Find Butter Process and Packing Equipment

Find innovative production technology for making butter and connect directly with world-leading specialists

People have always loved butter. Suffice it to say that Ancient Norsemen were buried with it to take to the afterlife. It seems impossible but making butter is all about separation. First, you separate the raw milk to get the buttercream using a cream separator. After cooling, mixing and pasteurizing your buttercream, the churning process separates it into buttermilk and butter grains. Then, mix butter grains with salt and use a butter churner to mix the ingredients again, before shaping begins using butter molds. Which butter-making equipment can improve your process?

Technology picks for butter production

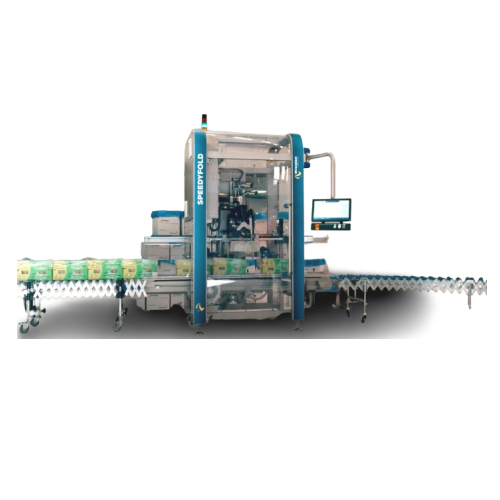

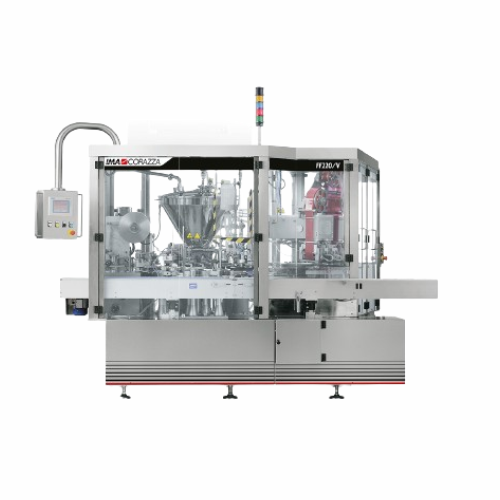

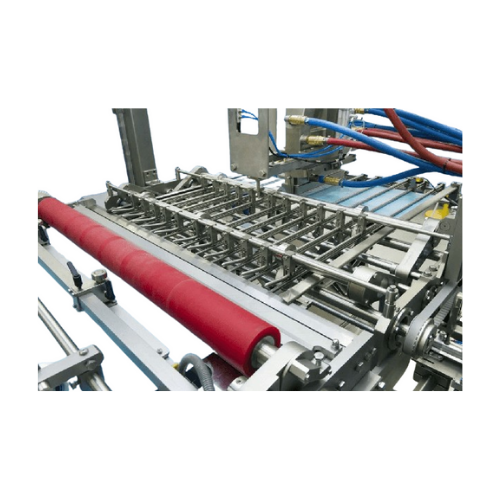

Automatic butter wrapping machine

Do you pack your butter wraps in aluminium foil, parchment paper or ecoline solutions? An...

Automatic moulding and wrapping for butter and margarine

Looking to reduce packaging waste and increase dosing precision?...

