Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities with precision control, ensuring perfect consistency for varied applications.

Melts and Maintains Temperature of Chocolate and Confectionery

The QUICK MELTER QM40 and QM25 from Prefamac Chocolate Machines are designed for efficiently melting and maintaining the temperature of chocolate, cocoa butter, and jams. These machines feature a robust heating grid system and a double-walled collector with an agitator, enabling them to melt up to 500 kg of chocolate per hour. Applications range across chocolate bars, truffles, coatings, and bakery products, making the QUICK MELTER essential for chocolate production and bakery industries. The systems integrate smoothly into high-speed, continuous operations with ergonomic designs to reduce manual strain, featuring adjustable melting grids, digital thermostats, and a central control panel for precise temperature settings. Constructed from pearled stainless steel, they offer corrosion resistance and long-lasting operation, with options for additional features like chocolate pumps and stainless steel piping for enhanced processing capabilities.

Benefits

- Increases production speed by melting up to 500 kg of chocolate per hour.

- Enhances product quality with precise, independent temperature control for various ingredients.

- Reduces manual labor and physical strain with ergonomic design and lower insertion height.

- Maintains consistent processing with a robust heating system and dedicated circulation pumps.

- Offers customization to meet specific production needs with optional features and configurations.

- Applications

- Cocoa butter, Jam, Confectionery, Fats, Food production, Sweets, Bakery products, Chocolate

