Making Cannabinoids

Find innovative cannabinoids equipment and connect directly with world-leading technology suppliers

Cannabinoids are natural compounds obtained from the Cannabis sativa plant. Delta-9-tetrahydrocannabinol or THC is a psychotropic substance. Cannabidiol, or CBD, is non-psychotropic and often used for nutraceutical purposes. Cannabinoid equipment extracts THC and CBD from the plant and prepares the substance for formulations that treat pain, nausea, anxiety, and inflammations. Cannabinoids are processed in various forms, including creams, capsules, and oils.

Top technology picks for making cannabinoids

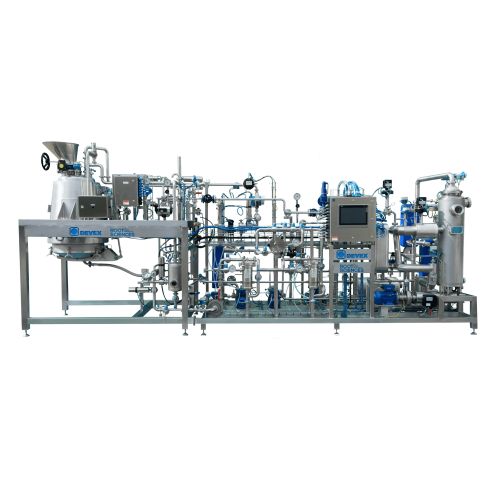

Cannabis and hemp processing nanofiltration system

Enhance the clarity and potency of your extracts with advanced membran...

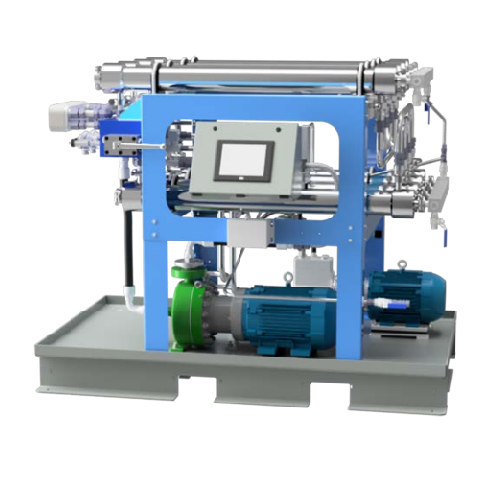

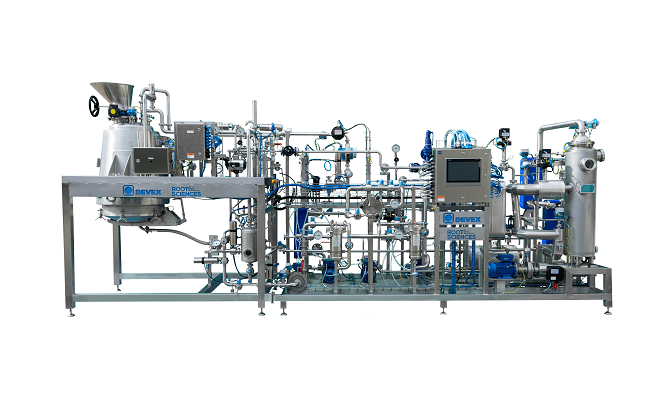

Cannabis distillate production system

Achieve high-purity cannabinoid distillates with continuous, high-volume processing t...

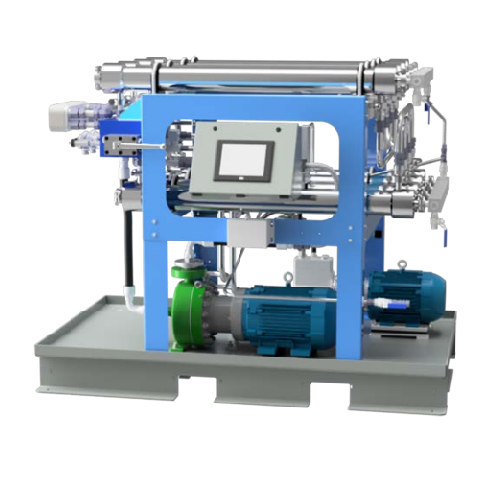

Cannabis nanoemulsion equipment

Achieve clear, stable, and bioavailable cannabis nanoemulsions with high-pressure homogeniza...

