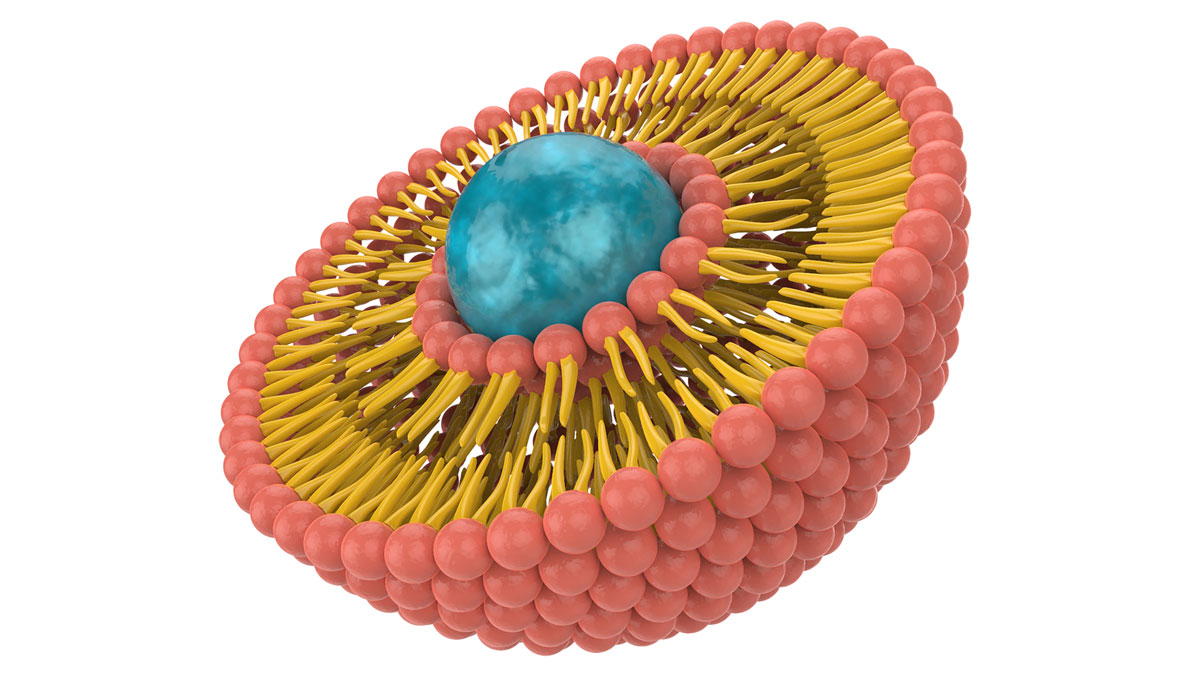

Complex preparation system for industrial microsphere production

Achieve precise particle size and uniform drug encapsulation in your microsphere manufacturing process with advanced mixing and emulsifying technology, ensuring product consistency and optimal encapsulation rates.

Processes and Sterilizes Injectable Pharmaceutical Products

The Biopharmaceutical Freeze Dryer System from TRUKING TECHNOLOGY LIMITED is designed to streamline the production of injectable and lyophilized products, including vaccines, freeze-dried pharmaceuticals, and sterile solutions. This system utilizes a vacuum-assisted freeze-drying process to efficiently remove moisture while maintaining product integrity. It’s an integral component in pharmaceutical production lines, ensuring sterility and quality control.

With a PLC-controlled automation system, it integrates seamlessly into existing production setups, allowing for remote monitoring and adjustment. Capable of handling batch operations with high throughput, it supports GMP and FDA compliance, ensuring it meets the rigorous standards required in pharmaceutical manufacturing.

Constructed from durable stainless steel, it offers excellent corrosion resistance and is equipped with a CIP system for efficient cleaning, minimizing downtime between batches. Customization options include chamber sizes and control settings, supported by TRUKING’s dedicated engineering team to fit specific operational needs.

Benefits

- Ensures product sterility and integrity, supporting GMP compliance.

- Increases operational efficiency with PLC-controlled automation and remote monitoring capabilities.

- Reduces downtime with easy-to-use CIP cleaning systems.

- Optimizes energy usage during moisture removal processes, lowering operating costs.

- Customizable design allows for tailored solutions to meet specific production requirements.

- Applications

- Liposomes, Injectable, Softbag production, Lyophilization production, Diagnostic reagents, Large volume oral liquid, Drops and sprays, Fatmilk, Bfs production, Suspension, Microspheres, Pre-filled syringe production, Ampoule production, Chinese traditional medicine, Oral preparation

- End products

- Sterile blow-fill-seal ampoules, Vaccines, Iv saline bags, Pre-filled insulin syringes, Liquid oral pharmaceuticals, Time-release microsphere drug formulations, Fortified milk substitutes, Sterile liquid suspensions, Liposomal vitamin c, Diagnostic test kits, Herbal extracts, Freeze-dried pharmaceuticals, Nasal sprays, Liquid ampoules, Oral rehydration solutions

- Steps before

- Extraction, Concentration, Drying, Emulsification, Mixing

- Steps after

- Sterilization, Packing, Inspection, Filling, Coating

- Input ingredients

- APIs (Active Pharmaceutical Ingredients), organic solvents, oil, water, pharmaceutical materials, reaction tank materials

- Output ingredients

- freeze-dried products, vials, ampoules, soft bags, glass bottles, plastic bottles, microspheres, liposomes, fatmilk emulsions, suspension formulations

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Automation

- PLC-controlled

- Aeration device

- Non-standard customized

- Shearing device

- Targeted reaction tank design

- Particle size distribution control

- Uniformity and reproducibility ensured

- Mixing oil and water ratio

- Designed for optimal emulsification

- Nitrogen protection

- Ensures product quality and safety

- Ball milling/homogenizing design

- High-speed mixing for drug solution uniformity

- Isolator system

- Ensures sterile environment

- Liposome debris collection

- Ensures effective process implementation

- Homogeneous emulsification equipment

- Ensures particle size distribution

- Buffer tank filling design

- Avoids suspension subsidence risk

- Sterility and personnel protection

- Feed isolator and α/β valve

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Control panel type

- HMI / Touch screen

- Integration possibilities

- SCADA / PLC integration

- Aeration device customization

- Non-standard

- Shearing equipment selection

- Customized

- Isolator system

- Matching isolator