Sweets Processing Equipment

Find innovative sweets equipment and connect directly with world-leading technology suppliers

During the Middle Ages, sugar sweets were a delicacy only for the rich due to the high cost of sugar. Thankfully, the discovery that sugar could be extracted from sugar beets made sweets affordable for everyone. The sweet category is broad, covering chocolates, chewing gums, sugar candies, and candied/glazed products with sugar. To make these confections, sugar manufacturing equipment needs to cover different steps within the production line such as sugar dissolution, syrup cooking and cooling.

Top technology picks for sweets production

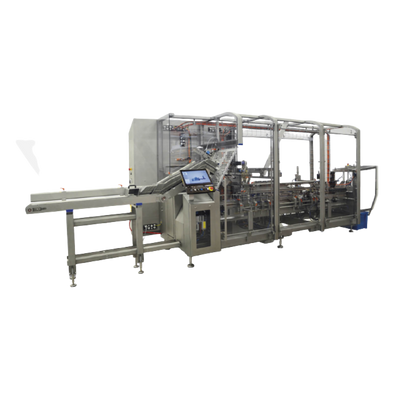

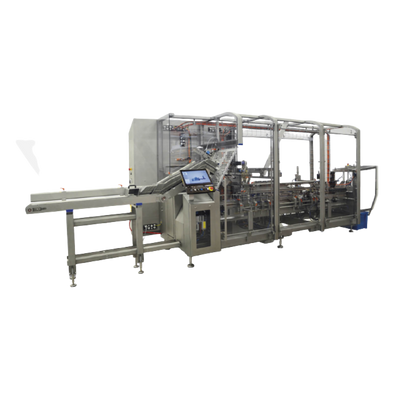

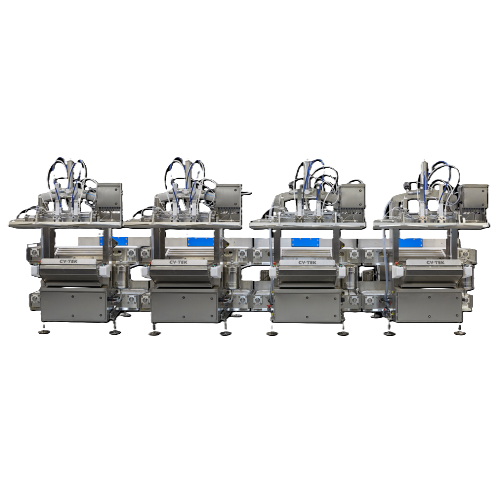

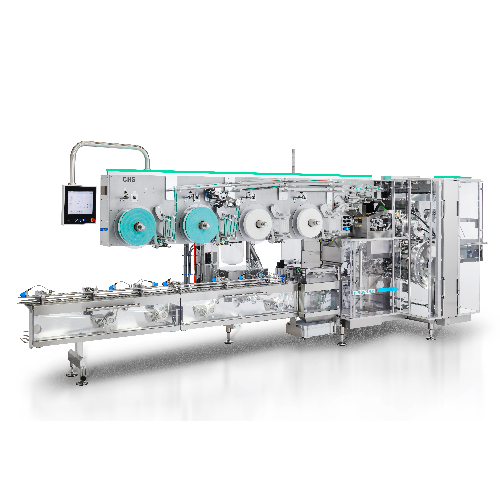

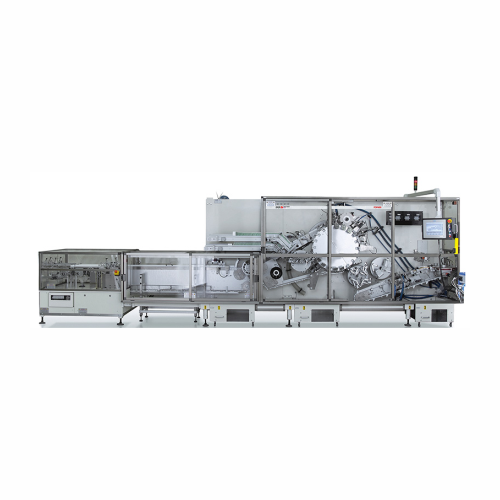

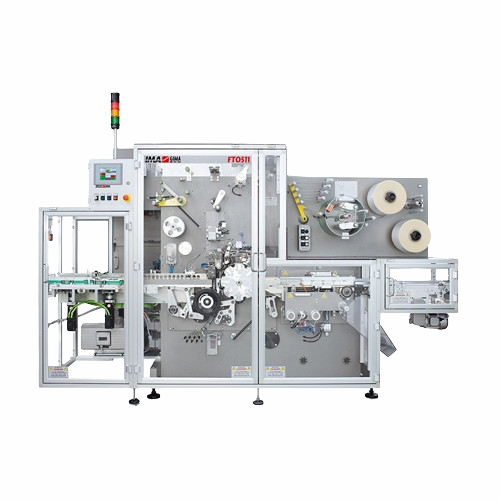

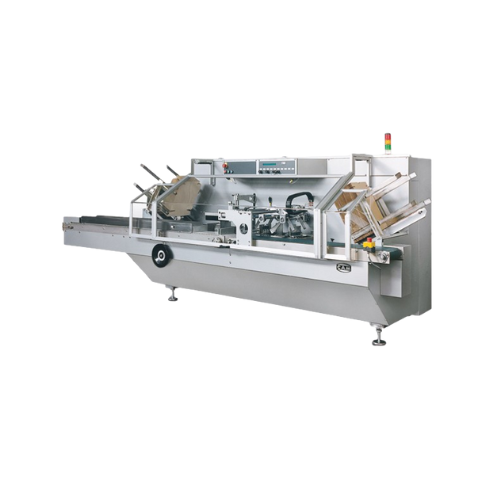

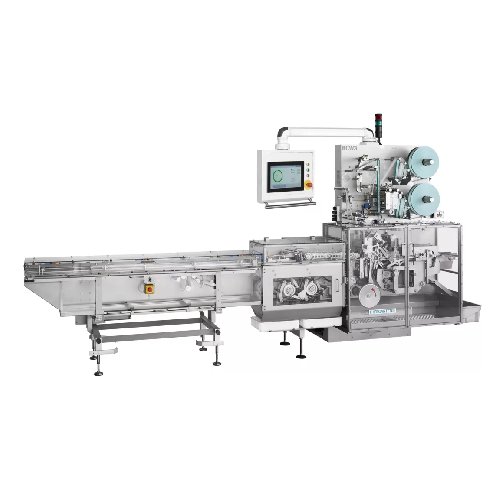

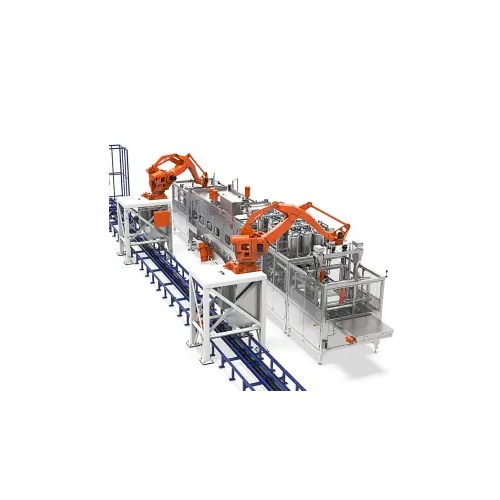

Cartoning Machine For Snacks and Sweets

When producing different snacks and sweets, each product will match a different car...

Continuous cooker for hard caramels

Continuously cook ingredients for your hard caramel-based product. This is a three-stag...

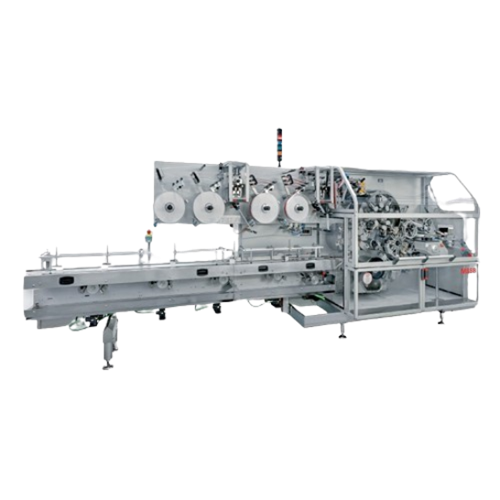

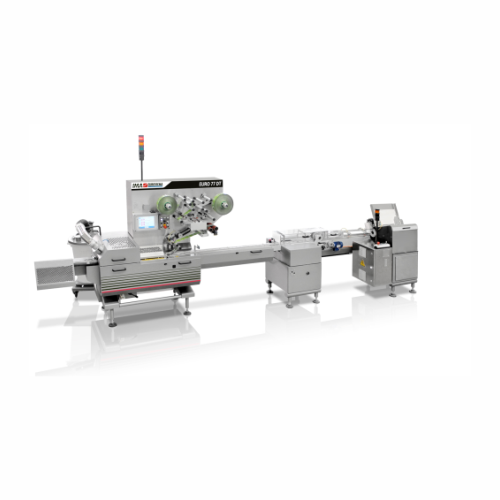

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

Muffin and cake production line

Enhance your bakery production with a line that meticulously controls every stage, from mixi...

Stories about sweets

Preserving gummy texture in low or no sugar confectionery

How to craft gummy bears in 8 simple steps

Exploring the artistry of candy-making

Experts in a box – What type of snack bar are you packing?

Remember when big biscuit producers still used thermoformed plastic trays?

Gluten morgen… Temperature control in your sponge cake production

Liquorice: from root to candy

Perfect cake slices with ultrasonic cutting technology

Chocolate surface filling for cup cakes

Stevia. What is it and how is it made?

Select your sweets process

What are you making?

Water-ice push-up

Water-ice lolly

Wafer sticks

Wafer rolls

Wafer biscuits

Truffles

Torrone

Toffees

Sugar-coated sweets

Sandwich cookies

Pectin jellies

Marzipan

Mango sorbet

Macarons

Nut brittle

Halva

Gelatin desserts

Fruit jellies

Dulce de leche

Confectionery fillings

Confectionery coatings

Cheesecake

Pralines

Muffins

Jelly

Foam kisses

Molasses

Sugar

Ice cream

Vitamin gummies

Nougat

Caramel

Gummy Bears

Licorice

Marshmallows

Lollipops

Brittles

Jam

Sugar coated nuts

Cookies

Biscuits

Chocolate bonbons

Truffle balls

Hollow chocolate figures

Chocolate bars

Compound chocolate

Tell us about your production challenge

Boiled sweet manufacturing equipment and process

Boiled sweets, also known as hard candy, are primarily made by boiling sugar syrups mixed with water and flavorings of your choice. Boiled sweet making equipment must involve ingredient preparation, mixing, cooking, cooling/forming, and packaging.

The main ingredient in boiled sweets is sugar (almost 100%). The process begins by combining sugar and water and boiling them together. Sweet makers may add glucose, fructose or another type of sugar. The mixture is heated to 160 °C. After cooking, manufacturers pour the homogeneous mixture into a cooling table and when it is cool enough, it can be molded as in the shape you want.

Jelly sweets for soft treats

What makes jelly sweets different from candies? Unlike the latter which only has sugar as their source of structure, jelly sweets have additional ingredients: hydrocolloids. These functional ingredients make your jelly sweets obtain the elasticity you are looking for. Three hydrocolloids are used for jelly candies: gelatin, pectin and carrageenan.

Although both products use the same sweet manufacturing equipment, jellies differ specifically in the addition of the gelatin solution. You will have to prepare and cook the gelatin separately at 80 – 90 °C, allowing its protein strands to rearrange and help form the jelly structure. Mix these with the cooked sugar solution at temperatures of 70 °C to stabilize the jelly structure. Feed your mixture to the candy depositor for molding. Finally, your molded sweets are cooled at 5 – 10 °C through a cooling tunnel and dried for 8 to 12 hours before packing.

Sweets for immunity and longevity

Considering the recent COVID-19 pandemic hitting the world, producers are challenged to manufacture products with better nutritional value as consumers are demanding more of these. Currently, sweets are already being used as health supplements. A survey conducted by Innova Market Insights last 2020 indicated that 6 out of 10 global consumers are leaning into consuming food that boosts their immune health. Food naturally high in vitamins, minerals, and antioxidants was the top choice, with a notable increase in botanical ingredients and organic raw materials.

This is an opportunity for the international confectionery industry, specifically for chocolates since these are rich in flavanols. The addition of botanical ingredients, such as orange, elderberry, and turmeric, can further improve your products and position these at the top of consumer preferences.

On the other hand, chocolates can also be used as vehicles for nutritional supplementation. Avida Health from Singapore launched chocolate balls which act as functional foods aiming to improve kids’ immunity. These sweets contain mushroom-derived beta-glucan, a soluble fiber essential for insulin resistance, hypertension, and obesity prevention.

Regulations and laws for sweets

Before distributing to your target market, it is best to check what regulations your product needs to comply with. An example of this is the regulation by Codex Alimentarius (CODEX STAN 192-1995) listing allowable limits and additives permissible for sweets. If you are exporting in the US, take note of the lead content of your candy. The US FDA has established a limit of not more than 0.1 ppm as the maximum level for lead in candies. In the UK, as part of their drive to reduce childhood obesity, confectioneries are one of the target products that must be reformulated to reduce sugar quantity by 20%.

It is imperative to check all applicable regulations for your product, including food safety controls, labeling, and recall systems since these can result in legal actions if not complied with. In Europe, sweets must be labeled containing the name of the food, any allergenic ingredients or intolerances that may be present in the finished product and the net quantity of the food.

Which sweets technology do you need?

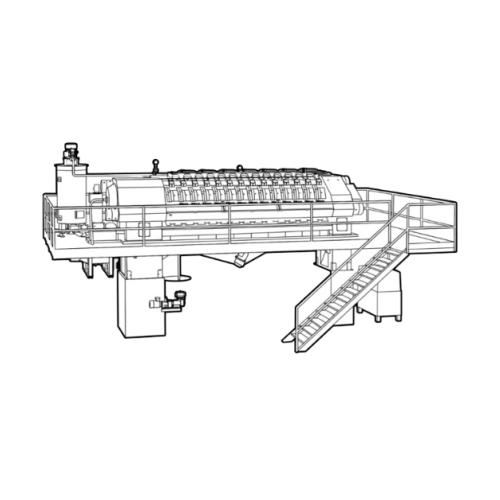

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Double twist wrapping machine for sweets

Optimize your confectionery packaging line with high-speed double twist wrapping, ...