- End products

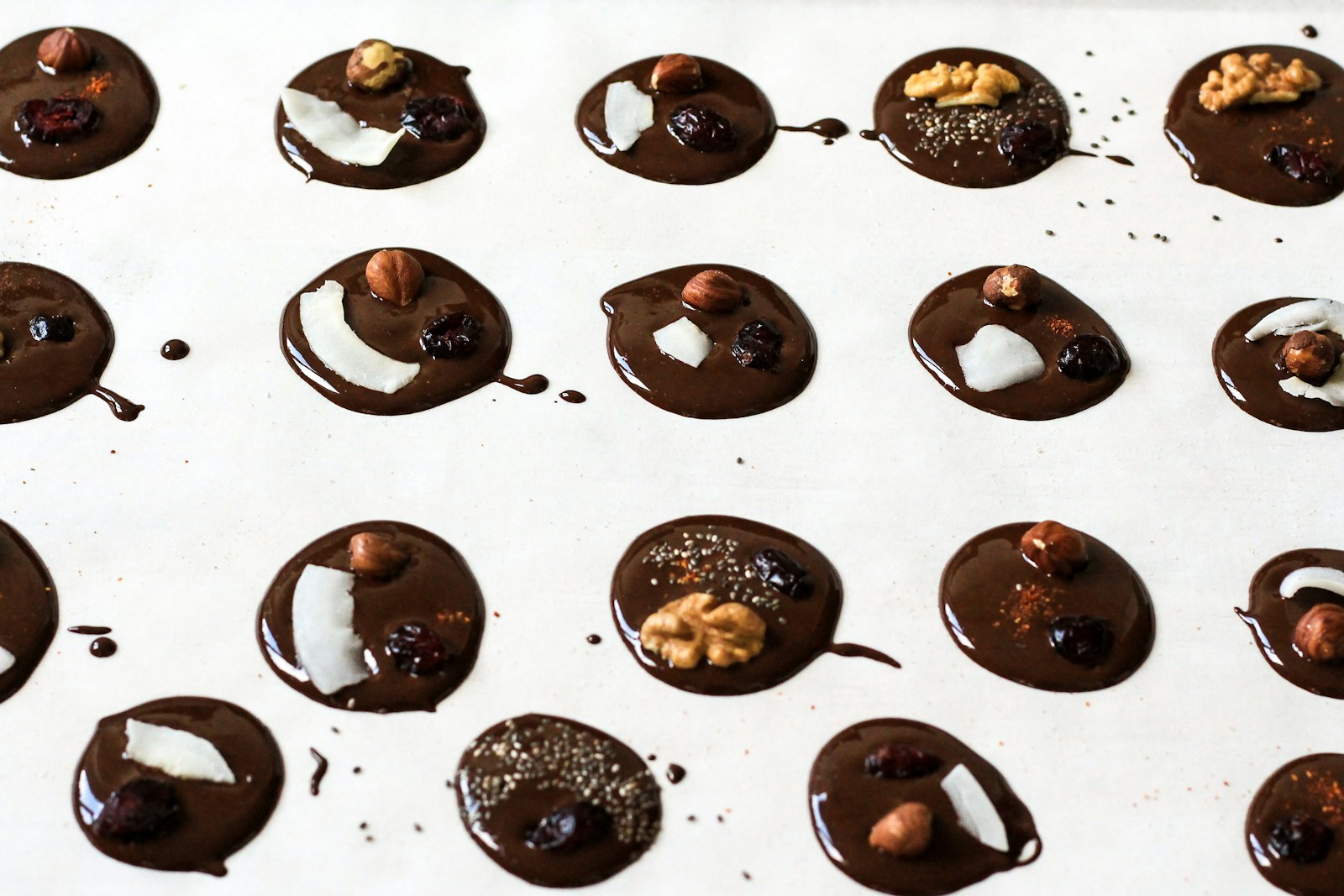

- Chocolate truffles, Butter blocks, Filled chocolates, Baking chocolates, Chocolate coating, Chocolate bars, Melting chocolates, Chocolate drops, Chocolate fondue, Fruit jams, Cocoa butter blocks, Pastry fillings

- Steps before

- Ingredient preparation, Chocolate block or drop selection, Cocoa butter selection, Jam selection, Butter selection

- Steps after

- Chocolate molding, Confectionery production, Tempering, Coating, Enrobing

- Input ingredients

- chocolate drops, chocolate blocks, butter, jam

- Output ingredients

- melted chocolate, melted butter, melted jam

- Market info

- Prefamac is known for manufacturing high-quality chocolate processing equipment, including tempering, enrobing, and cooling machines. The company is recognized for innovative and custom-engineered solutions tailored to the confectionery industry, emphasizing precision, efficiency, and reliability.

- Melting Capacity

- 500 kg/h

- Material Compatibility

- Chocolate / Butter / Jam

- Heating System

- Double-walled and agitator equipped

- Water Circuits

- 4 for QM40, 3 for QM25

- Dimensions

- 3000 x 960 x H 1450 mm

- Electricity

- Three-phase 220/240 V – 50Hz/60Hz

- Automation

- Central control panel

- Agitator

- Horizontal

- Melting capacity

- Up to 500 kg/h

- Temperature control

- Individual for grids and central container

- Automation level

- Central control panel

- Agitation

- Horizontal agitator

- Water circuits

- 4 circuits (QM40), 3 circuits (QM25)

- Heating system

- Double-walled water jacket

- Energy efficiency

- Heated melting grid and collection tray

- Changeover flexibility

- Position adjustable melting grids

- Batch vs. continuous operation

- Batch operation

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Yes

- Cleanability

- High

- Density/particle size

- 0.5–2.5 g/cm³

- Container size and shape

- Drops/Blocks

- Machine footprint

- 3000 x 960 x H 1450 mm

- Discharge method

- Draining valve on the side of tray

- Control panel type

- Central control panel

- Compact footprint

- Yes

- Tank shape and size

- Cylindrical horizontal collection tray

- Feed/discharge method

- Agitator with mixers

- Control panel type

- Central control panel

- Integration possibilities

- Custom piping and metal detection

- Covers type

- Polycarbonate (PC) with gas springs

- Material

- Pearled stainless steel, PVC option

- Chocolate pump

- Optional installation

- Double-walled piping

- Fixed or flexible options available