Molding Equipment

Find innovative moulding equipment and connect directly with world-leading technology suppliers

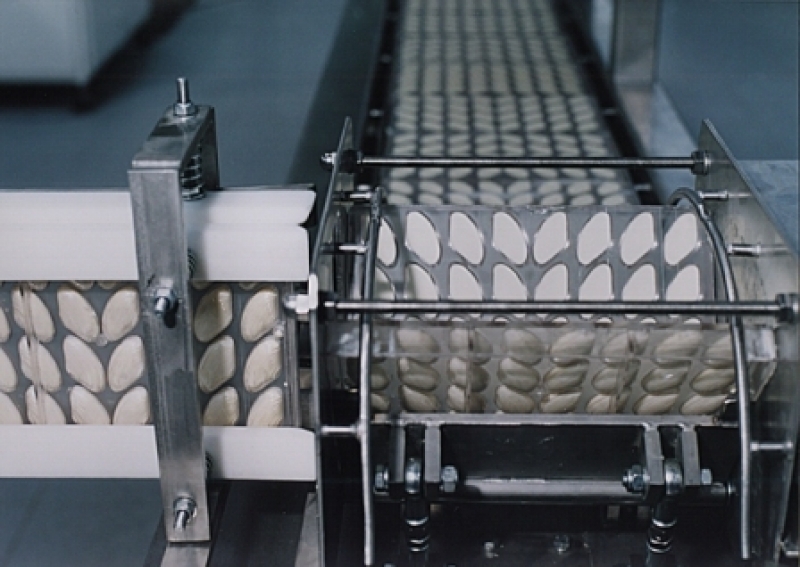

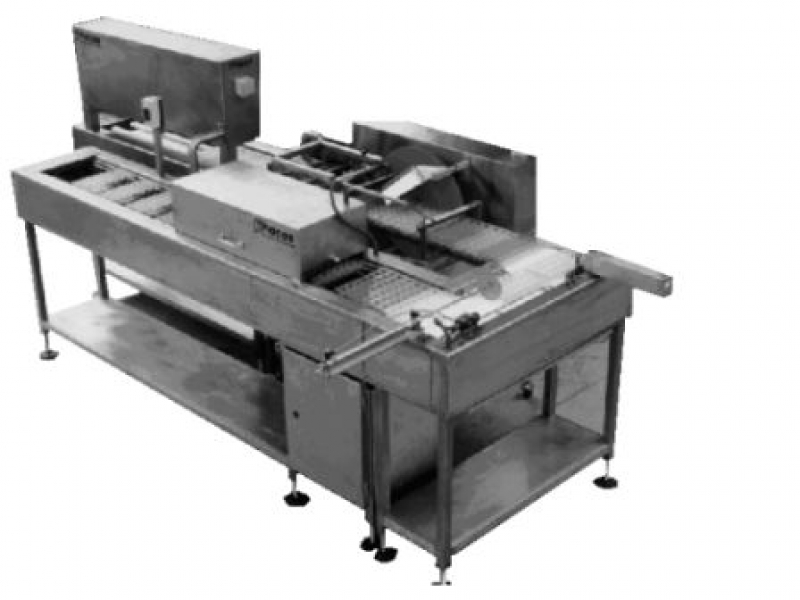

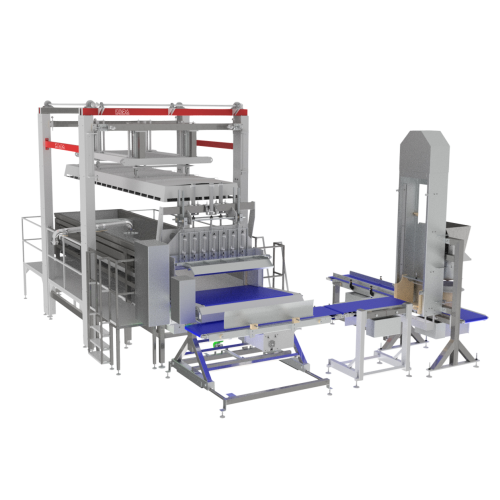

The molding process is often included in bakery products. Utilizing molding equipment guarantees a uniform shape, weight, and size. The molding machine first gently flattens the dough mix by going through a sheeter, where a series of rollers press the thin piece of dough. The sheet is then cut into the specified shape and, depending on your final product, may be rolled by using a curling chain. After the molding, other ingredients may be added before the products are conveyed for baking or freezing.

What are you making?

3d lollipops

Aerated chocolate

Alfalfa meal

Alloys

Automotive

Biscuits

Bread

CBD gummies

Chocolate fillings

Compound chocolate

Cookies

Croissants

Dental implants

Dry pet food

Glass

Grated cheese

Gummy Bears

Halloumi

Hand soap

Hollow chocolate figures

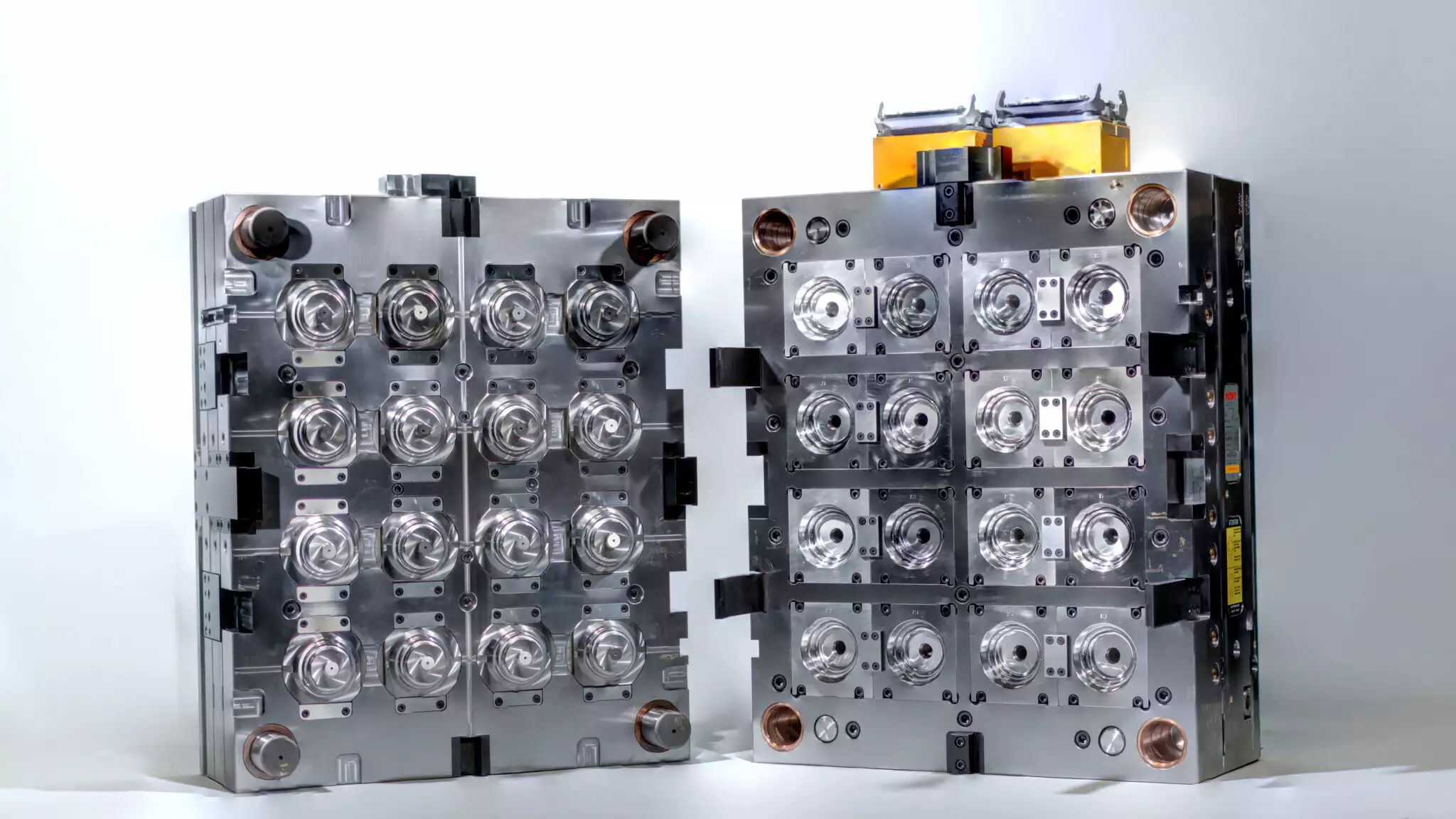

Injection molding

Latex

Longmoulded rolls

Medical gummies

Molasses

PET

Frozen pizza

Polymers

Raisin rolls

Rice cakes

Slit rolls

Synthetic resin

Tofu

Truffle balls

Vitamin gummies

Which moulding technology do you need?