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

Stories about cannabinoids

Starting up your OTC non-starch gummy production

Modular equipment that helps you grow organically

How to turn a bag of sugar into a bag of scrumptious gummies

There’s way more to see with CBD

Get sweet with weed in the endeavor of crafting cannabis candy

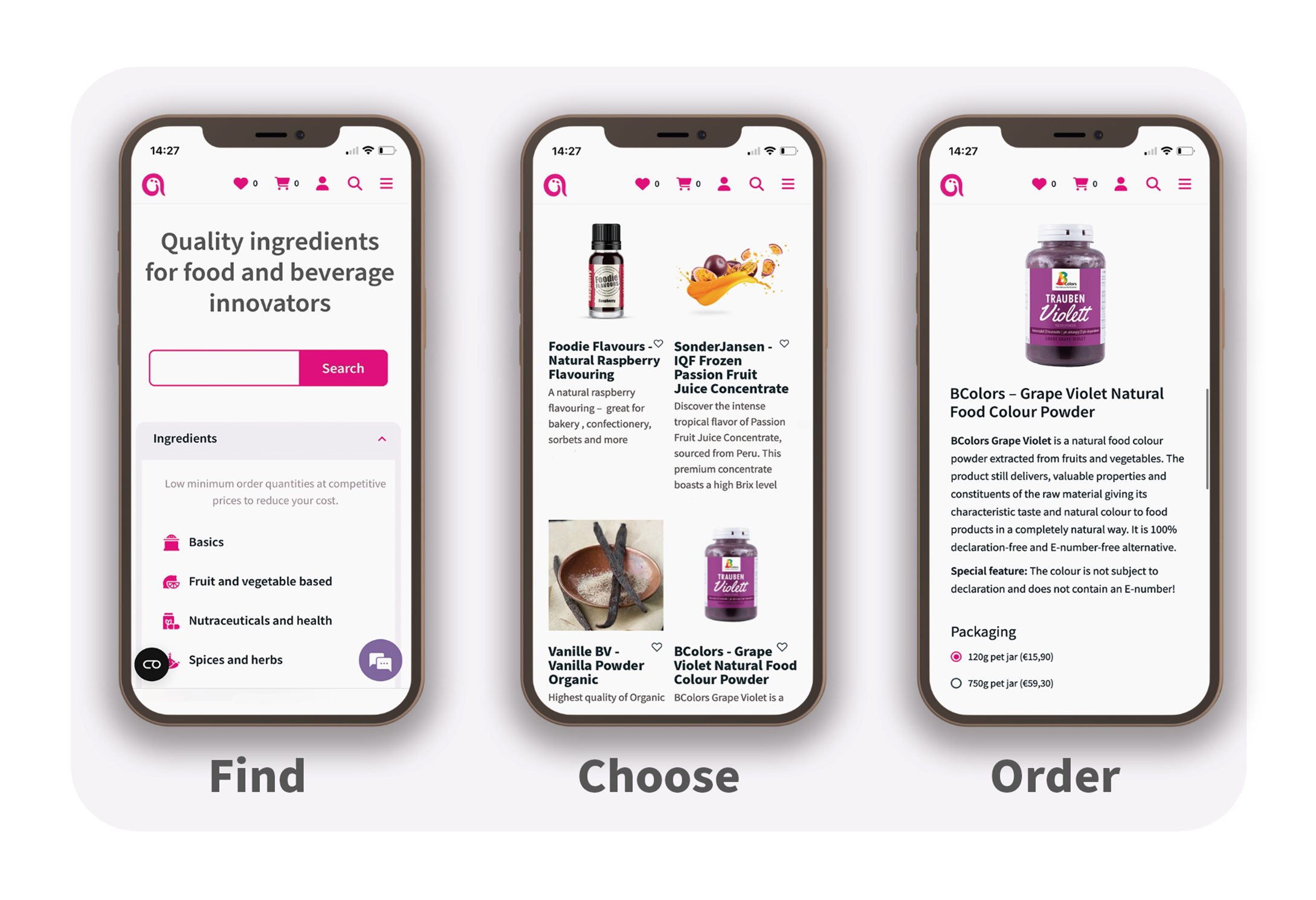

Order all your food Ingredients easily online at 1-2-Taste

How cannabis harvesting affects the quality of your final extract?

How to create less waste when extracting CBD oil

The value of GMP certification when making CBD products

Which type of CBD oil could you make?

Cryogenic ethanol for CBD oil extraction

CBD oil production to achieve a new 'high'

How to separate seeds from hemp crop

Freeze drying microencapsulated hemp seed oil

Select your cannabinoids process

What are you making?

Tell us about your production challenge

Go for cannabinoid equipment that delivers gentle extraction

The Cannabis sativa goes through a complex process after harvest. Specialized cannabinoid equipment chops the plant in preparation for gentle drying. Solvent extraction techniques using ethanol or supercritical fluids produce crude cannabis oil. But this requires further purification.

Distill the substance to separate THC from terpenes, lipids, impurities, and solvent residues. Finally, treat the cannabis isolate with a homogenizing system to break down the bonds and reduce the size of CBD particles.

Apply cold ethanol extraction to shorten the process stages

One method of CBD solvent extraction uses ethanol at a temperature of -40° C. In contrast to other techniques, this does not need a pressurized system. Feed the cold ethanol directly into the extraction equipment with the cannabis biomass.

The solvent forces the volatile compounds out of the plant, leaving behind the lipids. By removing the need for winterization, solvent recovery, and decarbing, cold ethanol extraction minimizes the cannabinoid equipment line and the process.

Decrease the THC content according to market requirements

THC levels of distilled oils must be decreased to meet the thresholds defined by regulatory bodies. For instance, most EU countries impose a THC content limit of 0.2% in CBD products, including edibles such as CBD gummies.

Purified CBD extracts must be filled using sterile systems and deposited in sealed formats, whether capped jars or pouches. Another essential equipment category in cannabinoid production is labeling machines with serialization functions.

Remove starch from CBD gummies

Starch can lead to bacterial growth, and many jurisdictions restrict its use for molding. But starchless depositing equipment for CBD gummies has more advantages than contamination-free products.

The gum syrup takes much less to dry in the molding trays than by moisture absorption from starch. Moreover, starchless depositing produces high-definition shapes and a better yield from demolding.

Formulate CBD oil products with other ingredients

CBD oil for medical treatment is dispensed in dosage forms such as ampoules, syringes, and capsules. Filling medicinal dosage utensils requires cannabinoid equipment to meet GMP standards made from materials like 316L grade stainless steel or PTFE.

CBD oil formulations are typically mixed with other ingredients like olive oil and terpenes. End products base the extract ratio on the target medicinal potency of cannabinoids per dose determined by pharmaceutical requirements.

Which cannabinoids technology do you need?

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

Portable ethanol extraction processing lab

Accelerate your extraction process with a fully portable and compliant lab solu...

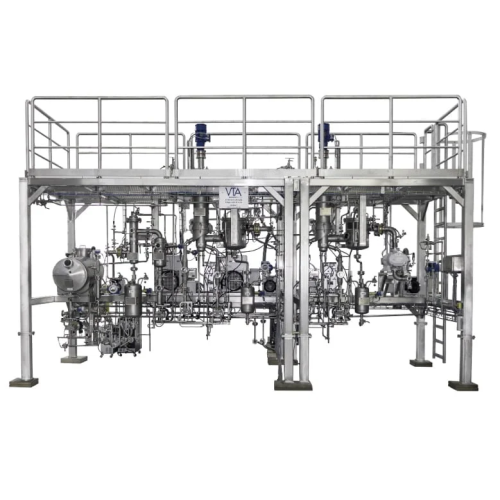

Filtration skid for ethanol extraction of cannabis and hemp oil

Enhance the clarity and color of your ethanol-extracted ...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

Ice water extraction system for solventless extract production

Optimize your plant-based extraction processes with a mod...