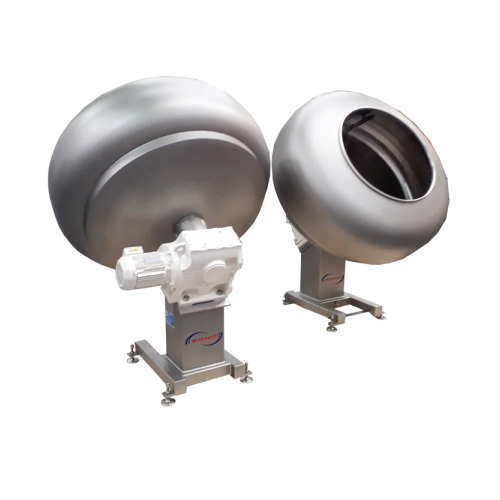

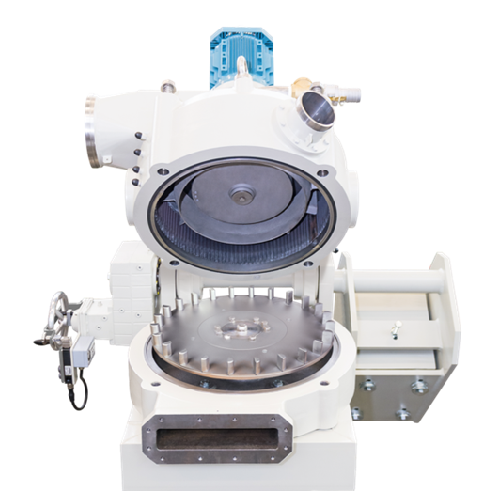

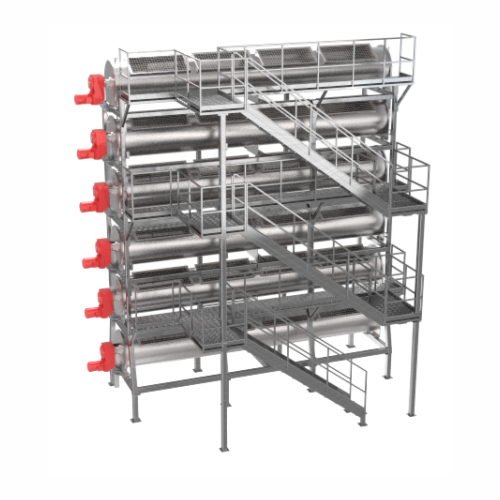

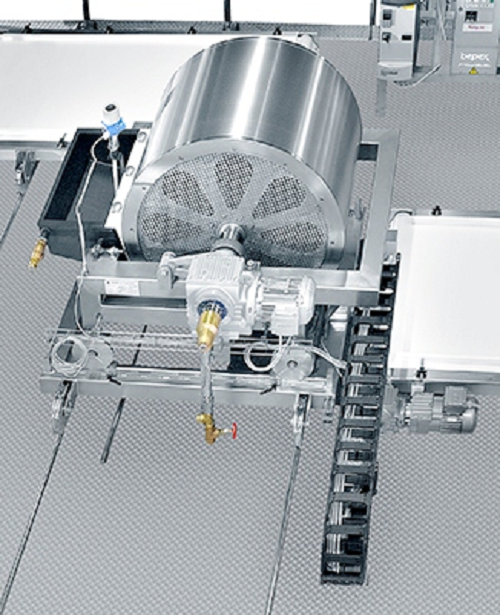

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

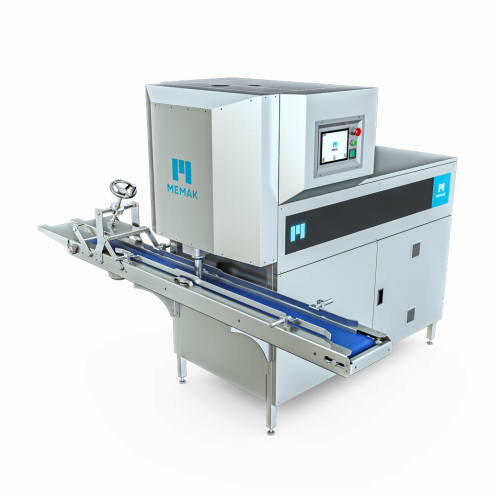

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

Cartoning Machine For Snacks and Sweets

When producing different snacks and sweets, each product will match a different car...

Rotary molder for softdough biscuits and shortbreads

For high output bakeries, achieve precise dough piece formation and ...

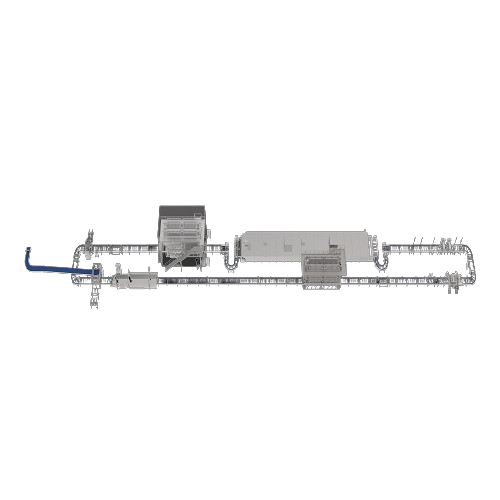

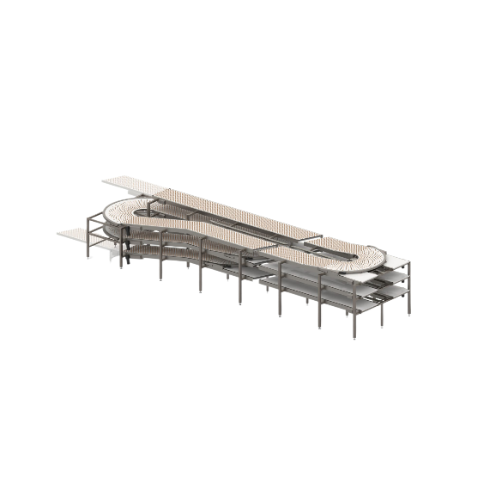

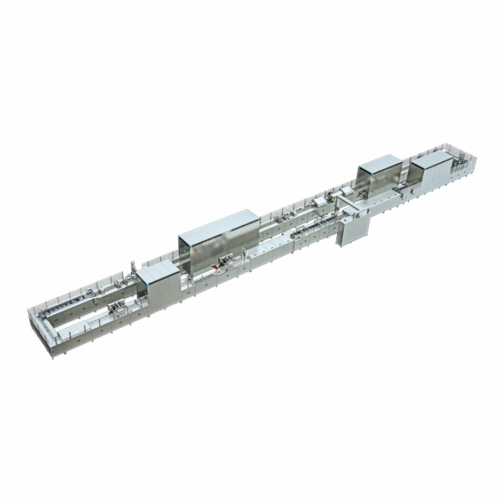

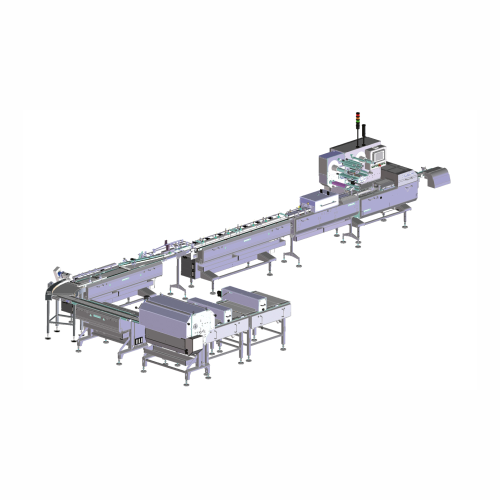

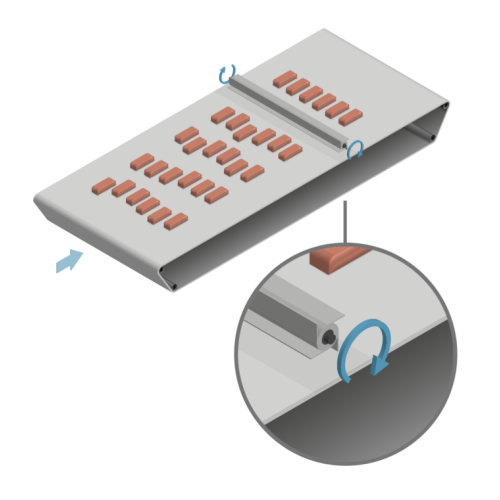

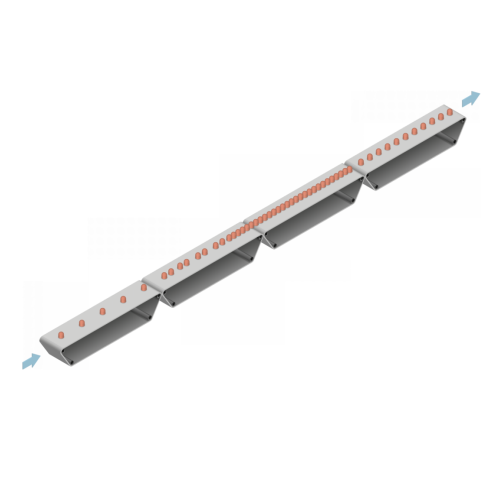

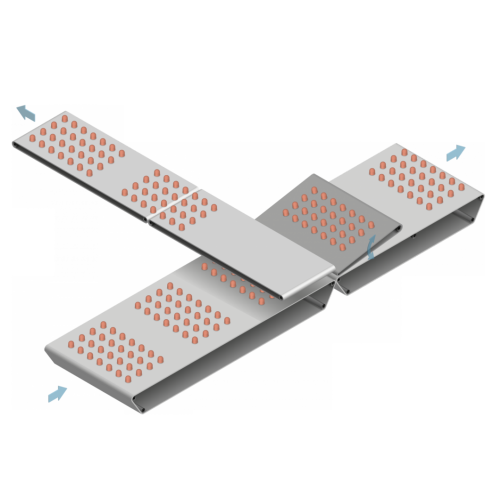

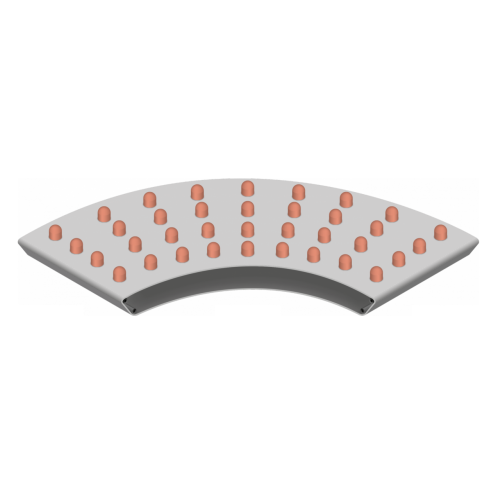

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Chocolate enrobing system for industrial production

Effortlessly transition between chocolate types in your high-speed pr...

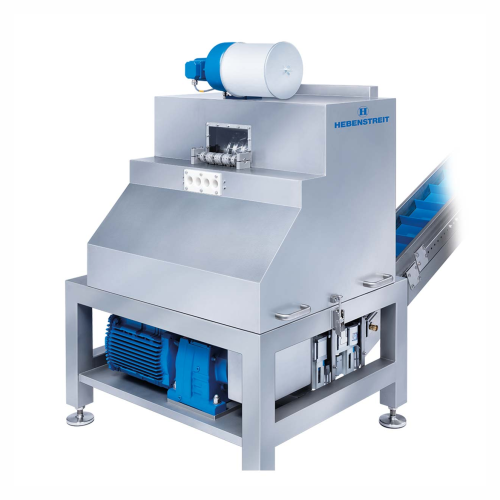

Turbo block flaker for cacao butter

Efficiently transform large chocolate and fat blocks into uniform flakes, enhancing pro...

Precision chocolate production from cocoa nibs

Achieve ultra-fine chocolate textures by utilizing stone conching to bring ...

Industrial chocolate enrobing system for biscuits and fillings

Enhance your production line with this innovative enrobin...

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

Figure moulding for pliable mixes

Transform pliable mixtures into intricate 3D figures with precision and efficiency, cater...

Tablet press for confectionery products

Optimize your confectionery production with a high-speed tablet press capable of sh...

Powder and oil coating system for gummies

Enhance your gummy production with precise powder and oil coating, achieving con...

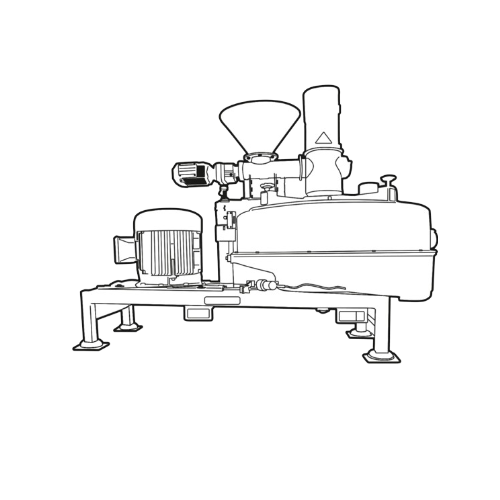

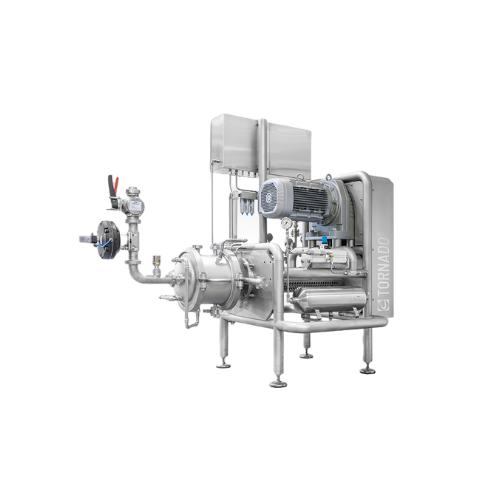

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

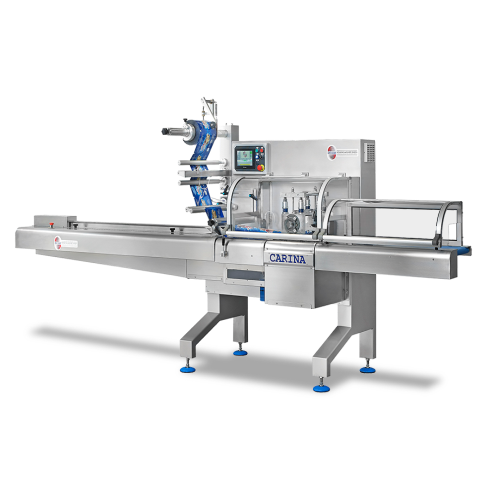

Horizontal flow pack packaging system for flexible materials

Enhance your packaging line efficiency with a system design...

Flow pack packaging for flexible wrapping material

Achieve precise and secure packaging with three-sided sealed packages ...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

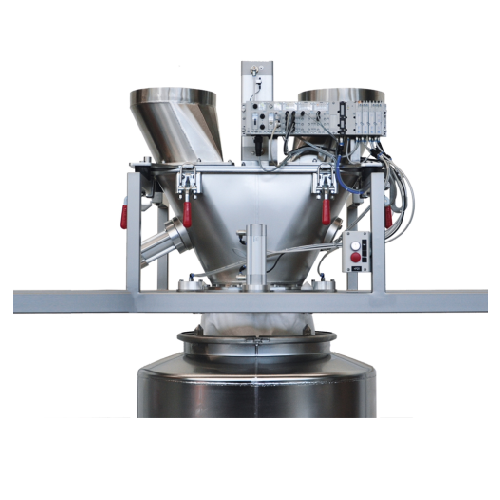

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

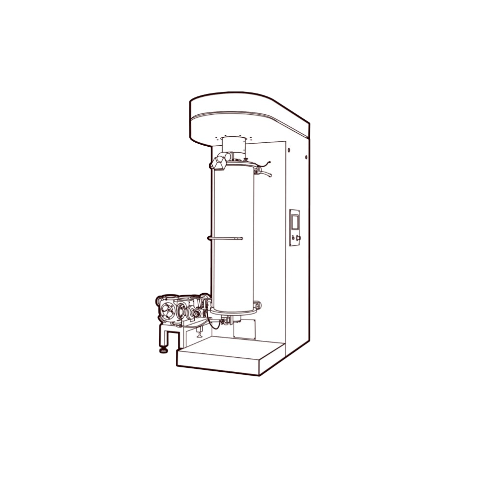

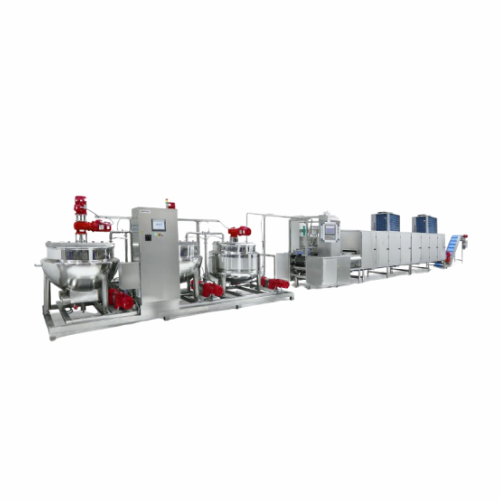

Hard candy production system

Enhance your candy production line with a comprehensive system that optimizes processes from co...

