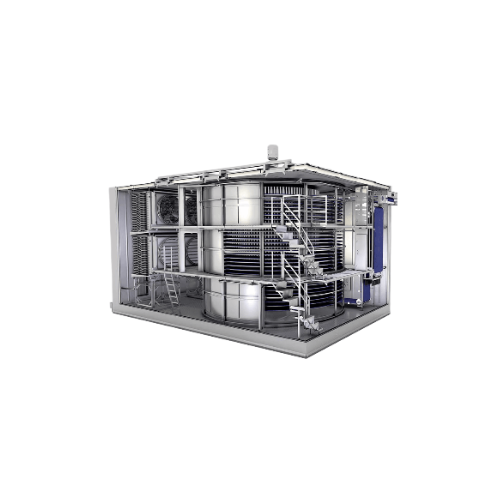

Customized spiral freezer solution for food industry

Designed to enhance your freezing efficiency, our spiral solution handles high-capacity production while minimizing yield loss and optimizing hygiene standards, ensuring seamless integration with existing processes.

Freezes and Monitors Diverse Food Products

The GEA A-Tec Spiral Freezer from GEA is engineered specifically for the food and dairy industries, designed to meet rigorous hygiene standards. Featuring a fully welded stainless steel construction, it efficiently freezes a variety of products, such as chicken nuggets, fish fillets, and pastries, within continuous, high-speed operations. Utilizing horizontal airflow and the Callifreeze® control system, the freezer maintains precise temperature control and product integrity. Handling capacities from 0.2 to 7 tons per hour, it integrates seamlessly with automated lines and minimizes downtime with the Intelligent Valve System (IVS) and belt steam defrost technology. The freezer supports clean-in-place (CIP) systems, ensuring reduced cleaning cycles and enhanced productivity. Configurable evaporator options, like Sequential Defrost (SD) or Snow Removal System (SRS), enable customization to specific operational needs. GEA provides global sales and engineering support, offering tailored solutions for diverse industrial applications.

Benefits

- Ensures product consistency with precise temperature control and real-time monitoring.

- Minimizes yield loss through efficient horizontal airflow design.

- Reduces cleaning and maintenance time with integrated CIP system.

- Enhances production uptime using advanced belt steam defrost technology.

- Offers flexibility with customizable configurations to match specific processing needs.

- Applications

- Ready meals, Meat, Poultry, Bakery products, Dairy products, Fish

- End products

- Chicken nuggets, Bread rolls, Frozen lasagna, Pizza, Croissants, Ice cream, Butter, Sausages, Yogurt, Fish fillets, Cheese

- Steps before

- Food preparation, Product loading, Pre-cooling

- Steps after

- Packaging, Storage, Distribution

- Input ingredients

- meat, poultry, fish, ready meals, bakery products, dairy products

- Output ingredients

- frozen meat, frozen poultry, frozen fish, frozen ready meals, frozen bakery products, frozen dairy products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 0.2 to 7 tons per hour

- Automation

- PLC-controlled

- Defrost system

- Sequential Defrost (SD) or Snow Removal System (SRS)

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- CIP/SIP

- CIP

- Cleaning method

- CIP

- Working mechanism

- Spiral freezing

- Integrated steps

- Callifreeze® control, IVS

- Cleanability

- Fully welded stainless steel, CIP system

- Corrosive resistance

- Stainless steel construction

- Abrasion resistance

- A-Tec proprietary materials

- Machine footprint

- Customizable based on facility space

- Material

- Fully welded stainless steel

- Cleaning system

- CIP (Clean-In-Place) system

- Defrost system

- SRS (Snow Removal System) / SD (Sequential Defrost)

- Capacity range

- 0.2 to 7 tons per hour

- Evaporator configuration

- Sequential Defrost (SD) or Snow Removal System (SRS)

- Cleaning system

- CIP (Clean-In-Place) system

- Airflow design

- High efficient horizontal airflow

- Material

- Fully welded stainless steel

- Defrost system

- Belt steam defrost system

- Freezer control system

- CALLIFREEZE® control system

- Temperature control

- IVS (Intelligent Valve System)