Industrial Purification Systems

Find innovative purification equipment and connect directly with world-leading technology suppliers

Purification is the removal of contaminating substances and by-products to increase the level of purity of the desired substance. Considerations for choosing a suitable purification system in the industry, include the physical state of the mixture, the desired product, required level of purity, the type of mixture, heat sensitivity of the product, number of purification steps needed, and the production volume. Industrial purification systems are used for the production of pure water in the food pharmaceutical and biotech industries.

What are you making?

Alternative proteins

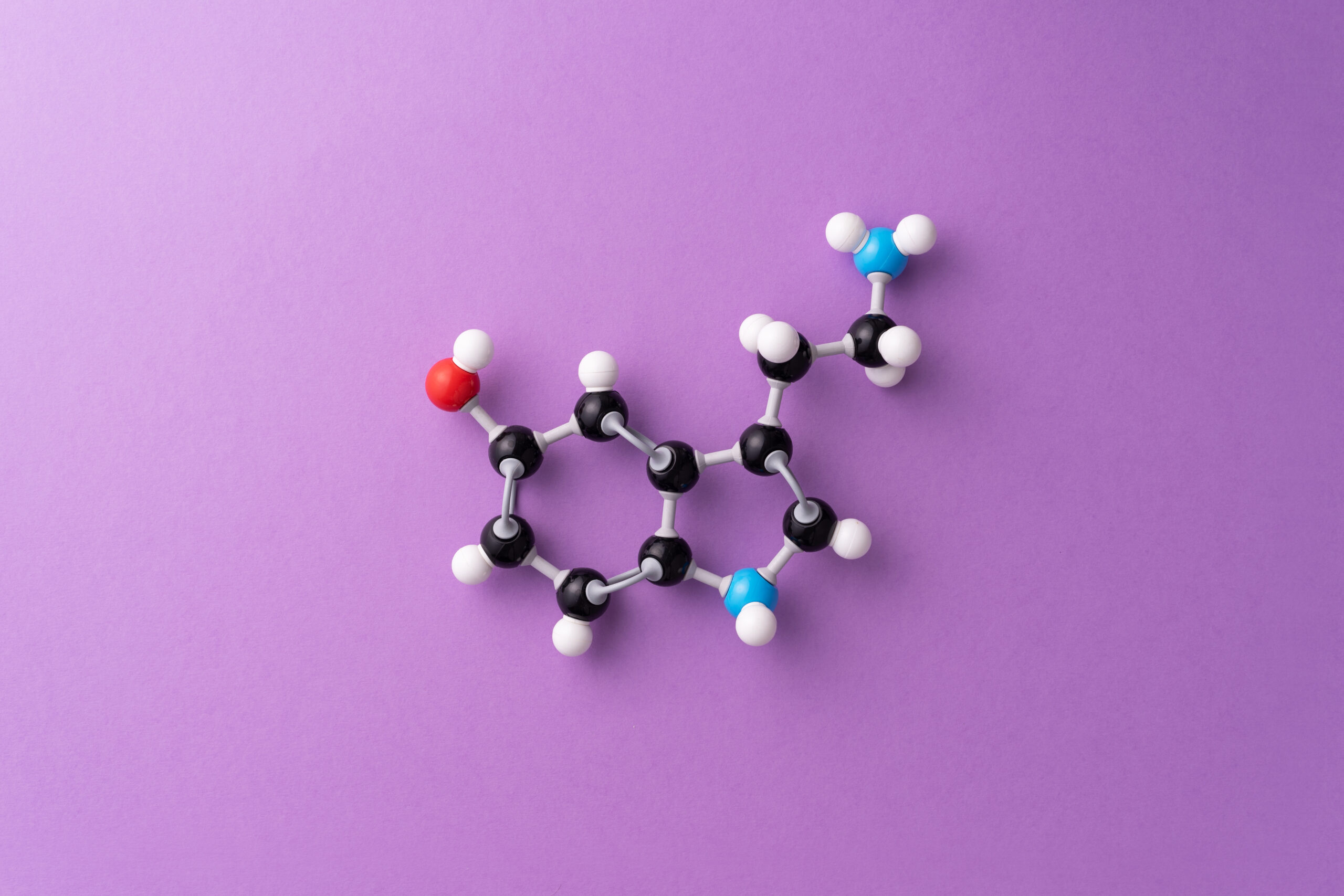

Amino acids

Ammonia

Antibiotic tablets

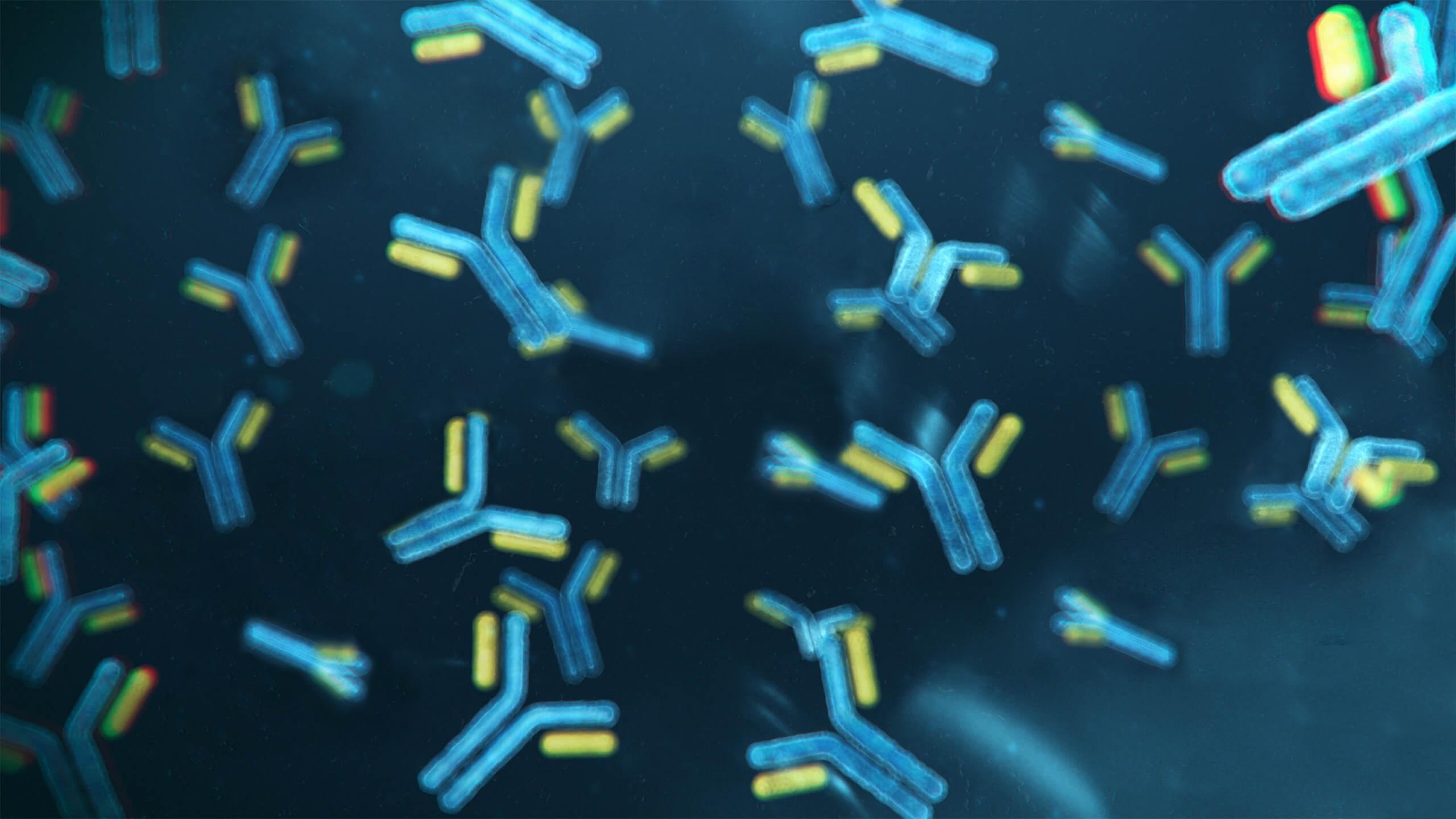

Antibodies

Antioxidant supplements

Aromatherapy oils

Artificial sweeteners

Aspartame

Aspirin

Baking soda

Bentonite clay

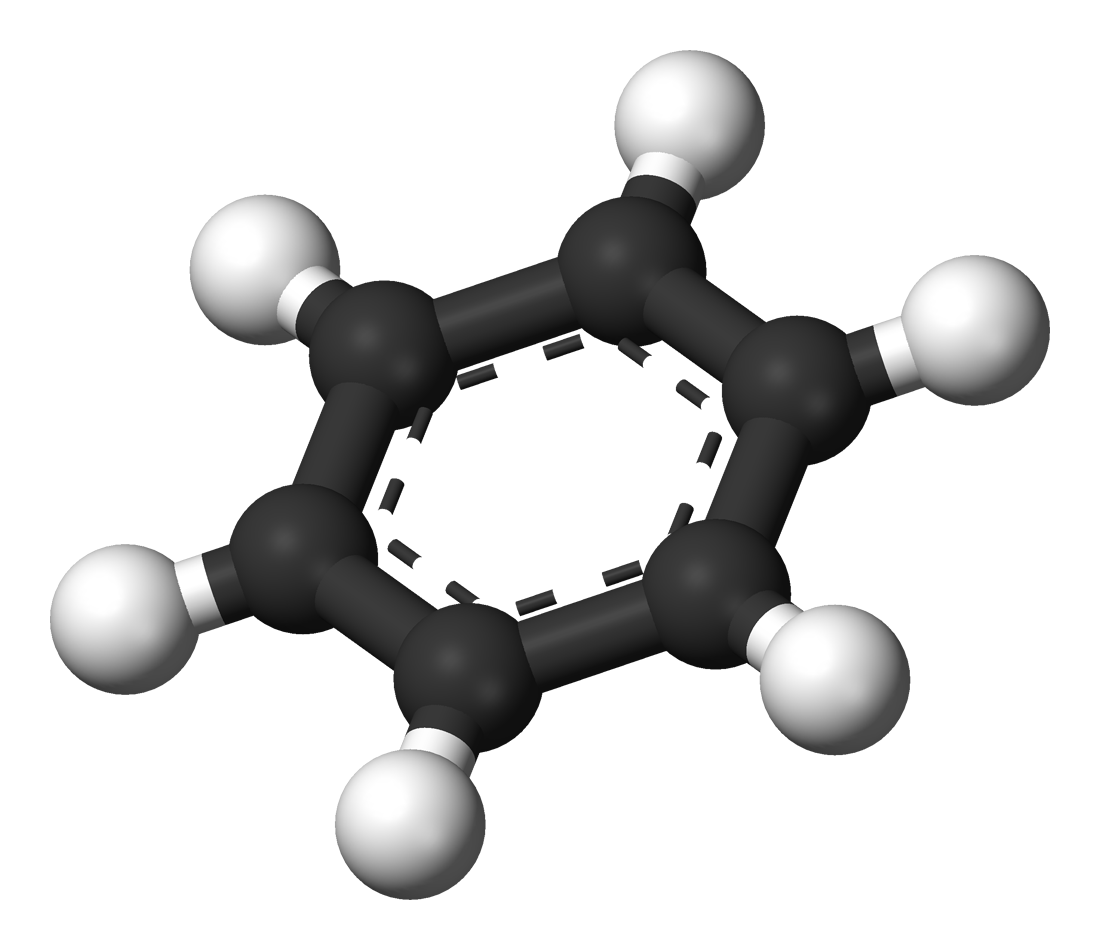

Benzene

Beverage ingredients

Bio-pharmaceuticals

Bioactive compounds

Biochemistry

Biocides

Bioenergy

Biofuel

Biofuels

Biologic drug formulations

Biomethane

Biosimilars

Blood plasma products

Botanical extracts

