High capacity cannabis cryo-ethanol extraction line

Boost extraction efficiency with high-capacity cryo-ethanol technology designed for seamless integration, automated solvent recovery, and reduced processing time, ensuring optimal purity and minimizing labor costs.

Extracts and Processes Botanical Oils Efficiently

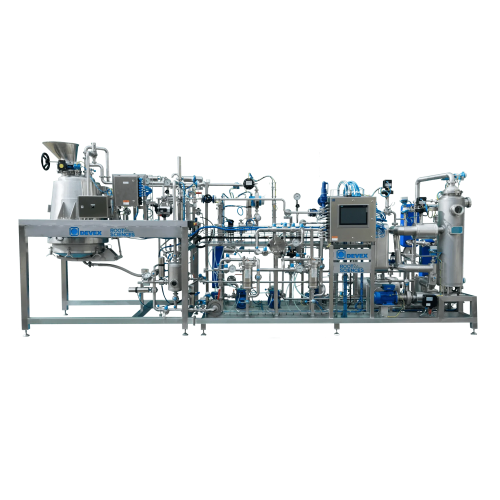

The CryoEXS 800 from Root Sciences is an integrated cryo-ethanol extraction system designed for high-capacity production of cannabis and hemp oils. This all-in-one system combines solvent cooling, extraction, biomass desolventization, filtration, recovery, and decarboxylation in a skidded and scalable design. Capable of handling up to 800 lb per 8-hour shift, it effectively serves cannabis producers and hemp processors seeking efficient extraction solutions for oils, tinctures, and isolates.

Utilizing a robust multi-stage process, the CryoEXS 800 enables continuous, automated operations with precise temperature control down to -40°C for optimal extraction. The system recovers solvents efficiently, reusing cold ethanol to reduce energy consumption and operational costs. Its modular filtration negates the need for separate winterization, promoting flexibility and easy maintenance.

Constructed for GMP readiness, the CryoEXS 800 includes tailored documentation and expert on-site training to ensure compliance and ease of integration. Its PLC control and touchscreen interface facilitate seamless monitoring, while the CIP system supports contamination-free cleaning. Suitable for essential oil and nutraceutical production, this system guarantees potency and purity, transforming biomass into high-value oils and extracts.

Benefits

- Maximizes oil extraction with high-capacity throughput of 800 lb per shift.

- Lowers utility costs through efficient solvent and energy recovery.

- Streamlines production with integrated, automated extraction to decarboxylation processes.

- Ensures regulatory compliance with GMP-ready construction and documentation.

- Simplifies equipment upkeep with modular filtration and CIP for easy cleaning.

- Applications

- Botanical extracts, Nutraceuticals, Hemp, Cannabis, Essential oils

- End products

- Cannabis oil, Cbd gummies, Nutraceutical capsules, Hemp oil, Thc distillate, Herbal extracts, Essential oil blends, Cbg isolate, Botanical tinctures, Full-spectrum cbd oil

- Steps before

- Grinding, Biomass Preparation, Solvent Selection

- Steps after

- Decarboxylation, Concentrate Packing, Product Distribution

- Input ingredients

- cannabis biomass, ethanol, raw material

- Output ingredients

- cannabis crude extract, recovered ethanol, decarboxylated product

- Market info

- Root Sciences is known for providing high-quality extraction, distillation, and other processing equipment for the cannabis and hemp industries, offering solutions for creating purified concentrates and extracts, emphasizing efficiency and innovation.

- Extraction Capacity

- 300 L

- Extraction Temperature

- -40 °C

- Evaporation Capacity

- 264 kg/h ethanol (350 L/h)

- Feed Quantity

- 100 – 800 kg/h (variable)

- Evaporation Pressure

- 50 – 600 mbar (abs)

- Power Consumption

- 67.5 kW

- Machine Dimensions

- 17.62' x 5.09' x 7.97' (L x W x H)

- Throughput Capability

- 800 lb per 8-hour shift

- Automation

- Automated solvent cooling, extraction, desolventization, filtration, recovery, and decarboxylation

- Cooling Method

- Reliable refrigeration solutions

- Modular Filtration

- Reconfigurable assembly

- Solvent Recovery

- 350 liters per hour

- Energy Efficiency

- Recaptures latent heat

- Materials Conveyance

- Automated system integration

- Daily Concentrate Yield

- 26 kg - 77 kg

- Throughput Capability

- 800 lb per 8-hour shift

- Automation Level

- PLC / SCADA

- Modular Filtration

- Modular and reconfigurable

- Energy Efficiency

- Recaptures latent heat

- Cleaning Method

- Complete automated solution

- Batch vs. Continuous Operation

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- GMP Compliance

- Included with tailored GMP documentation

- Machine Dimensions

- 17.62’ x 5.09’ x 7.97’ (L x W x H)

- System Configuration

- Skidded, scalable

- Extraction Temperature

- -40 °C

- Feed Quantity

- 100 – 800 kg/h (variable)

- Evaporation Pressure

- 50 – 600 mbar (abs)

- Throughput Capability

- 800 lb per 8-hour shift

- Integration possibilities

- Automated materials conveyance system

- Modular design

- Scalable, skidded system

- Filtration assembly

- Modular and reconfigurable

- Control panel type

- Simple touch-screen interface

- Custom documentation

- Tailored GMP documentation included

- Temperature control

- Reliable refrigeration solutions

- Energy efficiency

- Recaptures latent heat