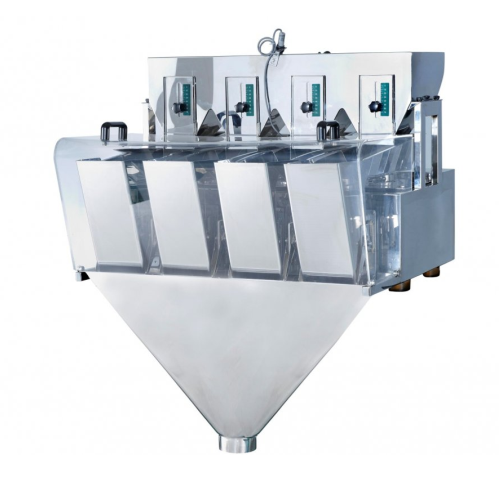

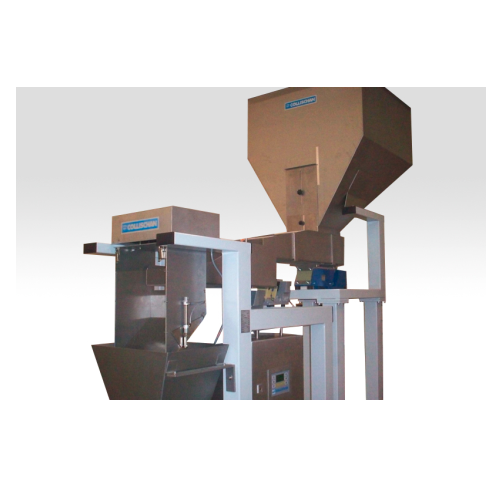

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Forming line for croquant, hard candy, and chewy candies

Optimize your candy production with precision forming and emboss...

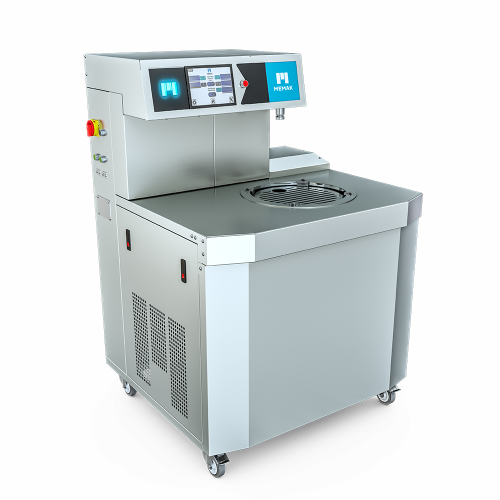

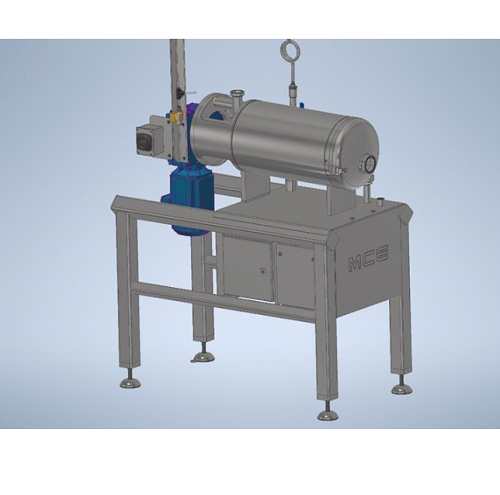

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

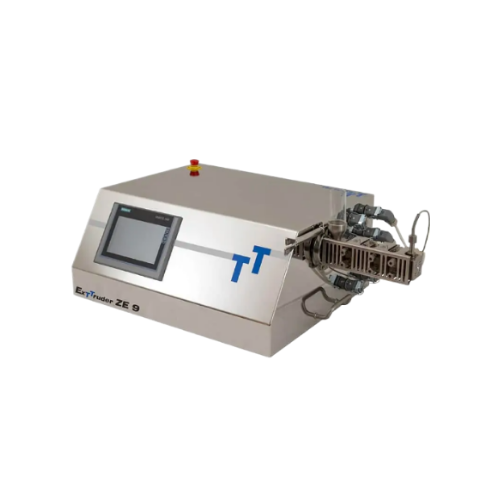

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

Cut and flow pack system for cylindrical and rectangular pieces

Enhance your confectionery production with a high-speed ...

Flow wrapper for preformed pieces

Optimize your high-speed packaging line with a reliable flow wrapper that seamlessly wrap...

Sugar drum for coating gummy candy

Achieve a uniform sugar or wax layer on your gummy candies with precision and reliabilit...

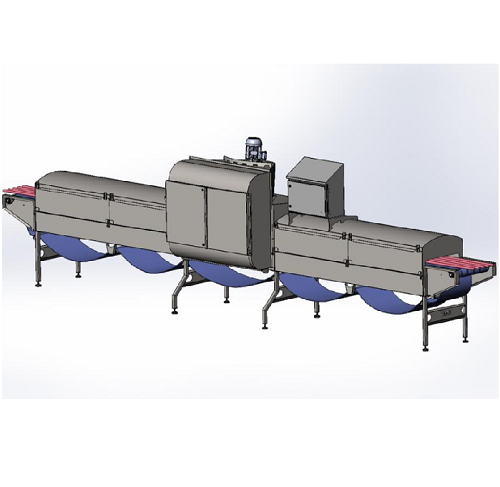

Chestnut glazing tunnel

Achieve perfectly glazed chestnuts every time with our linear glazing tunnels that ensure consistent ...

Checkweighers for medium and small products

Ensure precise weight control in high-speed production lines with advanced che...

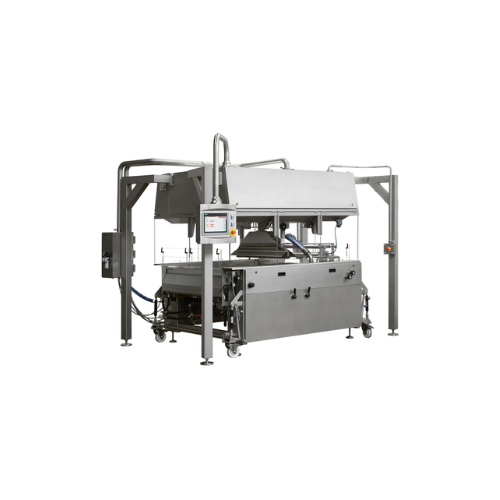

Automated quesadilla production system

Streamline your quesadilla production with a high-speed system designed to efficient...

Versatile confectionery cut and wrap system

Enhance your confectionery production with a high-speed solution capable of ac...

Double twist wrapping solution for confectionery

Optimize packaging speed and precision with a machine designed to wrap di...

Batch roller for hard candy and toffee production

Enhance your confectionery production with a versatile solution that se...

High boiled sugar continuous batch cooker

Streamline your confectionery production with efficient high boiled sugar cookin...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Laboratory cold-press chocolate shell maker

Enhance your R&D capabilities with a solution that enables precise cold-p...

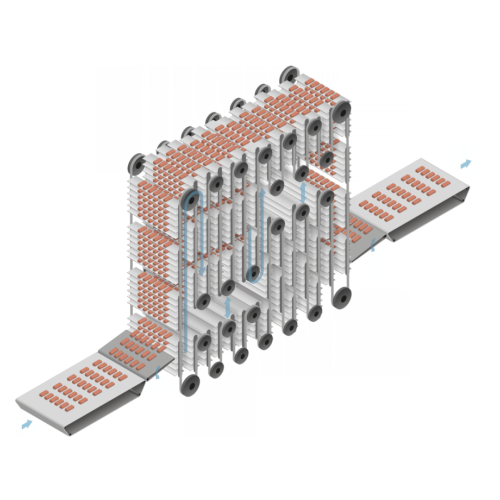

Fifo inflow buffer for efficient production lines

Optimize your production flow with a solution that seamlessly absorbs d...

Vacuum sealing system for glass jars with metal lids

Efficiently vacuum seal glass jars with metal lids to transform pres...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

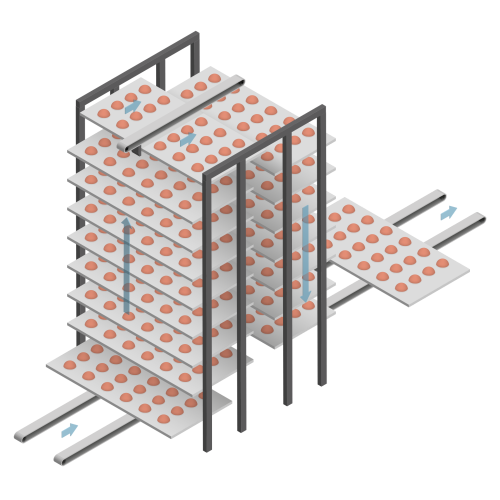

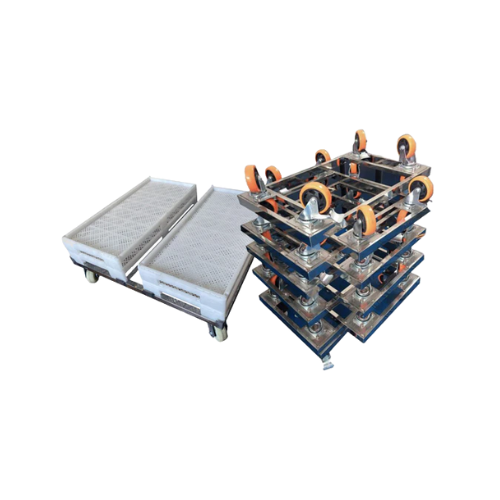

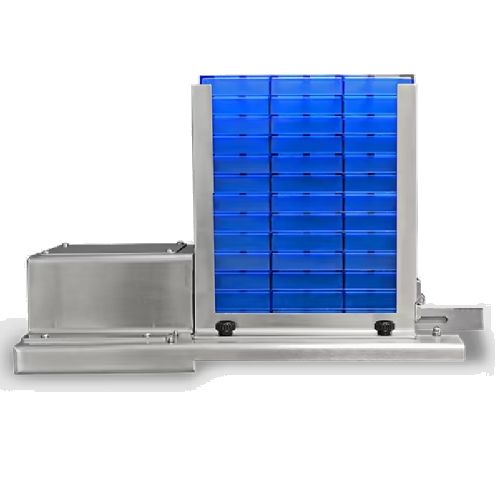

Plate and counter mould storage system for confectionery products

Streamline your confectionery production with an effi...

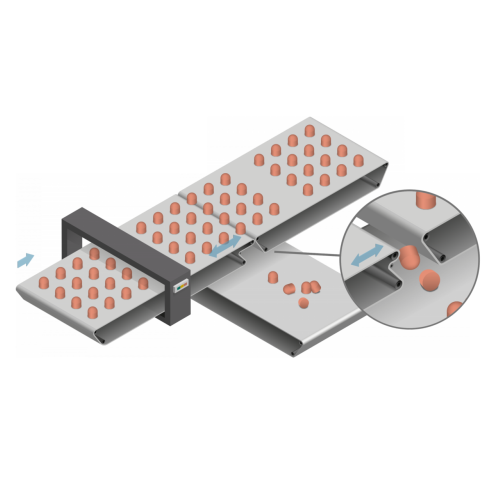

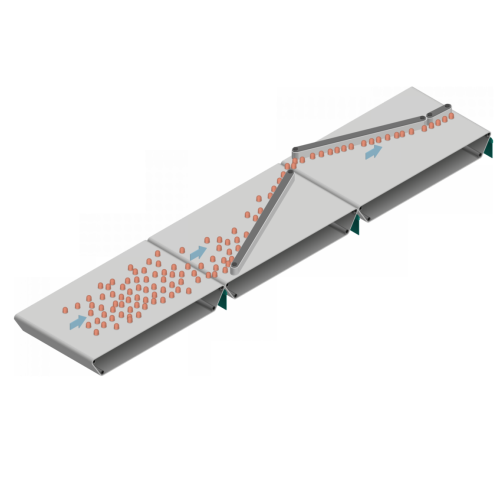

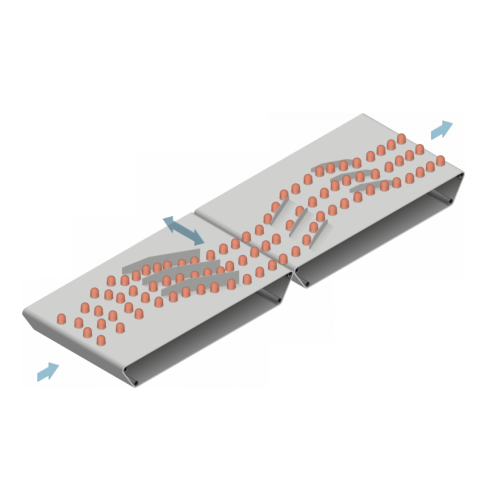

Separating and aligning conveyor for packaging systems

Efficiently manage the flow of diverse solid products like confect...

High-speed double twist packaging for face cut confectionery

Achieve optimal presentation of multi-colored face cut conf...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

Gondola storage system for efficient product handling

Manage production line inconsistencies with precision by employing ...

High speed wrapping solution for pre-formed products

Achieve seamless integration of primary and secondary packaging with...

High speed forming, cutting and wrapping machine for soft caramels

Enhance your confectionery line with a versatile sol...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

Forming, cutting, and wrapping system for soft caramels

Optimize your confectionery production line with a solution desig...

Forming, cutting, and wrapping products in multiple styles

Achieve versatile and efficient packaging for confections and...

Forming and wrapping system for soft caramels with comic strip

Elevate your confectionery packaging with a high-speed fo...

High speed wrapping solution for hard candies and toffees

Enhance your production with a high-speed solution designed fo...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

High-speed wrapping solution for preformed candies

Ensure consistent wrapping of diverse confectionery products with a hi...

Double twist wrapping system for preformed products

Achieve optimal wrapping speed and precision for your confectionery p...

Multihead weighers for food production

Optimize your food production line with precision and speed by integrating advanced ...

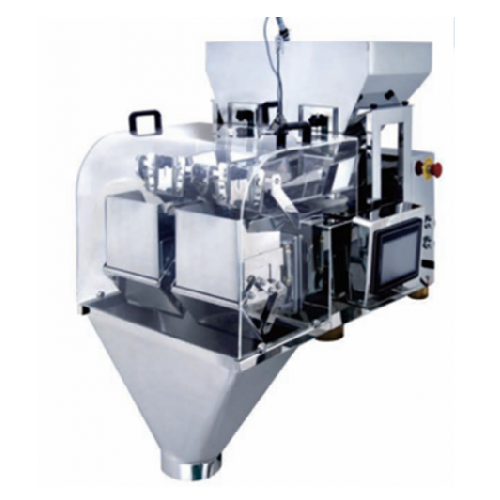

Linear weigher for dry free-flowing products

Optimize your packaging line with precise weighing for snacks, sweets, and gr...

Food production metal detector for packaged products

Ensure product safety and compliance by detecting metal contaminants...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

14 head multihead weigher for dry products

Achieve precise and rapid weighing for a variety of dry, free-flowing products ...

Batch cooker for pectin jelly and caramel production

Achieve precise temperature control and uniform cooking with steam-h...

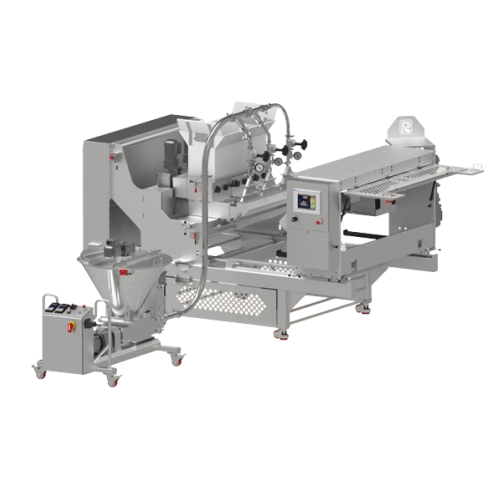

Peanut brittle forming and cutting system

Efficiently transform sticky ingredients into uniform treats with our cutting-ed...