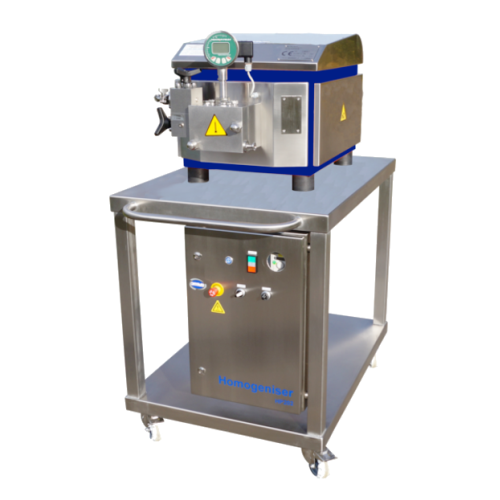

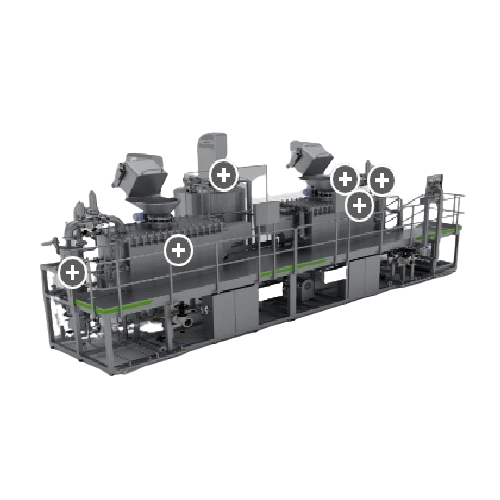

Butter Churner Machine

When processing smaller quantities of cream, you need to experiment with butter characteristics to cat...

Butter Re-packaging Line

Although bulk butter blocks are commonly used in commercial food production, they are heavy and diff...

Stories about butter

Tell us about your production challenge

Separate, pasteurize, and churn your buttercream

Butter making starts with raw milk going through a separator to get buttercream and skim milk. To maintain the consistency of your buttercream, you need to cool and stir it in a stainless steel bulk tank. After removing unwanted bacteria through a pasteurizer, you can add starter culture and leave the buttercream to age in the aging tank. The cultured buttercream needs about 24 hours to age before moving it to a churn. During the churning process, a separation takes place where you will obtain buttermilk and butter grains.

After extracting the buttermilk by draining, you can now add salt to the butter grains to improve flavor and shelf life. Now it’s time to churn your mixture again to get a homogenous blend of butter that will be transferred to a milling machine for shaping before packaging.

Are you producing sweet cream, cultured, clarified or whipped butter?

There are so many varieties of butter out there: sweet cream, cultured, clarified, and whipped… and the list can go on. Their names may give you an idea of what the difference between them is. Sweet cream butter is made from fresh, pasteurized cream that does not undergo any fermentation process. As the name suggests, if you want to make cultured butter, you have to add the cultures and ferment the buttercream before churning.

Skim whey protein or inject with nitrogen

With 9,978,022 tonnes of butter produced annually worldwide, India is the leading butter producer thanks to a clarified butter variety: Ghee. To get it, you have to heat and stir the butter in a boiler tank until more of its water content evaporates. Then, whey protein or milk solids on the surface are skimmed off by using a strainer. For whipped butter, all you have to do is to inject nitrogen into the butter after churning. The result gives more volume but is less dense than standard butter.

Process vegan butter alternatives in an emulsifier tank

Nowadays, there is demand in the market for food alternatives or substitutes. Non-dairy products like plant-based butter are a demand for consumers practicing a vegan diet or for lactose-intolerant consumers. A combination of oils and milk from nuts such as almonds, soy, or coconut, and other emulsifiers are mixed in an emulsifier tank at a high temperature. You can also add other dry ingredients such as salt. When you achieve the right emulsion, the mixture goes through a high-shear mixer and pasteurizer before cooling it through a plate-type heat exchanger. The result is dairy-free butter!

Add vegetable oils for spreading butter at ambient room temperature

Regular butter usually takes time to melt from refrigeration temperature to ambient room temperature. So, manufacturers formulated ways to create butter that you can spread easily from refrigeration temperature to ambient room temperature. Spreadable butter is made the same way as regular butter. The difference lies in adding vegetable oils to make the butter melt quicker at ambient room temperature. Food manufacturers use butter depositors as toppings, filling or decoration for bread and other baked goods that are then packaged in plastic containers for consumers.