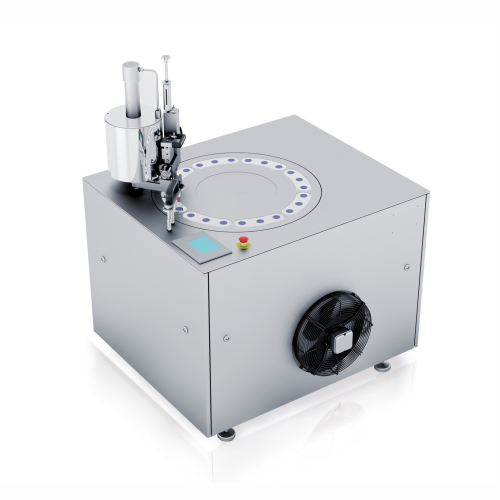

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

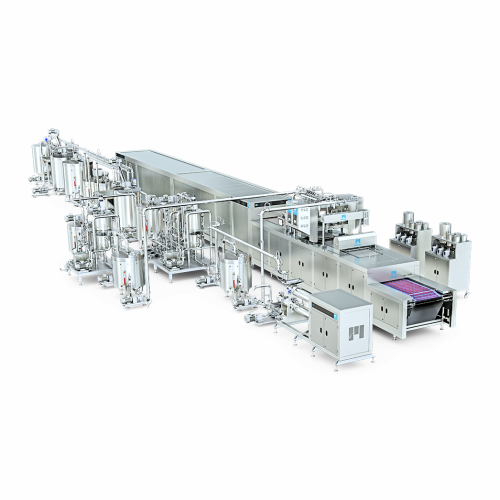

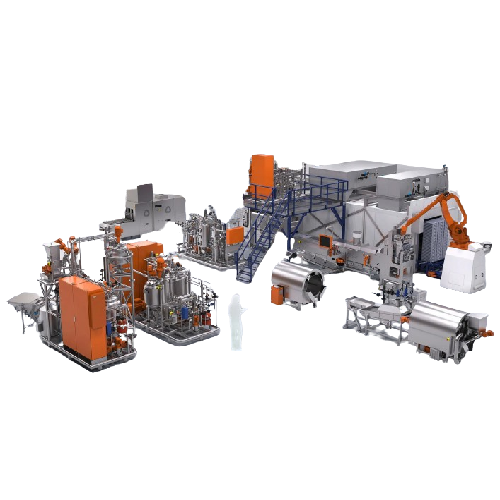

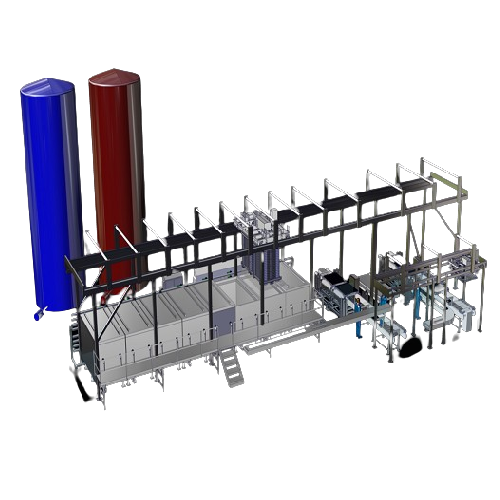

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

Automatic chocolate shell moulding line

Enhance your production capabilities with a cutting-edge moulding line that deliver...

Chocolate moulding press for coco mass

Enhance your production line with precise chocolate moulding capabilities, shaping e...

Lipstick moulding system

Achieve precision and efficiency in your cosmetic production line with advanced moulding and dosing ...

Semi-automatic lipstick moulding system

Streamline your lipstick production with a versatile system that effortlessly mould...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

Figure moulding for pliable mixes

Transform pliable mixtures into intricate 3D figures with precision and efficiency, cater...

Automatic moulding and wrapping for butter and margarine

Looking to reduce packaging waste and increase dosing precision?...

Lipstick moulding solution for cosmetics manufacturing

Streamline lipstick production with high-speed molding and flexibl...

Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed p...

Chocolate moulding line for filled and inclusions bars

Achieve seamless chocolate production with modular flexibility, al...

Automatic Pet preform injection moulding

Optimize your production with high-speed injection molding capable of shaping dive...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

Wafer and biscuit feeder for chocolate moulding

Efficiently integrate wafers and biscuits into your chocolate production l...

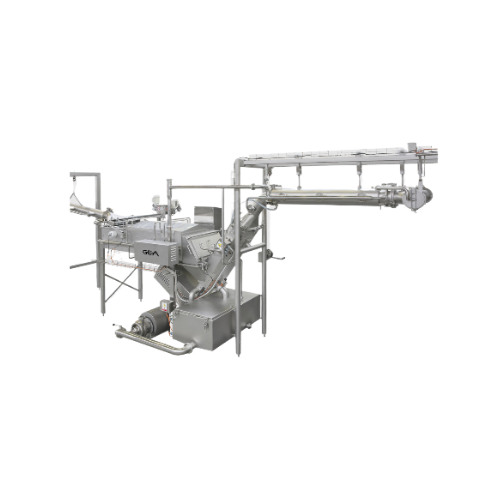

Dough divider and moulding system for industrial bakeries

Effortlessly transform soft and challenging doughs into perfec...

Dough dividing and round moulding solution for bread rolls

Achieve precision and consistency in your bakery line with a ...

Precision moulding and cutting for pasta filata string cheese

Eliminate variations in string cheese production with prec...

Mozzarella cheese moulding system

Optimize your cheese production with fully automated moulding and setting, ensuring consi...

Polvoron and mung bean cake moulding system

Efficiently mold and shape your confectionery creations with this versatile sy...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

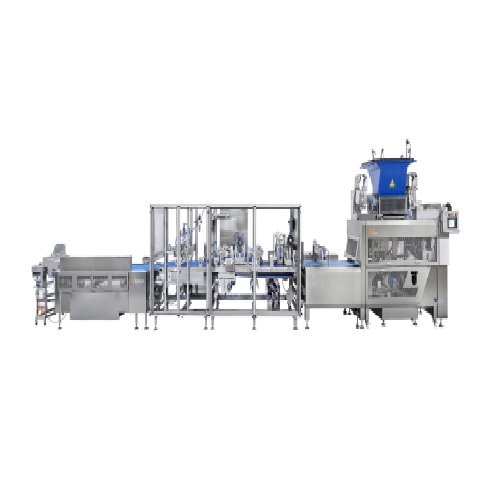

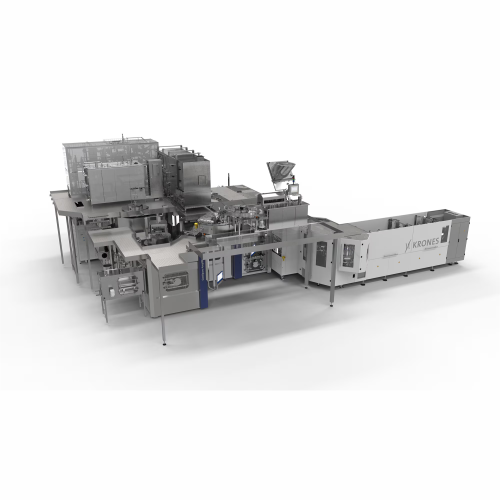

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

Vertical tunnel for cooling and moulding chocolate

Efficiently manage chocolate temperature control and molding precision...

Chocolate enrobing, moulding, and cooling tunnel

Optimize your chocolate production with this advanced tunnel, designed fo...

