What gummy are you making?

Find innovative gummies equipment and connect directly with world-leading technology suppliers

Gummies, a staple in the confectionery industry, can come in various forms, such as gummy bears, vitamin gummies, heart-shaped jellies, and many more mouth-watering alternatives. They are manufactured using specialized equipment for mixing, molding, coating, and packaging. From precise mixers to efficient packaging lines, industrial gummy production relies on a range of equipment to ensure consistent quality and meet consumer demand worldwide.

Top picks for processing gummies

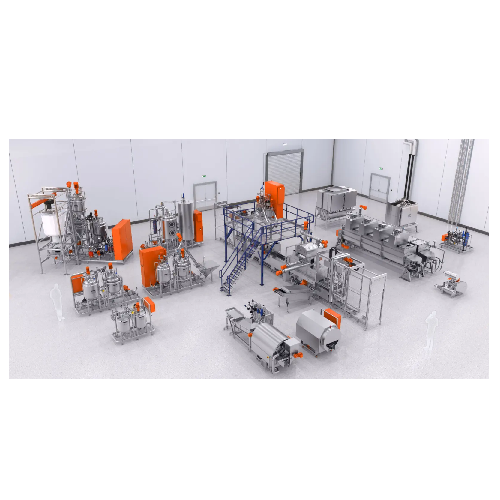

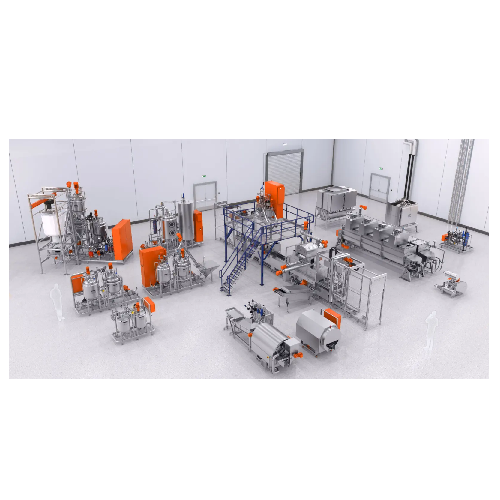

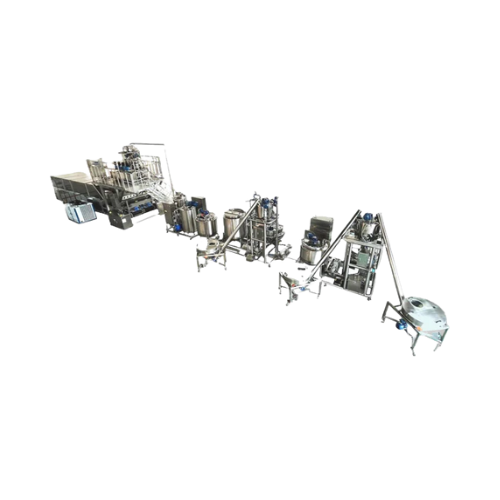

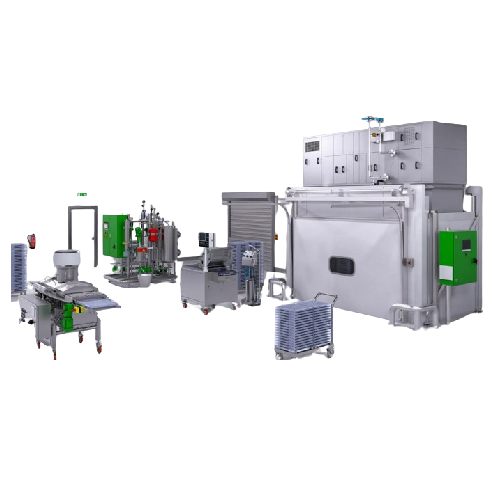

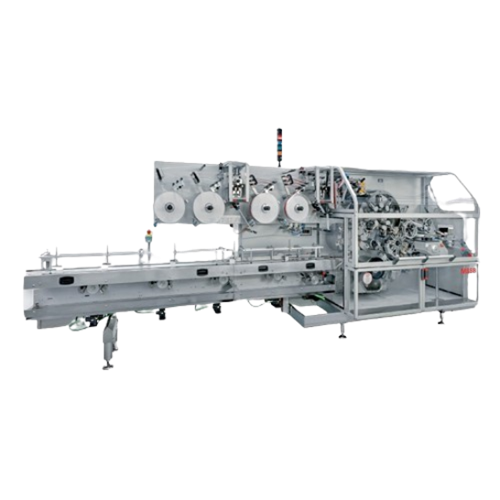

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

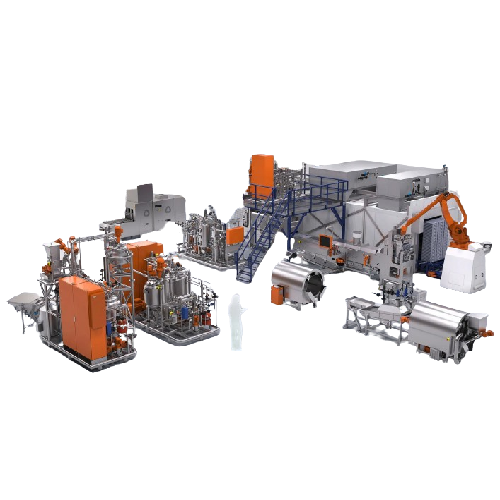

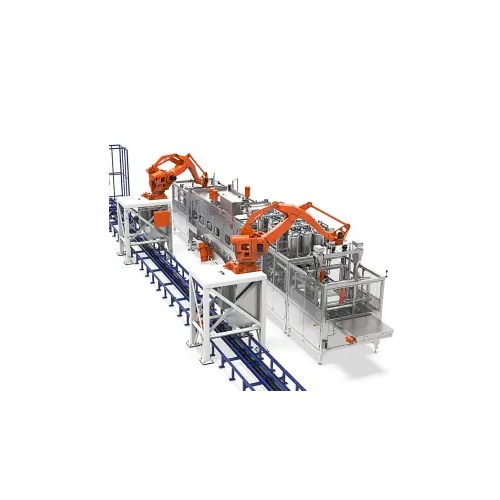

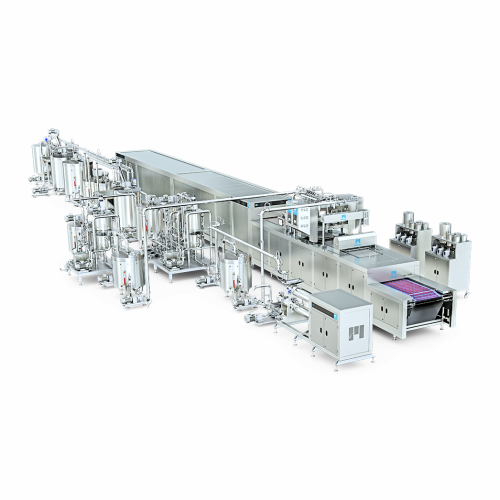

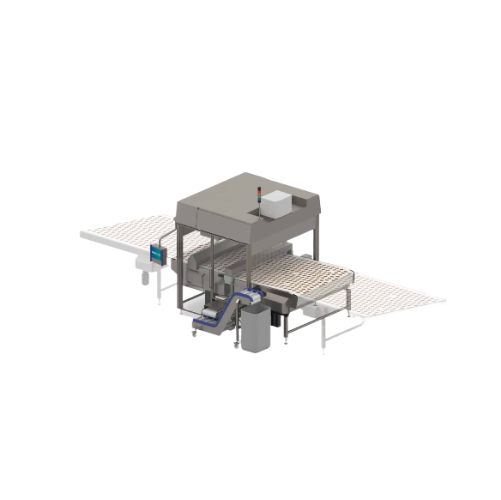

Robotic production line for gummies and nutraceuticals

Streamline your gummy and nutraceutical production with a versatil...