Form and wrap your butter blocks or fill them into containers

When your butter is ready, you can shape it in blocks before packaging it in paper with an outer aluminum coating. The aluminum coating prevents light from penetrating the packaging and making the butter rancid. But you can always decide to make spreadable butter and pack it in plastic tubes or different containers.

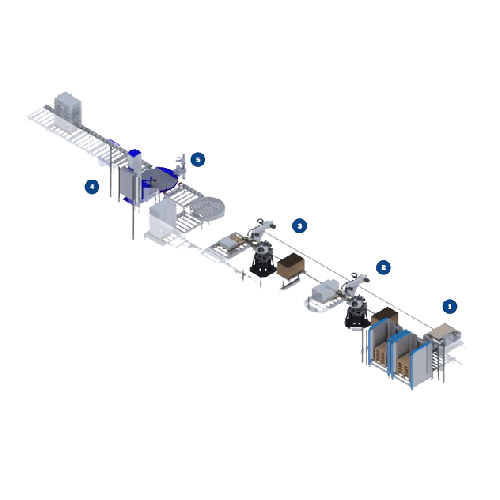

Processing steps involved in butter making

Which butter technology do you need?

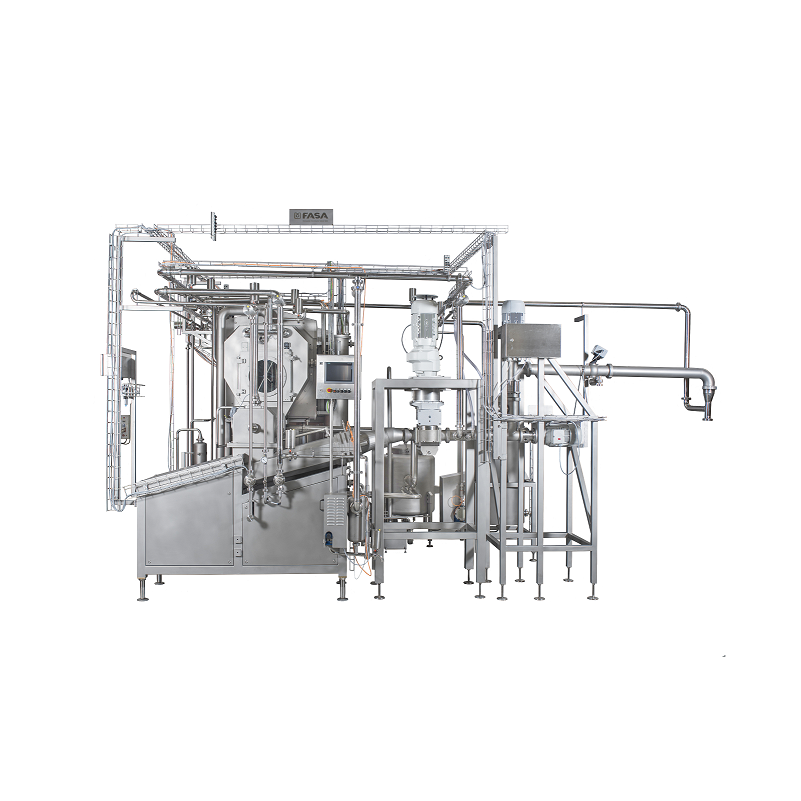

Continuous butter maker for industrial butter production

Streamline your butter production with a system designed for sea...

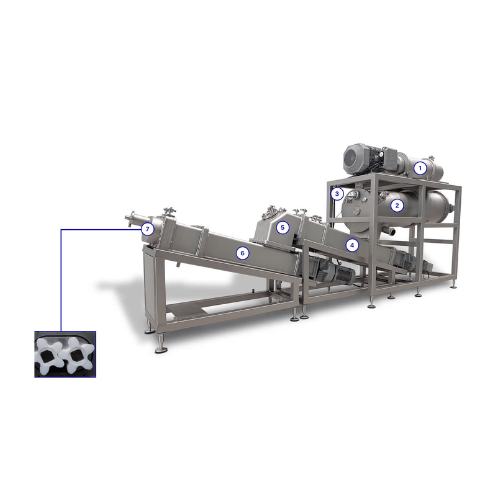

Continuous butter production system

Efficiently transform cream into versatile butter products, ensuring consistent quality...

