Candy Making Equipment

Find innovative candy equipment and connect directly with world-leading technology suppliers

To make candy, all you need to do is create a syrup by dissolving sugar and boiling it to your desired consistency. For medium to large scale candy production, candy making equipment fully automates the whole process and takes care of other production regulations and standards (such as hygiene and proper homogenization). Planning on getting one? There’s a wide range of choices to pick from.

Innovative technologies for manufacturing candy

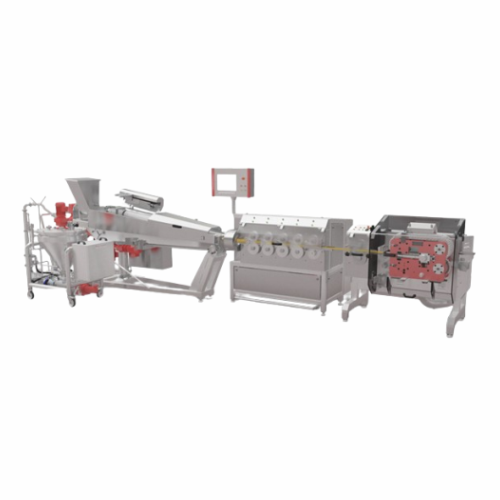

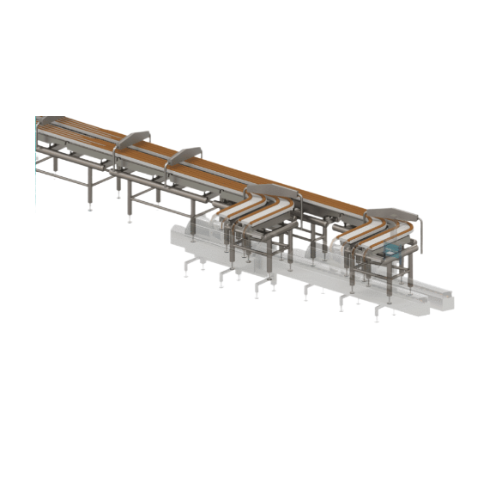

Candy rope sizer

Ensure precision in candy production by seamlessly reducing and sizing candy ropes for uniformity and quality...

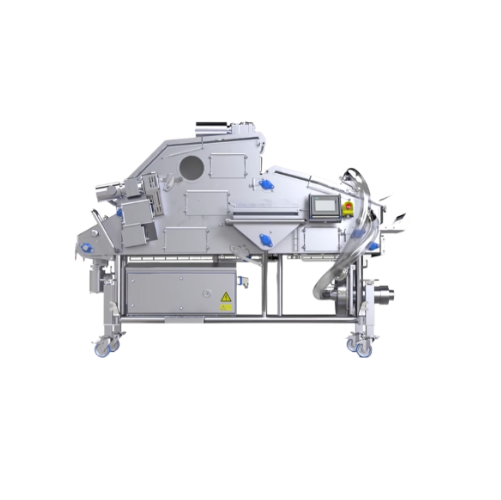

Batch roller for hard candy and toffee production

Enhance your confectionery production with a versatile solution that se...

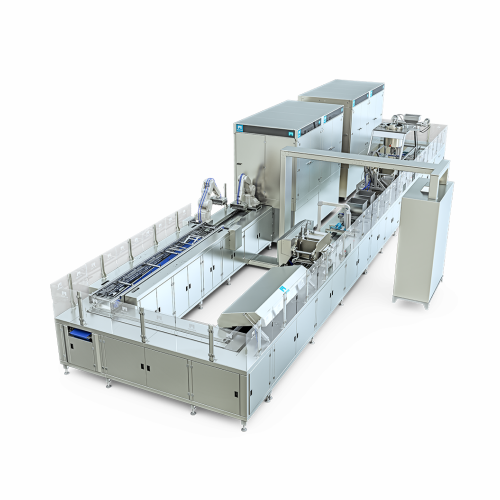

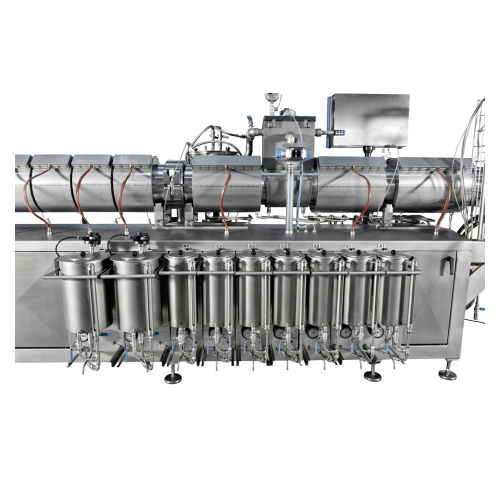

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

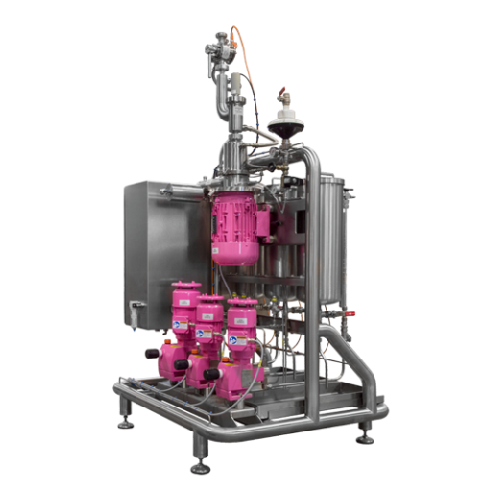

Aerator for candy masses

Enhance your candy production with precise and efficient aeration, transforming textures and creatin...

Stories about candy

Starting up your OTC non-starch gummy production

Modular equipment that helps you grow organically

Making healthier gummy formulations

Chew on this: craft gummies with pectin

Enter the world of relaxation by making sleep gummies

Delving into the fungal fun of gummy goodness

Activate your candy game: from a nutraceutical idea to an active candy

How to turn a bag of sugar into a bag of scrumptious gummies

There’s way more to see with CBD

Get sweet with weed in the endeavor of crafting cannabis candy

Find the perfect balance between sweets and wellness with vitamin candies

Preserving gummy texture in low or no sugar confectionery

How to craft gummy bears in 8 simple steps

Exploring the artistry of candy-making

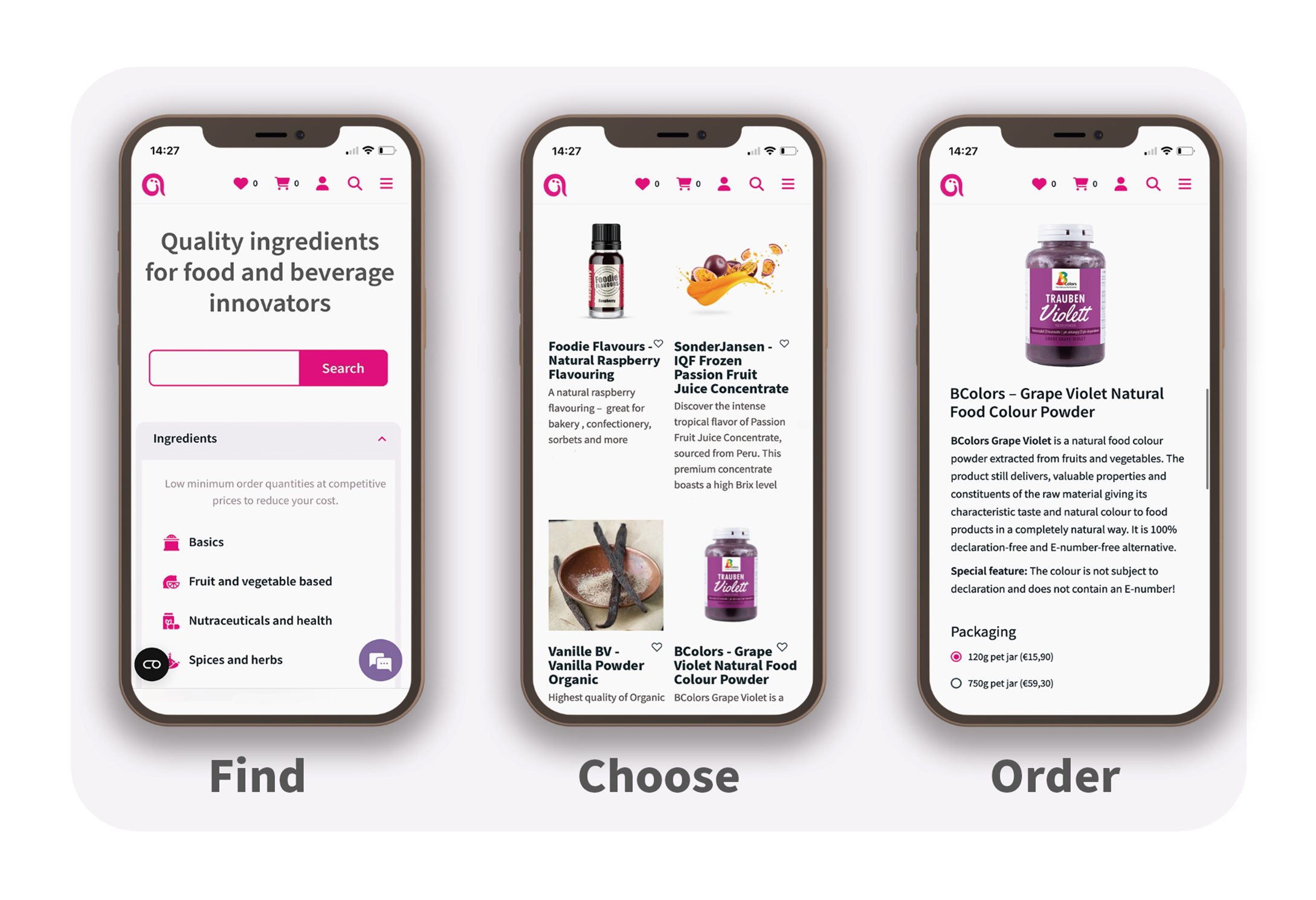

Order all your food Ingredients easily online at 1-2-Taste

Giving aerated jelly some bite

Tech is [was] keeping vitamin gummy manufacturers from cutting starch

Two steps to stop formula deviation in CBD Gummies

Liquorice: from root to candy

Select your candy process

Tell us about your production challenge

Candy making equipment for hard and soft candies

Candy consists mostly of sugar and water, although you can include flavor and coloring as well. Depending on how you prepare these ingredients, they can result in a number of different textures and recipes for candies.

To make hard candy, you need to mix more sugar in your syrup and cook the mixture to a higher temperature (about 300°F or 154°C). For soft candy, boil the syrup to a lower temperature (250° F or 121° C) and use a lower concentration of sugar.

Candy thermometers are useful for special recipes. Temperature plays a major role in determining whether candy ends up being soft or hard. However, they may not be necessary if you’re working with a semi-automatic or automatic candy making machine. These types of equipment handle almost all the steps in the production process, from mixing the ingredients to drying the candy to a specific texture. Some industrial candy making machines even include stainless steel die forming elements that are used to form the candies into various shapes and sizes.

Producing sugar-free candies

Sugar is an essential ingredient in candies, as it affects their texture and also helps with their preservation. Yet, sugar can be replaced with other ingredients which serve as binders in the making of candies. To produce sugar-free candy, honey can be the base ingredient without any noticeable difference in texture or flavor. Isomalt is another alternative since it melts and hardens in the same way as sugar. That said, isomalt works best for hard candy because it is non-sticky and doesn’t absorb too much water. You may also use sugar-free sweetened corn syrups instead of sugar.