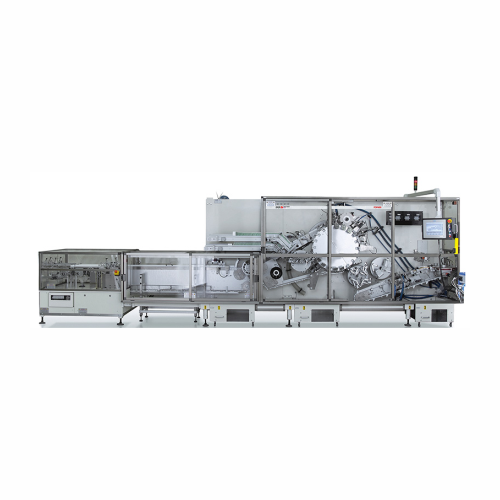

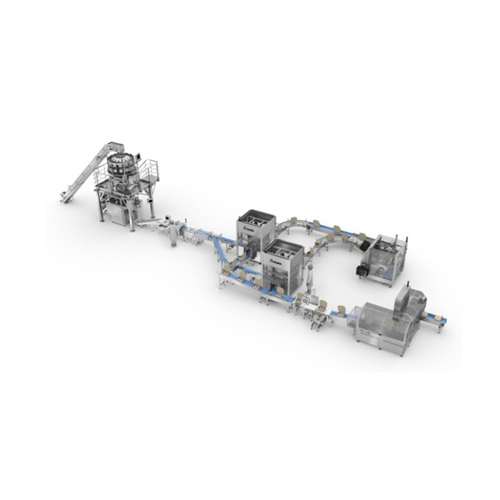

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

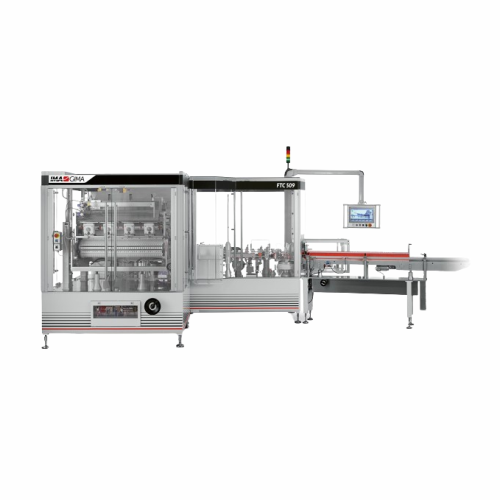

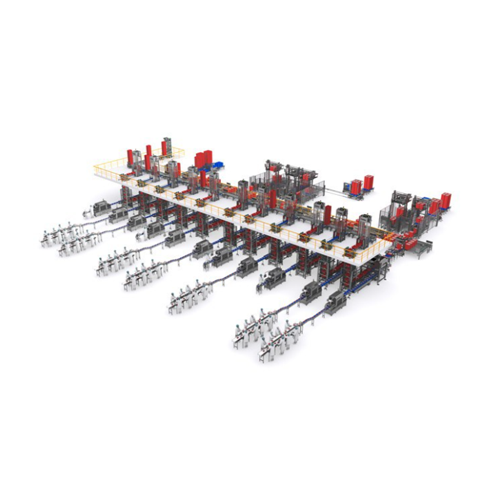

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Stories about gummies

Starting up your OTC non-starch gummy production

Starchless gummy depositing for limited risk on cross-contamination

Modular equipment that helps you grow organically

Making healthier gummy formulations

Chew on this: craft gummies with pectin

Enter the world of relaxation by making sleep gummies

Delving into the fungal fun of gummy goodness

Select your gummies process

What are you making?

Tell us about your production challenge

Making gummies on an industrial scale

Gummies are crafted from a thickening agent like gelatin or pectin, sweeteners, flavors, and colors. First you must mix the ingredients and then cook the gummy mass with an industrial cooker. Make sure that you spend time developing the right recipe to fit your gummy needs, otherwise your gummy mixture can turn out too sticky, cloudy or wet.

Next, you can mold the mixture into various shapes and sizes using high-speed molding machines. After molding, your gummies can undergo additional processing steps such as coating or polishing to enhance appearance and texture. And finally you can pack your sweet treats.

Start making functional gummies

In addition to being little sweet treats, gummies can also enhance wellness or serve as medicine. Therefore you can add functional and active ingredients to your gummy mixture, such as vitamins, Omega-3, CBD, active pharmaceutical ingredients (APIs), or even herbal extracts. Functional gummies can also promote hair growth or help you sleep better.

Producing them on an industrial scale requires precise gummy formulation, since the active ingredients can change the properties of the mixture. Adding an ingredient means balancing out the rest, and many functional ingredients, for example vitamins, require the addition of antioxidants, coloring agents, or buffer salts.

Formulation is key

Achieving uniform taste, texture, and appearance across large gummy and jelly batches requires precise ingredient measurement and processing control. Conduct thorough testing and stability studies on ingredients to ensure they maintain their quality throughout production and shelf life. You can also consider encapsulation techniques or alternative ingredient forms to improve stability of your gummies.

To make your production process more seamless use automated mixing systems and precise ingredient measuring equipment to ensure uniformity. You should also implement strict quality control checks throughout the production process.

Which gummies technology do you need?

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

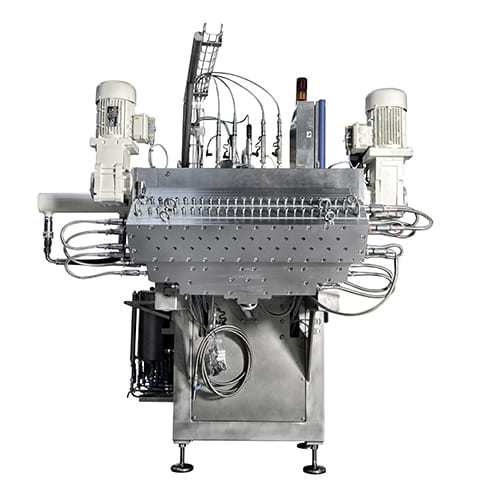

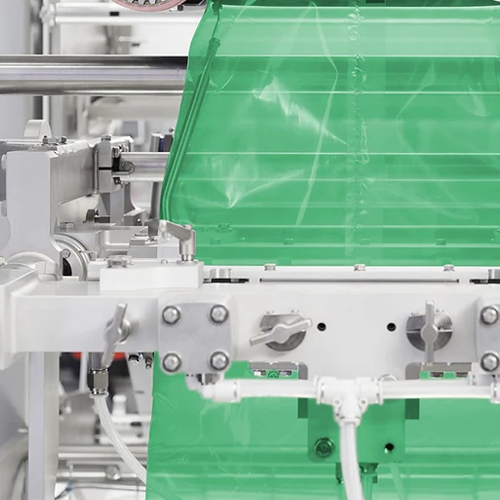

Powder and oil coating system for gummies

Enhance your gummy production with precise powder and oil coating, achieving con...