Botanical medicine

Bottled water

Bulk chemicals

Cannabis distillate

Cannabis extracts

Cannabis oil

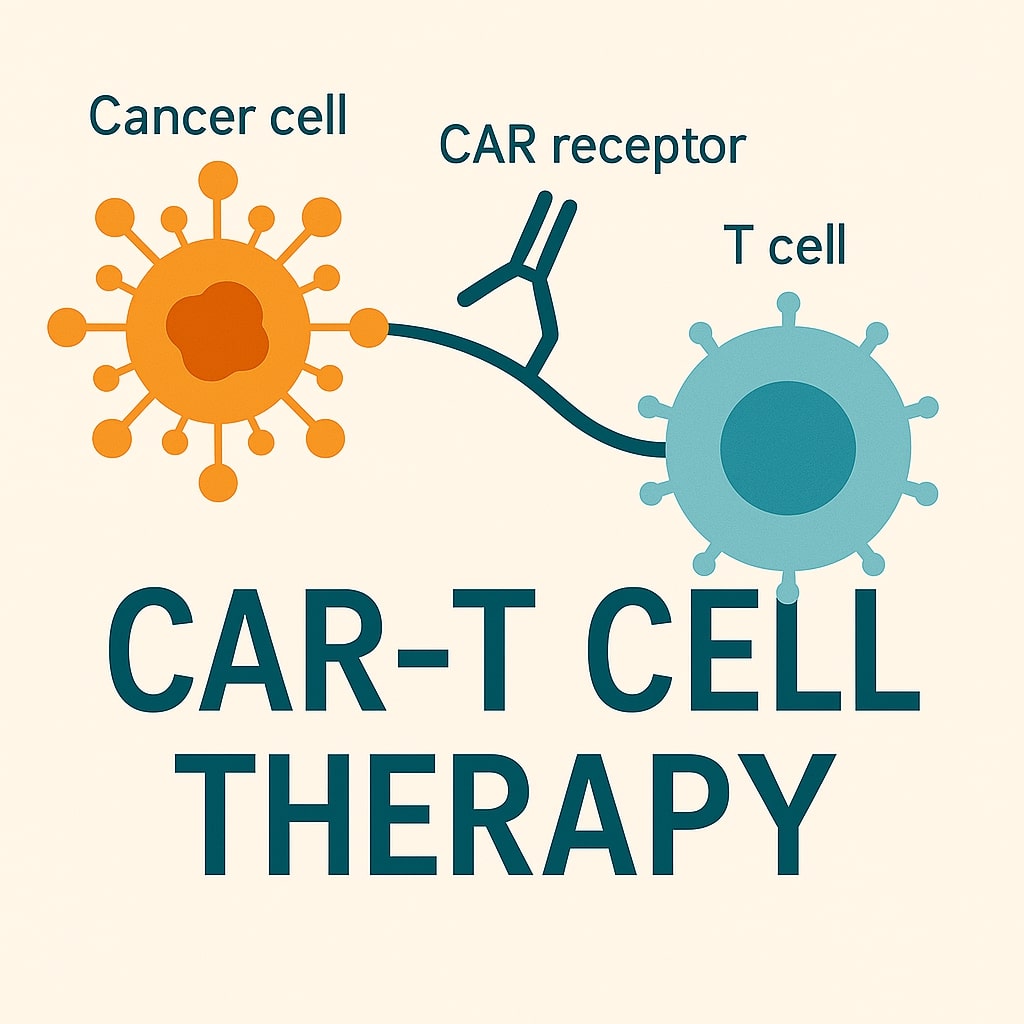

Car-t cell therapies

Carbon capture

Carbon materials

Carbon nanotubes

Cbd distillate

Cell and gene therapy

Cell therapy

Cellulose

Chemical compounds

Chemical intermediates

Chemical reagents

Chemical solvents

Chemistry

Chemotherapy drugs

Citric acid

Citrus Fruit

Collagen peptides

Collagen powder

Copper sulfate

Covid-19 vaccines

Dextrose

Dna

Eardrops

Electrochemistry

Electrolyte solutions

Electronic materials

Environmental applications

Enzyme catalysts

Enzyme replacement therapies

Enzymes

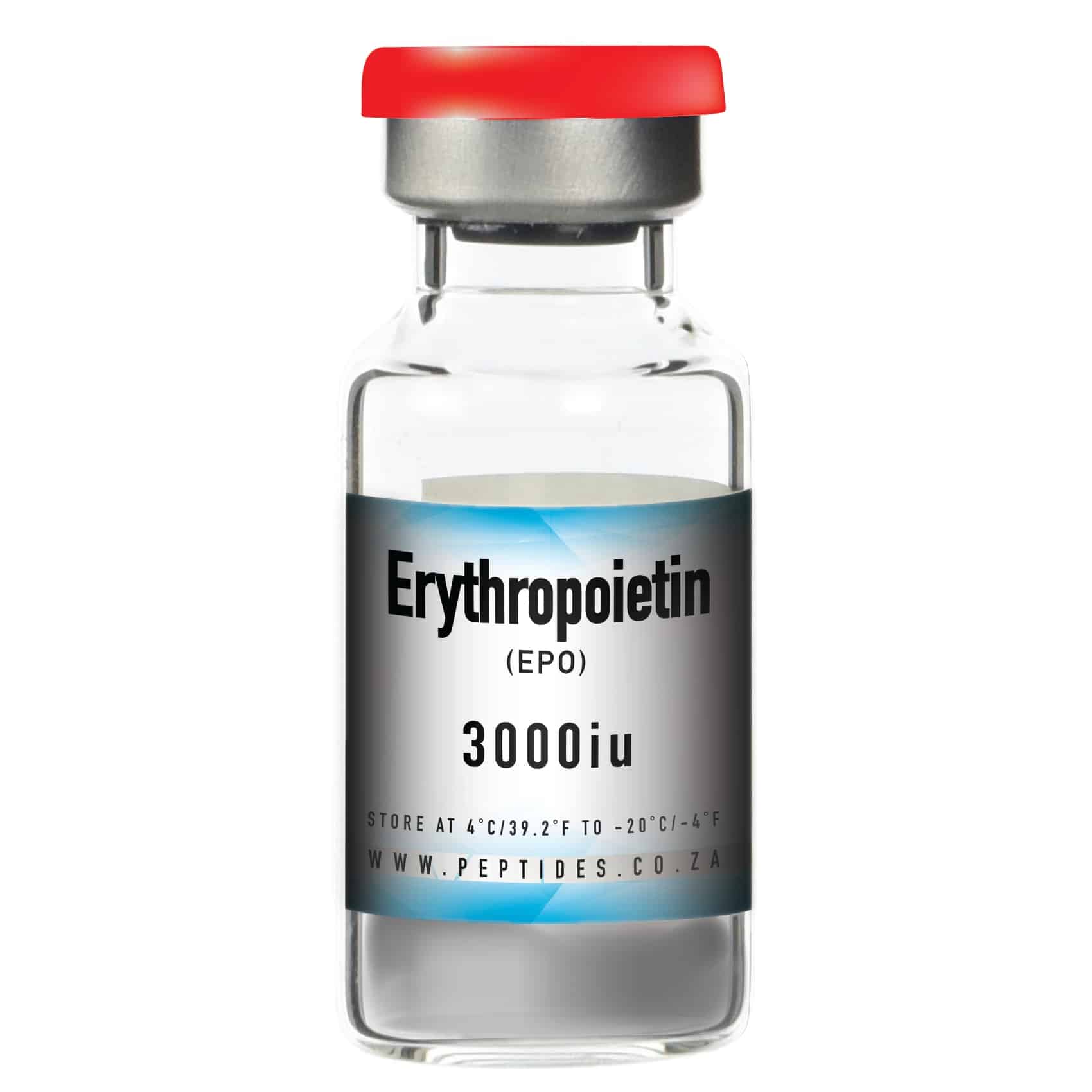

Erythropoietin

Essential oil extracts

Ethanol

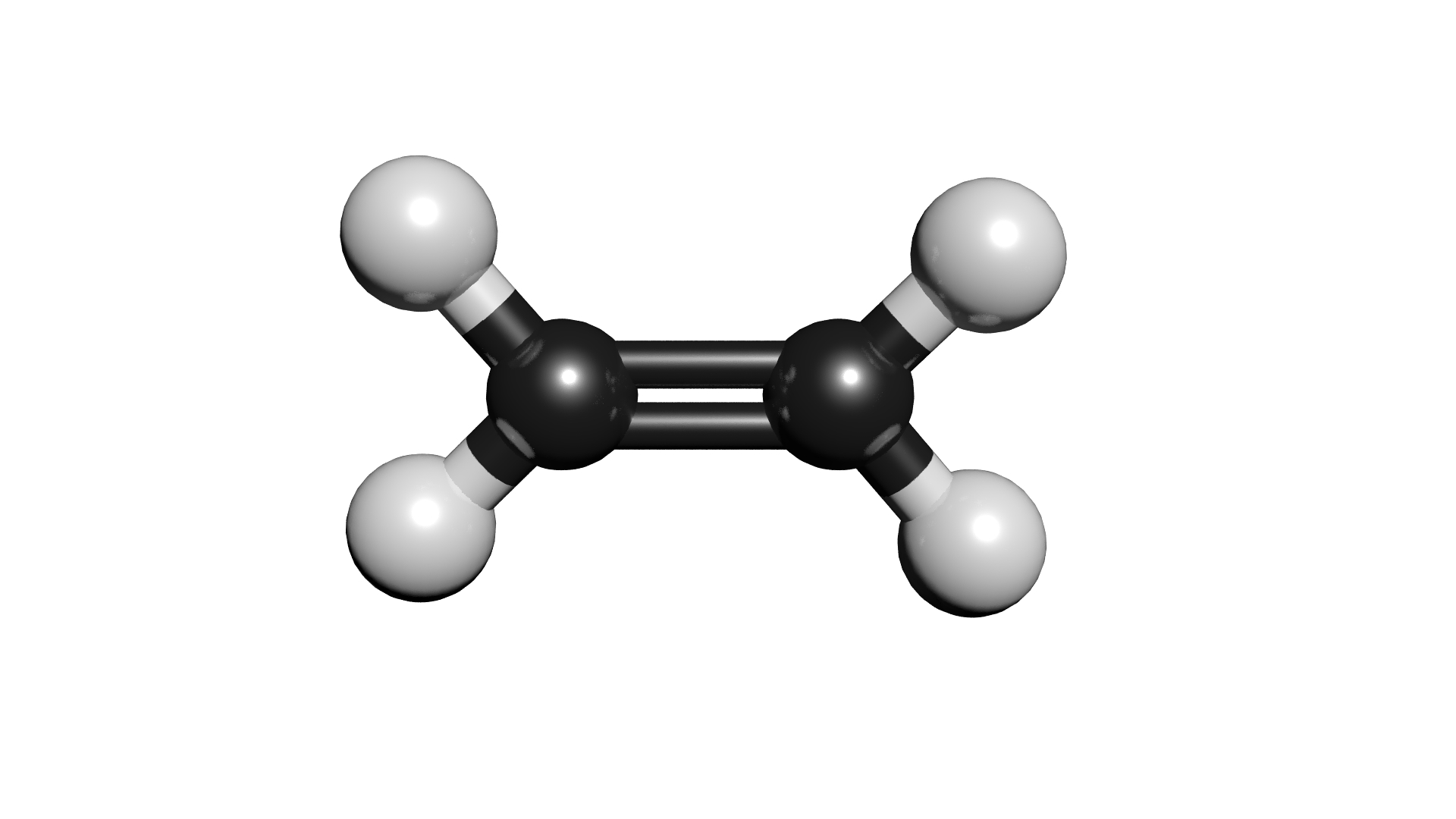

Ethylene

Ethylene glycol

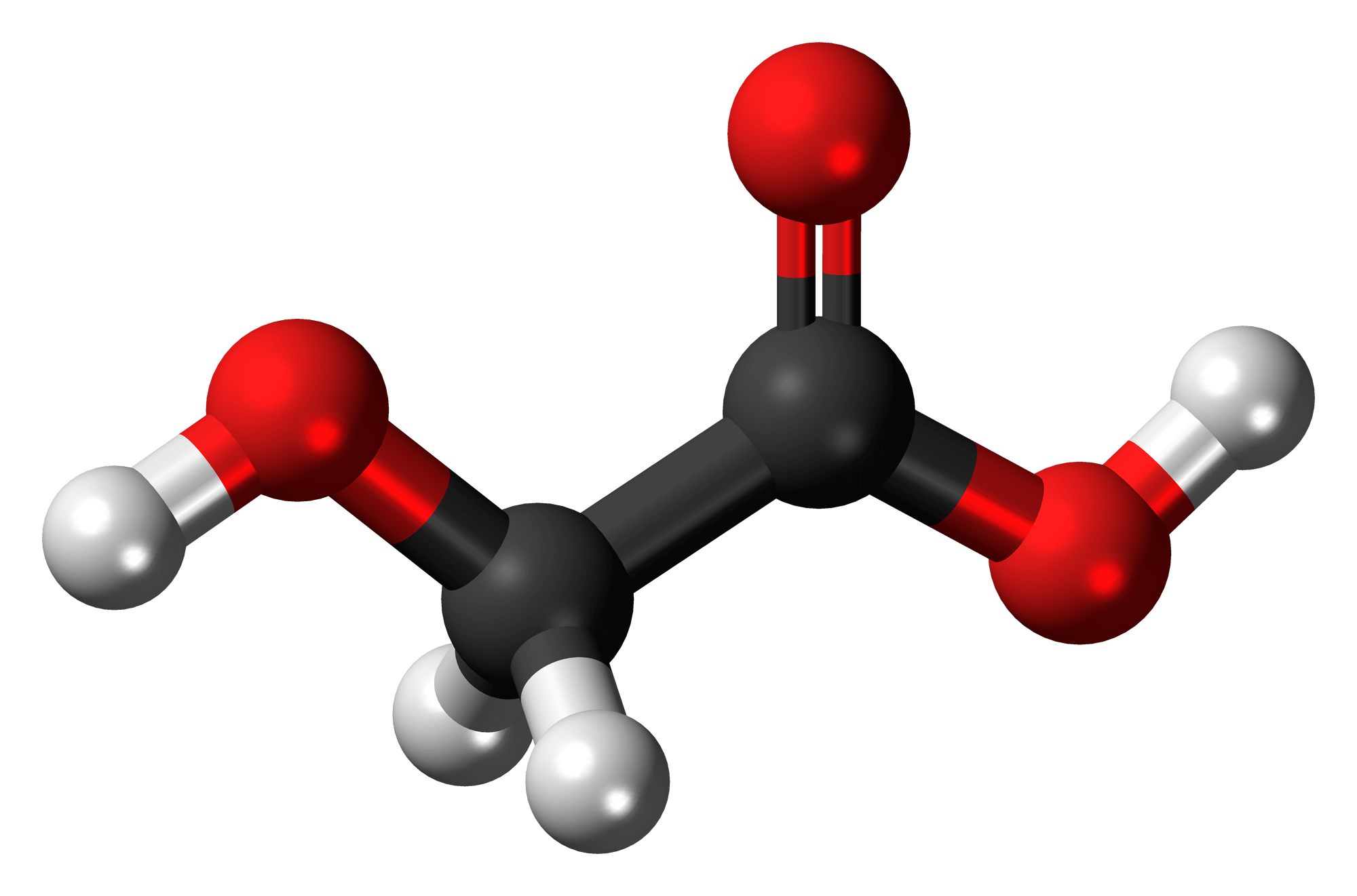

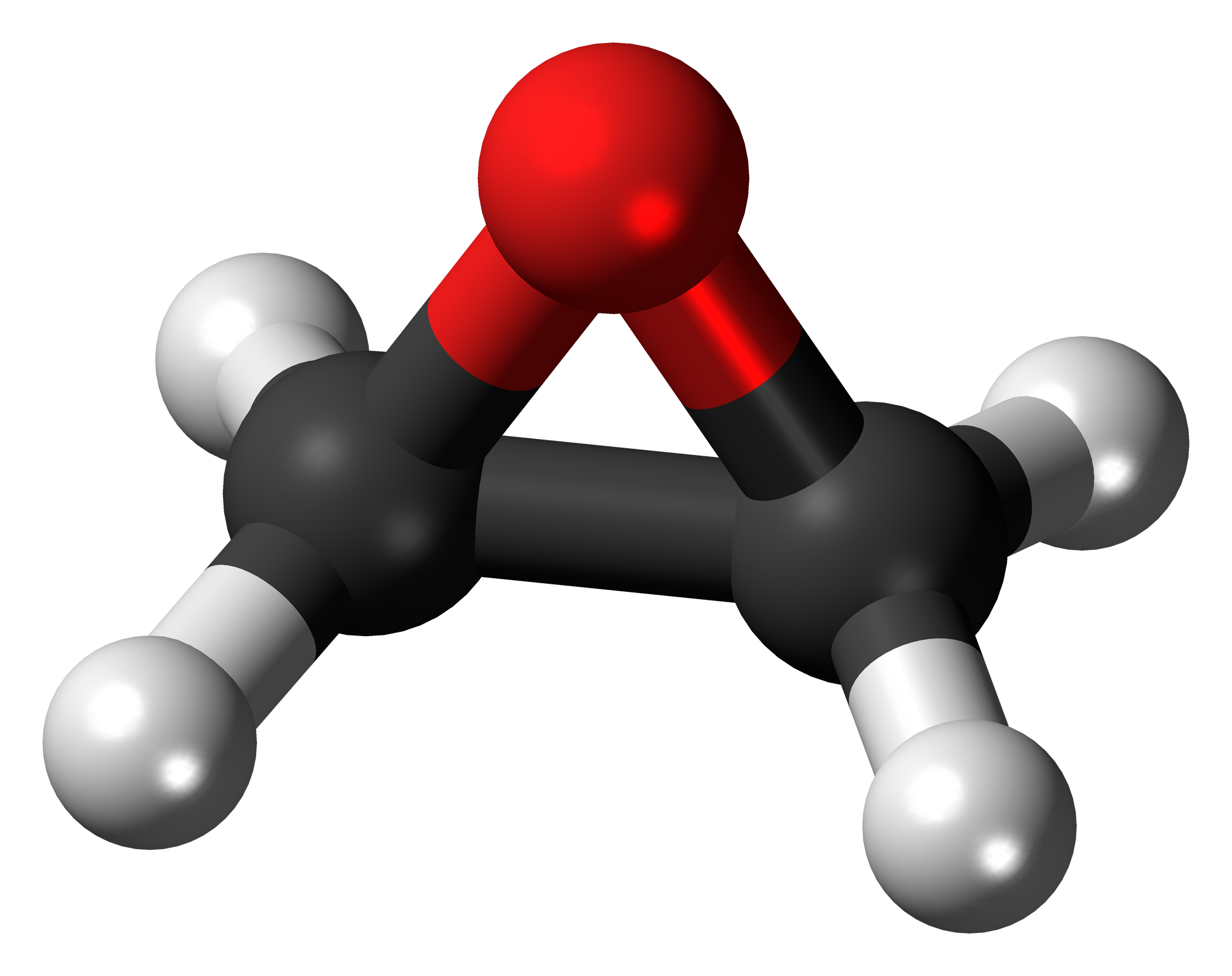

Ethylene oxide

Excipients

Extracts

Eye care products

Fatty acids

Fermentation broths

Fermented products

Fine chemicals

Fish by-products

Fish oil

Fish oil capsules

Fish oil supplements

Flavor enhancers

Flavor extracts

Flavors

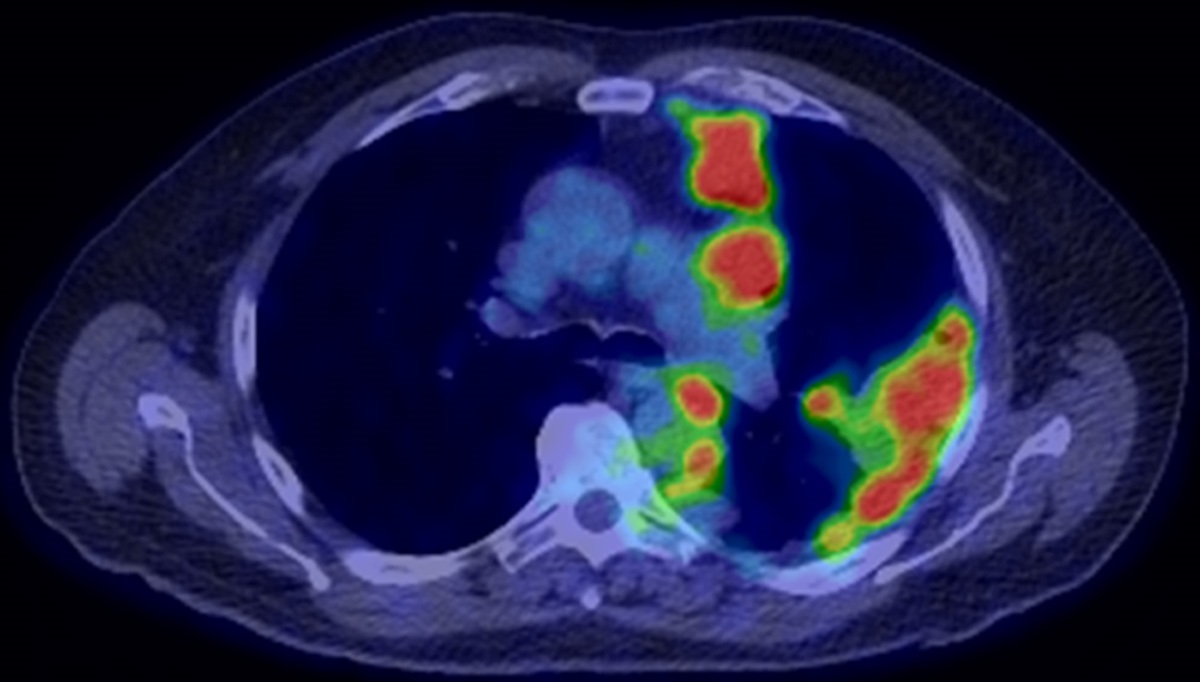

Fludeoxyglucose (fdg)