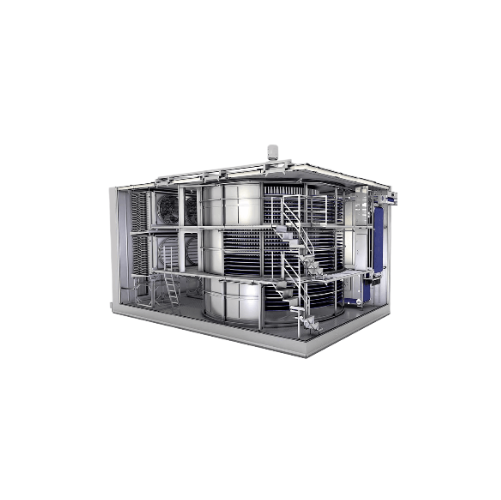

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

Steam cooking system for dairy production

Ensure precise temperature regulation and efficient moisture control in cheese a...

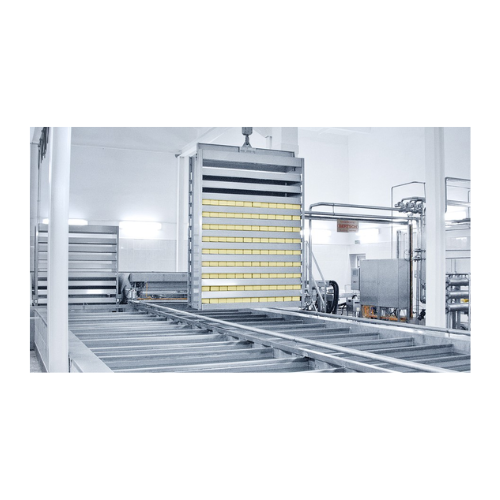

Industrial cold storage solutions

Ensure precise temperature control and optimal storage conditions for a diverse range of ...

Deodorizing units for milk pasteurization

When handling dairy products, controlling odors during pasteurization is crucial...

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

Melting and mixing kettles for chocolate production

Achieve consistent melting and mixing of chocolates, butter, and jams...

Rapid chocolate and fat melting system

Optimize your confectionery production with an efficient solution designed to rapidl...

Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities wit...

Chocolate melting and mixing kettle for small-scale production

Streamline your confectionery production with a compact k...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

Continuous mixer for batters and cremes

Achieve consistent texture and uniform cell structure in your cake batters and crèm...

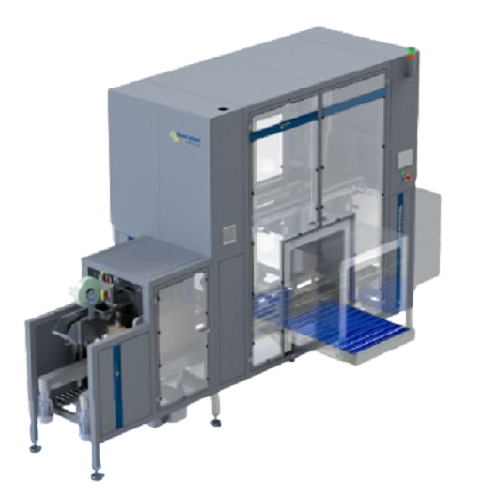

Automated bagmaker inserter for crystallizing products

Enhance your hygienic packaging efficiency by seamlessly integrati...