Oil coater for gummies

Optimize your gummy production with high-speed oil coating for consistent, flavorful finishes, ensurin...

Sugar coating system for gummies

Achieve a flawless sugar coat on up to 240,000 gummies per hour, seamlessly integrating int...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automat...

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

Robotic production line for gummies and nutraceuticals

Streamline your gummy and nutraceutical production with a versatil...

Robotic high capacity production line for gummies and jellies

Optimize your gummy and jelly production with a high-capac...

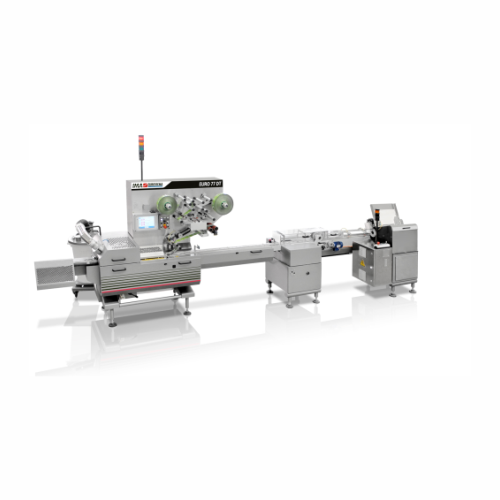

Candy packaging solution for gummies and hard candies

Maximize your confectionery efficiency with high-speed packaging so...

