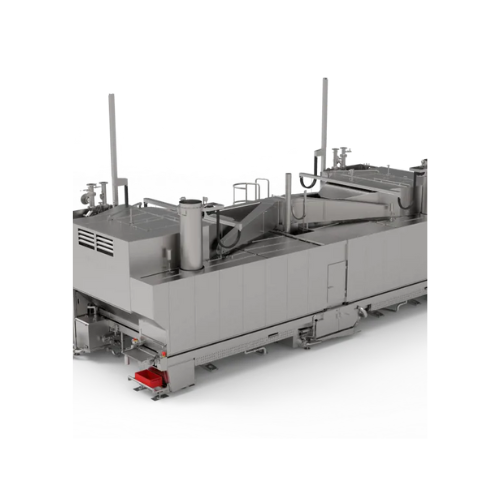

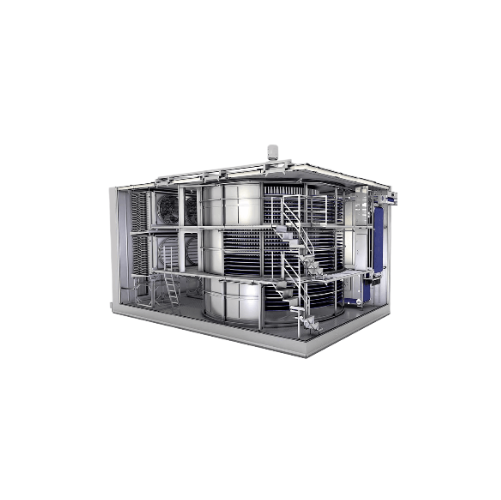

Industrial cheese processing plants

Streamline your cheese production with custom-engineered systems designed to enhance ef...

Cheese processing plant

Transform your dairy processing with comprehensive, tailored systems designed to optimize production ...

Cheese processing plant for hard and semi-hard cheese

Optimize your cheese production with a versatile solution designed ...

Cheese vat for varied cheese types

Ensure consistent high-quality cheese production with a vat that accommodates multiple c...

Cheese vat for diverse cheese production

Optimize your cheese production with a versatile cheese vat designed for precision...

Blue cheese loaf cutting system

Optimize your cheese production with precise and flexible cutting, transforming whole loaves...

High-speed fixed-weight cheese portion cutter

Optimize your cheese production with high-speed, precise portioning equipmen...

Cheese portioning system for pre-divided cheese loaves

Efficiently transform pre-divided cheese loaves into neatly segmen...

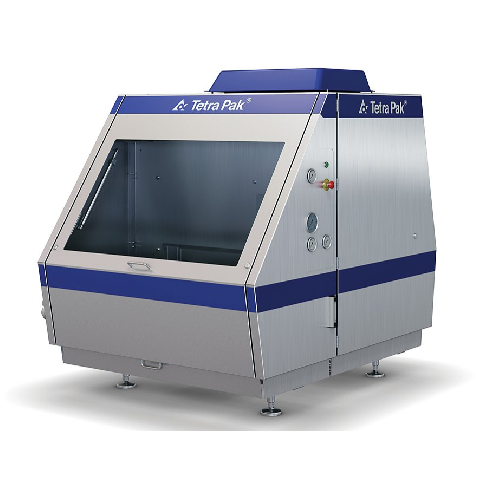

Inspection system for detecting film shreds and mould on cheese blocks

Ensure flawless cheese quality by detecting hidd...

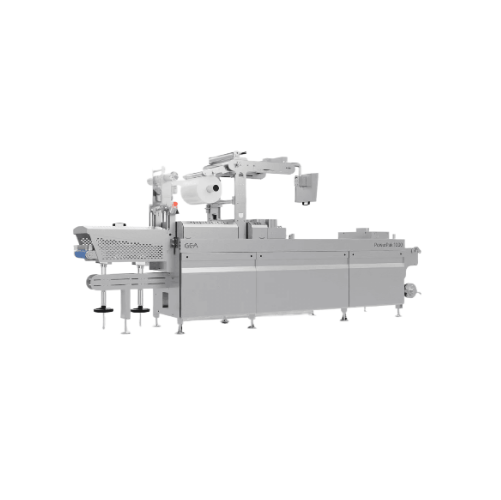

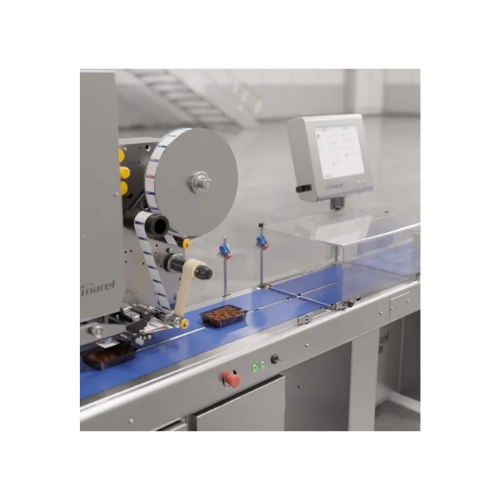

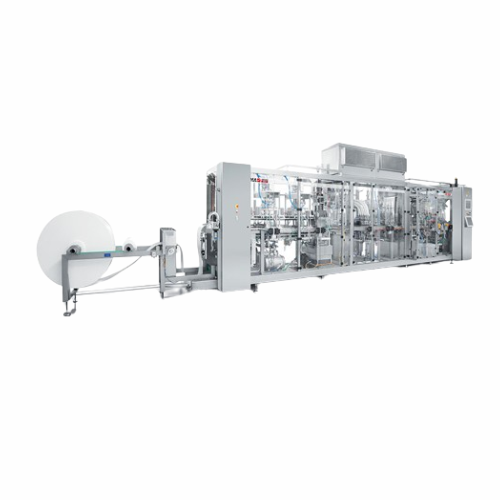

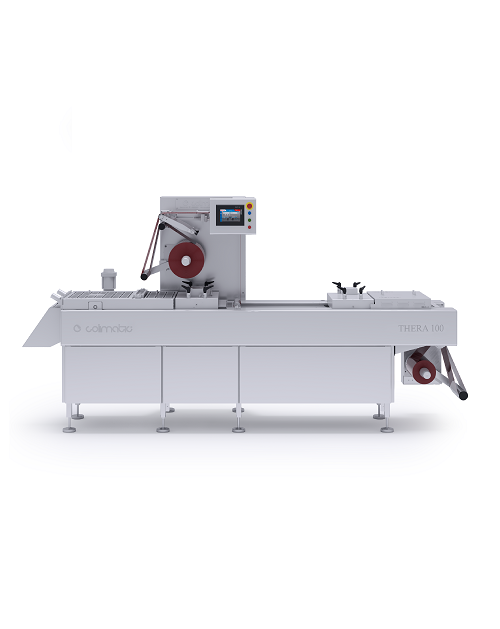

Automatic packaging for small cheese products

Effortlessly package a variety of cheese shapes and sizes with quick format ...

Packaging solution for soft cheese portions

Maximize your production efficiency by seamlessly cutting, wrapping, and boxin...

Industrial cheese cube cutter

Achieve precise and consistent cheese cube portioning with high-speed operation, ensuring idea...

Fixed-weight portion cutter for cheese bars

For cheese manufacturers requiring precision, this equipment ensures consisten...

Square portion cutting system for cheese

Optimize portion consistency and reduce waste with an advanced cutting system that...

