Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamlessly integrates color and flavor into licorice and fruit gum, enabling the creation of diverse, multicolored confectioneries without the need for multiple systems.

Enables Multicolored and Flavored Extrusion

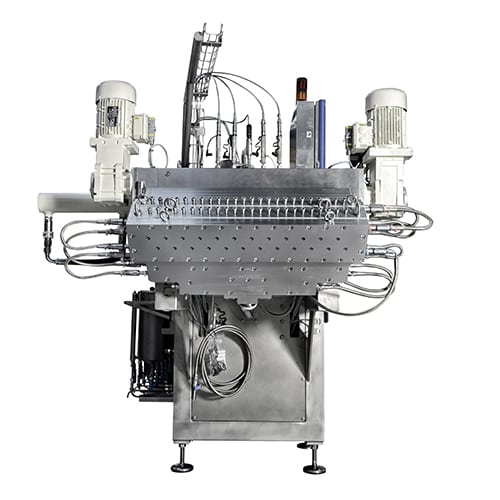

Extrugroup’s Diemix® is an innovative solution that transforms a single extruder into a versatile production unit capable of producing licorice, fruit gum, and other multicolored confectioneries. The system employs unique stream-dividing technology that allocates equal flows from the extruder, each precisely dosed and dynamically mixed with colors and flavors, achieving a homogeneous output. Ideal for confectionery and pet food manufacturers, the Diemix® supports the production of licorice ropes, fruit gum bears, and co-extruded pet treats. Featuring a compact design, it integrates seamlessly into existing production lines with minimal modifications and can be fitted to any Extrufood extruder type, allowing a single cooking extruder to produce six-color products. The Diemix® accommodates continuous high-speed operations, with options for installing a dosing skid for accurate customization. Maintenance is user-friendly, thanks to its accessible design, and it offers adaptability across various mass types, exemplifying a tailored approach to diverse manufacturing challenges.

Benefits

- Enhances product variety with a single extruder setup, reducing equipment costs.

- Streamlines production with accurate color and flavor dosing for consistent quality.

- Adapts easily to existing systems, minimizing installation time and expenses.

- Simplifies maintenance with an accessible design, reducing downtime.

- Expands production capabilities, allowing simultaneous manufacturing of six distinct products.

- Applications

- Snacks, Pet food, Confectionery, Sweets, Plastics, Licorice, Fruit gum

- End products

- Co-extruded snacks, Multi-flavored confectionery, Sugar paste-filled licorice, Fruit gum bears, Co-extruded pet treats, Co-extruded sweets, Licorice ropes, Licorice laces, Multicolored sweets, Multicolored plastics

- Steps before

- Cooking, Initial Mixing, Extrusion

- Steps after

- Forming, Cooling, Sand Coating, Cutting, Packing

- Input ingredients

- licorice mass, fruit gum mass, colors, flavors, sugar paste

- Output ingredients

- colored licorice, colored fruit gum, homogeneous colored and flavored products, single colored products

- Market info

- Extrufood is known for manufacturing custom-engineered food extrusion equipment, particularly in the confectionery sector. They excel in designing machinery tailored to specific client needs, emphasizing innovation, quality, and efficiency in the production process.

- Colors and Flavors

- Up to 6

- Extrusion Type

- Single and Co-extrusion

- Adaptability

- Compatible with all Extrufood extruder types

- Compact Design

- Yes

- Maintenance Accessibility

- Easy maintenance

- Dosing

- Accurate color and flavor dosage with dosing skid

- Working mechanism

- Co-extrusion with Diemix®

- Integrated steps

- Color and flavor addition, dynamic mixing

- Batch vs. continuous operation

- Inline Continuous

- Adaptability

- Fits into existing systems

- Maintenance accessibility

- Easy maintenance

- Automation level

- Integrated dosing skid

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Dosage accuracy

- Enhanced with dosing skid

- Compact footprint

- Yes

- Discharge method

- Individual, equal streams

- Control panel type

- Adaptable design

- Customization

- Adaptable to various mass types

- Maintenance accessibility

- Easy maintenance

- Integration

- Fits existing production systems

- Adaptability

- Fits existing systems with minimal modification

- Integration Possibilities

- Can be fitted to all Extrufood extruder types

- Compact Design

- Yes

- Dosing Skid

- Optional for accurate dosage

- Co-extrusion Capability

- 6 single-colored products on one extruder