Stainless steel bioreactors

Enhance your bioproduction capabilities with robust solutions designed for efficient fermentation and cultivation processes, ensuring optimal yields of critical biopharmaceuticals and cell therapies.

Facilitates Fermentation and Cultivation for Biomanufacturing

The Biostat® Cplus and Biostat® D-DCU from Sartorius are stainless steel bioreactors designed specifically for biopharmaceutical manufacturing. These systems stand out due to their integration of advanced process analytical technologies (BioPAT®) for precision control and regulation during fermentation and cultivation processes. Ideal for producing monoclonal antibodies, mRNA vaccines, and other biologics, these bioreactors offer scalable solutions from pilot to small production scales. Each unit supports seamless PLC-based automation, ensuring consistent product quality and efficiency while reducing manual intervention.

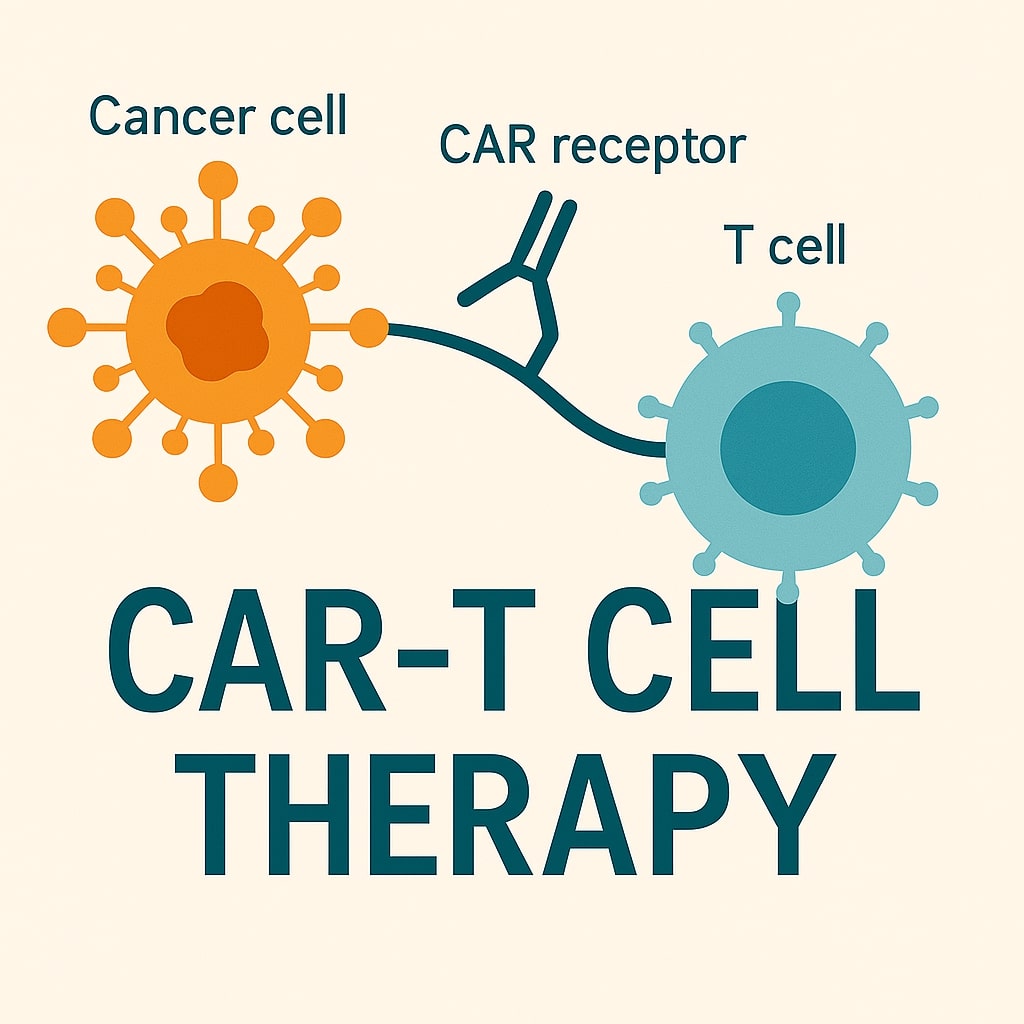

With capabilities extending from 5L to 2,000L, they facilitate diverse operations such as mixing, separation, and purification, essential for maintaining high purity levels in bioproducts like insulin and CAR-T cell therapies. Available in corrosion-resistant stainless steel, these bioreactors are designed for durability and compliance with GMP and FDA standards, ensuring suitability for regulated environments. Their design includes features for easy cleaning and maintenance, including a CIP system, making them an optimal choice for hassle-free operation and long-term reliability in demanding bioprocess settings. Customization options further enhance the adaptability of Biostat® systems to specific application needs, backed by Sartorius’s expert engineering support.

Benefits

- Enhances production efficiency with precise process control, minimizing variability in output quality.

- Scales flexibly from 5L to 2,000L, meeting evolving production needs without equipment overhaul.

- Ensures regulatory compliance, supporting GMP and FDA standards for peace of mind in biotech manufacturing.

- Reduces maintenance time with CIP system, maintaining high uptime and operational continuity.

- Supports diverse bioprocess applications, increasing facility versatility and return on investment.

- Applications

- Vaccines, Nutraceuticals, Monoclonal antibodies, Mrna production, Biosimilars, Regenerative medicine, Bioconjugation, Biopharmaceuticals, Blood and plasma, Cell and gene therapy

- End products

- Car-t cell therapies, Insulin, Covid-19 vaccines, Rituximab, Antibody-drug conjugates, Epoetin alfa, Omega-3 supplements, Pfizer-biontech covid-19 mrna vaccine, Albumin, Growth factors

- Steps before

- Sample Preparation, Media Preparation, Cell Line Development, Cell Banking

- Steps after

- Sterility Testing, Batch Release Testing, Product Characterization, Downstream Processing

- Input ingredients

- cell culture media, microbial culture media, buffer solutions, cells, microorganisms

- Output ingredients

- bioproducts, fermented products, culture supernatant, biomass, cell culture harvest

- Market info

- Sartorius AG is renowned for manufacturing high-precision laboratory and bioprocess equipment. They specialize in filtration, fermentation, and cell cultivation systems, known for their innovation and reliability in the pharmaceutical and biotech industries.

- Capacity

- 5 L to 2, 000 L

- Fermentation temperature range

- 18–37°C

- Automation

- Advanced process analytical technologies (BioPAT®)

- Material

- Stainless Steel

- Integration

- Component of hybrid systems

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance

- Stainless steel

- Density/particle size

- Varied

- Process scale

- Pilot / Production

- Capacity

- 5 L to 2, 000 L

- Tank shape

- Cylindrical

- Material

- Stainless Steel

- Integration capability

- Hybrid systems

- Control panel type

- PLC / HMI

- Integration possibilities

- Hybrid systems

- Customization capacity

- 5 L to 2, 000 L

- Process Analytical Technologies (PAT)

- BioPAT® Integration

- Application range

- Pilot to Production

- Engineering Solutions

- Customized solutions available