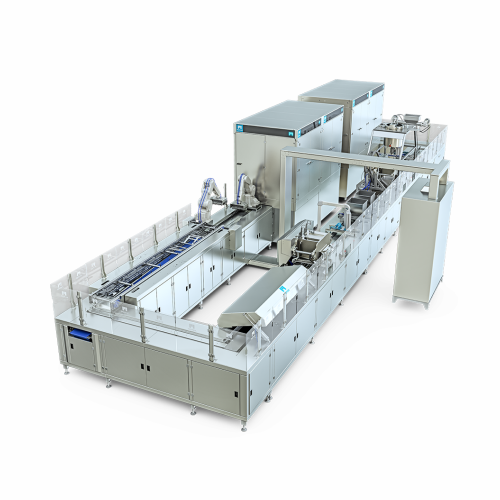

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line that efficiently produces a variety of chocolate forms, from solid bars to center-filled delicacies, ensuring precise moulding, filling, and cooling.

Moulds and Fills Various Chocolate Types

The MKCD-O Series from Memak offers a sophisticated solution for chocolate and confectionery manufacturers seeking reliable high-speed moulding capabilities. This line is engineered to handle a variety of chocolate forms, including solid bars, center-filled candies, and double-colored chocolates, integrating efficiently into existing production operations. The equipment’s advanced moulding, filling, and cooling processes ensure precision and consistency, achieving throughputs of up to 900 kg/h. Utilizing PLC-controlled automated systems, the line ensures seamless integration with minimal manual intervention, making it ideal for high-demand environments. Its design includes energy-efficient components and is built with durable materials suitable for prolonged use in demanding food production conditions. Additionally, Memak provides robust support for equipment customization and maintenance, ensuring tailored operational efficiencies.

Benefits

- Enhances production efficiency with high-speed moulding up to 900 kg/h.

- Reduces labor costs through PLC-controlled, automated operations.

- Supports a wide product range from solid bars to center-filled chocolates, increasing versatility.

- Minimizes energy consumption with optimized motor functions.

- Ensures product consistency and quality with precise moulding and filling technology.

- Applications

- Bakery products, Sweets, Chocolates, Confectionery

- End products

- Chocolate with hazelnuts, Chocolate shell desserts, Center-filled chocolate candies, Solid chocolate bars, Chocolate with sesame seeds, Chocolate with granules, Double colored chocolates, Chocolate with peanuts, Chocolate with walnuts, Chocolate with crispies, Chocolate with almonds

- Steps before

- Chocolate Pre-Mixing, Ingredient Preparation, Raw Material Handling, Fat Melting, Sugar Grinding

- Steps after

- Cooling, Automatic Demolding, Packaging, Chocolate Wrapping, Quality Control

- Input ingredients

- cocoa mass, sugar, milk powder, cocoa butter, fillings (e.g., nuts, crispies), coloring agents

- Output ingredients

- solid chocolates, center filled chocolates, double colored chocolates, chocolates with crispies, almond chocolates, walnut chocolates, hazelnut chocolates, peanut chocolates, chocolates with sesame, granule-filled chocolates

- Market info

- Memak is known for manufacturing high-quality, engineered-to-order equipment primarily for the food processing industry, with a reputation for innovation, precision engineering, and reliable customer support.

- Capacity

- 12-18 shots/min up to 450 kg/h

- Capacity

- 12-18 shots/min up to 900 kg/h

- Total Power

- 30 Kw

- Total Power

- 33 Kw

- Product Options

- Solid chocolates, center filled chocolates, double colored chocolates, solid or center filled chocolate with crispies, almond, walnut, hazelnut, peanut, sesame and granules (2-4 mm)

- Cooling System

- Cooling paternosters

- Demolding System

- Automatic demolding system

- Automation level

- Fully automatic with PLC control

- Batch vs. continuous operation

- Batch

- Changeover time

- Minimal due to automatic demolding system

- Cleaning method

- Automatic CIP

- Energy efficiency

- Optimized for 30–33 kW

- Density/particle size

- 2-4 mm

- Feed/discharge method

- Automatic demolding system

- Capacity

- 12-18 shots/min

- Cooling system

- Cooling paternosters

- Product types

- Solid chocolates, center filled chocolates, double colored chocolates

- Included ingredients compatibility

- Almond, Walnut, Hazelnut, Peanut, sesame, granules (2-4 mm)