Caramel Making Equipment

Find innovative production technology for making caramel and connect directly with world-leading specialists

It’s important to get timing and temperature right when making caramel, and this implies being vigilant. For small scale production of caramel, ensure that your heat source distributes heat evenly and monitor the caramelization process closely. This prevents recrystallization and burning the sugar. For medium to large scale caramel production, consider investing in automated caramel making equipment.

Technology picks for caramel production

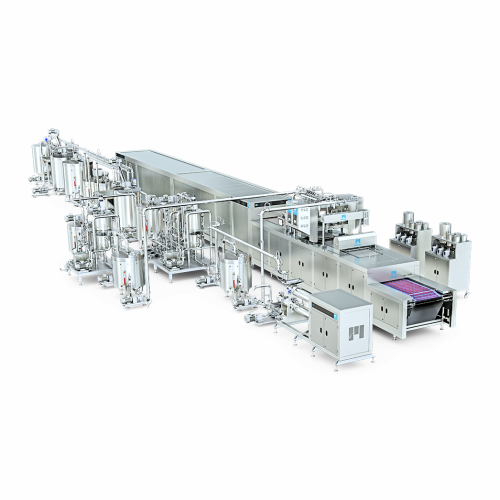

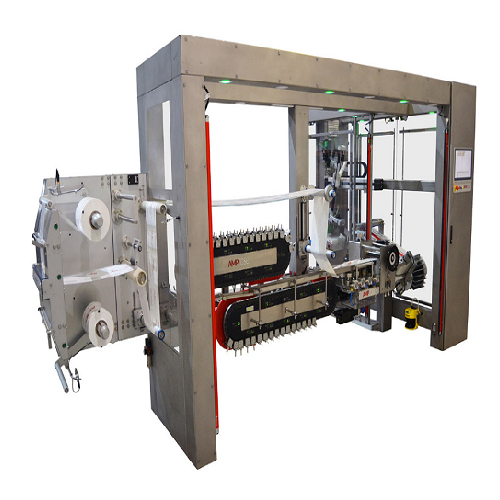

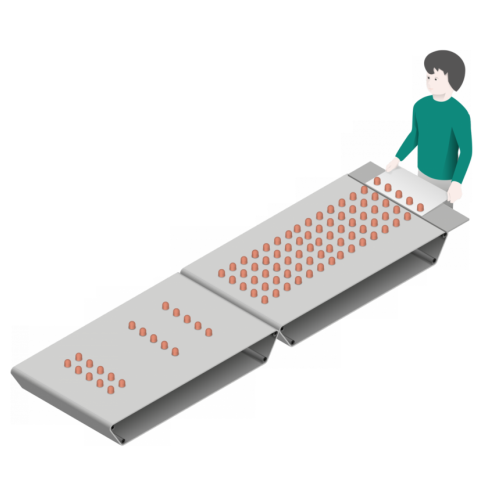

Caramel treats production line

Enhance your snack production with a comprehensive solution for crafting caramel treats, effi...

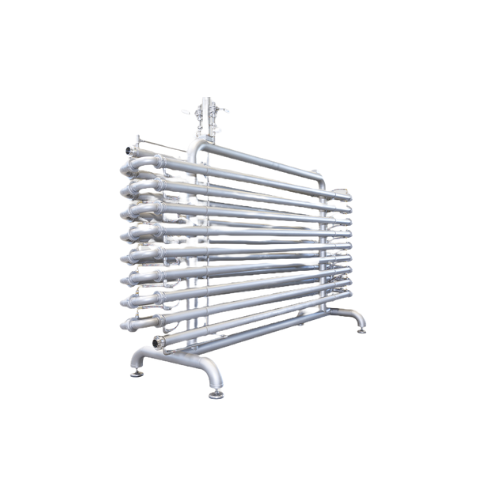

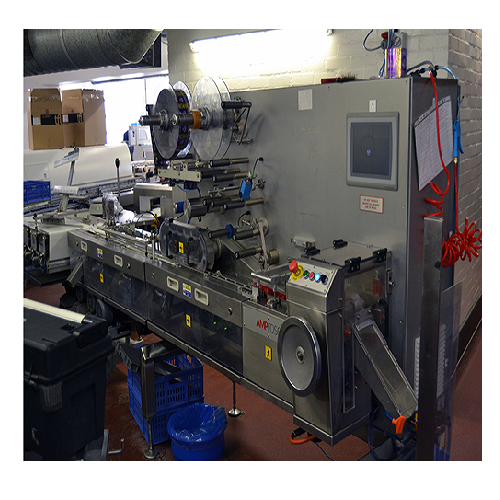

Caramel cooking solution

Optimize your confectionery production with precise mixing, dissolving, and heat transfer technologi...