Fluorodeoxyglucose (fdg)

Food additives

Food colorants

Food ingredients

Fragrance oils

Freeze-dried pharmaceuticals

Freeze-dried plasma

Fruit concentrate

Fruit leather

Fruit pastes

Gas

Gas and energy

Gasoline

Gene therapy

Glucose syrup

Glycerol

Glyphosate

Graphite

Green chemistry

Hemp seed oil

Hepatitis b vaccines

Herbal Extracts

High-fructose corn syrup

Hormones

Hydrocolloids

Hydrogen peroxide

Hydrometallurgy

Immunochemistry

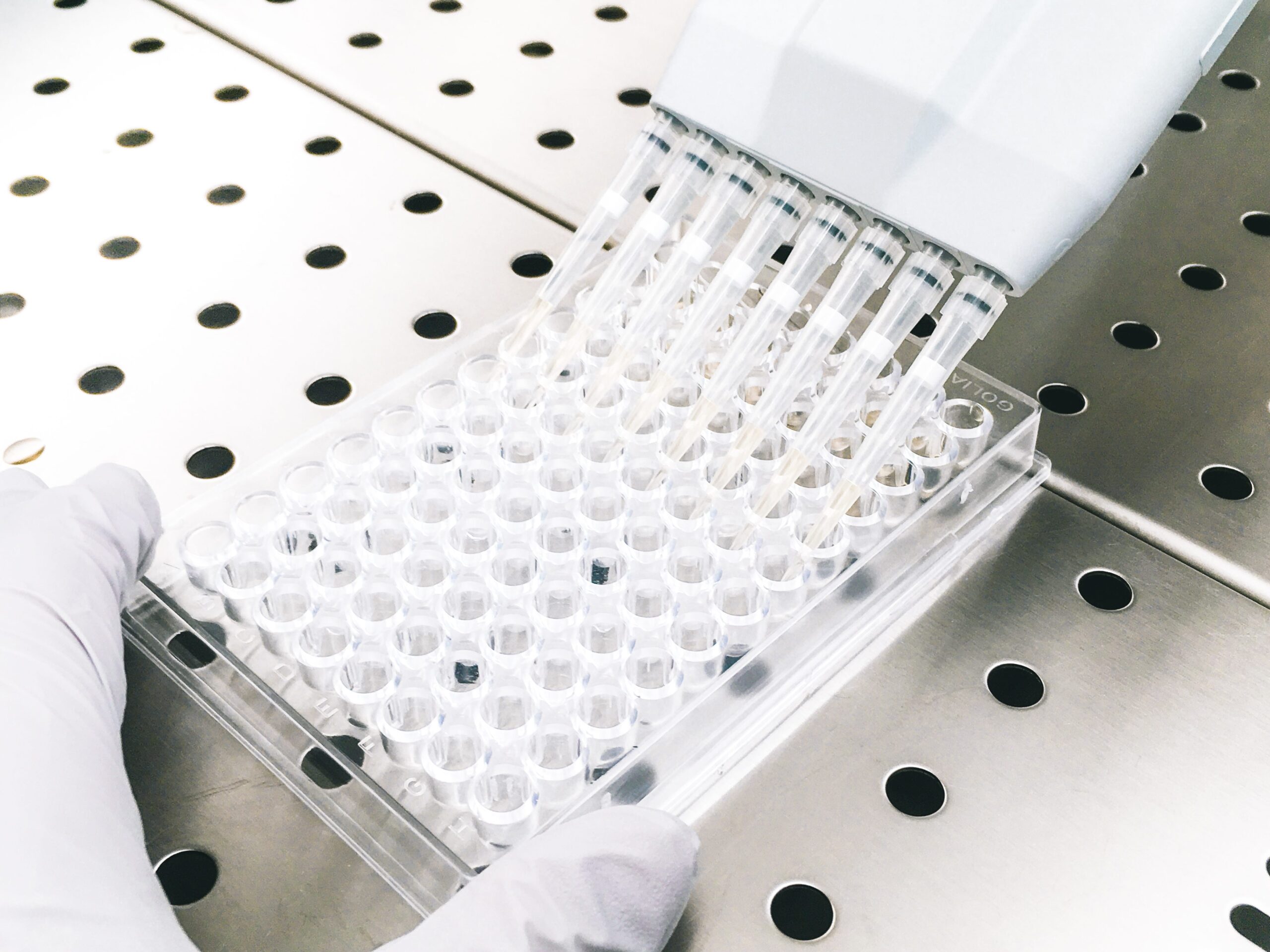

In-vitro diagnostics

Industrial waste water

Influenza vaccines

Injectable biologics

Insulin

Insulin injections

Intermediates

Intravenous solutions

Iodine-131

Kombucha

Lactic acid

Lactose

Lecithin

Life science

Lignin

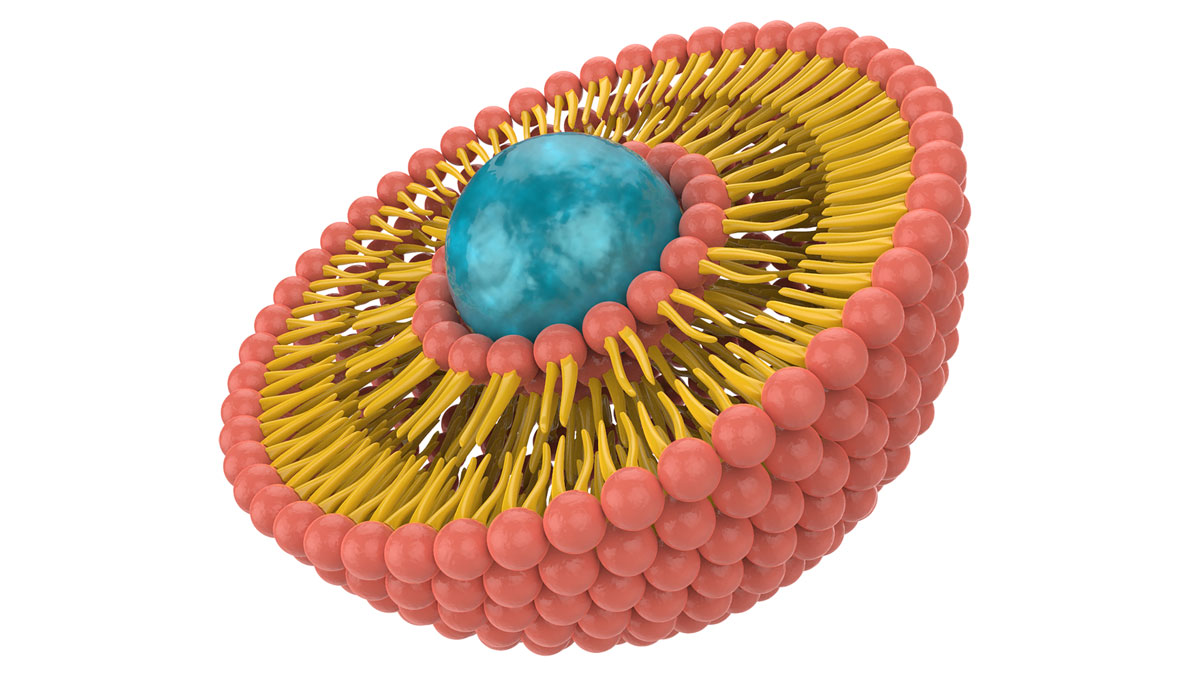

Liposomes

Liquid sweeteners

Lutetium-177

Maltodextrin

Marine algae

Medicinal cannabis

Medicine

Metal recycling

Metal salts

Methanol

Microcrystalline cellulose

Mineral water

Molecular biology

Monoclonal antibodies

Monomers

Mrna vaccines

Multi-fruit solutions

Next generation biologics

Nuclear medicine

Oncology drugs

Oral vaccines

Organic acids

Organic chemicals

Orphan drugs

Orthopedic implants

Pectin

Penicillin

Peptides

Pharmaceutical intermediates

Phosphates

Phosphoric acid

Plant waste

Plasmid dna

Plastic intermediates

Plastic resins

Plasticizers

Platinum catalysts

Polyester resin

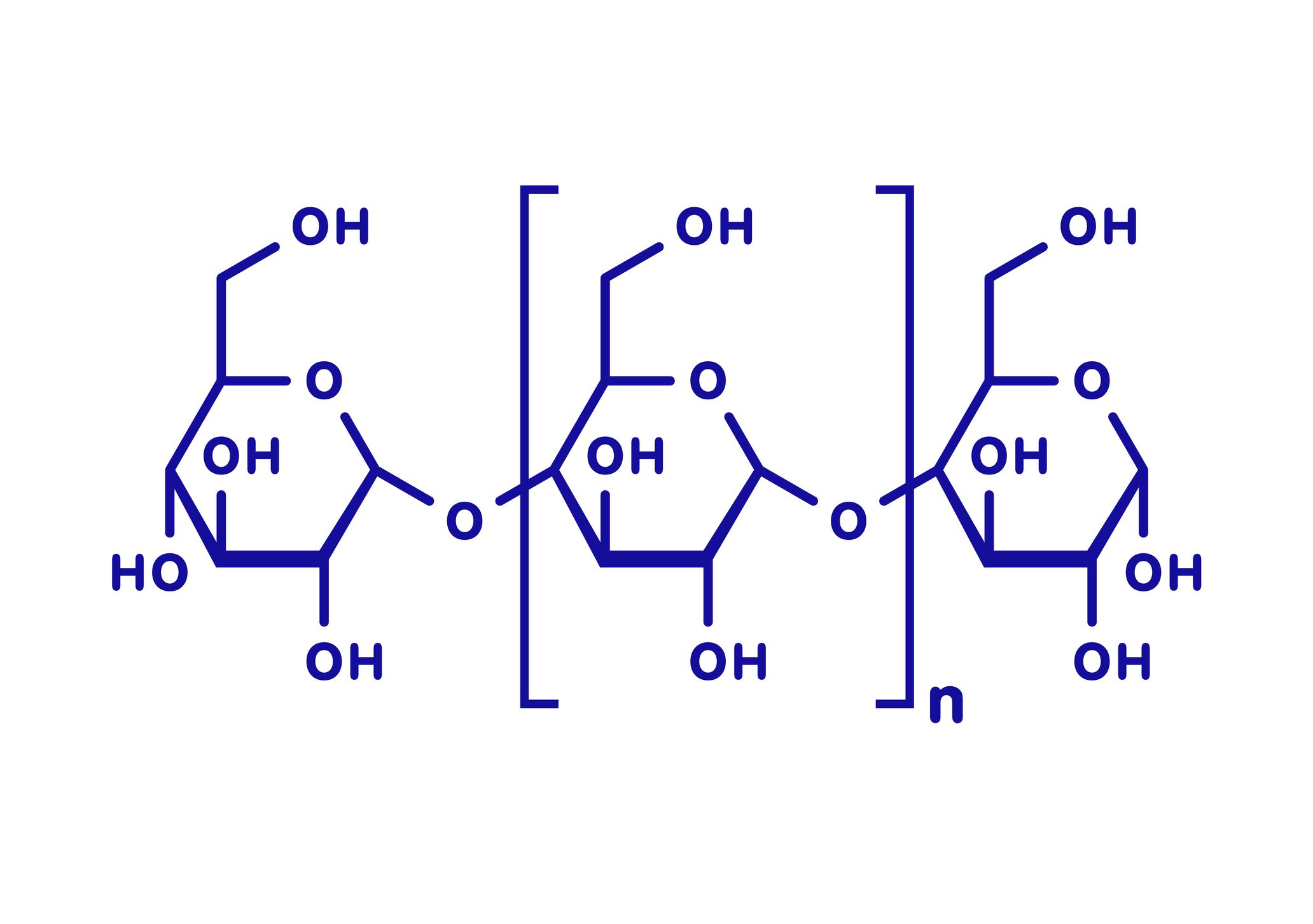

Polysaccharides

Precious metals

Propylene

Protein-based drugs

Protein powder

Protein therapeutics

Quartz

Radiopharmaceuticals

Recombinant proteins

Refined vegetable oils

Regenerative medicine

Rituximab

Silica

Small molecule drugs

Sodium chloride

Solid-state batteries

Sorbitol

Sour gas

Sparkling water

Specialty chemicals

Starch

Stearic acid

Sterile saline solutions

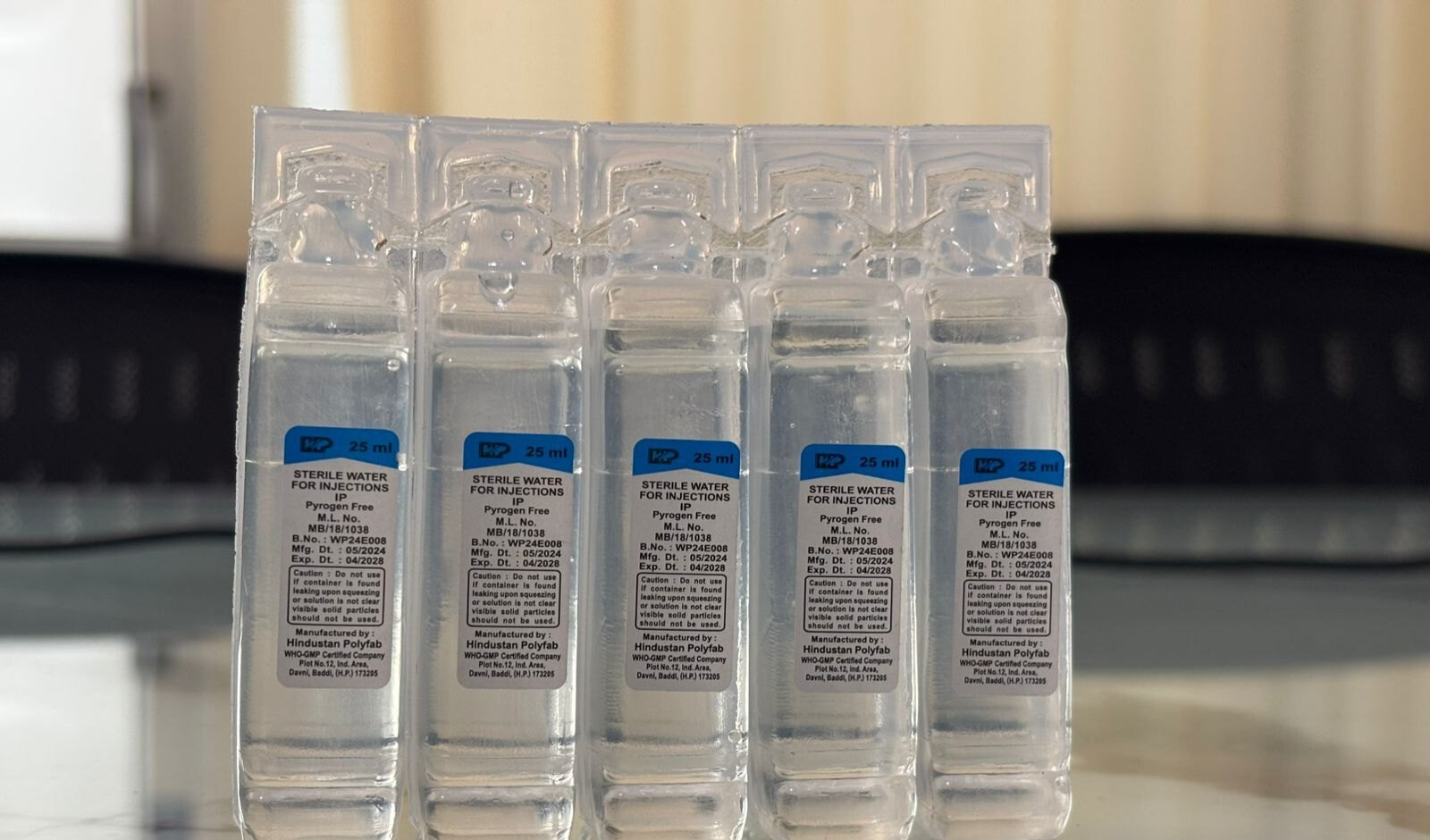

Sterile water for injection

Straw

Sugar

Sulfuric acid

Sulphur

Surfactants

Sweeteners

Synthetic pigments

Talc powder

Tea extracts

Tea tree oil

Technetium-99m

Technetium-99m radiopharmaceuticals

Terpenes

Textile dyes

Thc distillate

THC

Thc oil

Therapeutic proteins

Thickening agents

Thin film coatings

Thinners

Titanium dioxide

Toluene

Vaccines

Vanilla extract

Varnishes

Viral vector vaccines

Wastewater

Water for injection

Wheat gluten

Wheat starch

Whey protein isolate

Xanthan gum

Which purification technology do you need?