Should you use natural or artificial sweeteners?

Artificial sweeteners such as saccharin, sucralose, neotame, aspartame, and acesulfame can replace natural sugars in the production of candies. They provide minimal nutritional value, but the absence of calories in artificial sweeteners can be an advantage as well, healthwise. Artificial sugars are also less expensive than natural sugars and offer greater protection against cavities. On the flip side, many people dislike the overly sweet taste of artificial sugars. Also, if consumed in excess, they may also pose health problems.

Which candy technology do you need?

Continuous cooking unit with vacuum for candy production

Achieve precise caramelization and cooking with enhanced flavor ...

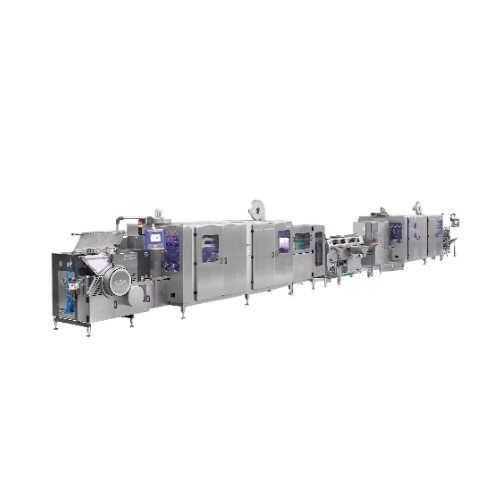

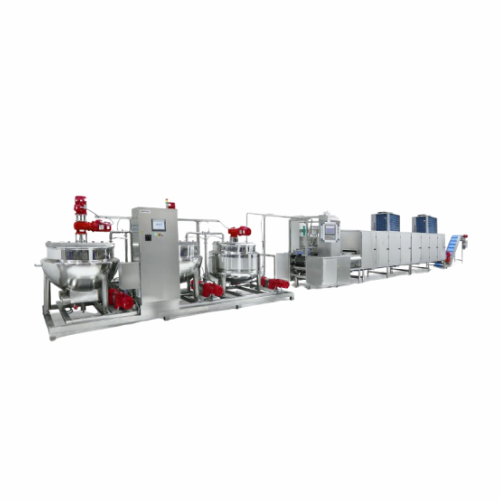

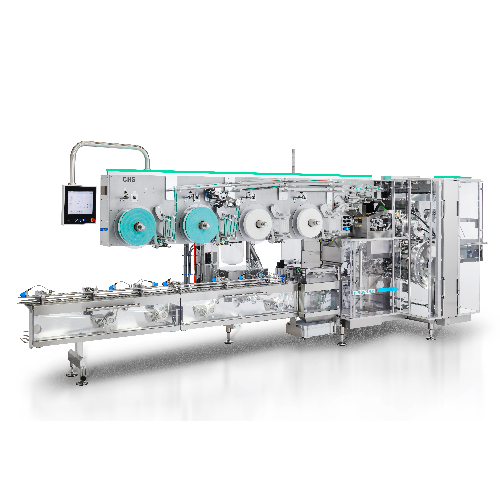

Soft candy production line

Optimize your candy production with a versatile line that efficiently handles everything from car...

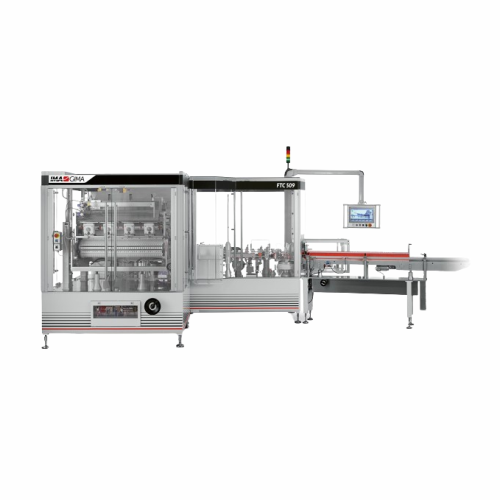

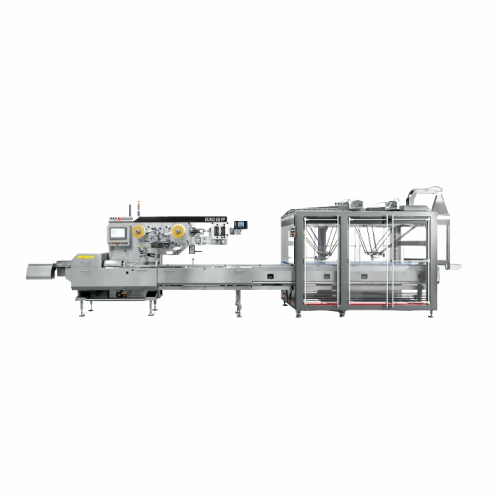

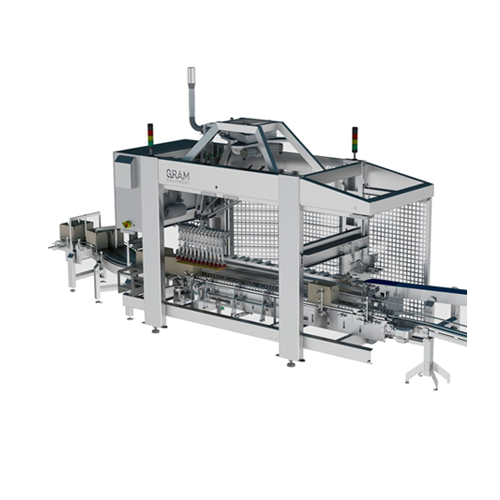

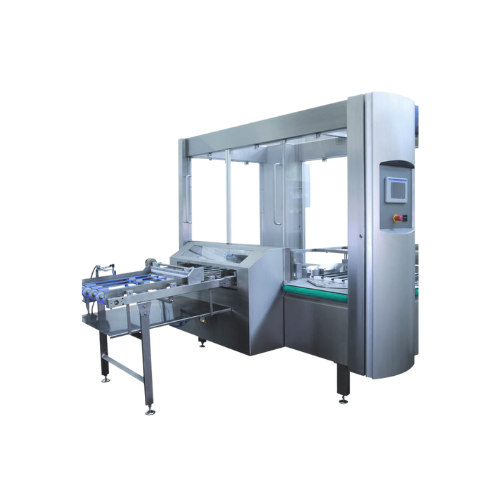

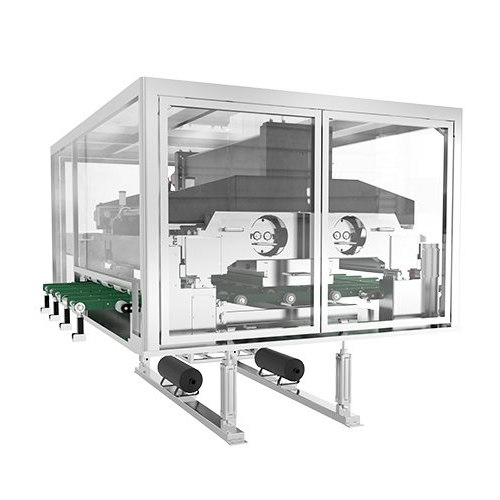

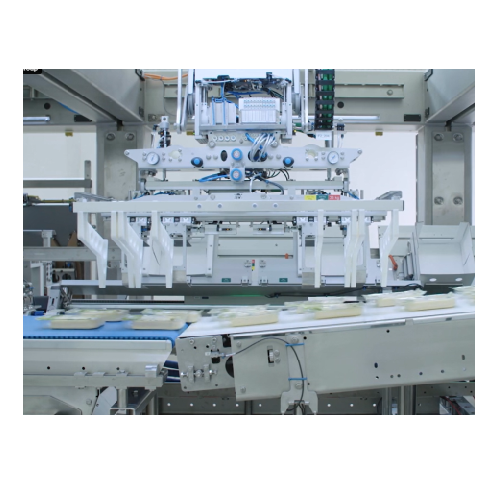

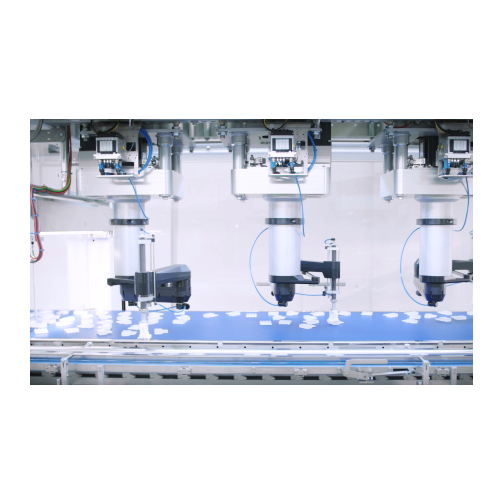

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

Pre-cooking and final cooking for candy production

Optimize your candy production with a versatile cooker designed to han...

Hard candy forming line for manufacturing

Experience seamless candy production with advanced forming technology, ensuring ...

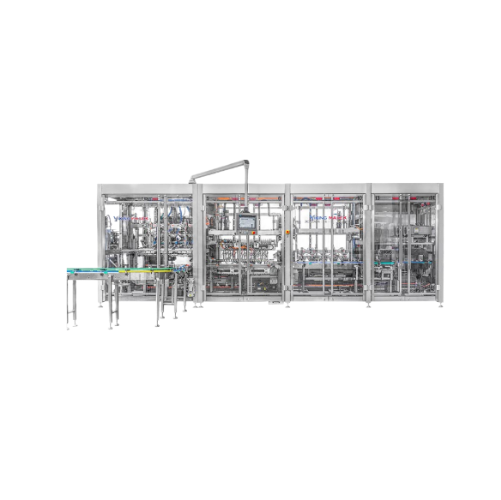

Hard candy production system

Enhance your candy production line with a comprehensive system that optimizes processes from co...

Continuous caramel cooker for candy production

Achieve perfect caramel consistency with precise control as this solution c...

Crystallization process for chewy candy production

Optimize your confectionery production with precision crystallization,...

Forming line for croquant, hard candy, and chewy candies

Optimize your candy production with precision forming and emboss...

Aerator for candy masses

Enhance your candy production with precise and efficient aeration, transforming textures and creatin...