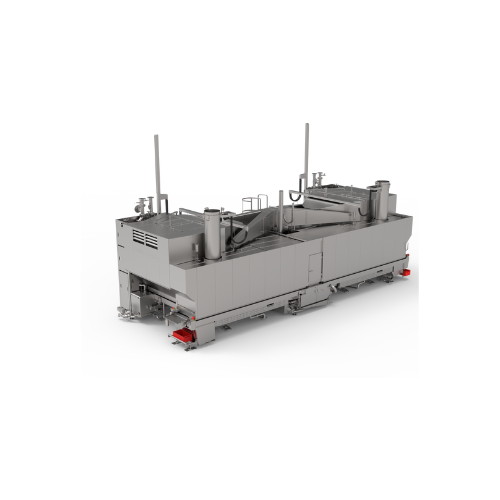

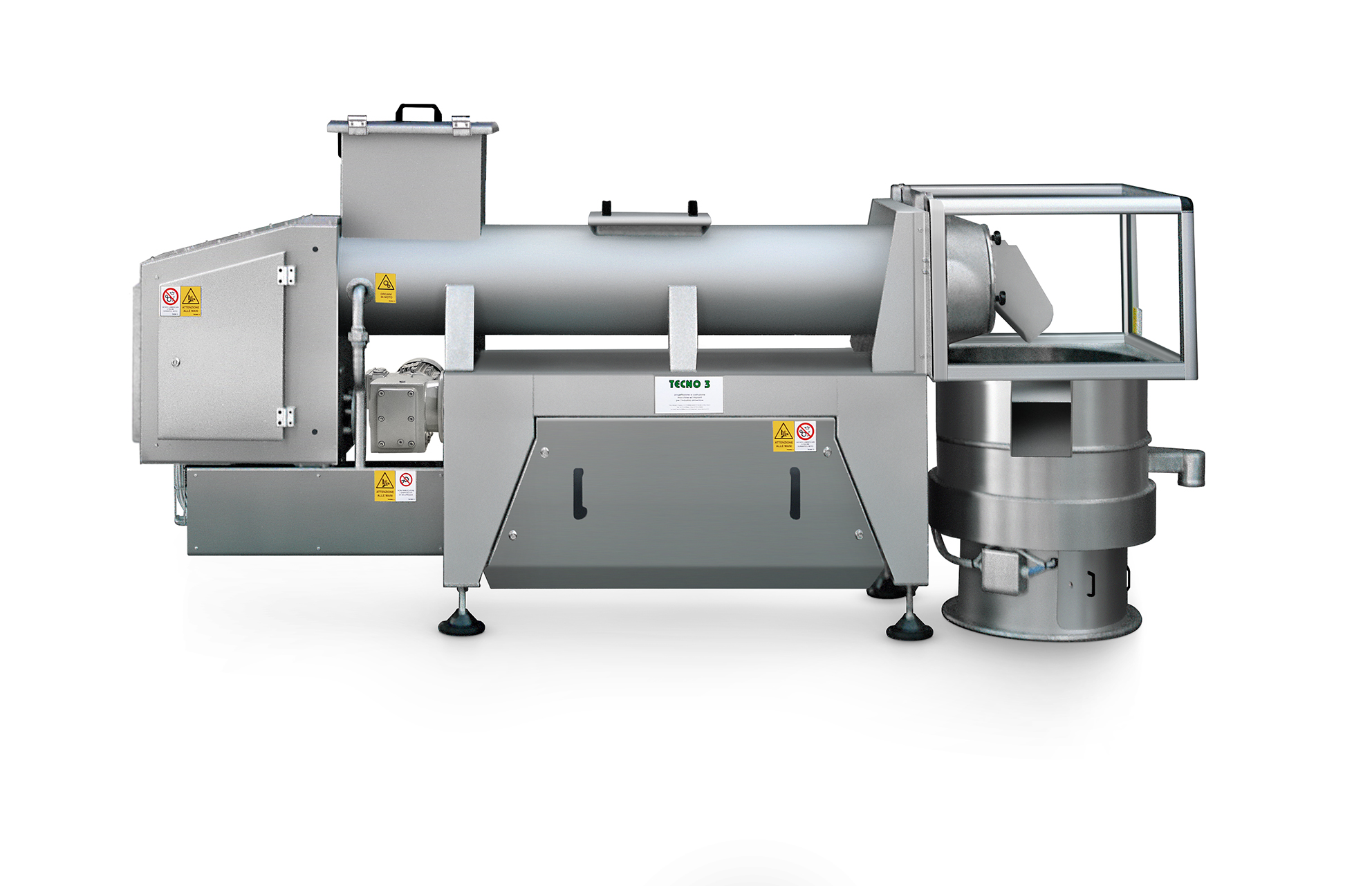

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

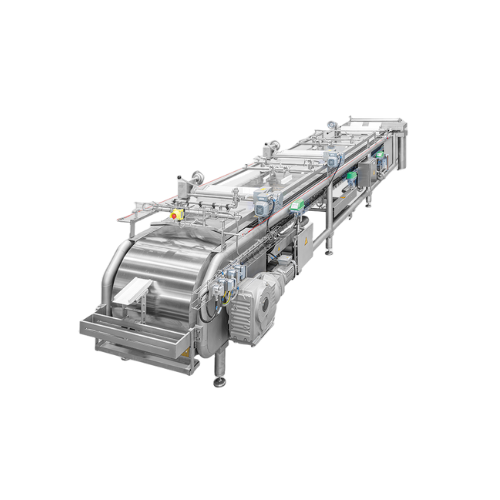

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Chocolate coating panning machine for confectionery

Enhance your confectionery product line with a precision coating solu...

Continuous extruder for protein bars and super foods

Optimize your snack production with a continuous extrusion solution ...

Grain dispenser for decoration of chocolate tablets

Elevate your confectionery with precise grain decoration, enhancing t...

Carton Tray Forming Machine for Biscuits

Trays used as packaging for products for biscuits, cookies, chocolates and other s...

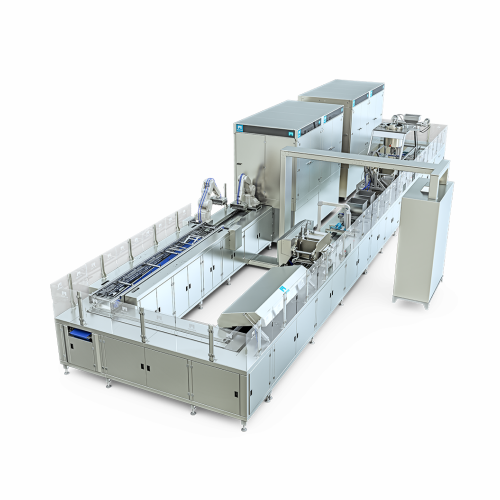

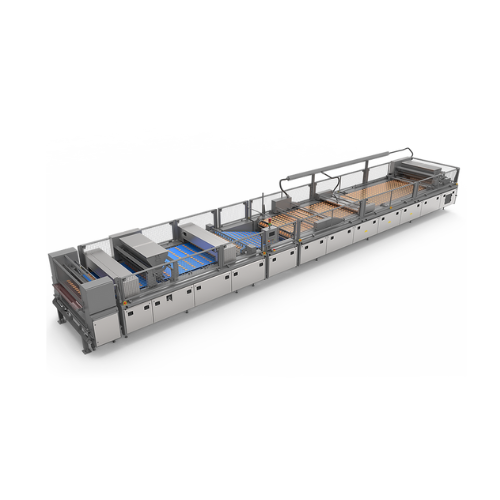

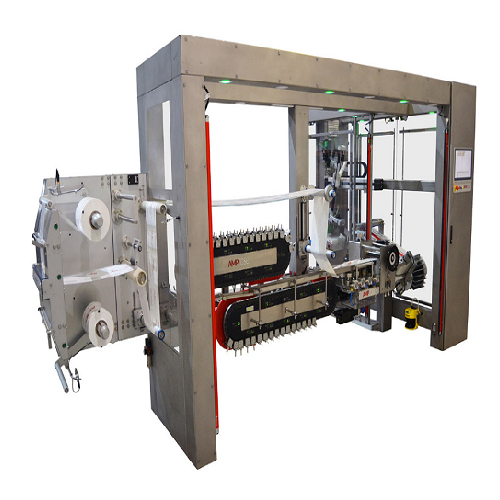

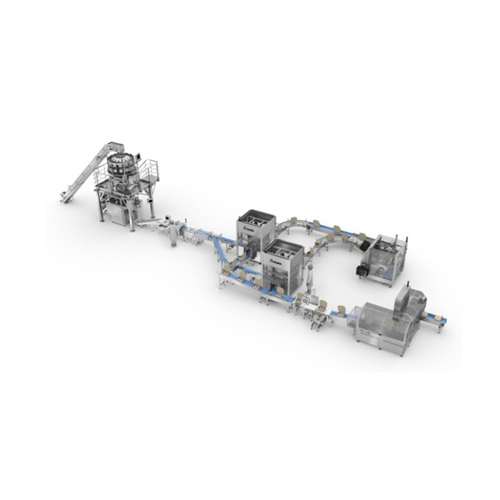

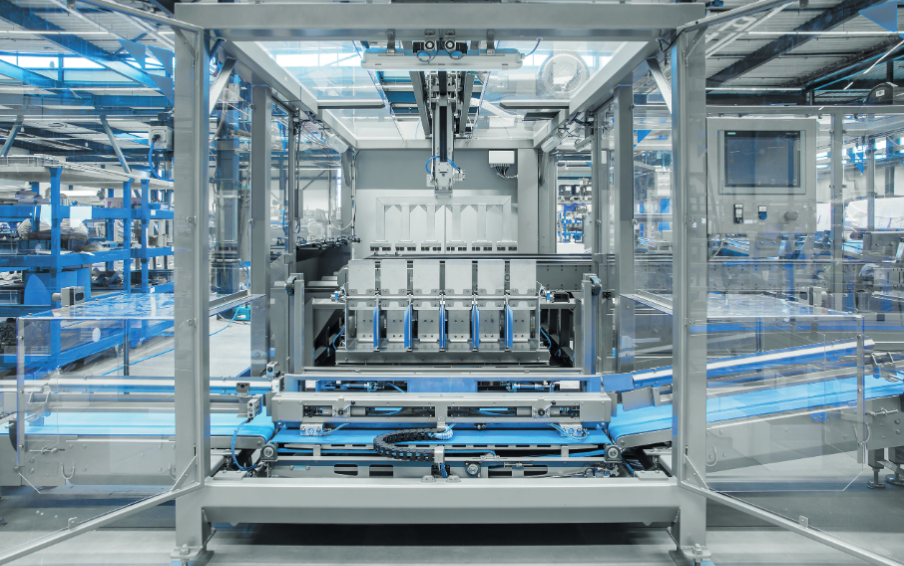

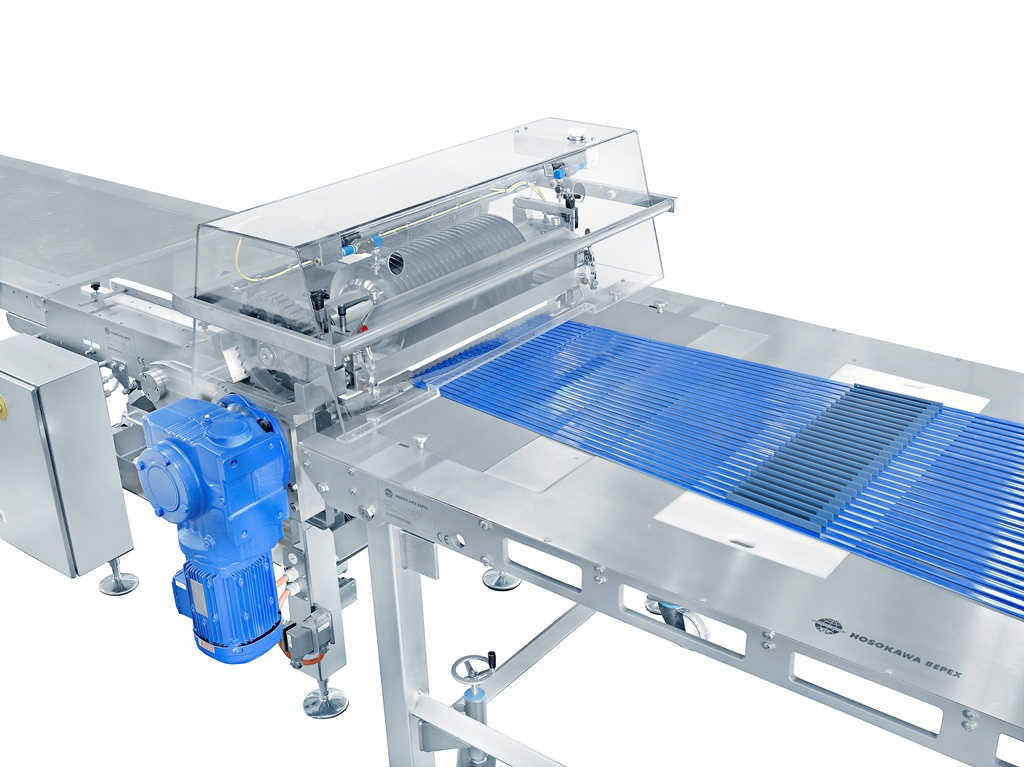

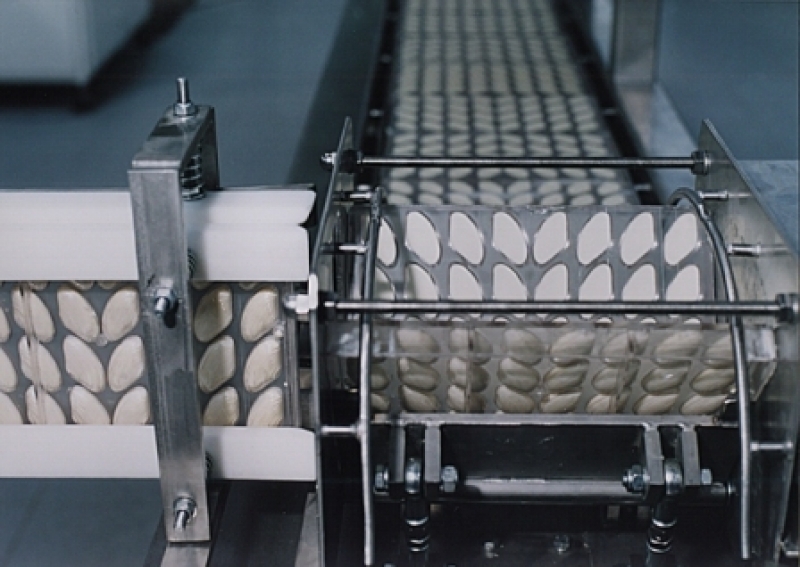

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

Production machine for deposited candies and jellies

For smaller production volumes, fully automated depositors for produ...

Continuous cooker for hard caramels

Continuously cook ingredients for your hard caramel-based product. This is a three-stag...