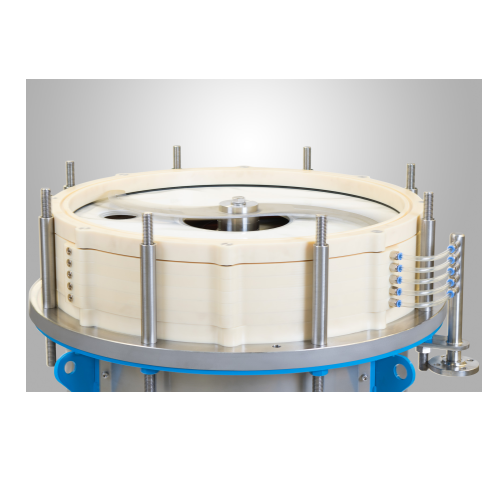

Centrifugal Partition Chromatography System for Purification and Separation

Traditional chromatography methods for nat...

Marine oil and water purification separators

Optimize your marine operations with high-efficiency separators designed to p...

Brine purification system for reducing bacteria and molds

Ensure pristine brine quality by continuously removing bacteri...

Laboratory vacuum cold trap for extract purification

Optimize your vacuum purging and drying applications with this advan...

Amine purification system for heat stable salt removal

Efficiently remove corrosive heat stable salts from amine circuits...

Sulfuric acid purification for aluminum anodizing

Improve the efficiency of your metal finishing operations with systems ...

Continuous acid purification for aluminum anodizing

Eliminate costly impurities from your process acids and ensure consis...

Ultrapure water purification system for ion chromatography

Achieve consistent ultrapure water supply for analytical appl...

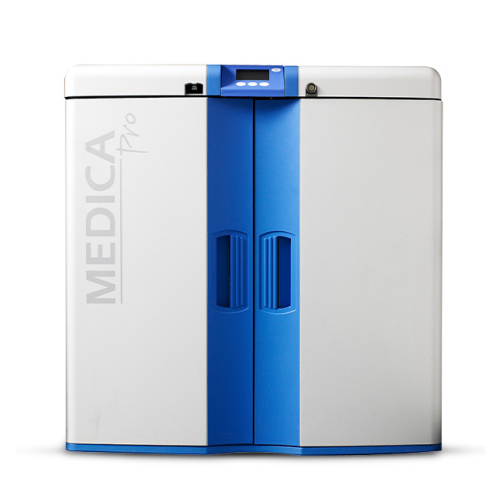

Pharmaceutical water purification system

Ensure compliance with stringent pharmaceutical standards by integrating a reliabl...

Water purification system for Pem electrolyser

Achieve premium water purity essential for hydrogen electrolysers with this...

Clinical analyzer water purification system

Ensure your clinical analyzers receive a constant supply of high-purity water ...

Clinical water purification system

Ensure your clinical analyzers are running with exacting standards by using state-of-the...

Water purification system for clinical diagnostics

Ensure consistent high-purity water supply for your critical clinical ...

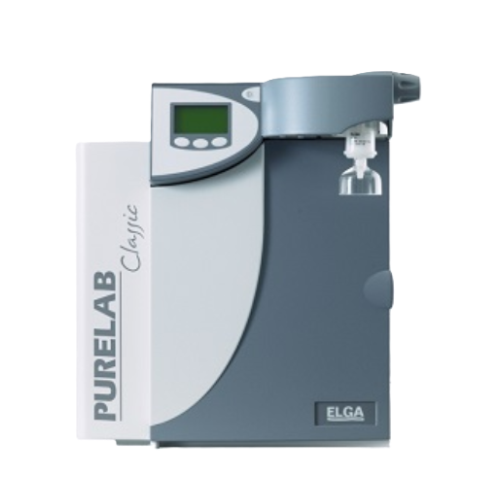

Laboratory water purification system

Achieve consistent water purity with a flexible and modular system designed to meet hi...

Type Iii water purification system for general lab use

Achieve consistent and reliable Type III water quality for laborat...

Water purification system for endoscope reprocessors

Ensure reliable water quality with a purification system designed to...

Central water purification system for laboratories

Ensure consistent supply of ultrapure water essential for critical lab...

Centralized water purification system for laboratories

Ensure consistent purity and reliability for your laboratory proce...

Centralized lab water purification system

Ensure consistent high-purity water delivery across your facility, optimizing la...

Iot monitoring system for laboratory water purification

Optimize your laboratory’s water purification with real-tim...

Supercritical Co2 fluid purification system

Optimize your extraction process with our supercritical CO2 fluid purification...

Industrial activated carbon filters for air purification

Optimize air quality control and odor management with versatile ...

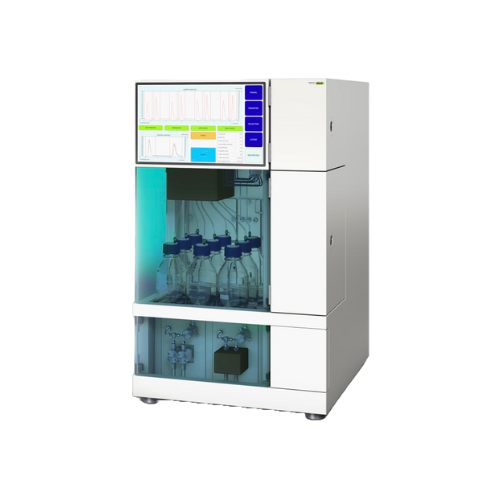

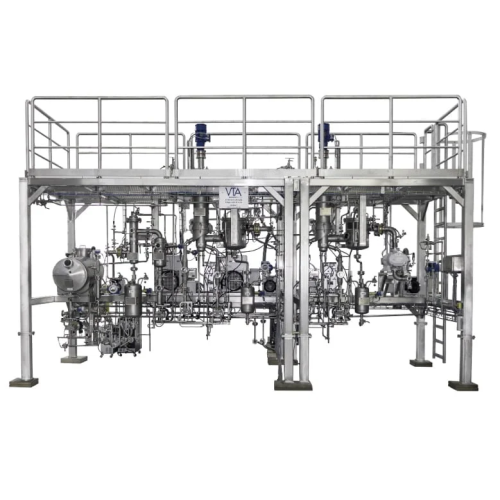

Customized chromatographic system for bioprocess purification

Streamline your bioprocess purification with advanced chro...

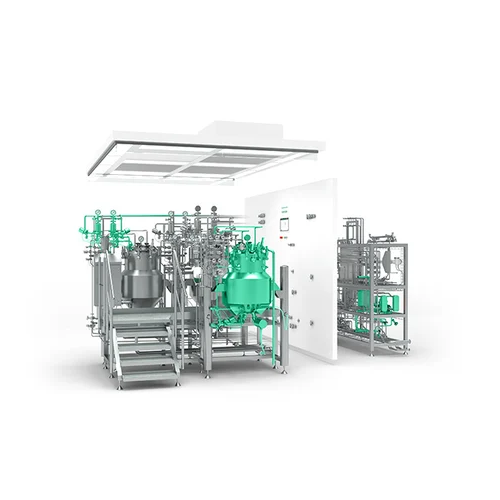

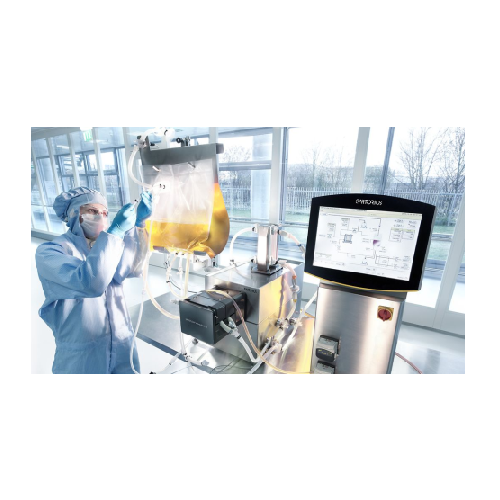

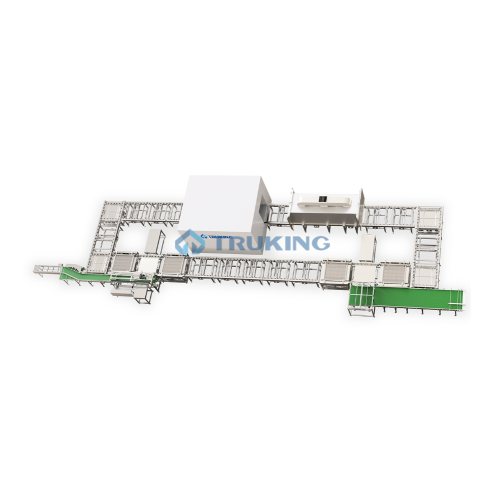

Hybrid bioprocess system for cell culture and purification

Streamline your bioprocessing operations with a versatile sol...

Industrial ion exchange system for chemical purification

Ensure precise ion removal and high-purity output in your produc...

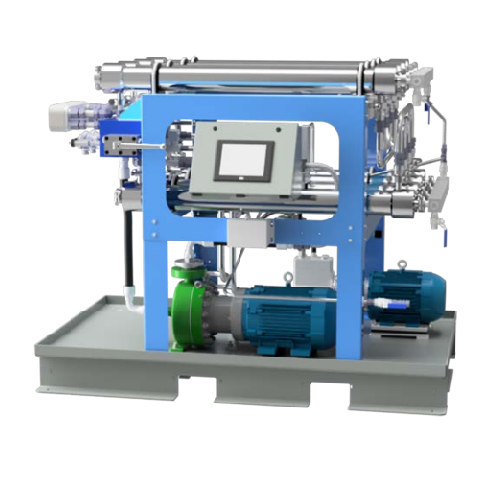

Cross flow filtration for industrial liquid purification

Optimize your production process with advanced cross flow filtra...

Olive oil purification separator

Achieve unparalleled clarity and purity in your olive oil production with advanced separati...

Oil purification system for industrial applications

Enhance oil quality and prolong machinery life with our unique filtra...

Solid-wall bowl separators for marine oil purification

Optimize your marine operations with solid-wall bowl separators, d...

Solid-wall bowl separator for power plant lube oil purification

Optimize your power plant’s performance by address...

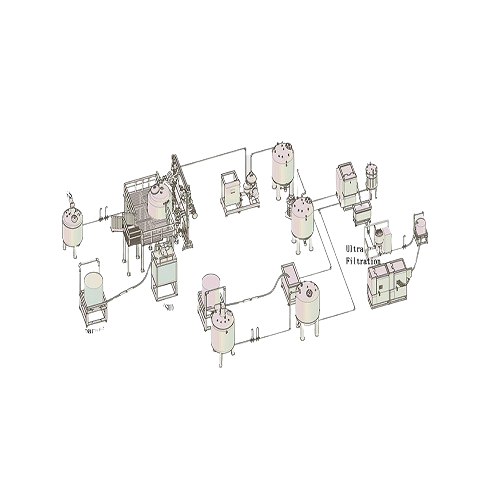

Water purification systems for fruit processing plants

Ensure high-quality fruit products with pristine water through adv...

Jet filter for industrial air purification

For facilities grappling with dust and pollutant control, enhancing air quality...

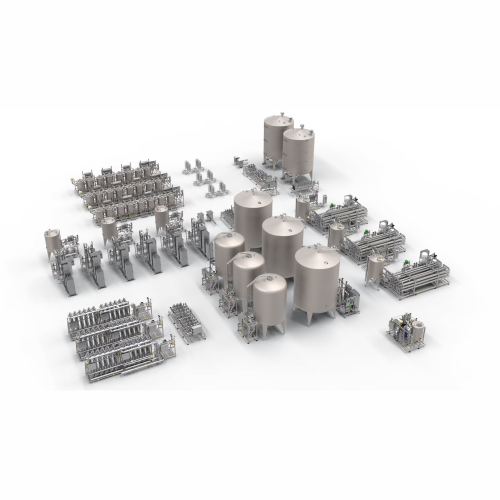

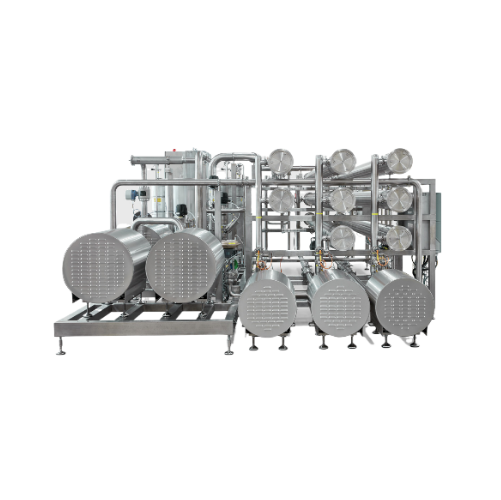

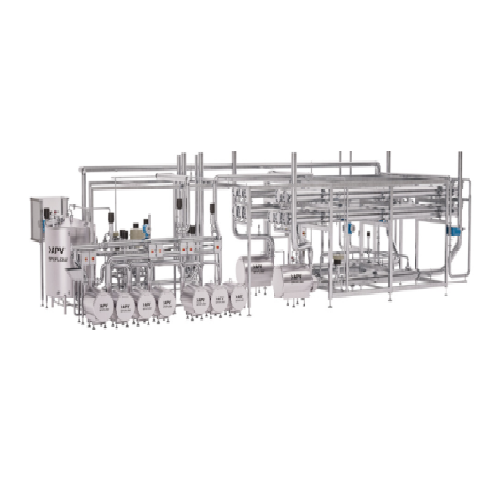

Chromatography systems for large-scale biopharmaceutical purification

Ensure precision purification of biopharmaceutica...

High-capacity centrifuge for vaccine purification

Optimize vaccine production with high-speed centrifuging that ensures p...

Ultrapure water purification system for laboratories

Achieve consistent high-purity water essential for sensitive laborat...

Reverse osmosis water purification system

Efficiently purify and maintain high-quality laboratory-grade water crucial for ...

Combined lab water purification system

Optimize lab efficiency with a streamlined system delivering ultrapure and pure wate...

Compact ultrapure water purification system

Achieve consistent, high-purity water ideal for critical lab applications with...

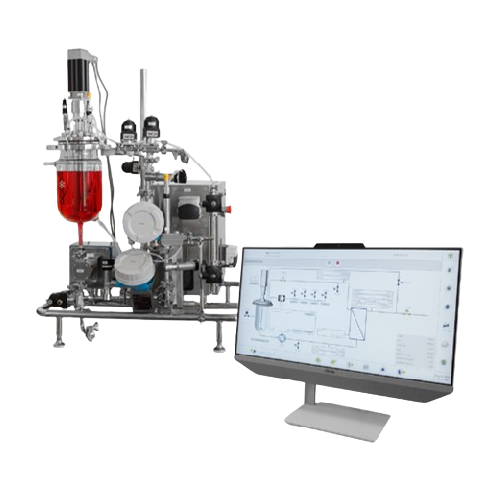

Plasmid process pack for your pDNA purification process

When developing a pDNA purification process for eventual transfer...

Purification screening kit for large biomolecules

To purify a specific large biomolecule, for example IgM or a virus or v...

Exhaust gas recirculation and bilge water treatment system

Ensure compliance with environmental maritime regulations by ...

Marine bilge water separator

Achieve ultra-low residual oil content in marine operations with a compact separator system, en...

Biofuel separator for marine applications

Efficiently separate and purify marine biofuels while meeting the stringent envi...

Separators for animal and fish by-products

Efficiently extract, purify, and recover valuable components such as high-quali...

High-speed separator for oil and water phases in oil & gas

Ensure continuous operation in harsh oil and gas environments...

Separators for oil recovery

Enhance oil recovery and purity with advanced separators designed to efficiently handle and proc...

Nozzle separator for baker's yeast production

Achieve consistent yeast concentration and reduce product losses with advanc...

Pharmaceutical separator for high solid contents

Ensure optimal purity in biopharmaceutical processing with a separator de...

Pharma separator for biopharma processing

Streamline your production with this advanced separator, designed to efficiently...

Separators for biochemicals

Achieve precise separation and purification of complex biochemical mixtures with self-cleaning c...

Clarifier for industrial fluids

Optimize fluid purity and extend equipment lifespan by efficiently separating contaminants f...

Co2 recovery system for breweries

Unlock the full potential of fermentation by capturing and purifying CO2 for immediate re...

Vacuum cold trap for lab applications

Ensure efficient separation and purification in biopharmaceutical applications with t...

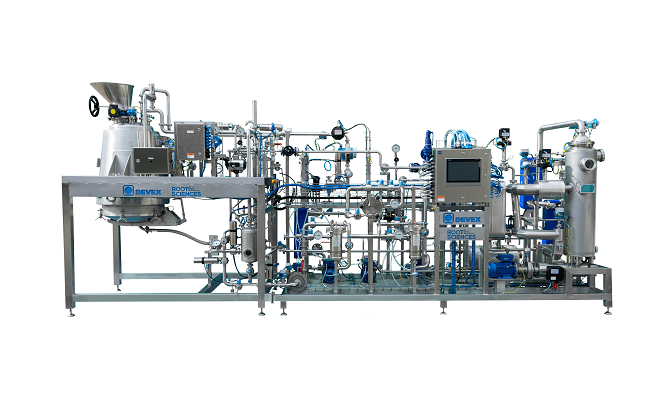

Hydrocarbon solvent distillation unit for extractors

Ensure high purity levels in your extraction process by integrating ...