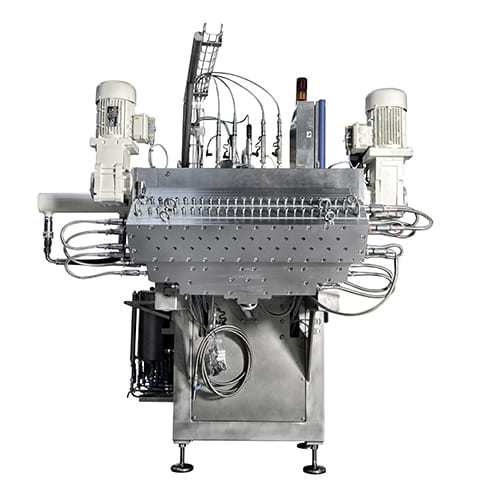

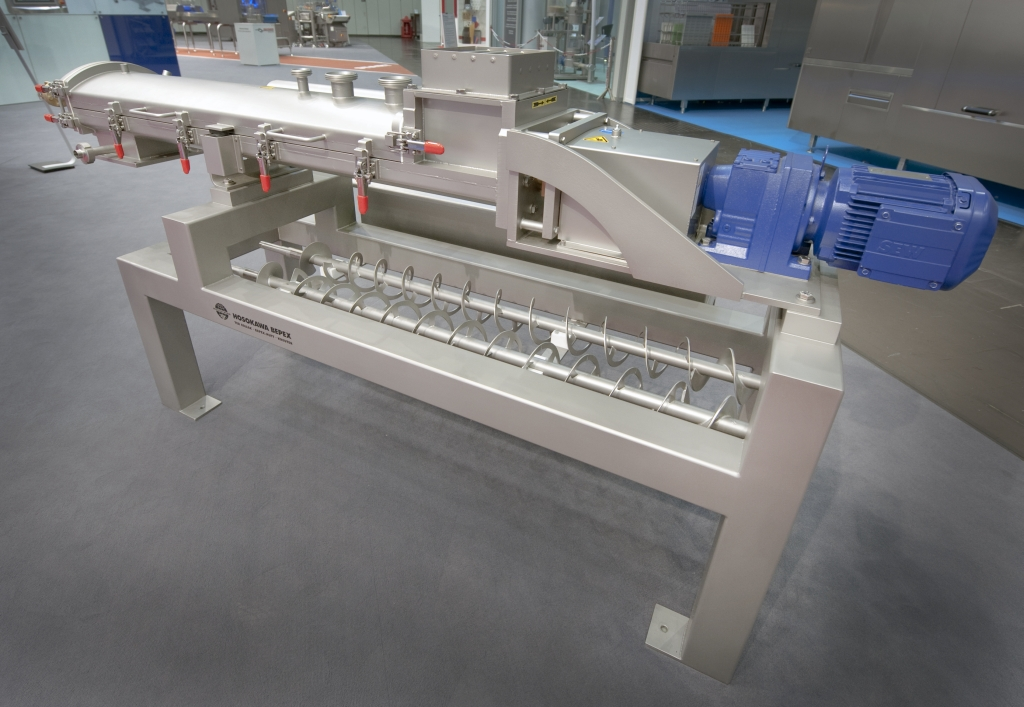

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

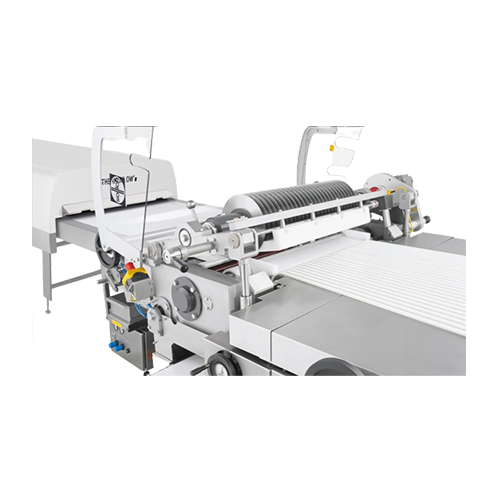

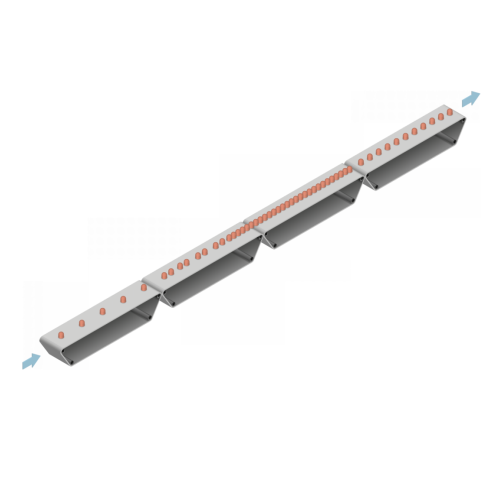

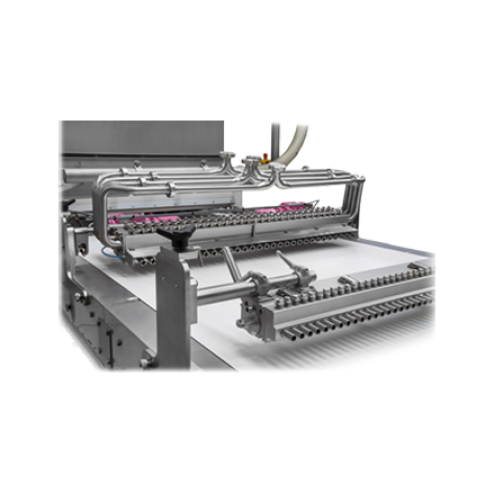

Preforming line for candy rope production

Achieve consistent sugar ropes and lollipop centers with precise forming and siz...

Ball former for bubble-gum and soft candy production

Achieve precise ball forming for bubble gum and soft candies with cu...

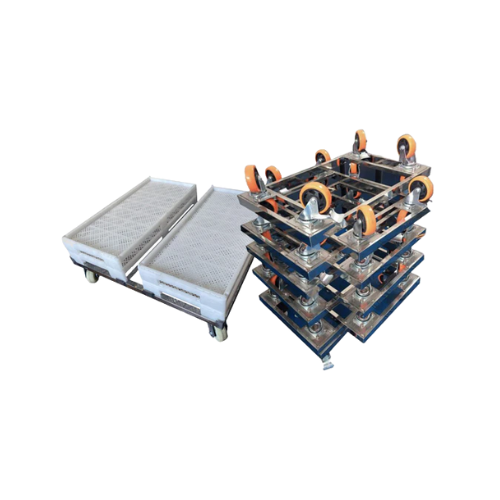

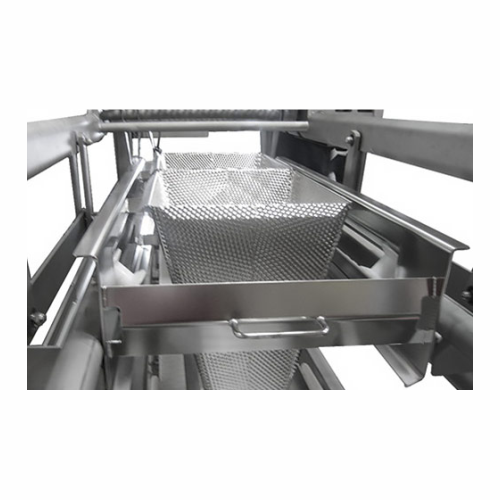

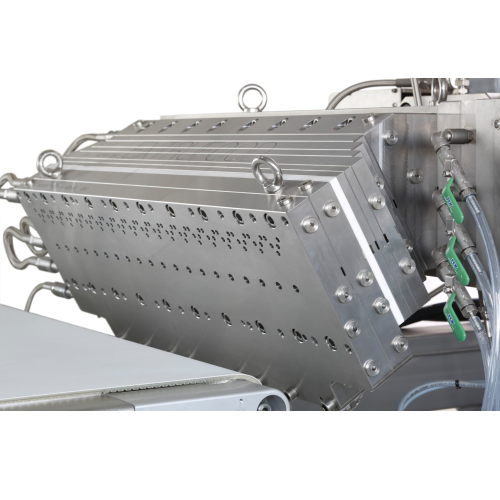

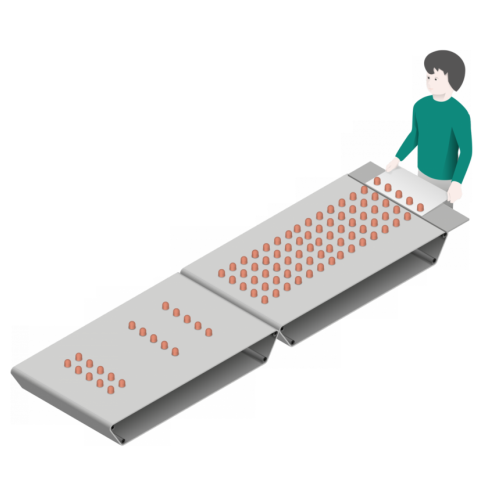

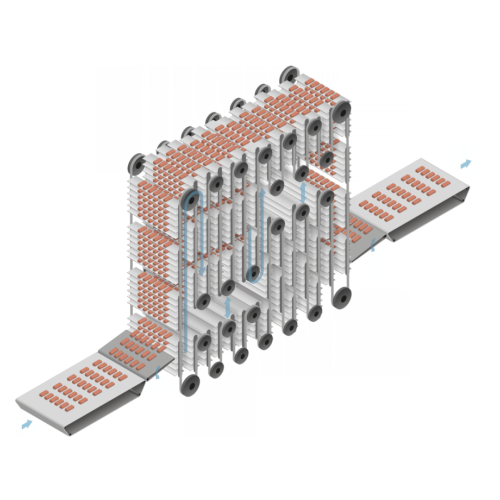

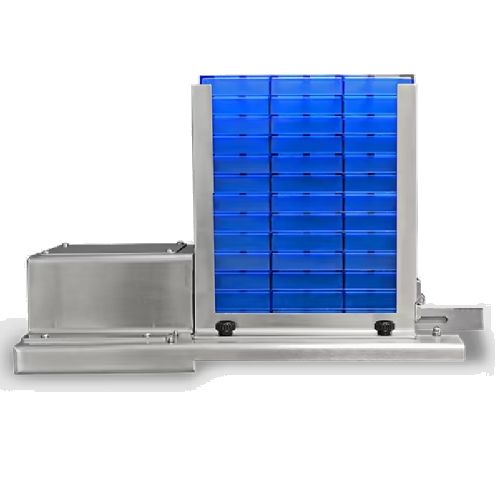

Drying trays for gummy candy production

Ensure proper drying and setting of your gummy candies and gelatin-based products w...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

Mini candy depositor for gummy production

Optimize your confectionery production with a compact depositor, delivering prec...

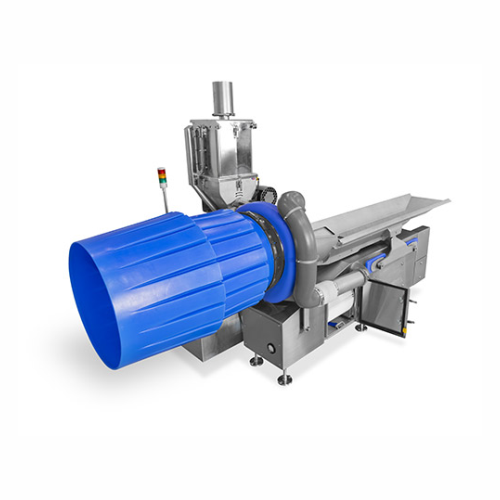

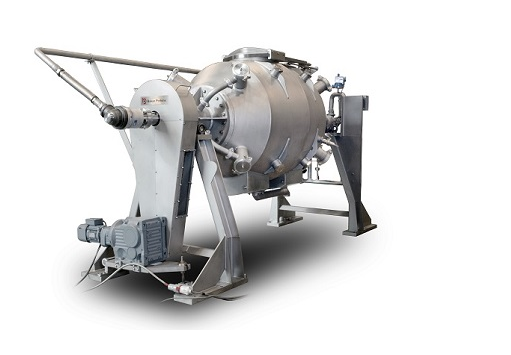

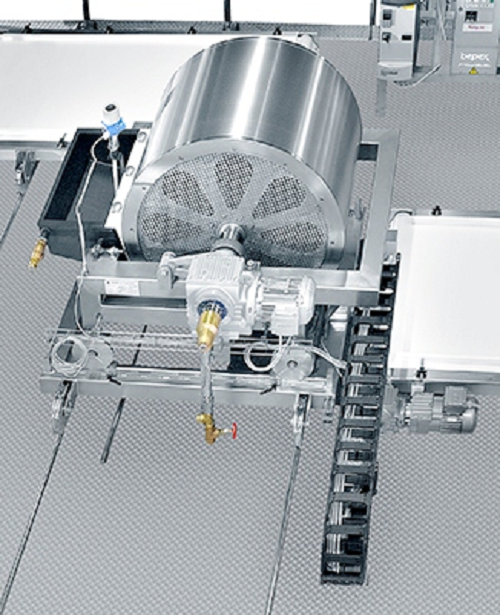

Sugar drum for coating gummy candy

Achieve a uniform sugar or wax layer on your gummy candies with precision and reliabilit...