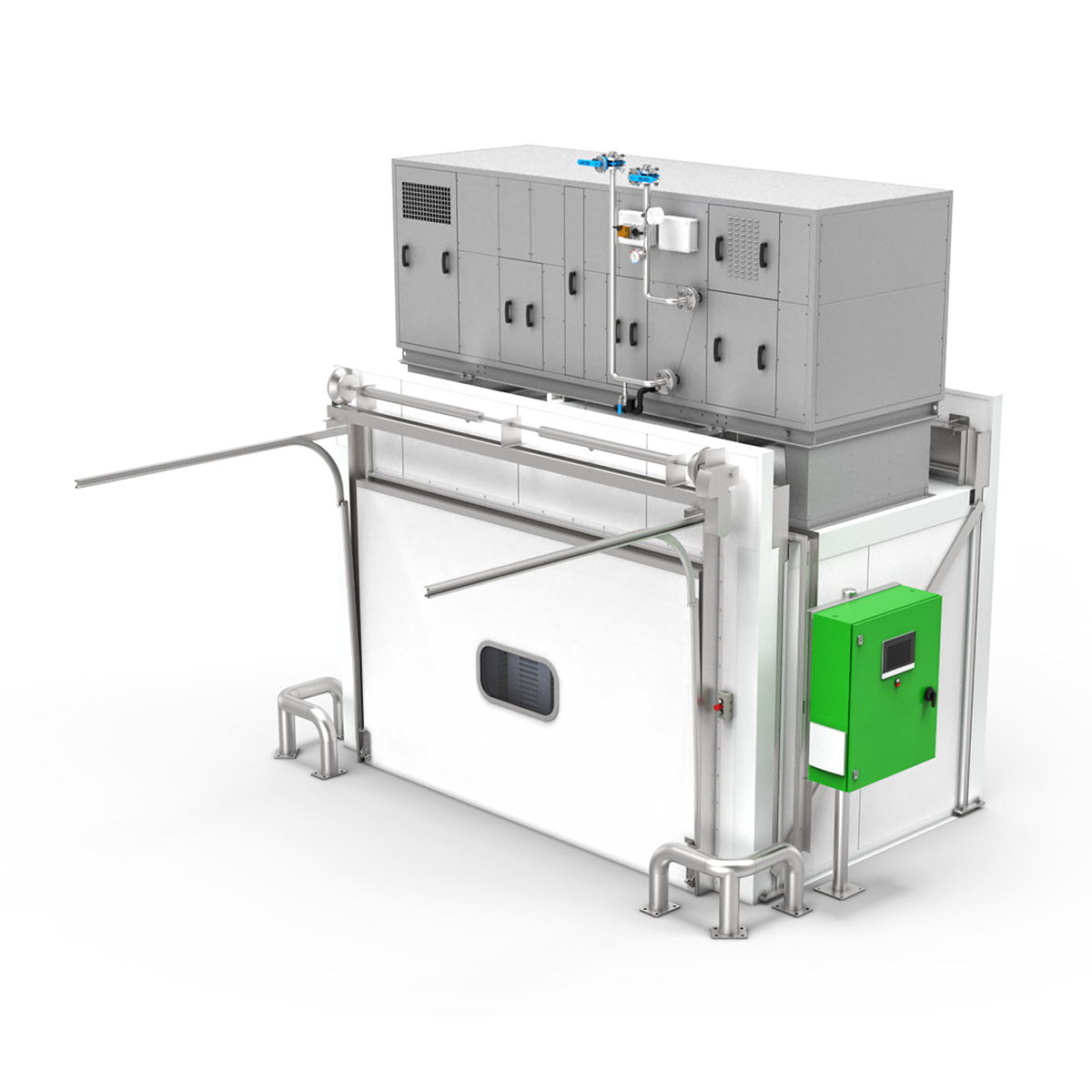

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

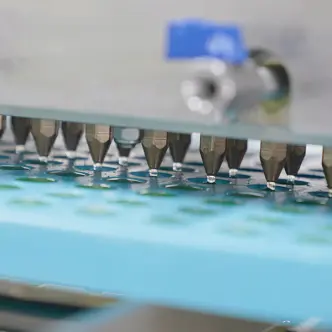

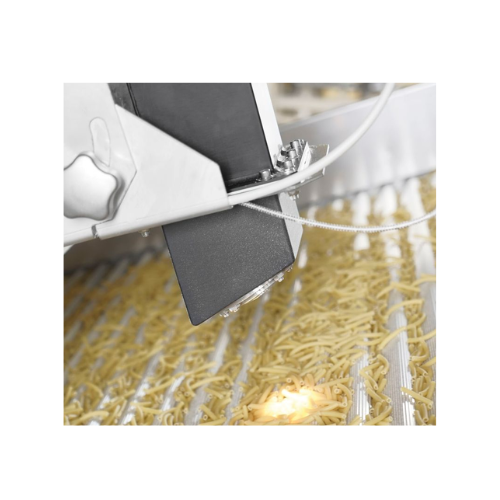

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

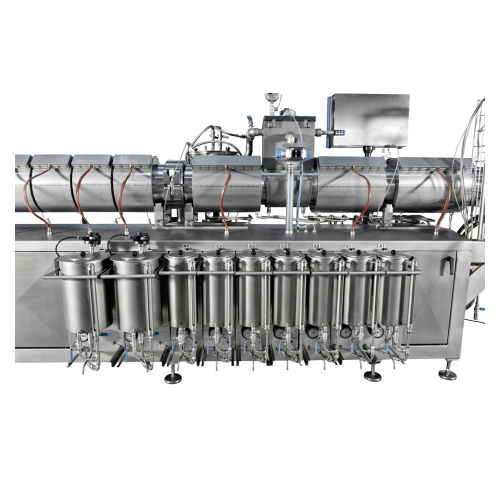

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

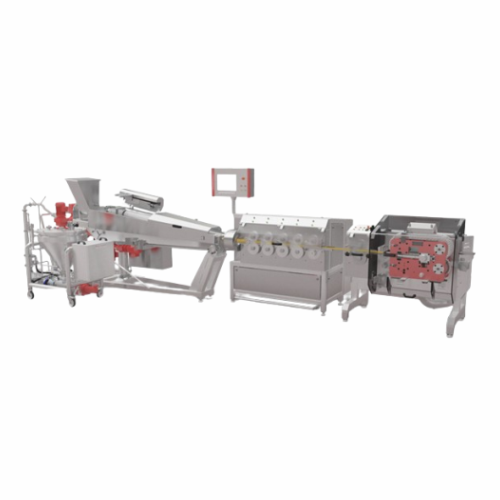

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

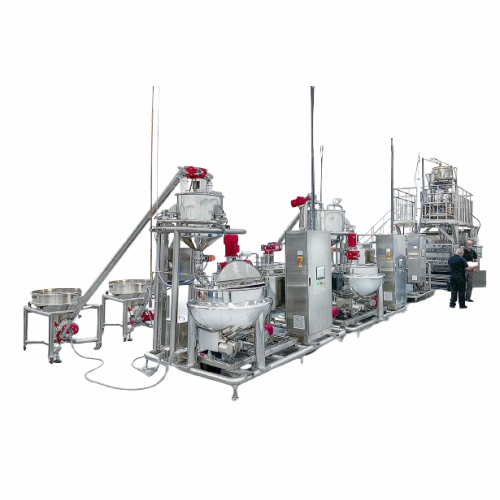

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

Adjustable weighing system for raw materials

Optimize your confectionery and nutraceutical production with precise weighin...

Pre-cooking and final cooking for candy production

Optimize your candy production with a versatile cooker designed to han...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Hard candy forming line for manufacturing

Experience seamless candy production with advanced forming technology, ensuring ...

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small ...

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

Rapid gummy channel counter

Ensure accurate gummy counts and streamline your production process with a solution designed to ...