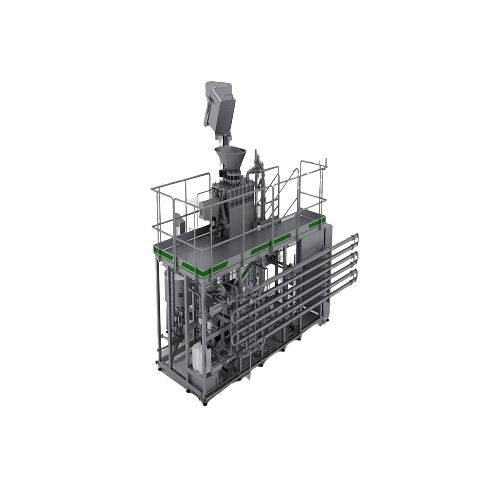

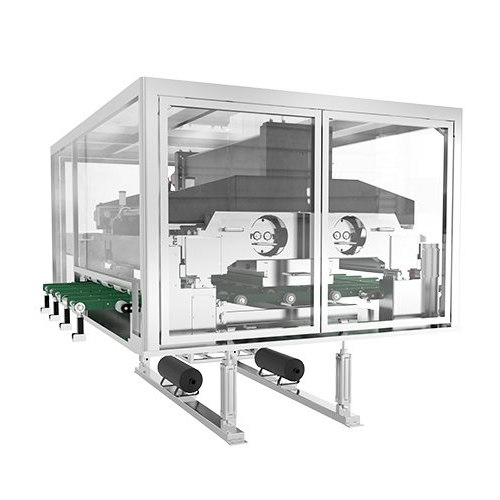

Batch cooker for pectin jelly and caramel production

Achieve precise temperature control and uniform cooking with steam-h...

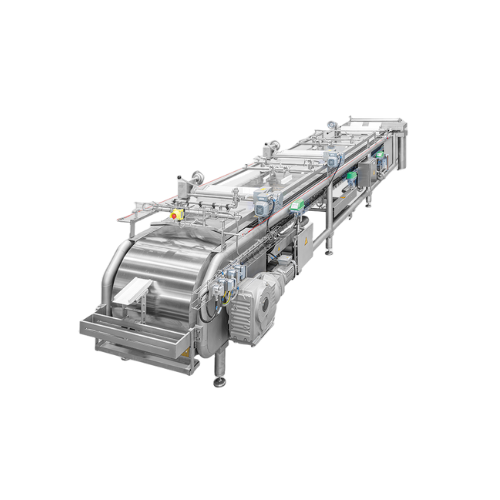

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Stories about caramel

Tell us about your production challenge

Caramel machines for long and short caramel

“Short” and “long” caramels are terms that refer to soft and hard caramels, respectively. Short caramels are very moist and soft and would usually stick to their wrappers when you unwrap them. Short caramels follow a similar process to gummies. Long caramels, on the other hand, are chewy and do not leave residue on their wrappers.

The difference between these caramel types is in the amount of moisture present in each, and how much heat you use when cooking them. When making soft caramels, mix water (about a quarter of the sugar’s quantity) with sugar and transfer the syrup to a confectionary batch cooker. To make hard caramels, sprinkle sugar in a dissutator and cook over low heat (around 32 °C or 90 °F), stirring constantly to prevent burning. Special caramel making machinery is neither necessary nor recommended for small scale production, but for much more than that, investing in a batch or continuous caramel making machine would be a smart move. A high quality electronic mixer is a good starting point as well.