Dissolving tilt kettle for gummy candy production

Optimize your gummy candy production by melting and dissolving ingredie...

Gummy candy depositor for precision manufacturing

Achieve consistent gummy size and shape while maintaining precise weigh...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

Chestnut candying system

Optimize your candying process with a modular system that enhances syrup distribution and concentrat...

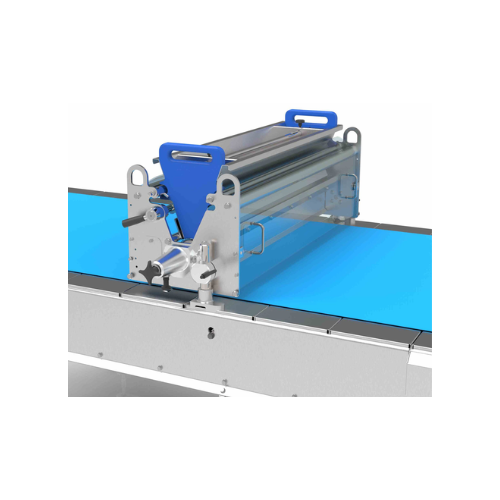

Batch roller for hard candy and toffee production

Enhance your confectionery production with a versatile solution that se...

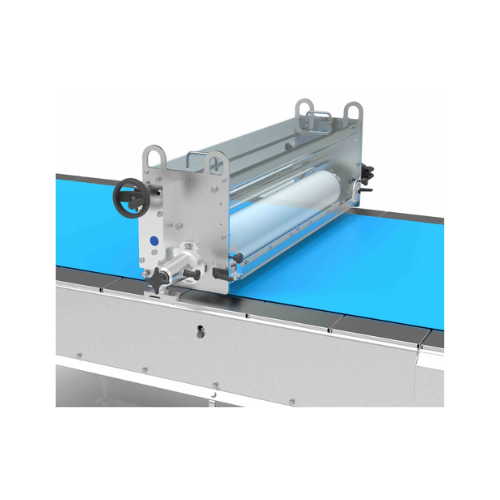

Candy rope sizer

Ensure precision in candy production by seamlessly reducing and sizing candy ropes for uniformity and quality...

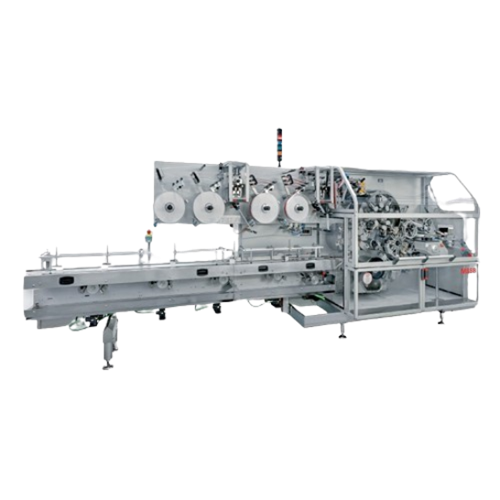

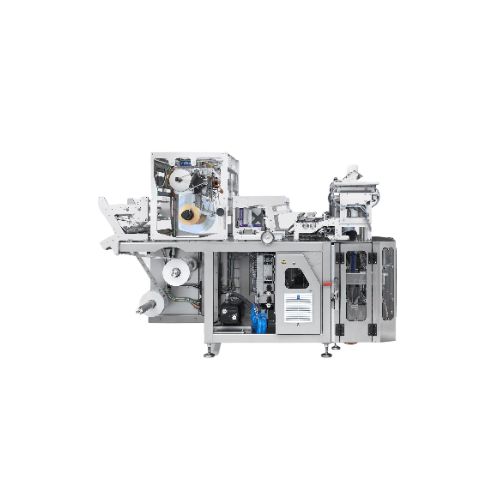

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Double twist wrapping solution for candy packaging

Enhance your candy and gum production with high-speed wrapping that en...

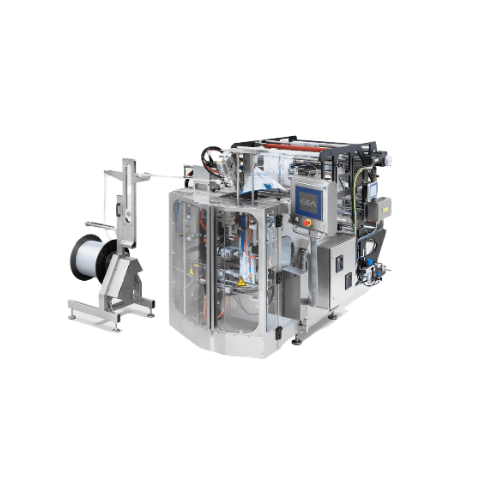

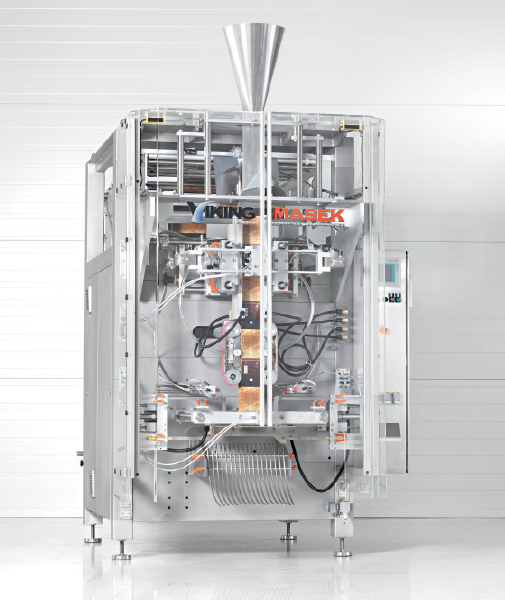

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Candy packaging solution for gummies and hard candies

Maximize your confectionery efficiency with high-speed packaging so...

Forming solution for candy and cereal bars

Achieve precision in bar production with a system that ensures minimal weight v...

High-speed fold wrapping machine for hard candy

Bottom fold wrapping is an attractive solution for hard candies, toffees, ...

Automatic premixer for hard candy

Feed materials to your confectionery process equipment in a consistent and convenient way...

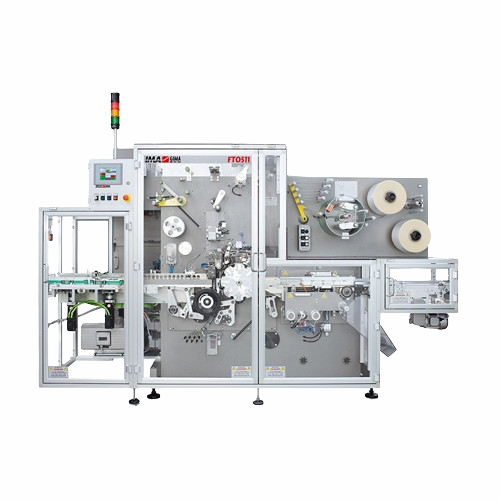

High-speed flow pack wrapping machine for hard candy and jellies

For some high-quality candy which require individual wr...

High-speed double twist wrapping machine for hard candy

Double-twist wrapping is the preferred packaging method for many ...

Starch-free depositor for hard candy

Forming hard candies requires careful handling of syrups in order to avoid quality iss...

Continuous cooker for hard candy

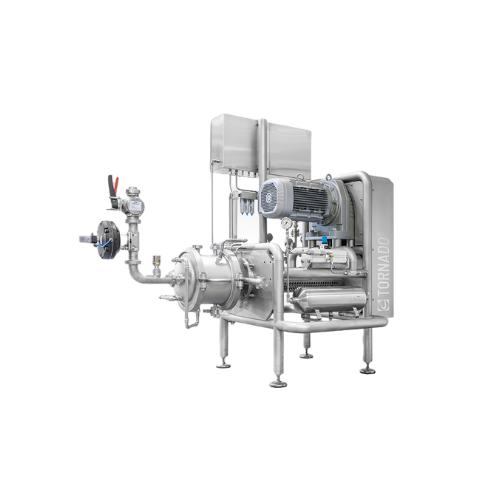

Prepare your ingredients for hard candy production. This is a continuous dissolving, cookin...

Batch cooker for hard candy

Prepare your ingredients for the production of hard candy. This is a line of universal candy coo...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Chocolate wrapping machine for confectionery production

Achieve precision and elegance in packaging with high-speed wrapp...

High-speed overwrapping for display boxes

Achieve seamless overwrapping of display boxes with ultra-high-speed capabilitie...

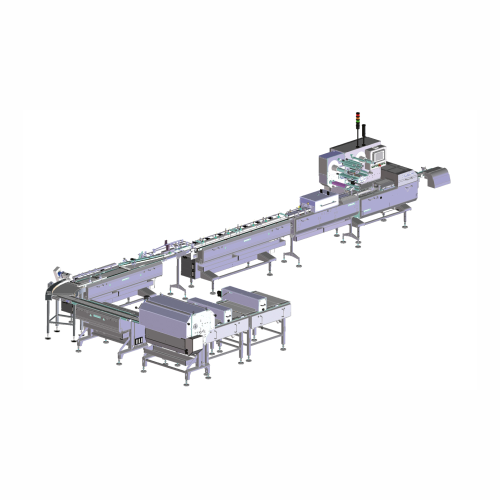

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

Overwrapping solution for medium size display boxes

Streamline your packaging line with high-speed, continuous overwrappi...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

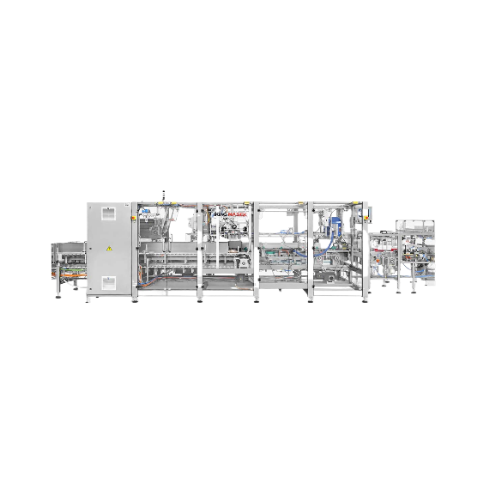

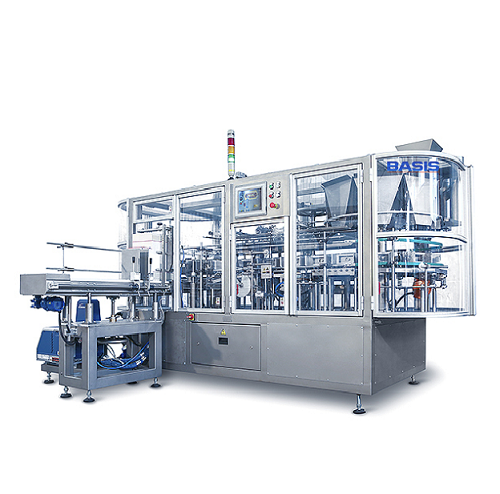

Intermittent motion cartoner for confectionery packaging

For manufacturers needing versatile packaging solutions, this ca...