Cheese cutting solution for large round cheeses and blocks

Efficiently segment and portion diverse cheese types, whether...

Hydraulic cutter for semi-hard cheese

Efficiently portion and cut semi-hard cheese and mozzarella into precise blocks, whee...

Hydraulic cheese cutter for round and block cheese

Optimize your cheese production with precise cutting for various chees...

Speciality cheese cutting system

Efficiently cut and portion a variety of cheese types, from mozzarella to cheddar, into pre...

Cheese slicer for brie wheel segmentation

Achieve precise cheese segment slicing effortlessly, optimizing your production ...

Block cutter for dividing cheese into bars

Effortlessly transform blocks of semi-hard cheese into uniform bars, ensuring o...

Cheese block cutting solution for small to medium batches

Efficiently divide large cheese blocks into precise bars or po...

Cheese bar and halved loaf cutter

Streamline your dairy production by efficiently transforming semi-hard and soft cheeses i...

Automatic loading system for sliced cheese packaging

Streamline your packaging operations with precise loading and contin...

Industrial slicer for cooked ham and cheese

Enhance your processing efficiency with high-precision slicing for deli meats ...

Industrial slicer for sausage, ham, and cheese

Achieve precise and consistent slicing for meats and cheeses while minimizi...

Slicer for calibrated meat and cheese products

Achieve precise, high-speed slicing and portioning of calibrated meats and ...

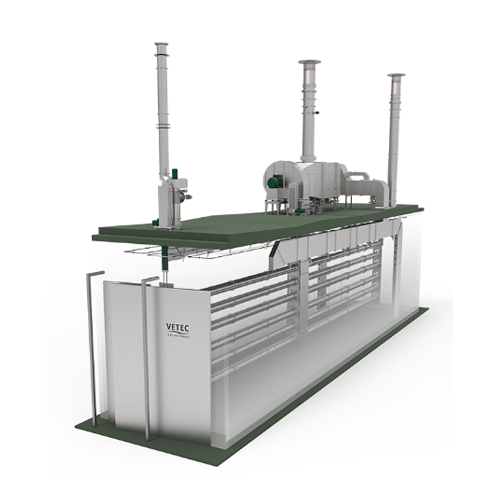

Filtration brine sanitation unit for cheese production

Ensure your cheese retains its premium quality and flavor by effec...

Stretching machines for dry and hard cheeses

Enhance your cheese production with a system that ensures precise stretching ...

Hot water stretching and molding unit for cheese production

Revolutionize your cheese manufacturing process with a compa...

Hot water stretching machines for mozzarella cheese production

Enhance mozzarella cheese production with precision-contr...

Drum molding machine for soft pasta filata cheeses

Achieve precise molding and consistent product quality in your cheese ...

Molding equipment for provolone and caciocavallo cheese

Optimize your cheese production with advanced molding equipment, ...

Molding and pre-hardening unit for pizza cheese

Achieve precise molding and effective pre-hardening of pizza cheeses with ...

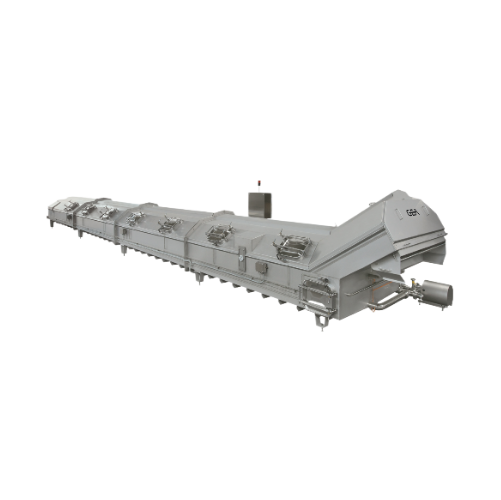

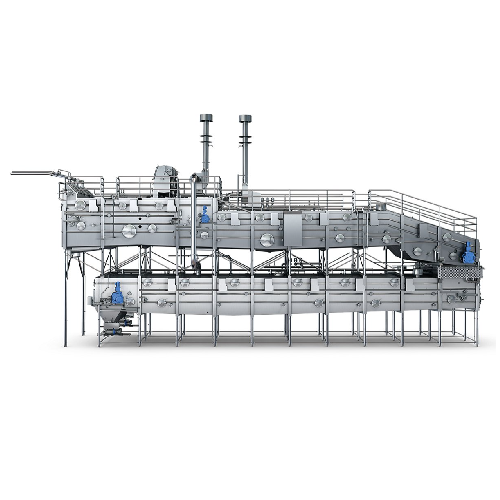

Continuous curd drainage and maturation systems for pasta filata cheese

Enhance your cheese production by optimizing cu...

Curd drainage and maturation system for pasta filata cheese

Enhance your cheese production with an automated system desi...

Curd handling and cutting for cheese production

Optimize curd processing with precise cutting and feeding, ensuring consis...

Hydraulic cradle vats for pasta filata cheese production

Optimize your cheese production line with versatile hydraulic se...

Brining vats for pasta filata cheese

Enhance your cheese production with modular brining vats, designed for precise salt ad...

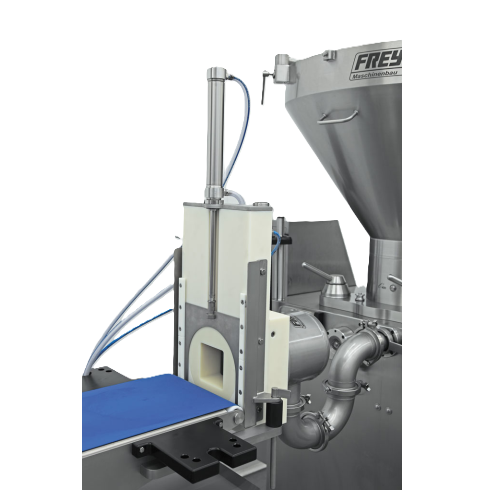

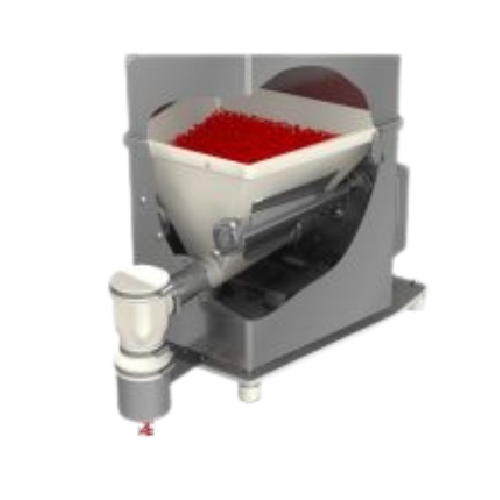

Dry salt dosage system for curd cheese production

Streamline your cheese production with precise salt dosing, ensuring op...

Hot water heaters for pasta filata cheese

Optimize your pasta filata cheese processing with precise heating control and ef...

Liquid salt dosage systems for pasta filata-type cheeses

Achieve precise salinity control and optimal temperature for you...

Steam stretching system for pasta filata cheese

Optimize your cheese production with a system that seamlessly integrates s...

Clarifying decanters for cheese curd production

Achieve precise separation and clarification of cheese curds, casein, and ...

Circular blade slicer for cheese and deli products

Optimize your slicing operations with precise portion control and vers...

Drying and smoking solution for meat, fish, and cheese

Optimize your production with precise climate control, ensuring co...