Control the temperature to get good caramels

When making caramels, recrystallization is one big pitfall you need to be very careful to avoid. It happens when you subject caramels to an abrupt change of temperature while cooking. To avoid ending up with clumpy, burnt, or otherwise useless caramel, keep a firm grip on the temperature which should be around 118 °C (245 °F). For one thing, don’t introduce the cream, butter, or other ingredients when the caramel is still on the cooker. Also, take the caramel off the cooker as soon as it adopts an even, amber color. Once it reaches the stage, burning is just a step away.

Making salted caramel candies

The popularity of salted caramel candies is certainly on the rise. You can find them practically everywhere, from ice cream to confectionary. The best part is that salted caramel candies only require a slight modification to the making process. To make salted caramel candies, sprinkle coarse sea salt (approximately the same quantity as the sugar you used to make the caramel) over the top of the caramel after you’ve allowed it to cool for between 8-10 minutes. For large scale production, water-cooling is handled by the cooling wheel. Machines come with cutters for cutting the candy into different shapes and sizes. As well as wrapping for the final step.

Processing steps involved in caramel making

Which caramel technology do you need?

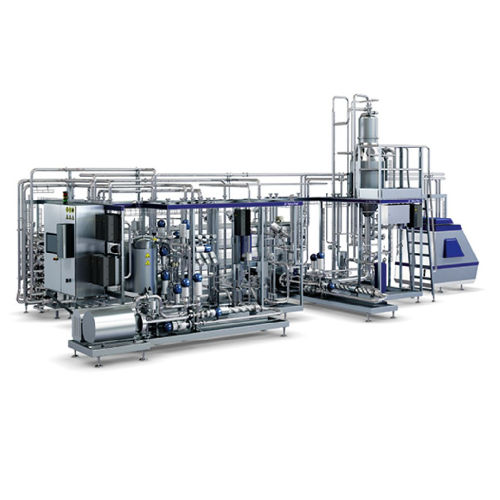

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Industrial cream doser for pastry applications

Efficiently dose and fill a variety of bakery and confectionery mixtures wi...

Continuous cooking unit with vacuum for candy production

Achieve precise caramelization and cooking with enhanced flavor ...

Fat melting tank for confectionery production

Melt solid fat blocks efficiently to streamline your caramel, nougat, and ch...

Soft candy production line

Optimize your candy production with a versatile line that efficiently handles everything from car...

Cooling system for vegetables and meat

Optimize cooling efficiency with dual counterrotating agitators and expansive surfac...

Hot-fill dosing system for soups and sauces

Ensure precise and efficient dosing of hot and cold liquid foods with integrat...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

Industrial vacuum kettle for sauce production

Achieve optimal flavor retention and nutrient preservation with an industria...

Wafer sheet cream application system

Achieve precision in cream application with high-capacity, continuous film spreading, ...

Batch cooker for confectionery production

Achieve consistent confectionery texture and flavor with a flexible cooking solu...

Caramelization system for industrial confectionery production

Achieve precise caramelization and cooking of sensitive co...

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel cooking kettle for food, pharma, and cosmetics

Efficiently streamline your production with versatile sta...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

Confectionery forming extruders for viscous masses

Efficiently transform viscous ingredients into uniform, high-quality c...

Caramel cooking solution

Optimize your confectionery production with precise mixing, dissolving, and heat transfer technologi...

Compact cooker for confectionery and catering

Effortlessly prepare diverse culinary and cosmetic creations, from sauces to...

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Industrial chocolate tempering belt

Achieve precise mass tempering for diverse confectionery textures with a stainless-stee...

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Continuous caramel cooker for candy production

Achieve perfect caramel consistency with precise control as this solution c...

Static cooler for jelly and foam manufacturing

Ensure the integrity of your confectionery with a cooling system designed f...