Decarboxylation package for botanical extraction

Optimize decarboxylation and reaction processes with precise temperature ...

Decarboxylation package for botanical extraction

Ensure precise temperature control and efficient reaction conditions in y...

Solventless cannabis extraction system for large-scale operations

Optimize your large-scale cannabis, hemp, or hops pro...

Solventless extraction for cannabis and hemp

Achieve iceless hash production with a precision-engineered system that optim...

Solventless cannabis extraction system

Optimize solventless extraction of cannabis and hemp with precise agitation and filt...

Solventless terpene extractor for cannabis processing

Preserve the most volatile aromatic compounds during extraction, en...

Cannabis distillation system for high-potency extracts

Ensure your extracts achieve up to 99% cannabinoid purity with pre...

Cold processed ethanol extraction system

Streamline your extraction process by integrating an all-in-one system that combin...

Hydrocarbon extraction system for cannabis extraction

Achieve high-efficiency extraction with precise solvent control, op...

Hydrocarbon extraction system for cannabis and hemp

Streamline your extraction process with a versatile system capable of...

Hydrocarbon extraction system for cannabis industry

Optimize your extraction process with cutting-edge technology designe...

Hydrocarbon extraction equipment for cannabis and hemp processing

Optimize your extraction processes with a high-capaci...

Hydrocarbon extraction system for cannabis

Optimize your cannabis concentrate production with a flexible hydrocarbon extra...

Advanced rosin press for solventless extraction

Enhance your extraction capabilities with precision-controlled pressure an...

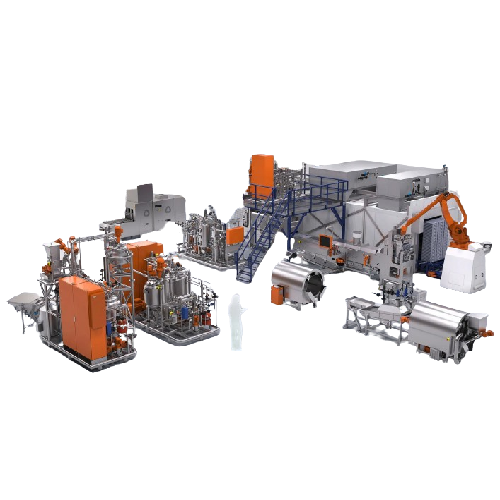

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

High capacity cannabis cryo-ethanol extraction line

Boost extraction efficiency with high-capacity cryo-ethanol technolog...

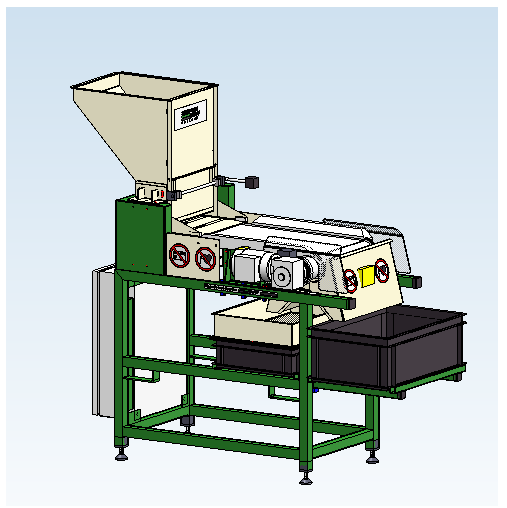

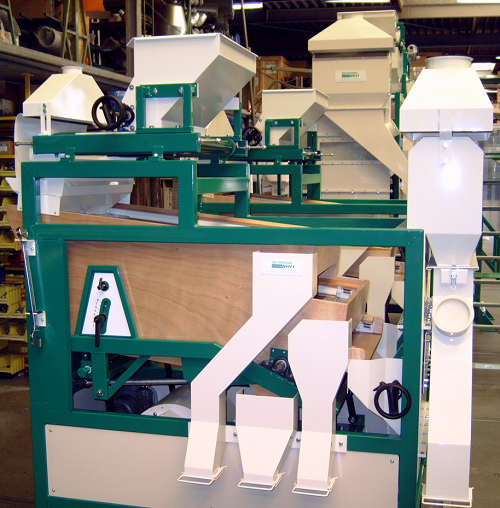

Seed extraction machine

The supply of high quality seeds is essential as it significantly contributes to the success of every...