Tangential filtration system for wine production

Achieve precise filtration, purification, and concentration of compounds ...

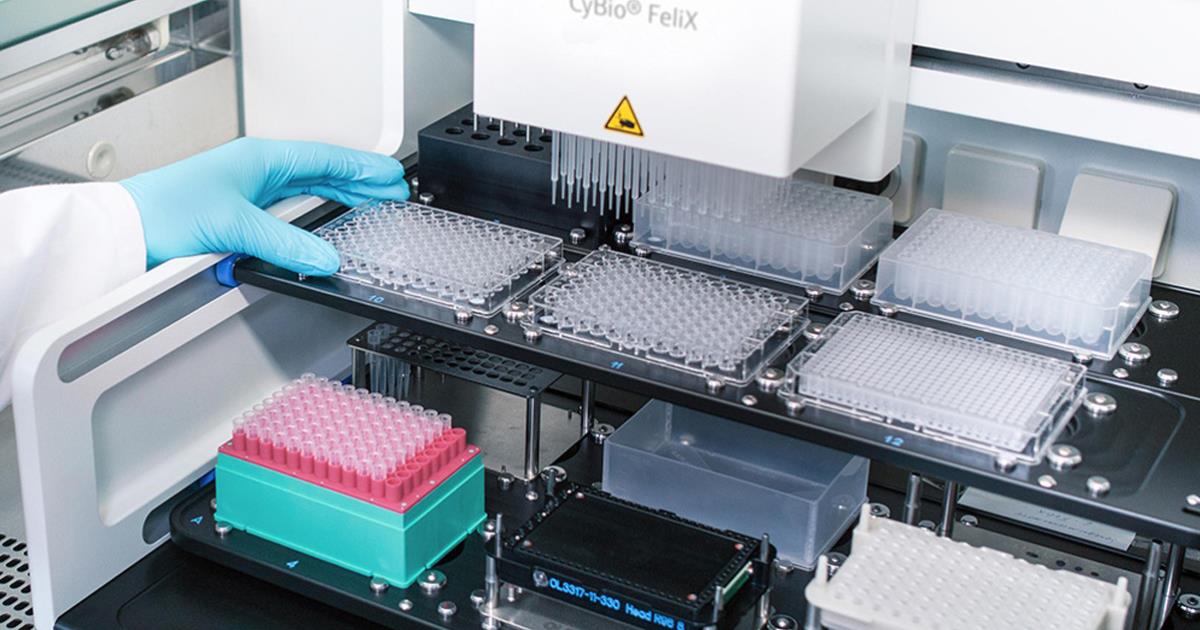

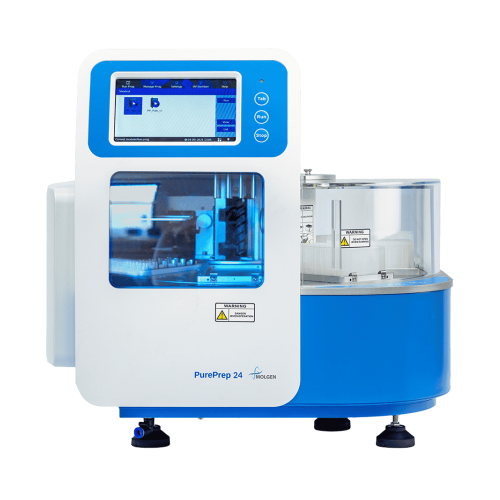

High-volume nucleic acid extraction system

Effortlessly handle large sample volumes with precision and consistency, removi...

High-throughput nucleic acid extraction system

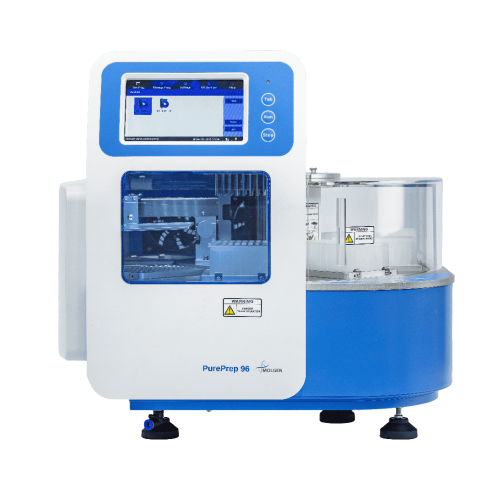

Streamline your nucleic acid extraction process with high-throughput effici...

Compact automated nucleic acid extraction system

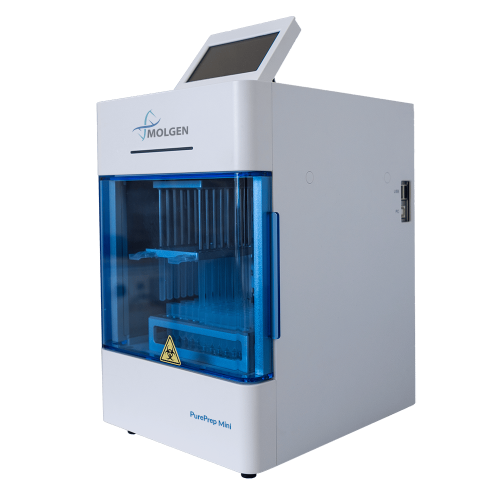

Quickly automate nucleic acid purification to reduce hands-on time and mi...

Industrial water treatment system

Ensure your beverage production maintains optimal purity and taste with tailored water tr...

Water ozonisation system for enhanced disinfection

Ensure impeccable water quality with cutting-edge ozonisation that eff...

Selective ion exchange for copper refining operations

Optimize your copper refining process by efficiently removing conta...

Ion exchange system for electroplating and steel pickling acids

Achieve continuous separation and recovery of metal salt...

Ion exchange for chloride and potassium removal in kraft mills

Optimize your kraft mill operations by efficiently removi...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Hollow fiber membranes for wastewater treatment

Ensure consistent, high-quality effluent from industrial water and wastewa...

Gas contactor for hydrogen sulfide removal from biogas and sour gas

Efficiently convert harmful hydrogen sulfide into m...

Crossflow filter for liquid filtration in food industry

Enhance your liquid filtration process with a versatile crossflow...

Water treatment and lotion preparation for wet wipes

Ensure the integrity of your wet wipe production by implementing con...

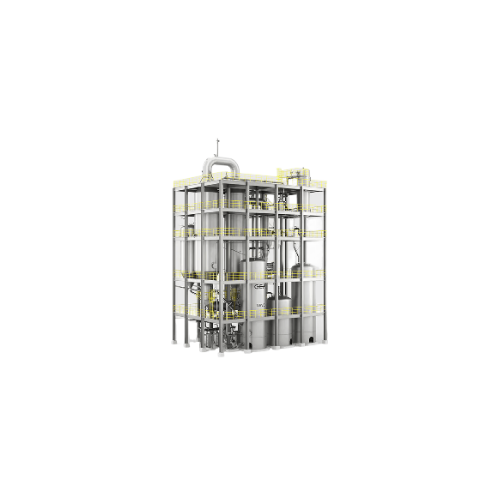

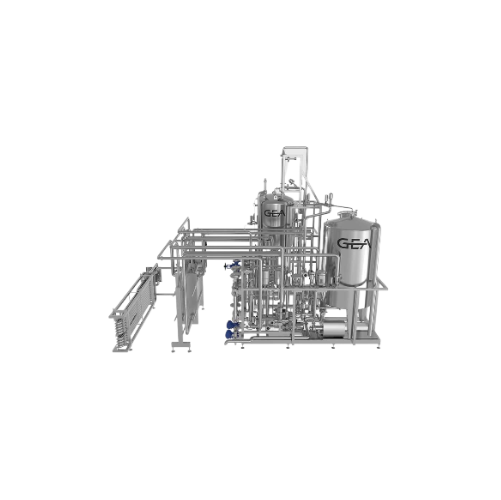

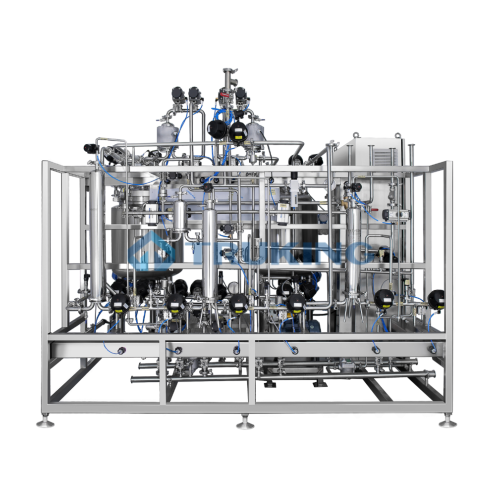

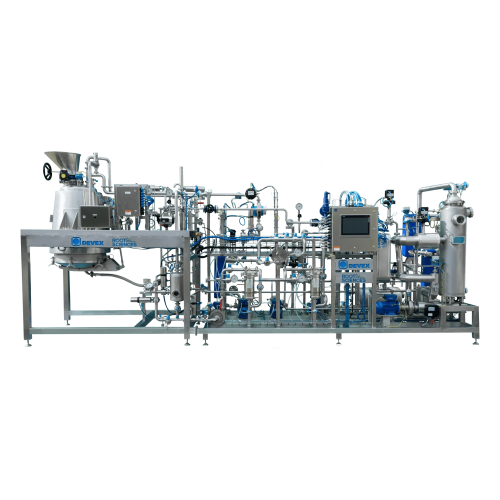

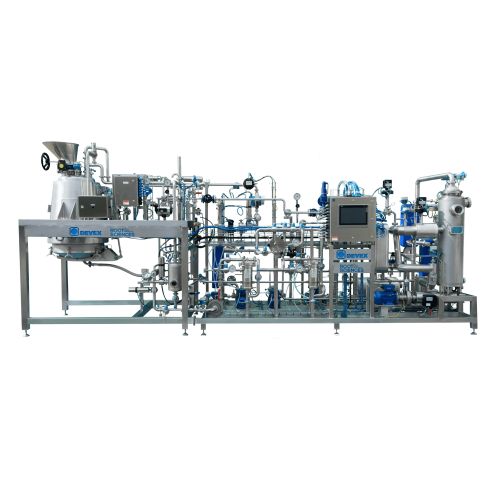

Purified water generation system for pharma applications

Ensure consistent purity in your therapeutics production with a ...

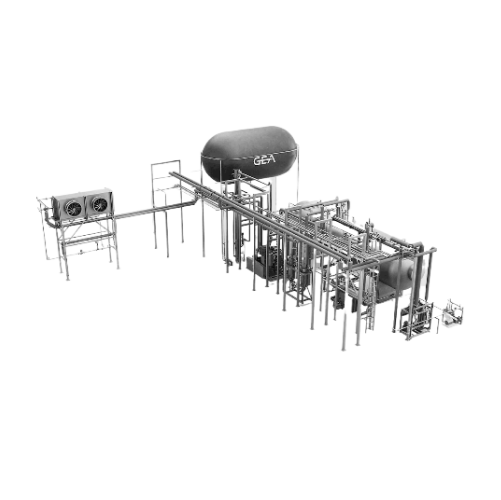

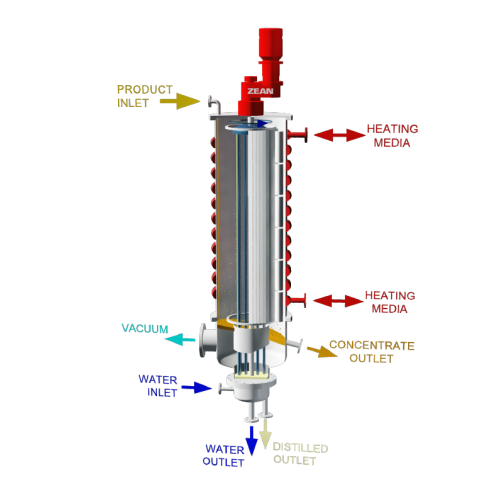

Water for injection (wfi) generation technology

Optimize your purification process with precise distillation and efficient...

Biogas upgrader for high methane yield

Optimize biogas production by efficiently converting raw biogas into high-purity bio...

Magnetic bag filter unit for heating and cooling systems

Efficiently remove magnetic and non-magnetic particles to enhanc...

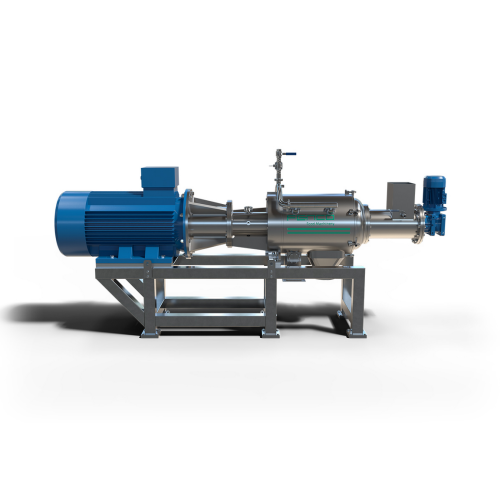

Horizontal peeler centrifuge for chemical applications

Achieve high-throughput product separation and purification with p...

Din standard glass-lined reactors

Streamline your chemical reactions with these DIN standard glass-lined reactors, designed...

Packed and tray columns for distillation, absorption, and extraction

Enhance your production line with columns designed...

Glass lined columns for chemical plants

Optimize your chemical processing with glass-lined columns, designed to ensure maxi...

Water for injections generation system

Ensure compliance with strict regulatory standards while providing pyrogen-free wate...

High-speed centrifuge for laboratory applications

Maximize efficiency in high-volume centrifugation tasks with this versa...

Refrigerated bench-top centrifuge

Ensure efficient cellular and molecular sample preparation with versatile separation and ...

Ultrapure water system for analytical applications

Ensure critical purity for your molecular and analytical processes wit...

High-purity water system for clinical diagnostic analyzers

Ensure your clinical analyzers receive uninterrupted, high-pu...

Ultrapure water system for molecular biology and cell culture

For laboratories demanding consistent high-purity water, t...

Ultrapure water system for laboratory use

Achieve consistent 18.2 MΩ.cm ultrapure water for your laboratory processes, ens...

High-pressure catalytic system for air pollution control

Enhance your exhaust management with a high-pressure catalytic s...

Low-pressure catalytic system for Voc removal

Efficiently remove volatile organic compounds while reducing energy consumpt...

Industrial liquid distillation for solvent recovery

Optimize your solvent separation and purification process with advanc...

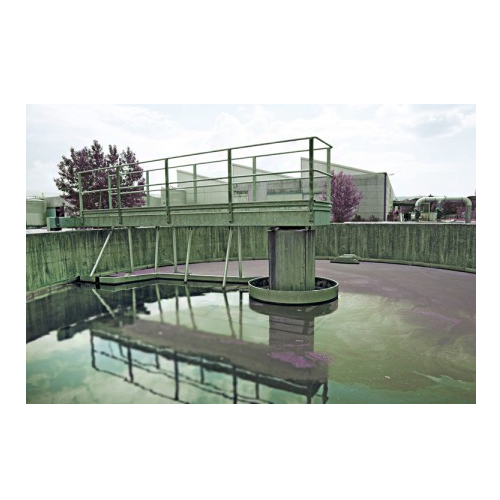

Biological water treatment systems

Maximize efficiency in water treatment with advanced biological systems designed to seam...

Nanofiltration systems for water pretreatment

Achieve precise water quality with advanced nanofiltration systems designed ...

Organic ultrafiltration for water bottling lines

Optimize your beverage production with efficient pre-treatment, ensuring ...

Reverse osmosis systems for industrial water treatment

Achieve optimal water purification in beverage production lines wi...

Evaporative crystallizers for chemical processing

Optimize your crystallization process with state-of-the-art evaporative...

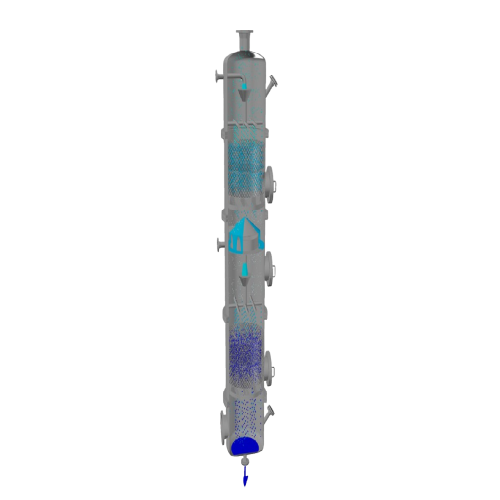

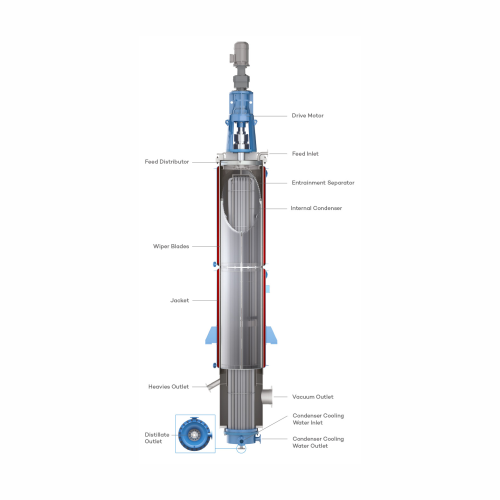

Short path evaporator for high vacuum distillation

Achieve high-efficiency separation and purification of sensitive compo...