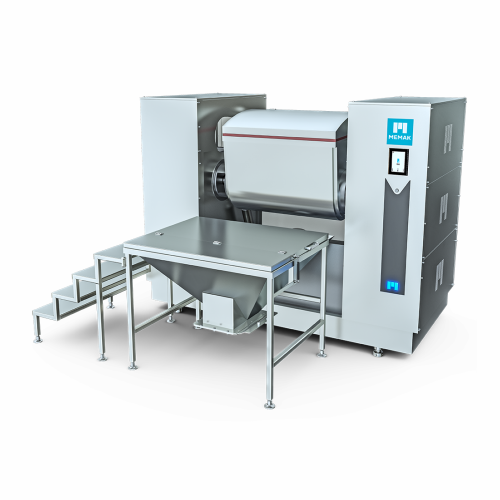

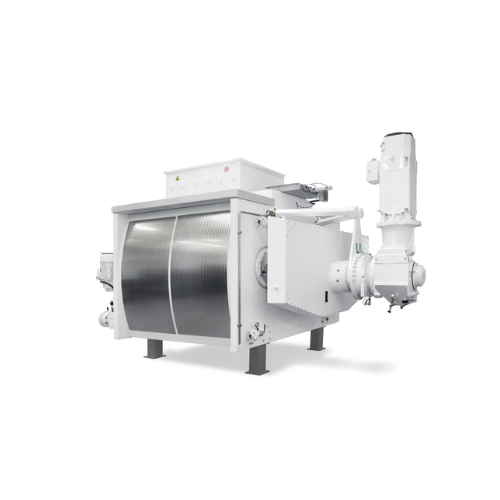

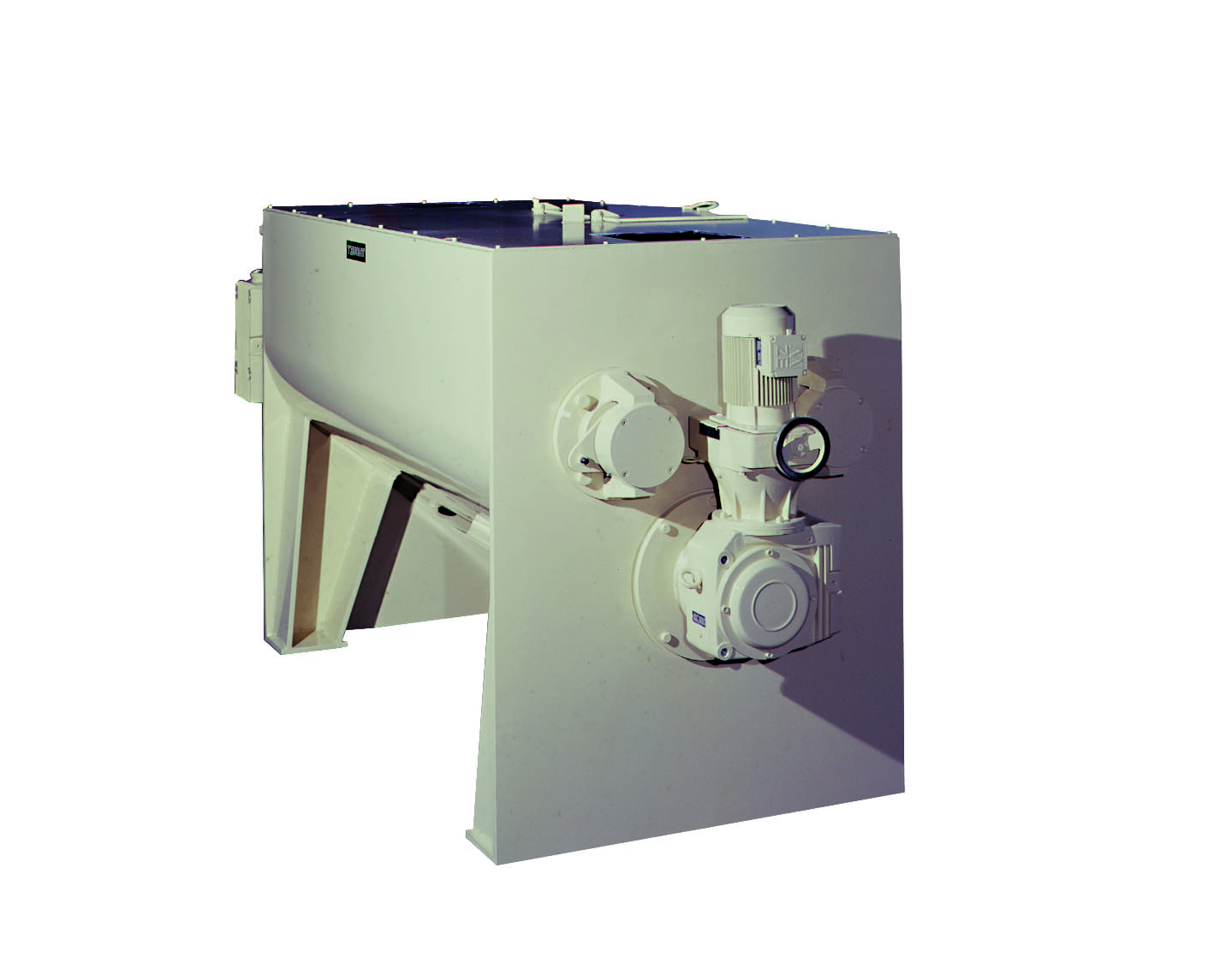

Industrial mixer for various dough types

Efficiently mix a wide range of doughs with precise temperature control to achieve...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

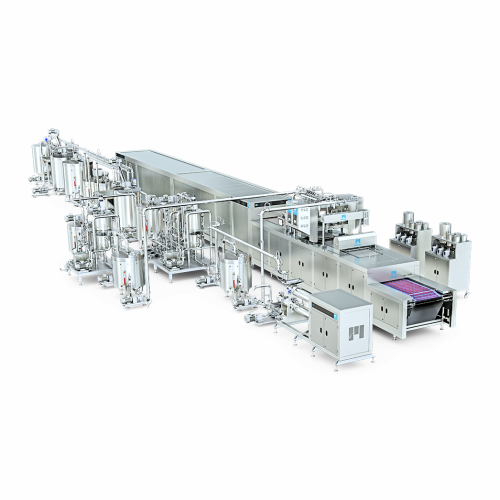

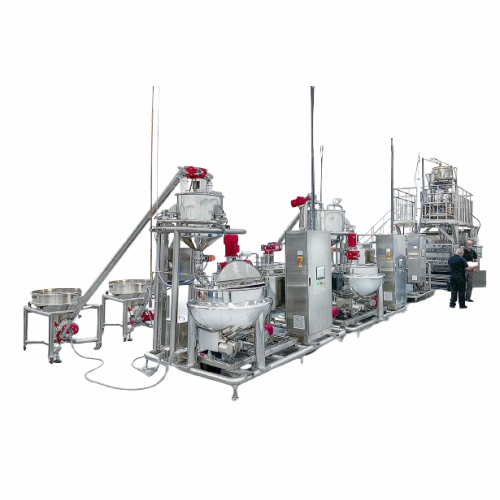

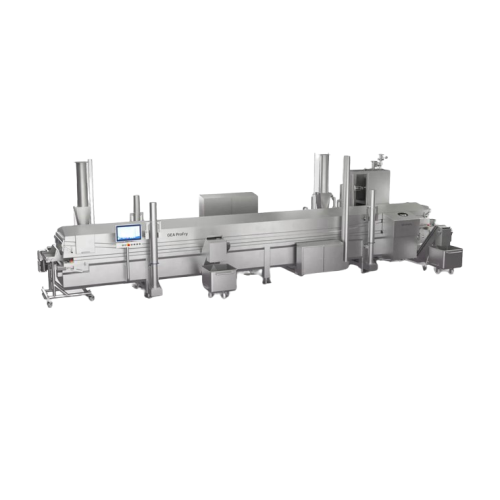

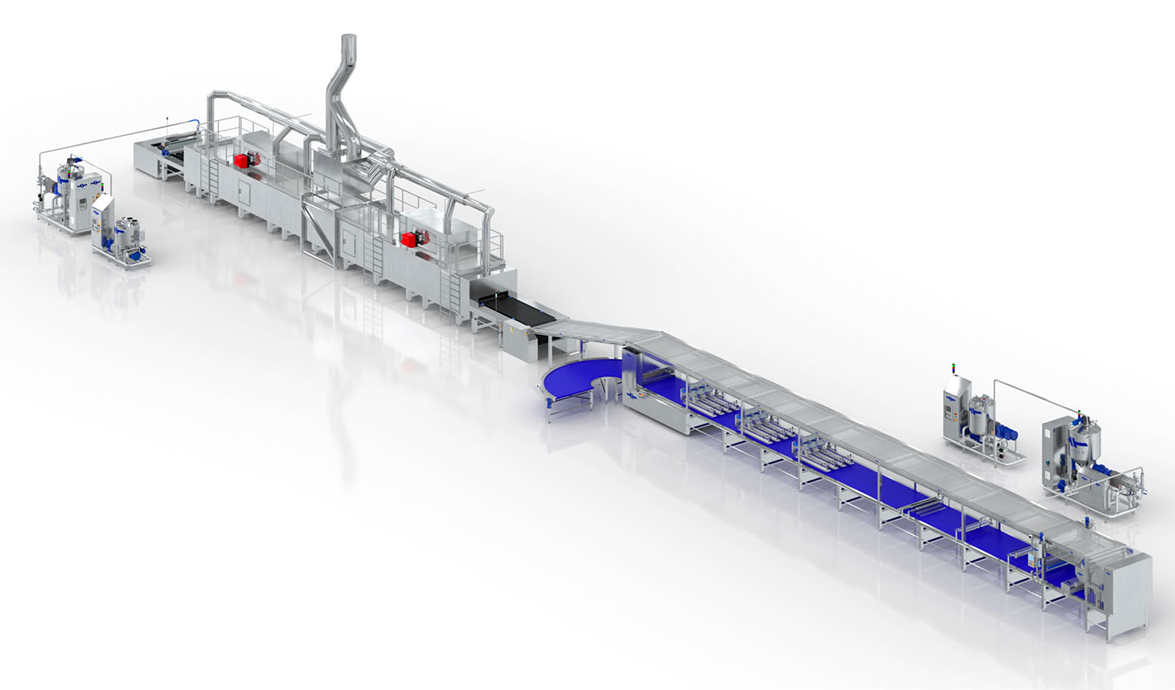

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

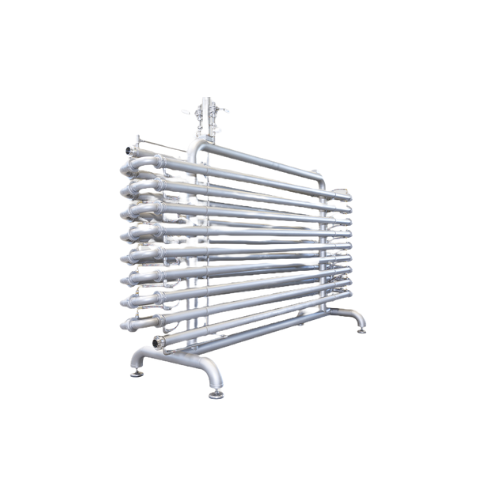

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Chocolate tempering quality analyzer

Ensure your chocolate’s tempering precision with a device that accurately assess...

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Chocolate block flaking solution

Enhance your confectionery production with versatile flaking capabilities, perfect for crea...

Heating cabinets for chocolate processing

Optimize your confectionery production by maintaining precise temperature contro...

Chocolate melting trays for small-scale applications

Efficiently melt chocolate with precision and ease using compact, el...

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

Double spinning machine for hollow chocolate figures

Achieve perfect distribution of chocolate in molds with precision sp...

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

Cooling tunnel for biscuits and chocolates

Ensure product quality and consistency with precision-controlled cooling tunnel...

Industrial chocolate flaking solution

Optimize your confectionery production with high-speed flaking technology, ensuring p...

Melting and mixing kettles for chocolate production

Achieve consistent melting and mixing of chocolates, butter, and jams...

Continuous tempering machine for chocolate production

Streamline your chocolate production with precise tempering, ensuri...

Chocolate transport system for feeding and packaging

Enhance your chocolate production with a versatile transport system ...

Industrial chocolate flakes production equipment for decorative applications

Achieve perfect decorative chocolate curl...

Modular system for chocolate drops production

Enhance your chocolate production with a versatile machine that forms and co...

Nuts dosing system for chocolate drops

Effortlessly create consistently accurate chocolate-covered nut products with precis...

Coating solution for nuts and dried fruits

Easily apply multiple layers of chocolate to nuts, coffee beans, and more, achi...

Continuous cooler for biscuits and chocolates

Enhance cooling efficiency for your confectionery and bakery production with...

Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities wit...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

Hollow chocolate figure spinning solution

Achieve uniform chocolate coating in hollow figurines with precision spinning te...

Compact chocolate tempering solution

Enhance your chocolate products’ finish and efficiency: this compact solution en...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Cooling tunnel for industrial pre-cooling

Efficiently reduce product temperatures with this custom-designed air cooling tu...

Batch tempering solution for chocolate production

Achieve precise temperature control for chocolate consistency and quali...

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

Industrial chocolate flaking system

Achieve precise chocolate flake dimensions effortlessly, enhancing product textures and...

Double heating cabinet for melting and preheating chocolate

Optimize space while ensuring precise temperature control fo...

Electric melting tray for small-scale chocolate applications

Effortlessly melt and prepare chocolate with precision and ...

Buttercream filling applicator for chocolates

Enhance your confectionery process with precision dosing and moulding to cre...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Dosing system for chocolate tablets

Enhance your confectionery production with a versatile solution for precise dosing and ...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

Chocolate flake production system

Streamline your production line with our adjustable machine for versatile chocolate flake...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Curl flaking machine for chocolate production

Achieve precise chocolate curl production with adjustable flake thickness an...

Linear belt vibratory weigh filler for solid chocolate

Optimize your chocolate production by minimizing product giveaway ...

Bulk box filler for bakery and pastry products

Efficiently pack fragile bakery and pastry products with gentle handling an...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Vertical fill and seal bagging machine for bakery products

Streamline your bakery product packaging with this versatile ...

Compact palletizing solution for limited space

Optimize your space with versatile palletizing that adapts to diverse produ...

Impact classifier mill for fine grinding of brittle materials

Achieve precise particle size distribution with advanced g...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

Pastry depositor for versatile product shapes

Enhance your bakery’s production with a versatile depositor that effor...

Rotating nozzle depositor for pastry production

Optimize your pastry production with precise dosing and shaping capabiliti...

Co-extruder for filled sweet and savoury products

Effortlessly create a variety of filled sweet and savoury products, fro...

Fat melting tank for confectionery production

Melt solid fat blocks efficiently to streamline your caramel, nougat, and ch...

Fat slurry homogenization mill for chocolate processing

Achieve precise chocolate and confectionery homogenization with e...

Invert sugar and glucose storage tank

Optimize your sweet and confectionery production by efficiently storing and resting g...

Chocolate and bakery fermentation unit

Achieve consistent quality and flavor in chocolate and bakery products with precisio...

Condensed milk preparation system

Enhance the quality of your dairy-based products with a system designed for efficient mix...

Pressurized buffer tank for aerated products storage

Ensure consistent aeration and product quality with this pressurized...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Cup filling system for jars and buckets

Optimize your confectionery and bakery filling processes with this high-speed cup f...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

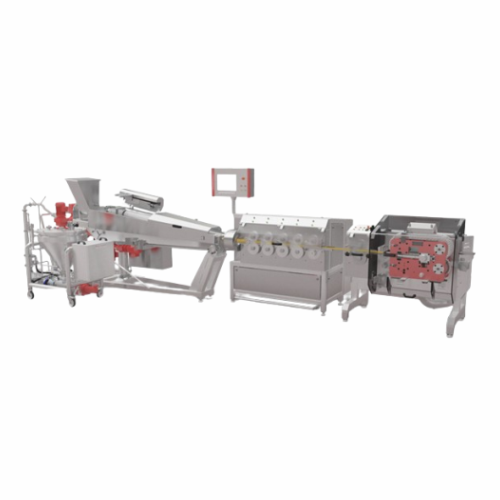

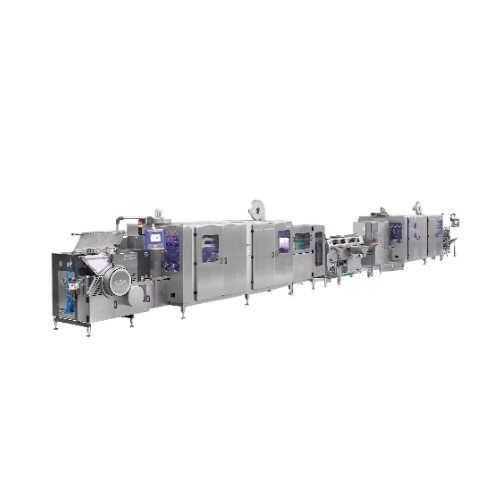

Soft candy production line

Optimize your candy production with a versatile line that efficiently handles everything from car...