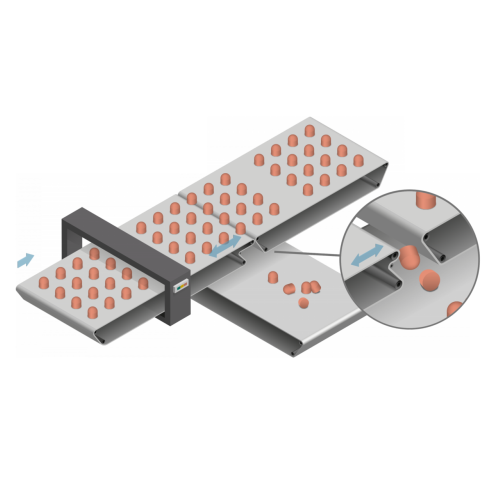

Crystallization process for chewy candy production

Optimize your confectionery production with precision crystallization,...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

High shear mixer system for hydrocolloids

Streamline your confectionery production with a high-shear mixer designed for pr...

Aerator for candy masses

Enhance your candy production with precise and efficient aeration, transforming textures and creatin...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

Continuous butter toffee processing system

Achieve precise caramelization and nut integration while maintaining the perfec...

Industrial sugar melter

Efficiently melt and mix sugar with precision using a gas-fired batch cooker designed for optimal hea...

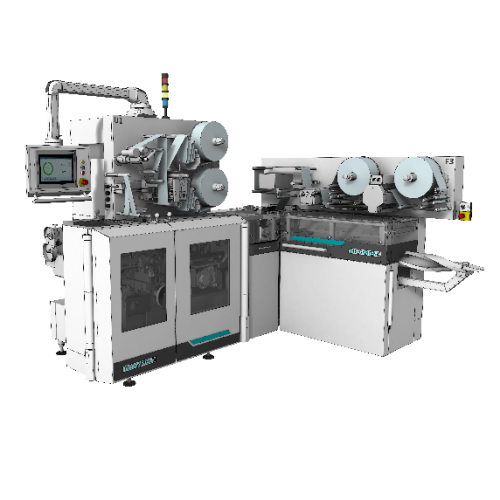

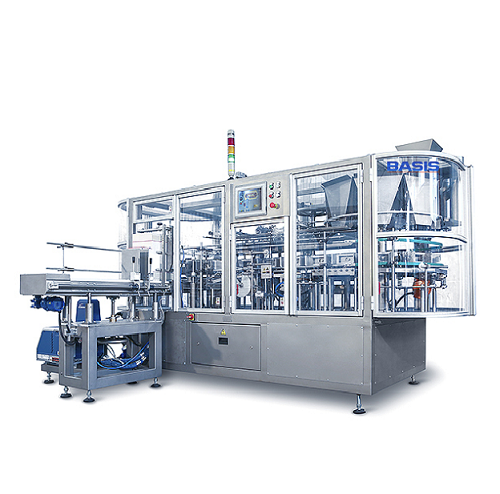

High-speed cut and wrap solution for confectionery products

Achieve seamless integration in your confectionery productio...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Batch cooker for confectioneries

Achieve consistent texture and flavor in every batch with this precision-driven cooker desi...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Cooling tunnel for cream-filled wafer blocks

Ensure your wafer products maintain optimal texture and integrity with a stat...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Aseptic cooking line for industrial food processing

Achieve seamless aseptic cooking and filling for diverse food product...

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

Versatile confectionery cut and wrap system

Enhance your confectionery production with a high-speed solution capable of ac...

Double twist wrapping solution for confectionery

Optimize packaging speed and precision with a machine designed to wrap di...

Wrapper for flat bottomed chocolate articles

Optimize your confectionery packaging with a machine designed for swift, secu...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Double twist wrapping machine for sweets

Optimize your confectionery packaging line with high-speed double twist wrapping, ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Automatic popcorn ball forming equipment

Streamline your snack production with high-speed, precise popcorn ball forming tec...

Popcorn cooker/coater for caramel corn

Enhance your snack production efficiency with a versatile solution that combines coo...

High-viscosity mass depositor

Efficiently deposit high-viscosity masses like caramel and jam with precision, while the integ...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Leak testing system for aerosol cans

Ensure the integrity of your aerosol and metal packaging with a high-speed leak testin...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Industrial buffer tank for temperature and texture control

Achieve precise temperature control and optimal texture with ...

Stainless steel centrifugal pump for liquid transfer

Optimize your food and dairy production with a reliable centrifugal ...