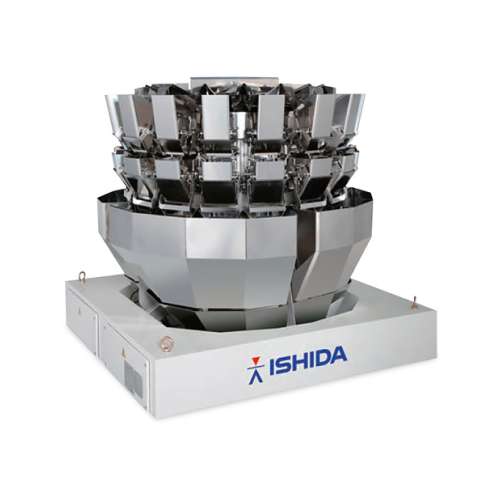

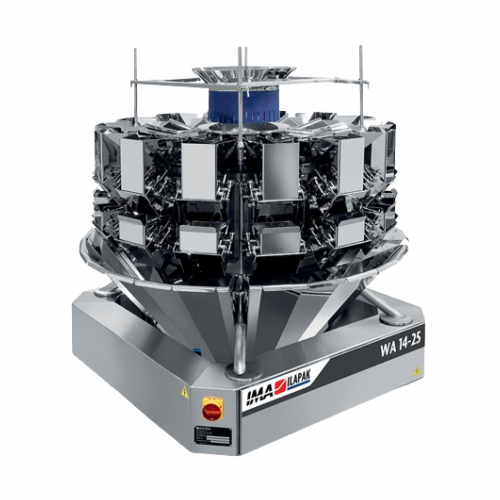

Blending multihead weigher for accurate component mixing

Achieve precise blending in high-speed operations with individua...

Caramelization system for industrial confectionery production

Achieve precise caramelization and cooking of sensitive co...

Continuous production fondant beater

Achieve consistent fondant quality by gently controlling crystallization and temperatu...

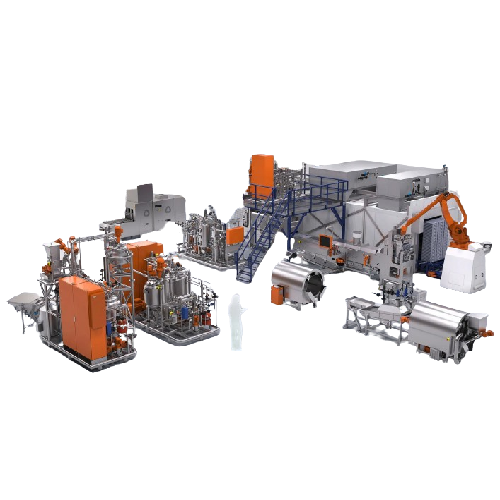

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Systems for processing confectionery rework

Optimize resource use and reduce waste by transforming confectionery rework in...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Fondant mass production system

Achieve precise crystal size and uniform fondant quality with a two-step crystallization proc...

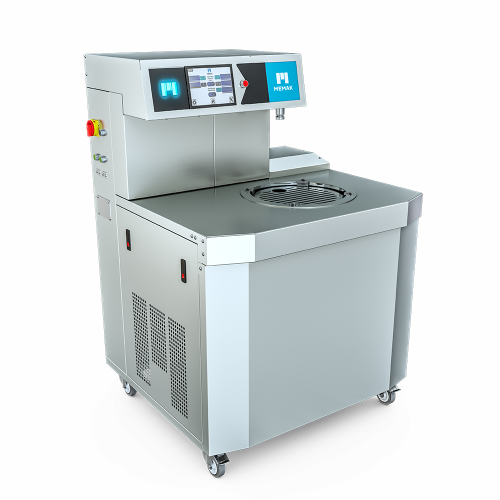

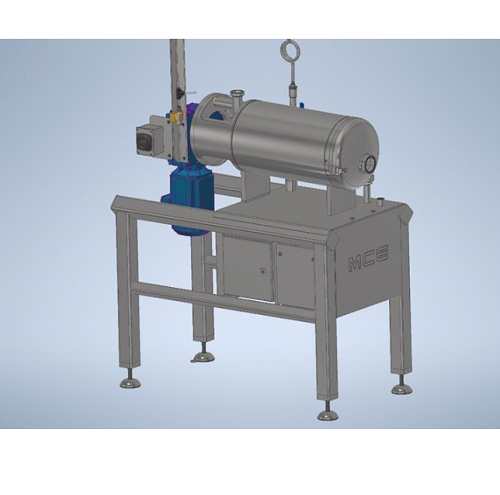

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

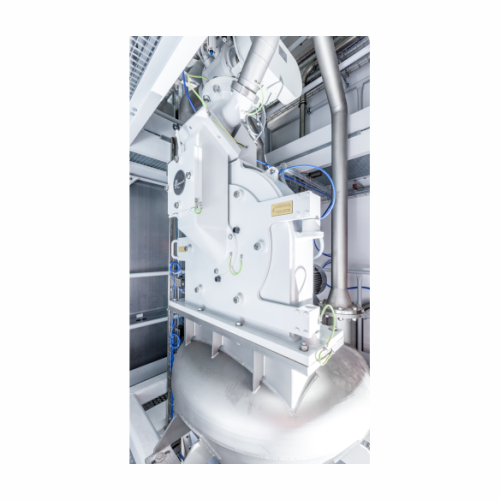

Aeration system for sugar masses

Optimize your production of aerated confectioneries with a two-step aeration system designe...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

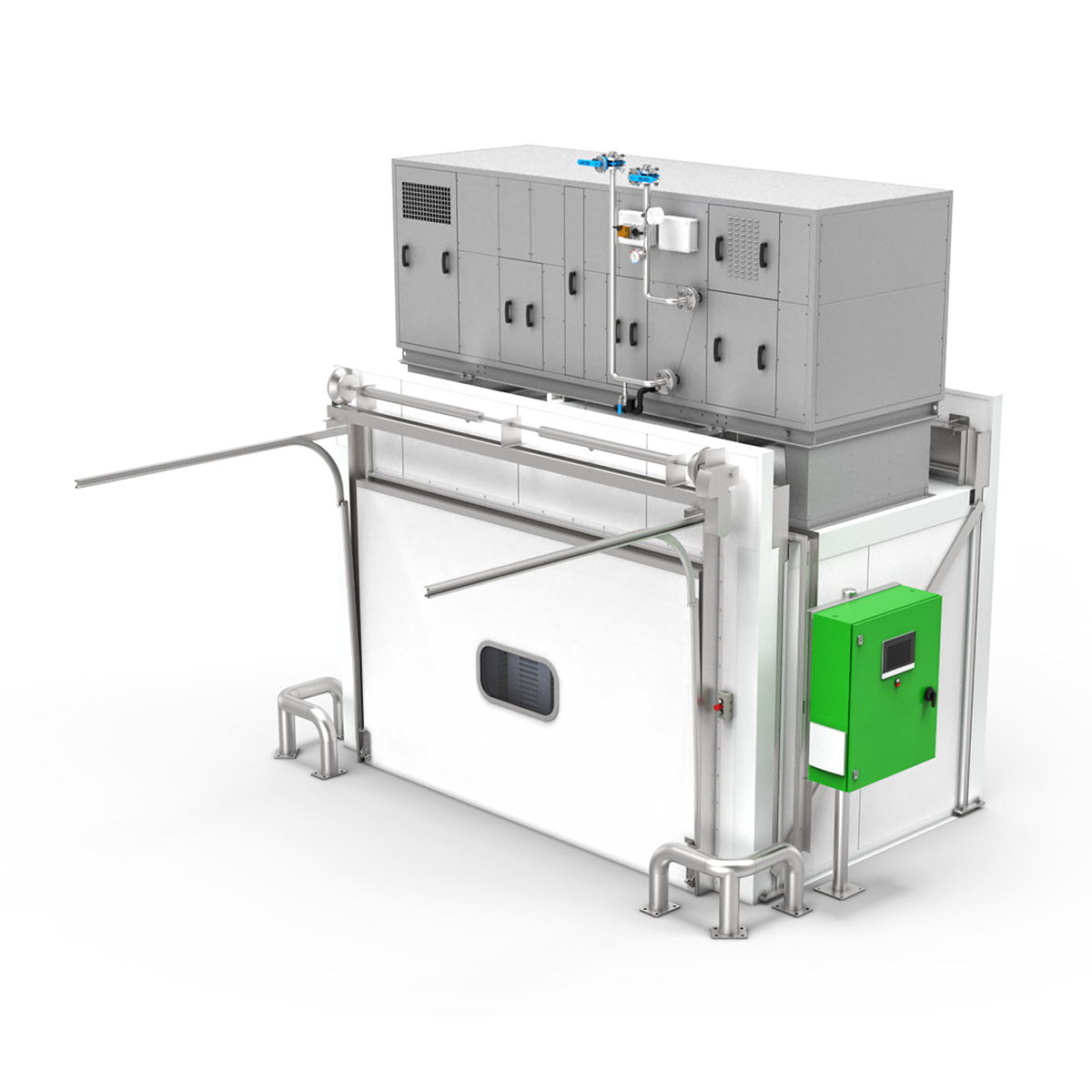

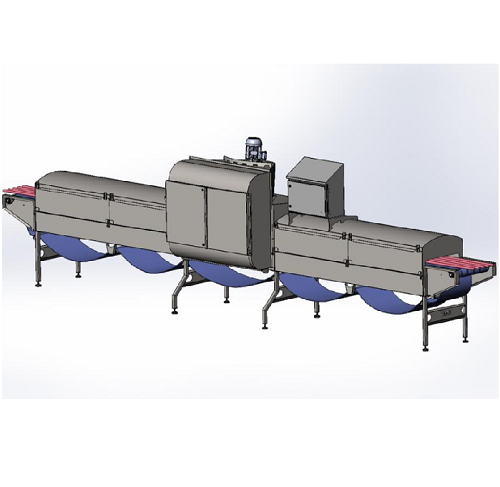

Industrial cooling tunnel for bubble gum and toffee

Ensure your confectionery maintains its shape and quality with high-p...

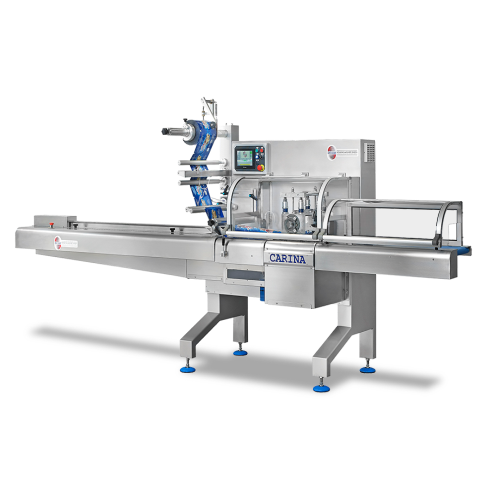

Flow wrapper for preformed pieces

Optimize your high-speed packaging line with a reliable flow wrapper that seamlessly wrap...

Flow wrapper for lollipops packaging

Achieve precise and high-speed lollipop packaging with continuous-motion flow wrapping...

Continuous lollipop forming system

Refine your confectionery production with a high-speed forming system that creates diver...

4-sides seal wrapping for lollipops

For lollipop producers seeking precision and efficiency, this 4-sides seal wrapper ensu...

Bunch wrapper for lollipops

Achieve precise and efficient single twist wrapping for ball and 3D lollipops with high-speed ca...

