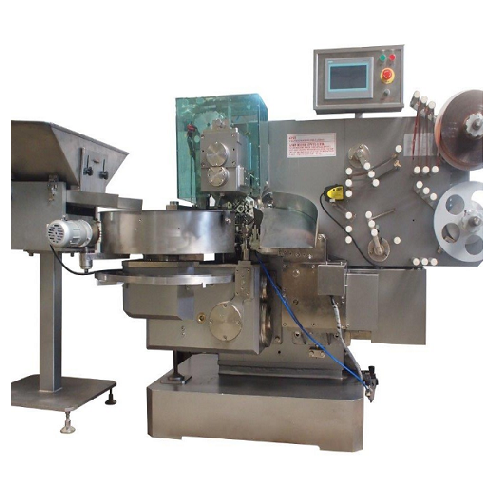

Double twist wrapping machine for sweets

Optimize your confectionery packaging line with high-speed double twist wrapping, perfect for ensuring consistent wrapping of various sweet shapes and sizes while minimizing material waste.

Wraps Confectionery in Double Twist Styles

The 6IST Double Twist Wrapping Machine from AMP-Rose provides confectionery producers with high-speed, efficient packaging solutions. Capable of wrapping up to 500 pieces per minute, this versatile machine accommodates a wide range of sweet products, from solid to center-filled confections, with precise double twist wrapping. Standard features include an AC variable speed drive, ensuring adaptable integration into existing production lines, while optional upgrades like a hot air blower and vibratory feeder enhance functionality. Its user-friendly design allows for minimal product and wrapper wastage, streamlined size changes, and reliable operation, requiring only a single operator for multiple machines. Built with durability in mind, the 6IST’s robust frame supports long-term production efficiency, making it an excellent choice for confectionery manufacturers aiming for high output and quality packaging.

Benefits

- Maximizes production efficiency by wrapping up to 500 pieces per minute.

- Minimizes material waste with reliable product and wrapper wastage control.

- Reduces labor demands with single-operator capability for multiple machines.

- Enhances operational flexibility with quick and simple size changes.

- Integrates seamlessly into existing lines with variable speed and automated controls.

- Applications

- Jellies, Biscuits, Snacks, Hard candies, Gum, Toffee, Marshmallow, Sweets, Chocolate, Caramel, Chews, Wafer

- End products

- Chocolate truffles, Gummy bears, Toffee squares, Soft marshmallows, Wafer sticks, Chewing gum tablets, Hard peppermint candies, Fruit chews, Butter biscuits, Caramel bites

- Steps before

- Pre-formation of sweets, Center filling, Boiling

- Steps after

- Packing, Boxing, Cartoning

- Input ingredients

- pre-formed sweets, solid sweets, centre-filled sweets, high boiled lines, cellulose film, waxed paper, PVC, cast polypropylene, tissue backed aluminium foil

- Output ingredients

- double twist wrapped sweets

- Market info

- AMP Rose is renowned for manufacturing and supplying high-quality machinery for the confectionery, chocolate, and snack industries, offering innovative solutions and engineered-to-order equipment tailored to meet specific customer needs.

- Output Speed

- Up to 500 cycles per minute

- Size Range Length

- 12 – 34 mm

- Size Range Width

- 12 – 34 mm

- Size Range Thickness

- 6 – 20 mm

- Size Range Diameter

- 14 – 29 mm

- Power Requirement (Machine)

- 2.2 KW

- Power Requirement (Vibratory Feeder)

- 0.5 KW

- Power Requirement (Hot Air Blower)

- 600 W

- Wrappable Product Types

- Solid, Centre-filled high boiled lines

- Wrapping Style

- Double twist

- Wrapping Material

- Cellulose film, waxed paper, PVC, cast polypropylene

- Drive Type

- AC variable speed drive

- Operational Modes

- Single and double machine

- Net Weight

- 900 kg

- Gross Weight

- 920 kg

- Automation level

- Manual / PLC

- Changeover time

- Fast/simple

- Cleaning method

- Manual

- Energy efficiency

- 2.2 kW

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- Not applicable

- Machine Speed

- Up to 500 cycles per minute

- Wrapping material

- Cellulose film / Waxed paper / PVC / Cast polypropylene

- Inner wrap material

- Tissue backed aluminium foil

- Control panel type

- AC variable speed drive

- Guard Type

- Full canopy style guard

- Wrapping type

- Double twist wrapping

- Feeding type

- Vibratory feeder

- Heating option

- Hot air blower

- Product control features

- No product no paper control

- Operation control features

- Reel run out/wrapper breakage control