Cheese moulder for cylindrical portions

Ensure precise portioning and molding of cheese into cylindrical forms, enhancing y...

Uht system for processed cheese

Ensure the extended shelf life and freshness of various cheese products with precise ultra-h...

Steam cooker and stretcher for cheese processing

Optimize your cheese production with a versatile solution designed to eff...

Steam cooker and stretcher for cheese production

Easily integrate versatile steam cooking and stretching to enhance your c...

Multifunctional cheese and sauce processor

Optimize your production of sauces, dressings, and confectionery fillings with ...

Multifunctional industrial mixer for processed cheese and sauces

Optimize your batch production with a versatile solutio...

Cheese vat for various cheese types production

Optimize curd formation and whey separation for diverse cheese types with a...

Industrial cheese shredder

Optimize continuous food processing with a machine that handles high-speed shredding, slicing, cu...

Industrial cheese shredder for dairy processing

Optimize your cheese and potato processing with this advanced shredding so...

Precision cheese dicer for small to mid-range cuts

Efficiently transform cold-temperature cheeses into precision cuts wit...

Cheesecake production system for automated baking

Enhance your dessert production line with a versatile system that autom...

Automated filling and coagulation line for u.f. white cheese

Enhance your cheese production with a state-of-the-art syst...

Glass jar filling system for processed cheese

Streamline your production line with a robust, high-speed filling solution d...

Professional slicer for cold cuts, meat, cheese, and bread

Achieve precise and consistent slicing of cold cuts, cheese, ...

Professional meat and cheese slicer

Achieve precision in slicing cold cuts, cheese, and bread with consistent thickness and...

Professional cheese grater tool

Optimize your food preparation with a versatile tool that efficiently grates, slices, and gr...

Industrial hard cheese grater

Optimize your food preparation process with high-speed grating, perfect for transforming hard ...

String cheese cutter for continuous production

Enhance your cheese production line with precise, adjustable length cutting...

Extruder for string cheese production

Efficiently process pasta filata cheeses into uniform shapes with precise temperature...

Precision moulding and cutting for pasta filata string cheese

Eliminate variations in string cheese production with prec...

Cheese mould handling system for semi-hard and hard cheeses

Streamline your cheese production with an advanced system de...

Whey tray system for cheese pressing

Optimize cheese production with an innovative system that efficiently presses semi-har...

Gdl and rennet dosing solution for white cheese production

Optimize white cheese production by dramatically reducing aci...

Inline white cheese rennet dosing unit

Optimize your cheese production with precise rennet dosing, ensuring consistent and ...

Mozzarella cheese moulding system

Optimize your cheese production with fully automated moulding and setting, ensuring consi...

Cottage cheese curd drainer

Achieve optimal whey-free cheese production with this advanced drum drainer that ensures gentle ...

Cooling system for cottage cheese curd washing

Enhance your cheese production with a cooling tower designed for precise cu...

Salting mellowing conveyor for cheese curd

Achieve optimal salt distribution and retention in your cheese production with ...

Salt dispenser for cheddar cheese production

Achieve consistent salt concentrations in cheese production with a reliable d...

Cheese salt dosing unit

Optimize your cheese production with precise salt dosing, ensuring consistent flavor and quality in e...

Fresh cheese vat paddles for gentle curd preparation

Ensure optimal curd integrity and reduce product loss with advanced ...

Cheese curd preparation vat for cottage cheese

Streamline your cheese production process with a high-efficiency vat tailor...

Draining matting solution for granular or matted curd cheese

Optimize your cheese production with a continuous, automate...

Continuous cheese and whey production system

Streamline your cheese production process with a system that handles whey dra...

Fresh cheese former for hygienic production

Streamline your cheese production with a hygienic and no-mould solution that s...

Cottage cheese draining and washing unit

Enhance your production line efficiency with a high-capacity unit that drains, was...

Cooking and stretching solution for pasta filata cheese

Streamline your cheese production with precise cooking and stretc...

Cooker stretcher for pasta filata cheese

Enhance cheese quality and yield with this high-capacity cooker stretcher, designe...

Vertical blender for cottage cheese production

Optimize your cottage cheese production with a first-of-its-kind vertical b...

Crumbled cheese buffer for blending with additives

Effortlessly create diverse cheese products with precise ingredient bl...

Curd making vat for cheese production

Achieve optimal curd consistency and maximize cheese yield with advanced dual agitato...

Cheese curd production vat for semi-hard cheese

Optimize your cheese production with a vat designed to ensure precision in...

Cheese vat for high-yield cheese production

Maximize cheese production with minimal space, ensuring superior quality and e...

Horizontal curd making vat for cottage cheese

Achieve consistent curd quality with a fully enclosed vat that minimizes con...

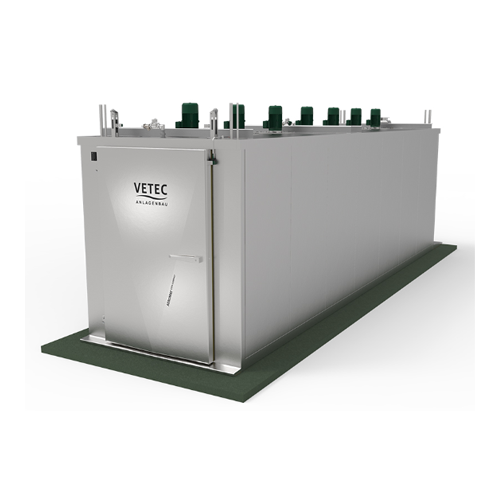

Efficient brining system for cheese production

Ensure precise temperature control and consistent quality in your cheese pr...

Brining system for semi-hard cheeses

Achieve consistent salt uptake and quality control in semi-hard cheese production with...

Automatic bag former for cheese blocks

Streamline your cheese production with a high-speed solution that forms and loads ba...

Cheese curd cooling system for crumbled cheese

Ensure optimal cheese quality and yield with precise, gentle cooling for cr...

Industrial-scale vacuum packing for fresh meat and cheese

Optimize packaging operations with this machine designed for h...

Automatic belt chamber vacuum packing for meat and cheese

Achieve seamless integration into your packaging line with a m...

Filler for yoghurt and white cheeses

For manufacturers seeking efficient, versatile filling for products like yoghurt and s...

Foil wrapping machine for cream cheese

When producing cream cheese and selling them in foil wrapped bricks you need a relia...

Grated cheese case packing machine

Large-scale cheese manufacturers process and handle products of different sizes and volu...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Cheese grater

Breaking down large blocks into grated, shredded, powdered or planed cheese requires multiple graded discs that ...

Centrifuge water saving unit for sustainable cooling

Reduce your cooling water consumption by 99.9% with this efficient s...

Bacteria removal separators for milk and whey

Optimize your dairy production by effectively removing bacteria and spores f...

Topping depositor for pizzas and baked goods

Enhance your production line’s efficiency by uniformly adding both dry ...

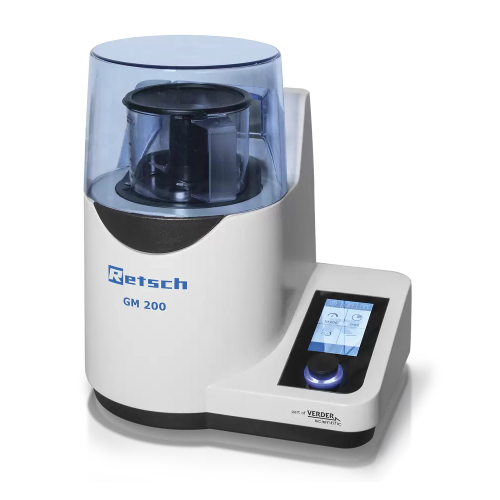

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reduc...