Cake and pastry enrobing system

Enhance your bakery production line with seamless enrobing and icing capabilities, ensuring ...

Automatic tray sealer for cut & seal and Map applications

Optimize tray packaging efficiency with a versatile solution f...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

High-speed forming, cutting, and wrapping for long soft caramels

Optimize your confectionery production with high-speed ...

High-speed double twist packaging for face cut confectionery

Achieve optimal presentation of multi-colored face cut conf...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High-speed forming, cutting, and wrapping for side and bottom folds

Streamline your confectionery production with a mac...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

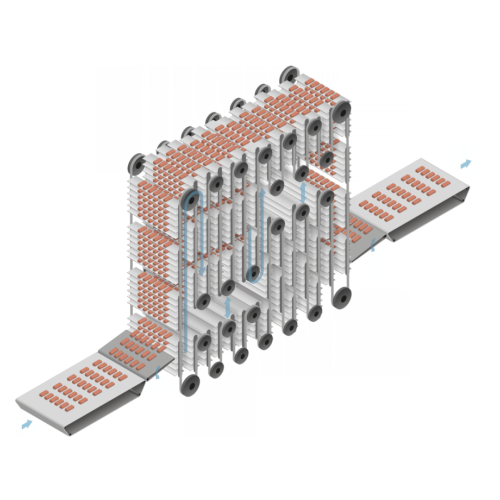

Gondola storage system for efficient product handling

Manage production line inconsistencies with precision by employing ...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High speed forming, cutting and wrapping machine for soft caramels

Enhance your confectionery line with a versatile sol...

Twin-lane high-speed forming, cutting, and wrapping system

Achieve unparalleled packaging efficiency with a high-speed t...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed forming, cutting, and wrapping for side fold packaging with comic strip

Maximize your output with high-spe...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

Forming, cutting, and wrapping system for soft caramels

Optimize your confectionery production line with a solution desig...

Forming, cutting, and wrapping products in multiple styles

Achieve versatile and efficient packaging for confections and...

Forming and wrapping system for soft caramels with comic strip

Elevate your confectionery packaging with a high-speed fo...

Modular high-speed forming, cutting, and wrapping for soft caramels

Streamline your confectionery production with a hig...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Integrated stirring cooking kettles for commercial kitchens

Streamline your culinary operations with innovative cooking ...

Ice cream dipping and transfer unit

Streamline your ice cream production with a multi-lane system designed for precise dipp...

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with cont...

High shear mixer for emulsification and powder dissolving

Achieve seamless mixing and emulsification for high and low vi...

Contherm scraped-surface heat exchanger for viscous food products

Optimize your heating and cooling processes for stick...

Batch cooker for pectin jelly and caramel production

Achieve precise temperature control and uniform cooking with steam-h...

Thermosyphon cooker for marshmallow and confectionery production

Achieve precise and consistent cooking of confectionery...

Dough mixer for pastry food processing

Achieve perfect dough consistency efficiently with this dough mixer, designed for se...

Caramel treats production line

Enhance your snack production with a comprehensive solution for crafting caramel treats, effi...

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

Candy packaging solution for gummies and hard candies

Maximize your confectionery efficiency with high-speed packaging so...

Food processing scraped surface heat exchanger

Enhance your production line with precise temperature control and continuou...

Vertical scraped surface heat exchanger for food processing

For continuous production that demands consistent texture an...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Caramel enrobing system for biscuits and wafers

Achieve consistent caramel coverage with precise temperature control, ensu...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Dosing system for packaging lines

For producers looking to optimize their packaging lines, this dosing system offers precis...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

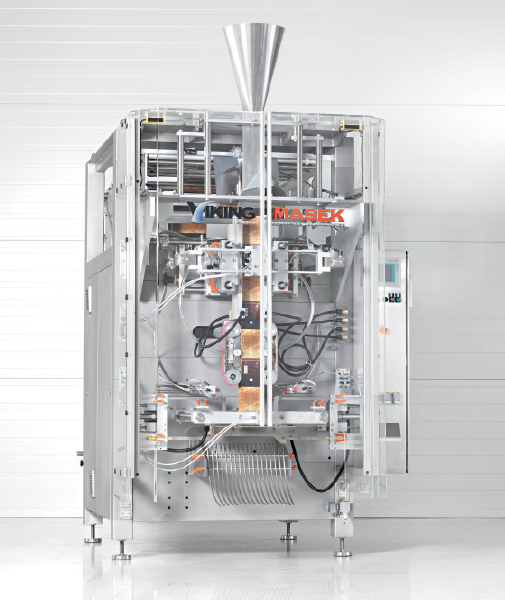

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...