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

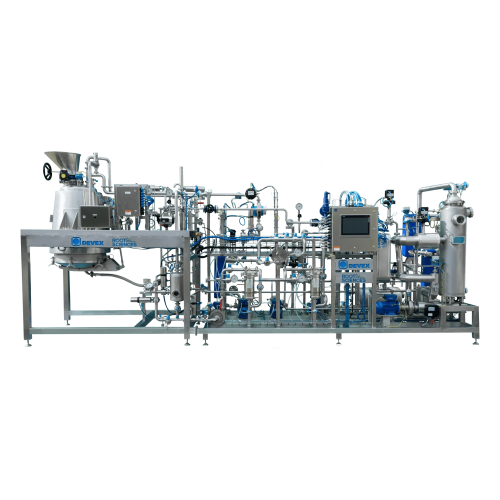

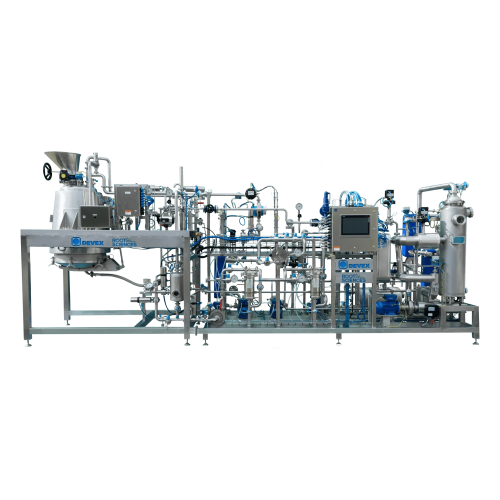

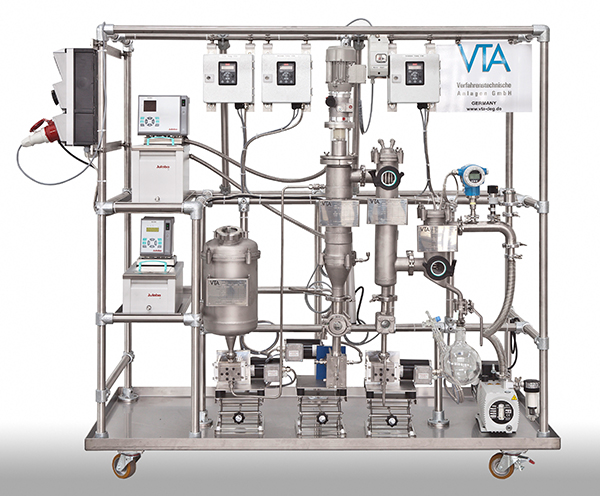

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

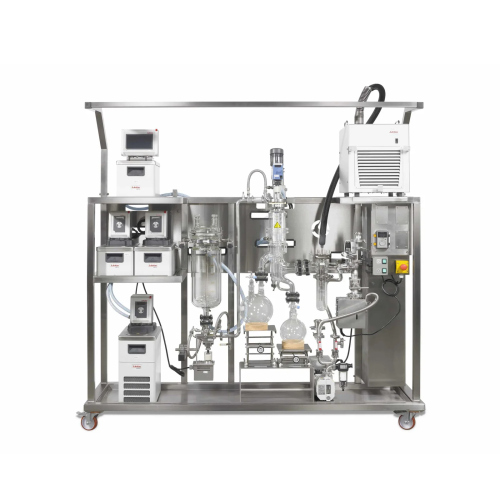

Pilot extraction plant for natural ingredients

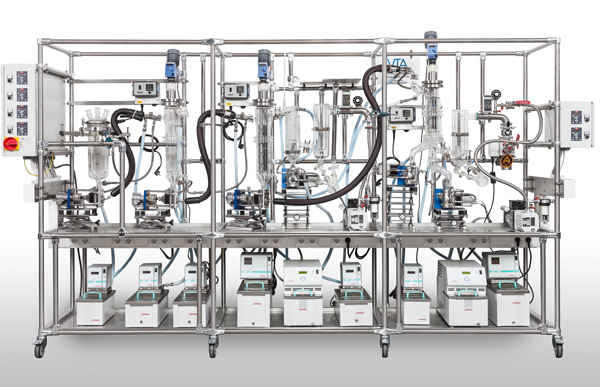

Before purchasing a full-scale extraction plant you need to exactly determi...

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

Continuous feed solvent evaporator for cannabis and hemp industries

Streamline your extraction process with a system de...

Digital vapor temperature monitor for fractional distillation

Achieve precise temperature monitoring during fractional d...

2-stage rotary vane vacuum pump for distillation processes

Achieve precise control and efficiency in distillation and fr...

Pharmaceutical and med-tech drying solution

Achieve precise moisture control and adaptability across diverse products with...

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Pharmaceutical size reduction shredder

Achieve fast, efficient material size reduction with this shredder, enabling seamles...

Rolled film distillation system for cannabis oil refinement

Achieve high-quality cannabis distillates with impressive cl...

Solventless trichome separation for bubble hash production

Achieve high-quality, solventless extracts with superior tric...

Supercritical Co2 fluid purification system

Optimize your extraction process with our supercritical CO2 fluid purification...

Industrial low temperature freeze dryer for high sugar or acid content products

For processing challenging high sugar ...

Cannabis freeze dryer for commercial use

Optimize moisture removal in cannabis products with precise control and high-speed...

Commercial freeze dryer for cannabis products

Enhance your cannabis production with precise moisture control and achieve h...

Wiped-film short-path distillation equipment for cannabis processing

Achieve up to 99% cannabinoid purity with this dis...

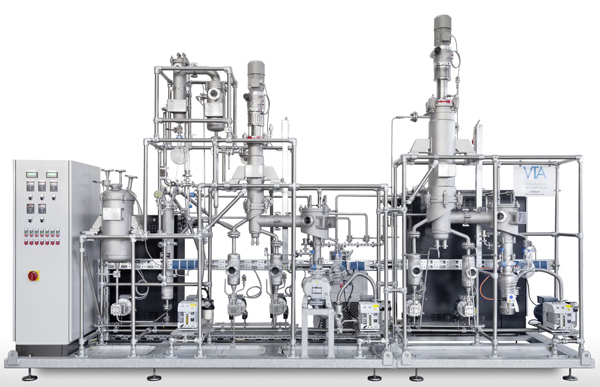

Cannabis distillate production system

Achieve high-purity cannabinoid distillates with continuous, high-volume processing t...

Cannabis oil nanofiltration system

Achieve high-purity cannabinoid extracts with advanced nanofiltration, ensuring precise ...

Cannabis and hemp processing nanofiltration system

Enhance the clarity and potency of your extracts with advanced membran...

Membrane nanofiltration for cannabis and hemp processing

Optimize your extraction processes with advanced nanofiltration,...

Cannabis nanoemulsification system

Transform your cannabis extracts into fast-acting, shelf-stable products with advanced n...

Solvent recovery and decarboxylation system

Enhance solvent recovery and streamline decarboxylation processes with an inno...

Custom distillation builds for cannabis processing

Achieve precise cannabinoid separation and purity in large-scale disti...

Cannabis and hemp distillation system

Achieve up to 99% cannabinoid purity with high-throughput, continuous distillation th...

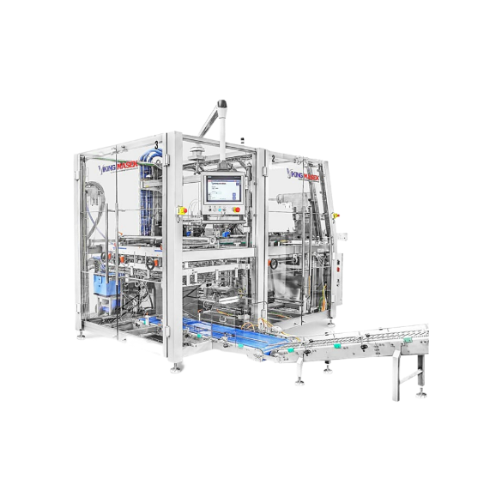

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Conditioned seed drying machine

It’s essential to dry moist seeds before you process and store them. Seeds with too high or ...

