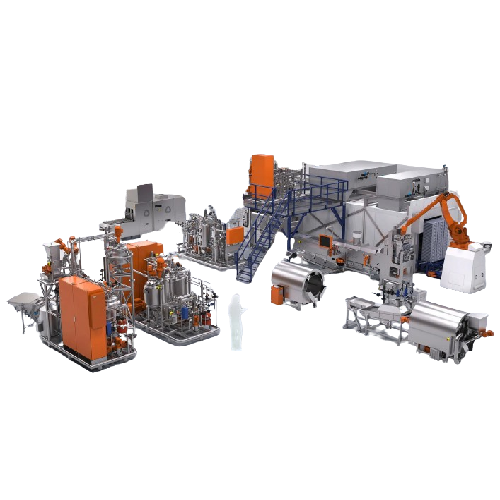

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automatic line that effortlessly handles diverse gelling agents.

Processes Non-Starch Gummies and Jellies

The 400R-NS from Tanis is a fully-automatic polycarbonate moulding line tailored for non-starch gummy and jelly production. It eliminates contamination risks with its innovative use of cleanable plastic moulds, first developed for significant capacity by Tanis. Operating continuously, it processes up to 150,000 pieces per hour using an efficient depositing and demoulding system. Ideal for confectionery, nutraceuticals, and cannabis candy industries, it produces diverse end-products like fruit-flavored gummies, vitamin-infused gummies, and CBD gummies with precision. Minimal operator intervention is required due to its recipe-driven automation, making it easy to integrate into existing production lines while ensuring high-speed, contamination-free output.

Benefits

- Ensures contamination-free production with easy-to-clean polycarbonate moulds.

- Increases operational efficiency by producing up to 150,000 pieces per hour.

- Reduces labor costs through minimal operator requirements and automated processes.

- Offers production flexibility with easily interchangeable moulds for varied shapes and sizes.

- Facilitates seamless integration into existing lines with recipe-driven controls.

- Applications

- Jellies, Cannabis candy, Nutraceuticals, Confectionery, Gums

- End products

- Cbd-infused gummies, Sugar-free confections, Sour gummy bears, Vitamin-infused gummies, Pectin-based candies, Multivitamin jellies, Gelatin-based jellies, Fruit-flavored gummies, Pectin-based fruit snacks

- Steps before

- Purification, Mixing, Heating, Blending

- Steps after

- Cooling, Packing, Inspection

- Input ingredients

- pectin, gelatin, gelling agents

- Output ingredients

- gummy candies, confectionery pieces

- Market info

- Tanis Confectionery is renowned for designing and manufacturing customized equipment for the production of confectionery. They are experts in tailor-made solutions, emphasizing innovative processes and high-quality machinery tailored to meet specific client needs in the confectionery industry.

- Capacity

- Up to 150k pieces per hour

- Automation

- Fully-automatic

- Mould type

- Polycarbonate

- Material compatibility

- Pectin, Gelatin, Other gelling agents

- Operator requirement

- Minimal number of operators

- Mould cleaning

- Easy/Manual

- Mould changeability

- Easily changed out

- Depositing pump accuracy

- High accuracy

- Production Capacity

- Up to 150k pieces per hour

- Non-Starch Line

- Yes

- Automation level

- Fully-automatic

- Changeover time

- Quick mold change

- Cleaning method

- Cleanable polycarbonate molds

- Moulding Material

- Polycarbonate

- Recipe-driven Product Preparation

- Yes

- Cleanability

- Polycarbonate moulds, easy to clean

- Corrosive resistance (e.g. acids)

- N/A

- Biological compatibility

- N/A

- Abrasion resistance

- N/A

- Machine footprint

- Compact

- Mould type

- Polycarbonate, cleanable, interchangeable

- Maximum output capacity

- 150, 000 pieces per hour

- Feed type

- Pectin, gelatin, other gelling agents

- Discharge method

- Demoulding process

- Line Capacity

- Up to 150k pieces/hr