Automatic chocolate feeding conveyor

Efficiently connect your chocolate production to wrapping stages with this high-speed ...

Chocolate wrapping machine for confectionery production

Achieve precision and elegance in packaging with high-speed wrapp...

Jelly and chocolate ball wrapping solution

Efficiently wrap jelly candies and chocolate balls with precision and high spee...

Chocolate storage tank

Optimize your chocolate production with seamless storage solutions that ensure consistent quality and ...

Chocolate tempering solution for industrial production

Achieve consistent chocolate crystallization with a machine that e...

Conching solution for chocolate processing

Achieve optimal chocolate texture and flavor by ensuring efficient conching, cr...

Continuous chocolate mill

Enhance the texture and quality of your chocolate products with this high-speed milling solution, ...

Industrial fat melting tank for bakery and chocolate production

Efficiently melt solid fats to precise temperatures with...

Laboratory type ball mill for chocolate and bakery applications

Optimize your R&D processes with precise grinding a...

Industrial sugar powder mill

Achieve precise sugar granulation with a high-speed mill designed for continuous production, en...

High viscosity material mixer for bakery and chocolate

Efficiently mix and knead high-viscosity materials for premium cho...

Automatic chocolate shell moulding line

Enhance your production capabilities with a cutting-edge moulding line that deliver...

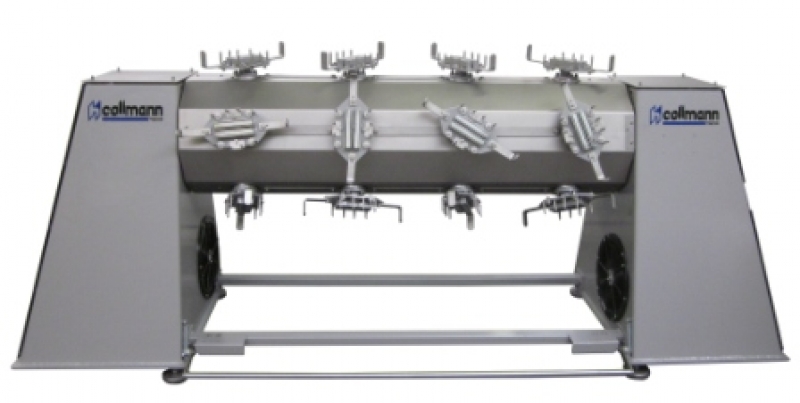

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Chocolate moulding press for coco mass

Enhance your production line with precise chocolate moulding capabilities, shaping e...

Chocolate cooling tunnel

Enhance your confectionery production with efficient cooling and precise crystallization, critical f...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

Chocolate ball mill for processing chocolate mass

Enhance your confectionery production with precision mixing and uniform...

Conical rounder for bakery products

Optimize your dough handling process with efficient shaping solutions, ensuring consist...

Industrial chocolate and dough sheeter

Streamline your chocolate and pastry production with robust dough sheeting and rolli...

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

Industrial bakery oven with proofing cabinet

Optimize your bakery production with an all-in-one solution that seamlessly i...

Sesame seed roaster

Achieve consistently roasted sesame seeds and nuts with optimal moisture control, designed to enhance fla...

Nut dicing machine

Efficiently transform whole nuts into uniform cubes with precision cutting technology, ideal for creators ...

Cooling system for heat-treated products

Efficiently reduce temperatures of high-heat products to protect quality and textu...

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Spiral oven for cooking plant-based and conventional products

Achieve perfectly cooked products every time with advanced...

Inline chocolate filter for large particle removal

Ensure the purity and consistency of your chocolate products by effici...

Laboratory refiner/conche for chocolate processing

For chocolate producers seeking precise control over texture and flavo...

Commercial chocolate refiner/conche

Elevate your chocolate production with a versatile 5-in-1 solution, integrating cocoa m...

Chocolate refiner/conche system

Streamline your chocolate production with a versatile solution that combines grinding, mixin...

Artisan line for fine chocolate mass production

Transform raw cocoa beans into exquisite chocolate through precise control...

Cocoa butter and cocoa liquor melting unit

Optimize your chocolate production with a unit designed for efficient melting a...

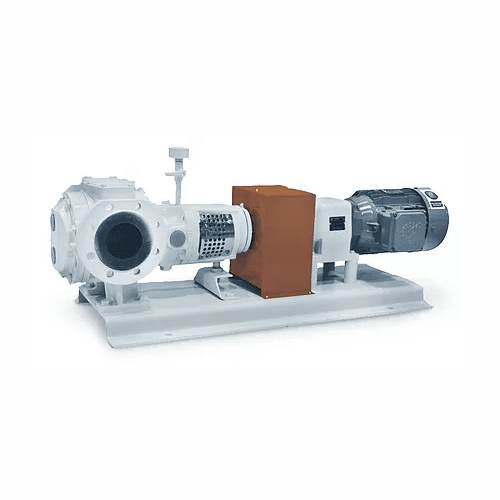

Chocolate pump for confectionery production

Effortlessly pump and convey a range of chocolate-based products with precisio...

Chocolate storage tank for large-scale manufacturing

Enhance your chocolate production line with a storage system designe...

Top-loading cartoner for bar and confectionery packaging

Optimize your high-speed packaging operations with a flexible ca...

Horizontal flow wrap solution for chocolate bars

Achieve high-speed precision in packaging with a machine designed to hand...

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

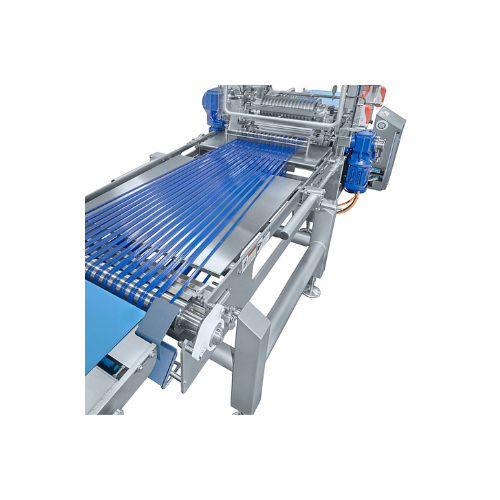

High speed rolling line for confectionery production

Enhance your confectionery production with a versatile rolling line ...

Rotationally symmetric product rolling machine

Achieve precision shaping of chocolate balls, candy drops, and more with ou...

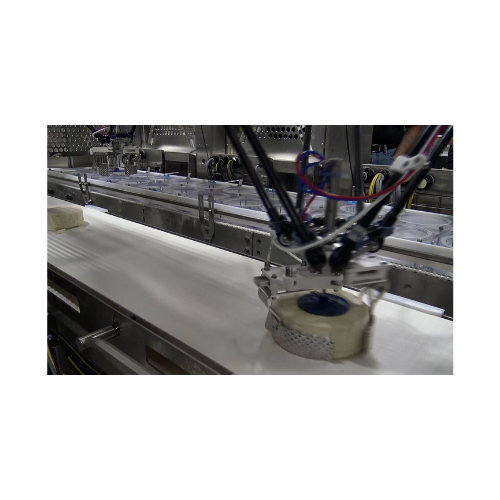

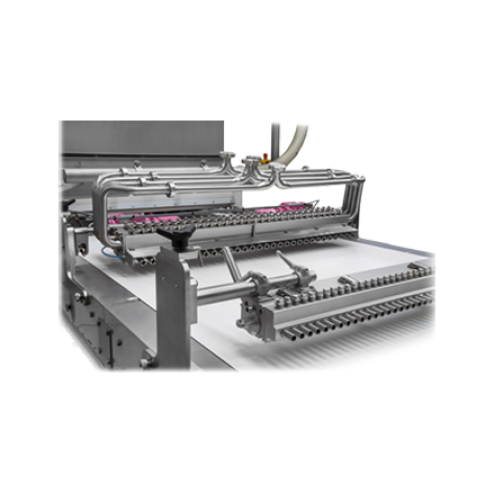

Pick and place robotic system for confectionery decoration

For food producers seeking precision in snack decoration, thi...

Entry-level food packaging machine for pillow bags

Achieve space-saving packaging versatility with a machine designed for...

Jam kettle for preserve and marmalade production

Ensure consistent flavor and texture in your jams and marmalades with pre...

Extruder for pliable mixes in industrial applications

Achieve precision in creating diverse extruded food products with t...

Laboratory mill for dry sample preparation

Achieve precise particle size reduction for pharmaceuticals and fine chemicals ...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Horizontal cartoning solution for pharmaceutical packaging

Streamline your confectionery packaging with high-speed, cont...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

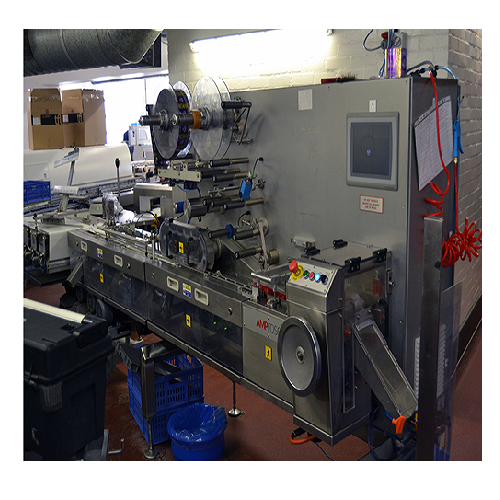

Horizontal form fill and seal for biscuits on edge

Optimize your packaging line with a machine that streamlines wrapping ...

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrappin...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

High-speed overwrapping for display boxes

Achieve seamless overwrapping of display boxes with ultra-high-speed capabilitie...

Stand-up pouch making system

Efficiently transform pre-printed reels into customizable stand-up pouches with precise unwindi...

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

Flow wrapper for high-speed confectionery packaging

Achieve gentle, high-speed packaging for delicate confectionery items...

Flow wrapping system for hygienic food packaging

Enhance your packaging line with a modular flow wrapping solution that en...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Overwrapping solution for medium size display boxes

Streamline your packaging line with high-speed, continuous overwrappi...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Intermittent motion cartoner for confectionery packaging

For manufacturers needing versatile packaging solutions, this ca...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

High-speed flow wrapper for candies and gums

Achieve top-speed packaging with unparalleled flexibility for diverse confect...

Gum slabs flow wrapping solution

Streamline your confectionery production with precision-engineered portioning and wrapping,...

High-speed cut & wrap flow wrapping for confectionery

Experience efficient packaging with high-speed flow wrapping techno...

Flow wrapping for bulk confectionery products

Efficiently orient, feed, and wrap bulk confectionery items with seamless in...

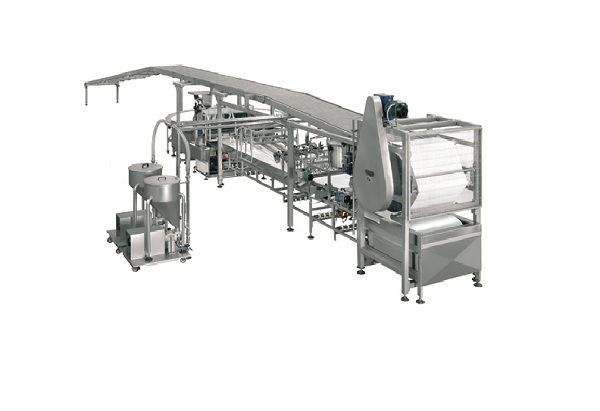

Automatic wafer batter preparation system

Optimize wafer production with precision dosing and homogeneous mixing, ensuring...

Cream preparation plant for wafer production

Achieve consistent cream texture and optimal weight for perfect wafer product...

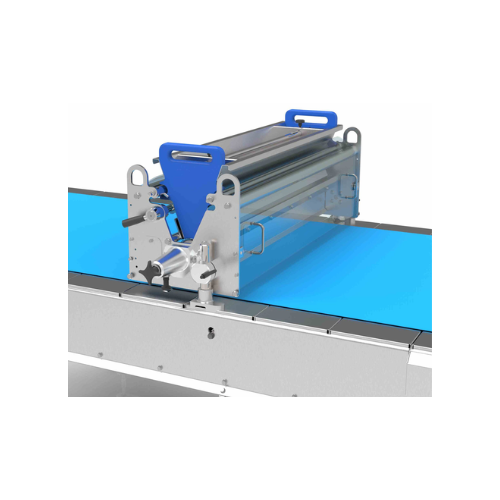

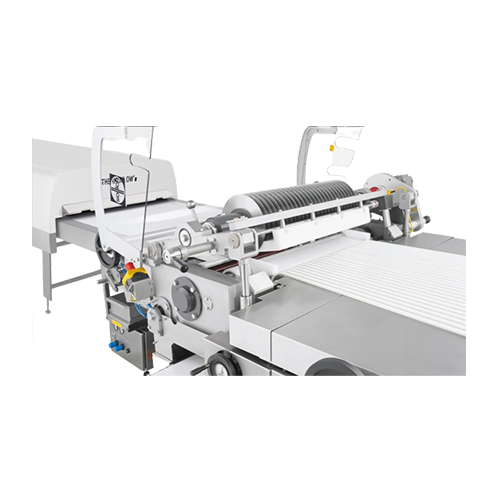

Wafer sheet cream application system

Achieve precision in cream application with high-capacity, continuous film spreading, ...

Hollow wafer spreading machine for consistent coating

Optimize your snack production with precise spreading—achieve unifo...

Semi-automatic batter preparation plant for wafer production

Enhance your wafer production with a versatile system desig...

Spiral wafer sandwich cooler for consistent cooling

Ensure precise temperature control and optimal firmness for wafer san...

Cooling drum for seasoned extrudates

Ensure consistent texture and quality in your extruded snacks by effectively cooling s...

Cream preparation plant for homogeneous mixing

Optimize your snack production with precise mixing technology, ensuring con...

Seasoning drum for extruded snack products

Achieve consistent seasoning and mixing for extruded snacks with precision and ...

Continuous extruded snack dyeing system

Enhance the aesthetics of your extruded snacks with precise and continuous dyeing, ...

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

Roller embossing system for snack production

Effortlessly shape and press multiple product strands into diverse, precise f...

Seasoning mixing system for extruded snacks

Achieve consistent flavor profiles in your extruded snacks with this high-spee...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Cocoa pressing plant for high-capacity cocoa liquor processing

Optimize your cocoa processing by converting cocoa liquor...

Batch cooker for confectionery production

Achieve consistent confectionery texture and flavor with a flexible cooking solu...

Chocolate refiner and conche solution

Elevate your chocolate production with a versatile solution that seamlessly integrate...

Chocolate refining five-roll refiner

Achieve optimal chocolate texture with high-efficiency refining, reducing energy usage...

Cocoa nib grinding system

Optimize your cocoa and nut processing with precision grinding to achieve a pumpable mass, ensurin...

Spindle mill for fine and super fine grinding of cocoa liquor

Achieve precision in grinding cocoa liquor and nut pastes ...

Caramelization system for industrial confectionery production

Achieve precise caramelization and cooking of sensitive co...

Adjustable weighing system for raw materials

Optimize your confectionery and nutraceutical production with precise weighin...

Pre-cooking and final cooking for candy production

Optimize your candy production with a versatile cooker designed to han...

Continuous production fondant beater

Achieve consistent fondant quality by gently controlling crystallization and temperatu...

Dosing unit for automated mixing in of ingredients

Achieve precise ingredient integration for confectionery and nutraceut...

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Batch-wise cooking and aerating system for aerated candies

When producing aerated candies, achieving uniform texture and...

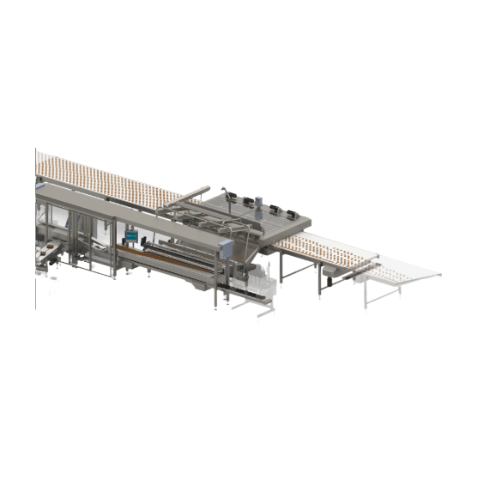

Hard candy forming line for manufacturing

Experience seamless candy production with advanced forming technology, ensuring ...