Moulding machine for croissant

Croissants are a popular line in commercial bakeries and are sold in high volumes. An automat...

Moulding machine for rolled bread

As great snacks and accompaniments to meals rolled bread is a staple product in commercia...

Moulding machine for pizza

A pizza molding machine must be able to size and shape doughs suitable for pizzas and pitas. It s...

Moulding machine for bread sticks

Breadsticks are popular as an appetizer in restaurants or as a starter served with prosci...

Square or rectangular moulding machine for bread

Automated bread molders should form various types of dough into a range o...

Automatic book-moulding system

Closes ‘book-moulds’ in order to produce eggs, balls, sea shells, and other 3-dim...

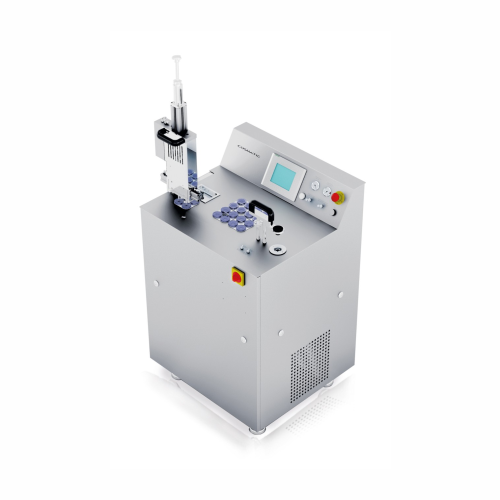

Hand moulding machine

Melting and tempering for convenient moulding of chocolates by hand.

Semi-automatic moulding line for solid chocolates

Perfect for scaling up your production of tablets or filled chocolates.

Moulding line for pralines, tablets and cups

To automatize the process of moulding pralines, tablets, and cups in artisan ...

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

Croissant production module for pastry make-up lines

Enhance your bakery’s product range with a versatile module de...

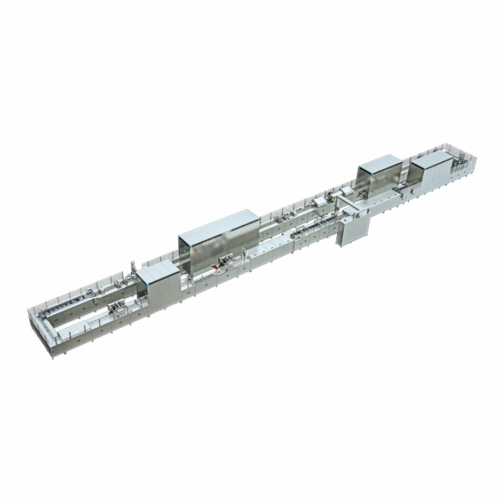

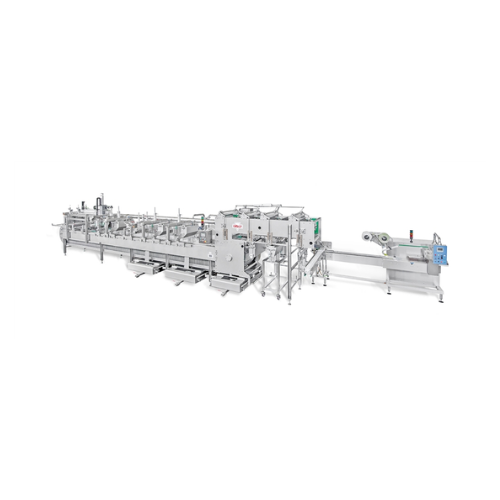

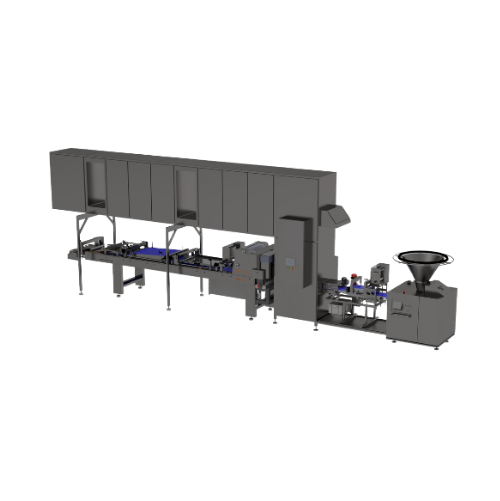

Industrial croissant production line

Streamline your bakery’s operations with a versatile solution capable of produci...

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

Hollow chocolate figure spinning solution

Achieve uniform chocolate coating in hollow figurines with precision spinning te...

Buttercream filling applicator for chocolates

Enhance your confectionery process with precision dosing and moulding to cre...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Dosing system for chocolate tablets

Enhance your confectionery production with a versatile solution for precise dosing and ...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

Compact dough depositor for artisan confectioneries

Ideal for crafting intricate and uniform pastries, this machine enhan...

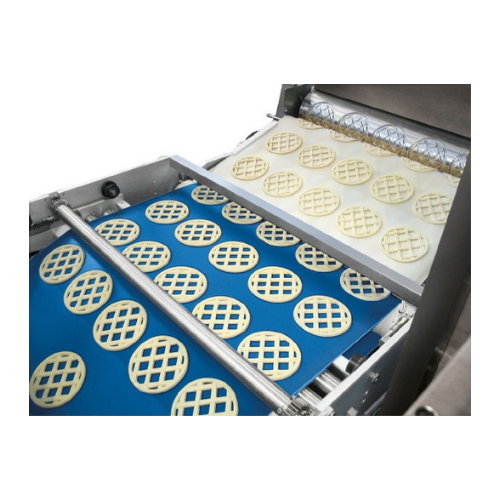

Rotary moulder for shortbread and pie crust production

Achieve precise molding of diverse baked goods with high-speed eff...

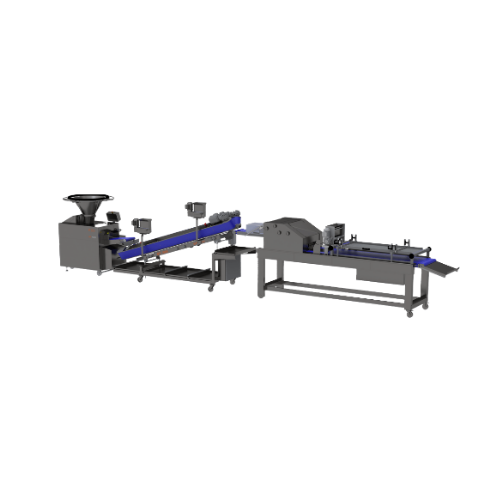

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

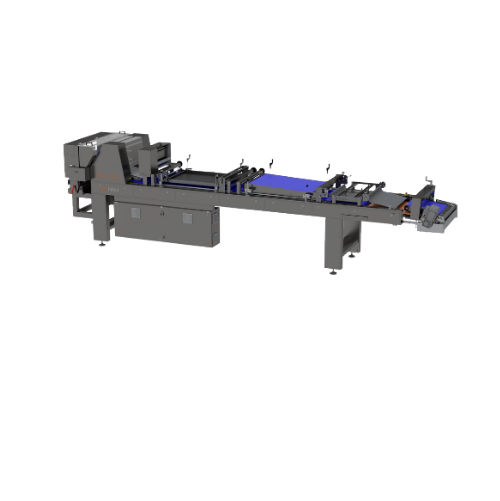

Soft candy production line

Optimize your candy production with a versatile line that efficiently handles everything from car...

Preparation system for lipstick production in stores

Streamline your cosmetic production by transforming raw ingredients ...

Cosmetic pencil filling system

Streamline your cosmetic production with high-speed filling and precise molding capabilities,...

Lipstick production laboratory system

Optimize lipstick production with precise moulding and controlled temperature systems...

High speed rolling line for confectionery production

Enhance your confectionery production with a versatile rolling line ...

Extruder for pliable mixes in industrial applications

Achieve precision in creating diverse extruded food products with t...