Milk standardization system

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

Clarifier for milk and whey

Optimize dairy and beverage production by efficiently removing fine curd residuals, ensuring hig...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

Cup filling and sealing system for dairy products

Optimize your production line with versatile cup filling and sealing ca...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Steam cooking system for dairy production

Ensure precise temperature regulation and efficient moisture control in cheese a...

Refrigerated fermentation tank with cold water jacket

Enhance the precision of your cheese production with advanced therm...

Dynamic brine salting system for dairy production

Streamline your cheese salting process with a system designed to handle...

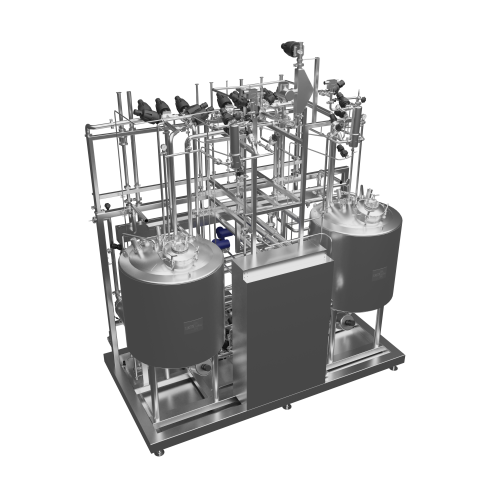

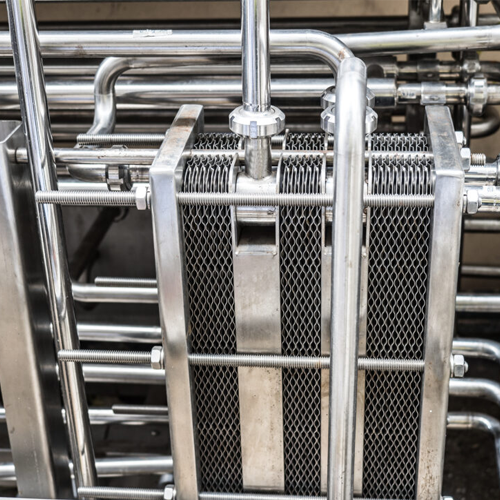

Ultrafiltration system for brine regeneration

Optimize your cheese and brine processes with a versatile ultrafiltration sy...

Whey concentration system with reverse osmosis

Optimize your cheese and dairy production with our reverse osmosis concentr...

Ice storage tanks for dairy industry

Ensure optimal temperature control and efficiency in cheese production with robust ice...

Condensing unit for ice storage tanks

Enhance the longevity and quality of your dairy and cold storage products with a robu...

Industrial cold storage solutions

Ensure precise temperature control and optimal storage conditions for a diverse range of ...

Automated milk dosing system for dairy production

Ensure precise milk allocation for diverse cheese types with this robus...

Precise starter culture dosage system for dairies

Ensure precise integration of starter cultures into your cheese product...

Stacked block mold tipping solution

Efficiently manage block molds with this tipping solution designed to streamline cheese...

Deodorizing units for milk pasteurization

When handling dairy products, controlling odors during pasteurization is crucial...

Mechanical conveyors for powder transport

Optimize your powder and granule handling with precise, customizable conveying s...

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

Flexible connector system for bulk powder processing

Eliminate leaks and enhance hygiene in your powder processing line w...

Food product smoothing system for dairy and purees

Achieve unparalleled texture and fineness in viscous food products wit...

Laboratory homogenizer for viscous products

Achieve ultra-fine textures and improved consistency in pasty and semi-pasty p...

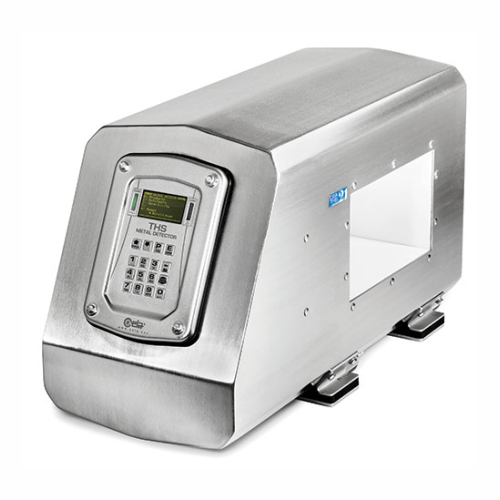

Industrial metal detector for packaging lines

Ensure product safety and compliance by detecting metallic contaminants in p...

Labelling and marking solutions on flowpackers

Achieve unmatched precision and flexibility in packaging with labelling and...

Industrial shrink and drying units for food products

Ensure optimal product integrity and extended shelf life by seamless...

Belt loaders for automated food packaging

Streamline your packaging line with precision-engineered belt loaders, designed ...

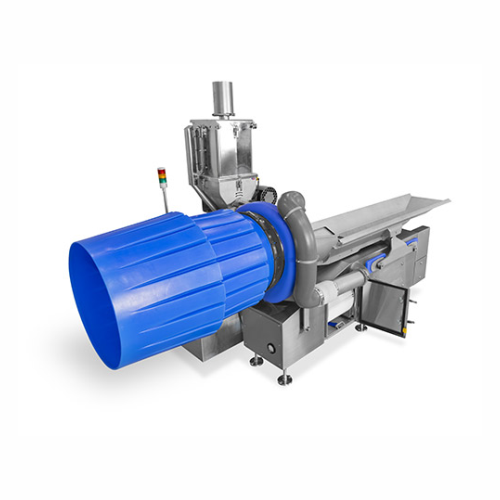

Centrifuge feeder for sausage production lines

Optimize your sausage production line with an efficient centrifuge feeder t...

Automatic checkweighers for precise weight control

Ensure accurate weight compliance and enhance quality control with adv...

Automatic gravity slicer for retail and supermarkets

Perfect for precision slicing, this equipment offers high-speed oper...

Multi-purpose vegetable cutter for various cuts

For efficient kitchens needing versatile precision, this solution excels i...

Vacuum preservation system for professional packaging needs

Enhance your food product longevity and quality with precise...

Airless vacuum packaging system

Ensure maximum freshness and extend shelf life with advanced vacuum packaging technology, fe...

Gravity slicer for supermarkets and catering

Enhance your deli section with precision slicing, delivering uniform cuts for...

Vertical slicing for retail and catering

Optimize your deli slicing with precision-engineered vertical slicers, designed fo...