Cabinet dryer for cannabis

If you need careful drying for products like pharmaceutical-grade cannabis buds then traditional ...

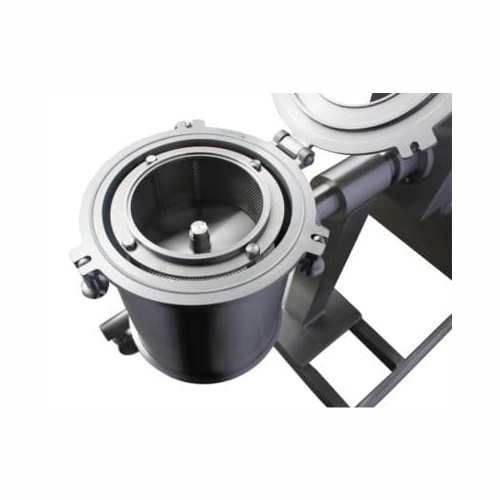

Automatic centrifuge for cannabis

Centrifugation is an effective method for producing cannabis extracts. The extraction pro...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Lab-scale milling and processing platform

Effortlessly transition from lab-scale research to full production with a versat...

Conical mill for high-capacity powder milling

Optimize your powder milling process with efficient conical milling systems ...

Atex compliant milling equipment for explosive atmospheres

Ensure operator safety and process integrity with milling equ...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Deagglomeration and delumping system

Ensure product integrity and streamline operations by effectively breaking down agglom...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

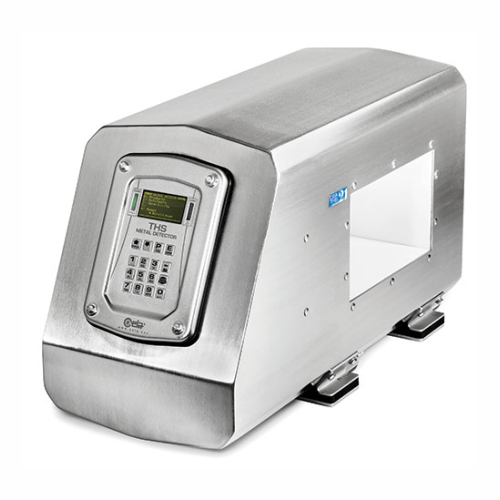

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

High precision weigher for small package weights

Achieve precise micro-dosing with unmatched accuracy at high speeds, opti...

Large continuous tunnel dryer

Optimize your production with advanced drying and dehumidification technologies, ensuring prec...

Continuous tunneling drying system for industrial applications

Streamline your drying process with precision-controlled ...

Batch drying solution for industrial applications

Achieve precise and gentle moisture control in diverse production proce...

Drum dryer for animal feed

Achieve efficient and uniform drying for a variety of products, from nuts to medicinal cannabis, ...

Batch drying system for food, pet feed, pharmaceuticals, and more

Optimize your drying needs with precision control for...

Ultra-hygienic vacuum conveyor for pharmaceutical industry

Optimize powder transfer with ultra-hygienic vacuum conveying...

Ultra-hygienic vacuum conveyor for pharmaceutical and food industries

Streamline material handling with this ultra-hygi...

Vacuum conveyor for hygienic material transfer

For operations demanding swift, dust-free material handling, this solution ...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

Pre-breaker for initial material size reduction

Efficiently prepare your bulk materials for further processing by swiftly ...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

Hygienic vacuum conveyor for pharmaceutical and food industries

Optimize your material handling process with a vacuum co...

Rotary crushing valve for lump breaking

When handling bulk solids, effective pre-breaking and sizing are crucial to ensure ...

High-accuracy rotary dosing valve for fine material feeding

Ensure precise dosage of fine powders and granules, enhancin...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Industrial container and drum handling solution

Effortlessly maneuver and position heavy containers such as IBCs and drums...

Stainless steel intermediate bulk containers for pharmaceutical use

Ensure safe, efficient transport and handling of po...

Stainless steel drums for powder storage

For high-value powder storage, these stainless steel drums offer reliable containm...

Conical mill for particle size reduction

Achieve precise particle size control and reduce thermal stress on materials with ...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

Industrial lump breaker for compact material deagglomeration

Efficiently deagglomerate compacted materials to enhance fl...

Over-driven conical mills for precise particle size reduction

Achieve consistent particle size reduction with minimal he...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Drum tippers for precise and safe drum handling

Streamline your operations by eliminating manual lifting and aligning proc...

Industrial drum tumblers for uniform batch processing

Achieve precise mix uniformity in your batches with drum tumblers, ...

Industrial container lifting system

Optimize your production line with a versatile lifting solution designed to safely hand...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

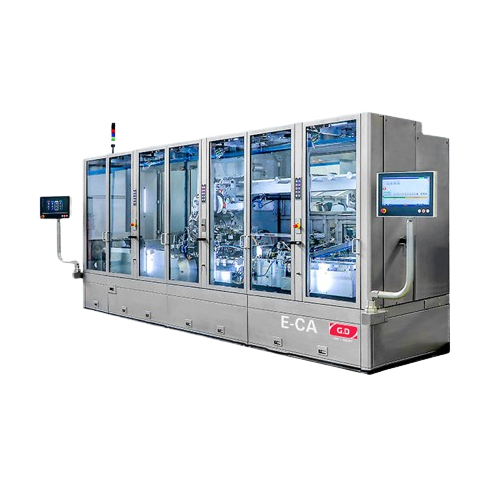

Cartridge assembler for next generation vapour products

Optimize your production of vape cartridges and e-cigarette pods ...

Cartridge assembler and filler for next generation tobacco products

Boost your production line’s efficiency with ...

High-speed cutting mill for versatile material comminution

Efficiently transform diverse materials like plastics, textil...

High-shear processors for uniform nanoparticles

Optimize particle size reduction and achieve uniformity in nanoparticle fo...