Thin film evaporator for temperature sensitive products

Need to purify temperature-sensitive compounds efficiently? Achie...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Rectification column for close boiling point separation

Achieve high-purity separation and distillation for compounds wit...

Industrial oil bleaching process

Optimize your oil purification process with advanced bleaching technology, significantly en...

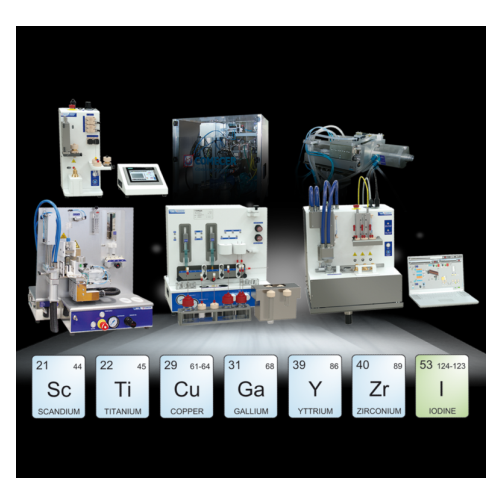

Ra-223 dichloride production and dispensing suite

Ensure precise production of Ra-223 dichloride and related radiopharmac...

Radioactive waste disposal system for medical facilities

Handle radioactive waste safely by utilizing an automated system...

Semiautomatic lu-177 production and dispensing plant

Optimize your radiopharmaceutical production with an advanced system...

Automated ioflupane i-123 injection dispensing solution

Ensure precision and efficiency in radiopharmaceutical production...

Solid target processing system for radionuclide production

Effectively produce a wide range of medical isotopes with pre...

Uv reactor and activated carbon filter for odor reduction

Effectively mitigate VOC and odor emissions with a compact sys...

Catalytic system for industrial odour and Voc elimination

Tackle VOC and odour emissions with a versatile catalytic syst...

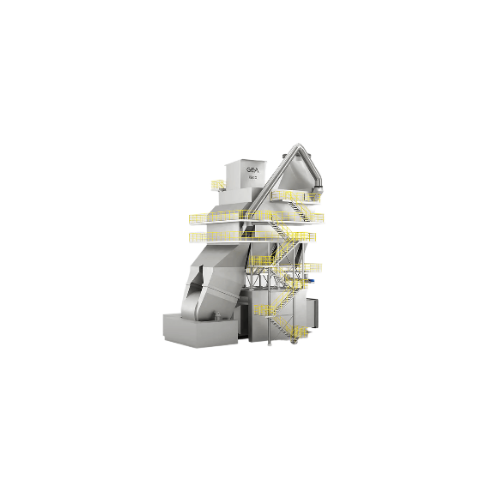

Grain purifier for wheat and corn milling

Optimize grain processing with a high-throughput purifier designed to enhance pu...

Grain purifier for high-yield flour and semolina

Optimize your milling process with advanced purification and grading, ens...

Purifier for semolina and middlings in grain mills

Upgrade your milling efficiency with a high-speed purifier that ensure...

Supercritical fluid chromatography system for preparative separations

For complex substance formulations requiring rapi...

Compact flash and prep Hplc chromatography system

Streamline your purification processes with a versatile system that int...

Flash chromatography system for basic applications

Streamline your purification process with a modular system designed fo...

Hydrocarbon recovery unit for chemical plants

Maximize your hydrocarbon capture and reuse with an advanced recovery unit t...

Monomer recovery unit

Effectively recover valuable monomers while ensuring high purity and low operating pressures, ideal for...

Propylene and nitrogen recovery system for industrial applications

Enhance your production efficiency by recovering hig...

Hydrogen separation membranes for refineries

Optimize hydrogen recovery and purification in your production line with adva...

Organic solvent nanofiltration for liquid separation

Optimize your process streams with solvent recovery that minimizes e...

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

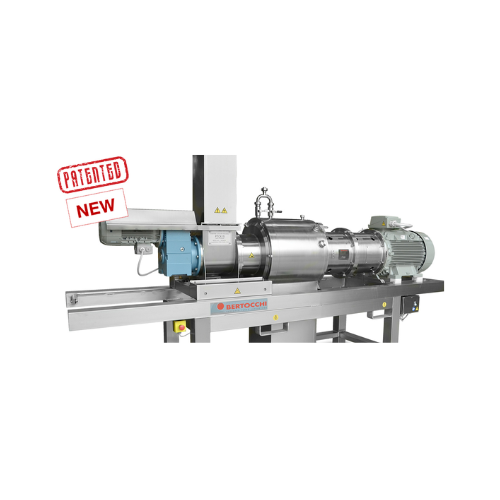

Continuous wet granulation equipment

Achieve optimal particle size and uniformity in pharmaceutical production with our con...

Customized Hvac system for pharmaceutical clean rooms

Achieve seamless sterilization and contamination control in clean r...

Ultrafiltration and depth filtration system for biopharmaceuticals

Achieve precise separation and purification of bioph...

Chromatography process for high-purity industrial separation

Achieve continuous high-purity separation and purification ...

Horizontal peeler centrifuge for filtration

Optimize your batch processing with a centrifuge designed for high-speed, effi...

Automatic reverse osmosis water treatment plant

Ensure high-purity water by seamlessly integrating this reverse osmosis tr...

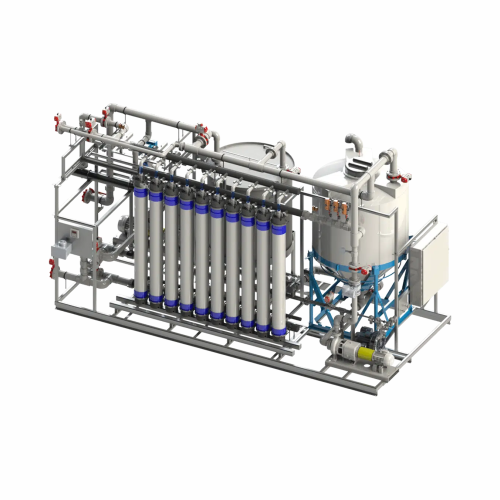

Ultra filtration water treatment system for drinking water

Achieve exceptional water purity with advanced hollow fiber u...

Plant-based protein extraction technology

Achieve optimal purity in plant-based milk, yogurt, and cheese production with c...

Biopharma cell centrifuge for gentle protein recovery

Ensure gentle cell harvesting and enhanced yield in bioprocessing w...

Decanter centrifuge for vegetable oil clarification

Maximize oil recovery and purity with advanced decanter centrifuge te...

Cip recovery system with membrane filtration

Reduce chemical waste and operating costs by recovering over 90% of spent cau...

Filtration brine sanitation unit for cheese production

Ensure your cheese retains its premium quality and flavor by effec...

Custom-designed membrane filtration systems for industrial applications

Optimize your production with advanced membrane...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Melt crystallization for high purity chemical products

Achieve ultra-pure products with minimal energy by integrating mel...

Emergency gas scrubber for chlorine leaks

Ensure air safety during chlorine emergencies with a reliable scrubbing solution...

Packed column scrubber for exhaust gas cleaning

For efficient gas cleaning across diverse processes, this packed column sc...

Co2 utilization and sequestration system

Optimize CO2 emissions management by converting captured CO2 into valuable product...

Batch distillation plants for diverse compound mixtures

Optimize your separation processes with flexible batch distillati...

Industrial distillation testing services

Ensure optimal purity and performance by utilizing advanced pilot and mobile disti...

Mvr and Tvr heated distillation system

Achieve superior energy efficiency and reduced steam consumption in your distillatio...

Ultrafiltration and reverse osmosis for beverage industry

Optimize water treatment with combined ultrafiltration and rev...

Air cleaning system for office spaces

Combat airborne viruses and allergens efficiently with a compact air cleaning system ...

Industrial fruit bin washing system

Optimize your fruit and vegetable processing with a high-speed bin washing system that ...

Industrial roller mill for high-stability milling

Optimize your milling process with a high-speed roller system designed ...

Automatic chromatography column for biopharmaceutical separation

Ensure high-purity monoclonal antibodies and herbal ext...

Advanced color sorting for mining applications

Optimize mineral purification with precision color sorting, ensuring consis...

Precast agarose gels for Dna electrophoresis

Achieve precise DNA separation and purification effortlessly with bufferless ...

Centrifugal oil filter for removing oil impurities

Enhance oil purity and ensure efficient removal of impurities with thi...

Modular pharmaceutical formulation systems

Achieve unparalleled flexibility and efficiency in liquid pharmaceutical formul...

Reverse osmosis system for dairy and plant-based processing

Enhance your production line with high-pressure reverse osmo...

Ultrafiltration system for heavy particle-laden process media

Designed for efficient particle removal, this advanced fil...

Laboratory freeze dryer

Achieve precise moisture control and enhanced product stability with this advanced freeze-drying solu...

Pilot industrial tangential flow filtration system

Enhance precision in filtration and separation processes with this sys...

Benchtop tangential flow filtration system

Ensure high-purity yields and streamline your filtration processes with this be...

Reverse osmosis water treatment system for medical device cleaning

Ensure purity and compliance by seamlessly integrati...

Industrial ultraviolet air purifier

Ensure a sterile environment in your medical facility with advanced ultraviolet technol...

Net-gas medicine storage cabinet for volatile chemicals

Ensure safe and efficient storage of volatile chemical agents wit...

Ductless fume hood for medium chemistry experiments

Eliminate the need for cumbersome air duct installations while ensuri...

Single-use batch chromatography systems for biopharmaceuticals

Streamline your purification process with high productivi...

Tangential flow filtration system for cell harvesting

Optimize your biopharmaceutical production by integrating a versati...

Laboratory water storage system for protecting water quality

Optimize your lab processes with a closed water storage sys...

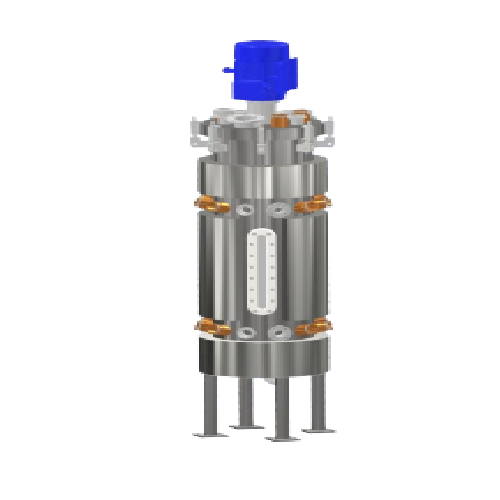

Stainless steel bioreactors

Enhance your bioproduction capabilities with robust solutions designed for efficient fermentatio...

Cannabis and hemp short path distillation system

Achieve optimal cannabinoid purification with continuous high-volume dist...

Wiped-film short-path distillation equipment for cannabis processing

Achieve up to 99% cannabinoid purity with this dis...

Cannabis distillate production system

Achieve high-purity cannabinoid distillates with continuous, high-volume processing t...

Cannabis oil nanofiltration system

Achieve high-purity cannabinoid extracts with advanced nanofiltration, ensuring precise ...

Cannabis and hemp processing nanofiltration system

Enhance the clarity and potency of your extracts with advanced membran...

Short-path wiped-film distillation for cannabis

Achieve optimal cannabinoid purity with precise thermal separation, perfec...

Cannabis and hemp distillation system

Achieve up to 99% cannabinoid purity with high-throughput, continuous distillation th...

High-speed decanting centrifuges for solid-liquid and liquid-liquid separation

Optimize your separation processes with...

Glycerine manufacturing plant

Glycerol or glycerin is the major by-product generated in the biodiesel production process. Bu...

Water oil separation centrifuge

Some industries, such as petrochemical, generate large volumes of oily wastewater due to the...

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...

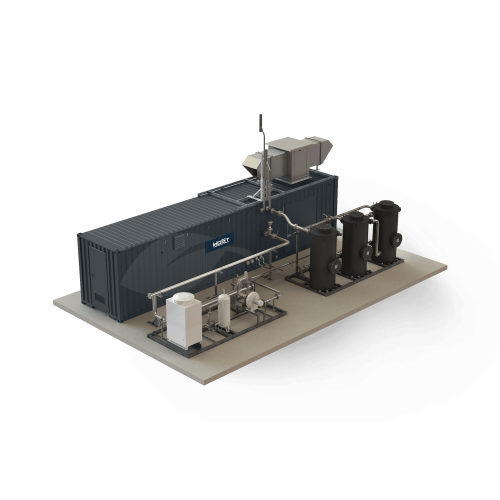

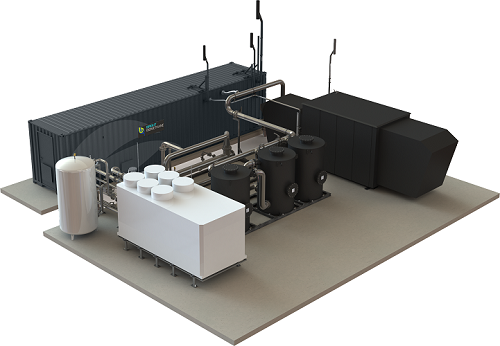

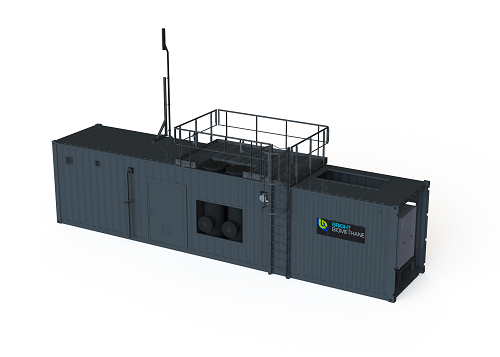

Efficient sized biomethane production system

Also referred to as biogas purification, biogas upgrading is an excellent alt...

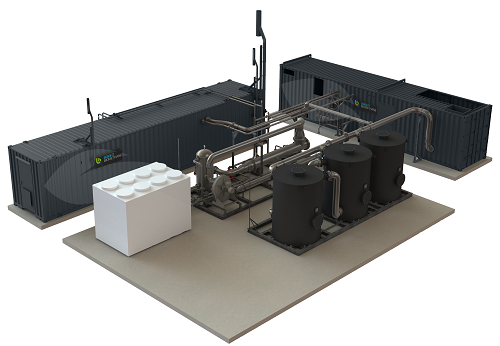

Large-scale biomethane production system

Membrane separation technology for biogas purification is considered as an effecti...

Small-scale biogas upgrading system

Biogas upgrading refers to the process of purifying biogas through separating methane f...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

Plug and play natural gas to hydrogen generator

Hydrogen is an all-purpose element and can be simply defined as energy’s S...

Containerized hydrogen upgrading system

Usually, all spent protective gas is vented from metal treatment processes, such as...

Pharmaceutical pure steam generator

Dry, saturated steam can be used to sterilise pharmaceutical manufacturing equipment, a...

Disposable monolithic columns

Chromatographic monolithic columns for working with large proteins, viruses, VLPs and pDNA req...

Short bed monolithic columns for analytics

Samples taken at various process steps need to be analysed quickly and accurate...

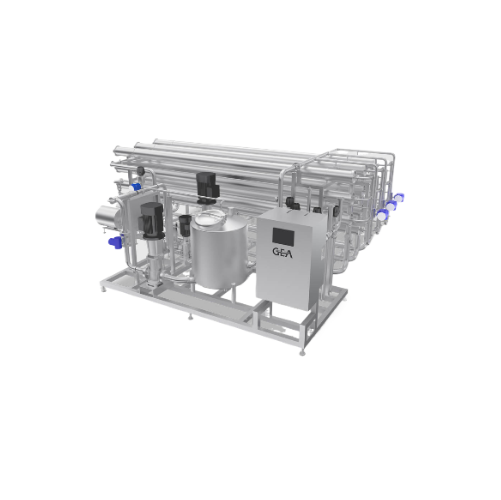

Purified water systems

Highly Purified water is used in the preparation of medicinal products where bacterial endotoxins need...

Biocompatible tubing for peristaltic pumps

Sensitive bioprocess applications requires equipment that will not interfere wi...

Bag holder and weighing platform for bioprocesses

Single use bags for biopharmaceutical process containment and liquid st...