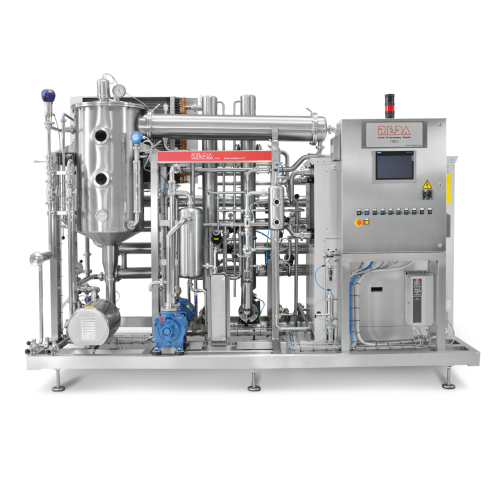

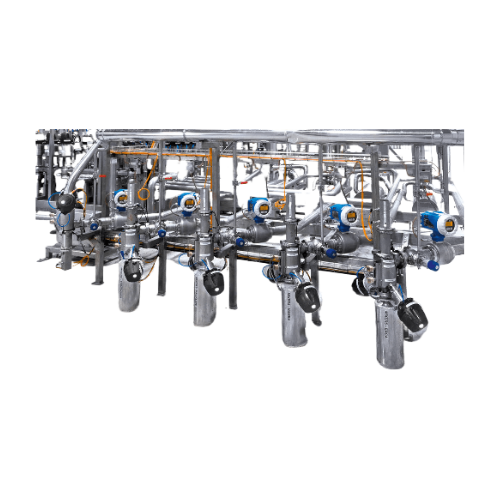

Cleaning-in-place (cip) systems for hygienic processing

Elevate hygiene standards in your liquid processing line with an ...

Homogenizer for dairy products

Achieve precise texture and quality in dairy products with this versatile homogenizer, design...

High-speed portion cutter with preforming option

Achieve precision and efficiency in portioning with high-speed cutting an...

Industrial fryer for uniformly cooked convenience foods

Ensure perfectly fried textures and flavors with cutting-edge oil...

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

Inline mixer for uniform powder blends

Achieve uniform powder blends in minutes with this high shear inline mixer, designed...

Vegetable and fruit dicer for commercial use

Efficiently transform a variety of produce into precise cubes, slices, or shr...

Commercial vegetable processing line for cabbage

Efficiently handle high-capacity vegetable processing with versatile slic...

Vegetable and fruit shredder for medium-sized operations

Enhance your vegetable and fruit processing efficiency with this...

Commercial food drum mixer for sauerkraut and salads

Streamline your batch production with this versatile commercial food...

Hollow fiber membranes for clarification in food and beverage industry

Optimize filtration and separation processes wit...

Curd unloader for dairy production

Streamline your cheese production with efficient curd unloading and transfer, ensuring s...

Curd coagulation detection system

Ensure precise coagulation timing with a system that monitors curd firmness, enhancing yi...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Cip cleaning system for dairy industries

Ensure hygienic operation with this system, designed to maintain optimal cleanline...

Dosing and wrapping solution for pasty products

Achieve precise dosing and efficient wrapping of pasty products with high-...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

High-speed dosing and wrapping for butter and margarine

Achieve precision in butter and margarine packaging with a high-s...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

Filling and sealing system for yoghurts and desserts

Efficiently fill and seal a variety of dairy and dessert products wh...

Tub filling and sealing for pasty products

Experience high-speed, precision tub filling and sealing designed for pasty pro...

Map flow wrapper for chilled food packaging

Optimize your chilled food packaging with a flow wrapping solution that easily...

Cup forming, filling, and sealing solution

Optimize your cup production with a compact solution designed for precise formi...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Multifunctional batch cooker for various food products

Optimize your production line with a versatile batch cooker design...

Continuous cooker for high-volume food processing

Elevate your production efficiency with a continuous cooker that ensure...

R&d scale steam cooker for small batch processing

Optimize your R&D with a steam cooker that replicates large-scale ...

Mozzarella cooker stretcher for continuous production

Experience continuous mozzarella production with steam injection te...

Hygienic conveyor belts for food manufacturing

Ensure bacteriological safety and boost productivity with hygienic conveyor...

Magnet for emulsion technology for lump-free blends

Achieve perfectly smooth and stable emulsions in a single pass with a...

Automated filter cleaning system for food production lines

Eliminate frequent production interruptions by utilizing an a...

Seasoning drum for extruded snack products

Achieve consistent seasoning and mixing for extruded snacks with precision and ...

Pipeline metal detection for pumpable products

Ensure safety and quality by detecting and rejecting metal contaminants in ...

In-line seal checker for high-speed snack packaging

Ensure flawless package integrity with in-line leak detection, enhanc...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this...

Oil cooling module for industrial fryers

Quickly cool frying oil to prevent thermal shock and maintain oil quality, allowin...

Flexible fryer for various snack products

Optimize your snack production with a fryer that adapts to varied product requir...

Multi-lane forming system for 3d food product shapes

Achieve precise weight accuracy and high-speed production of diverse...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Precision emulsification equipment for food industry

Achieve precise comminution and emulsification for diverse food text...

Laboratory mixing plant for small scale food production

Achieve precise control over small batch food processing with a v...

High-speed mixer for granulating and mixing powders

Achieve consistent granulation and mixing with precise temperature co...

Emulsifying plant for pasty and liquid products

Optimize your production line with seamless emulsification processes, desi...

Pneumatic knife for forming and cutting pasty products

Achieve precision and speed in forming and cutting various pasty p...

High-capacity belt dicer for meat and poultry

Enhance your processing line’s versatility with a solution engineered ...

Vegetable and fruit dicer

Achieve uniform cuts and reduce waste in your food processing line with a versatile dicer designed...

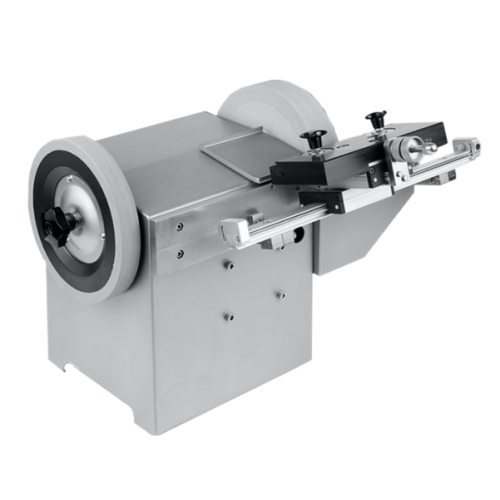

Knife honing equipment for industrial use

Enhance blade precision with minimal effort and cost, ensuring your cutting tool...

Strip cutter for recovering defective fries

Enhance your potato processing line efficiency by transforming rejected strips...

V-belt slicer for larger diameter leafy vegetables

Optimize your slicing operations with high-speed, precision cutting fo...

High-capacity dicer for frozen and large fresh vegetables

Optimize your vegetable and protein cutting processes with thi...

Centrifugal shredder and slicer for vegetables and fruits

Achieve precise slicing and shredding with reduced waste and e...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Interchangeable tool stainless steel kneader

Streamline your batch processing with this flexible mixing technology that of...

Modified atmosphere packaging for bulk bins

Achieve ultra-low oxygen levels and preserve product quality during bulk proce...

In-line condiment feeder for emulsion batter processing

Eliminate overworking in emulsion batter by seamlessly integratin...

Storage tank for dairy products and juices

Designed for optimal preservation and hygiene, these storage tanks prevent sedi...

Cip cleaning systems for dairy processing plants

Optimize cheese production with precise curd handling and exceptional sti...

Stainless steel molds for shaping meat products

Enhance product consistency and hygiene with custom-designed stainless ste...

Automatic wrapping for small products

Achieve precise and efficient packaging of diverse small products with seamless verti...

Rack presentation and de-stacking system

Optimize your cheese and snack production with a high-speed de-stacking system tha...

Plant-based protein extraction technology

Achieve optimal purity in plant-based milk, yogurt, and cheese production with c...