Cannabis freeze drying system

Optimize cannabis drying with precision-engineered freeze drying technology, designed to prese...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Food freeze dryer for bulk materials

Achieve efficient and uniform drying of fruits, herbs, and other materials with advanc...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

High-capacity stick pack packaging solution

Enhance your production efficiency by packaging diverse products like powders ...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

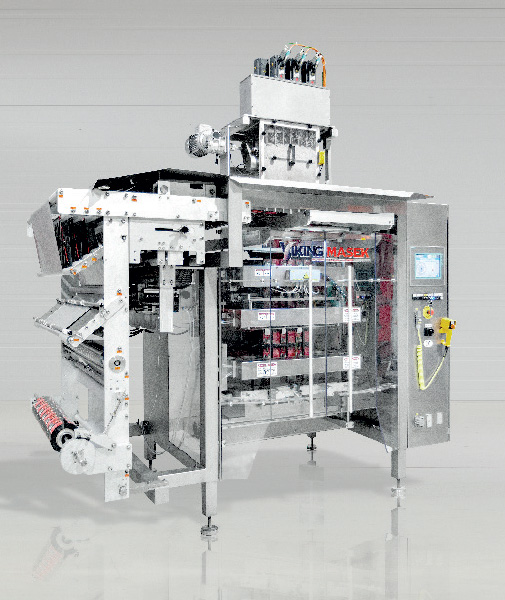

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

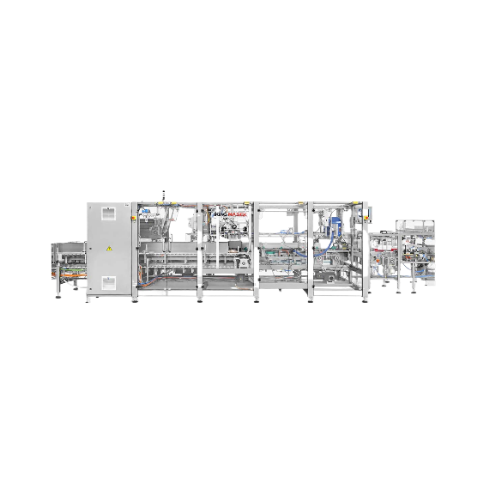

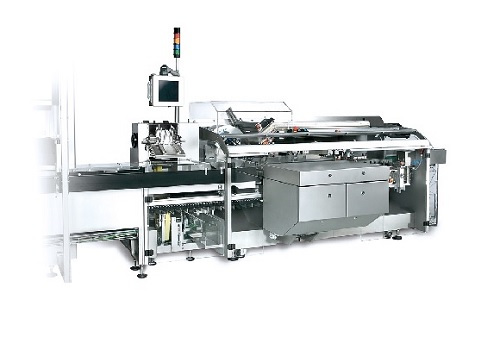

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

High accuracy hammer milling for precise particle size reduction

Achieve precise particle size control to enhance produc...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Pilot-scale milling and screening platform

Achieve precise powder consistency and integrity with flexible milling and scre...

Roller compactors for dry granulation

Optimize your powder processing with advanced roller compaction, ensuring consistent ...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Industrial powder milling solution

Achieve precise particle size control and improve material flowability with this advance...

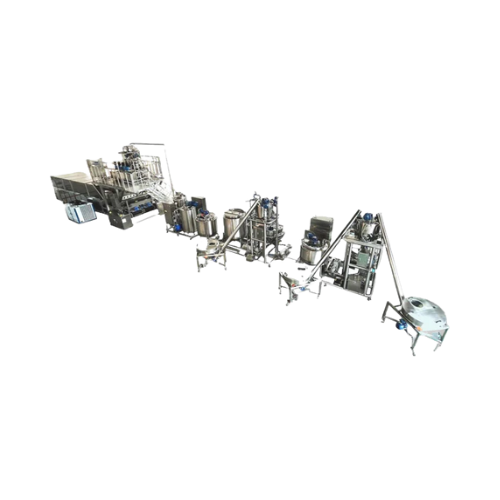

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automat...

Vertical space-saving glassware washer

Maximize lab efficiency with a space-saving washer that ensures thorough cleaning an...

Cannabis and hemp short path distillation system

Achieve optimal cannabinoid purification with continuous high-volume dist...

Industrial-scale cannabis distillation system

Achieve up to 99% cannabinoid purity effortlessly with an industry-standard ...

Short-path wiped-film distillation for cannabis

Achieve optimal cannabinoid purity with precise thermal separation, perfec...

Cannabis nanoemulsion equipment

Achieve clear, stable, and bioavailable cannabis nanoemulsions with high-pressure homogeniza...

Laboratory homogenizer for cannabis nanoemulsion production

Achieve exceptional bioavailability and stability with high-...

Cannabis nanoemulsification system for high-precision production

Achieve rapid bioavailability and stable formulations i...

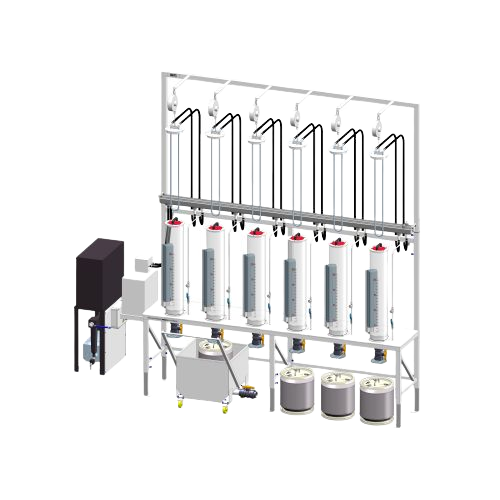

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

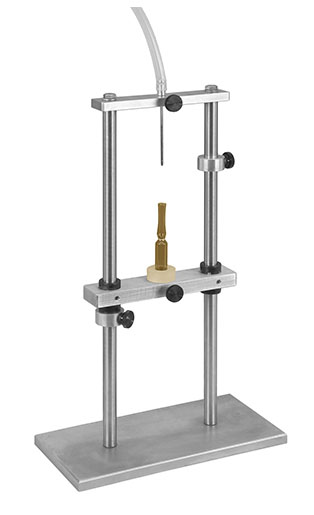

Benchtop peristaltic dispenser

When you fill vials and ampoules, high standards of hygiene are required to avoid the risk of...