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Hygienic buffer tanks for process optimization

Enhance your production flow with hygienic buffer tanks that ensure consist...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

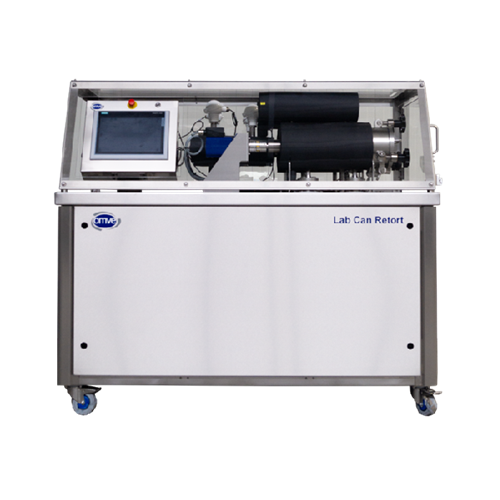

Small-scale in-container spray pasteurizer for laboratory use

Optimize your R&D processes with precise control over...

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Crystallizer for small-scale aeration and crystallization processes

Streamline your production with a versatile crystal...

Lab-scale margarine and spread crystallizer

Achieve precise control over margarine and spread crystallization with lab-sca...

Batch deaerator for reduced oxidation in liquid processing

Optimize product shelf life and quality by efficiently removi...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

High-speed bag placing system for e-commerce fulfillment centers

Optimize your packaging line with a high-speed system t...

Automated bag sealing for packaging lines

Enhance your packaging efficiency by seamlessly integrating an automated bag sea...

Automated bag folding for packaging

Streamline your packaging operations with a high-speed solution that seamlessly integra...

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

Compact palletizing solution for limited space

Optimize your space with versatile palletizing that adapts to diverse produ...

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Bag folding solution for high-speed packaging

Effortlessly enhance your packaging line efficiency with this high-speed bag...

Manual bag placing solution for various materials

Increase your efficiency in manual bag placing with an ergonomic soluti...

Vacuum preservation system for professional packaging needs

Enhance your food product longevity and quality with precise...

Cleaning-in-place (cip) systems for hygienic processing

Elevate hygiene standards in your liquid processing line with an ...

Atmospheric fermenter for lab and pilot scale projects

Streamline your fermentation process with precise control over tem...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Cylindrical buffer tank for processing lightly liquid products

Optimize production continuity with this cylindrical buff...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Dosing and wrapping solution for pasty products

Achieve precise dosing and efficient wrapping of pasty products with high-...

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

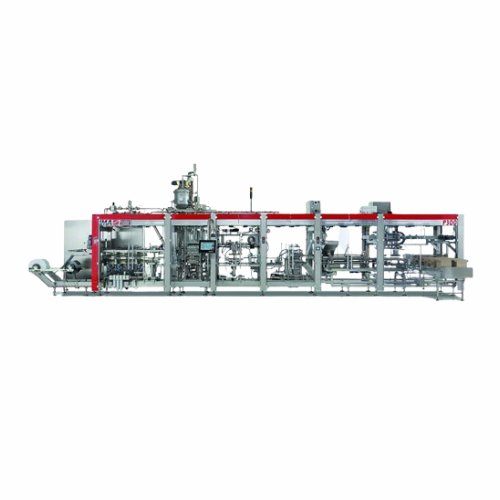

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

Cheese portioning dosing and wrapping solution

Effortlessly streamline cheese portioning with high-speed dosing and wrappi...

Filling and wrapping system for pasty products

Achieve precise dosing and flexible wrapping of diverse pasty products, ens...

High-speed dosing and wrapping for butter and margarine

Achieve precision in butter and margarine packaging with a high-s...

Automatic moulding and wrapping for butter and margarine

Looking to reduce packaging waste and increase dosing precision?...

Butter portion dosing and wrapping system

Efficiently manage butter portion packaging with a compact system designed for p...

Tub filling and sealing for pasty products

Experience high-speed, precision tub filling and sealing designed for pasty pro...

Wrap-around cartoning solution for butter and yeast

Optimize your packaging line with a high-speed cartoning system that ...