Automatic boxing system for wrapped products

Streamline your packaging line with precision as this high-speed boxing solut...

Fully automatic packaging solution for butter and pasty products

Streamline your production line with this versatile pac...

Automatic wrapping solution for large products

Effortlessly handle and package large dairy and food products with precisio...

De-boxing system for cheddar blocks

Streamline your cheddar cheese production with efficient de-boxing, ensuring seamless i...

Automatic system for removing ripening bags

Optimize your cheese production with a high-speed system designed to efficient...

Cube cutter for dairy products

Achieve precise and consistent cheese and dairy snack cubes effortlessly with high-speed, con...

Milk clarifier for dairy industry

Enhance your dairy production with efficient milk and whey clarification, ensuring produc...

Automated butterfly valve actuator for hygienic processing

Streamline your flow control operations with a robust and mai...

Industrial meat grinder for meat and vegetable processing

Streamline your food processing with our grinder that effortle...

Automatic double clipper for sausage and deli meats production

Optimize your meat and deli production line with seamless...

Automatic single clipper for sausage production

Streamline your sausage and cheese packaging with high-speed, reliable clo...

Automatic clipper for pre-tied casings

Streamline your casing process with a solution designed for efficient stuffing and c...

Air-powered vacuum packaging for poultry and meats

Ensure optimal freshness and extend shelf life in food applications wi...

Vacuum packaging system for whole birds and meat products

Optimize your packaging line with this high-speed vacuum syste...

Slicing loader for automatic portion loading

Efficiently manage portion loading with a system designed to balance slicing ...

Industrial slicer for natural shaped food products

Achieve superior slicing precision and efficiency with high-speed tech...

Industrial slicer for natural shaped products

Achieve precise and high-speed slicing of diverse food products, optimizing ...

High precision slicer for calibrated products

Achieve precise slicing and portioning for deli products with high speed and...

Industrial slicer for cooked ham and calibrated products

Achieve precision slicing and flexible portioning of meats and c...

Belt loader for slicing and packaging lines

Enhance your production line with seamless integration and efficient portion h...

Industrial robot picker for automatic packaging

Streamline your food packaging line with high-speed robotic picking, ensur...

Automatic loader for sliced portions and burgers

Streamline your production line with a flexible loader that efficiently h...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

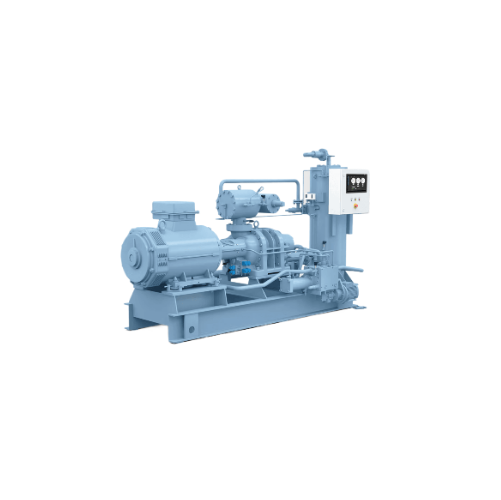

Sustainable packaged compressor system

Enhance your production with a scalable compressor system designed for high efficien...

Pasteurizer system for dairy applications

Achieve optimal pasteurization with precise temperature control and energy-effic...

Small-scale milk pasteurizer with skimming centrifuge

Quickly integrate a versatile pasteurization system into your produ...

Standardization unit for cream fat or milk fat

Optimize your milk standardization process to achieve precise cream and fat...

Microparticulation unit for whey protein processing

Enhance your dairy and food formulations with optimized whey protein ...

Compact milk pasteurizer for milk, cream, and whey

Ensure consistent product quality with precise pasteurization and skim...

Cylindrical coagulators for curd processing

Optimize your cheese production with cylindrical coagulators designed to ensur...

Steam stretching equipment for mozzarella production

Optimize cheese production with advanced steam stretching equipment,...

Industrial curd cutters for dairy processing

Optimize your cheese production with curd cutters designed for precision cutt...

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

Vertical form-fill-seal packer for frozen vegetables

Efficiently streamline your packaging line with a versatile solution...

Entry-level thermoforming packaging system for food products

Streamline your packaging process with a versatile thermofo...

Thermoforming packaging system for meat products

Enhance your packaging capabilities with a modular thermoforming system d...

Thermoforming packaging for skin applications

Enhance your packaging line’s versatility with a solution designed for...

High-efficiency ammonia chiller package for industrial applications

Optimize your cooling and refrigeration processes w...

High-speed paddle mixer for food industry blends

Achieve rapid, high-energy blending of varied particulate materials with ...

High-performance slicer for food processing

Achieve precise and consistent slices for your diverse range of food products ...

High-performance slicer for variety of meat products

Elevate your slicing precision with a high-speed system designed for...

Compact slicer for small batch production

Ideal for food producers seeking high-speed, precision slicing, this compact sol...

Involute blade slicer for diverse product range

Maximize throughput and efficiency with this advanced slicing solution, id...

Circular blade slicer for caliber-consistent meat products

Achieve precise, high-speed slicing for diverse food products...

Laser scanner for precise slicing results

Achieve unparalleled slicing accuracy and enhanced yield with laser scanning tec...

Precise weight determination system for up to four lanes

Achieve consistent portion control and ensure quality standards ...

Automated cold cuts loading system

Optimize your production line with a flexible side loading solution designed for precise...

Automatic infeeder for cold cuts

Ensure seamless integration of portioned products into your packaging line with this compac...

Automated picking and placing system for cold-cuts

Optimize your food production line by implementing a high-speed roboti...

Automatic stacking system for food industry

Optimize your production line with high-speed, fully automated stacking, ensur...

Automatic underlay system for food products

Efficiently placing paper or film underlays beneath food slices optimizes port...

End-of-line converging solution for food packaging

Streamline your food packaging line with compact converging robots tha...

Compact belt separator for food packaging lines

Streamline your packaging line by efficiently merging up to six packing la...

Thermoforming packaging system for medium production volumes

Optimize your food packaging with high-speed, continuous op...

Thermoforming packaging solution for medium production volumes

Optimize your medium-volume packing with a compact thermo...

Automated insertion system for food processing

Streamline your food processing line with this versatile solution, designed...

High-capacity industrial smoking and drying system

Maximize your production volume without expanding your facility footpr...

Friction smoke generator for hot smoking and climatic maturing

Optimize your production with a friction smoke generator ...

Glowing smoke generator for hot smoking installations

Enhance your production line with dense, aromatic smoke that ensure...

Liquid smoke system for meat and seafood processing

Achieve uniform smoking results across diverse products by employing ...

Advanced processing unit for meat and fish products

Transition seamlessly from hot to cold processing with a system that ...

Dual-method cooling system for sausage and meat products

Achieve optimal freshness, flavor, and shelf life for your meat ...

Horizontal air flow drying and smoking system for meat products

Achieve superior drying and smoking efficiency with hori...

Air-conditioning curing for raw sausage production

Enhance your meat processing line with precise climate management for ...

Grinding and separating solution for meat processing

Optimize your meat and plant-based production lines by integrating a...

Milk reception unit for dairy processing

Ensure precise measurement and streamlined handling of raw milk with an engineered...

Clean-in-place (cip) system for sanitation processes

Ensure thorough sanitation in your production line with a streamline...