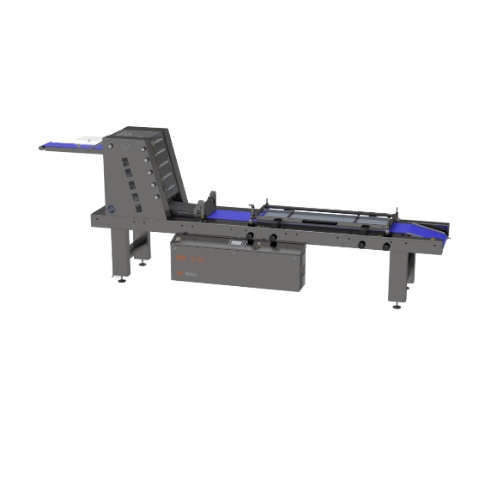

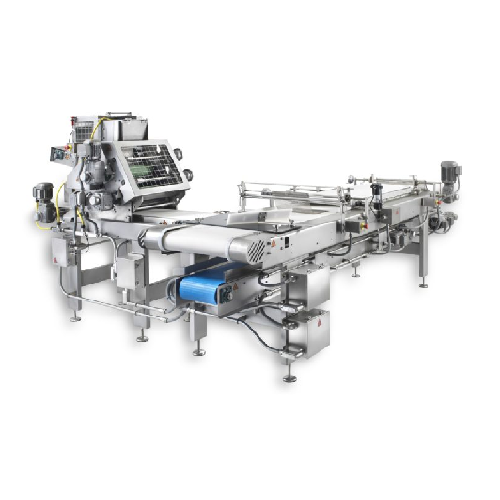

Bread moulder for consistent dough shaping

Ensure uniform dough shaping and enhance bread quality with precision moulding,...

Bread dough rounder for consistent shaping

Achieve uniform dough shaping and enhance product consistency for high-speed ba...

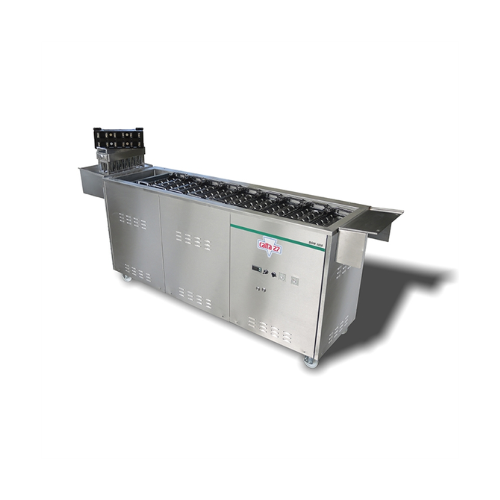

Linear mould system for ice cream production

Optimize your ice cream line with modular flexibility, allowing seamless adap...

Rotary mould machine for ice cream production

Streamline your ice cream production with a rotary mould machine designed fo...

Industrial manju cake production system

Transform traditional treats into innovative 3D cakes with precise filling and perf...

Soft bread production system

Optimize your bakery operations by integrating a high-speed system for producing a wide variety...

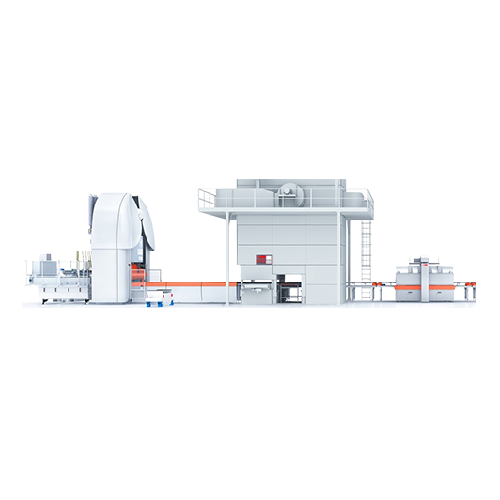

Industrial sheeting and laminating systems for baked goods

Elevate your bakery’s production line with cutting-edge...

Chocolate depositor for small to medium production

Optimize your confectionery production with a versatile depositor that...

Depositor for solid and filled chocolates

Optimize your chocolate production with precision depositing for medium to large...

Industrial dough divider and rounder for rolls and buns

Achieve precise, high-speed dough dividing and rounding for consi...

High-performance donut and ball donut production line

Efficiently produce a wide variety of donuts with precise shape and...

Dough strip line for producing artisan rolls and breads

Optimize your bakery’s production with a modular dough stri...

Dough strip and roll line for artisan and classic rolls

Eliminate the need for separate machines by seamlessly integratin...

Dough strip line for artisan rolls and small breads

Achieve precision and artisanal quality in bread and roll production ...

Ryena bread production line for soft dough and ancient grains

Efficiently process soft dough and ancient grains into var...

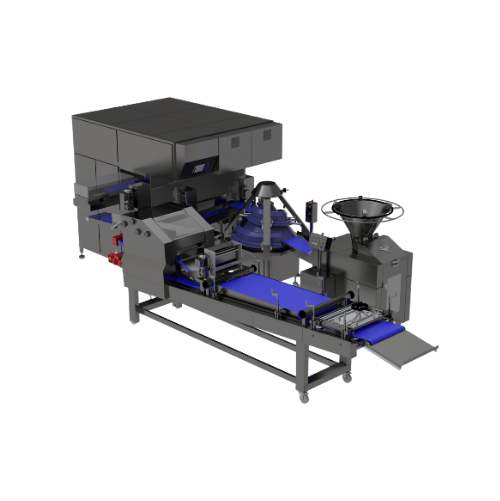

Automated dough make-up line for sweet bread production

Effortlessly handle diverse dough weights and consistencies to pr...

Compact bread production line for varied dough types

Optimize your bakery’s space with a compact line that produces...

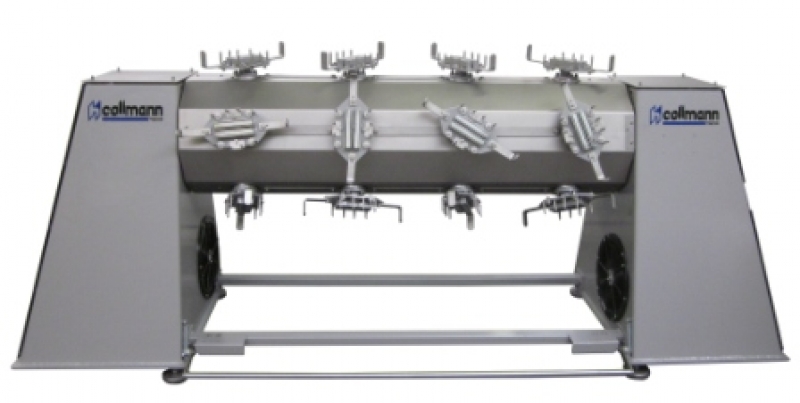

Round- and long-moulder for bakery dough production

Achieve precise and consistent bread shaping with a compact solution ...

High-speed moulder for baguettes and oblong bread

Streamline your bakery’s production line with a high-speed mouldi...

Automatic baguette production system

Efficiently shape and perfect long, oblong bread varieties with high consistency and m...

Bread production line for classic bread types

Unlock versatile bread production with a modular line that adapts to any bak...

Automated artisan bread production line

Enhance your bakery’s efficiency with this versatile bread production line, d...

Long moulder for toast and tin breads

Achieve perfect dough consistency with precise sheeting and moulding, ensuring your b...

Industrial long moulder for pan and hearth bread

Enhance your bread production with precise sheeting and curling that impr...

Industrial long moulder for pan bread

Seamlessly mold diverse dough types into uniform loaves with high-speed precision, op...

Industrial long moulder for high-capacity dough processing

Optimize your bakery production with a high-speed moulder tha...

Small bakery item baking system

Effortlessly craft artisan-quality bakery items with precision moulding and gentle dough han...

Compact roll baking system for high capacity

In tight bakery spaces, achieving high volume production without sacrificing ...

Modular roll baking system for small bakery items

Optimize your bakery production with a modular roll baking system that ...

Dough divider and moulder for artisan bakeries

Achieve precise and gentle dough handling, ensuring exceptional product qua...

Industrial dough divider and round moulder

Optimize your bakery’s operations with a machine that ensures precise dough div...

Rotary moulder for ice cream production

Achieve high-speed, precise ice cream moulding with seamless integration into your ...