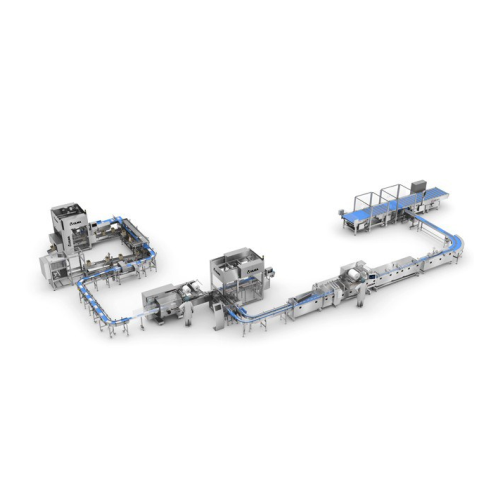

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Colorful marshmallow extrusion for confectionery production

Elevate your confectionery offerings with a high-speed extru...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Double twist wrapping solution for confectionery

Optimize packaging speed and precision with a machine designed to wrap di...

High boiled sugar continuous batch cooker

Streamline your confectionery production with efficient high boiled sugar cookin...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

Continuous cooling system for ball lollipops

Ensure perfect shape retention and quality of ball lollipops with this contin...

Coated lollipop production line

Transform your confectionery line with a solution that forms, cools, and coats 3D lollipops ...

Flat lollipop forming and wrapping system

Enhance your candy production with precision-engineered lollipop forming and wra...

Continuous flat lollipop cooling system

Ensure your lollipops retain perfect shape and quality with this high-speed cooling...

Lollipop wrapping solution

Ensure precision and faster production with a high-speed wrapping solution that adapts seamlessly...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

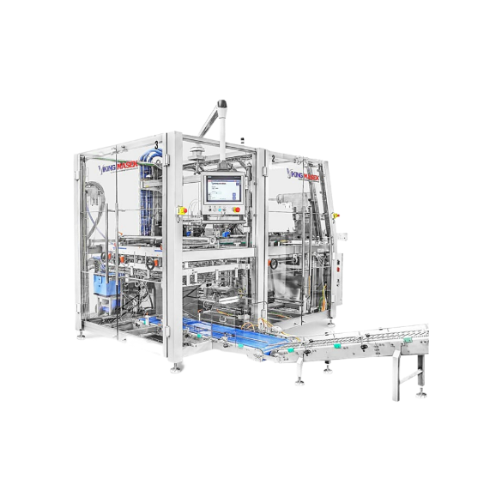

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

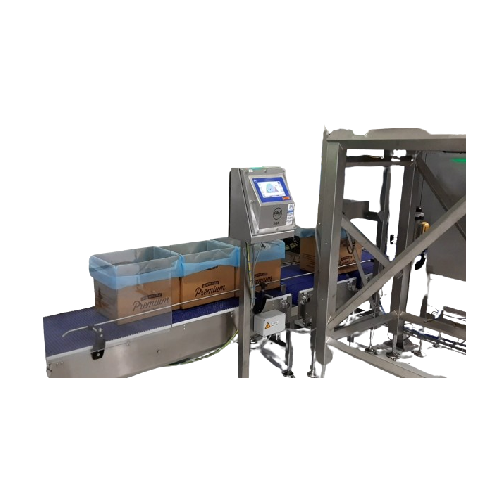

Checkweigher for pharmaceutical and food industries

Ensure precise weight measurement and reliable product rejection in h...

Forming, cutting, and wrapping system for soft caramels

Optimize your confectionery production line with a solution desig...

Linear weigher for dry free flowing products

Streamline your packaging process with precise weighing capabilities, ensurin...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

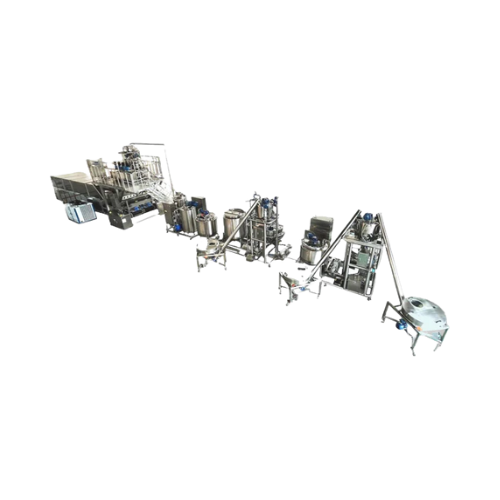

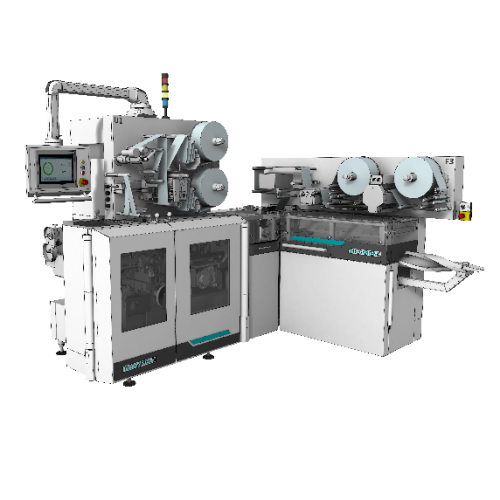

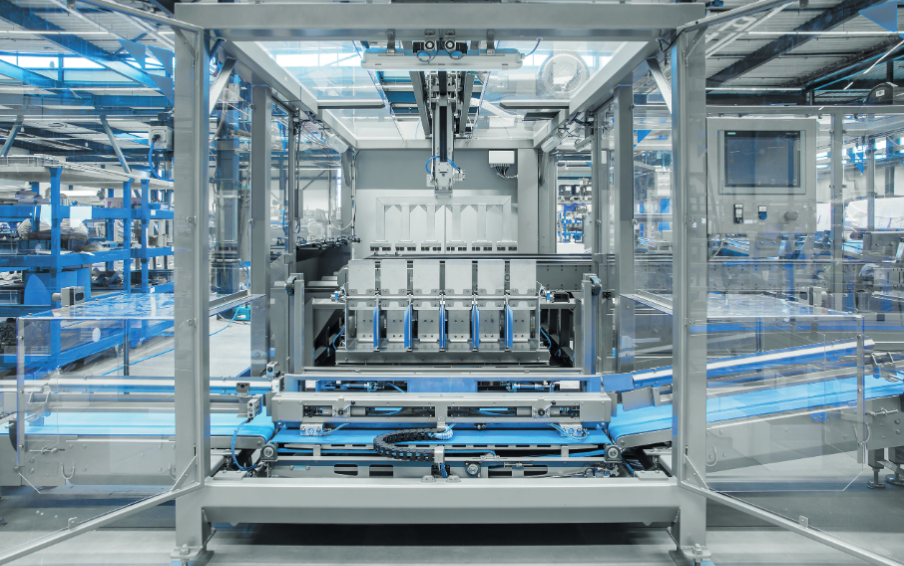

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automat...

Peanut brittle forming and cutting system

Efficiently transform sticky ingredients into uniform treats with our cutting-ed...

Automatic cereal bar production line

Efficiently transform diverse ingredients into consistent, high-quality cereal bars wi...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

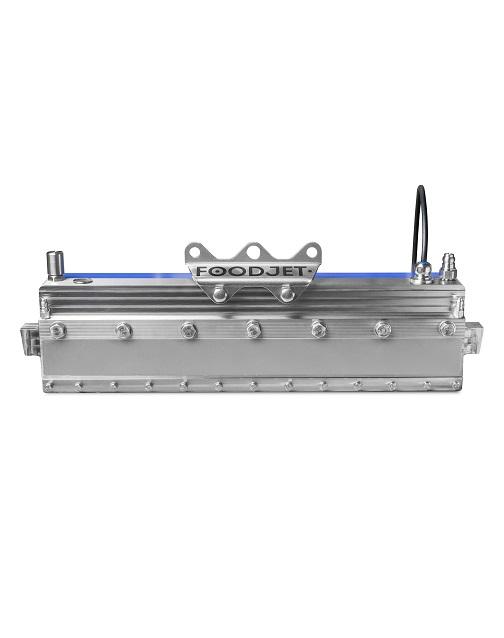

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

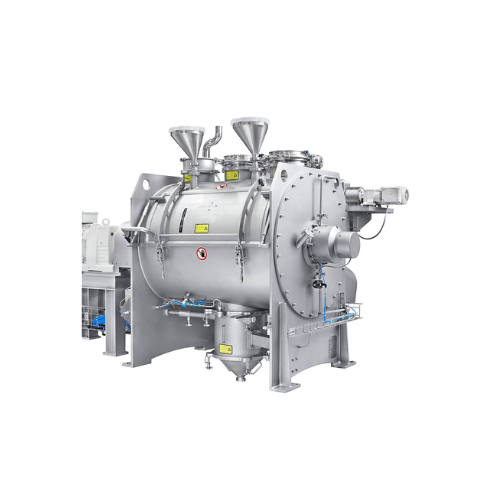

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Caramel enrobing system for biscuits and wafers

Achieve consistent caramel coverage with precise temperature control, ensu...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Small Scale Industrial Jam Cooker

Production of marmalades, jams, fruit concentrates, and sauces requires multiple steps. T...

Vegan Sauce Processing System

Having a multipurpose machine allows one to perform different tasks like cooking, frying, brai...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Compact flexible cooker for confectionery products

In confectionery production flexibility can be the key to increased ef...

Single twist cut & wrap lollipop machine

Soft caramel lollipops require more gentle handling during production than ot...

High-speed cut and wrap flow pack machine

Flow pack wrapping is a popular option for the individual wrapping of soft caram...

High-speed cut & wrap fold machine

For large scale production of toffees, caramels and chewy candy products, speed of throu...

High-speed cut and wrap double twist machine

Many gums, chewy candies, toffees and caramel products are most suited to ind...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

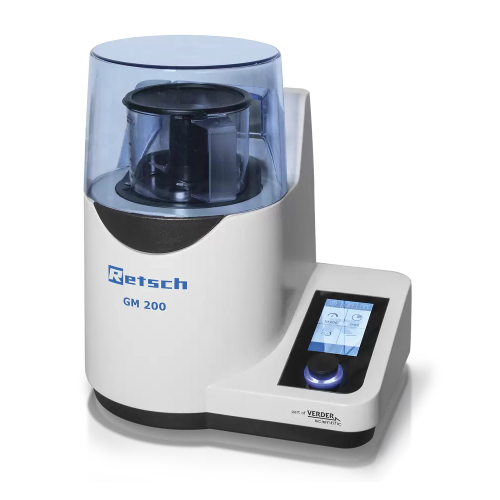

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Continuous cooler for biscuits and chocolates

Enhance cooling efficiency for your confectionery and bakery production with...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

Industrial chocolate flaking system

Achieve precise chocolate flake dimensions effortlessly, enhancing product textures and...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

Fully automatic rotary ring wrapper for large pallets

Optimize packaging efficiency by securing large, diverse pallet loa...

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Horizontal continuous motion cartoner

Streamline your packaging process with a high-speed cartoning solution that ensures p...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Fat melting tank for confectionery production

Melt solid fat blocks efficiently to streamline your caramel, nougat, and ch...

Fat slurry homogenization mill for chocolate processing

Achieve precise chocolate and confectionery homogenization with e...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

Jelly and chocolate ball wrapping solution

Efficiently wrap jelly candies and chocolate balls with precision and high spee...

Chocolate tempering solution for industrial production

Achieve consistent chocolate crystallization with a machine that e...

Conching solution for chocolate processing

Achieve optimal chocolate texture and flavor by ensuring efficient conching, cr...

Industrial fat melting tank for bakery and chocolate production

Efficiently melt solid fats to precise temperatures with...