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

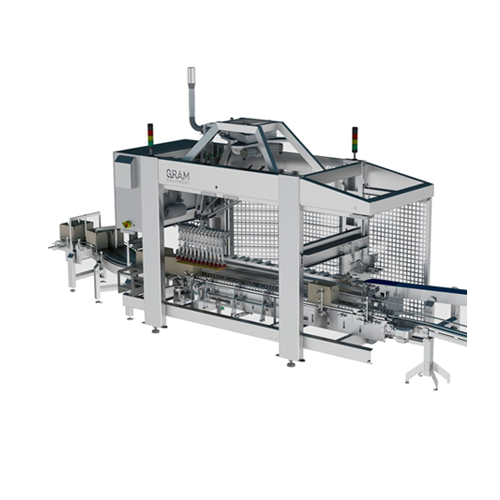

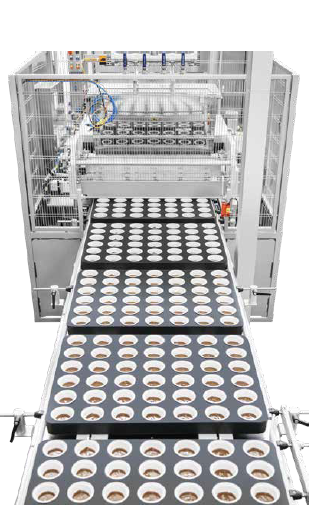

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small ...

Oil coater for gummies

Optimize your gummy production with high-speed oil coating for consistent, flavorful finishes, ensurin...

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

Rapid gummy channel counter

Ensure accurate gummy counts and streamline your production process with a solution designed to ...

Sugar coating system for gummies

Achieve a flawless sugar coat on up to 240,000 gummies per hour, seamlessly integrating int...

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

Portable water activity meter for gummy production

Ensure consistent gummy quality and extended shelf life by precisely m...

Systems for processing confectionery rework

Optimize resource use and reduce waste by transforming confectionery rework in...

Gummy counter for gusseted bags

Optimize your gummy production line with precise counting and packaging into re-sealable gus...

Automatic gummy manufacturing system

Efficiently streamline your candy production with a system capable of producing up to ...

Small automatic gummy line

Streamline your gummy production with a compact system designed to deliver precision deposits and...

High-capacity gummy production system

Optimize your gummy production with a starchless system that deposits up to 240,000 g...

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for con...

Multi-lane ice cream wrapping system

Optimize your production line with a high-speed, multi-lane wrapping system designed t...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Continuous flow-wrapping system for high productivity

Optimize your packing line with a high-speed flow-wrapping system d...

Laboratory knife mill for fast comminution

Achieve rapid and precise sample preparation with this versatile knife mill, de...

Tablet coating system for aqueous, solvent, and sugar films

Achieve precision coating with flexible application capabili...

Industrial sugar sander for confectionery coating

Enhance product appeal and longevity with a sugar sander designed to un...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

Extrusion system for color changing confectionery strands

Easily switch colors in confectionery strands mid-production, ...

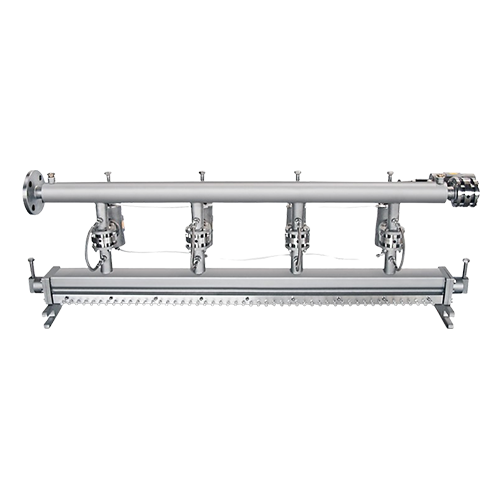

High precision dosing system for color, flavor, and acid

Achieve precision and reliability in dosing color, flavor, and a...

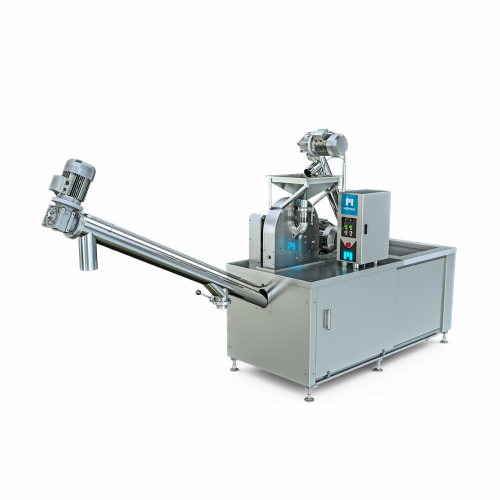

Confectionery forming extruders for viscous masses

Efficiently transform viscous ingredients into uniform, high-quality c...

Lab cooking and forming extruders for r&d

Optimize your R&D processes by testing new recipes and improving formulatio...

Screen changer for extrusion lines

Prevent clogs and maintain quality with this screen changer, designed to filter out soli...

Slurry preparation for licorice production

Ensure a continuous and homogeneous feed of licorice slurry to your extruder, o...

Caramel cooking solution

Optimize your confectionery production with precise mixing, dissolving, and heat transfer technologi...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Biscuit depositing system for two-color biscuits

Enhance your bakery line’s efficiency with a high-speed depositing ...

Horizontal flow pack packaging solution

Achieve seamless packaging with versatile flow pack machines, designed to efficient...

Flow pack packaging solution for flexible wrapping material

Optimize your packaging line with this compact flow pack sol...

Horizontal flow pack packaging machine for multi-format packaging

Streamline your packaging process with a versatile ho...

Biscuit depositing system

Optimize your biscuit production with a high-speed depositing system designed for continuous opera...

Flow pack packaging system for flexible wrapping material

Achieve seamless, high-speed packaging of solid foods with thr...

Horizontal packaging system for high-speed operations

Achieve unmatched sealing precision and packaging speed with this h...

Flow pack packaging for irregularly shaped products

Achieve precise packaging for irregularly shaped and delicate items w...

Horizontal flow-pack solution for flexible wrapping material

Simplify your packaging process with a high-speed, three-si...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Three-side sealing packaging machine

Achieve precise, three-side sealed packaging for both food and non-food products, enha...

Cooker for nougat and hard mixtures

Optimize the production of high-density mixtures like nougat and meat sauces with this ...

Planetary cooker for medium-high density mixtures

Achieve smooth, consistent textures with a planetary cooker designed fo...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Static checkweigher for accurate measurement

For those needing unparalleled precision, this static checkweigher ensures ex...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Counting system for tablets and capsules

Effortlessly count a variety of tablets, capsules, and dragées with precision, ens...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

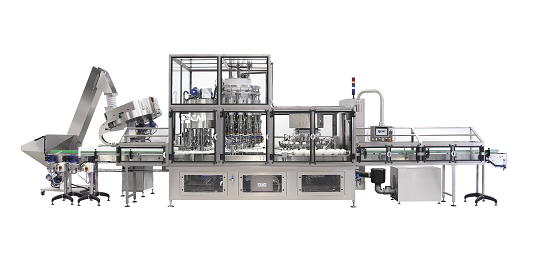

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Industrial chocolate tempering belt

Achieve precise mass tempering for diverse confectionery textures with a stainless-stee...

Continuous cooking system for jelly and marshmallow production

Elevate your confectionery production with a system desig...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Continuous caramel cooker for candy production

Achieve perfect caramel consistency with precise control as this solution c...

Static cooler for jelly and foam manufacturing

Ensure the integrity of your confectionery with a cooling system designed f...

Crystallization process for chewy candy production

Optimize your confectionery production with precision crystallization,...

Fondant mass production system

Achieve precise crystal size and uniform fondant quality with a two-step crystallization proc...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

High shear mixer system for hydrocolloids

Streamline your confectionery production with a high-shear mixer designed for pr...

Aerator for candy masses

Enhance your candy production with precise and efficient aeration, transforming textures and creatin...

Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed ...

Aeration system for sugar masses

Optimize your production of aerated confectioneries with a two-step aeration system designe...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

Continuous butter toffee processing system

Achieve precise caramelization and nut integration while maintaining the perfec...

Industrial sugar melter

Efficiently melt and mix sugar with precision using a gas-fired batch cooker designed for optimal hea...

High-speed packaging system for flow-wrapping

Streamline your packaging operations with a high-speed flow-wrapping solutio...

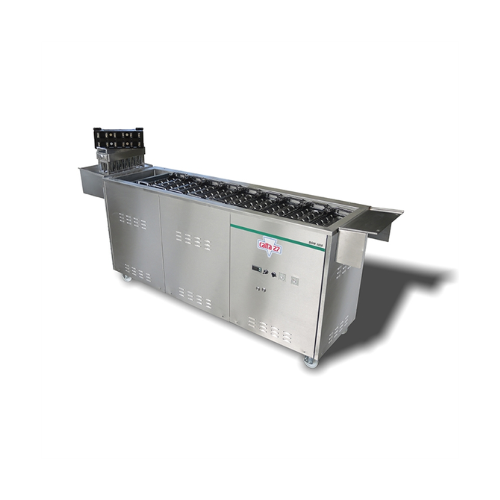

Hardening tank for water-ice lollies

Enhance your small-scale ice cream production with a versatile solution that allows yo...

Pilot plant for ice cream production

Optimize your ice cream production with a flexible pilot plant that seamlessly integra...

Preforming line for candy rope production

Achieve consistent sugar ropes and lollipop centers with precise forming and siz...

Stickpack wrapper for lollipops

Enhance your confectionery line’s efficiency by wrapping up to 480 lollipops per minut...

Industrial cooling tunnel for bubble gum and toffee

Ensure your confectionery maintains its shape and quality with high-p...

High-speed cut and wrap solution for confectionery products

Achieve seamless integration in your confectionery productio...

Flow wrapper for lollipops packaging

Achieve precise and high-speed lollipop packaging with continuous-motion flow wrapping...

Double sigma kneader for viscous product mixing

Optimize the mixing and kneading of high-viscosity products with our doubl...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

High precision lollipop cooling system

Ensure your lollipops maintain their shape and quality with precision cooling, reduc...

Continuous lollipop forming system

Refine your confectionery production with a high-speed forming system that creates diver...

4-sides seal wrapping for lollipops

For lollipop producers seeking precision and efficiency, this 4-sides seal wrapper ensu...

Ball former for bubble-gum and soft candy production

Achieve precise ball forming for bubble gum and soft candies with cu...

Bunch wrapper for lollipops

Achieve precise and efficient single twist wrapping for ball and 3D lollipops with high-speed ca...

Nut and seed pre-grinder

When dealing with high-fat roasted nuts and seeds, achieving optimal particle size distribution can ...

Pre-grinder for roasted nuts and seeds

Maximize efficiency in creating smooth nut and seed spreads with this pre-grinding s...

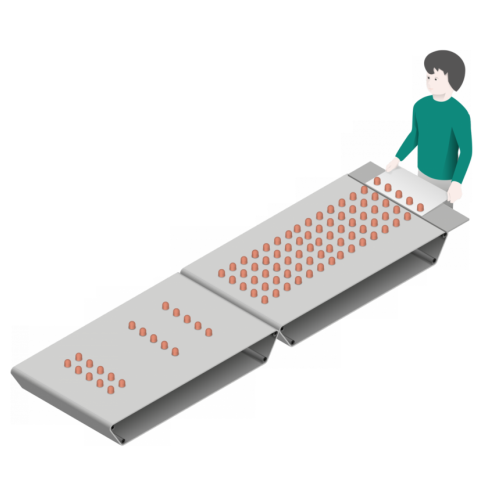

Drying trays for gummy candy production

Ensure proper drying and setting of your gummy candies and gelatin-based products w...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

Dissolving tilt kettle for gummy candy production

Optimize your gummy candy production by melting and dissolving ingredie...

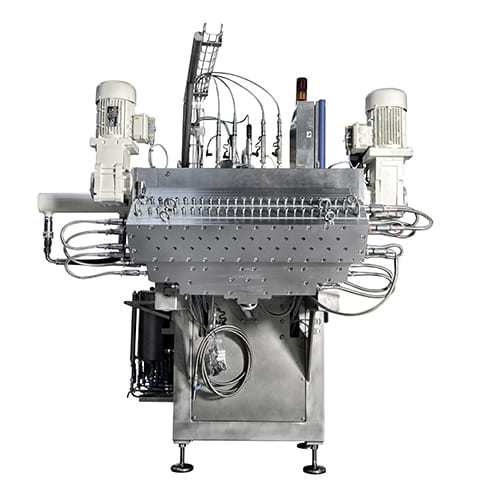

Gummy candy depositor for precision manufacturing

Achieve consistent gummy size and shape while maintaining precise weigh...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

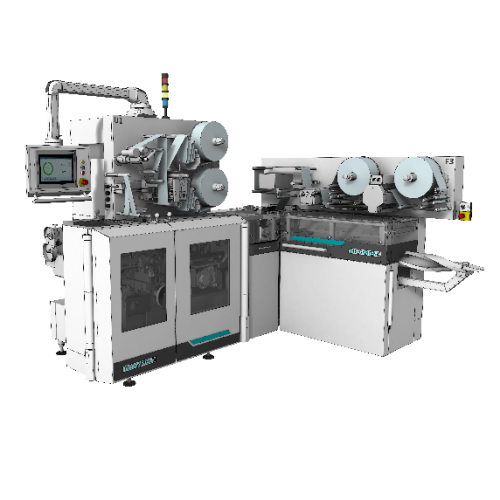

High speed blister packaging for pharmaceuticals

Need efficient packaging with quick format changeovers for various capsul...

High speed horizontal cartoner for pharmaceuticals

Ideal for high-speed cartoning tasks, this equipment ensures efficient...

High-speed continuous motion overwrapper for thin films

For those needing high-speed, efficient wrapping, this equipment ...

Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly fo...

High-speed continuous motion horizontal cartoner

Achieve seamless high-speed cartoning with precision cartoner systems des...

Biscuit overwrapper for x-fold or hermetic sealing

Ensure each biscuit, cookie, and sweet treat is securely wrapped and s...

High speed stick packaging solution

Optimize your packaging line with this high-speed vertical solution, designed to effici...

Intermittent motion overwrapper for cosmetic and food products

Achieve flawless packaging with precision wrapping and se...

Industrial manju cake production system

Transform traditional treats into innovative 3D cakes with precise filling and perf...

Industrial sandwich pancake system

Streamline your production with a machine that seamlessly integrates baking, filling, pr...

Enrober for complete dry topping coverage on dough pieces

Ensure consistent, high-speed enrobing of dry toppings on doug...

Lidding system for cups and trays

Enhance your packaging line with precise, space-saving lidding technology, ideal for seal...

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and ...

Colorful marshmallow extrusion for confectionery production

Elevate your confectionery offerings with a high-speed extru...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Biscuit wire cutter and depositor for confectionery production

Streamline your production of intricately designed cookie...

Batch cooker for confectioneries

Achieve consistent texture and flavor in every batch with this precision-driven cooker desi...

Compact batter mixing system

For food producers aiming to ensure consistent batter quality, this modular system streamlines ...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Turbo cream mixer for fat cream production

Achieve consistent and homogeneous cream fillings quickly with this advanced hi...

Hollow wafer film-spreading machine for confectionery

Achieve precise and uniform cream distribution on hollow wafer shee...

Double-overthrow conche for chocolate production

Achieve precise taste and texture in chocolate production with reduced en...

Wafer acceleration belt for chocolate enrobing

Optimize your confectionery production with precise wafer separation and al...

Automatic sleeving for rolled and molded cones

Optimize your cone production line with precision sleeving and reliable det...

