Clean purge system for spray dryers

Enhance safety and efficiency by preventing fire risks in spray dryers while improving product recovery and minimizing downtime, ensuring consistent operations in demanding 24/7 production environments.

Reduces Fire Risks and Enhances Yield

The GEA Clean Purge system from GEA is designed to enhance safety and efficiency in food and dairy spray drying operations. By purging and atomizing residual feed from nozzle lances, it significantly reduces the risk of fires and explosions—a common challenge in spray dryers. This system facilitates seamless 24/7 operations by preventing feed residue buildup and ensuring continuous atomization, thereby enhancing yield. Applications include the production of milk powder, nutritional formulas, and various dairy-based powders. The system can be easily retrofitted to existing setups and offers automation for minimal downtime. It is engineered for more efficient cleaning cycles, reducing the consumption of water and chemicals, thus also decreasing wastewater disposal costs. Customizable to your operational needs, the GEA Clean Purge system is poised to ensure maximum safety and efficacy across large-scale dairy and food production lines.

Benefits

- Mitigates fire and explosion risks, enhancing workplace safety.

- Increases yield by efficiently purging residual feed before cleaning.

- Reduces water and chemical use, cutting operational costs.

- Supports seamless 24/7 operation with minimal disruption.

- Easily retrofittable, allowing for quick integration into existing systems.

- Applications

- Food, Dairy

- End products

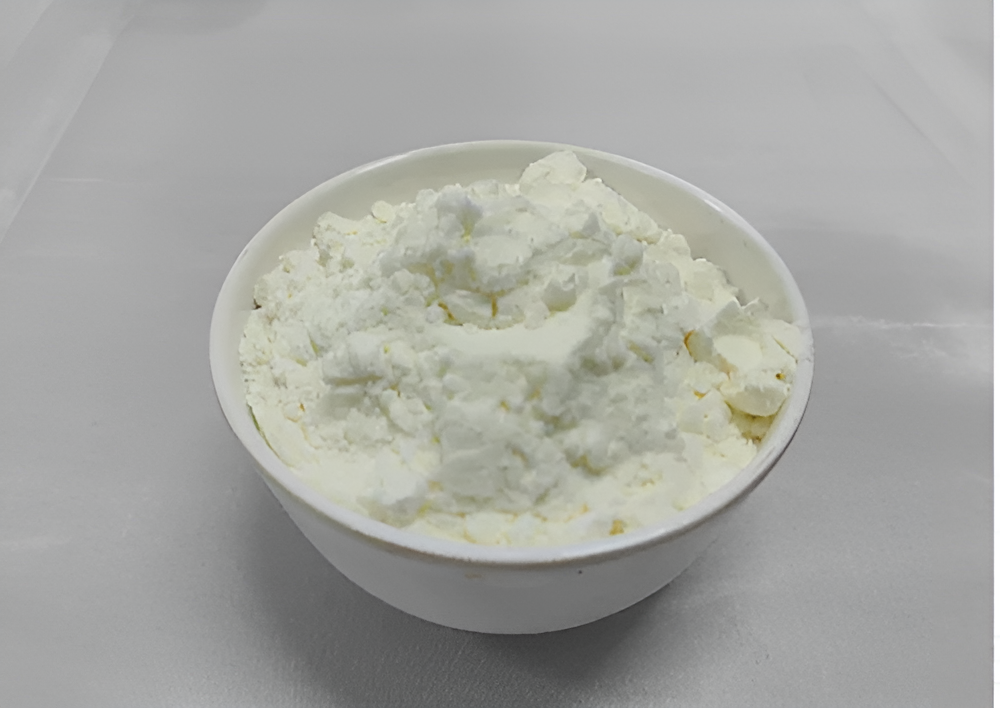

- Protein powders, Yogurt powder, Powdered baby food, Nutritional formula, Milk powder, Dairy-based creamers, Cheese powder

- Steps before

- Emulsification, Concentrate feed preparation, Feed line connection, Production setup

- Steps after

- Cleaning-in-place, Sterilization, Product recovery, Waste water disposal

- Input ingredients

- feed systems, feed lines, concentrate feed, dairy

- Output ingredients

- spray dryer chamber, powder, nutritional formula, milk powder

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Feed systems

- Multiple feed lines

- Cleaning method

- Clean-in-place (CIP)

- Operation time

- 24/7 operation

- Risk reduction

- Fire and explosion prevention

- Process time

- 3-4 hours for CIP

- Savings

- Reduced water and chemical consumption

- Product recovery

- Optimized feed recovery

- Retrofit capability

- Available for existing installations

- Working mechanism

- Purging residual feed from nozzles

- Integrated steps

- Continuous purging and cleaning

- CIP principles

- Effective cleaning in place without stopping operations

- Batch vs. Inline flow

- Inline continuous operation

- Automation level

- Automated purging system

- 24/7 operation capability

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- High resistance to acidic environments

- Density/particle size

- Suitable for varying densities and particle sizes

- Machine Footprint

- Compact design for easy retrofitting

- Feed/Discharge Method

- Purging of feed lines, atomization into chamber

- System Integration

- Retrofit available

- Control Panel Type

- Automated control

- Compact footprint

- Designed for existing installations

- Discharge Method

- Efficient atomization into spray dryer chamber

- Integration possibilities

- Retrofit / New Installation

- Footprint size

- Compact

- Customization for 24/7 operation

- Available