Laboratory type ball mill for chocolate and bakery applications

Optimize your R&D processes with precise grinding a...

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

Chocolate ball mill for processing chocolate mass

Enhance your confectionery production with precision mixing and uniform...

Commercial chocolate refiner/conche

Elevate your chocolate production with a versatile 5-in-1 solution, integrating cocoa m...

Artisan line for fine chocolate mass production

Transform raw cocoa beans into exquisite chocolate through precise control...

Top-loading cartoner for bar and confectionery packaging

Optimize your high-speed packaging operations with a flexible ca...

Fold wrapping solution for chewing gum tabs

Streamline your high-speed packaging line with a solution that expertly wraps ...

Twin station fold wrapping machine for chocolate bars

Efficiently transform diverse chocolate and confectionery items int...

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

High speed rolling line for confectionery production

Enhance your confectionery production with a versatile rolling line ...

Pick and place robotic system for confectionery decoration

For food producers seeking precision in snack decoration, thi...

Entry-level food packaging machine for pillow bags

Achieve space-saving packaging versatility with a machine designed for...

Packaging solution for bulk vegetables and fruits

Ensure precise, high-speed packaging for diverse product sizes with a f...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Flow wrapper for high-speed confectionery packaging

Achieve gentle, high-speed packaging for delicate confectionery items...

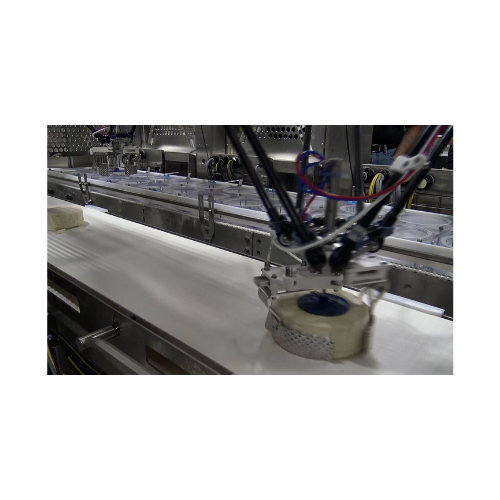

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Tablet press for confectionery products

Optimize your confectionery production with a high-speed tablet press capable of sh...

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

High-speed multi-head weigher for confectionery products

Achieve precise measurements and minimize waste in high-speed fo...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

High-speed flow wrapper for candies and gums

Achieve top-speed packaging with unparalleled flexibility for diverse confect...

High-speed cut & wrap flow wrapping for confectionery

Experience efficient packaging with high-speed flow wrapping techno...

Flow wrapping for bulk confectionery products

Efficiently orient, feed, and wrap bulk confectionery items with seamless in...

Hollow wafer spreading machine for consistent coating

Optimize your snack production with precise spreading—achieve unifo...

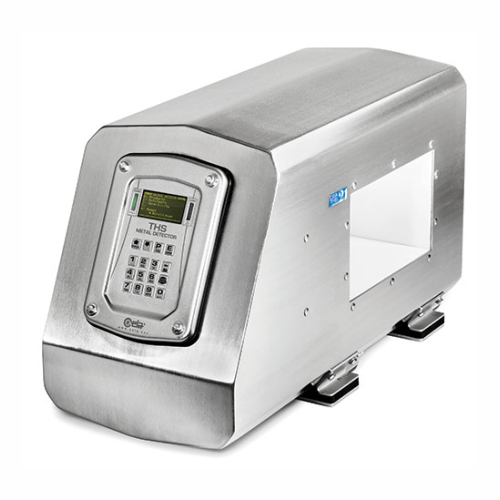

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tra...

Multihead weigher for precise bulk product weighing

Optimize your weighing operations with highly accurate multihead tech...

Linear weigher for dry or frozen free-flowing products

Optimize precision in high-speed weighing tasks with a compact sol...

Multihead weigher for food processing

Enhance production efficiency and accuracy with multihead weighing technology, offeri...

Forming system for multi-lane production of shaped foods

Streamline your production of uniform shaped foods with a multi-...

Batch cooker for confectionery production

Achieve consistent confectionery texture and flavor with a flexible cooking solu...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

Dosing unit for automated mixing in of ingredients

Achieve precise ingredient integration for confectionery and nutraceut...

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Batch-wise cooking and aerating system for aerated candies

When producing aerated candies, achieving uniform texture and...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small ...

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

Sugar coating system for gummies

Achieve a flawless sugar coat on up to 240,000 gummies per hour, seamlessly integrating int...

Portable water activity meter for gummy production

Ensure consistent gummy quality and extended shelf life by precisely m...

Gummy counter for gusseted bags

Optimize your gummy production line with precise counting and packaging into re-sealable gus...

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for con...

Industrial sugar sander for confectionery coating

Enhance product appeal and longevity with a sugar sander designed to un...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

Extrusion system for color changing confectionery strands

Easily switch colors in confectionery strands mid-production, ...

High precision dosing system for color, flavor, and acid

Achieve precision and reliability in dosing color, flavor, and a...

Confectionery forming extruders for viscous masses

Efficiently transform viscous ingredients into uniform, high-quality c...

Slurry preparation for licorice production

Ensure a continuous and homogeneous feed of licorice slurry to your extruder, o...

Caramel cooking solution

Optimize your confectionery production with precise mixing, dissolving, and heat transfer technologi...

Planetary stirrer for bakery and confectionery

Achieve consistent textures and presentation by effortlessly stirring, beat...

Flow pack packaging system for flexible wrapping material

Achieve seamless, high-speed packaging of solid foods with thr...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Three-side sealing packaging machine

Achieve precise, three-side sealed packaging for both food and non-food products, enha...

Cooker for nougat and hard mixtures

Optimize the production of high-density mixtures like nougat and meat sauces with this ...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Product unscramblers for industrial automation

Efficiently organize and orient jumbled products for seamless integration w...

Continuous cooking system for jelly and marshmallow production

Elevate your confectionery production with a system desig...

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Static cooler for jelly and foam manufacturing

Ensure the integrity of your confectionery with a cooling system designed f...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

High shear mixer system for hydrocolloids

Streamline your confectionery production with a high-shear mixer designed for pr...

Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed ...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Continuous butter toffee processing system

Achieve precise caramelization and nut integration while maintaining the perfec...

Industrial sugar melter

Efficiently melt and mix sugar with precision using a gas-fired batch cooker designed for optimal hea...

Stickpack wrapper for lollipops

Enhance your confectionery line’s efficiency by wrapping up to 480 lollipops per minut...

High-speed cut and wrap solution for confectionery products

Achieve seamless integration in your confectionery productio...

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

High precision lollipop cooling system

Ensure your lollipops maintain their shape and quality with precision cooling, reduc...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

High-speed continuous motion overwrapper for thin films

For those needing high-speed, efficient wrapping, this equipment ...

Intermittent motion overwrapper for cosmetic and food products

Achieve flawless packaging with precision wrapping and se...

Lidding system for cups and trays

Enhance your packaging line with precise, space-saving lidding technology, ideal for seal...

Robot module for aligning sorting and loading products

Optimize your packaging line with a versatile robot module that al...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Transversal cutting for confectionery production

Achieve precise and customizable cuts in high-speed confectionery and bak...

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and ...

Pressing roller for cookie thickness adjustment

Ensure consistent cookie thickness and unique product patterning with a hi...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Batch cooker for confectioneries

Achieve consistent texture and flavor in every batch with this precision-driven cooker desi...

High-speed wafer block building device

Streamline your wafer production with this high-speed device, expertly folding and p...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Wafer block cutter

Optimize your confectionery production with precision cutting technology that transforms wafer blocks into...

Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed p...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Chestnut glazing tunnel

Achieve perfectly glazed chestnuts every time with our linear glazing tunnels that ensure consistent ...

Automated retail ready case closer

Optimize your retail packaging process with a solution that seamlessly seals and closes ...

Vision-guided variety pack solution for confectioneries

Achieve seamless variety pack assembly by dynamically loading var...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Versatile confectionery cut and wrap system

Enhance your confectionery production with a high-speed solution capable of ac...

Double twist wrapping machine for sweets

Optimize your confectionery packaging line with high-speed double twist wrapping, ...

Non-contact accumulator for packaging lines

Experience seamless integration and reduced product interference with this inn...

High speed horizontal flow wrapper for food products

Achieve precise, high-speed packaging for snacks with this versatile...

Split peanut blancher for snack food processing

Efficiently transform roasted or dried peanuts into perfectly blanched pro...

Popcorn cooker/coater for caramel corn

Enhance your snack production efficiency with a versatile solution that combines coo...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Compact extruder and depositor for confectionery and bakery production

Streamline your confectionery and bakery product...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Depositor for aerated masses and fat fillings

Enhance your confectionery production with a depositor that precisely handle...

High-viscosity mass depositor

Efficiently deposit high-viscosity masses like caramel and jam with precision, while the integ...

Depositor for solid and filled chocolates

Optimize your chocolate production with precision depositing for medium to large...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Rotating stencil depositor for confectionery products

Streamline your confectionery operations by precisely depositing in...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Dough feeder for flexible and gentle dough handling

Ensure precise, gentle handling and optimal integration with your pro...

Robotic chocolate assortment system

Streamline your chocolate production by precisely assorting various filled chocolate ar...

Spiral freezer for bakery and confectionery

Maximize space and efficiency while preserving the quality and freshness of di...

Preduster for fine-grain coating in food processing

Ensure your products receive a perfect, consistent fine-grain coating...

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Lollipop forming system for various shapes

Create perfectly shaped lollipops with precise control over size and design whi...

High-capacity lollipop former

Effortlessly boost your confectionery operation with a high-capacity forming machine designed ...

Lollipop forming and wrapping solution

Streamline your confectionery production with this innovative system designed to eff...

High-speed lollipop wrapping solution

Achieve unrivaled speed and efficiency in lollipop packaging with a continuous wrappi...

Advanced lollipop forming system

Craft diverse lollipop shapes with precision and efficiency, reducing downtime with rapid c...

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and ...

Conveyor system for ambient product cooling

Ensure precise cooling of baked and confectionery products while maintaining l...

Automated material flow system for starch processing

Streamline the handling of powdered starches with precise dosing, mi...

Coating pans for precision culinary coatings

Achieve consistent, high-quality coatings on a diverse range of products, fro...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Industrial tank mixer for high-volume containers

Optimize your mixing processes with a robust solution designed for high-v...

Magnetic coupling agitator for sealed mixing

Achieve leak-free, hermetically sealed mixing for critical and aggressive med...

Laboratory stirrer for high-viscosity materials

Streamline your laboratory mixing processes with a powerful stirrer design...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Topload cartoning system for efficient product packaging

Streamline your packaging line with this compact system that com...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Industrial buffer tank for temperature and texture control

Achieve precise temperature control and optimal texture with ...

Stainless steel centrifugal pump for liquid transfer

Optimize your food and dairy production with a reliable centrifugal ...

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Automated line for baked goods packaging

Enhance your packaging efficiency with a seamless integration of precise loading a...

Batch evaporators for fruit juice and tomato concentration

Achieve high-quality fruit and tomato concentrates while pres...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

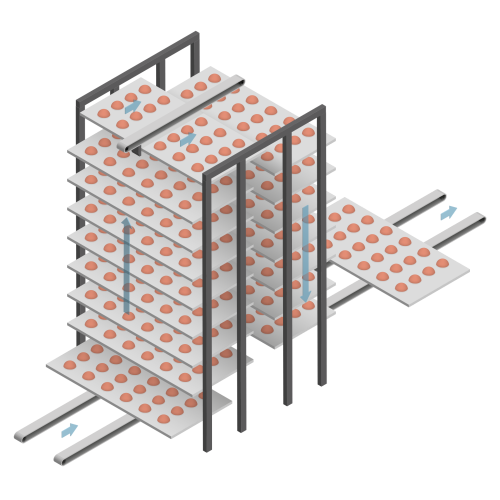

Plate and counter mould storage system for confectionery products

Streamline your confectionery production with an effi...