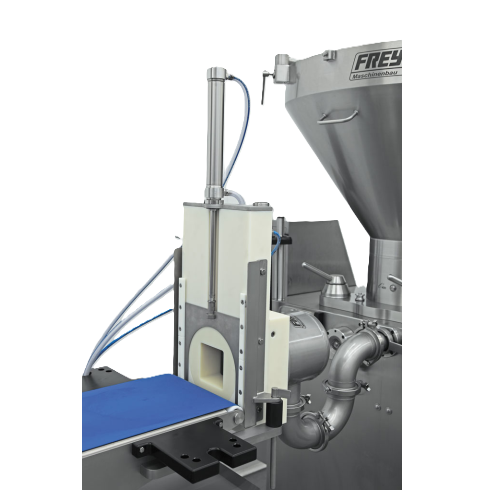

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Cheese and butter block grinder

Efficiently transform frozen cheese and butter blocks into manageable sizes for continuous p...

Cheese grinder for fine cheese grinding

Achieve optimal protein emulsification and minimize waste with this high-capacity g...

Open milk cooler with 2,000 liters capacity

Ensure optimal milk quality and temperature with this open milk cooler, design...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

Pneumatic knife for forming and cutting pasty products

Achieve precision and speed in forming and cutting various pasty p...

Chocolate, syrup, and fat melting tank

Achieve precise melting and temperature control for chocolate, syrups, and fats, ens...

Pilot plant system for margarine and bakery fats production

Streamline your development and testing of diverse spreads a...

Continuous butter toffee processing system

Achieve precise caramelization and nut integration while maintaining the perfec...

Cleaning-in-place system for oils and fats

Streamline your production line by efficiently cleaning oils and fats processin...

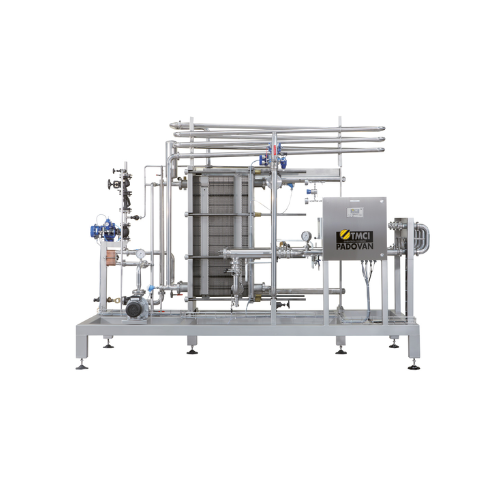

Margarine and butter pasteurizers for oils and fats

Ensure the safety and quality of your margarine and butter spreads wi...

Continuous remelt systems for oils and fats

Optimize your production line with continuous remelt systems designed to effic...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

Lidding system for cups and trays

Enhance your packaging line with precise, space-saving lidding technology, ideal for seal...

Lumps melting system for chocolate and cocoa mass

Efficiently transform solid butter, grease, and chocolate into uniform ...

Storage tank for oils and greases

Efficiently store and preserve various liquid products with integrated heating, cooling, ...

Industrial cheese processing plants

Streamline your cheese production with custom-engineered systems designed to enhance ef...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Cheese processing plant

Transform your dairy processing with comprehensive, tailored systems designed to optimize production ...

Cheese processing plant for hard and semi-hard cheese

Optimize your cheese production with a versatile solution designed ...

Cip cleaning systems for dairy processing plants

Optimize cheese production with precise curd handling and exceptional sti...

Cheese vat for varied cheese types

Ensure consistent high-quality cheese production with a vat that accommodates multiple c...

Cheese vat for diverse cheese production

Optimize your cheese production with a versatile cheese vat designed for precision...