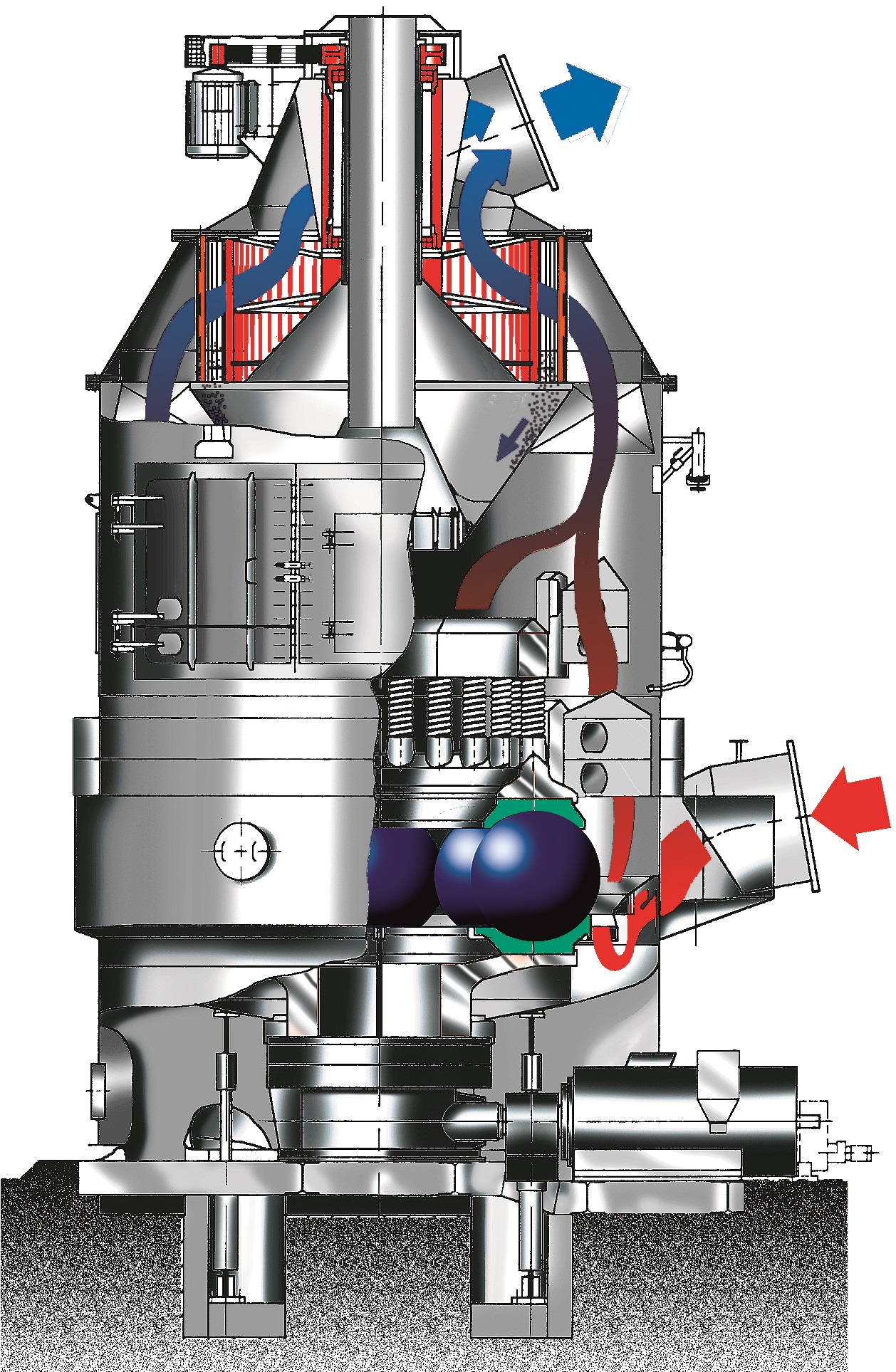

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

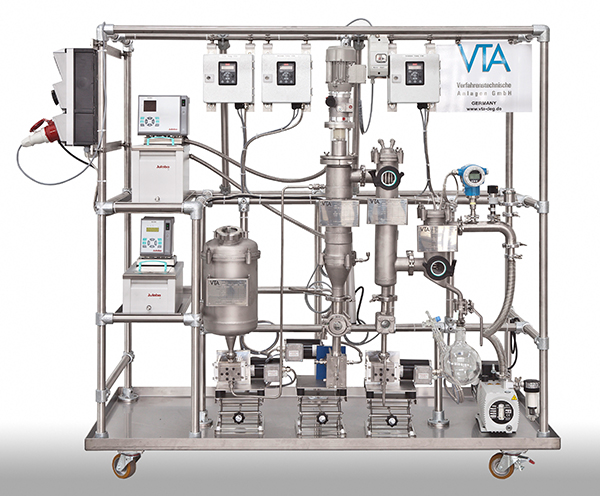

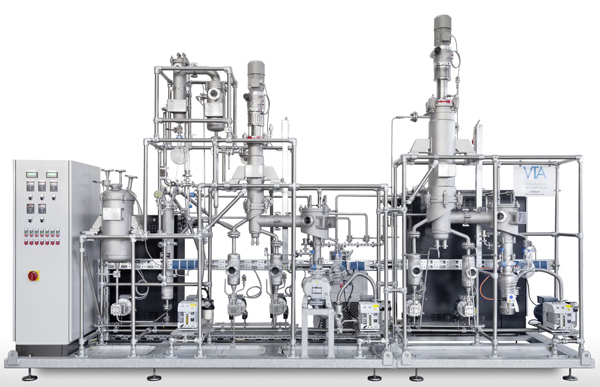

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

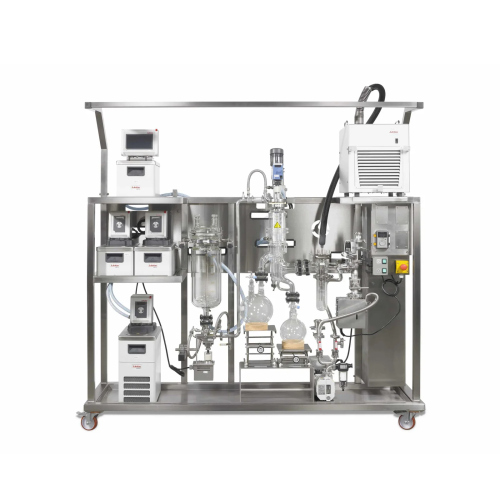

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

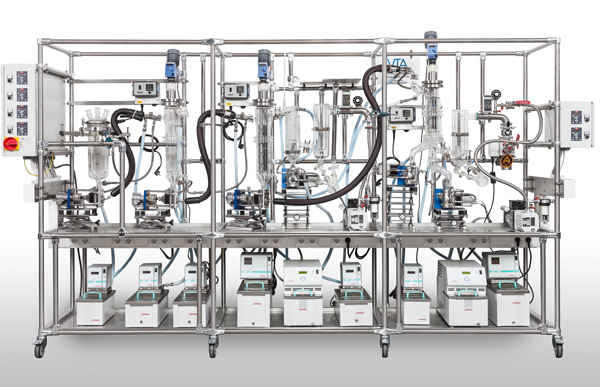

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...

Short path evaporators

With short path distillation, a substantial decrease of boiling temperature is obtained by reducing th...

Mill for calcining gypsum

Quality of gypsum and stucco products are highly influenced by the quality of the calcining proces...

Energy recovery system for lube oil treatment

Maximize energy efficiency by recovering lost heat in your lube oil treatmen...

Marine exhaust gas recirculation water purifier

As shipping regulations tighten, achieving compliant exhaust emissions whi...

Citrus juice de-oiling separator

Achieve optimal citrus juice clarity and essential oil separation with this advanced three-...

Pharma extraction clarifier

Achieve superior purity in pharma extraction with efficient separation of solids and liquids, se...

Biopharma separator for low to medium solid content

Ensure precise separation and high yield in biopharmaceutical product...

Nozzle separators for palm oil recovery

Maximize your oil recovery and reduce waste with nozzle separators, designed to eff...

Aseptic separator for high solid content in biopharma

Ensure high yield and optimal purity in biopharmaceuticals with thi...

Membrane filtration unit for hard seltzer production

Effortlessly produce a clear, aroma-free base for hard seltzers by e...

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Bacteria removal separator for dairy products

Ensure top-quality dairy and plant-based products with reliable bacteria rem...

Gas compressor for solvent recovery in hydrocarbon extraction

Need efficient, explosion-proof gas recovery for butane or...

Continuous feed solvent evaporator for cannabis and hemp industries

Streamline your extraction process with a system de...

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

Evaporators for grape juice and dairy products

Optimize the concentration of grape juice and dairy products with precision...

Continuous deaeration solution for laboratory and pilot systems

Achieve superior product stability and minimize foaming ...

Pem electrolyzers for efficient hydrogen production

Transform fluctuating renewable energy into storable, high-purity hyd...

Hydrogen refueling stations planning and construction

Facing challenges in setting up hydrogen infrastructure? Our soluti...

Virus filtration systems for biologics processing

Ensure efficient virus retention in biopharmaceutical production by int...

Vacuum filtration for sterile media and buffer preparation

Achieve reliable sterilization and filtration of cell culture...

Syringe filters for liquid and gas samples

Ensure particle-free liquid and gas samples with high-precision filtration, ide...

Flake ice production system for direct ammonia refrigeration

Optimize your cooling processes with a highly efficient ice...

Laboratory refiner/conche for chocolate processing

For chocolate producers seeking precise control over texture and flavo...

Duplex refiner/conche for chocolate production

Effortlessly transform cocoa, sugar, and other ingredients into smooth, fin...

Commercial chocolate refiner/conche

Elevate your chocolate production with a versatile 5-in-1 solution, integrating cocoa m...

Chocolate refiner/conche system

Streamline your chocolate production with a versatile solution that combines grinding, mixin...

Citrus fruit juicing system

Efficiently extract and refine citrus juices and oils with a streamlined system designed to hand...

Hollow fiber membranes for clarification in food and beverage industry

Optimize filtration and separation processes wit...

Mbr module for wastewater treatment

Optimize your wastewater management with efficient membrane bioreactors, designed to en...

Lactose drying system for high-quality edible powder

Achieve precise and cost-effective lactose transformation into high-...

Hygienic pipeline product recovery system

Efficiently recover valuable residuals from pipelines while streamlining your cl...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

Micro-filtration system for beverage industry

Achieve microbiological stability at cold temperatures with our micro-filtra...

Wine recovery system for bottling processes

Streamline bottling operations by recovering and re-dosing valuable wine, redu...

Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrat...

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Purified water storage and distribution for pharmaceuticals

Ensure seamless water quality for critical pharmaceutical pr...

Co2 recovery and liquefaction system for biogas upgrading

Maximize methane recovery while producing food-grade liquid CO...

Organic waste biogas plant

Transform abundant organic waste into renewable energy and valuable byproducts with a high-effici...

Organic residue and manure biogas plant

Transform organic waste into renewable energy while efficiently reducing carbon emi...

Rdf-fired combined heat and power plants

Transform refuse-derived fuel (RDF) into renewable energy, effectively reducing re...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

Beer production filtration system

Enhance your beverage production with cutting-edge filtration systems designed to maintai...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...

Continuous kneader for viscous applications

For engineers tackling high-viscosity challenges, this continuous kneader stre...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Waste powder recovery cyclone for pharmaceutical processes

Efficiently recover up to 99.9% of waste powder from oral sol...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

Chocolate refiner and conche solution

Elevate your chocolate production with a versatile solution that seamlessly integrate...

Chocolate refining five-roll refiner

Achieve optimal chocolate texture with high-efficiency refining, reducing energy usage...

Industrial continuous distillation system

Enhance product purity and efficiency with a robust continuous distillation syst...

Acid recovery system for industrial waste acids

Optimize your production with an innovative acid recovery system that tran...

Wiped film evaporator for high boiling point materials

For challenging separations of high boiling, viscous, or heat-sens...

Powder synthesis reactors for nanometer and micrometer particles

Achieve precise particle control and enhance material p...

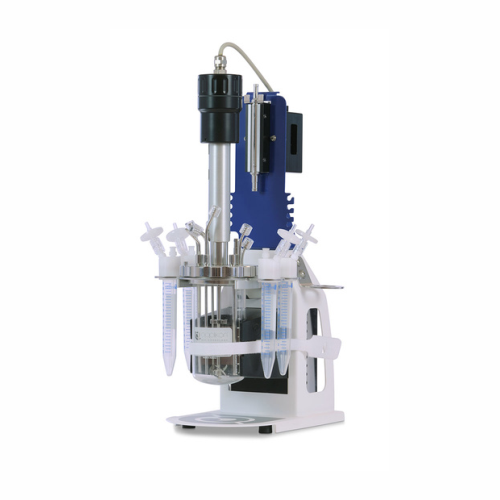

Small size multi-use glass autoclavable bioreactor

Optimize your laboratory space with this compact bioreactor that reduc...

3-phase liquid separation solution

Achieve precise separation of liquids and solids to enhance product quality and streamli...

Pulper finisher for tomato and cold extraction

Enhance your production line efficiency with a pulper finisher designed to ...

Strip cutter for recovering defective fries

Enhance your potato processing line efficiency by transforming rejected strips...

Pure steam generation system for sterilization purposes

Ensure sterile production with pure steam capable of eradicating ...

Consumables for elemental analyzers

Optimize your laboratory’s elemental analysis with high-quality consumables desig...

Ultrapure water system for laboratory applications

Ensure uncompromised water purity for critical applications with a sys...

Pilot plant for highly viscous applications

Perfect for R&D, this pilot plant efficiently handles complex mixing and ...

Battery electrode coating line

Optimize your battery production with a comprehensive coating line that enhances throughput a...

Solvent recovery systems for battery electrode manufacturing

Efficiently recover and purify solvents in battery electrod...

Organic rankine cycle for decentralized power generation

Harness waste heat and renewable energy sources to efficiently g...

Rolled film distillation system for cannabis oil refinement

Achieve high-quality cannabis distillates with impressive cl...

Evaporation plant for liquid mixtures

Achieve precise thermal separation of multi-component liquid mixtures, optimizing con...

Reverse osmosis with remineralization for drinking water production

Enhance your beverage production with precise water...

Industrial sand and carbon filtration system

Enhance your beverage and water production with precise filtration solutions ...

Ceramic ultrafiltration for treating oily emulsions

Optimize your oily emulsion treatment process with advanced ceramic u...

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Crossflow filter for clarified and unclarified wines

Optimize your filtration process with ceramic membrane technology th...

Pharmaceutical reactor for efficient cleanability

Optimize your production with this reactor, designed for efficient mixi...

Solid/liquid extraction unit for process development

Optimize your extraction processes with flexible operation modes for...

Distillation equipment for large reactors

Efficiently achieve high-purity separations and syntheses with distillation equi...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

Mineral oil absorption system for solvent vapor recovery

Optimize solvent recovery and reduce atmospheric emissions with ...

Renewable diesel pretreatment system

Extend hydrotreater catalyst life and boost plant uptime by optimizing feedstock purit...

High containment isolator for wet analysis in pharma

Achieve high containment and precise wet analysis with this isolator...

Ventilated pass-through for classified environment transition

Ensure sterile and secure transfer between environments wi...

Industrial exhaust air treatment for food processing

Effectively eliminate volatile organic compounds and odors while max...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

Wine filtration system for microbiological purity

Ensure your wines achieve the highest clarity and microbiological purit...

Glove box furnace for high-temperature applications

Optimize your high-temperature heat treatment and containment process...

Hydrogen gas safety system for high-temperature tube furnaces

Ensure safe and efficient hydrogen gas handling in high-te...

Controlled atmosphere oven for high-temperature applications

Achieve precise atmosphere control and uniform heating for ...

Vacuum concentrator for juice and chemical processing

Reduce energy and concentration costs significantly while enhancing...

Pre-cleaning system for Iqf berries

Ensure the purity of your IQF berries with advanced pre-cleaning technology that expert...

Purifier for high-quality semolina production

Achieve consistent semolina purity with this high-capacity purifier, ensurin...

Five-roll refiner for chocolate production

Achieve precise particle size control and energy efficiency in your chocolate r...

Ion exchange system for fruit juices and syrups

Enhance juice quality and optimize sugar processing with efficient ion exc...

Synthesis gas cooler for partial oxidation of oil or natural gas

Optimize high-temperature gas streams efficiently by em...

Replacement waste heat boiler for formaldehyde plants

Optimize energy recovery in high-temperature chemical reactions wit...

Ethylene recovery unit for ethylene oxide and glycol production

Recover valuable ethylene monomer efficiently from cycle...

Retrofit for active carbon recovery systems

Facing inefficiencies in vapor recovery and emission control? This retrofit so...

Marine vapour recovery unit

Maximize port efficiency and comply with stringent emission controls by capturing and processing...

Vent recovery systems for car filling stations

Enhance emission control and safety at car filling stations by optimizing v...

Carbon capture membranes for Co2 separation

Efficiently reduce carbon emissions in power plants and industrial operations ...

Fuel gas conditioning system

Optimize your fuel gas for efficient turbine operation and pipeline distribution with an advanc...

Pervaporation membrane for solvent dehydration

Efficiently separate and dehydrate solvents at molecular levels, ensuring p...

Aromatic recovery unit for refineries

Ensure compliance with stringent emission standards by effectively recovering and sep...

Glass cleaning system for recycling applications

Optimize glass recycling by efficiently removing contaminants and minimiz...