Portable water activity meter for gummy production

Ensure consistent gummy quality and extended shelf life by precisely m...

Gummy counter for gusseted bags

Optimize your gummy production line with precise counting and packaging into re-sealable gus...

Automatic gummy manufacturing system

Efficiently streamline your candy production with a system capable of producing up to ...

Small automatic gummy line

Streamline your gummy production with a compact system designed to deliver precision deposits and...

High-capacity gummy production system

Optimize your gummy production with a starchless system that deposits up to 240,000 g...

Extrusion system for color changing confectionery strands

Easily switch colors in confectionery strands mid-production, ...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

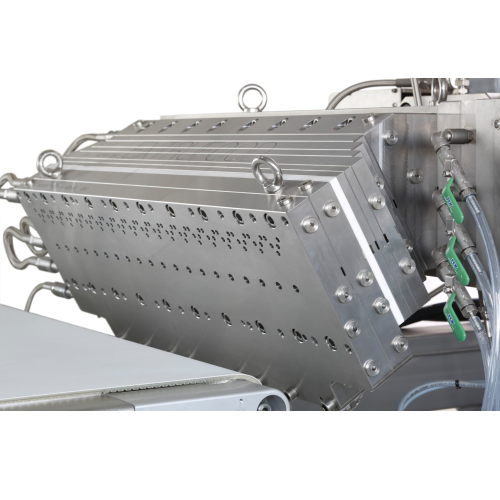

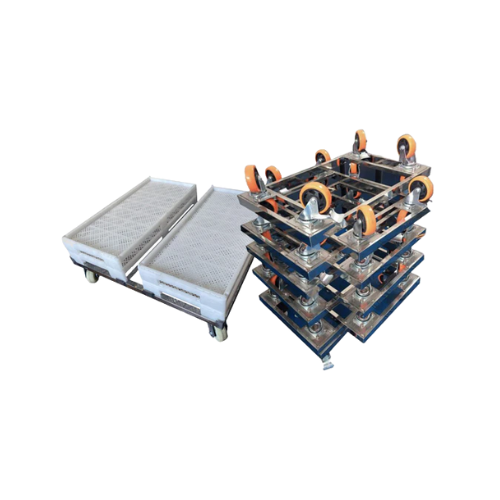

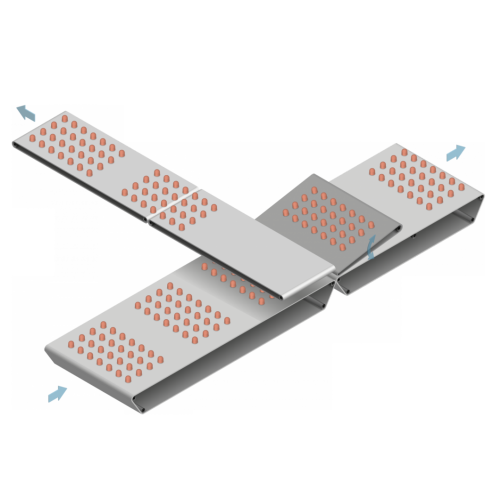

Drying trays for gummy candy production

Ensure proper drying and setting of your gummy candies and gelatin-based products w...

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

Mini candy depositor for gummy production

Optimize your confectionery production with a compact depositor, delivering prec...

Sugar drum for coating gummy candy

Achieve a uniform sugar or wax layer on your gummy candies with precision and reliabilit...

Gummy candy depositor for precision manufacturing

Achieve consistent gummy size and shape while maintaining precise weigh...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

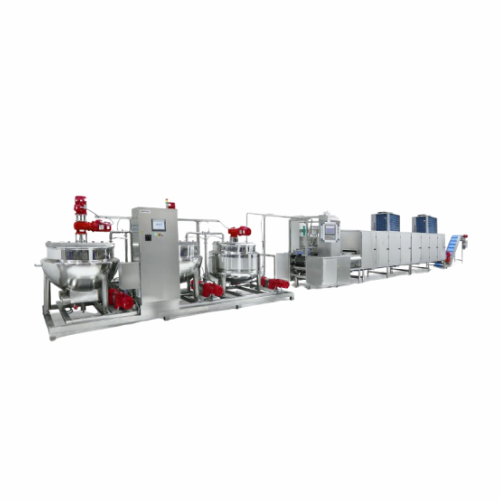

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Cooling tunnel for industrial pre-cooling

Efficiently reduce product temperatures with this custom-designed air cooling tu...

Linear belt vibratory weigh filler for solid chocolate

Optimize your chocolate production by minimizing product giveaway ...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Vertical fill and seal bagging machine for bakery products

Streamline your bakery product packaging with this versatile ...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Horizontal continuous motion cartoner

Streamline your packaging process with a high-speed cartoning solution that ensures p...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Soft candy production line

Optimize your candy production with a versatile line that efficiently handles everything from car...