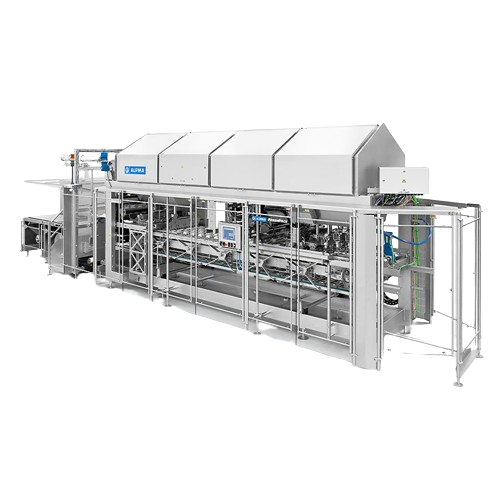

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Automatic wrapping for small products

Achieve precise and efficient packaging of diverse small products with seamless verti...

Fully automatic packaging solution for butter and pasty products

Streamline your production line with this versatile pac...

Packaging solution for soft cheese portions

Maximize your production efficiency by seamlessly cutting, wrapping, and boxin...

Cheese cutting solution for large round cheeses and blocks

Efficiently segment and portion diverse cheese types, whether...

Milk clarifier for dairy industry

Enhance your dairy production with efficient milk and whey clarification, ensuring produc...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Gasketed plate heat exchanger for hygienic applications

Achieve precise temperature control for sensitive products with a...

Vacuum breaker valve for Htst pasteurization systems

Prevent vacuum conditions in high-temperature pasteurization systems...

Industrial melt tanks for butter and chocolate

Reduce manual labor and elevate safety in your production line with a melt ...

Industrial block melt system for butter and chocolate

Efficiently transition solid blocks of butter, chocolate, or waxes ...

Ergonomic melt systems for solid food and personal care products

Eliminate manual lifting and enhance safety by integrat...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

Twin screw pump for viscous media

Streamline your production with a twin screw pump that effortlessly handles viscous media...

Screw compressor package for efficient industrial cooling

Optimize your cooling processes with a flexible, space-saving ...

Standardization unit for cream fat or milk fat

Optimize your milk standardization process to achieve precise cream and fat...

Marination injecting solution for fresh poultry

Enhance product consistency and maximize yield in your production line wit...

Compact milk pasteurizer for milk, cream, and whey

Ensure consistent product quality with precise pasteurization and skim...

Customized spiral freezer solution for food industry

Designed to enhance your freezing efficiency, our spiral solution ha...

Compressors for Co₂ freezing applications

Optimize your cooling and heating processes with advanced reciprocating compress...

Solid-wall bowl separators for milk & whey

Achieve precise skimming and standardizing of milk and whey with this advanced ...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Milk reception unit for dairy processing

Ensure precise measurement and streamlined handling of raw milk with an engineered...

Clean-in-place (cip) system for sanitation processes

Ensure thorough sanitation in your production line with a streamline...

Stainless steel centrifugal pump for liquid transfer

Optimize your food and dairy production with a reliable centrifugal ...

Turnkey stainless steel tanks

Optimize your liquid processing with versatile stainless steel tanks designed for efficient st...

Industrial water recycling system

Reduce excess water consumption in your process line by recycling and reusing up to 96% o...

Instrumentation calibration services for accurate measurements

Ensure precise control over your production variables by ...

Compact food depositor for direct container use

Streamline your depositing process with a versatile solution that handles ...

Single piston food depositor

Achieve precise portion control for diverse food products, from soups to chunky fillings, with ...

Compact food filling and portioning solution

Ideal for facilities needing precise portioning, this versatile filling machi...

Tabletop food depositor for portion control

Streamline your food production with precise portion control, reducing waste a...

Semi-automatic butter bulk filling system

Optimize your dairy production with a seamless butter packaging solution that en...

Rotary cup filling and closing system

Maximize production efficiency with a system that offers precision filling and secure...

Bulk filling and wrapping for butter and margarine

Streamline your butter and margarine production with efficient bulk fi...

Butter and margarine homogenizer

Optimize your butter and margarine production by seamlessly restoring the texture of frozen...

Butter block cutting system

Effortlessly transform large, unwieldy butter blocks into precise, uniform pieces for seamless p...

Forming, filling, and sealing solution for mini portions

Optimize your production line with a high-speed machine designed...