Ice cream rotary moulder 35 a2

Streamline your frozen treat production with high-capacity moulding that supports a variety o...

Volumetric bottom filler for ice cream

Achieve precise distribution and inclusion integrity in moulded ice creams and froze...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

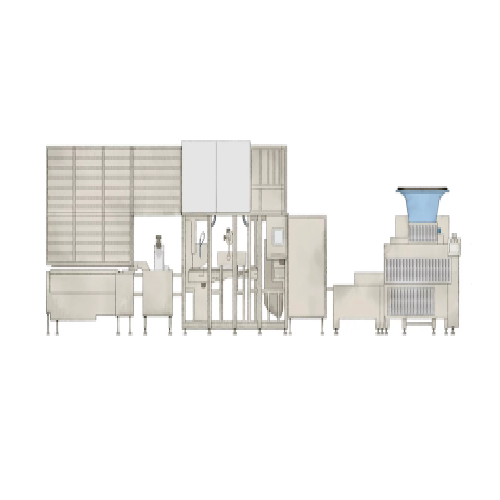

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

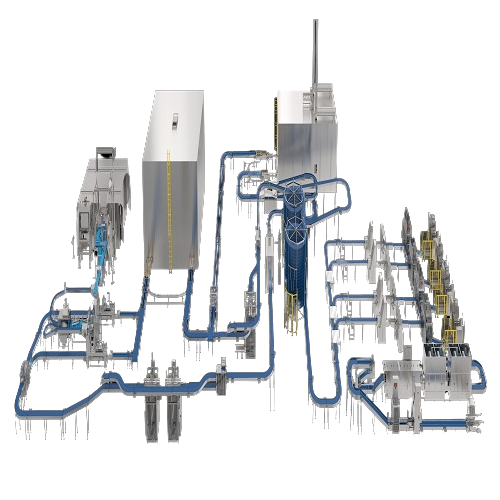

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

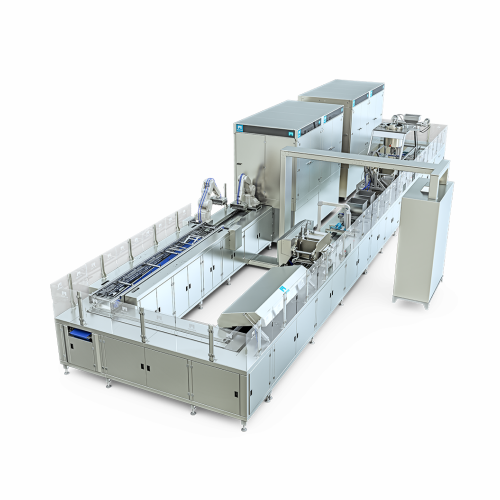

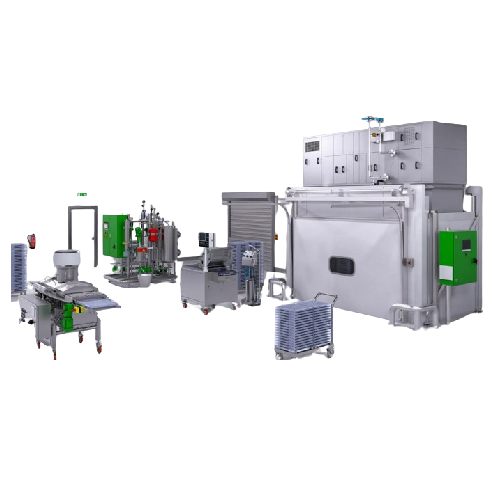

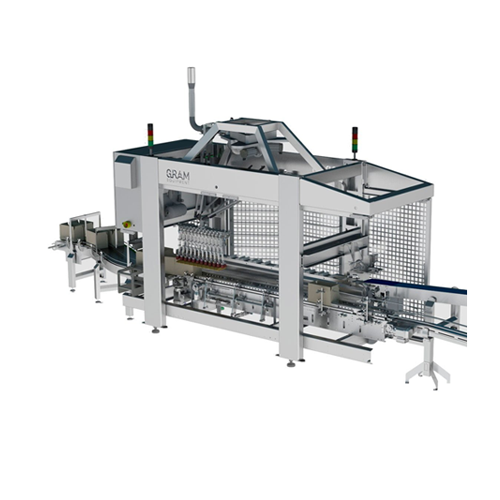

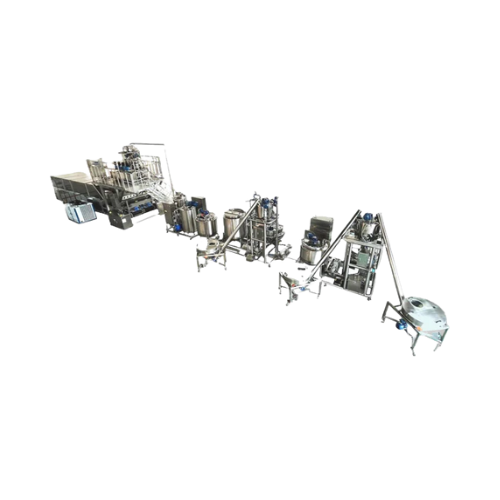

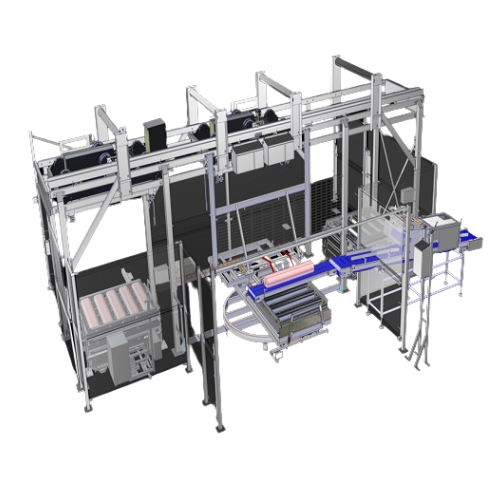

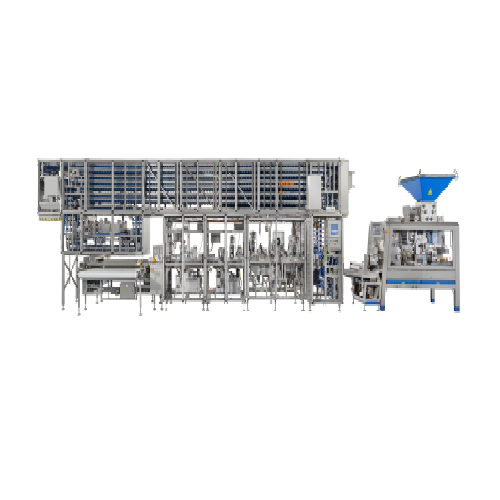

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automat...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

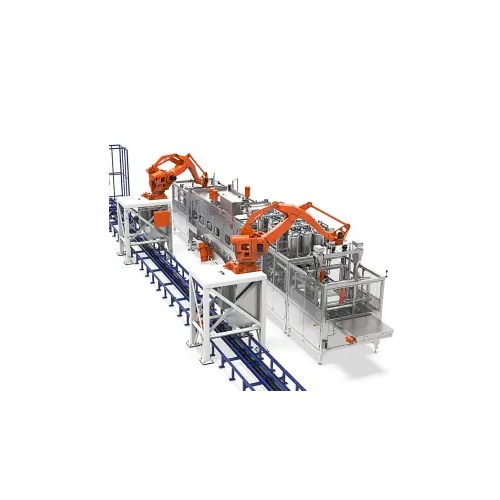

Robotic production line for gummies and nutraceuticals

Streamline your gummy and nutraceutical production with a versatil...

Robotic high capacity production line for gummies and jellies

Optimize your gummy and jelly production with a high-capac...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Rotary stretch-blow moulders for Pet bottles

Achieve efficient and high-speed production of diverse plastic containers wit...

Bread moulders for bakery production

Efficiently shape various bread types like baguettes and ciabatta, ensuring consistent...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Simultaneous chocolate dosing solution

Achieve high-precision chocolate and ganache filling in a single step with this effi...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Professional chocolate tempering solution for large workshops

Enhance your chocolate production efficiency with a machin...