Continuous wafer oven

Optimize your wafer production with precise temperature control and efficient energy use, minimizing ga...

Chocolate enrober for bars, cookies, and wafers

Ensure consistent and high-quality enrobing for confections with advanced ...

Advanced enrobing line for confectionery

For confectionery producers seeking seamless chocolate coating versatility, our en...

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Wafer block cutter

Optimize your confectionery production with precision cutting technology that transforms wafer blocks into...

Cocoa nibs and malt roasting system

Enhance your flavor profile with precise roasting, sterilization, and taste control cap...

Industrial recirculating chiller for laboratory applications

For consistent distillation results, maintain accurate temp...

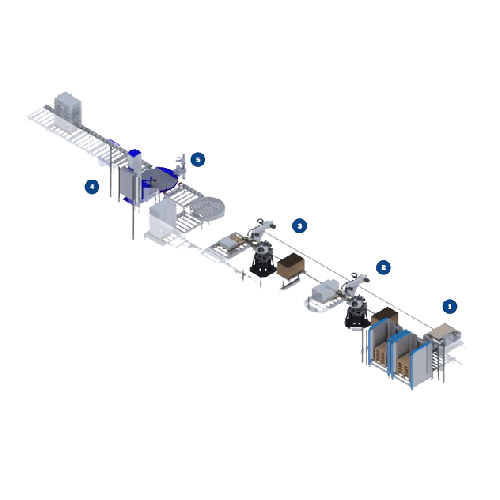

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Lab-scale twin screw extruders for material development

Accelerate your formulation testing and material development with...

Lab-scale extruders for material development

Optimize your lab and pilot-scale extrusion processes with advanced material ...

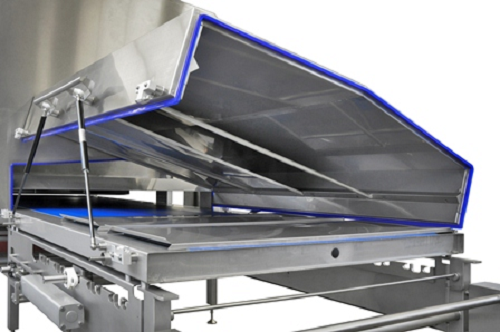

Chestnut candying system

Optimize your candying process with a modular system that enhances syrup distribution and concentrat...

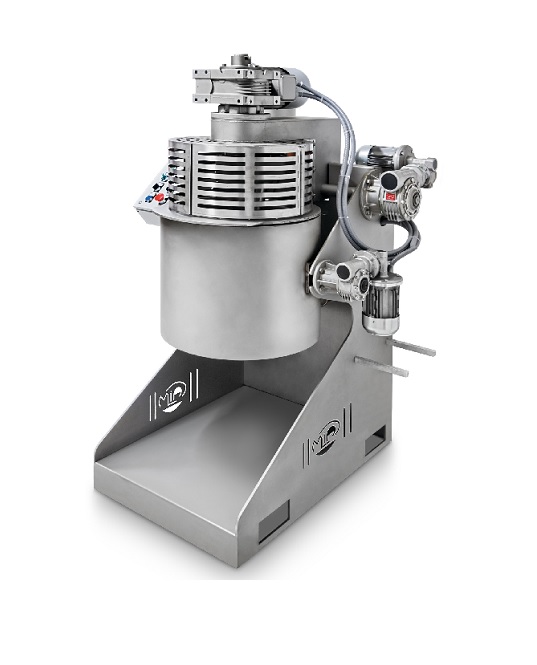

Centrifugal separator for reworking chocolate and chopped hazelnuts

Efficiently separate chocolate from chopped hazelnu...

Vision-guided variety pack solution for confectioneries

Achieve seamless variety pack assembly by dynamically loading var...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

Multifunctional dessert line for layered dessert production

Effortlessly create complex, multi-layer desserts or meal co...

Industrial cream whipping machine

Elevate your production with a whipping machine that amplifies cream volume by up to 50%,...

Precise weighing solutions for small batch production

Streamline handling of diverse ingredient blends with precise dosin...

Contamination-free docking system for bulk solids

Achieve contamination-free transfer of bulk powders and granules while ...

Combi x-ray inspection and checkweighing for small products

Optimize your production line’s quality control with a...

Combi x-ray and checkweigher for vertical products

Ensure precise weight control and contamination detection for vertical...

Integrated metal detector and checkweigher for small/medium formats

Ensure precise quality control and contaminant-free...

Icebox cookies extrusion solution

Streamline your cookie production with a solution that efficiently extrudes, shapes, refr...

Spring roll production line

Efficiently produce diverse spring rolls with a machine that optimizes filling and wrapping, str...

Automatic stamping and aligning system for mooncakes

Elevate your snack production with precision stamping and aligning, ...

Automatic filming and pressing solution for dough products

Streamline your dough processing with this pressing and filmi...

Pita bread production system

Streamline flatbread production by reducing dough resting time with a layered resting conveyor ...

Automatic rounding conveyor for food production

Effortlessly transform diverse food products into uniform spherical shapes...

Vietnamese rice paper spring roll production system

Efficiently transform rice papers into delicious spring rolls with a ...

Continuous-type sealing solution for food packaging

Enhance your food production line with efficient sealing technology, ...

Submerging batter breading machine for thicker batter coating

Ensure even coating for your specialty foods with this sub...

Automatic table-type encrusting and forming machine for diverse ethnic foods

Optimize your food production with a comp...

Industrial stir fryer for food production

Maximize cooking efficiency with a multi-function stir fryer that excels in cont...

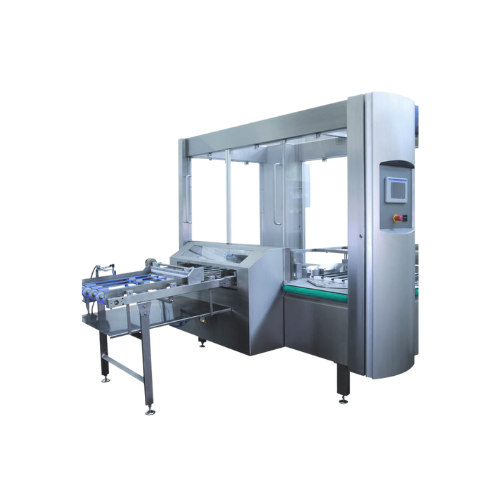

Automatic horizontal cake slicer

Achieve uniform, precise slices with double-blade vibration technology, ensuring each cake ...

Customized puff pastry production line

Streamline your pastry production process with this customizable solution, capable o...

Empanada production line

Streamline your snack and pastry production with a compact solution that seamlessly integrates filli...

Automatic cutting and rounding solution for tapioca products

Optimize your production of tapioca pearls, tang yuan, and ...

Multipurpose filling and forming solutions for dumplings

Enhance your food production with versatile equipment that trans...

Automatic aligning and rack loading solution for xiao long bao production

Improve efficiency in food production by sea...

Stir fryer for industrial food production

Streamline your culinary operations with this innovative stir fryer, designed to...

Automated blini production line

Enhance your food production efficiency with a blini solution that combines precise filling,...

Burrito forming equipment

Streamline your burrito production by automating the delicate tasks of filling, folding, and wrapp...

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

Chocolate chip depositor for small scale production

Achieve precise chocolate chip production with consistent size and we...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Wrapper for flat bottomed chocolate articles

Optimize your confectionery packaging with a machine designed for swift, secu...

Neapolitan chocolate wrapping solution

Efficiently wrap and label square chocolates with this fold wrap solution, ideal for...

Pillow bag horizontal form-fill-seal solution

Optimize production efficiency with seamless integration of continuous, high...

Candy rope sizer

Ensure precision in candy production by seamlessly reducing and sizing candy ropes for uniformity and quality...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Chocolate moulding line for filled and inclusions bars

Achieve seamless chocolate production with modular flexibility, al...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Double twist wrapping solution for candy packaging

Enhance your candy and gum production with high-speed wrapping that en...

Split peanut blancher for snack food processing

Efficiently transform roasted or dried peanuts into perfectly blanched pro...

Automatic popcorn ball forming equipment

Streamline your snack production with high-speed, precise popcorn ball forming tec...

Popcorn cooker/coater for caramel corn

Enhance your snack production efficiency with a versatile solution that combines coo...

Stoneless corn masa mill for snack food processing

Achieve consistent grinding precision while eliminating the hassle of ...

Spiral chute for gentle product handling in limited space

Optimize your snack and nut production by minimizing product d...

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

Lab-scale chocolate chip depositor

Enhance your R&D capabilities with precision depositing of chocolate masses, allowi...

Chocolate temper measurement device

Ensure your chocolate maintains optimal temper by measuring and analyzing the chocolate...

Cooling simulator for chocolate production optimization

Optimize your chocolate cooling processes and refine production s...

Laboratory roller for chocolate production

Easily switch between producing chocolate lentils, balls, and eggs with these f...

Chocolate enrober for large scale production

Efficiently enrobe a wide range of products, from chocolate bars to delicate ...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Compact extruder and depositor for confectionery and bakery production

Streamline your confectionery and bakery product...

Flexible depositor and extruder for small-scale production

Achieve precise multi-mass creations with a compact, versatil...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Depositor for aerated masses and fat fillings

Enhance your confectionery production with a depositor that precisely handle...

High-viscosity mass depositor

Efficiently deposit high-viscosity masses like caramel and jam with precision, while the integ...

Chocolate depositor for small to medium production

Optimize your confectionery production with a versatile depositor that...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Small scale chocolate enrober

Ideal for creative small-scale producers, this enrober allows you to experiment with chocolate...

Energy efficient enrober for chocolate coating

Enhance your production with energy-efficient enrobing that ensures precise...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Industrial chocolate enrober

Achieve exceptional chocolate coating consistency and efficiency with this advanced enrobing te...

Cooling unit for chocolate mass extrusion

Optimize your chocolate production by precisely cooling chocolate masses during ...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Cooling tunnel for chocolate and bakery products

Achieve precise cooling and crystallization for chocolate and confectione...

Rotating stencil depositor for confectionery products

Streamline your confectionery operations by precisely depositing in...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Robotic chocolate assortment system

Streamline your chocolate production by precisely assorting various filled chocolate ar...

Chocolate decoration stringer for bakery and confectionery

Elevate your confectionery creations with precision chocolate...

Double-shaft paddle mixer for homogeneous raw masses

Optimize your mixing efficiency with a dual-shaft system designed fo...

Direct discharge descender for product handling

Efficiently transport granulated materials without compromising their inte...

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Circular distribution feeder for fragile product handling

Achieve precise dosing and reduced product damage with a versa...

Tempura coating system for food processing

Achieve consistent and efficient tempura coating with a versatile system that s...

Industrial food processing fryer

Ensure consistent frying quality and enhanced sediment removal for high-volume food product...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Lollipop forming system for various shapes

Create perfectly shaped lollipops with precise control over size and design whi...

High-capacity lollipop former

Effortlessly boost your confectionery operation with a high-capacity forming machine designed ...

Lollipop forming and wrapping solution

Streamline your confectionery production with this innovative system designed to eff...

Continuous cooling system for ball lollipops

Ensure perfect shape retention and quality of ball lollipops with this contin...

High-speed lollipop wrapping solution

Achieve unrivaled speed and efficiency in lollipop packaging with a continuous wrappi...

Coated lollipop production line

Transform your confectionery line with a solution that forms, cools, and coats 3D lollipops ...

Flat lollipop forming and wrapping system

Enhance your candy production with precision-engineered lollipop forming and wra...

Continuous flat lollipop cooling system

Ensure your lollipops retain perfect shape and quality with this high-speed cooling...

Lollipop wrapping solution

Ensure precision and faster production with a high-speed wrapping solution that adapts seamlessly...

Advanced lollipop forming system

Craft diverse lollipop shapes with precision and efficiency, reducing downtime with rapid c...

Product distribution system for multiple stencil creamers

Facilitate seamless product flow distribution across multiple ...

Product distribution system for large capacity wrappers

Optimize your high-speed production lines by efficiently distribu...

Robotic pick and place system for cookies

Streamline your bakery production with a flexible robotic system that seamlessly...

Biscuit slug loading system

Enhance your confectionery line with high-speed, precise slug loading that integrates seamlessly...

Chicane system for portion pack flowrapper

Streamline your packaging process with a system that ensures precise portioning...

Cooling system for post-baking stabilization

Optimize your production line by integrating a cooling system that ensures po...

Vision-based product inspection system for rejecting defective items

Enhance your production line efficiency by ensurin...

Product manipulation and stacking systems

Efficiently transition products from flat to stacked on a conveyor while minimiz...

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and ...

Tray buffering system for downstream absorption

Handle production line disruptions effortlessly by temporarily absorbing t...

Sandwich and biscuit depositing system

Achieve high-capacity sandwich and biscuit production while maintaining precision wi...

High-volume product distribution system

Efficiently manage high-volume snack and confectionery production flows with a syst...

Laned product distribution for high-capacity wrappers

Efficiently distribute high-capacity product flow across multiple w...

Large production autoclaves for laboratory and pharmaceutical use

Enhance your production line with our large autoclave...

Automated material flow system for starch processing

Streamline the handling of powdered starches with precise dosing, mi...

Donut glazing system for rapid production

Streamline your bakery operations with a compact system that thaws and glazes do...

Industrial deep fryer for high-volume donuts

Streamline your high-volume pastry production with an advanced fryer system d...

Industrial donut fryer for high output and customization

Enhance your donut and pastry production efficiency with a custo...

Continuous deep fryer for catering

Achieve consistent frying results while reducing fat absorption and frying time, perfect...

Continuous deep fryer for consistent and efficient frying

Streamline your frying processes with this innovative continuo...

Continuous open kettle fryer for donut production

Effortlessly produce high-quality donuts with precise temperature contr...

Industrial fryer for donuts and ball donuts

Maximize your deep-fried pastry output with precise control over frying condit...

Stick press for pretzel and biscuit production

Transform your snack production with a versatile solution that presses, fil...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Industrial stativ mixer with adjustable height

Achieve precise mixing and stirring across diverse batches with a mobile, a...

Industrial tank mixer for high-volume containers

Optimize your mixing processes with a robust solution designed for high-v...

Mobile stainless steel tank agitator for various industries

Optimize liquid blending processes with this mobile tank agi...

Laboratory stirrer for high-viscosity materials

Streamline your laboratory mixing processes with a powerful stirrer design...

Industrial container mixing system for high viscosity media

Effortlessly blend high-viscosity liquids and slurries with ...

Drum blender for closed barrels

Efficiently mix liquids and slurries inside closed drums with a specialized agitator designe...

High-performance stirrer for open drums

Effortlessly homogenize high-viscosity liquids and slurries right in their storage ...

Industrial mixer for facade paint and plaster

Optimize your facade paint and plaster production with this mixer designed f...

Semi-automatic stands blender for facade paints

Optimize your paint production with a versatile stirring system designed f...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Conveyor belts for hot and cold product handling

Efficiently transport hot and cold goods with versatile conveyor solution...

Industrial pressing system for convenience food

Optimize your production line with a versatile pressing system, designed t...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Slicer for food processing applications

Efficiently achieve precise cuts and textures for a variety of food products, enhan...

Industrial food processor for diverse applications

Optimize your production line with a versatile processor capable of ch...

High performance dicer for fruits and vegetables

Optimize your food processing line with this versatile dicer, specificall...

Industrial dicer for small to intermediate size ranges

Boost your production capacity with a versatile dicing solution th...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Single piston food filler

Achieve precise portioning and consistent product flow with a versatile solution perfect for handl...

Multi piston depositors for high-volume baking production

Optimize your high-speed production line with precision deposi...

Cake and pastry enrobing system

Enhance your bakery production line with seamless enrobing and icing capabilities, ensuring ...

Servo multi-piston depositor for bakeries

Achieve precision and consistency in baked goods production with this solution, ...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Automated icing system for cakes

Efficiently layer, fill, and ice various cake types with precision and speed, securing cons...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

Flow pack wrapper for shrink and film wrapping

Optimize your packaging operations with a versatile solution capable of hig...