Efficient dairy product separator

Achieve precise fat separation and enhance product quality while reducing energy consumpt...

Lid unscrambler for unstackable lids in round containers

Streamline your packaging process with this lid unscrambler, eff...

In-line blender for dairy products

Streamline your dairy and beverage production with precision ingredient control and redu...

Automated milk standardization unit

Achieve precise in-line standardization of milk components, ensuring optimal quality an...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Buffer tanks for dairy processing

Optimize your dairy production with versatile buffer tanks, essential for balancing flow ...

Cleaning in place system for dairy processing plants

Streamline cleaning efficiency and ensure product quality in your da...

Continuous aerator for dairy products

Enhance the texture and flavor of dairy delights with precise gas infusion, transform...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

Scraped surface heat exchanger for high viscosity products

When dealing with complex formulations, achieve efficient hea...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

Milk pre-cooling systems for dairy farms

Optimize dairy production with advanced milk pre-cooling systems that significantl...

Remote monitoring app for milk coolers

Ensure milk quality and streamline operations with a remote monitoring app that prov...

High pressure plunger pump for edible fats processing

Ensure consistent, high-quality edible fat products with precision ...

Scraped surface heat exchanger for high-viscous products

For processors of high-viscosity spreads, efficient heat transfe...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

Flaker for frozen meat and food blocks

Efficiently transform solid blocks of frozen foodstuffs into precise cuts and flakes...

Butter Tub Filling And Sealing Machine

When packing paste-like products such as butter, spreads or margarine you need flexi...

Automatic butter wrapping machine

Do you pack your butter wraps in aluminium foil, parchment paper or ecoline solutions? An...

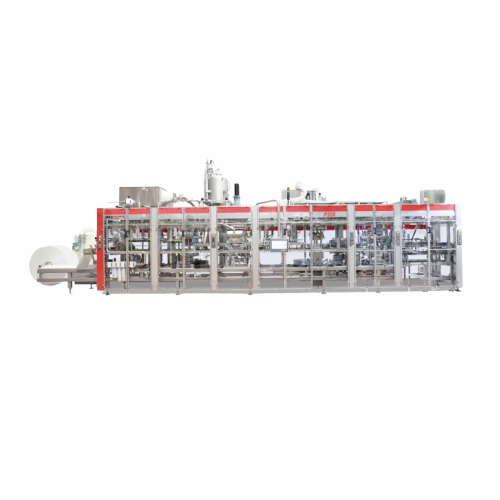

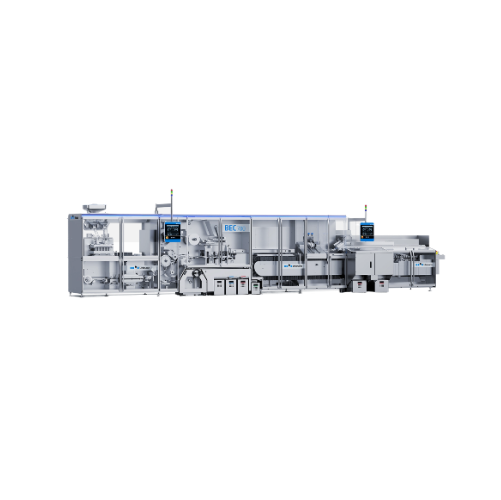

Continuous butter production line

When producing large volumes of butter in consistent quality, taste and appearance you ne...

Butter Re-packaging Line

Although bulk butter blocks are commonly used in commercial food production, they are heavy and diff...

Butter Churner Machine

When processing smaller quantities of cream, you need to experiment with butter characteristics to cat...

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

High-clean FFS machine for butter in mini portions

With the production of dairy products such as butter in mini portions ...

Food crates washer

With the increasing demand of food production sectors for cutting costs, while increasing quality of produ...

Flexible pasteurizer for packaged food

Autoclaves for sterilising and cooking food products are a mainstay of many producti...