Chocolate enrobing and cooling tunnel 300/400 mm

Ensure seamless enrobing and precise cooling for chocolate products with ...

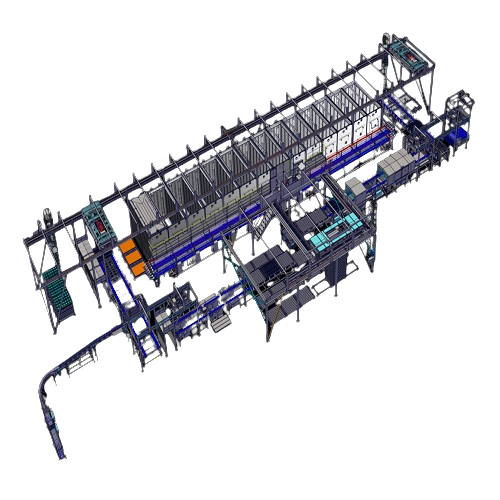

Advanced ceramic tile production line

Elevate your ceramic tile production with an all-encompassing solution that seamlessl...

Ductile alloys and cookware coining presses

Achieve precise metal forming with robust, highly automated coining presses de...

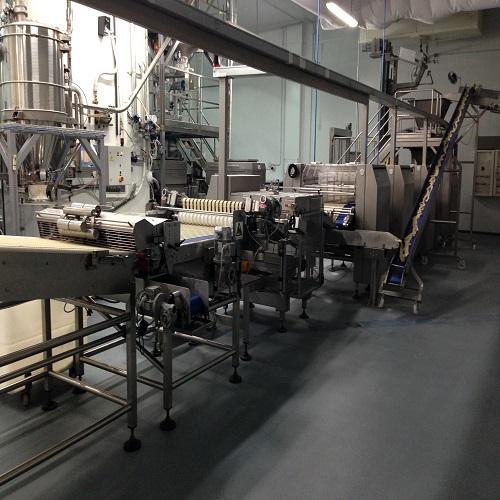

Industrial dough moulders for consistent bread quality

Achieve precision and uniformity in your bakery operations with ad...

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Automatic pastry dough sheeter

Industrial dough sheeters turn raw dough into sheets that match recipe thickness. This includ...

Powder pressing mould

Traditional powder pressing moulds are based on plain shapes or basic designs. In order to differentiat...

De-moulder for flat bottom chocolates

De-moulding is often found to be a bottleneck in chocolate production and can be solv...

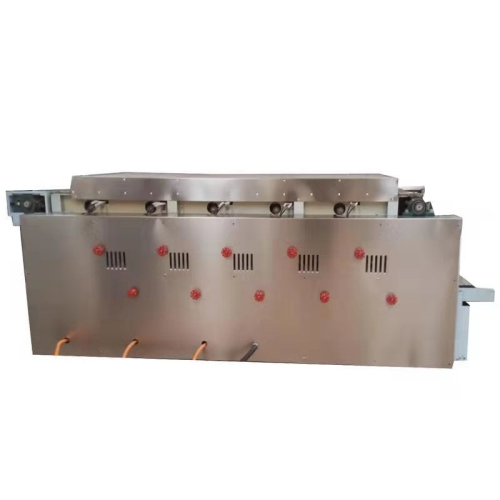

Horizontal cooling tunnels for chocolate moulds

The perfect tunnel for semi-automatic production lines.

Starch-free depositor systems for jelly

Traditional depositing for jellies and gummies requires the use of starch moulds. T...

Rotary molder for softdough biscuits and shortbreads

For high output bakeries, achieve precise dough piece formation and ...

Industrial pie making systems for high-volume bakeries

Elevate your bakery operations with a versatile solution that seam...

Rotary moulder for pie lids and lattices

Elevate your bakery’s offerings with precise molding and customization for a...

Rotary moulder for high-definition cookie dough shapes

Efficiently shape intricate dough designs with precision, ensuring...

Industrial bread process line

Optimize your bakery operations with a versatile bread processing line, designed to handle a v...

Hot mounting press for metallographic samples

Streamline your sample preparation with high-speed, modular hot mounting pre...

Curd drainers and portioners for cheese production

Enhance your cheese production with precise curd draining and portioni...

Double spinning machine for hollow chocolate figures

Achieve perfect distribution of chocolate in molds with precision sp...

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Precision chocolate production from cocoa nibs

Achieve ultra-fine chocolate textures by utilizing stone conching to bring ...

Manual patty formers for 180mm burgers

Effortlessly mold uniform 180mm patties from diverse ingredients, ensuring consisten...

Granular ice makers for display counters

Ensure optimal freshness and visual appeal with granular ice makers that provide t...

Pastry depositor for versatile product shapes

Enhance your bakery’s production with a versatile depositor that effor...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Industrial long moulder for bakery production

Enhance your bakery’s efficiency with a high-speed long moulder ideal ...

High-quality burger forming system

Effortlessly form a variety of burgers and proteins with consistent texture and shape, t...

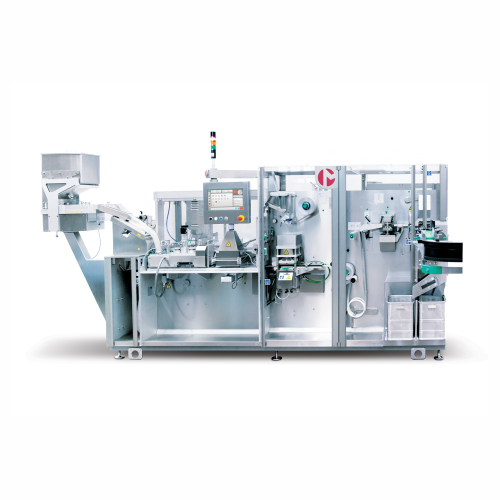

Blister thermoforming for Pvc/alu

Effortlessly mold and seal blister packs for a range of solid products, optimizing packag...

Automatic case packing solution for cosmetic products

Streamline your cosmetic production line with efficient case packin...

Rotationally symmetric product rolling machine

Achieve precision shaping of chocolate balls, candy drops, and more with ou...

Ultrahygienic block for aseptic filling

When handling sensitive beverages, ensuring microbiological safety and quick produc...

High-performance thermoforming tools for packaging

Optimize your packaging production with versatile thermoforming tools,...

Thermoforming solution for high-end cup production

Achieve precision and efficiency in cup forming with a machine that op...

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

Manual forming unit for burger patties

Produce up to 30 perfectly shaped burger patties per minute with consistent quality ...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy manufacturing system

Efficiently streamline your candy production with a system capable of producing up to ...

High capacity molding line for stick ice cream

Transform your frozen dessert production with an advanced molding line desi...

High capacity molding line for ice cream sticks

Optimize your frozen dessert production with a high-capacity system that i...

Electric injection molding for precision plastics

Ideal for precision molding, this electric injection system enhances ef...

Hydraulic press for frozen meat and bacon

Achieve consistent shaping and high-quality output for frozen meat and bacon pro...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

Hardening tank for water-ice lollies

Enhance your small-scale ice cream production with a versatile solution that allows yo...

Pilot plant for ice cream production

Optimize your ice cream production with a flexible pilot plant that seamlessly integra...

Hydraulic compression press for Astm plastic sample preparation

Achieve precision in molding and testing with this hydra...

Bench top press for Astm testing of plastics and rubber

Streamline your material testing with precision-controlled bench ...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

One-shot chocolate depositing system

Enhance your confectionery line with precise, high-speed depositing technology designe...

High-speed mixer for dough production

Achieve consistent dough quality and streamline your production process with this ver...

Baking oven for molded cones and cups

Effortlessly increase production efficiency with a high-capacity baking oven that del...

Loose mould line for chocolate production

Streamline your chocolate production with a high-throughput line that seamlessly...

Coffee processing system for integrated coffee production

Enhance your coffee production with a versatile system that in...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Integrated cooking and chilling system for hams

Streamline your production line with this system that optimizes the shapin...

Automated sous vide cooking and chilling system

Optimize your cooking process with a system that ensures consistent temper...

Automatic molding system for ham logs

Optimize your meat processing efficiency with precision-engineered molding systems de...

Rack log loader for ready-to-eat products

Efficiently streamline your loading and handling operations with a system design...