Curd cooking vat for dairy production

Optimize dairy production with a curd cooking vat that ensures precise cooking, mixin...

Fermentation vat for dairy products

Optimize your cheese production with a specialized fermentation vat that enhances curd ...

Industrial filter drum for whey extraction

Streamline your cheese production with a rotary drum filter designed to efficie...

Industrial buffer tank for temperature and texture control

Achieve precise temperature control and optimal texture with ...

Multifunctional industrial food mixer

Efficiently handle complex food processing tasks from mixing to homogenizing with a m...

High capacity shredder, slicer, and strip cutter

Optimize your production line with advanced cutting versatility, handling...

Industrial slicer for precise food cuts

Maximize your food processing efficiency with an industrial slicer that offers unpa...

Industrial dicing solution for food products

Enhance processing efficiency with high-speed dicing and slicing solutions, e...

Industrial food dicer for high-fat and cold-temperature products

Achieve precise and consistent cutting with a high-capa...

High-precision dicer for challenging food applications

Designed to handle challenging cutting tasks, this high-efficiency...

Vessel dome fittings for tank protection

Ensure seamless production by preventing tank damage due to overpressure or vacuum...

Industrial water recycling system

Reduce excess water consumption in your process line by recycling and reusing up to 96% o...

Storage tank integrity testing

Prevent costly contamination and streamline your operations with advanced tank integrity test...

Industrial depositor for large volume bakery products

Achieve precise and high-speed depositing for bakery items with sea...

Industrial food production depositor for bakery applications

Optimize your bakery production with precision depositing a...

Hygienic design thermoformers for skin packaging

Optimize vacuum sealing for enhanced shelf life and presentation with pre...

High-speed Map packaging for fresh food products

Ensure product freshness and safety with robust, high-speed packaging tha...

Horizontal flow wrapper for irregular products

Streamline your packaging line with a versatile wrapper designed for irregu...

Brick forming and wrapping system for food products

Optimize your production line with seamless forming and wrapping of v...

Grinder and grater combination for professional kitchens

This versatile meat processing and cheese grating solution integ...

Milk skimming separator

Achieve superior separation efficiency and reduced energy consumption in dairy processing with seamle...

Permeate powder spray dryer

Optimize permeate powder production with continuous spray drying, ensuring premium, non-caking o...

Automatic milk standardization unit

Achieve precise control over milk’s fat, protein, and solids content, reducing cr...

Pasteurizer for dairy products

Enhance food safety and minimize operational costs with a cutting-edge pasteurizer designed f...

Spore and bacteria removal unit for dairy products

Ensure superior quality by precisely removing spores and bacteria from...

Industrial powder mixer for food production

Enhance your production line with a high-speed batch mixer designed for precis...

Conical homogenizer for powder and granulated products

Achieve seamless homogenization of diverse powders and granulated ...

Drum unloader for liquid ingredients

Streamline the unloading of viscous liquid ingredients with advanced water injection t...

Plate heat exchanger for food products

Achieve precise temperature control in your processing line with this plate heat exc...

Industrial homogenizer for liquid food applications

Achieve unparalleled product consistency and quality with high-speed ...

Ultrafiltration system for concentrating milk or whey proteins

Effortlessly concentrate milk and whey proteins into high...

Dry salting system for mozzarella production

Optimize mozzarella consistency with precise dry salting—achieving perfect sa...

Cheddaring system for pasta filata production

Optimize cheese production with a system that enhances yield and consistency...

Curd distribution system for cheddar production

Ensure consistent curd distribution for optimal cheese quality with our ad...

Pneumatic conveyor for fragile powders

Handle your delicate powders with care, ensuring minimal breakdown while achieving h...

Continuous spray dryer for permeate powder

Efficiently transform liquid whey and milk into high-quality, non-caking, and n...

Automated milk standardization system

Achieve precise milk fat and protein control continuously with real-time adjustments,...

Automated milk standardization unit

Achieve precise in-line standardization of milk components, ensuring optimal quality an...

Nozzle separator for concentrated yoghurt production

Achieve precise separation and skimming for high-protein dairy produ...

Spore removal unit for dairy processing

Optimize your dairy production by efficiently removing spores and bacteria, ensurin...

Efficient milk skimming separator

Optimize your dairy processing with our high-efficiency separator, designed to ensure sup...

Energy-efficient dairy product separator

Achieve up to 40% energy savings in your dairy and beverage processing operations ...

Dairy pasteurizer

Ensure product safety and quality while reducing energy consumption and operational costs with this advance...

Contherm scraped-surface heat exchanger for viscous food products

Optimize your heating and cooling processes for stick...

In-line blender for dairy product formulation

Achieve seamless blending and standardization of complex dairy and liquid pr...

Aseptic filling solution for tetra classic packaging

Experience efficient aseptic packaging with high-speed operation, of...

Buffer tanks for dairy processing

Optimize your dairy production with versatile buffer tanks, essential for balancing flow ...

Cleaning in place system for dairy processing plants

Streamline cleaning efficiency and ensure product quality in your da...

Continuous aerator for dairy products

Enhance the texture and flavor of dairy delights with precise gas infusion, transform...

Hot water dip tank for immersion shrinking

Enhance the appearance and seal integrity of vacuum-packaged products with a ro...

Mid-size belt-chamber vacuum packaging for smallgoods and seafoods

Optimize your packaging line with efficient mid-spee...

Food processing scraped surface heat exchanger

Enhance your production line with precise temperature control and continuou...

Vertical scraped surface heat exchanger for food processing

For continuous production that demands consistent texture an...

Tubular ultra high temperature processing system for dairy products

Optimize your dairy processing with precise thermal...

Microfiltration system for dairy and plant-based applications

Enhance your production capacity and reduce waste with adv...

Laboratory loss-in-weight feeder for powders or pellets

Achieve precise dosing for lab-scale trials with this versatile f...

Ultrasonic food cutter for sticky and fragile foods

Achieve seamless cuts in sticky and fragile foods with ultrasonic pre...

Ultrasonic food cutting equipment

Experience precise and efficient ultrasonic cutting of various food products, optimizing ...

Ultrasonic food cutting system

Effortlessly achieve precise, clean slices on sticky and fragile foods with ultrasonic techno...

Ultrasonic cake slicing system

Achieve precise, high-speed slicing of delicate and sticky food products with ultrasonic tech...

Automated production line for ground meat products

Enhance your meat processing efficiency by seamlessly integrating grin...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

Milk pre-cooling systems for dairy farms

Optimize dairy production with advanced milk pre-cooling systems that significantl...

Open milk cooler from 300 to 1,500 liters capacity

Ensure optimal milk storage with a high-performance cooling solution t...

Cryogenic freezing for small fragile foods

Quickly freeze delicate food items with precision using advanced cryogenic imme...

Shredder for fine particle size reduction

Optimize your production line with high-speed shredding technology designed for ...

Skid mounted process plant

Simplify your production setup with skid-mounted process plants, designed for quick installation ...

Industrial Sauce Homogenization and Emulsifying System

Texture and consistency are critical to foods with delicate compos...

Homogenization and emulsifying system for fine foods

Texture and consistency are critical to foods with delicate composit...

Pellet snacks frying line

Pellet-style snacks represent a broad food sector category. They are consumed worldwide and vary a...

Pasteurization Machine for Milk

Manual processing of dairy products can cause inconsistent quality between batches due to po...