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

Figure moulding for pliable mixes

Transform pliable mixtures into intricate 3D figures with precision and efficiency, cater...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

Micro ingredients loading station for solid additives

Optimize precision dosing and ensure smooth transfer of powdered in...

Blender for high viscosity products

When handling thick mixtures that challenge conventional systems, this specialized blen...

Powder liquid mixer for pectins and starches

Struggling with clumpy, undissolved granules in your mixtures? This innovativ...

Horizontal cartoning solution for pharmaceutical packaging

Streamline your confectionery packaging with high-speed, cont...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Horizontal form fill and seal for biscuits on edge

Optimize your packaging line with a machine that streamlines wrapping ...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Tablet press for confectionery products

Optimize your confectionery production with a high-speed tablet press capable of sh...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

High-speed flow wrapper for candies and gums

Achieve top-speed packaging with unparalleled flexibility for diverse confect...

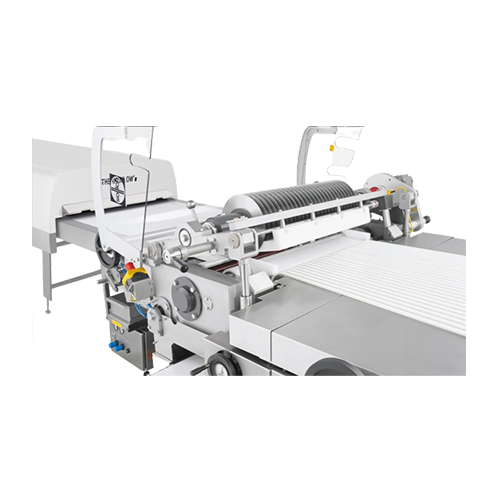

Gum slabs flow wrapping solution

Streamline your confectionery production with precision-engineered portioning and wrapping,...

Flow wrapping for bulk confectionery products

Efficiently orient, feed, and wrap bulk confectionery items with seamless in...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Product aligning and stacking solution

Enhance process stability and resource efficiency by integrating precise product ali...

Batch cooker for confectionery production

Achieve consistent confectionery texture and flavor with a flexible cooking solu...

Caramelization system for industrial confectionery production

Achieve precise caramelization and cooking of sensitive co...

Continuous production fondant beater

Achieve consistent fondant quality by gently controlling crystallization and temperatu...

Dosing unit for automated mixing in of ingredients

Achieve precise ingredient integration for confectionery and nutraceut...

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

High precision dosing system for color, flavor, and acid

Achieve precision and reliability in dosing color, flavor, and a...

Lab cooking and forming extruders for r&d

Optimize your R&D processes by testing new recipes and improving formulatio...

Industrial storage tanks for chemical and cosmetic industries

Need reliable storage that withstands aggressive chemical ...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

Flow pack packaging solution for flexible wrapping material

Optimize your packaging line with this compact flow pack sol...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Static checkweigher for accurate measurement

For those needing unparalleled precision, this static checkweigher ensures ex...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Continuous cooking system for jelly and marshmallow production

Elevate your confectionery production with a system desig...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

High-speed cut and wrap solution for confectionery products

Achieve seamless integration in your confectionery productio...

Dissolving tilt kettle for gummy candy production

Optimize your gummy candy production by melting and dissolving ingredie...

Robot module for aligning sorting and loading products

Optimize your packaging line with a versatile robot module that al...

Wafer block spiral cooler

Enhance your confectionery production with a modular spiral cooler that ensures gentle handling an...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Lab-scale twin screw extruders for material development

Accelerate your formulation testing and material development with...

Versatile confectionery cut and wrap system

Enhance your confectionery production with a high-speed solution capable of ac...

Double twist wrapping solution for confectionery

Optimize packaging speed and precision with a machine designed to wrap di...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Ultrafiltration and microfiltration module for low to medium viscosity products

Streamline the separation and concentr...

Ultrafiltration module for high-viscosity products

Achieve enhanced separation efficiency with a versatile module designe...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

High shear emulsifier for hygienic applications

Achieve precise emulsification and consistent mixture quality with enhance...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Double twist wrapping solution for candy packaging

Enhance your candy and gum production with high-speed wrapping that en...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Cooling tunnel for chocolate and bakery products

Achieve precise cooling and crystallization for chocolate and confectione...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Dough feeder for flexible and gentle dough handling

Ensure precise, gentle handling and optimal integration with your pro...

Industrial block melt system for butter and chocolate

Efficiently transition solid blocks of butter, chocolate, or waxes ...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Vision-based product inspection system for rejecting defective items

Enhance your production line efficiency by ensurin...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Clean-in-place (cip) system for sanitation processes

Ensure thorough sanitation in your production line with a streamline...

Automatic hamburger packaging solution

Streamline your hamburger production with a fully automated packaging system that en...

Complete packaging solution for meat products

Achieve seamless packaging integration with a solution designed to streamlin...