High-speed forming, cutting, and wrapping for long soft caramels

Optimize your confectionery production with high-speed ...

High-speed double twist packaging for face cut confectionery

Achieve optimal presentation of multi-colored face cut conf...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High-speed forming, cutting, and wrapping for side and bottom folds

Streamline your confectionery production with a mac...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

Gondola storage system for efficient product handling

Manage production line inconsistencies with precision by employing ...

High speed wrapping solution for pre-formed products

Achieve seamless integration of primary and secondary packaging with...

Flexible high-speed wrapper for confectionery products

Streamline your packaging process with a versatile machine designe...

Wrapping system for preformed products in double twist

Achieve precise packaging with our high-speed double twist wrappin...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High speed forming, cutting and wrapping machine for soft caramels

Enhance your confectionery line with a versatile sol...

Twin-lane high-speed forming, cutting, and wrapping system

Achieve unparalleled packaging efficiency with a high-speed t...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed forming, cutting, and wrapping for side fold packaging with comic strip

Maximize your output with high-spe...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

High-speed wrapping machine for chocolate or compressed powder products

For confectionery and pharmaceutical operations...

Forming, cutting, and wrapping products in multiple styles

Achieve versatile and efficient packaging for confections and...

Forming, cutting, and wrapping solution for soft caramel lollipops

Effortlessly streamline your confectionery productio...

Forming and wrapping system for soft caramels with comic strip

Elevate your confectionery packaging with a high-speed fo...

Modular high-speed wrapper for chocolate flow packs

Efficiently wrap a wide range of products, from chocolate bars to dis...

Modular high-speed forming, cutting, and wrapping for soft caramels

Streamline your confectionery production with a hig...

High speed wrapping solution for hard candies and toffees

Enhance your production with a high-speed solution designed fo...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Retrofit package for Ek1 packaging system

Upgrade older packaging systems to enhance efficiency and flexibility while acco...

High-speed wrapping solution for preformed candies

Ensure consistent wrapping of diverse confectionery products with a hi...

Double twist wrapping system for preformed products

Achieve optimal wrapping speed and precision for your confectionery p...

Modular packing system for multihead weighing

Streamline your production with a versatile multihead system designed for pr...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

Industrial checkweigher for food production

Ensure consistently accurate package weights with minimal downtime using a hig...

Ingredient doser for ice cream with large inclusions

Achieve precise and uniform inclusion of fruits, nuts, and candies i...

Ingredient doser for ice cream products

Ensure precise and consistent addition of ingredients like fruit pieces or cookie d...

Ice cream extrusion system

Optimize your ice cream production with a versatile system designed for efficient extrusion, shap...

Modular high-speed flow pack wrapper for preformed products

Eliminate packaging line bottlenecks with a versatile high-s...

Mallow make up line equipment

Achieve diverse marshmallow designs with precision using advanced extrusion and coating techno...

Large-scale marshmallow production equipment

Capture the essence of classic campfire treats with precision-engineered equi...

Mini marshmallow production system

Streamline your confectionery line with versatile mini marshmallow equipment designed fo...

Twisted marshmallow cable production manifold

Achieve precision in twisted marshmallow production with a manifold designed...

Dynamic mixer for bakery and confectionery applications

Enhance product consistency and reduce downtime with this advance...

Dry ingredient blending solution for confectionery and bakery products

Achieve seamless integration of dry inclusions i...

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

Batch cooker for pectin jelly and caramel production

Achieve precise temperature control and uniform cooking with steam-h...

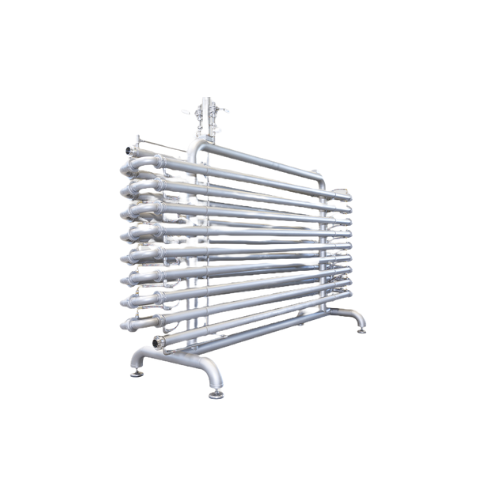

Thermosyphon cooker for marshmallow and confectionery production

Achieve precise and consistent cooking of confectionery...

Nut coating machine for snack food processing

Enhance your snack and confectionery production with a nut coating machine t...

Jacketed kettle for porridge and sauce cooking

Efficiently heat and mix diverse liquid and slurry products with precise te...

Commercial delimanjoo and taiyaki custard cake maker

Enhance your pastry production with high-speed, mold-customizable ca...

Caramel treats production line

Enhance your snack production with a comprehensive solution for crafting caramel treats, effi...

Tablet compression technology for pharmaceutical production

Enhance your production capabilities with advanced tablet co...

Airflow grain puffing machine

Unlock the potential of versatile snack production with precision-engineered airflow puffing t...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

Industrial dissolver for liquid-solid mixing applications

Optimize your production line with an industrial dissolver tha...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Industrial enrobing solution for quality coatings

Achieve high-quality coatings for pralines, bars, and pastries with a c...

Sugar and fondant coating solution

Achieve precise, multi-color or single coat applications with thin, uniform layers, seam...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Bottom coating system for confectionery production

Optimize your confectionery line with precision bottom coating, ensuri...

Vertical tunnel for cooling and moulding chocolate

Efficiently manage chocolate temperature control and molding precision...

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in ...

Chocolate coating panning machine for confectionery

Enhance your confectionery product line with a precision coating solu...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Cluster production system for chocolate with nut inclusions

Efficiently create customized chocolate clusters with precis...

Chocolate sprayer for panning machines

Enhance your confectionery creations with precision chocolate coating, ensuring ever...

Case packer for diverse packaging needs

Optimize your production line with this modular case packer, designed to handle div...

Compact carton packing solution for standardized tasks

Streamline your packaging workflow with a preconfigured solution d...

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Guillotine cutter for confectionery

Confectionery products such as marshmallows, licorice candies, and fudges come out of e...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

High-speed bunch wrapping machine for chocolate

Bunch wrapping with aluminium foil is a popular method to use for an attra...

Licorice cooker

When producing liquorice and other sticky or viscous food products, during the cooling or heating process, com...

Robotic case packing machine for snack bags

Automated packing with robotic suction arms can quickly pickup packaged produc...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Confectionery bags case packer for large scale

Mass production lines need faster and more efficient package processing to ...

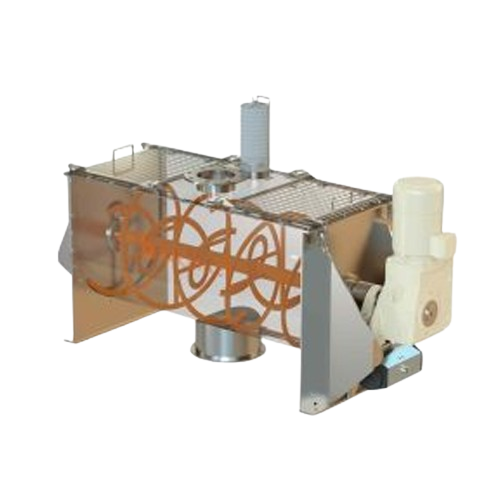

Mixer for aeration of confectionery and bakery products

Aerated products can be difficult to mix thoroughly without reduc...

Horizontal dough mixer

The mixing of hard doughs or highly viscous product like chewing gum requires specialist equipment to ...

Licorice cooling tunnel

Licorice and other extruded food products like vegan meats can be tricky to cool in the production pr...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Inline ultrasonic food cutting machine

Cutting sticky products in the food sector is not always an easy process. Small scal...

Aerator for low-viscosity media

Many industrial processes and products require a consistent foam with very particular and ti...

Aerator for high-viscosity media

Highly viscous ingredients in both the food and chemical processing industries require spec...

Laboratory aerator for food products

Successful innovators in the food, chemicals, and plastics industries need reliable mi...

Mobile depositor of tiger wash

Manufacturers of tiger bread and other similar consumables often find that achieving perfect ...

Chocolate decorator for extruded ice-cream

It is not uncommon for ice-cream decorator units to become faulty and produce a...

Medium-speed flexible wrapping machine for chocolates

Larger scale wrapping of individual chocolate products demands gent...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand forming machine for creamy mixtures

Turn your ingredients mixture into strands and slabs for further processing int...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Hygienic chocolate coating machine

Coat your product with chocolate or caramel. This is a next-generation chocolate coating...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Entry level cereal bar cutting table

The small-scale manual production of crunchy cereal bars, brittles, and similar produc...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Cooker for toffee and caramel products

Production of toffee and caramel products requires accurate and consistent cooking, ...

Starch-free depositor systems for jelly

Traditional depositing for jellies and gummies requires the use of starch moulds. T...

Starch-free depositor for soft confectionery

Soft confectionery such as toffees, fondants, fudges and jellies have traditi...

Starch-free depositor for lollipops

Traditional high volume continuous lollipop production can lead to inconsistent product...

In-line colour or flavour addition for confectionery

The addition of colourings and flavourings increases value and quali...

System for continuous production of fondant or fondant crème

Fondant creme is used in the production of a range of confe...

Thin-film cooker for confectionery products

Producing excellent confectionery products requires high quality cooking. Trad...

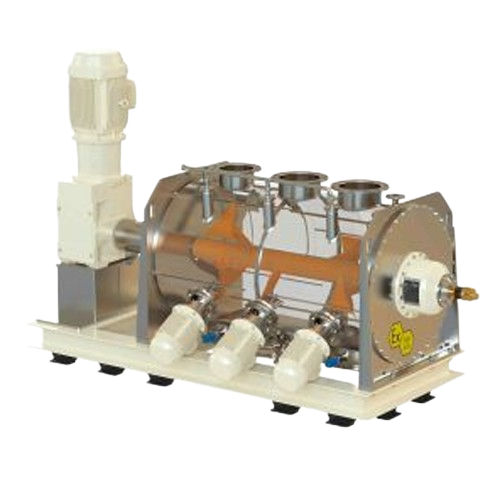

Dissolver of confectionery syrups

Many high quality confectionery products require a dissolved syrup as their starting poin...

Automatic weigher and mixer of confectionery ingredients

The production of accurately proportioned and homogenous slurrie...

Batch cooker of cereal foods

Controlled steam cooking of whole or milled grain products is the best way to ensure best textu...

Production machine for deposited candies and jellies

For smaller production volumes, fully automated depositors for produ...

Laboratory confectionery depositors

When designing new confectionery products, the ability to experiment on lab-scale equip...

Compact aerator for pumpable media

Many processes in food production and standard industry require high-quality, customized...

2-way diverter valves for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...

Continuous caramel mixer

Mix your recipe’s ingredients in preparation for further processing. This is a continuous mixe...

Cooling drum for soft and caramel mixtures

Cool your product to the temperature required for further processing. This is a...

Continuous cooker for hard caramels

Continuously cook ingredients for your hard caramel-based product. This is a three-stag...

Cooker for gums and jellies

Prepare your ingredients for use in gummy and jelly products. This is a static cooking system de...