Frozen food automatic case packer

Adequately packaged frozen fries retain their original color, taste, and texture. And bec...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

High-clean FFS machine for butter in mini portions

With the production of dairy products such as butter in mini portions ...

Inline ultrasonic big scale food cutting machine

In the food industry, where accuracy in the cutting process is desired, u...

Aseptic aerator for food products

Products such as mousse, yogurt, butter, cheese, and many more require mixing and aeratin...

Skin packaging machine

Skin packaging is when a product is placed on a tray or a paperboard with a thin layer of plastic plac...

Moulding machine for bread sticks

Breadsticks are popular as an appetizer in restaurants or as a starter served with prosci...

Stand-alone ultrasonic food cutting machine

For some foods such as cake, pizza, sandwiches or ice cream, the end product i...

Dairy Packaging Machine

The use of sachets and pouches for powdered or shredded dairy products is an increasingly popular for...

Complete cutting, mixing, emulsifying and heating system

From laboratory scale to large volume food or cosmetic productio...

Clarifiers for milk, whey, and calcium phosphate

Efficiently separate non-milk solids and impurities from milk, whey, and ...

Cold block piping solution for breweries

Achieve optimal beverage quality and reduce production costs with this advanced pi...

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

Low temperature evaporator for heat-sensitive food products

Efficiently concentrate sensitive liquid products while pres...

Wine dealcoholization system for low-alcohol wines

Struggling to meet market demands for low-alcohol wines? Achieve preci...

Juice clarification system

Ensure consistent beverage clarity with advanced separation technologies, enhancing production ef...

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Pulsed electric field system for food preservation

Enhance your production line with technology that extends shelf life a...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Ricotta smoothing mixer for dairy production

Achieve consistently smooth and perfectly blended ricotta with advanced mixin...

Cip systems for dairy production

Ensure consistent hygiene and sanitation levels in your production line with efficient, aut...

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

Industrial yogurt production line

Streamline your yogurt production with precise process control to ensure consistent quali...

Magnetic separators for metal contaminant removal in powder processing

Ensure product purity and safety by effectively ...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Cleaning and sterilization in place for hygienic control

Ensure maximum hygiene and sterility in your production line wit...

Stainless steel process vessels for biopharmaceutical applications

Ensure seamless mixing and sterilization with engine...

Close proximity cleaning-in-place solution for industrial hygiene

Enhance plant hygiene with a close proximity cleaning...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

Cip system for wine, grape juice, oil, and dairy

Ensure optimal hygiene and operational efficiency in processing lines wit...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Medium-speed shrink wrapper and case packer for food industry

Optimize your packaging line with a combined solution that...

Medium-speed wrap around case packer for food and dairy industries

Optimize your end-of-line efficiency with a reliable...

Automated bag sealing for packaging lines

Enhance your packaging efficiency by seamlessly integrating an automated bag sea...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Thermoforming packaging for high-output segment

Enhance your production efficiency with advanced thermoforming technology,...

Automatic traysealer for food packaging

Optimize your packaging efficiency with this advanced traysealer, designed to enhan...

Visual inspection systems for packaging quality control

Detect and eliminate packaging and labeling faults early in your ...

X-ray inspection system for food packaging

Ensure product integrity and safety with advanced detection of foreign bodies i...

Labelling solution for thermoformed packaging

Ensure flawless labeling integration with high-speed, continuous production....

Label dispenser integration for packaging lines

Streamline labeling operations with precision and flexibility, ensuring yo...

Marking solutions for traysealers

Ensure precise labeling and data printing on tray-sealed packages with integrated solutio...

Vacuum packaging chamber for industrial products

Achieve consistent sealing precision and extended shelf life for diverse ...

Flowpackers for efficient food packaging

Achieve seamless packaging with flowpackers designed for high-speed, sustainable o...

Mbs belt systems for seamless packaging integration

Optimize your packaging line with a system that seamlessly merges mul...

Automated conveyor systems for food packaging lines

Seamlessly integrate high-speed product transport and handling into y...

Automated pack stacker for packaging lines

Streamline your packaging line with a compact solution that stacks and organize...

Robotic loading systems for packaging applications

Enhance your production line with versatile robotic loading systems, d...

Food cutter for professional kitchens

Optimize your food preparation with precision mincing, cutting, and homogenizing, pre...

Professional food cutter for various ingredients

Streamline your food preparation with a versatile cutter designed to effi...

Atmospheric fermenter for lab and pilot scale projects

Streamline your fermentation process with precise control over tem...

Low pressure forming for plant-based products

Achieve precise shape and weight consistency in plant-based products with lo...

Industrial double shaft mixer for food processing

Ensure precise mixing in industrial food production with this double sh...

Industrial double shaft mixer for homogeneous blending

Achieve quick, gentle, and homogeneous mixing for diverse food mat...

Spiral oven for cooking plant-based and conventional products

Achieve perfectly cooked products every time with advanced...

Flake ice producer for food-safe ice

Enhance your production line with hygienic flake ice, optimized for energy efficiency ...

Low-pressure forming solution for plant-based products

Achieve a handcrafted look and precise texture retention for plant...

Checkweigher for food processing compliance

Ensure accurate package weights while preventing underweight or overweight pro...

Industrial mixer-grinder for food processing

Streamline your processing line with a robust mixer-grinder that combines eff...

Oven for high-yield cooking of prepared foods

Achieve unparalleled consistency and enhanced yield in food production with ...

Modular industrial oven for high-yield food processing

Need a solution that offers high-yield roasting and precision cook...

Automatic box and crate labeler

Achieve precise, high-speed labeling and weighing for various packaging needs, ensuring cons...

Compact grader for poultry and meat processing

Streamline your production line with this precise grading solution, designe...

Weigh price labeler for retail food products

Achieve consistent, high-speed labeling and pricing with precision—streamlini...

Automatic label applicator for food packaging

Enhance your packaging line with precise, high-speed labeling, ensuring your...

Pack turner for efficient label presentation

Optimize your packaging line efficiency and accuracy by ensuring precise labe...

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic freezer for food industry applications

Efficiently tackle high-speed freezing and chilling challenges with a ver...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Single-screw high shear extruder

Optimize your snack production with precise control over raw material transformation, from ...

Commercial vegetable peeler for potatoes and carrots

Efficiently integrate peeling and polishing vegetables into your pro...

Semi-automatic packaging system for sauerkraut and vegetables

Efficiently tackle the challenge of packing sticky product...

Automatic dosing and packing system for cabbage and sauerkraut

Streamline your vegetable processing line with a robust, ...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

Industrial mixer for vegetable, powder, rice, noodle blending

Effortlessly achieve consistent blends with this 100-liter...

Hydraulic box tipper for pallets

Streamline your material handling with precision and safety by integrating this hydraulic t...

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

Bulk bag filler with integrated palletizing system

Optimize your powder packaging with a seamless system that fills and a...

Mbr module for wastewater treatment

Optimize your wastewater management with efficient membrane bioreactors, designed to en...

Lactose drying system for high-quality edible powder

Achieve precise and cost-effective lactose transformation into high-...

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy an...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

Industrial magnetic agitator for homogenizing pharmaceutical products

Achieve precise dispersion and homogenization in ...

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Filling and wrapping system for pasty products

Achieve precise dosing and flexible wrapping of diverse pasty products, ens...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Form fill and seal solution for liquid and pasty products

Enhance your production efficiency with high-speed forming, fi...

Beer production filtration system

Enhance your beverage production with cutting-edge filtration systems designed to maintai...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...