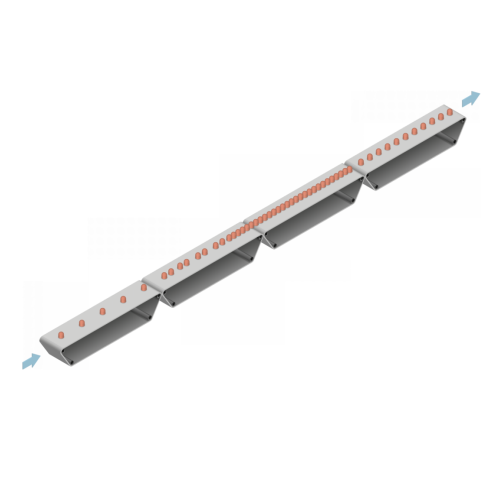

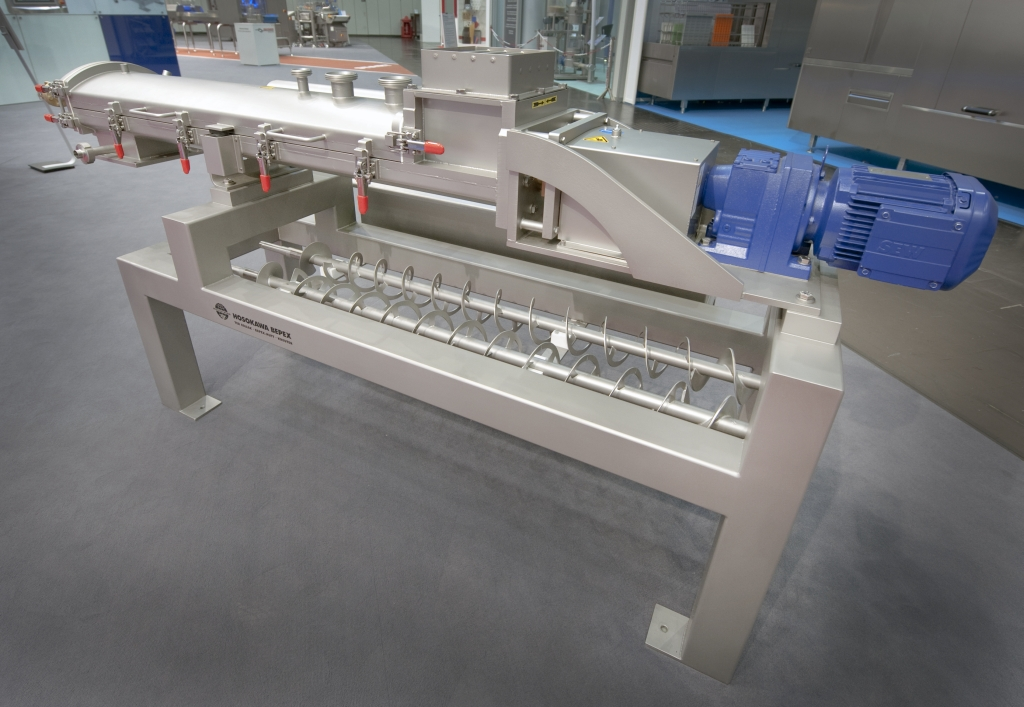

Continuous caramel mixer

Mix your recipe’s ingredients in preparation for further processing. This is a continuous mixe...

Continuous cooker for hard caramels

Continuously cook ingredients for your hard caramel-based product. This is a three-stag...

Continuous cooker for hard candy

Prepare your ingredients for hard candy production. This is a continuous dissolving, cookin...

Batch cooker for hard candy

Prepare your ingredients for the production of hard candy. This is a line of universal candy coo...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...