Sous vide water cook & chill system

Achieve precision in Sous Vide cooking with a system that ensures optimal temperature c...

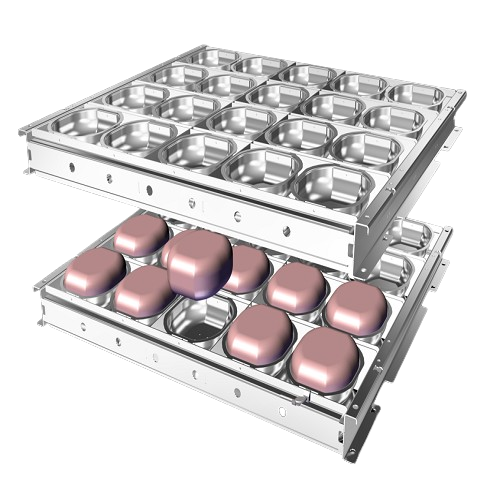

Multimolds for round log processing

Achieve consistent and precise shaping for ham and deli products while maximizing your ...

Stainless steel molds for shaping meat products

Enhance product consistency and hygiene with custom-designed stainless ste...

Ham molds for deli production

Achieve uniform shaping and consistent cooking of deli hams with this innovative molding solut...

Multimolds for shaped ham logs

Ensure uniformity and precision in shaping, cooking, and chilling ham logs, boosting producti...

English muffin production system

Maximize your bakery’s output with our high-speed system designed to efficiently produce co...

High-speed baguette production system

Achieve seamless, high-speed production of artisan baguettes with minimal downtime an...

Swirl bread production system for commercial bakeries

Elevate your bakery’s output with high-speed, efficient produ...

Pressed pan pizza production system

Elevate your pizza production with a system that enhances flexibility and consistency, ...

Precision dough dividing equipment for bread production

Achieve unmatched precision and speed in your bakery operations w...

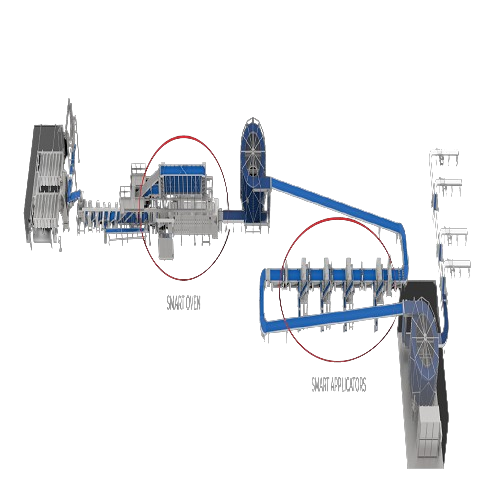

Ai solutions for pizza production in bakeries

Bring unparalleled precision and efficiency to your bakery with intelligent ...

Automatic Pet bottle blowing solution

Achieve precise PET bottle molding with high-speed, automated operations that seamles...

Servo type Pet bottle blowing molding solution

Optimize your production with high-speed PET bottle molding, designed to st...

Automatic servo Pet bottle blower

Elevate your production capabilities with a PET bottle blowing machine designed for high-...

Automatic popcorn ball forming equipment

Streamline your snack production with high-speed, precise popcorn ball forming tec...

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

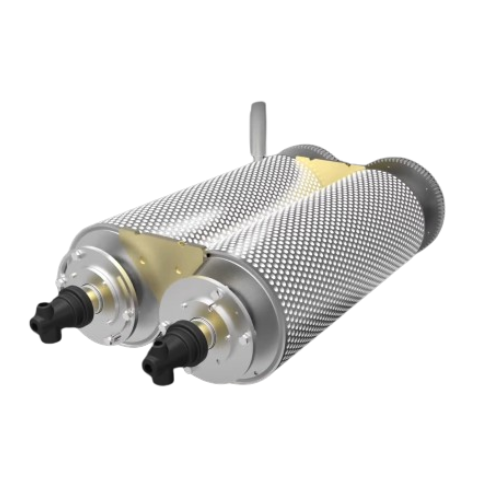

Laboratory roller for chocolate production

Easily switch between producing chocolate lentils, balls, and eggs with these f...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Single sheet former for fresh pasta production

Optimize your production line with a versatile machine designed to precisel...

Hot water stretching and molding unit for cheese production

Revolutionize your cheese manufacturing process with a compa...

Hot water stretching machines for mozzarella cheese production

Enhance mozzarella cheese production with precision-contr...

Drum molding machine for soft pasta filata cheeses

Achieve precise molding and consistent product quality in your cheese ...

Molding equipment for provolone and caciocavallo cheese

Optimize your cheese production with advanced molding equipment, ...

Molding and pre-hardening unit for pizza cheese

Achieve precise molding and effective pre-hardening of pizza cheeses with ...

Dry salt dosage system for curd cheese production

Streamline your cheese production with precise salt dosing, ensuring op...

Hygienic filling system for short shelf life milk

Optimize your cold-chain distribution with a filling system engineered ...

Esl beverage filling system

Ensure extended shelf life and maintain beverage quality with sterile filling and decontaminatio...

Modular roll line for high-capacity bakery production

Streamline your bakery’s production process with high-speed, ...

Industrial bread dough divider for accurate weight control

Achieve precise weight accuracy and gentle handling for a var...

Automated bread production line for toast bread and rolls

Streamline your bakery operations with a high-speed line desig...

Long moulder for wheat and wheat/rye dough

Achieve perfect uniformity and precision in every loaf with adjustable folding ...

Long dough moulder for rustic bread

Optimize your bakery’s production line by effortlessly handling various dough typ...

Seeding unit for bread dough

Enhance your bread production by achieving consistent seed distribution and decoration on your ...

High-speed dough dividing solution for accurate portioning

Optimize your bakery’s efficiency with precise dough po...

Dough divider and round moulder for artisan bakeries

Experience seamless dough management with equipment designed for pre...

Cheese moulder for cylindrical portions

Ensure precise portioning and molding of cheese into cylindrical forms, enhancing y...

Aseptic blow fill seal system

Ensure sterile, high-speed production of liquid pharmaceuticals by integrating a cutting-edge ...

Extruder for string cheese production

Efficiently process pasta filata cheeses into uniform shapes with precise temperature...

Continuous freezer for ice cream production

Optimize your ice cream production with precision freezing, mixing, and air in...

Fresh cheese former for hygienic production

Streamline your cheese production with a hygienic and no-mould solution that s...

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

Commercial tortilla press for small businesses

Effortlessly produce a variety of flatbreads and dough products with precis...

Commercial ice popsicle making solution

Optimize your frozen dessert production with a versatile machine capable of craftin...

Automatic pita bread making solution

Efficiently produce high-quality pita, Arabic bread, and tortillas with a seamless sol...

Commercial meatball forming solution

Boost your production efficiency by rapidly shaping a wide variety of meat and vegetar...

Commercial patty making machine

Optimize your patty production with a machine designed to meet diverse culinary demands, off...

Commercial crispy roll biscuit maker

Enhance your snack production with our advanced equipment that efficiently molds and s...

Commercial delimanjoo and taiyaki custard cake maker

Enhance your pastry production with high-speed, mold-customizable ca...

Industrial biscuit making solution

Enhance your biscuit production with precision engineering that seamlessly integrates do...

Industrial grid gravity casting system

For manufacturers seeking precise metal casting, this equipment ensures consistent q...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Single-stage plastic container production system

Eliminate multiple steps and minimize production costs with an integrated...

Injection stretch-blow molding system for Pet containers

For manufacturers aiming to produce versatile, high-quality PET ...

Large size container linear blow molder

Optimize your large-scale production of containers with a solution designed to stre...

Rotary blower for Pet bottle production

Optimize PET bottle production with cutting-edge efficiency, reducing energy consum...