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

High sensitivity metal detectors for food products

Ensure food safety and product quality by effectively detecting and re...

Cross transfer station for mould configuration products

Streamline the transfer of mould-configured products across your ...

Wrapping system for preformed products in double twist

Achieve precise packaging with our high-speed double twist wrappin...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Flow wrapper with quick format change

Streamline your packaging operations with a machine that offers rapid format changeov...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Continuous mixer for pumpable media

In the food industry, mixing processes often involve solid and liquid combinations such...

High precision dosing system for liquid media

Producing confectionery and bakery products implies mixing large amounts of ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

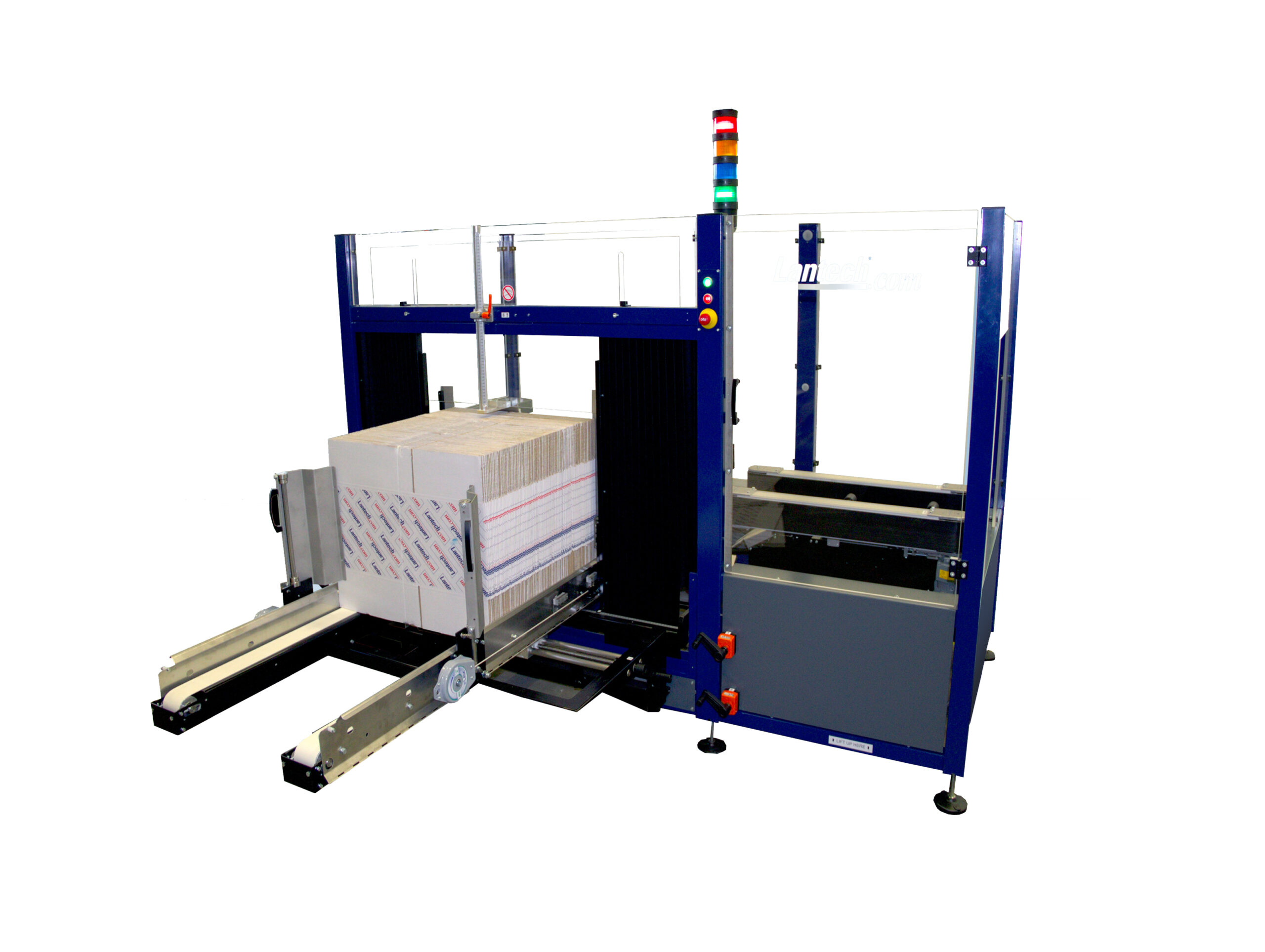

Case erector

To overcome common cases of manufacturing variations and optimize your packaging line, you need to be able to cou...

Cooker for gums and jellies

Prepare your ingredients for use in gummy and jelly products. This is a static cooking system de...

Batch cooker for hard candy

Prepare your ingredients for the production of hard candy. This is a line of universal candy coo...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...