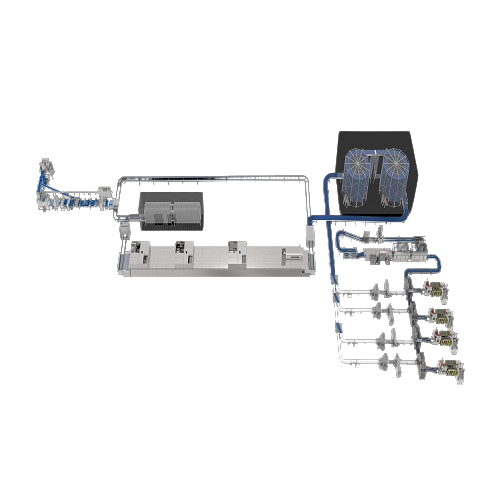

Swirl bread production system for commercial bakeries

Elevate your bakery’s output with high-speed, efficient production of swirl and tin breads, ensuring consistent quality and meeting the demands of high-volume operations.

Produces High-Volume Swirl and Tin Breads

The Swirl Bread System from AMF Bakery Systems revolutionizes bread production for high-volume bakeries with its advanced sheeting and mixing processes. This system excels in producing a range of swirl and tin breads, including cinnamon swirl and marble breads. It features high-speed sheeting that maintains dough integrity and consistent quality. The system’s integrated components—mixers, conveyors, proofers, ovens, and coolers—work seamlessly to ensure continuous, efficient production while preserving product quality. Capable of processing up to 9,000 pieces per hour, the system is designed for easy integration with existing lines and is equipped with AMFConnect™ technology for real-time monitoring and optimization. Built with robust, corrosion-resistant materials, it ensures longevity and low maintenance, while modular components allow for customizable configurations to meet specific production needs.

Benefits

- Increases production efficiency with output of up to 9,000 pieces per hour.

- Enhances product consistency with advanced sheeting and mixing technologies.

- Minimizes operational costs through energy-efficient design and easy integration.

- Improves decision-making with AMFConnect™ real-time monitoring system.

- Offers flexibility in production with customizable components for diverse product ranges.

- Applications

- Buns, Bread, Tin bread, Soft bread, Rolls, Cinnamon swirl bread, Swirl bread, Artisan bread

- End products

- Swirl rye bread, Cinnamon swirl loaf, Brioche swirl bread, Raisin cinnamon swirl bread, Sandwich tin bread, Tin loaf bread, Whole wheat swirl bread, Marble bread

- Steps before

- Mixing, Dough Distribution, Proofing

- Steps after

- Cooling, Slicing, Bagging, Packaging, Product Loading, Basket Stacking

- Input ingredients

- dough, flour, water, yeast, sugar, cinnamon, butter

- Output ingredients

- swirl bread, tin bread, toast bread, cinnamon swirl bread

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Production Speed

- Up to 9, 000 pieces per hour

- Dough Batch Capacity

- Up to 3, 200 lbs

- Zone Control

- Independent zone control in tunnel oven

- Cooling System

- Spiral cooler with modular design

- Slicing and Bagging Speed

- 35 actions per minute

- Basket Handling

- Handles up to 50 baskets per minute

- High-speed production capability

- Up to 9, 000 pieces per hour

- Process automation

- AMFConnect™ for real-time data and integrated monitoring

- Consistency in sheeting

- High-speed, stress-free sheeting line

- Bread type versatility

- Tin bread and cinnamon swirl bread

- Batch vs. continuous operation

- High-volume continuous production

- Cooling system configuration

- Vesta Spiral Cooler for efficient cooling

- Flexible production interface

- Integrated system communication

- Baking precision

- Den Boer Tunnel Oven with independent zone control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact, high-speed design for limited space

- Shape

- Open frame, tubular offset frame

- Feed method

- Chunker or pump to downstream operations

- Discharge method

- Conveyor system for efficient transport

- Basket Handling

- Efficient stacking, unstacking, and handling systems

- Conveyor material

- Anodized aluminum and rust-free materials

- Control panel type

- Advanced monitoring with AMFConnect™

- Cooling configuration

- Modular spiral cooler for customized cooling

- Modularity

- Pre-assembled, modular tunnel ovens

- Product handling

- Robotic gantry for gentle product loading

- Modularity

- Pre-assembled tunnel ovens

- Sanitation design

- Easy access frame

- Robotic automation

- VersaLoader Robotic Product Loader