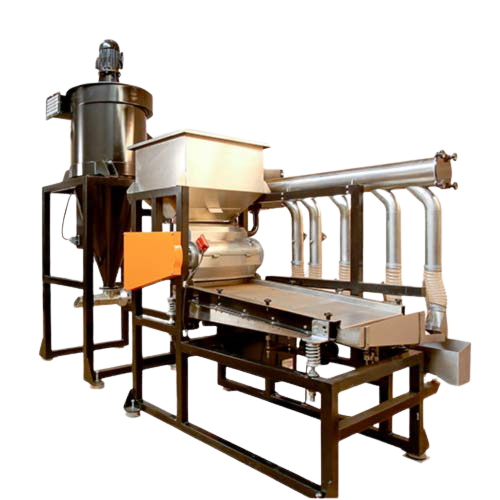

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Simultaneous chocolate and ice cream dispenser

Unite the worlds of chocolate and ice cream with a machine capable of seaml...

Professional chocolate tempering system for artisan chocolatiers

Achieve precise chocolate tempering with quick changeov...

Professional chocolate tempering equipment for efficient production

Enhance your production capabilities with a versati...

Wall chocolate fountain for continuous chocolate flow

Create a mesmerizing ambiance with a seamless chocolate waterfall, ...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Chocolate truffle extruder

Achieve precise and versatile production of chocolate truffles and snacks, with seamless integrat...

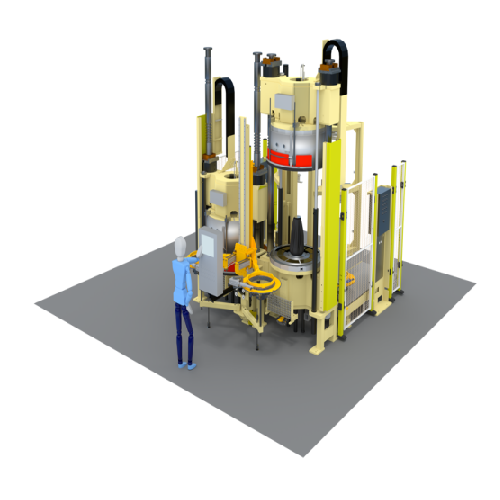

Hydraulic curing press for 2-wheeler and scooter tires

Achieve optimal tire concentricity and extended press life with th...

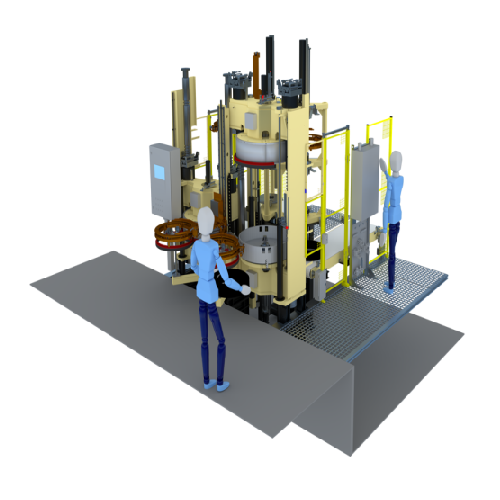

Hydraulic curing press for passenger car tires

Optimize tire production with precise molding and curing capabilities desig...

Coffee capsule filling and sealing system

Boost capsule production efficiency and reduce downtime with a high-speed system...

Coffee capsule filling and sealing line

Elevate your capsule production with a high-speed filling and sealing solution that...

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

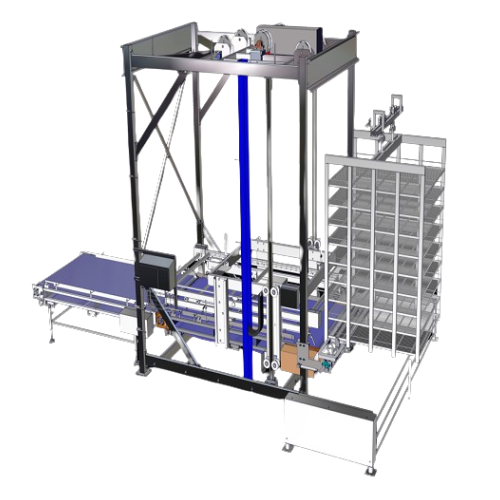

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Semi-automatic dough sheeter

There is a wide range of commercial dough sheeters available, many of which are purpose-built f...

Automatic bread dough sheeter

Dough for speciality breads must first be rolled into sheets of varying thickness, to facilita...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

Chocolate bean to bar line 10kg

Developing new products, producing specialty chocolates, laboratory testing, and in-shop pro...

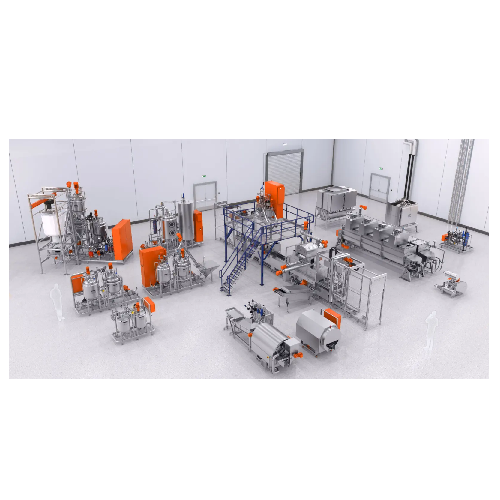

Chocolate bean to bar line 200kg

Installing a chocolate production line that works efficiently and smoothly can be a dauntin...

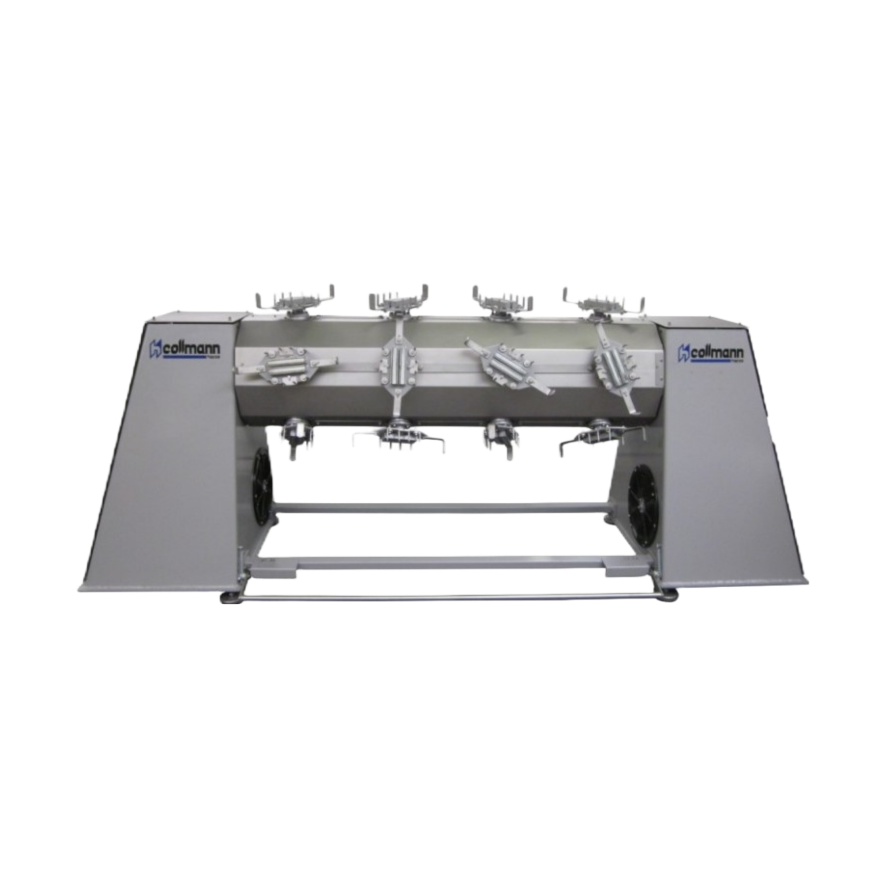

Compact 4-arm spinner for chocolate

For small productions or lab use in the manufacturing of chocolate hollow figures.

Big scale chocolate spinner

For larger production capacities of chocolate hollow figures.

Starch-free depositor for soft confectionery

Soft confectionery such as toffees, fondants, fudges and jellies have traditi...

Starch-free depositor for lollipops

Traditional high volume continuous lollipop production can lead to inconsistent product...

Starch-free depositor for hard candy

Forming hard candies requires careful handling of syrups in order to avoid quality iss...