Laboratory liquid viewer for colored glass bottles

In the pharmaceutical industry, an inspection to detect any particulat...

Laboratory liquid viewer for varying light conditions

In the pharmaceutical industry, you must inspect liquids in vials o...

Manual ampoule filler

When you fill ampoules it is essential to avoid wetting the inside walls of the container, as it may af...

Benchtop piston filling equipment for vials in trays

Vials are difficult to fill individually through manual methods due ...

Laboratory liquid viewer for transparent glass bottles

Impurities like hair, fibers, or glass, sourced from the environme...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

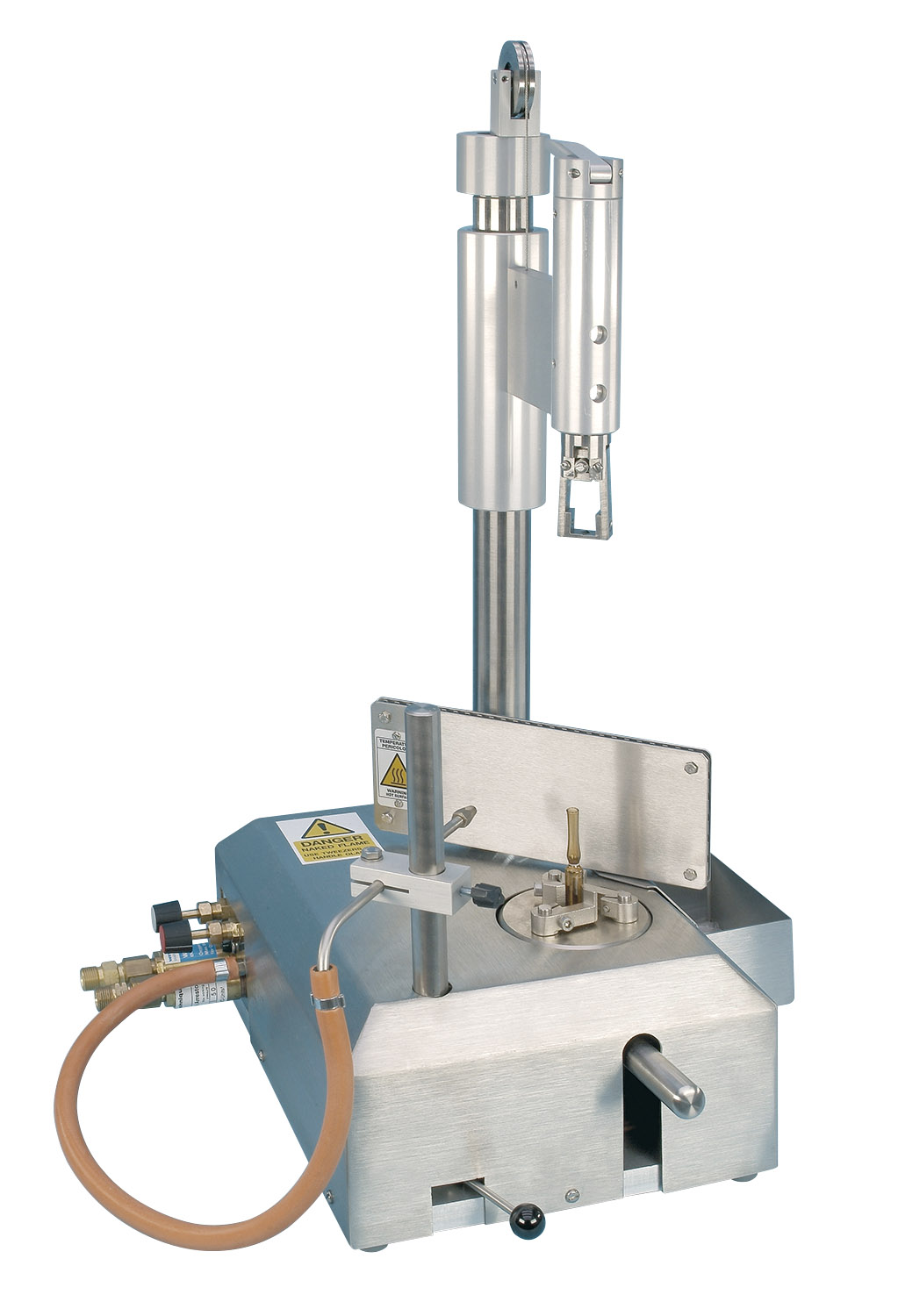

Benchtop ampoule opening and closing equipment

The procedure for opening or closing ampoules requires you to handle gas an...

Seed disinfection machine

It’s essential to disinfect seeds to eliminate bacterial infections and to protect them from these...

Seed priming equipment

Seed priming is a controlled hydration technique in which seeds are soaked in water or low osmotic pot...

Seed threshing machine

After threshing seeds from plant material, various cleaning steps still have to be done to ultimately ...

Magnetic Seed Separator Machine

It is challenging to separate seeds with cracks or holes from undamaged seeds. The way to do...

Air screen seed cleaning machine

The quality of seeds and grains starts to deteriorate once they have been harvested. Thus, ...

Seed storage cabinet

The proper storage of seeds is essential in conserving their vitality, and to maintain germination power...

Seed Coating Machine With Integrated Dryer

Seed coating, also known as seed dressing, refers to the covering of seeds with...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

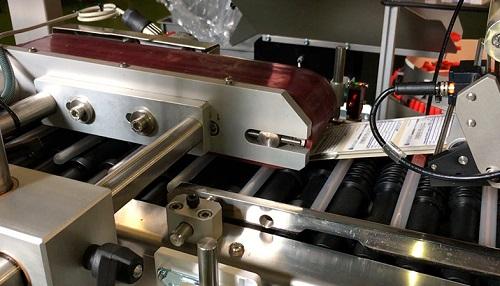

Labeling machine for ampoules

It’s essential for pharmaceutical companies to provide the highest quality ampoules to custome...