Chestnut puree production plant

Optimize your chestnut product line with a versatile production plant capable of transformin...

Evaporators for fruit juices and syrups

Optimize your beverage production line with advanced evaporators designed to effici...

Avocado processing plant for puree and oil extraction

Optimize your avocado processing with a complete system designed fo...

Industrial depitter for stone fruits

Effortlessly process stone fruits into smooth purees and nectars with a continuous, co...

Full-membrane water for injection (wfi) generation system

Ensure consistent high-quality injections by integrating real-...

Purified water system for pharmaceutical industry

Ensure consistent purity and compliance in your production line with a ...

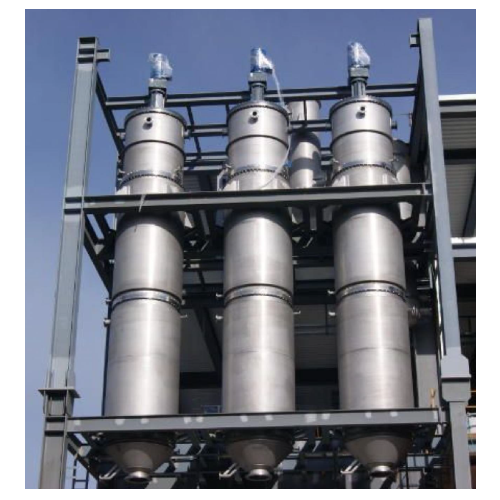

Multi-effect water distiller for pharmaceutical and biological applications

Achieve unmatched water purity for sterile...

Purified water storage tank for pharmaceutical use

Ensure the integrity of your pharmaceutical formulations with precisio...

Pharma peeler centrifuge for high purity separations

Achieve unparalleled product purity and yield in demanding pharmaceu...

Water treatment multi medium filter tank

Ensure your bottled water’s purity with a multi medium filtration system tha...

Ozone generator for water sterilization

Ensure the purity and safety of your water products with an ozone generator that ef...

Indirect cooling drums for process heat recovery

Optimize your production by effectively cooling hot solids while recaptur...

Ultrafiltration and microfiltration module for low to medium viscosity products

Streamline the separation and concentr...

Ultrafiltration module for high-viscosity products

Achieve enhanced separation efficiency with a versatile module designe...

Yeast centrifuge separator for pharmaceutical applications

Optimize microorganism recovery with high purity and efficien...

Animal protein and fat separator

Achieve exceptional purity and recovery in the separation of animal proteins and fats with ...

Decanter centrifuge for protein extraction

Efficiently enhance your recovery of valuable proteins and fats with customizab...

Edible oil dewaxing systems

Optimize your edible oil clarity and stability with dewaxing systems that effectively remove wax...

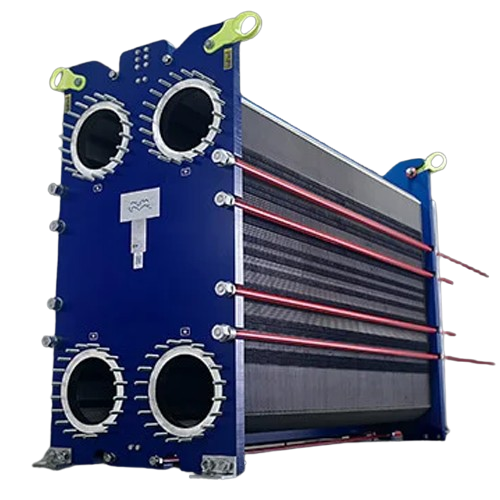

Gasketed plate-and-frame heat exchangers for industrial applications

Optimize your production with precise thermal mana...

Cleaning nozzle for pharmaceutical tank cleaning

Ensure complete tank hygiene with innovative cleaning technology that tar...

Decarboxylation package for botanical extraction

Ensure precise temperature control and efficient reaction conditions in y...

Large capacity jacketed glass reactor

Achieve precise control over temperature and vacuum conditions with this versatile re...

Liquid filling system for hard capsules

Easily fill two-piece hard capsules with liquids, pastes, and suspensions with prec...

Industrial water filtration and clarification systems

Enhance your production’s purity and quality with advanced fi...

High pressure processing water filtration system

Ensure super clear water after high pressure processing to protect your s...

Industrial oil filter for frying sediment removal

Enhance frying efficiency and product quality by removing fine sediment...

Variable-flow ejectors for heat recovery

Enhance your steam system efficiency by upgrading low-pressure steam to higher pre...

3a certified product recovery system for food and pharmaceuticals

Optimize your production line with a system designed ...

Condensate polisher for industrial water reuse

Transform waste streams into high-quality water, ready for reuse in diverse...

Beer recovery unit for breweries

Recover valuable beer from surplus yeast efficiently and integrate seamlessly into your exi...

Marine water treatment systems

Effectively manage marine water systems with solutions designed to purify bilge water, extrac...

Pasteurizer for non-alcoholic beverages

Ensure microbiological safety and extend shelf life of your non-alcoholic beverages...

Open type heat pumps for industrial heat recovery

Optimize your ammonia refrigeration system efficiency by recovering and...

Industrial solution crystallization plants

Optimize your production with tailored crystallization systems designed for eff...

Converter gas cleaning and recovery system

Enhance energy recovery and emissions control by capturing and cleaning CO-lade...

Falling film evaporator for temperature-sensitive products

Ensure consistent concentration and quality of heat-sensitive...

Multi-flash evaporators for alumina industry

Experience efficient thermal separation with enhanced heat recovery, ideal fo...

Waste heat recovery technology for industrial applications

Capture and utilize waste heat from industrial processes to e...

Compact and laboratory gas scrubbers for chemical emission control

For efficient gas treatment and emission control in ...

Radial flow scrubber for industrial gas cleaning

Optimize your gas cleaning process with a radial flow scrubber capable of...

Industrial carbon capture plant

Capture and purify CO2 emissions efficiently from industrial processes, tackling greenhouse ...

Clean purge system for spray dryers

Enhance safety and efficiency by preventing fire risks in spray dryers while improving ...

Aroma recovery system for instant coffee processing

Capture and enhance coffee aromas with a specialized system designed ...

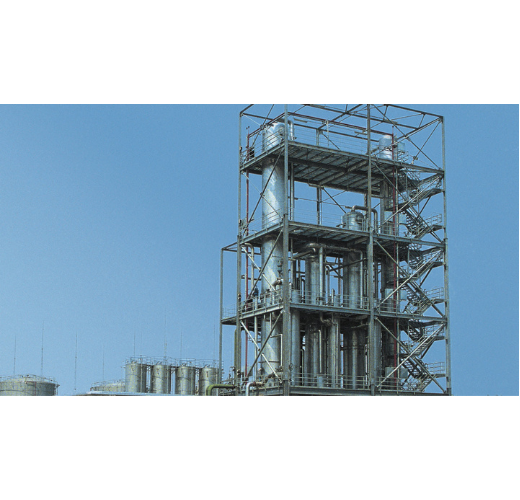

Multiple-effect distillation plants for industrial applications

Optimize your energy use with multiple-effect distillati...

High-yield fermentation system for raw material processing

Achieve precise control in fermentation with advanced systems...

Classifying decanter for barite recovery in oil & gas

Efficiently recover barite and clean drilling fluids with a high-pe...

2-phase decanter for olive oil recovery

Achieve significant water savings and reduce environmental impact with a 2-phase de...

3-phase centrifuge for animal and fish by-products

Optimize your by-product processing with a 3-phase centrifuge that eff...

Clarifying decanters for animal and fish by-products

Optimize your processing line with clarifying decanters designed to ...

Clarifying decanter for food ingredient processing

Optimize your protein recovery and ensure high-quality separation with...

Pulp separation system for citrus and pomegranate juices

Efficiently refine and separate pulp from juice to enhance produ...

Pure steam generator for industrial applications

Ensure the highest levels of steam purity and precise pressure control fo...

Steam conditioning plants for polyamide plastics

Enhance the durability and assembly readiness of polyamide components wit...

Manure treatment micro-filter for slurries

Enhance water reuse and nutrient recovery by transforming slurry into micro-scr...

Central traction clarifiers for wastewater sludge removal

Efficiently handle waste challenges with precision-engineered ...

Heavy duty aggregate separation and recovery system

Efficiently transform residual concrete into reusable resources with ...

Aggregate separation and recovery system for concrete batching plants

Streamline your construction waste management and...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Centrifugal separators for liquid/liquid/solid separation

Achieve efficient separation and clarification for diverse app...

Screw feeder for factory filtration systems

Optimize your factory systems with a screw feeder engineered to streamline was...

Semolina purifier for milling operations

Achieve precise separation and classification of semolina and bran with this purif...

Robotic sterilization logistics system

Ensure seamless aseptic transfers across production stages with this robotic logisti...

Feeding isolator for liquid preparation in pharmaceuticals

Ensure precise and contamination-free preparation of liquid p...

Ultra-pure water preparation system for pharmaceutical industry

Ensure your pharmaceutical production line meets stringe...

Hot press distilled water unit for pharmaceutical applications

Ensure superior water purity in pharmaceutical production...

Multi-effect water distillator for pharmaceutical applications

Ensure your production line meets stringent regulatory st...

Pure steam generator for pharmaceutical and biotech industries

Ensure optimal steam quality and compliance with stringen...

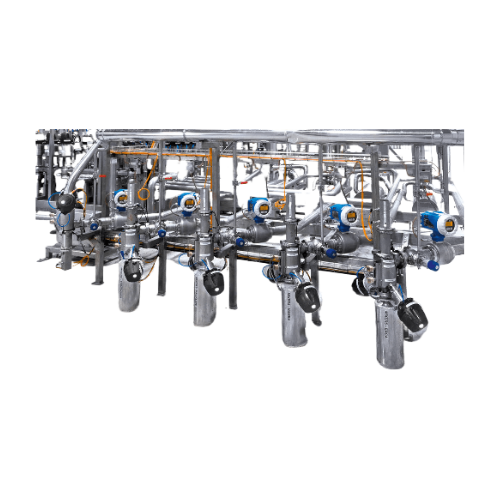

Pharmaceutical ultra pure water distribution system

Ensure stringent purity standards with a modular water distribution s...

Pharmaceutical preparation system

Achieve seamless integration in pharmaceutical processes with a preparation system that o...

Complex preparation system for industrial microsphere production

Achieve precise particle size and uniform drug encapsul...

Comprehensive auxiliary system for online cleaning and temperature control

Ensure reliable and precise control in phar...

Sanitary vessels for pharmaceutical applications

Ensuring the highest standards of aseptic processing, these sanitary vess...

Bioreactor system for protein and enzyme reaction

Ensure precise control in biopharmaceutical production with a bioreacto...

Isolator for sterility testing in pharmaceutical manufacturing

Ensure precise sterility testing with advanced isolators ...

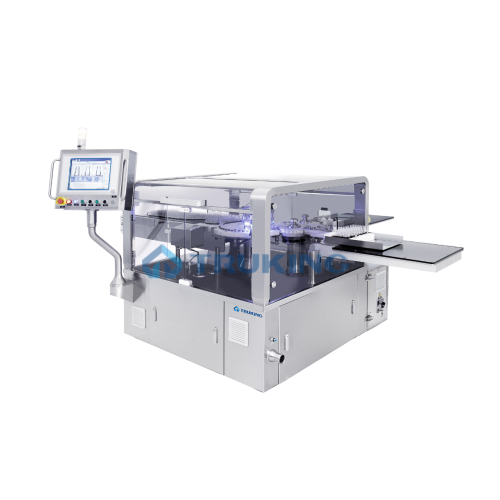

X-ray inspection for pharmaceutical vials

Ensure product purity by detecting contaminants in pharmaceutical vials with adv...

Automatic inspection system for sealing defects in ampoules

Ensure flawless ampoule sealing with a high-precision inspec...

Automatic leak detection system for pharmaceutical containers

Ensure the integrity of pharmaceutical containers with pre...

Fully automatic hard capsule filling machine

Enhance pharmaceutical production with precise capsule filling, ensuring opti...

High-purity nitrogen generator for pharmaceutical and food industries

Achieve ultra-high purity levels in your producti...

Gravity rotary filling for large infusion bottles

Ensure precise filling and secure stoppering of large infusion bottles ...

High capacity automatic blister packaging system

Streamline your production line with a high-speed blister packaging syste...

Secondary packaging cartoner for ampoules and vials

Optimize your aseptic production with efficient high-capacity carton ...

Automatic case packer for pharmaceutical industry

Optimize your packaging process with a versatile case packer designed t...

Single-use bioreactor for cell culture processes

Optimize your cell culture productivity with advanced mixing dynamics tha...

Vegetable washing solution for small and medium-sized operations

Efficiently wash and purify a wide range of fruits and ...

Pilot-scale bioreactors for bioprocess scale-up

Bridge the gap between experimentation and large-scale production with pil...

On-demand hydrogen generation system for laboratory use

Eliminate the risks and inconveniences of traditional hydrogen cy...

Spore removal unit for dairy processing

Optimize your dairy production by efficiently removing spores and bacteria, ensurin...

Clarifiers for dairy and plant-based beverages

Ensure optimal product purity and versatility by efficiently removing impur...

Helium recovery system for industrial applications

As helium costs rise and supply dwindles, efficiently recovering and p...

Aseptic barrier isolators for pharmaceutical applications

Enhance sterility and operator safety during aseptic processin...

Lab-scale microalgae cultivation system

Achieve precise control of microalgae cultivation with optimized growth conditions ...

Multiple-effect water still for pharmaceutical applications

Optimize your pharmaceutical water production with a system ...

Pure steam generator for pharmaceutical applications

Ensure your sterilization process consistently achieves high purity ...

Biodecontamination unit for clean rooms and laboratories

Achieve reliable, 6-log bioburden reduction with this automated ...

Solids retaining separator for liquid/liquid/solid separation

Achieve precise liquid-liquid-solid separation even with l...

Tubular juice pasteurizer

Ensure optimal safety and quality of liquid products with precise temperature control and high hea...

Deaerator for liquid food products

Enhance product quality by efficiently removing air and preserving vital aromas in liqui...

Mobile water treatment for industrial applications

Ensure continuous water quality with mobile treatment systems designed...

Industrial water treatment for cooling circuits

Optimize your cooling systems and reduce resource consumption with advance...

Full flow filtration system for bioprocess applications

Ensure sterile filtration of process liquids and aseptic chemical...

Mobile regrind sorting platform for plastics

Struggling with inconsistent regrind quality? This mobile sorting platform ef...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Industrial cocoa nib grinder for bean to bar production

Streamline your chocolate production with this versatile grinder,...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Paint mixing scale for high precision and reliability

Optimize paint mixing operations with high-precision scale systems,...

High-throughput surface plasmon resonance (spr) system

Rapidly achieve high-quality binding kinetics for drug discovery w...

Surface plasmon resonance (spr) sensor chips

Enhance your molecule interactions analysis with precise sensor technology th...

Cell culture bioreactor for mabs and vaccines

Optimize your biopharmaceutical production with advanced cell culture capabi...

Single-use bioreactors for mammalian cell culture

Enhance agility and cut costs with scalable, single-use bioreactors ide...

Lab-scale filtration system for micro- and ultrafiltration

Simplify complex microfiltration and ultrafiltration tasks wi...

Benchtop membrane filtration for process development

Eliminate fouling and achieve precise separation with a benchtop fil...

Membrane nanofiltration for cannabis and hemp processing

Optimize your extraction processes with advanced nanofiltration,...

Solvent recovery and decarboxylation system

Enhance solvent recovery and streamline decarboxylation processes with an inno...

Custom distillation builds for cannabis processing

Achieve precise cannabinoid separation and purity in large-scale disti...

Industrial-scale cannabis distillation system

Achieve up to 99% cannabinoid purity effortlessly with an industry-standard ...

Cannabis distillation system for high-potency extracts

Ensure your extracts achieve up to 99% cannabinoid purity with pre...

Cold processed ethanol extraction system

Streamline your extraction process by integrating an all-in-one system that combin...

Hydrocarbon extraction system for cannabis and hemp

Streamline your extraction process with a versatile system capable of...

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

High capacity cannabis cryo-ethanol extraction line

Boost extraction efficiency with high-capacity cryo-ethanol technolog...

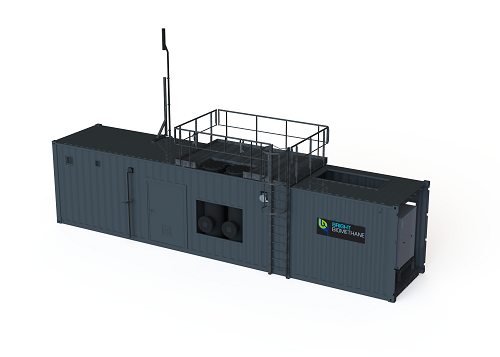

Modular biogas to biomethane system

The primary purpose of biogas upgrading technology is to increase the volumetric energy...

Plug & play water to hydrogen generator

One of the highest volume industrial gases, hydrogen serves a wide range of applica...