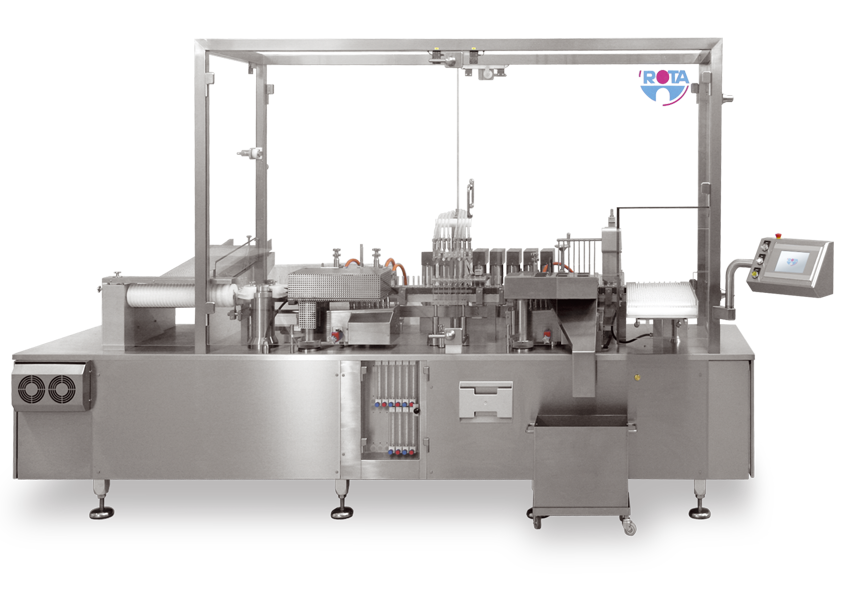

Ampoule filling machine

Filling ampoules or vials with parenteral fluids are an essential matter for which you need to consid...

Benchtop cannabis filter press

Therapeutic uses for cannabis oil are becoming more widely available. For pharmaceutical uses...

Air knife drying system for containers

In food or beverage production where a product is filled into jars, there is often r...

Filling machine for creams

Liquid cosmetics have particular requirements when it comes to filling and capping containers. Mo...

Blow off system for containers

Packaging powders into plastic or glass containers often leaves a residue that needs to be re...

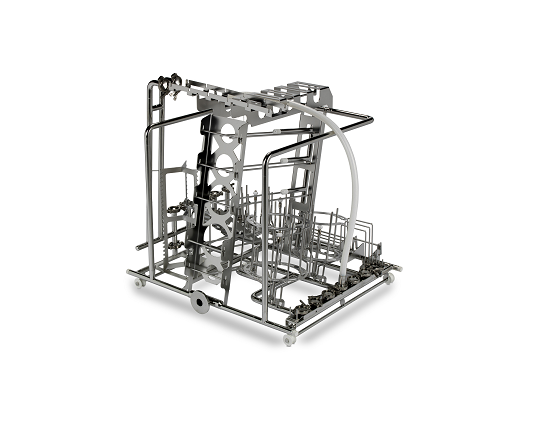

Rotary vial washing machine

When washing vial, ampoules, or cartridges for pharmaceutical production there is often a trade-...

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a wa...

Bulk chamber washer

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

High capacity cartoner for pharmaceutical applications

Many pharmaceutical products are packed in protective and decorati...

Vertical cartoner for pharmaceutical applications

Many pharmaceutical and cosmetic products are sold in protective and de...

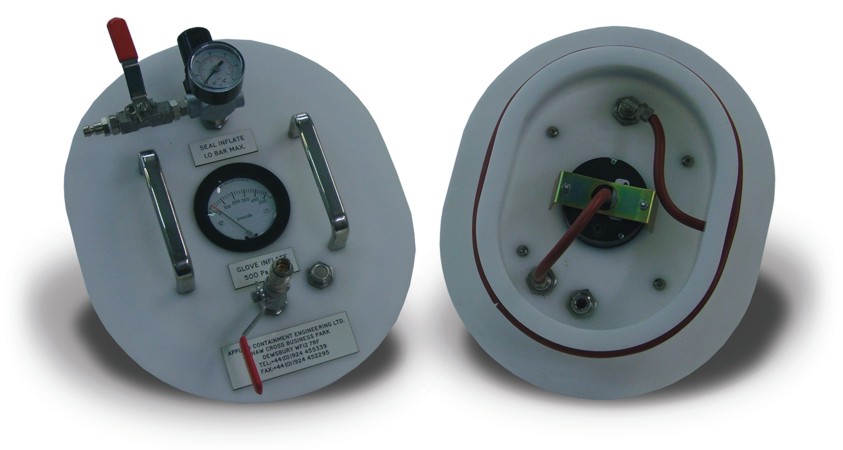

Half-suit tester

Designed to allow operators to perform sterility testing in an aseptic environment providing assurance of mat...

Glove tester

Testing device of the containment capability of gloves, which is as important as the other parts of the integrate...

Semi-automatic inspection machine for ampoules, vials or cartridges

If you need to increase the efficiency of your manu...

Visual and HVLD inspection for ampoules, vials and cartridges

Do you need to improve the efficiency and capability of yo...

Labeling machines for pharmaceutical bottles

Labels for ampoules, vials and bottles are typically applied at the end of th...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...

Horizontal thin film evaporators

Horizontal thin film evaporators can increase the residence time of the product and achieve...

Thin film dryers

Dry dissolved or slurried crystallizing or amorphous products to a pourable powder.

Short path evaporators

With short path distillation, a substantial decrease of boiling temperature is obtained by reducing th...

Automatic washing machine for ampoules

Automatic washing machine designed for cleaning ampoules and achieving a maximum out...

Monobloc small volume liquid filler

These intermittent motion monobloc machines are designed for filling various liquids in...

High-speed small volume liquid filler

Fill liquid pharmaceutical, nutraceutical and cosmetic products in ampoules and bottl...

Aseptic barrier systems

Designed for sterile product and Potent API’s either with low or high OEL requirements.